Cordyceps sinensis extraction liquid, and preparation method, composition and application thereof

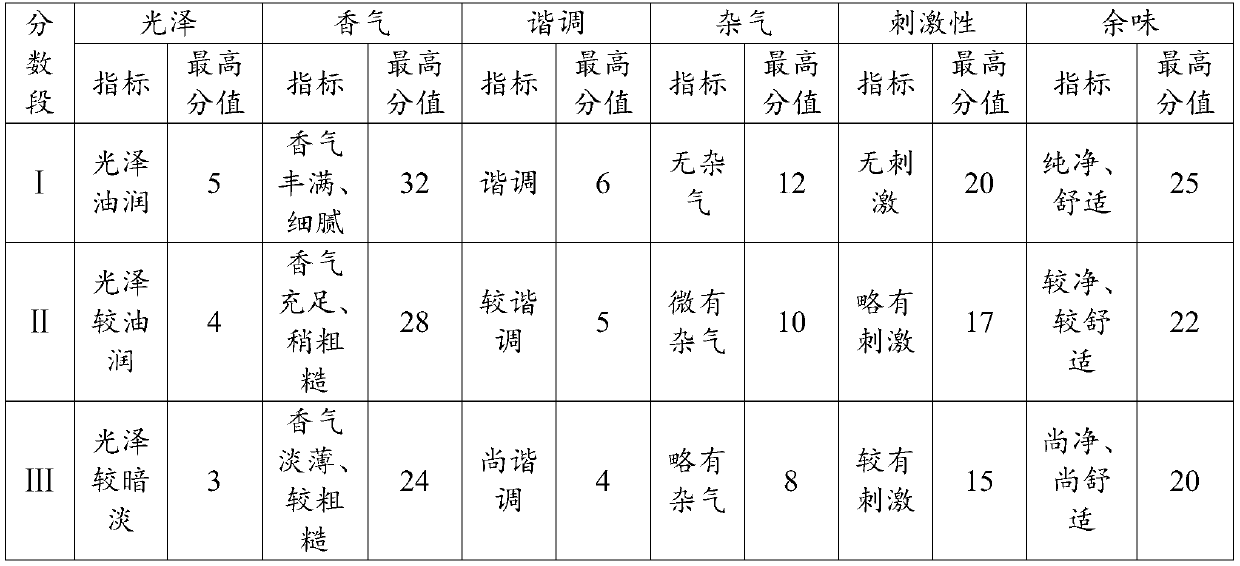

A technology of cordyceps sinensis and extracting solution, applied to cordyceps sinensis extract and preparation thereof, a composition containing cordyceps sinensis extract, application field in improving the quality of cigarettes, can solve the problems of inability to significantly reduce irritating cigarette aroma and sensory quality, etc., To achieve the effect of enhancing the feeling of fullness and pleasure, enhancing the feeling of thickness, and improving the quality of the senses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

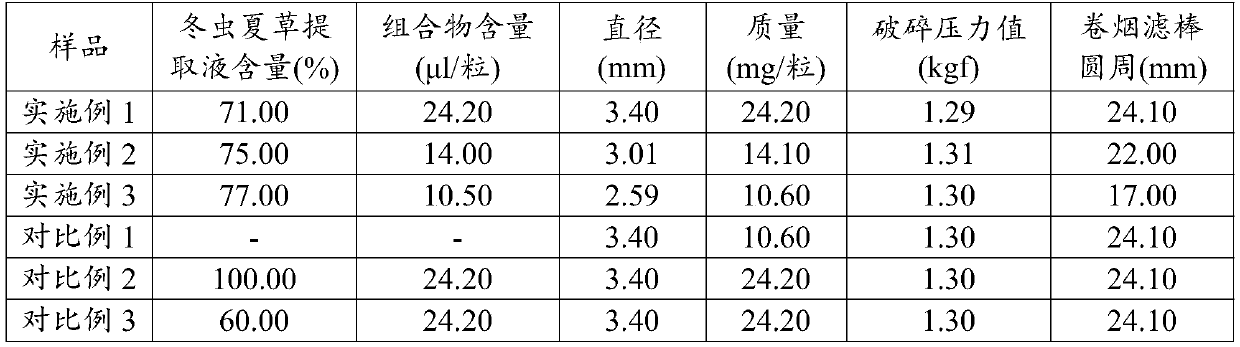

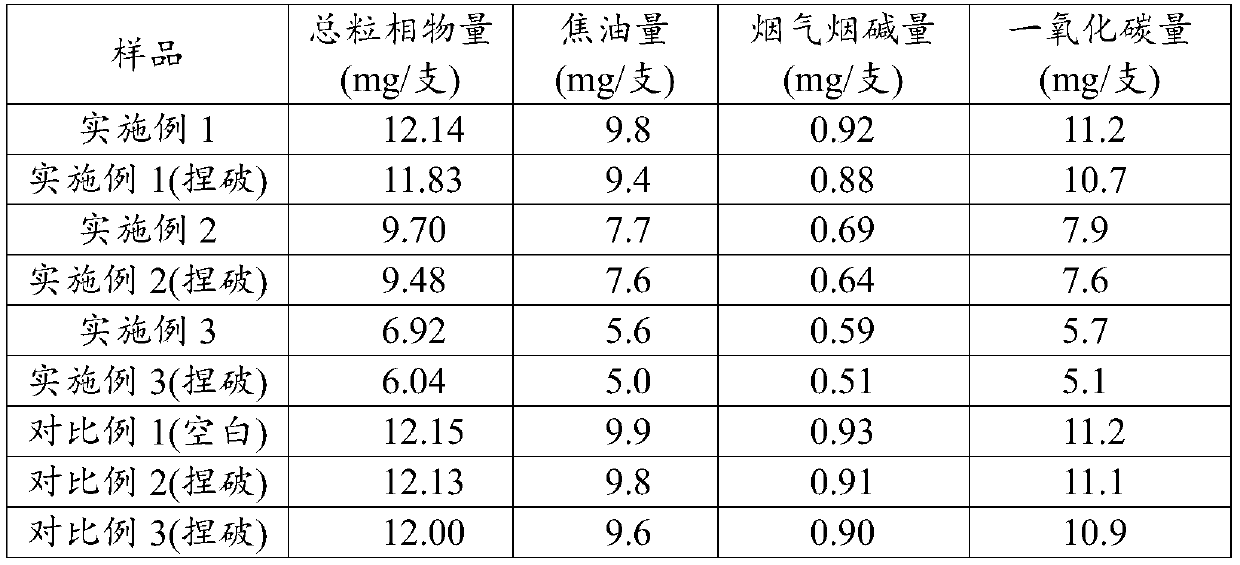

Examples

preparation example Construction

[0040] In a preferred embodiment, the preparation method of the Cordyceps sinensis extract specifically includes the following steps:

[0041] S1, Cordyceps sinensis is pre-treated by washing, removing impurities, and drying in the sun, then dried at 30-60°C, and crushed directly or in liquid nitrogen to 40-100 mesh to obtain Cordyceps sinensis powder;

[0042] S2, under 80-100°C or ultrasonic or microwave conditions, the Cordyceps powder is subjected to water bath heat reflux or vibration extraction for 1-12 hours with ethanol, wherein the solid-liquid ratio of the Cordyceps powder to the ethanol solution is: Cordyceps powder:Ethanol=1g :7-10ml;

[0043] S3, after the extract is cooled to 15-25°C, add a compound enzyme preparation containing cellulase, lipase, ligninase, and pectinase to it, the enzymolysis temperature is 20-25°C, and the enzymolysis time is 120-150min ;

[0044] S4, the extract solution added with various enzyme preparations is concentrated under reduced p...

Embodiment 1

[0047] A kind of Cordyceps sinensis extract, prepared by the following method:

[0048] Cordyceps sinensis is washed, removed impurities, aired, dried at 60°C, pulverized in liquid nitrogen to 100 mesh to obtain Cordyceps sinensis powder; at 100°C, use 80% ethanol, with Cordyceps sinensis powder:ethanol=1g:10ml The liquid ratio was shaken and extracted for 10 hours. After cooling to 25°C, 1.4ml of compound enzyme with a concentration of 1 million U / ml was added to each 100ml of Cordyceps sinensis extract, that is, 140,000 U of enzyme was added to each gram of Cordyceps sinensis dry matter. Among them, the compound The enzyme is composed of cellulase, lipase, ligninase and pectinase according to the enzyme activity ratio of 3:2:4:1. Add 420,000 U of cellulase and 280,000 U of lipase to every 100ml of Cordyceps sinensis extract. 560,000 U of prime enzyme, 140,000 U of pectinase; under 70kPa, it is divided into three stages of 33-50°C, 50-65°C, and 65-80°C under reduced pressure ...

Embodiment 2

[0055] A kind of Cordyceps sinensis extract, prepared by the following method:

[0056] Cordyceps sinensis is washed, removed impurities, aired, dried at 50°C, and directly crushed to 80 meshes to obtain Cordyceps sinensis powder; under ultrasonic conditions, use 70% ethanol with a material-liquid ratio of Cordyceps sinensis powder: ethanol = 1g: 8ml Heat reflux extraction in a water bath for 8 hours, after cooling to 20°C, add 1.2ml of compound enzyme with a concentration of 1 million U / ml to every 100ml of Cordyceps sinensis extract, that is, add 96,000 U of enzyme to each gram of Cordyceps dry matter, of which, the compound enzyme It is composed of cellulase, lipase, ligninase and pectinase according to the enzyme activity ratio of 2:1:5:2. Add 240,000 U of cellulase, 120,000 U of lipase, and lignin to every 100ml of Cordyceps sinensis extract. Enzyme 600,000 U, pectinase 240,000 U; under 50kPa, it is divided into three stages of 33-50°C, 50-65°C, and 65-80°C under reduced ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com