Macro preparation method of tobacco thermal reaction spice

A heat-reactive, macro-scale technology, applied in the directions of tobacco, tobacco preparation, essential oils/spices, etc., can solve the problems of unfavorable cleaning of heat-reaction spice extraction tanks, lack of concentration of core aroma component groups, and inability to meet continuous production requirements, etc. To achieve the effect of enhancing energy and aroma quality, good fluidity and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

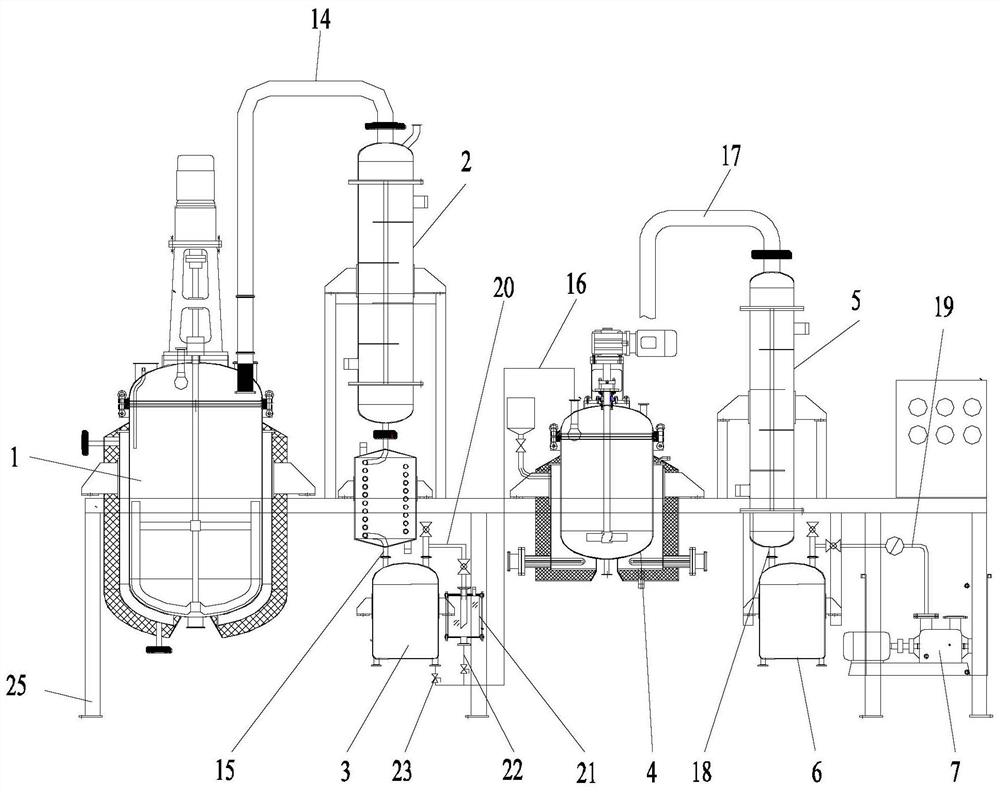

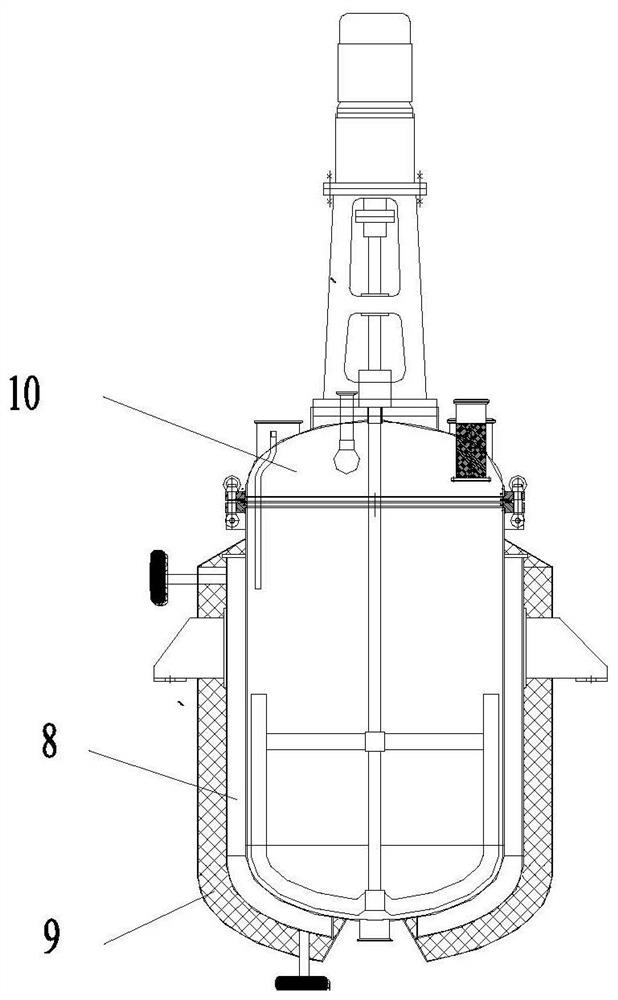

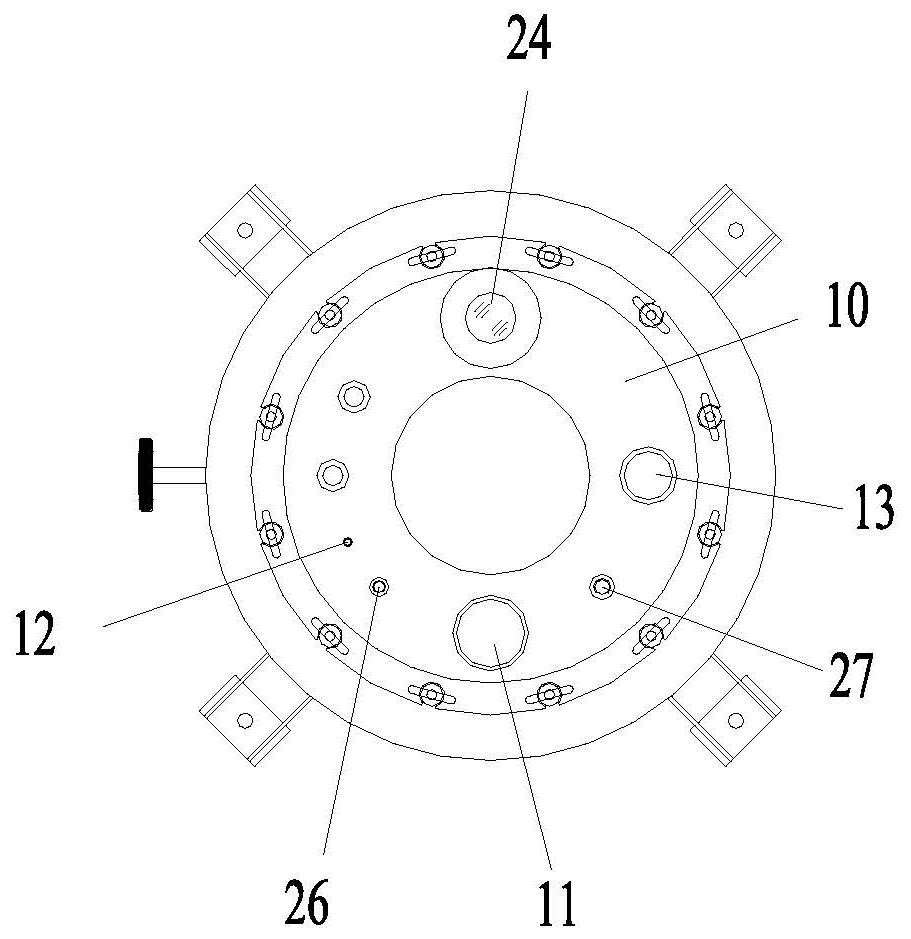

[0039] see Figure 1 ~ Figure 3 , this embodiment discloses a mass-preparation device for tobacco thermal reaction spices, including an extraction tank 1, a first condenser 2, a first liquid storage tank 3, a concentration tank 4, and a second condenser 5 connected in sequence through pipelines , the second liquid storage tank 6, the vacuum pump 7. The periphery of the tank body of the extraction tank 1 is wrapped with a heating jacket 8, and the inner cavity of the heating jacket 8 forms a heating chamber. Circulating hot oil is filled into the heating chamber of the heating jacket 8, and the extraction tank 1 is heated more evenly by means of peripheral circulating hot oil heating. The heating jacket 8 outside the extraction tank 1 is also wrapped with a layer of insulation cover 9 to prevent heat loss caused by the distribution of heat from the hot oil. The top of the tank body of the extraction tank 1 is provided with a tank cover 10, and the top of the tank cover 10 of ...

Embodiment 2

[0047] The preparation method of the present embodiment tobacco thermal reaction spices is as follows:

[0048] Mix 30kg of Zimbabwe flue-cured tobacco powder, 10kg of Hunan flue-cured tobacco powder and 10kg of flue-cured tobacco stem powder, use 10kg of water, 10kg of ethanol as wetting agent, 1kg of sodium alginate and 0.5kg of chitosan as binder, and use extrusion-spheronization The granulation method was carried out, dried at 80°C for 1 hour, and the tobacco particles of 10 to 40 meshes were screened out by a sieving machine.

[0049] Using the device and operation method shown in Example 1, the tobacco particles were dry-distilled and extracted at 240°C for 2 hours under the protection of nitrogen, and the obtained extract was concentrated by vacuum distillation at 55°C and 0.7MPa for 3 hours, thereby obtaining tobacco heat-reactive spice A, which The main chemical components are shown in Table 1.

[0050] Using a molecular distillation apparatus to molecularly distill ...

Embodiment 3

[0052] In this embodiment, 20kg Guizhou flue-cured tobacco powder, 25kg Hunan flue-cured tobacco powder and 5kg Burley tobacco powder are mixed, 11kg water, 9kg ethanol are used as wetting agent, 0.5kg carboxymethyl cellulose sodium and 0.5kg chitosan are mixed as binding agent The agent was centrifugally granulated, dried at 80°C for 1 hour, and granules of 20-50 mesh were screened out by a sieving machine.

[0053] Using the device and operation method shown in Example 1, the tobacco particles were dry-distilled and extracted at 150°C for 3.5 hours under the protection of nitrogen, and the obtained extract was concentrated by vacuum distillation at 50°C and 0.8MPa for 3.5 hours, thereby obtaining tobacco thermal reaction flavor B .

[0054] Add the obtained tobacco thermal reaction fragrance B from the feed port of the rectifier, and carry out rectification at a temperature of 95°C, a vacuum of 0.05MPa, and a reflux ratio of 2:1. After completion, collect the light component...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com