Casing flavor for reconstituted tobacco leaves produced by using paper-making method

A technology of reconstituted tobacco leaves and adding flavors, which is applied in the direction of essential oils/spices, tobacco, applications, etc., and can solve the problems of heavy woody odor, residual hot and sour feeling, and prominent added flavors, etc.

Inactive Publication Date: 2011-04-13

HUBEI CHINA TOBACCO IND +1

View PDF0 Cites 24 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

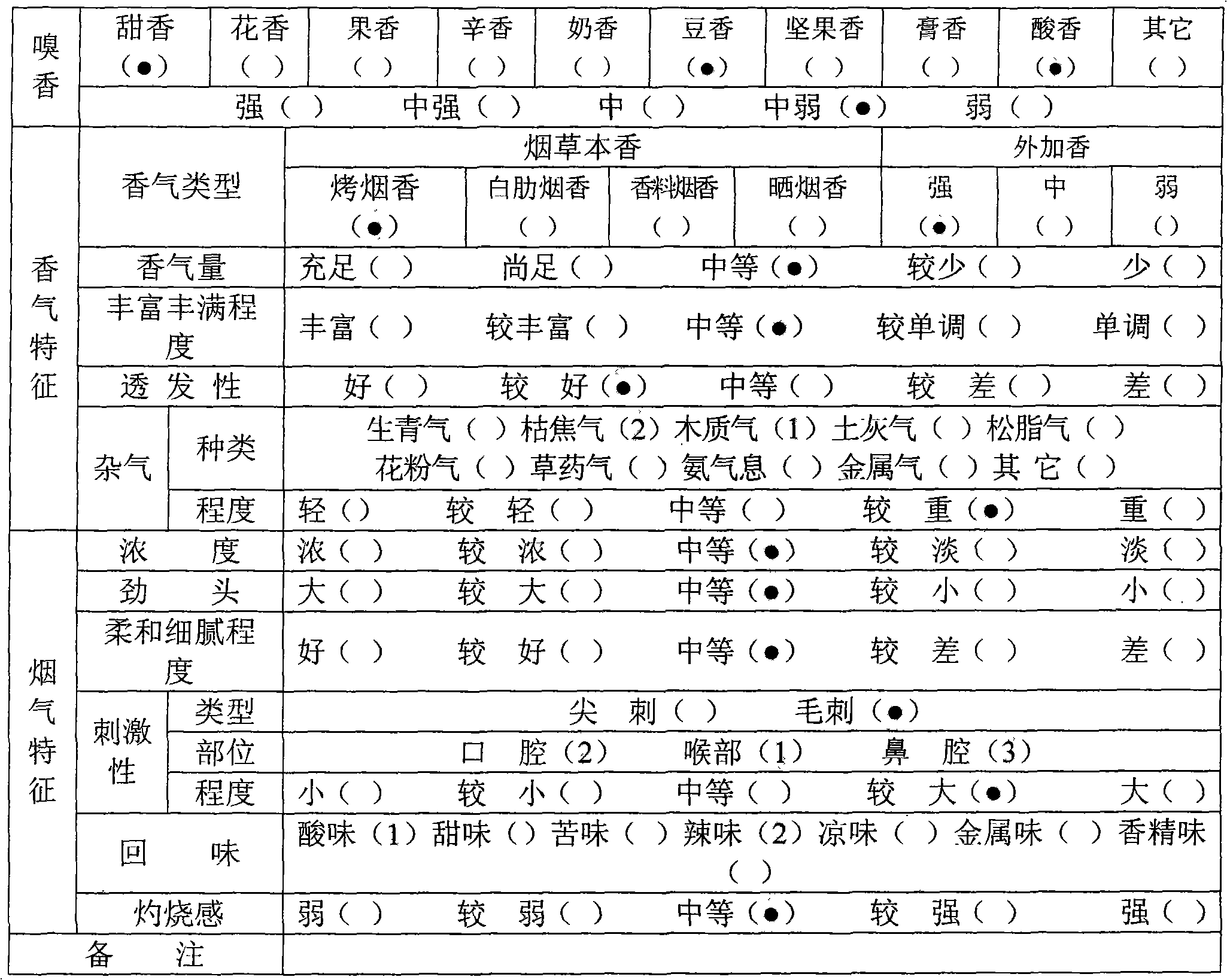

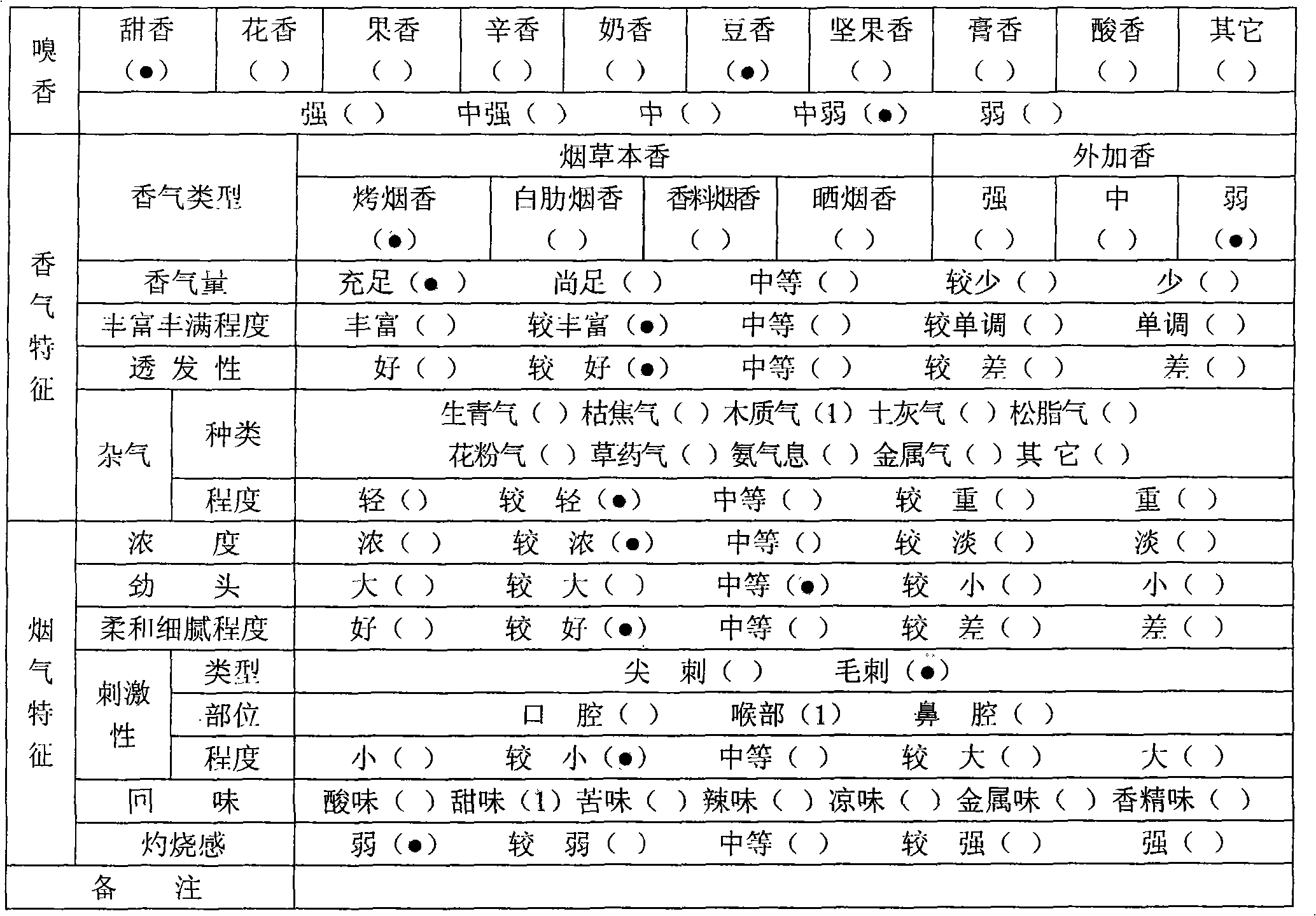

[0010] The object of the present invention is to provide a flavoring essence aiming at the sensory quality defects of the existing paper-making reconstituted tobacco leaves, which solves the existing problems of the existing paper-making reconstituted tobacco leaves with prominent added aroma, heavy woody odor, large stimulation, and hot and sour feeling. Residue, and has the disadvantage of a certain burning sensation, improving the usability of reconstituted tobacco leaves by papermaking method

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0023] raw material

[0024] flue-cured tobacco extract

[0025] The preparation method is to mix the above-mentioned raw materials evenly.

Embodiment 2

[0027] raw material

[0028] Plum Extract

[0029] The preparation method is to mix the above-mentioned raw materials evenly.

Embodiment 3

[0031] raw material

[0032] The preparation method is to mix the above-mentioned raw materials evenly.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to tobacco flavors, in particular to a casing flavor for reconstituted tobacco leave produced by using a paper-making method. The casing flavor is prepared by mixing the following raw material components according to weight percentage: 8-15 percent of cured tobacco extracts, 2-3 percent of yellow sun-cured tobacco extracts, 2-6 percent of red date extracts, 1-4 percent of reed root extracts, 2-8 percent of momordica grosvenori extracts, 3-8 percent of tamarind pulp extracts, 6-8 percent of plum extracts, 5-7 percent of wild jujube leaves extracts, 8-10 percent of elm bark extracts, 8-10 percent of water and 21-55 percent of propanediol. The invention overcomes the defects of insufficient fragrance quantity, denser wood miscellaneous gas, larger stimulation, remained sour and hot feeling and certain burning feeling of the reconstituted tobacco leaves produced by using the paper-making method. The casing flavor increases fragrance quantity, enriches fragrance, ensures better softness and fineness, smaller stimulation to the throat part and less residues, ensures that a firing sense basically disappears, and greatly improves the organoleptic quality of the reconstituted tobacco leaves by using the paper-making method.

Description

technical field [0001] The invention relates to a tobacco essence, in particular to a flavoring essence used for reconstituted tobacco leaves by papermaking. Background technique [0002] Paper-making reconstituted tobacco leaves are regenerated products made of tobacco materials such as tobacco dust, tobacco stems, and shredded tobacco sheets as raw materials in sheet (or silk) form, and are used as cigarette fillers. It can maximize the use of leftover tobacco leaves, effectively reduce the cost of cigarettes, and at the same time adjust and improve the physical properties and chemical components of cigarettes to a certain extent. It is one of the effective means of reducing tar and consumption of cigarette products, and is widely used In cigarettes, domestic tobacco companies began to use paper-making reconstituted tobacco leaves in 1999, and the consumption has increased year by year. At present, the domestic tobacco industry uses paper-making reconstituted tobacco leave...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C11B9/00A24B15/30A24B3/12

Inventor 马舒翼程书锋赵同林董世良赵国豪潘婷婷

Owner HUBEI CHINA TOBACCO IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com