Alfalfa leaf extract preparation method and use as tobacco product additive

A technology of leaf extract and alfalfa is applied in the directions of preparing tobacco, tobacco, processing tobacco, etc., can solve the problems of inability to meet the requirements for the use of cigarette additives, no literature report on alfalfa extract, etc., and achieves rich aroma and thick feeling. , the effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

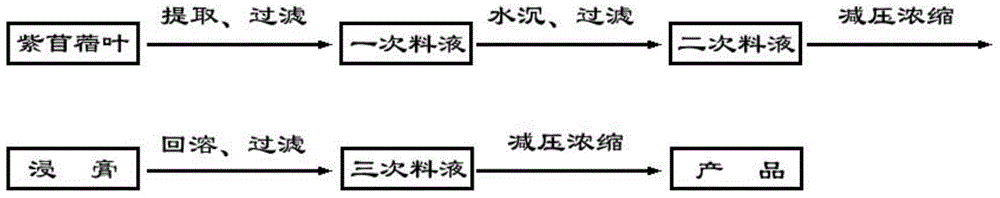

Embodiment 1

[0025] Firstly, phenylacetic acid is added to 75% ethanol aqueous solution by volume fraction, the pH value of ethanol aqueous solution is 5.0, the volume ratio of ethanol aqueous solution and alfalfa leaf is 30:1, extract at 90° C. for 3 hours, and after separating the primary feed liquid, add it to the primary feed Add 2 times the volume of water (sodium carbonate is added to adjust the pH value to 8.5) and separate the precipitate. The separated secondary feed liquid is concentrated to the extract with a density of 1.100. The volume fraction of the extract with 8 times the volume is 75 % of ethanol aqueous solution, filter again to separate the by-products and the three feed liquids, and concentrate the three feed liquids again to extract-like, that is, the alfalfa leaf extract 1 of the present invention is obtained.

Embodiment 2

[0027] First add citric acid to 75% ethanol aqueous solution by volume fraction, adjust the pH value of ethanol aqueous solution to 5.5, and the volume ratio of ethanol aqueous solution to alfalfa leaves is 15:1, extract at 50°C for 4 hours, separate the feed liquid once, and feed it once Add 4 times the volume of water to the feed solution (adding ammonia water to adjust the pH value to 9.5) and separate the precipitate. The separated secondary feed solution is concentrated to an extract with a density of 1.300. The volume fraction of the extract with 8 times the volume is 75 % of ethanol aqueous solution, filter again to separate the by-products and the third feeding liquid, and concentrate the third feeding liquid again to the extract form, that is, the alfalfa leaf extract 2 of the present invention is obtained.

Embodiment 3

[0029] First add malic acid to 75% ethanol aqueous solution by volume fraction, adjust the pH value of ethanol aqueous solution to 4.5, the volume ratio of ethanol aqueous solution to alfalfa leaf is 20:1, extract at 60°C for 2 hours, separate the feed liquid once, and feed it once Add 5 times the volume of water to the feed solution (sodium hydroxide is added to adjust the pH value to 10.0) and separate the precipitate. The separated secondary feed solution is concentrated to an extract with a density of 1.200. Use 5 times the volume of the extract in the volume fraction Redissolve in 75% ethanol aqueous solution, filter again to separate the by-products and the third feeding liquid, and concentrate the third feeding liquid again to the extract form to obtain the alfalfa leaf extract 3 of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com