Process for making hot-melt pressure sensitive adhesive type fabric base adhesive tape

A technology of hot-melt pressure-sensitive adhesive and manufacturing process, which is applied in the field of use and manufacture, adhesive product manufacturing, and belt-shaped adhesive product production. Cost, product softness, moderate price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

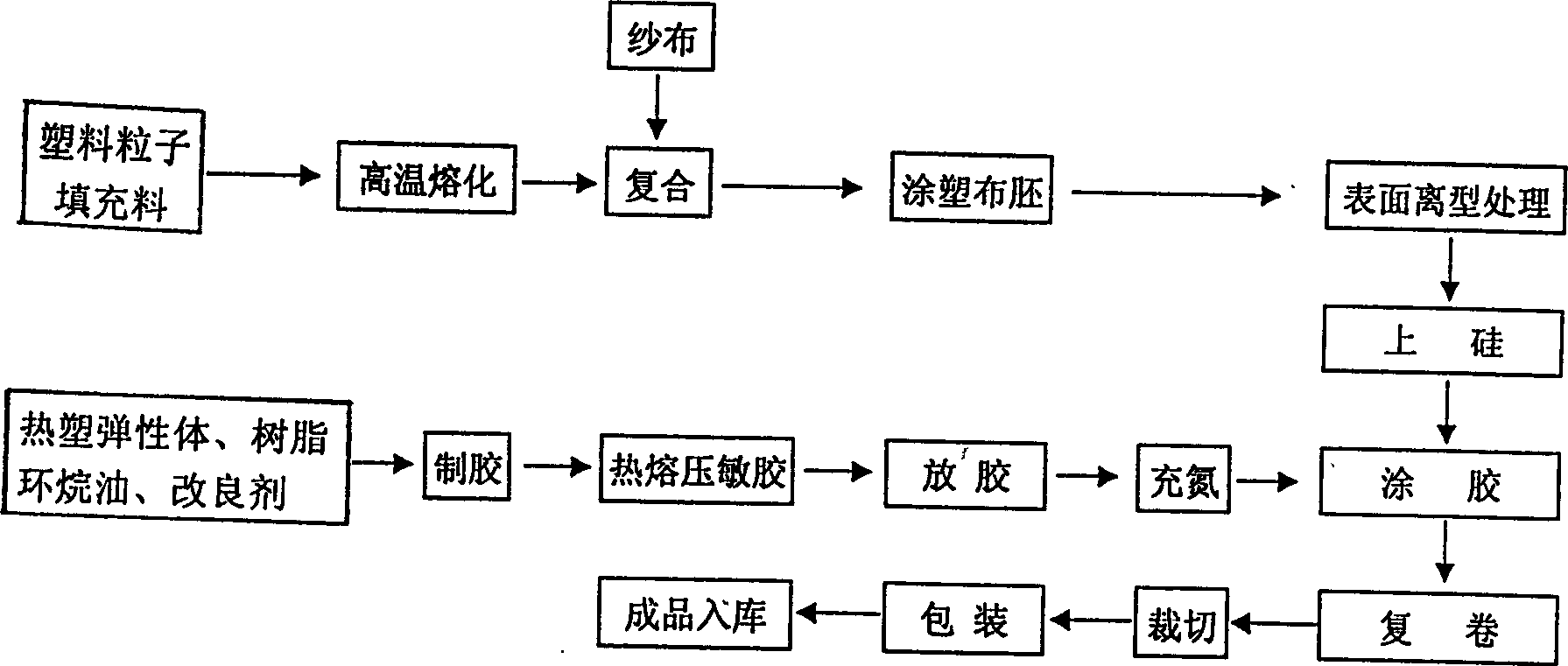

[0023] The present invention will be further described now in conjunction with accompanying drawing

[0024] In the past, one of the processes of making cloth tape was to cover the surface of the gauze with molten pure PE plastic particles; the current process is:

[0025] 1) PE plastic particles and fillers are mixed and melted at a weight ratio of 5:1 at a high temperature of 250°C-270°C; they are compounded and adhered to gauze to form a plastic-coated single-sided cloth embryo; and the following processes are combined to complete the product manufacturing,

[0026] 2) Mix the non-silicon and solvent gasoline used for surface release treatment into the trough as needed, drive the cloth embryo to rotate through the anilox roller in the trough, and evenly smear it on the plastic-coated surface of the plastic-coated cloth embryo. A layer of non-silicon, which is dried in an oven at 70-90°C, so that the non-silicon can be stably solidified on the surface of the cloth blank;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com