Cigarette flavoring coating material and application thereof

A coating material and cigarette technology, which can be used in applications, smoker supplies, essential oils/flavors, etc., and can solve problems such as the aroma quality of heat-not-burn tobacco leaves and the sense of smoking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

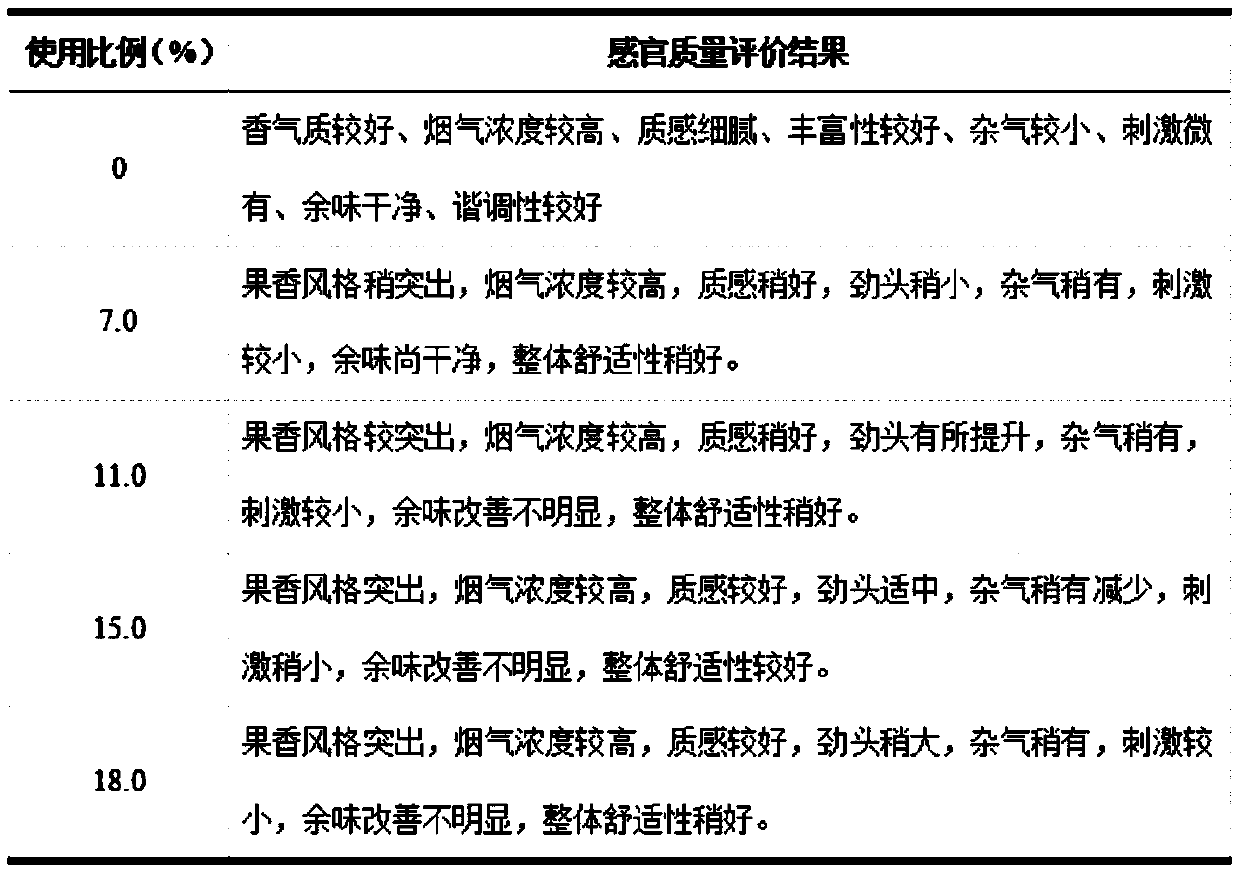

[0065] Embodiment 1 Coating Material Composition 1 Perfume Essence is Preferred

[0066] Various flavoring raw materials were prepared according to the preparation process of heat-not-burn cigarettes to obtain heat-not-burn cigarettes, in which the proportion of functional components and flavors and fragrances was 2.0%, and the smoking evaluation was carried out. The evaluation results are shown in Table 1, evaluation indicators It mainly includes the following five items:

[0067] (1) Increase the richness of cigarette aroma;

[0068] (2) Enhance the thickness and fullness of the cigarette aroma;

[0069] (3) Increase motivation and enhance satisfaction;

[0070] (4) Improve the comfort of suction;

[0071] (5) Improve aftertaste.

[0072] Table 1

[0073] raw material name

Evaluation results

A component

Improve smoke concentration, improve comfort, and increase sweetness

B component

Thickness and strength of rising smoke, slightly less...

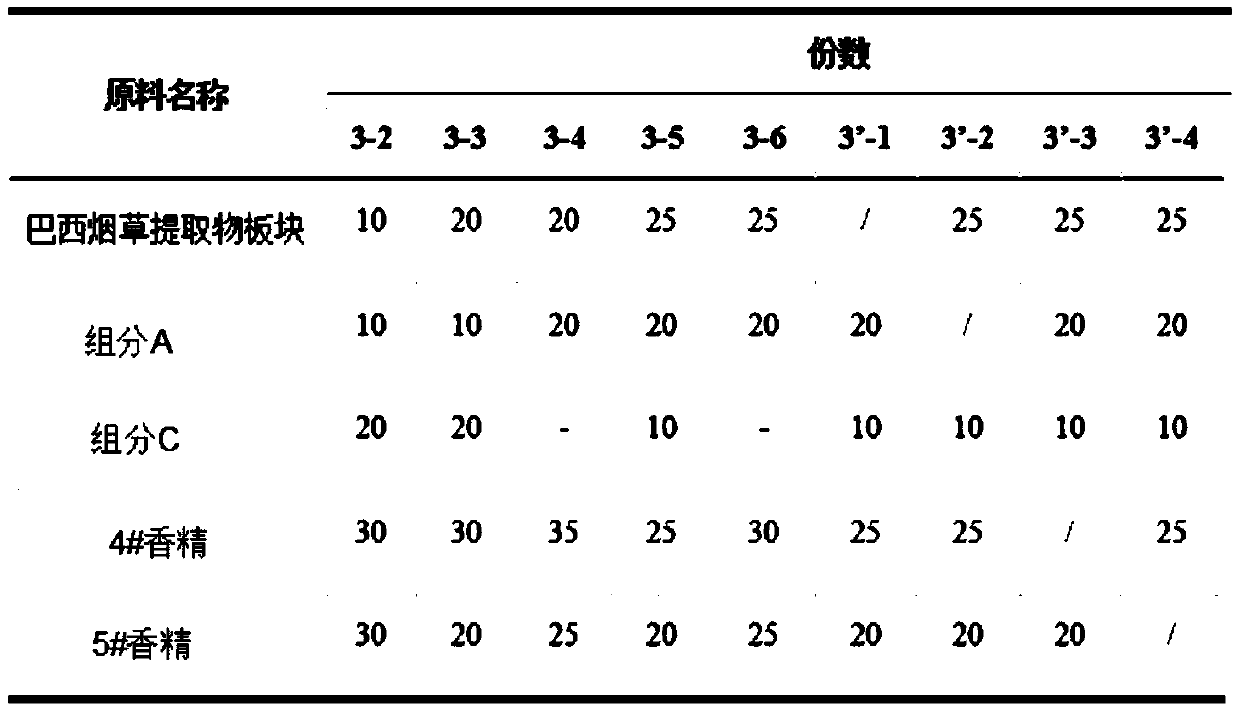

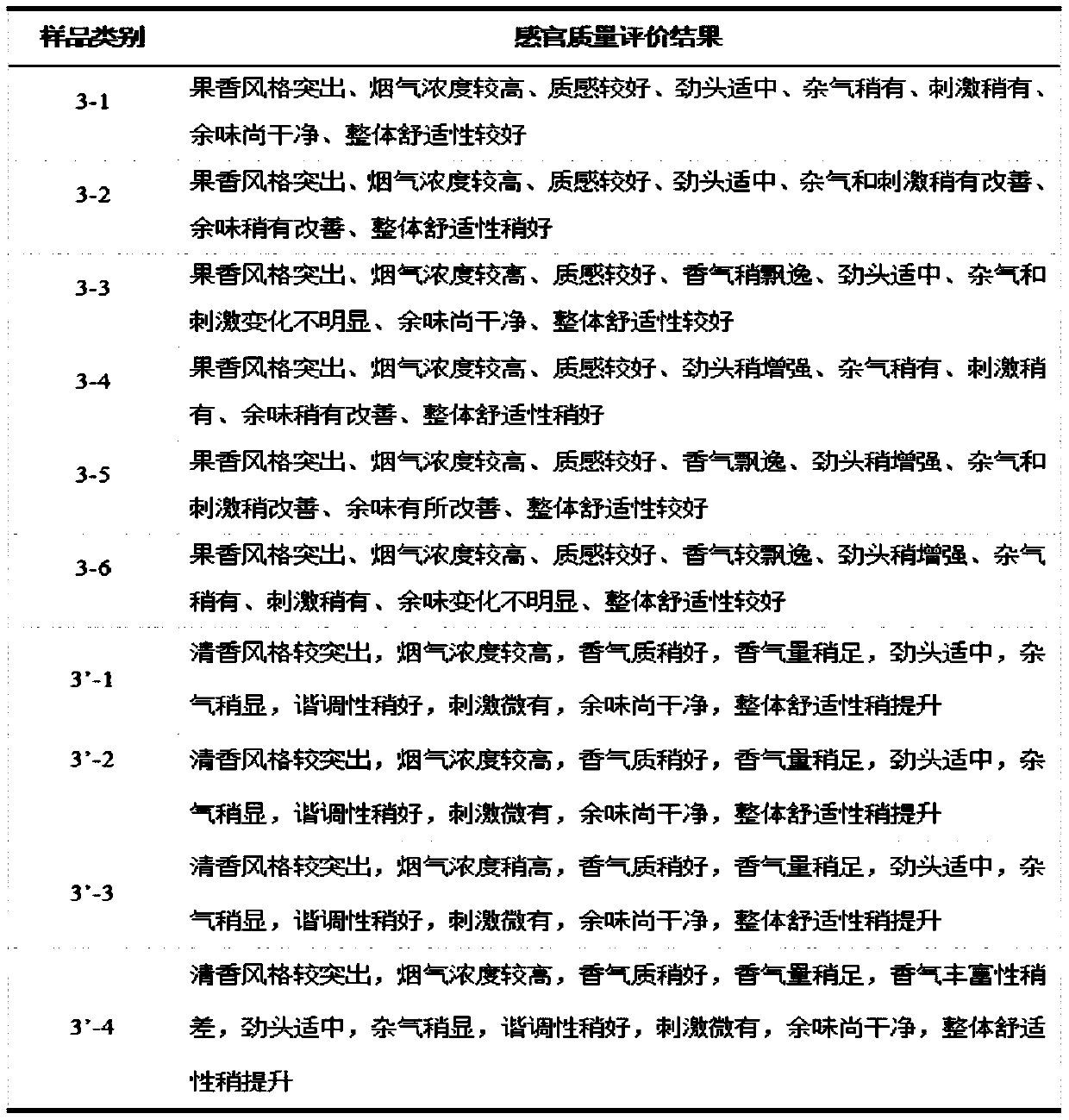

Embodiment 2

[0080] A flavoring coating material for heat-not-burn cigarettes, the distribution ratio of each component is: 20% of A component, 30% of B component, 20% of C component, 30% of 6# essence, and the added amount is 18%.

Embodiment 3

[0082] A flavoring coating material for heat-not-burn cigarettes, the distribution ratio of each component is: 30% of component A, 40% of component B, and 30% of component C, and the addition amount of the coating material in the coating liquid is 18% .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com