Patents

Literature

94 results about "Phenyl acetic acid" patented technology

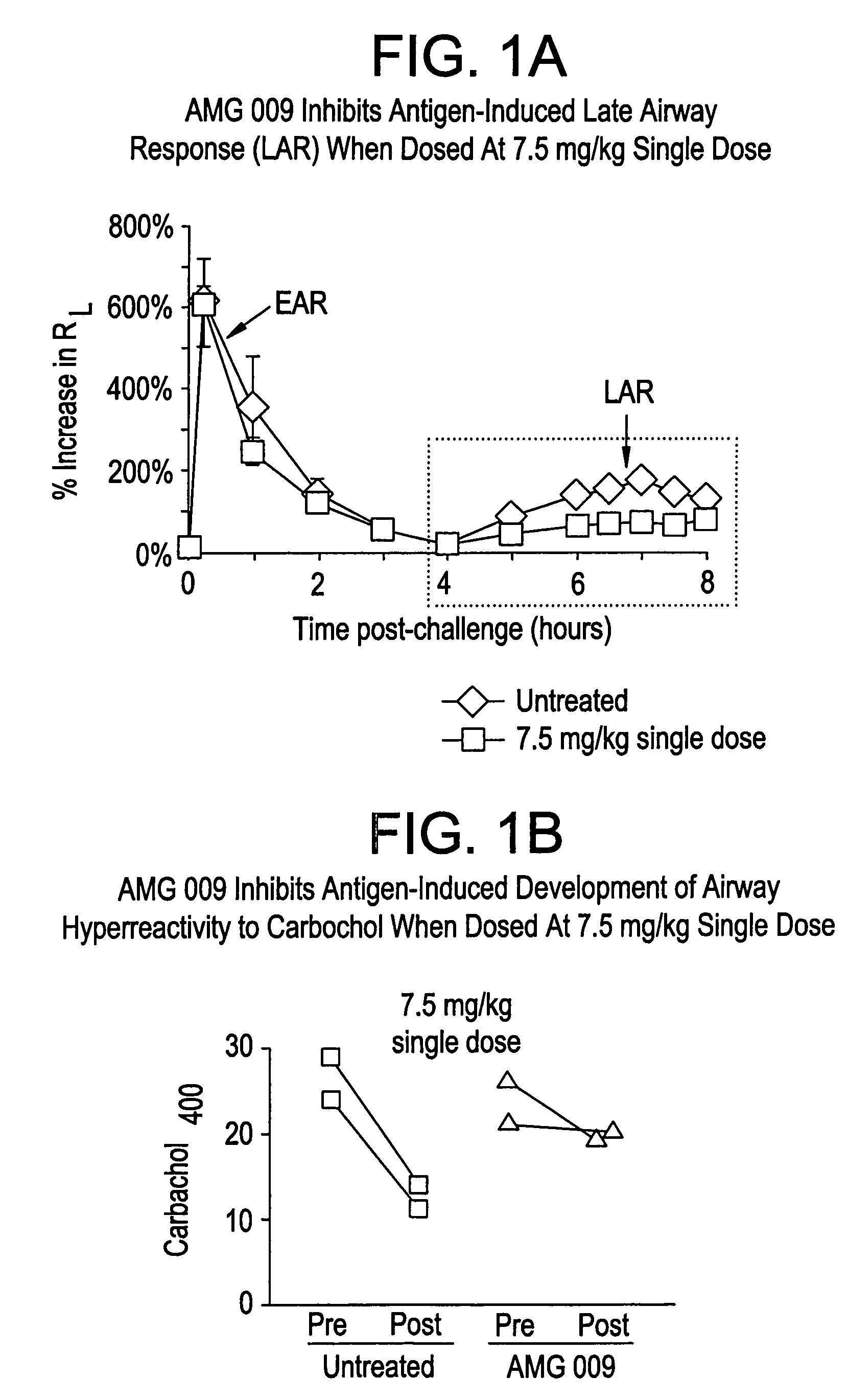

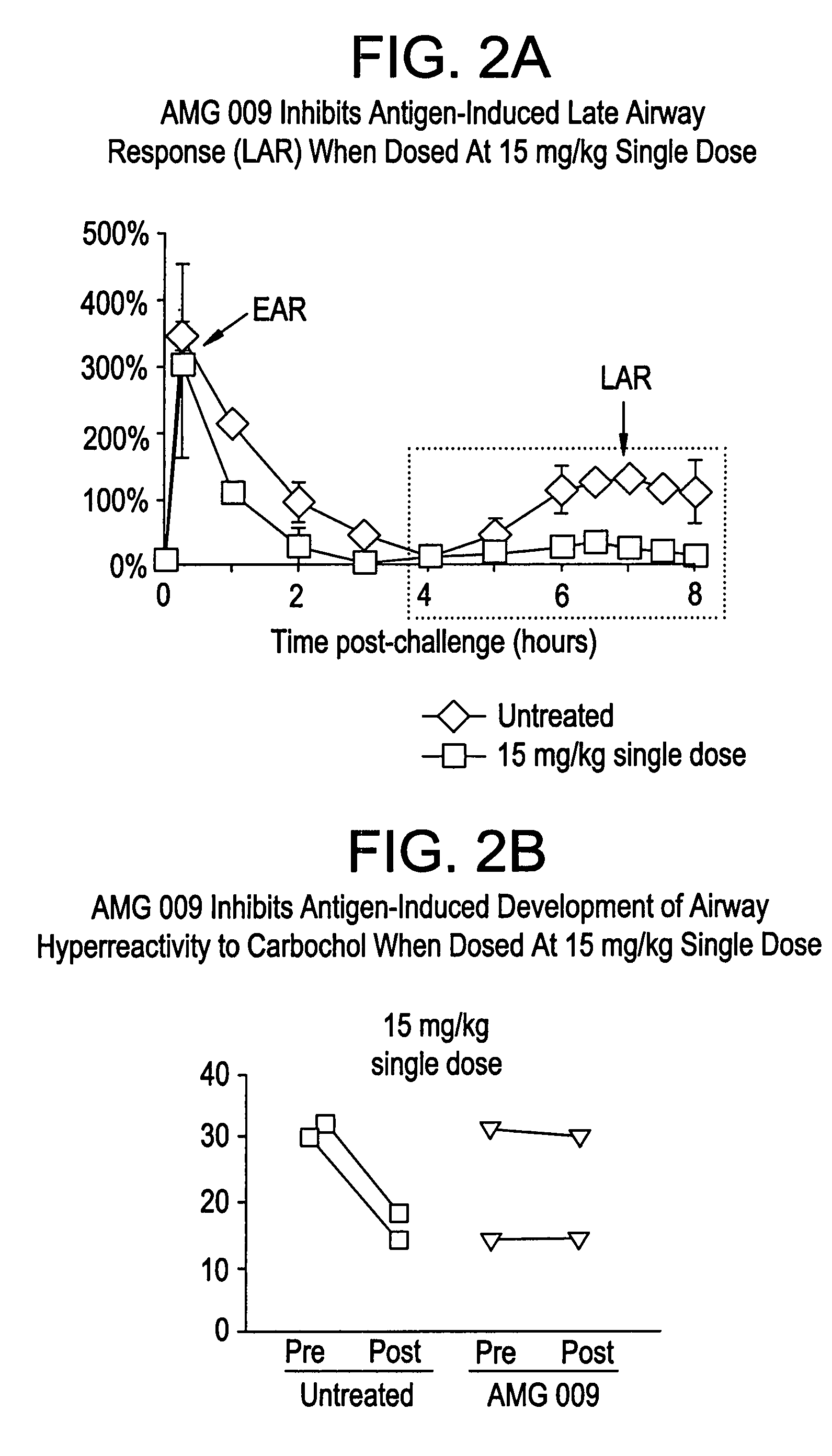

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

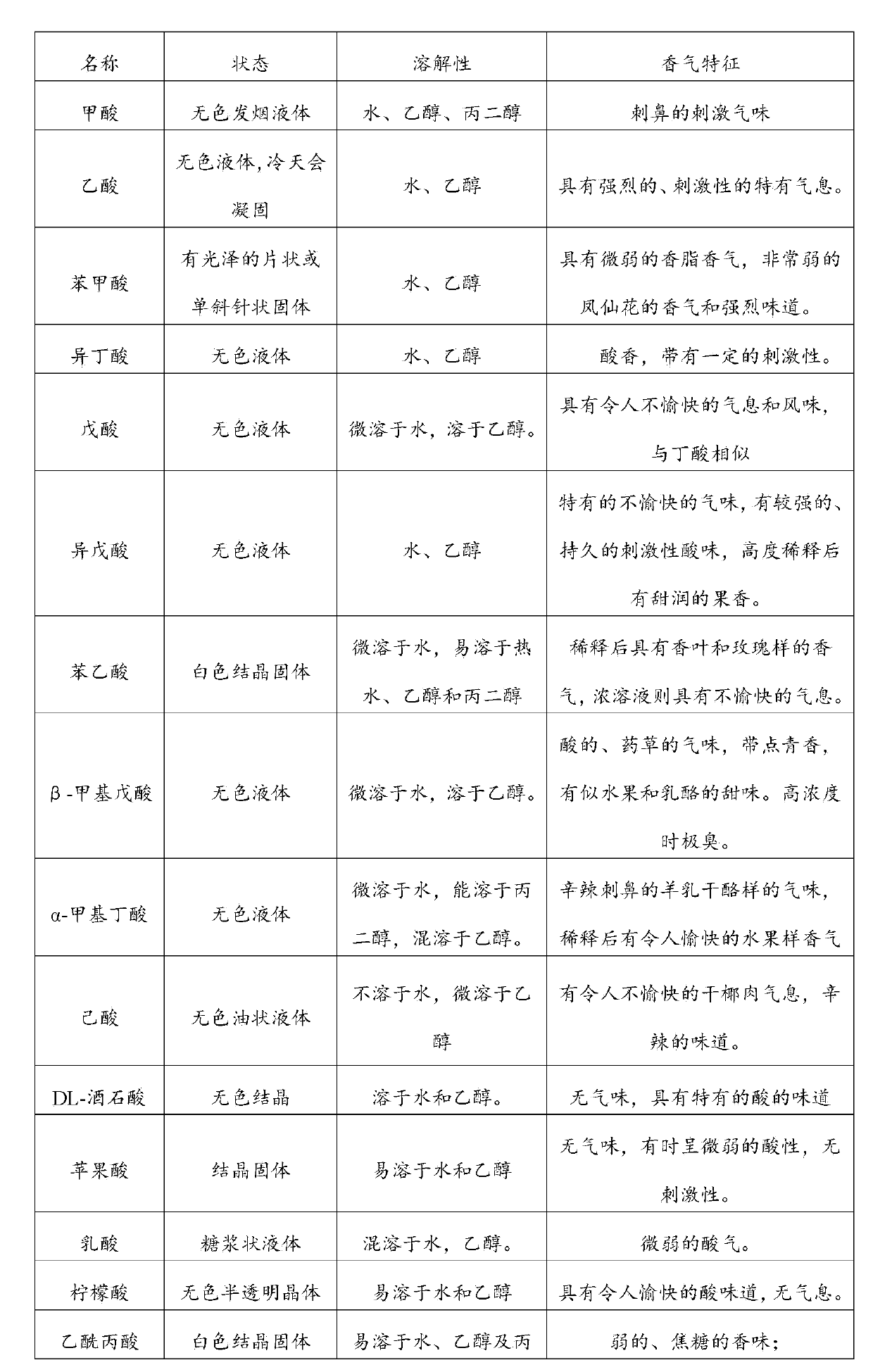

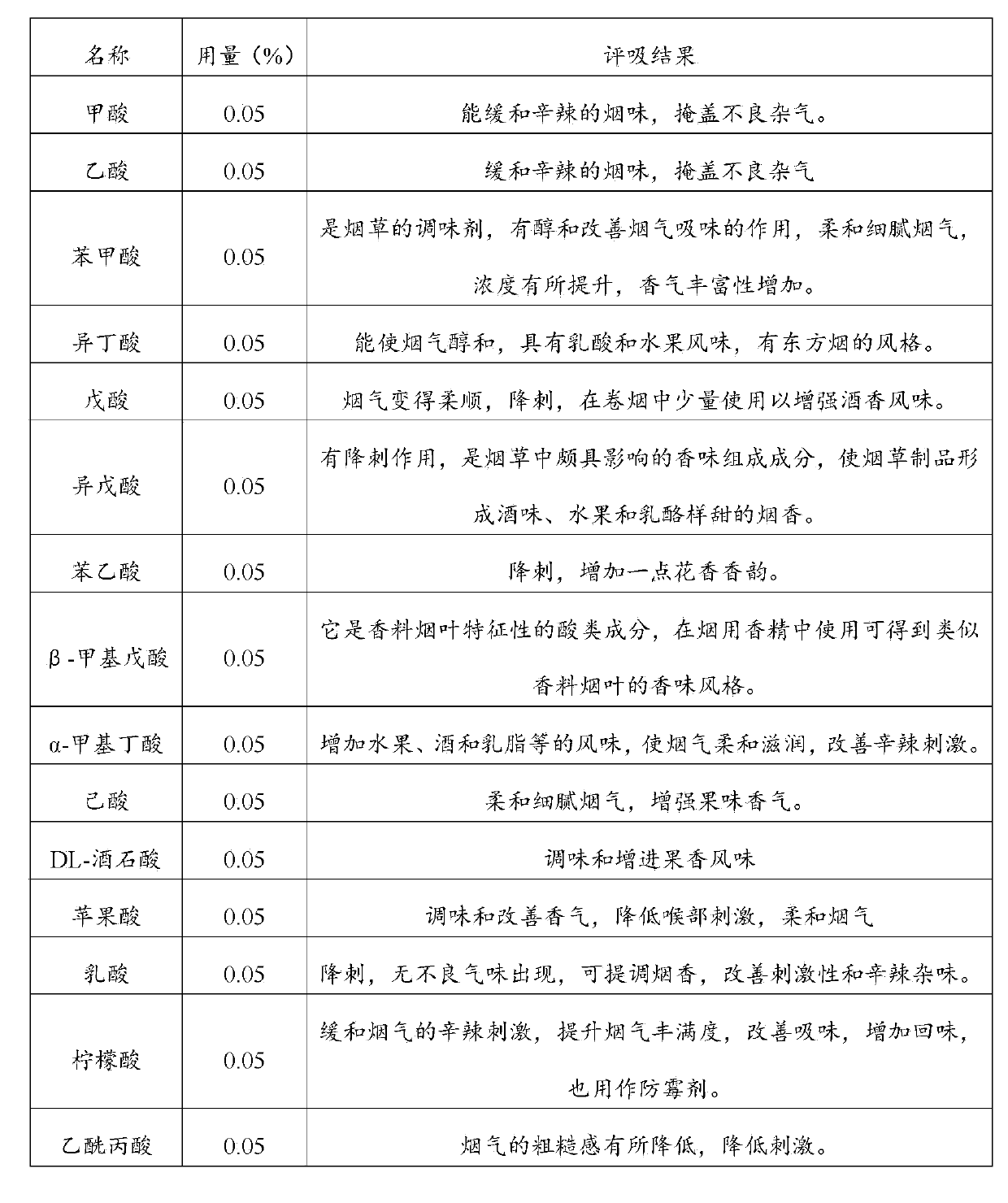

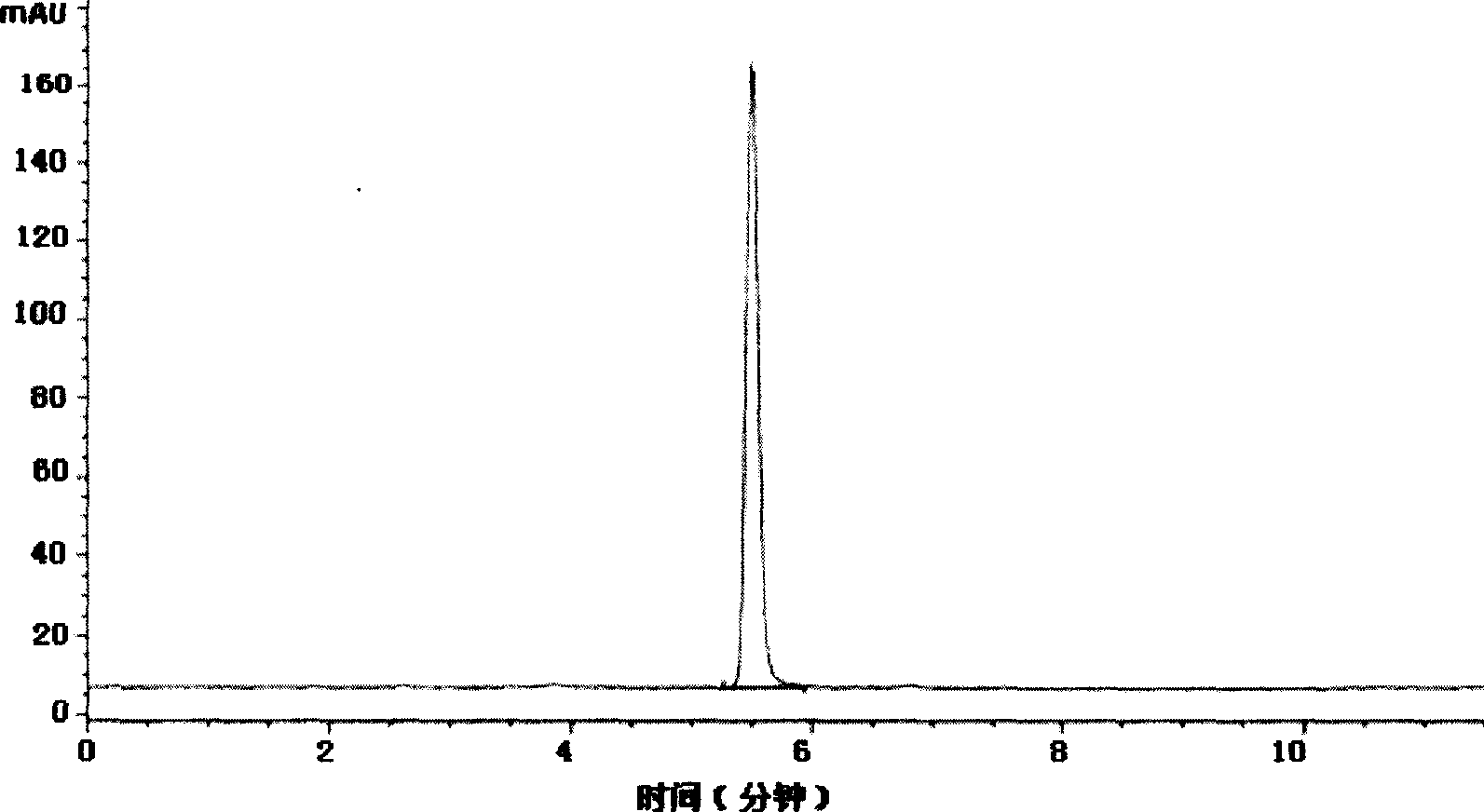

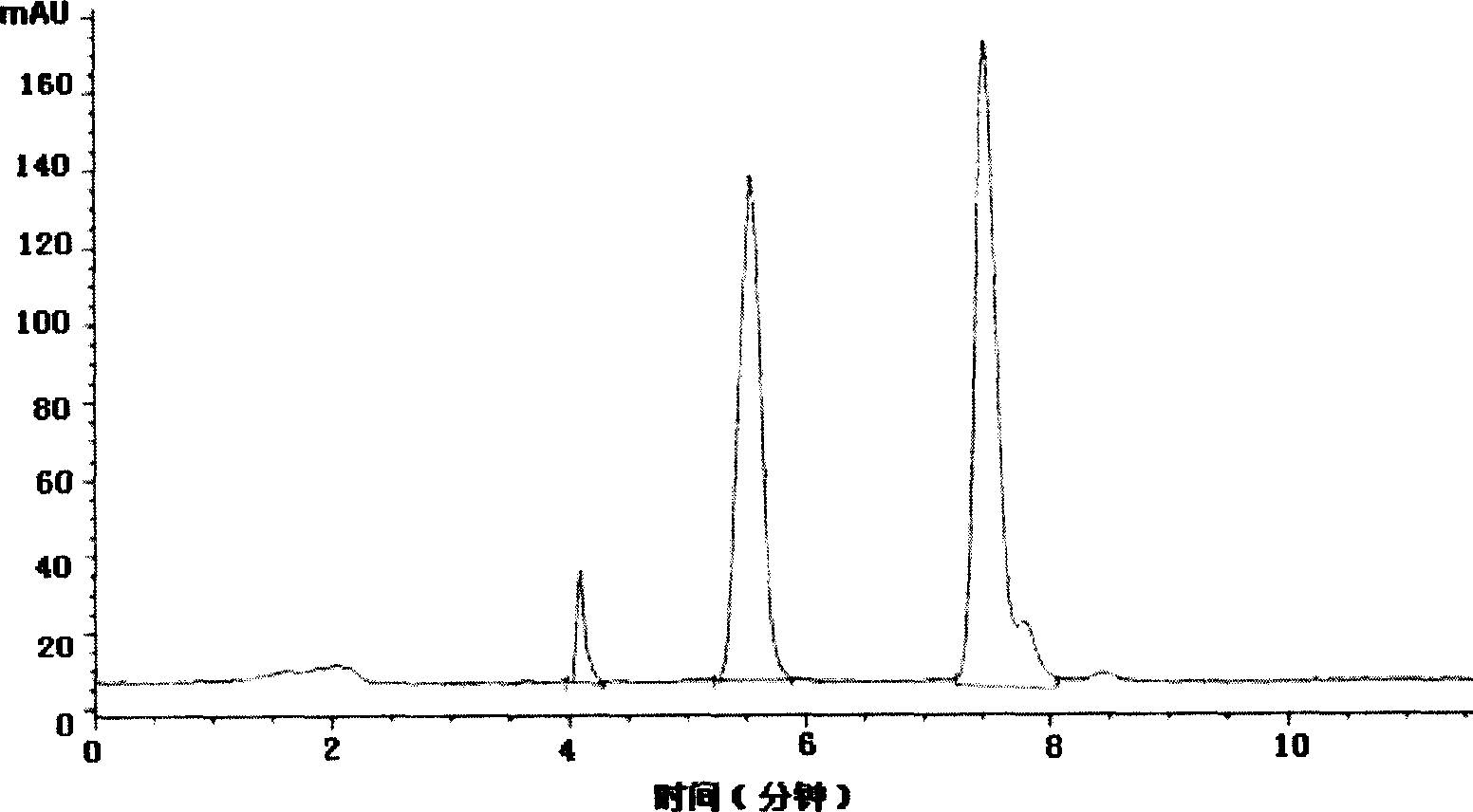

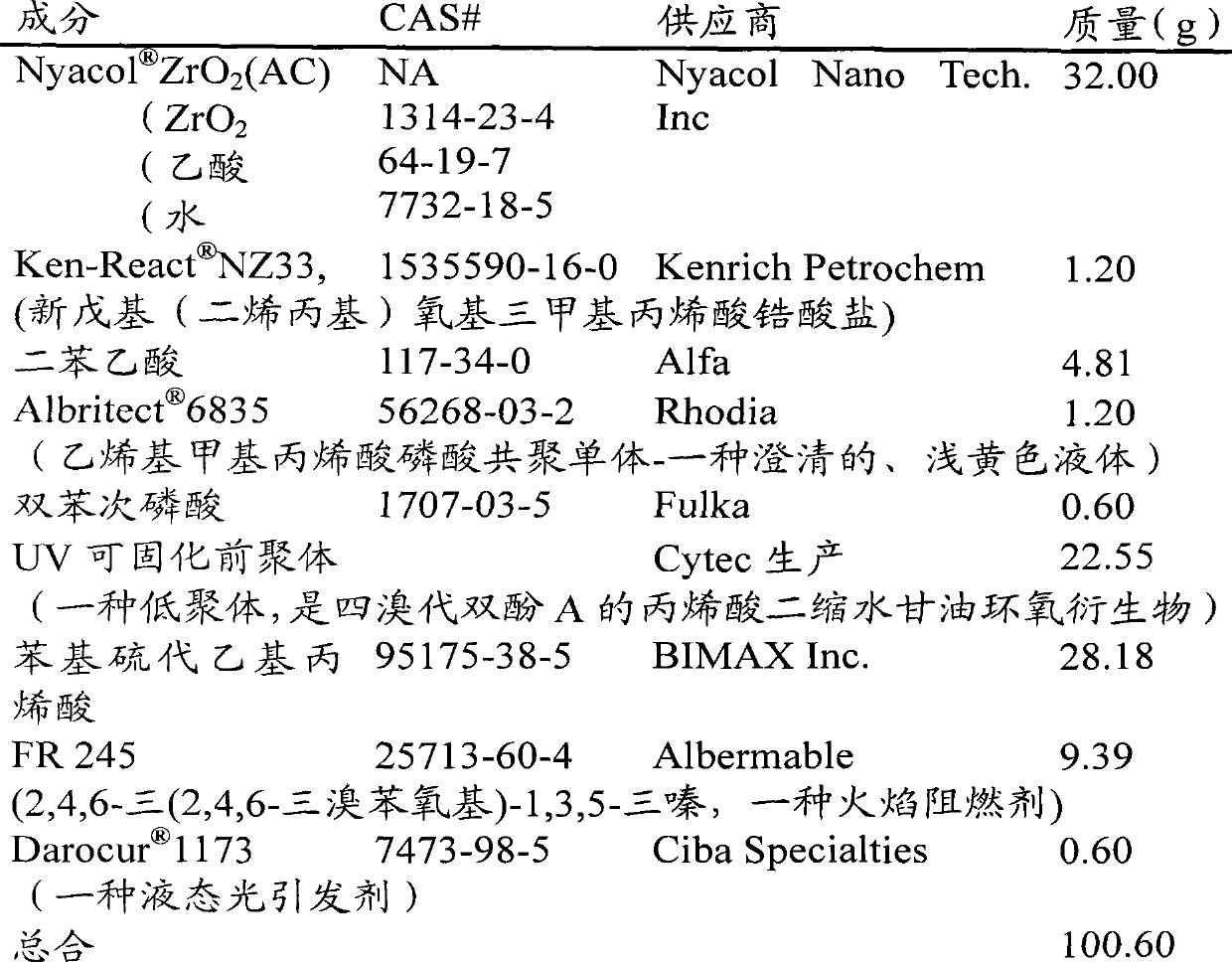

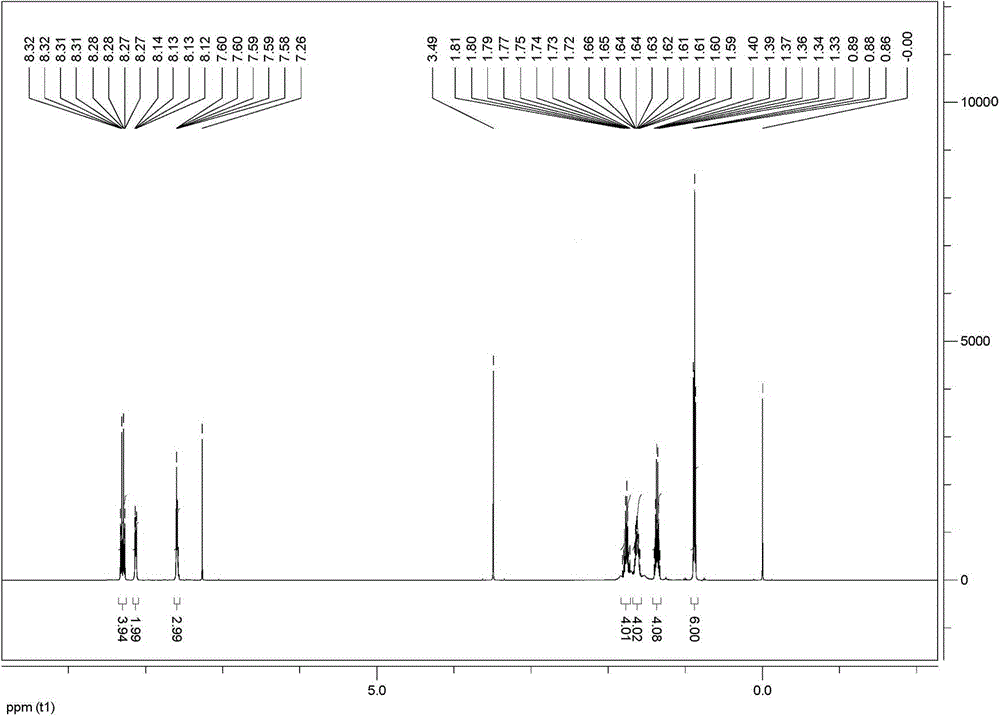

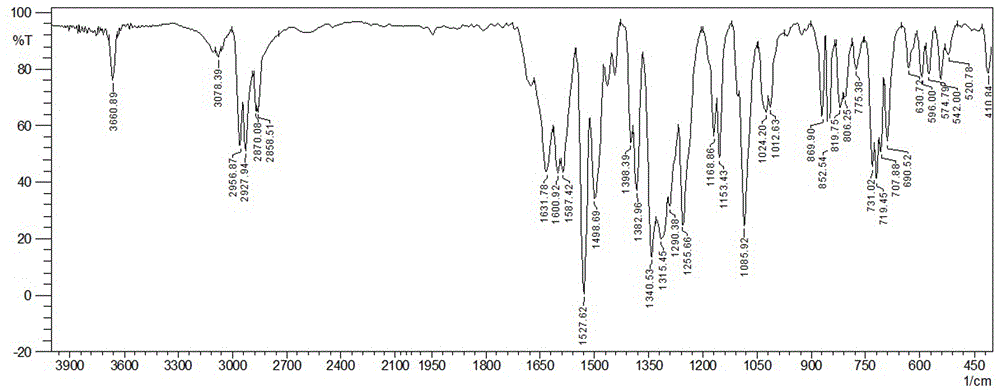

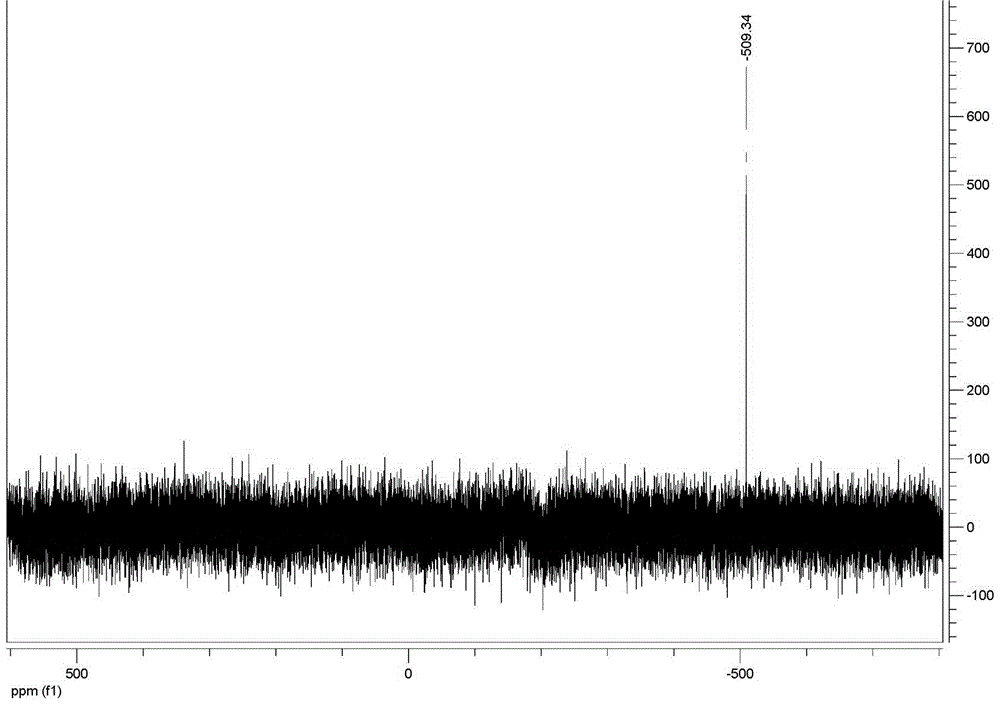

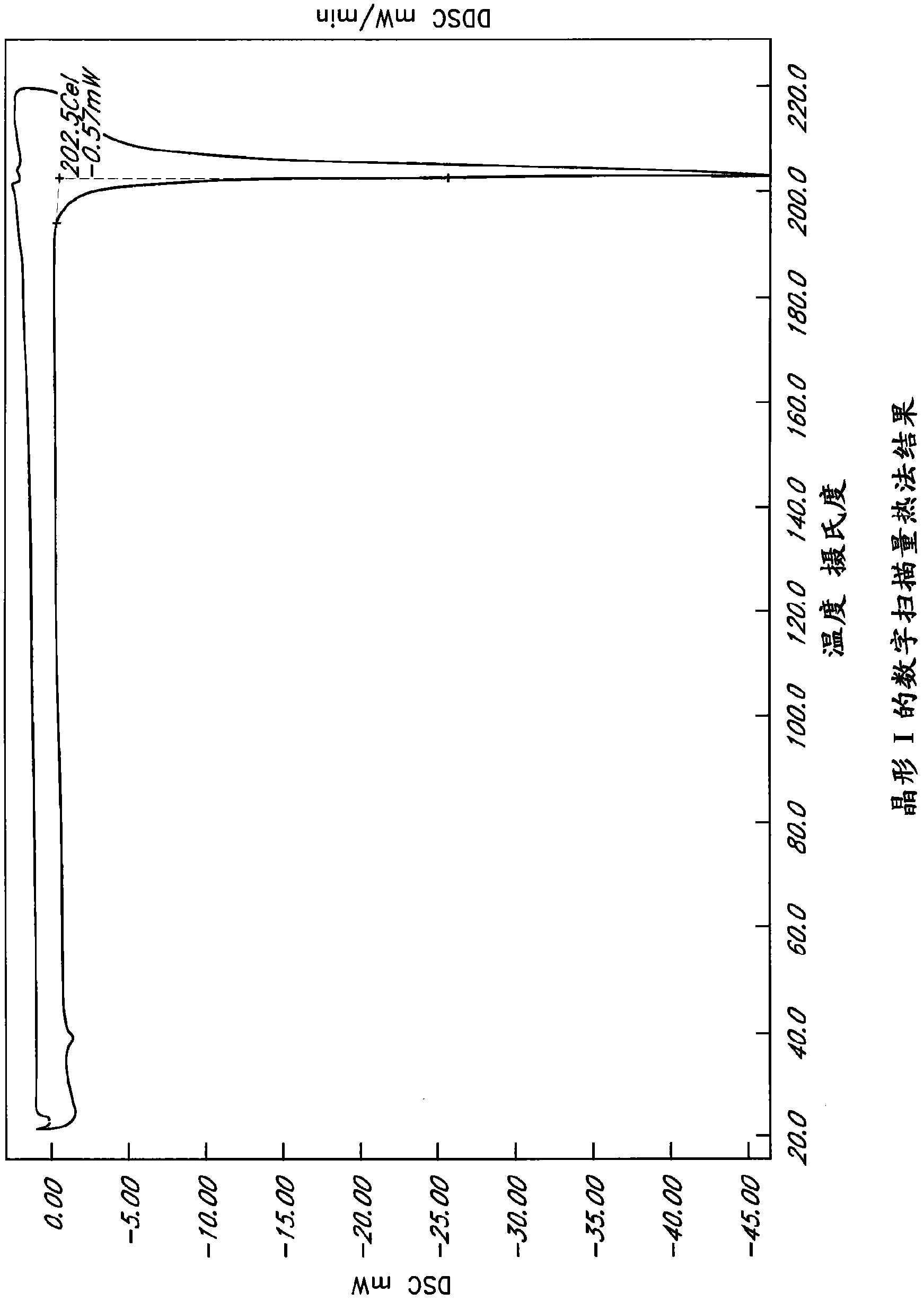

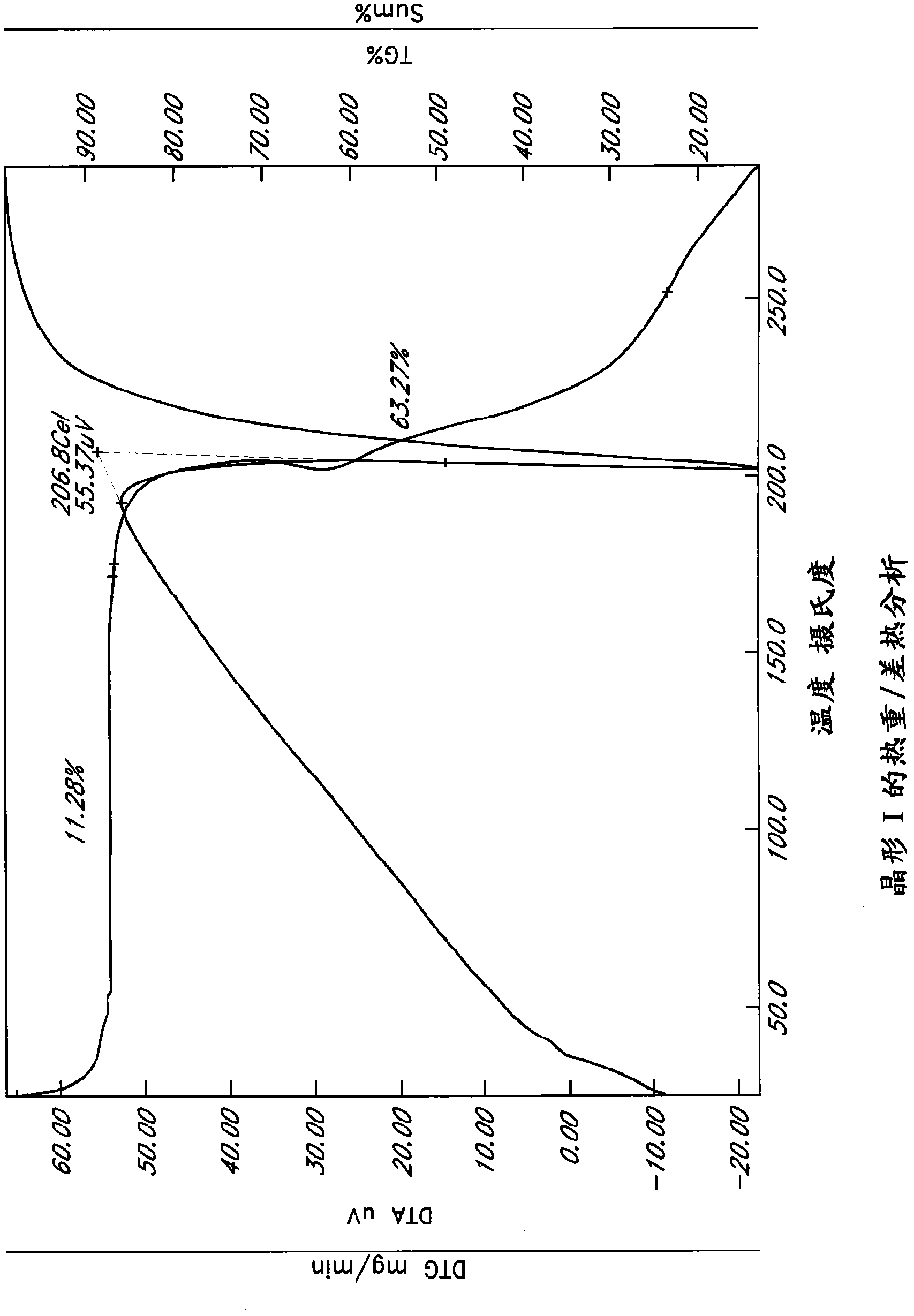

Novel crystalline forms of 4-[4-[4-(hydroxydiphenylmethyl)-1- piperidinyl]-1-hydroxybutyl]-$g(a)-dimethylbenzene acetic acid and its hydrochloride

The present invention is related to novel polymorph of Fexofenadine and Fexofenadine hydrochloride of formula 1 and process of preparation thereof. The present invention is also directed to provide pure novel polymorphs of Fexofenadine and its hydrochloride by a simple process which is cost effective, commercially viable and environment friendly.

Owner:DR REDDYS LAB LTD

Compositions of a chromene or phenyl acetic acid cyclooxygenase-2 selective inhibitor and an ACE inhibitor for the treatment of central nervous system damage

The present invention provides compositions and methods for the treatment of central nervous system damage in a subject. More particularly, the invention provides a combination therapy for the treatment of a central nervous system ischemic condition or a central nervous system traumatic injury comprising the administration to a subject of an ACE inhibitor in combination with a chromene or phenyl acetic acid cyclooxygenase-2 selective inhibitor.

Owner:PHARMACIA CORP

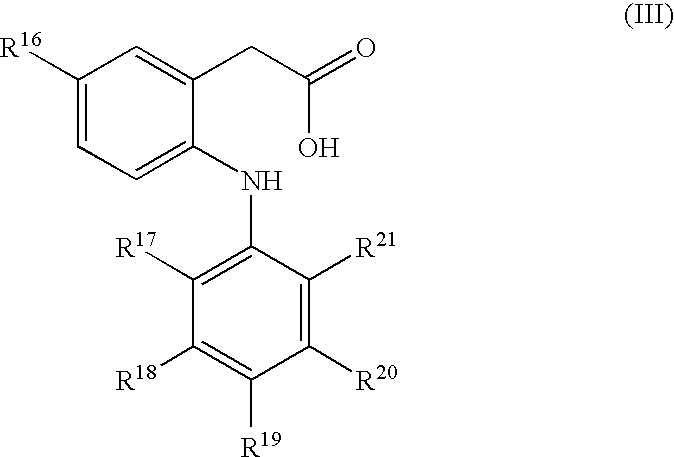

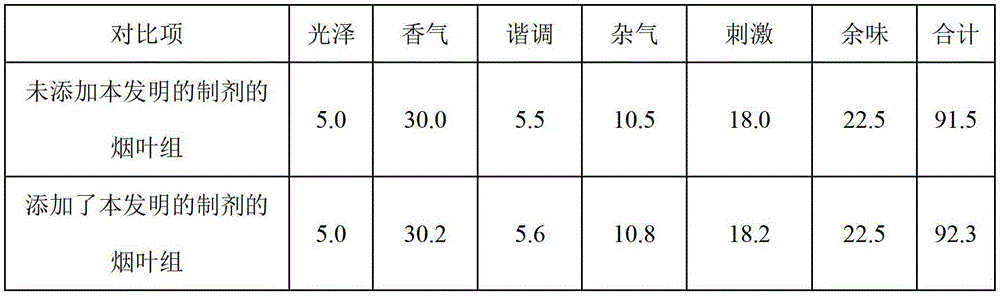

Enriching and thickening functional cluster substance preparation capable of obviously increasing richness and lumping of cigarette smoke

ActiveCN103141936AIncrease the sense of thicknessImprove clusteringTobacco treatmentEssential-oils/perfumesPhenyl acetic acidEthyl vanillin

The invention discloses an enriching and thickening functional cluster substance preparation capable of obviously increasing richness and lumping of cigarette smoke, relates to a tobacco additive, and aims to provide the enriching and thickening functional cluster substance preparation capable of obviously increasing the richness and the lumping of the cigarette smoke, which has the capabilities of enriching, thickening and improving the cigarette aroma and richness. The preparation is characterized in that the raw materials for preparing the preparation comprise the following basic raw materials in percentage by weight: ethyl vanillin, ethyl maltol, pineapple ketone, dihydroactinidiolide, heliotropin, phenyl acetic acid, plum extract, raisin extract, fenugreek concrete, breadfruit concrete and the balance of 95 percent ethanol. The preparation can be widely used in all the cigarette factories throughout the country.

Owner:SHENZHEN TOBACCO IND

Method for preparation of mixed benzol dimethanoic acid and benzene acetic acid

InactiveCN101318890AOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPhenyl acetic acidMANGANESE ACETATE

The invention discloses a method for making mixed benzene dicarbonic acids and a phenyl acetic acid, comprising the following steps of: performing an oxidization reaction by using mixed xylenes as a raw material, oxygen or oxygen in compressed air as an auxiliary raw material, an acetic acid as a solvent, cobalt acetate and manganese acetate as catalysts, a hydrobromic acid as an auxiliary catalyst, at a temperature of between 100 and 250 DEG C and a pressure of between 0.5 and 2.5 MPa for 50 to 180 minutes to obtain a mixture of mixed benzene dicarbonic acids of p-phthalic acid, m-phthalic acid and o-phthalic acid and a phenyl acetic acid; separating the phenyl acetic acid and the mixed benzene dicarbonic acids. The novel method for producing the phenyl acetic acid of the invention is a technical innovation with high economic value. The oxidization of phenylethane and the separation and refining of an oxide of the phenylethane are applied throughout the technological process for making mixed benzene dicarbonic acids from four components of the mixed xylenes, which is a technical problem in the field. The method creatively solves the technical problem.

Owner:CHINA PETROLEUM & CHEM CORP +1

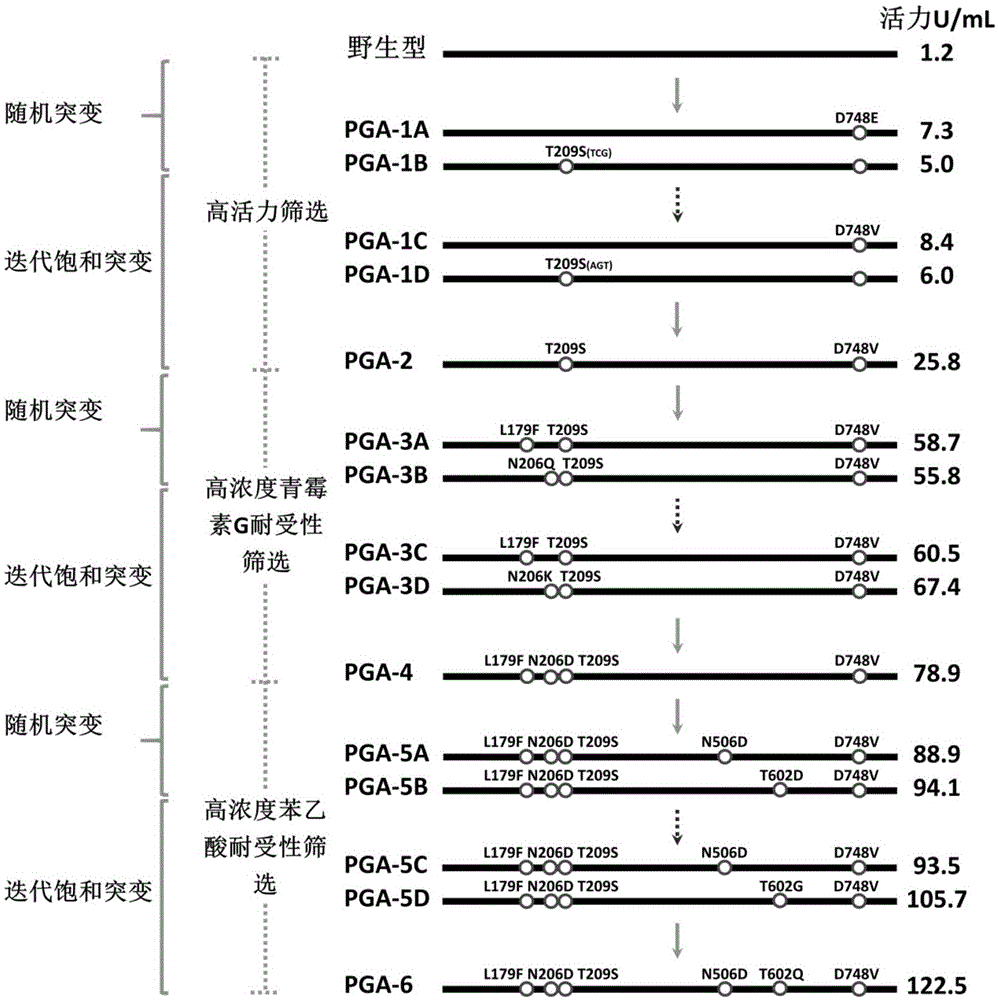

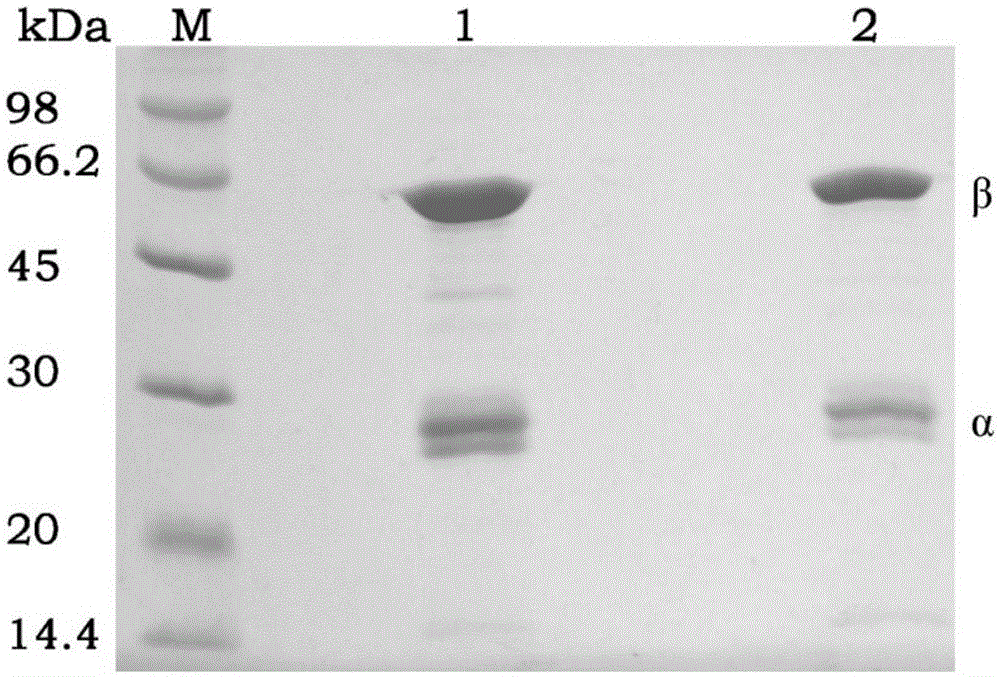

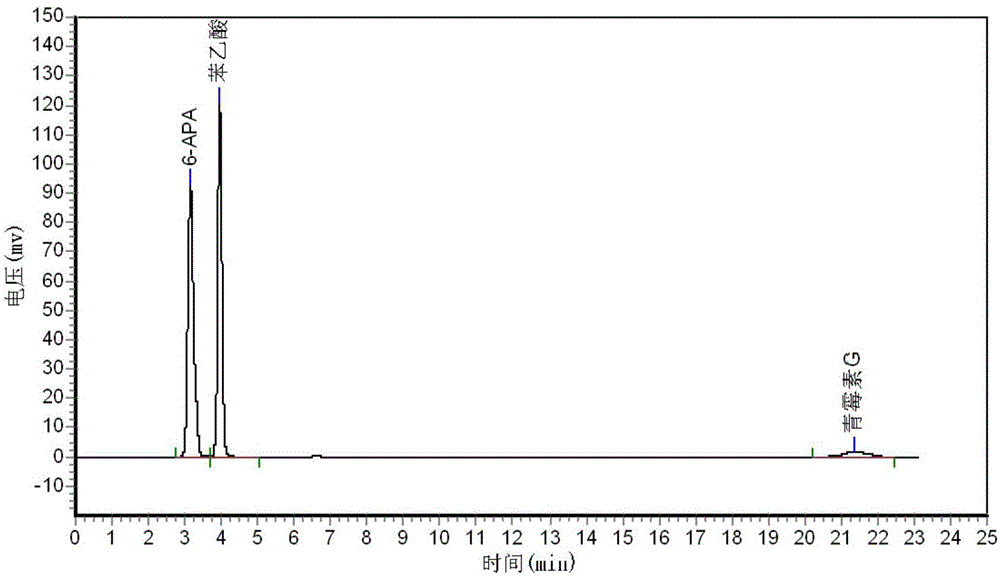

Mutant of penicillin G acylase (PGA) and preparation method and application of mutant

ActiveCN105087533AStrong concentration toleranceIncreased concentration toleranceHydrolasesFermentationPhenyl acetic acidEscherichia coli

The invention provides a mutant of penicillin G acylase (PGA) and a preparation method and application of the mutant. The non-rationally and semi-rationally designed enzyme engineering reconstruction technology is adopted for mutation of penicillin G acylase obtained from Escherichia coli ATCC 11105, so that a PGA mutant with higher reactivity, higher reaction rate, better conversion rate, stronger in penicillihe concentration tolerance, less substrate residue, and higher in phenyl acetic acid concentration tolerance; meanwhile, the mutant is subjected to recombinant expression, bacteria strain construction, fermenting cultivation, immobilization and application to prepare 6-amino-penicillanic acid (6-APA). The activity of the PGA-6 mutant prepared by the invention is increased by 102 times, the substrate penicillihe concentration tolerance is increased to 30%, and the phenyl acetic acid concentration tolerance is increased to 20 mmol / L; meanwhile, the immobilized PGA-6 mutant is used to decompose penicillihe with a concentration of 25% under the condition of pH 8.0 and 25 DEG C so as to prepare 6-APA, and the reaction time is shortened to 55 minutes, the substrate conversion rate is 98% or above, and after being used for 600 batches and above, the activity is not lost obviously, therefore, good operation stability is achieved.

Owner:HUNAN FLAG BIOTECHNOLOGY CO LTD

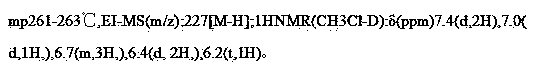

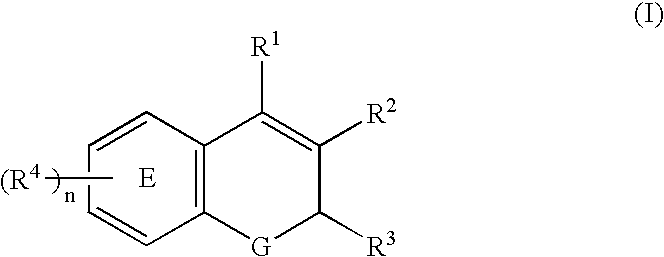

2- carbonyl- 2- phenyl acetic acid p-nitro benzoyl hydrazone 2-n-butyl tin complex and preparing method and application thereof

ActiveCN106317105AFriendly and beneficialHigh anticancer activityTin organic compoundsOrganic chemistry methodsPhenyl acetic acidHydrazone

The invention discloses a 2- carbonyl- 2- phenyl acetic acid p-nitro benzoyl hydrazone 2-n-butyl tin complex in the following structural formula (I) of (img file='dest_path_image002. TIF'wi='363'he='181' / ), wherein Ph is phenyl and R is normal-butyl. The invention also discloses the preparing method and application in preparing anti-cancer drugs for 2- carbonyl- 2- phenyl acetic acid p-nitro benzoyl hydrazone 2-n-butyl tin complex.

Owner:HENGYANG NORMAL UNIV

L-ornithine phenyl acetate and methods of making thereof

ActiveCN102421432AOrganic active ingredientsOrganic compound preparationPhenyl acetic acidOrnithine phenylacetate

Disclosed herein are crystalline forms of L-ornithine phenyl acetate and methods of making the same. The crystalline form may, in some embodiments, be Forms I, II, III and V, or mixtures thereof. The crystalline forms may be formulated for treating subjects with liver disorders, such as hepatic encephalopathy. Accordingly, some embodiments include formulations and methods of administering L-ornithine phenyl acetate.

Owner:OCERA THERAPEUTICS INC

2-carbonyl-2-phenyl acetic acid para methoxyphenyl carbonylhydrazone di-n-butyl tin complex and preparation method and application thereof

ActiveCN106366119AHigh anticancer activityLow costTin organic compoundsOrganic chemistry methodsPhenyl acetic acidAcetic acid

The invention discloses a 2-carbonyl-2-phenyl acetic acid para methoxyphenyl carbonylhydrazone di-n-butyl tin complex. The complex has a structural formula (I) shown in the specification, wherein Ph is phenyl, and R is n-butyl. The invention further discloses a preparation method of the 2-carbonyl-2-phenyl acetic acid para methoxyphenyl carbonylhydrazone di-n-butyl tin complex and application in preparation of anti-cancer medicine.

Owner:HENGYANG NORMAL UNIV

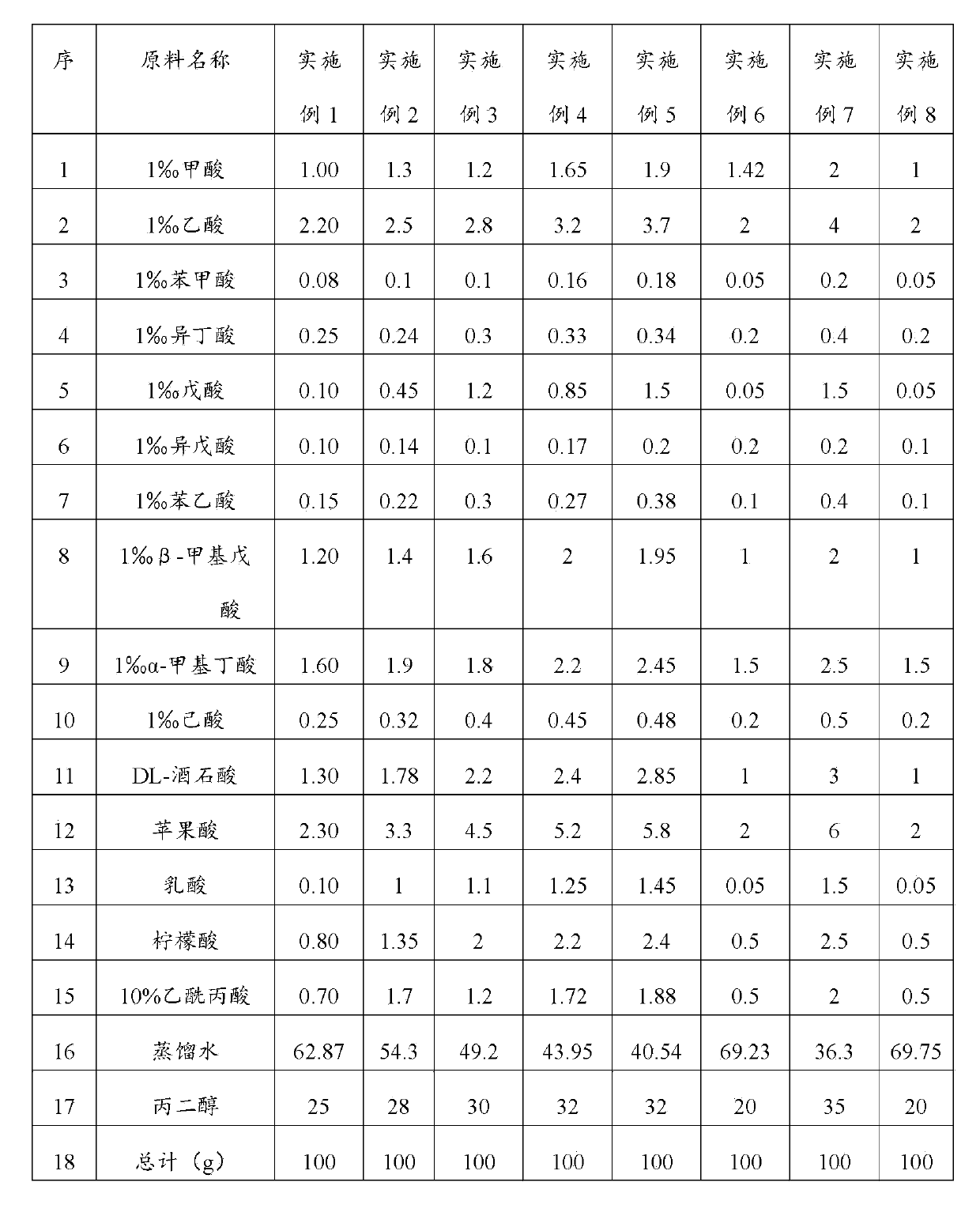

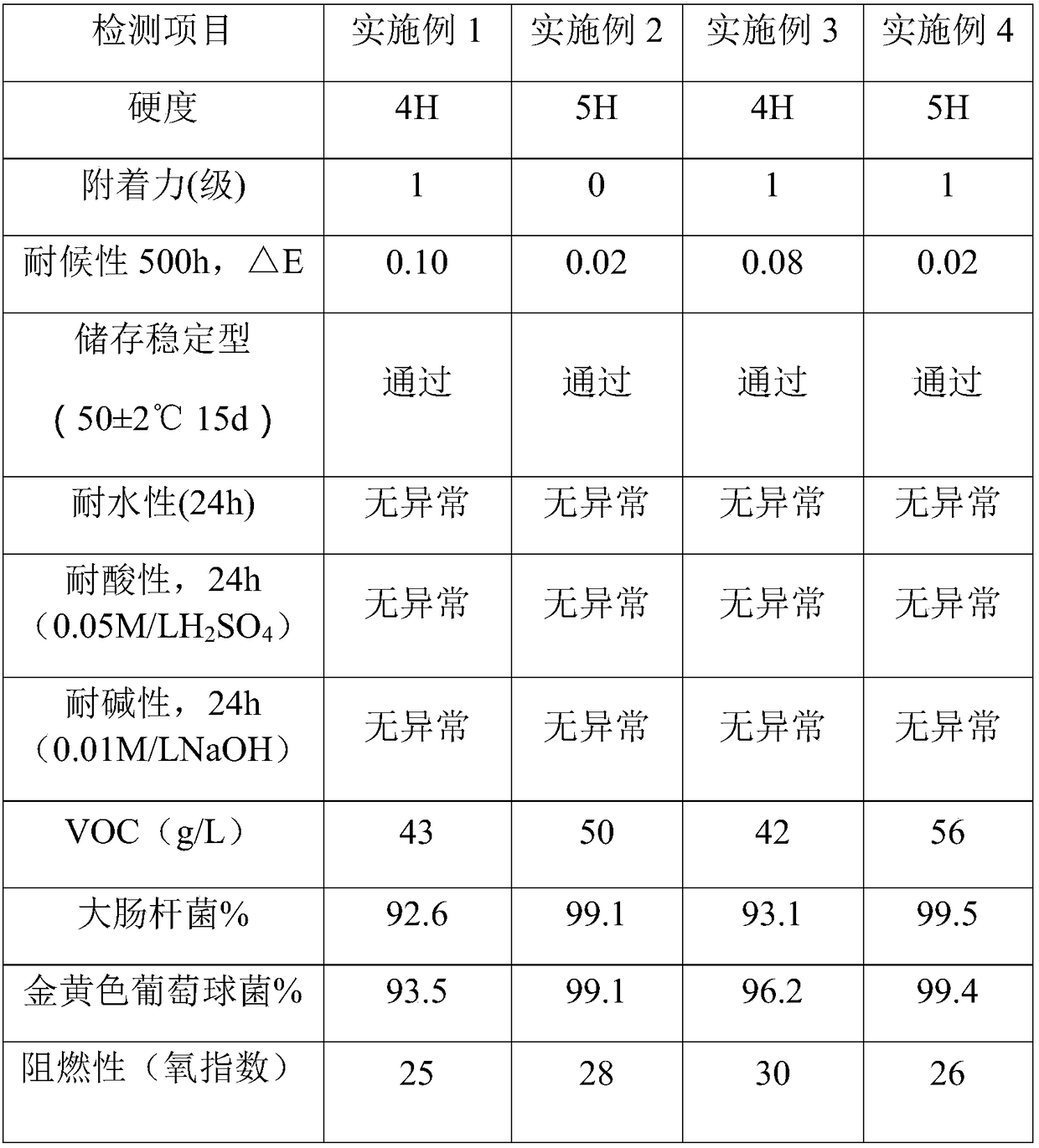

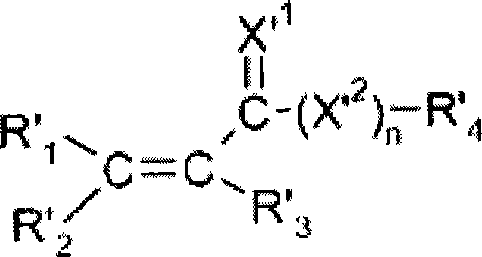

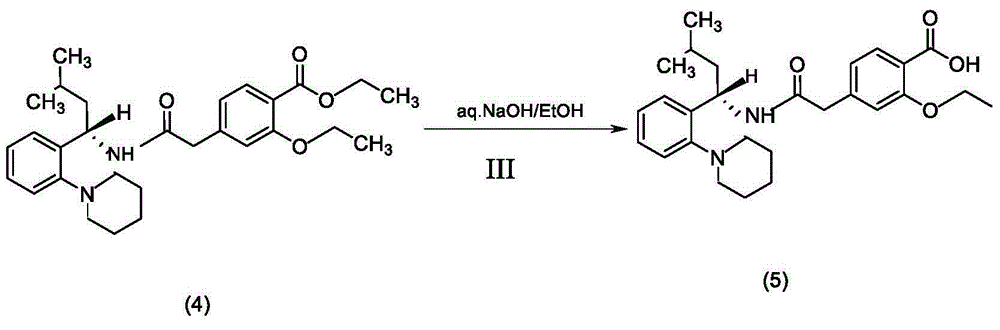

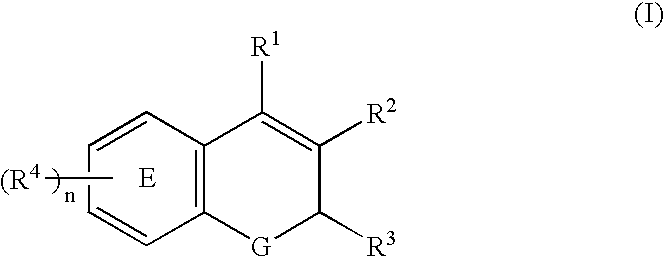

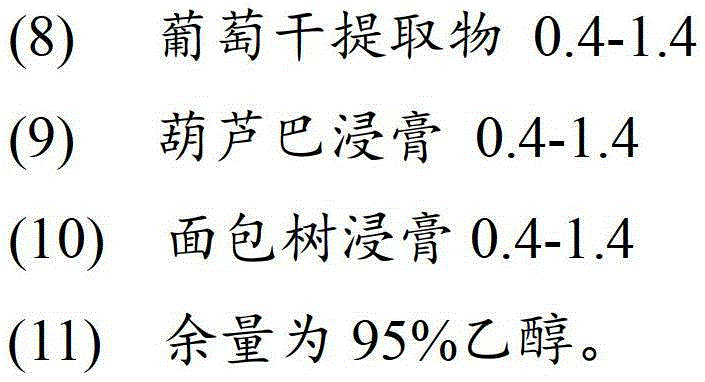

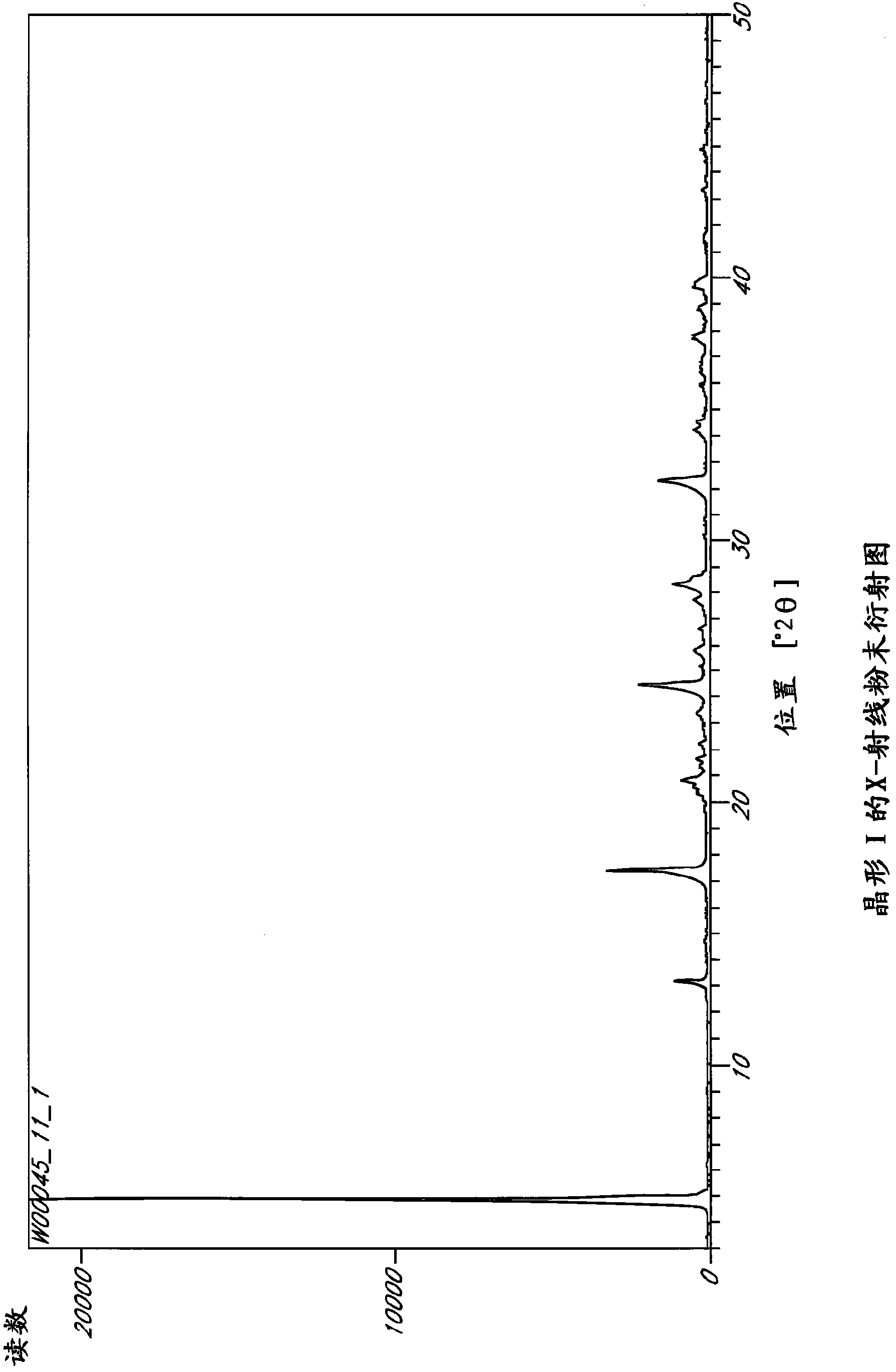

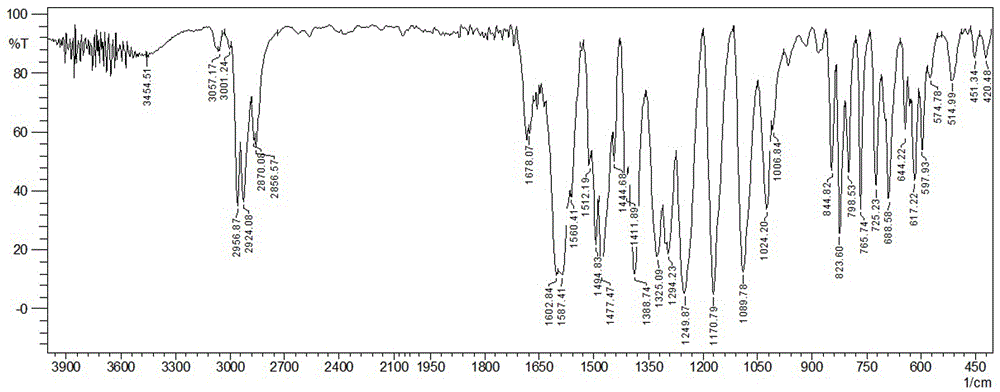

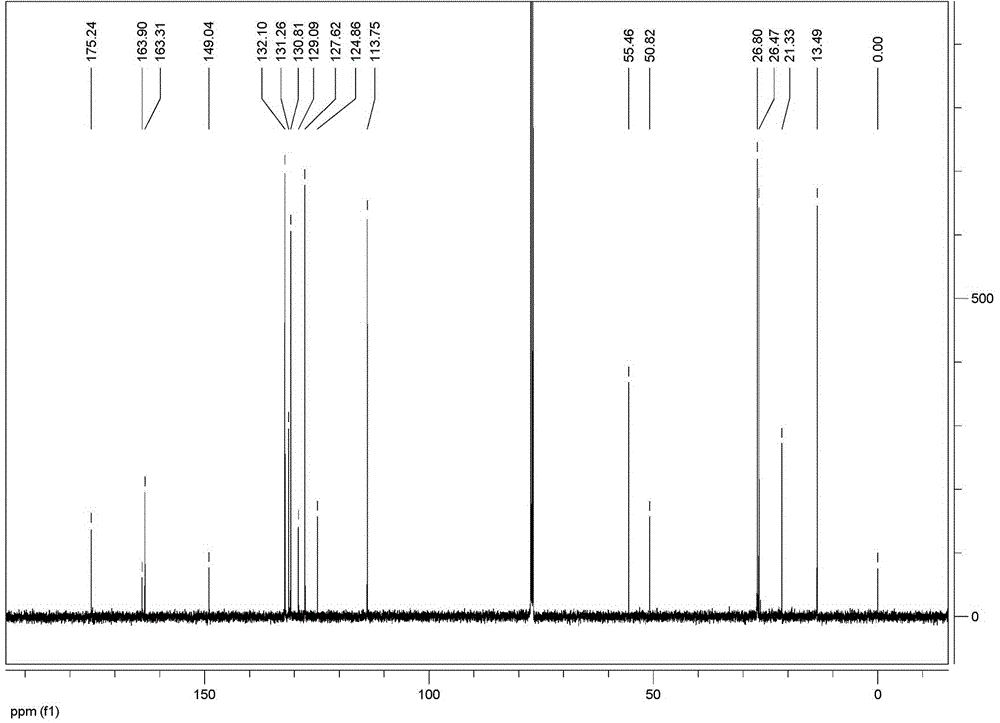

Polymorph of acid 4-[2-[4-[1-2-ethoxyethyl)-1h-benzimidazole-2-il]-1-piper idinyl]ethyl]-dollar G (A), dollar G (A)-dimethyl-benzeneacetic

The invention relates to polymorph 1 of acid 4-[2-[4-[1-(2-ethoxyethyl)-1H-benzimidazole-2-il]-1-piperidinyl]ethyl-alpha, alpha-dimethyl-benzeneacetic having formula (I), preparation methods thereof, pharmaceutical formulations containing polymoph 1 and the use of polymorph 1 for the treatment of allergic reactions and pathological processes mediated by histamine in mammals such as humans.

Owner:FAES FARMA SA

Building paint

InactiveCN105802376AHigh hiding powerImprove adhesionAntifouling/underwater paintsPaints with biocidesPhenyl acetic acidPerillaldehyde

The invention discloses building paint. The building paint is prepared from 3.5-7.5 parts by weight of methyl acetate, 2.3-4.5 parts by weight of hept-2-ene-2-methanol, 6.5-12.7 parts by weight of hydroxymethyl propyl cellulose, 10-15 parts by weight of titanium dioxide, 20-28 parts by weight of white emulsion, 1.2-3.5 parts by weight of perillaldehyde, 2.5-6.4 parts by weight of distyrylphenol polyoxyethylene ether and 3.5-6.8 parts by weight of (R)-(-)-alpha-methoxyphenylacetic acid. Compared with the existing exterior wall paint, the building paint improves an emulsion paint finished product covering capacity through use of a mixture of methyl acetate and white emulsion. Through mixing of hydroxymethyl propyl cellulose and titanium dioxide, latex finished product adhesion and water washing resistance are improved. Through the mixture of perillaldehyde, distyrylphenol polyoxyethylene ether and (R)-(-)-alpha-methoxyphenylacetic acid, the paint film has lasting and beautiful gloss and has lasting pollution resistance.

Owner:QINGDAO JINLIANXIN BUSINESS & TRADE

Low-tar cigarette flavoring essence with organic acids

ActiveCN103387876AGreat improvement in stimulationImprove smoke roughnessTobacco preparationEssential-oils/perfumesPhenyl acetic acidBenzoic acid

The invention discloses a low-tar cigarette flavoring essence with organic acids. The cigarette flavoring essence is a mixture of the following raw materials in percentage by weight: 1%-2% of 0.1% formic acid, 2%-4% of 0.1% acetic acid, 0.05%-0.2% of 0.1% benzoic acid, 0.2%-0.4% of 0.1% isobutyric acid, 0.05%-1.5% of 0.1% valeric acid, 0.1%-0.2% of 0.1% isovaleric acid, 0.1%-0.4% of 0.1% phenyl acetic acid, 1.0%-2.0% of 0.1% beta-mevalonic acid, 1.5%-2.5% of 0.1% alpha-methylbutyric acid, 0.2%-0.5% of 0.1% hexanoic acid, 1.0%-3.0% of DL-tartaric acid, 2.0%-6.0% of malic acid, 0.05%-1.5% of lactic acid, 0.5%-2.5% of citric acid, 0.5%-2.0% of 10% levulinic acid, 36.3%-69.75% of distilled water and 20%-35% of propylene glycol. Due to the use of organic acid raw materials, the effect of the blended essence is promoted greatly; the problems such as high irritation, rough smoke, uncomfortable aftertaste and insufficient aroma, existing in the existing low-tar cigarette, are covercome remarkably; the smoking quality of the low-tar cigarette is enhanced.

Owner:HUBEI CHINA TOBACCO IND +1

LED light cured aqueous woodenware paint and preparation method thereof

PendingCN108690389AEasy to operateEasy to manufactureFireproof paintsAntifouling/underwater paintsPhenyl acetic acidCarbon nanotube

The invention relates to the technical field of paints, and specifically discloses an LED light cured aqueous woodenware paint and a preparation method thereof. The aqueous woodenware paint comprisesfollowing components in parts by weight: 95 to 110 pars of LED acrylic emulsion, 2 to 6 parts of carbon nanotube modified polyphosphazene-polyether sulfone segmented copolymer, 3 to 10 parts of photoinitiator, 1 to 3 parts of co-initiator, 1 to 5 parts of water soluble active monomer, 2 to 5 parts of silver nano particle, 0.1 to 0.5 part of Ag-diphenylpyrazolopyridine-p-phenyl acetic acid complex, 3 to 10 parts of delustering agent, 1 to 7 parts of antiseptic, 8 to 20 parts of wetting dispersant, 1 to 6 parts of antifoaming agent, 5 to 13 parts of thickening agent, 1 to 3 parts of film forming additive, 0.2 to 0.5 part of pH adjuster, 6 to 10 parts of filler, 5 to 10 parts of coloring agent, and 25 to 35 parts of deionized water. The prepared aqueous woodenware paint has the advantages ofhigh hardness, good acid-resistant, alkali-resistant, aging-resistant, and waterproof performance, high storage stability, quick drying speed, and low VOC content, and the environmentally friendly property, hardness, and corrosion resistant performance are all enhanced.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

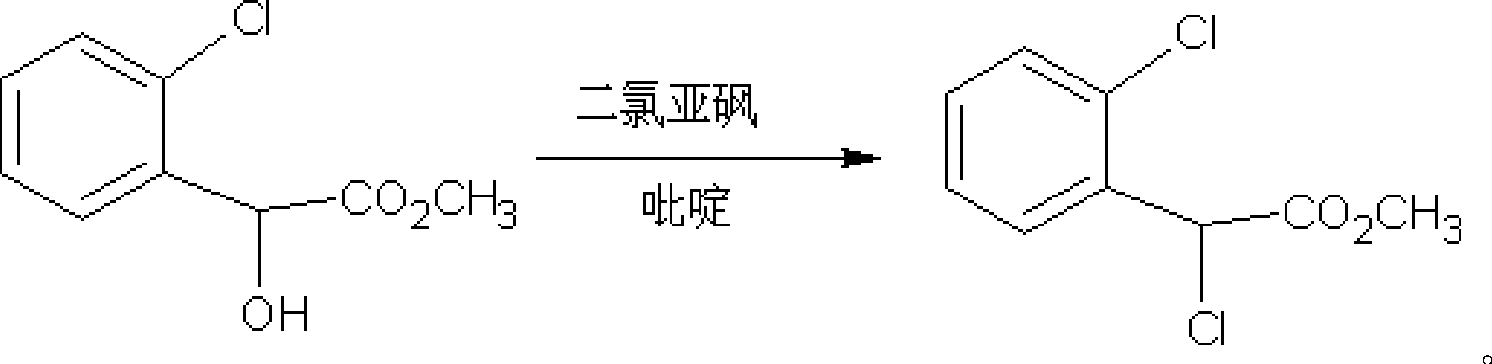

Method for synthesizing alpha-chlorine (2-chlorine) methyl phenyl acetate

ActiveCN101434540AHigh yieldHigh purityOrganic compound preparationCarboxylic acid esters preparationChemical synthesisMethyl o-chloromandelate

The invention relates to a synthetic method of Alpha-chloro-(2-chloro) methyl phenyl acetate, pertaining to the field of chemical synthesis. The technical problem to be solved by the invention is that a high-purity synthetic method of the Alpha-chloro-(2-chloro) methyl phenyl acetate with high purity is provided. The technical proposal comprises the steps as follows: pyridine is tanken as a solvent, and O-chloro mandelic acid methyl ester reacts with thionyl chloride under the condition of 25 DEG C to 80 DEG C for 0.5h to 5h, and then filtered. Filtrate is extracted by water for impurity removal, and anhydrous sodium sulfate is added for removing water. Filtering is carried out for removing solid sodium sulfate and the filtrate is depressurized for distilling off the solvent to obtain the Alpha-chloro-(2-chloro) methyl phenyl acetate. The reaction formula is shown as the formula in upper right side.

Owner:重庆莱美隆宇药业有限公司

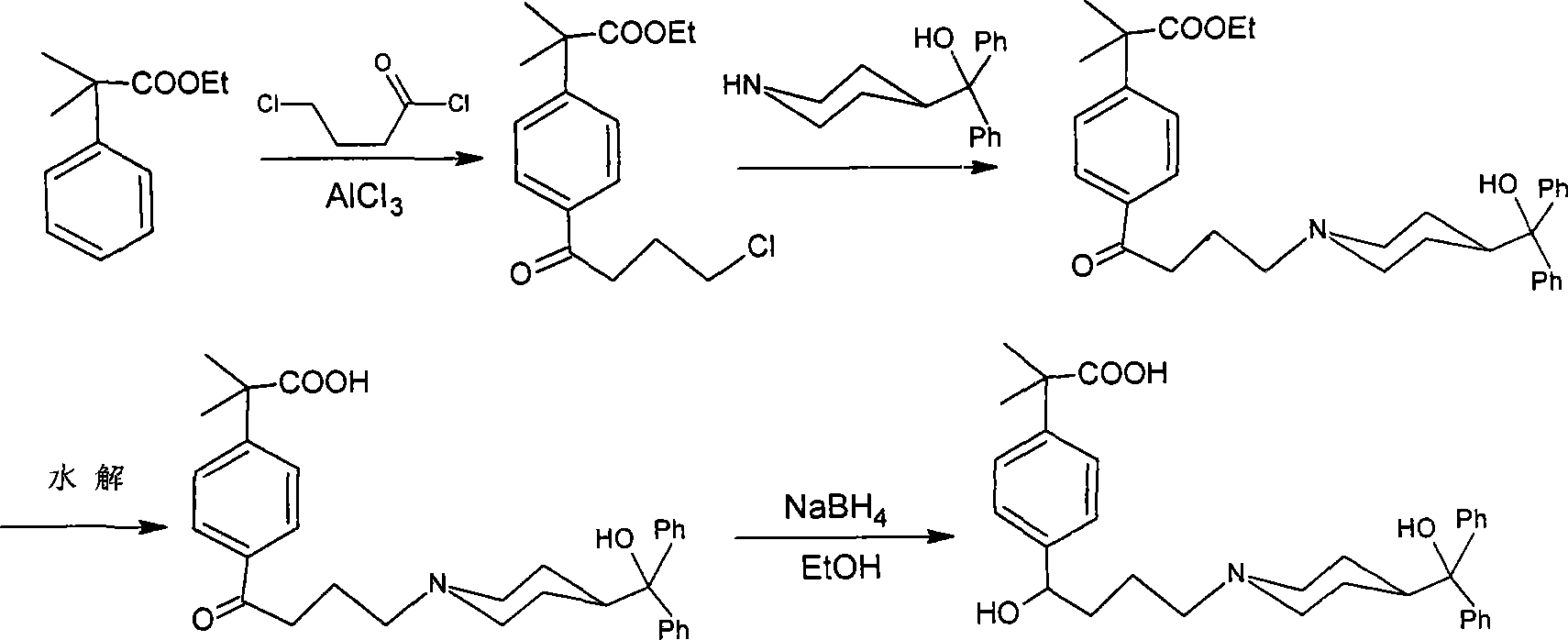

Radiation curable hybrid composition and process

InactiveCN101535391AHelp passGood dispersionCoatingsPigment treatment with non-polymer organic compoundsPhosphateZirconate

There is described a process for preparing a hybrid organic inorganic nano-composite used to prepare high (nD=1.52) refractive index (Rl) protective coatings for brightness enhancers for LCDs. The process comprising the steps of: a) diluting an aqueous solution of inorganic nano-particles (such as ZrO2) with a first solvent (such as acetic acid or methyl ethyl ketone (MEK)) to form a dispersion; b) adding surface modifiers (such as 1-benzoyl acetone, diphenyl acetic acid, diphenyl phosphonic acid, ethylene methacrylate phosphate; 2,2,6,6- tetramethyl-3,5-heptanedione or neopentyl(diallyl)oxy trimethacryl zirconate); c) removing the first solvent to enhance the interactions between the surface modifier and nano- particles; d) washing the resultant slurry of surface modified lipophilic nano particles by repeated dilution with an azeotropic solvent mixture (such as ethyl acetate, toluene and water) and distillation to remove low Rl impurities and / or OH groups, e) adding a radiation curable polymer precursor (such as an optionally brominated epoxy acrylate to the mixture opt with a photo initiator (Pl); and f) removing the remaining solvent to form a solid composite comprising an intimate mixture of surface modified inorganic nano-particles and uncured polymer precursor.

Owner:CYTEC SURFACE SPECIALTIES INC

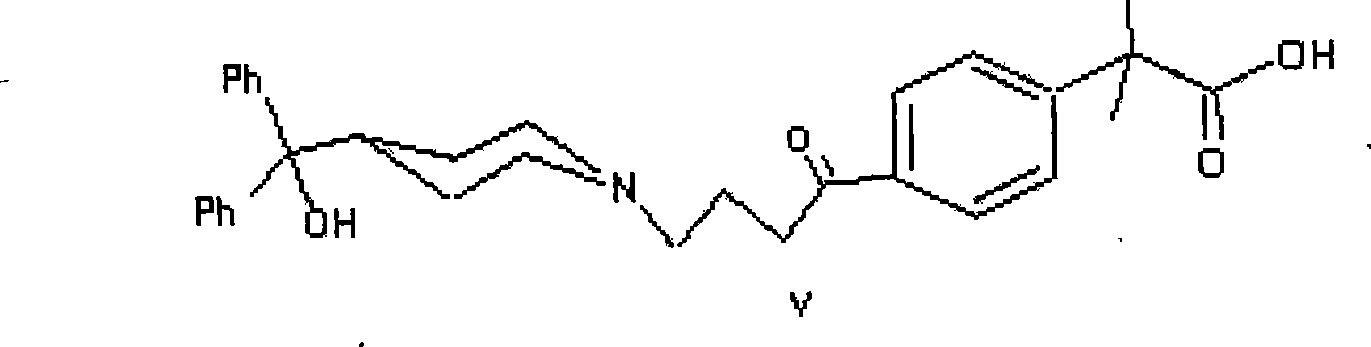

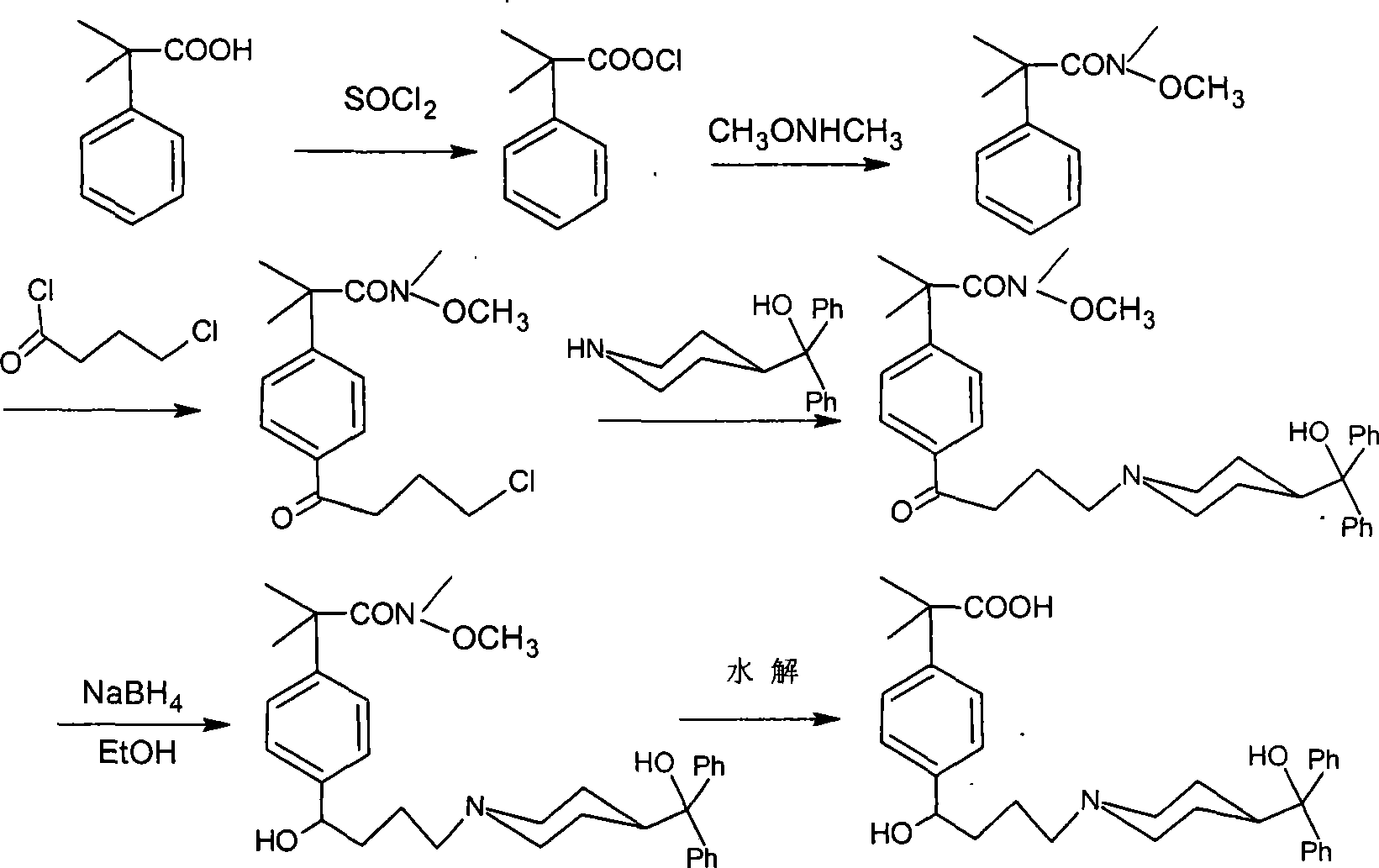

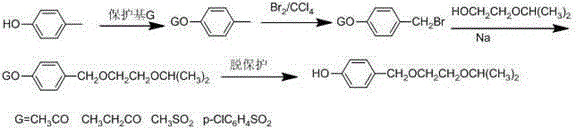

Method for synthesizing intermediate of fexofenadine

InactiveCN101182306AReduce the ratioIncrease steric hindranceOrganic chemistryPhenyl acetic acidFexofenadine

The present invention provides a synthesis method of the intermediates of fexofenadine. The intermediates are 4-[4-[4-(hydroxyl diphenyl methyl)-1-piperidyl]-1-butyryl]-alpha and alpha-dimethyl phenyl acetic acid (v). The method considers methyl allyl alcohol acetic ester and benzene as raw materials to be synthesized as the intermediate (i) by the Friedel-Crafts alkylation reaction, the ortho-para-orientation effect of phenylethyl alcohol and two methyl are used to increase steric hindrance; the intermediate (ii) with the comparatively pure intermediate is obtained by the Friedel-Crafts alkylation reaction; the intermediate (iii) is obtained by alkaline hydrolysis; then the intermediate (iv) is obtained by potassium permanganate oxidation; the intermediate (v) is generated by the condensation under the alkaline condition by the phase transfer catalysis; the v is deoxidized by sodium borohydride as slat to obtain the fexofenadine. The method has smooth technology, short route, high yield, low cost and friendly environment and is a feasible route for the industrialization.

Owner:CHONGQING UNIV

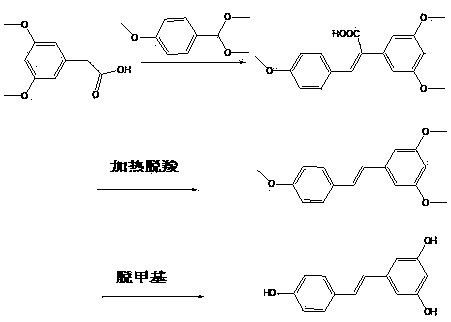

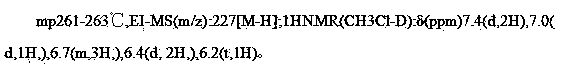

Preparation method for resveratrol

ActiveCN103664537AShort processEasy to operateOrganic chemistryOrganic compound preparationPhenyl acetic acidAcetic acid

The invention provides a preparation method for resveratrol. The method comprises the following steps: with (3,5-dimethoxyphenyl)acetic acid as a raw material, subjecting (3,5-dimethoxyphenyl)acetic acid and methoxybenzaldehyde dimethyl acetal to a one-pot reaction so as to obtain a crude resveratrol product; and then carrying out neutralizing with alkali lye, decoloring in alcohol and recrystallization so as to prepare a refined resveratrol product. Compared with the prior art, the preparation method provided by the invention has the advantages of short process flow, simple operation and suitability for industrial production, and the prepared refined resveratrol product has yield of more than 93%, a melting point of 261 to 263 DEG C, HPLC of greater than 99%, a whitish color, good quality and low preparation cost.

Owner:HUNAN KEYUAN BIO PRODS

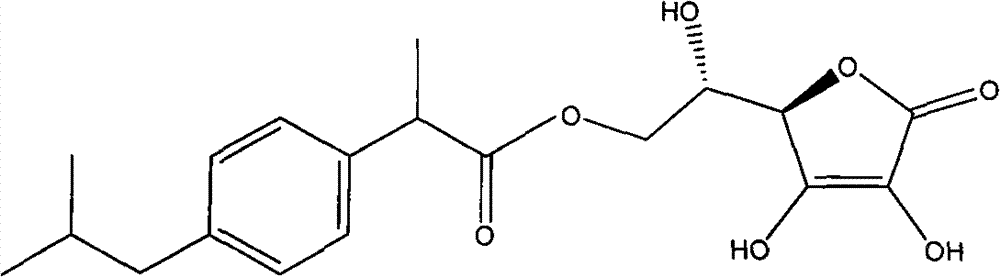

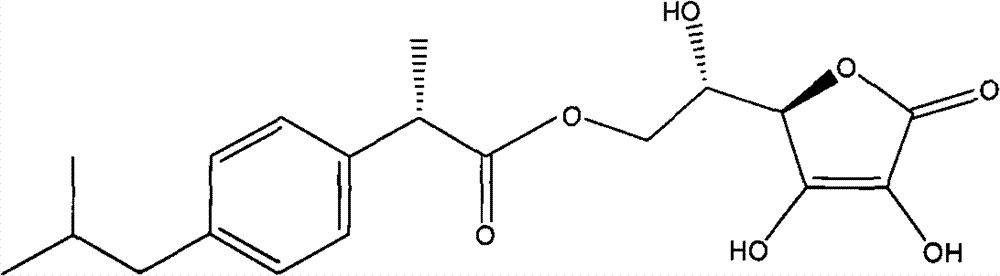

Ester exchange method synthesizing process of aryl acetic acid (propionic acid) L-ascorbic acid ester

InactiveCN102827893AMultiple conversion rate increasesHigh yieldOrganic chemistryChemical recyclingPhenyl acetic acidPropanoic acid

The invention belongs to the field of nonaqueous phase enzymatic organic synthesis, in particular to an ester exchange method synthesizing process of aryl acetic acid (propionic acid) L-ascorbic acid ester. The process is applicable to synthesis of the aryl acetic acid (propionic acid) L-ascorbic acid ester under catalysis of a biocatalyst (such as Novozym 435). The synthesizing process provides a commonly-used synthesizing process of the aryl acetic acid (propionic acid) L-ascorbic acid ester, can move to a ester synthesizing direction in balance through decompression and continuous alcohol removal on premises of influencing no catalytic activity of the biocatalyst, accordingly improves conversion rate of the enzymatic organic synthesis and guarantees reaction to trend to completion. Through simulated moving bed chromatography separation, through separation of reaction products and excess reaction raw materials are guaranteed, circulation and reuse problems of the excess reaction raw materials are solved, the conversion rate, product yield and product purity of the raw materials are all improved to be close to 100%, cost of production is substantially lowered, zero discharge of waste water and waste residues of product production is achieved, and the synthesizing process has wide application prospects in fields such as medicines and fine chemical engineering.

Owner:JIANGNAN UNIV +1

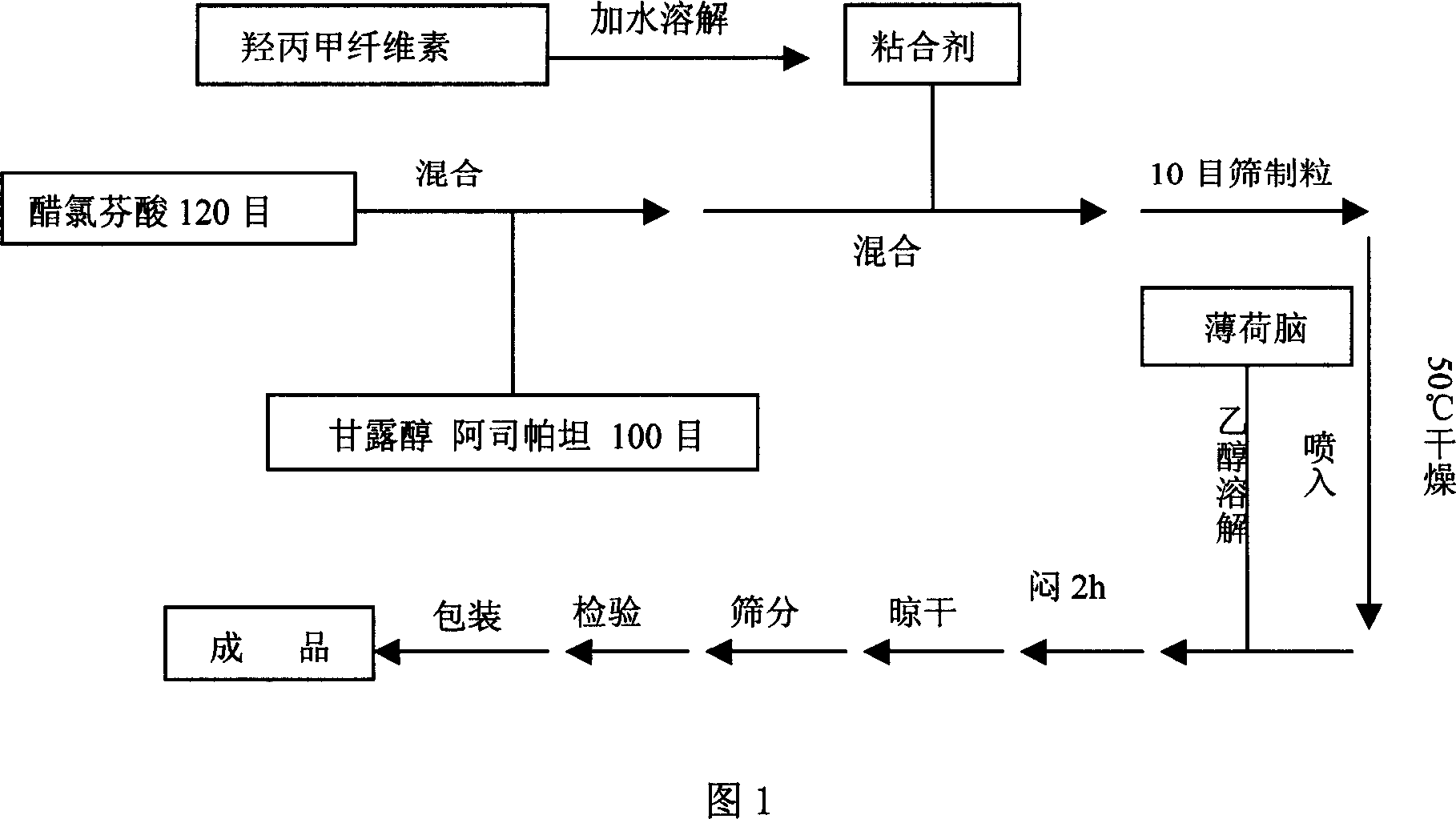

Aceclofenac granule

InactiveCN1989957AAppropriate retention timeOrganic active ingredientsAntipyreticDiseasePhenyl acetic acid

The invention belongs to the field of medicine and pharmacology, and is Pharmaceuticals oral granule. The Aceclofenac granule is made by raw material drug aceclofenac, findings and disintegrant. The Aceclofenac granule is phenyl acetic acid non-steroidal anti-inflammatory agent. It has notable anti-inflammatory, analgesic and antipyretic effect. It applies to the treatment of various rheumatoid arthritis, atrophic arthritis, osteoarthritis and spondylitis. It is fit for pain and fever caused by various diseases, and the toxic and side effects is lower than other varieties. Aceclofenac has not granule in prior medicine market; it is innovative formula and benefit for absorbing drug to getting better curative effect and better taste. It is safe, reliable and new drug for treatment of acute, chronic pain and anti-inflammation.

Owner:DISHA PHARMA GROUP BEIJING DISHA BIOTECH

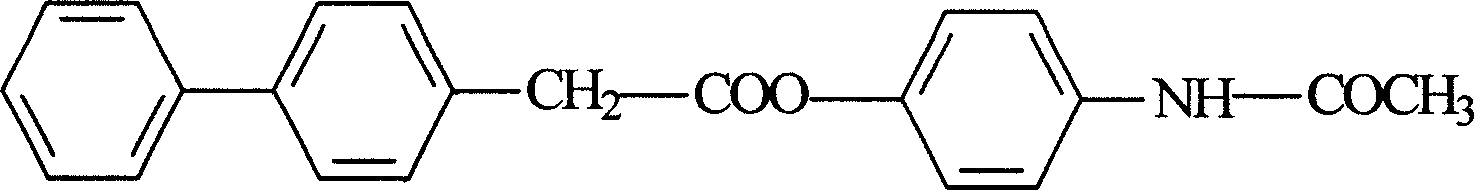

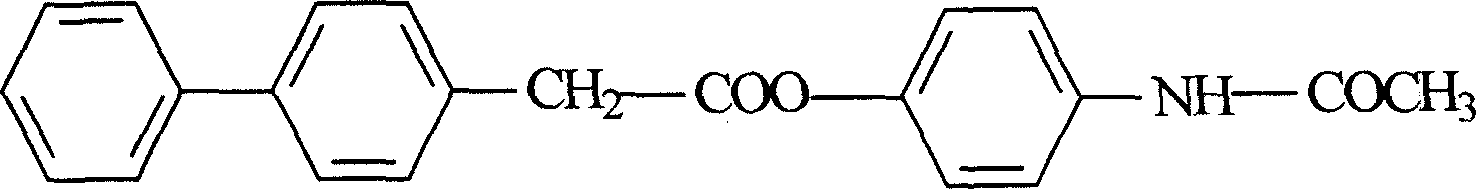

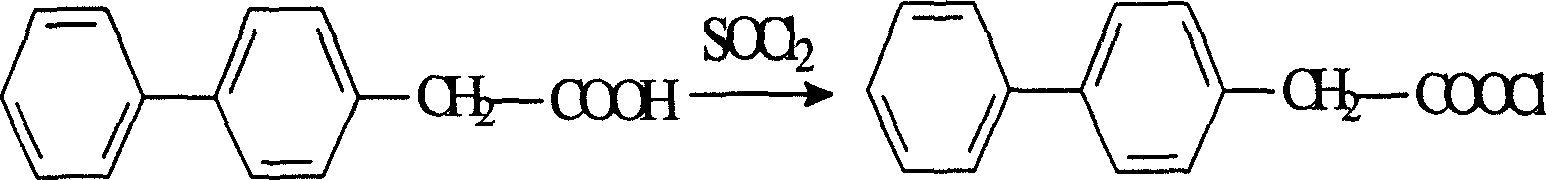

Felbinac acetaminopher ester and its preparation method

InactiveCN1962614ALess irritating to the gastrointestinal tractLess irritatingOrganic active ingredientsAntipyreticAcetyl chlorideActive component

The invention discloses a biphenyl acetate n-acetamido-phenolic ester compound and preparing method with active component as drug composition, which comprises the following steps: adopting biphenyl acetate and thionyl chloride as raw material to prepare biphenyl acetyl chloride; reacting biphenyl acetyl chloride and n-acetamido-phenolic ester to produce rough crystal of product; recrystallizing to obtain the product.

Owner:GUANGDONG ZHONGKE DRUG R&D

Method for removing ethanol, isopropanol and octyl alcohol from amino resin workshop wastewater

InactiveCN105084495AStrong complexing abilityFast precipitationWater contaminantsNature of treatment waterOctanolAcetophenone

The invention relates to a method for removing ethanol, isopropanol and octyl alcohol from amino resin workshop wastewater. The components adopted by the method comprises 1,3,3-trimethyl-2-oxabicyclo[2.2.2]octane, 1,8-dihydroxy-3-methoxy-6-methylanthraquinone, S(-)-2-amino-6-n-propyle-4,5,6,7-tetrahydrobenzothiazole dihydrochloride, 4-octylphenol ethoxylate, 3',4'-dihydoxy-2-(methylamino)acetophenone hydrochloride, 4-acetoxy-3-methoxy-(2-propenyl) benzene, 4-methoxybenzyl acetate, 6,6,10-trimethyl bicyclo-3,1,1-hept-2-ene, and 2-[[1-(3-acetylthio-2-methylpropionyl)pyrrolidine-2-formyl]amino]-3-phenylpropionic acid. The components adopted by the method have strong complexing capability with target substances, high speed of forming complex precipitates, and high removal rate up to 99.9%.

Owner:李海兰

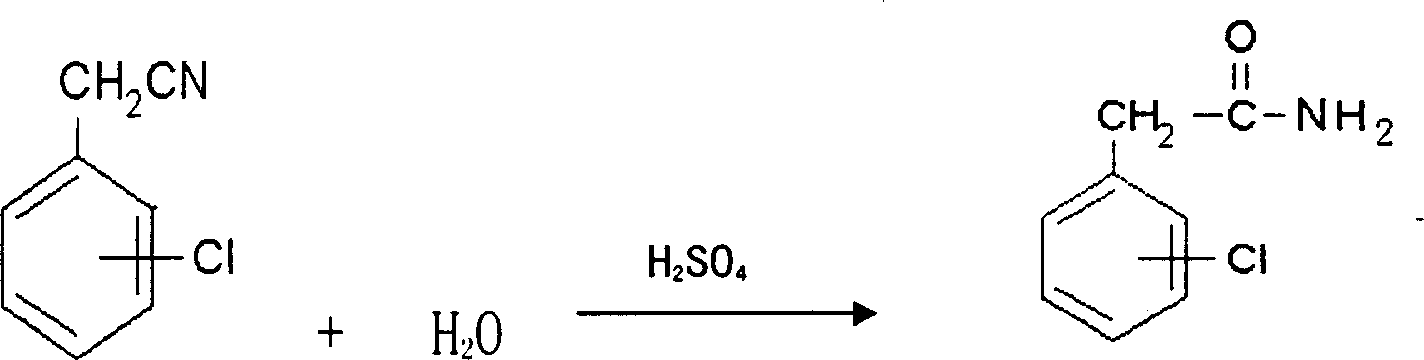

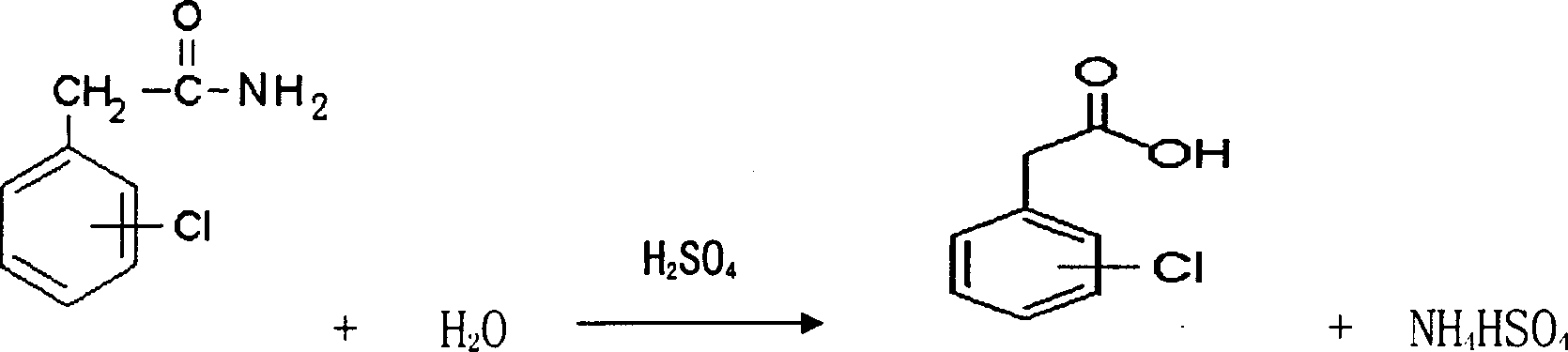

Preparation method of chlorophenyl acetic acid

ActiveCN1927810AEasy to operateThree wastes less pollutionPreparation from nitrilesPhenyl acetic acidAcetic acid

The present invention provides process of preparing chloro phenyl acetic acid. The technological process includes the main steps of hydrolyzing corresponding o-chloro benzyl cyanide, p-chloro benzyl cyanide or m-chloro benzyl cyanide in sulfuric acid solution to obtain course chloro phenyl acetic acid product; steam stripping to eliminate organic impurities; water washing and drying. The technological process of the present invention is simple, stable, less pollutant and suitable for industrial production.

Owner:WUHAN YOUJI IND

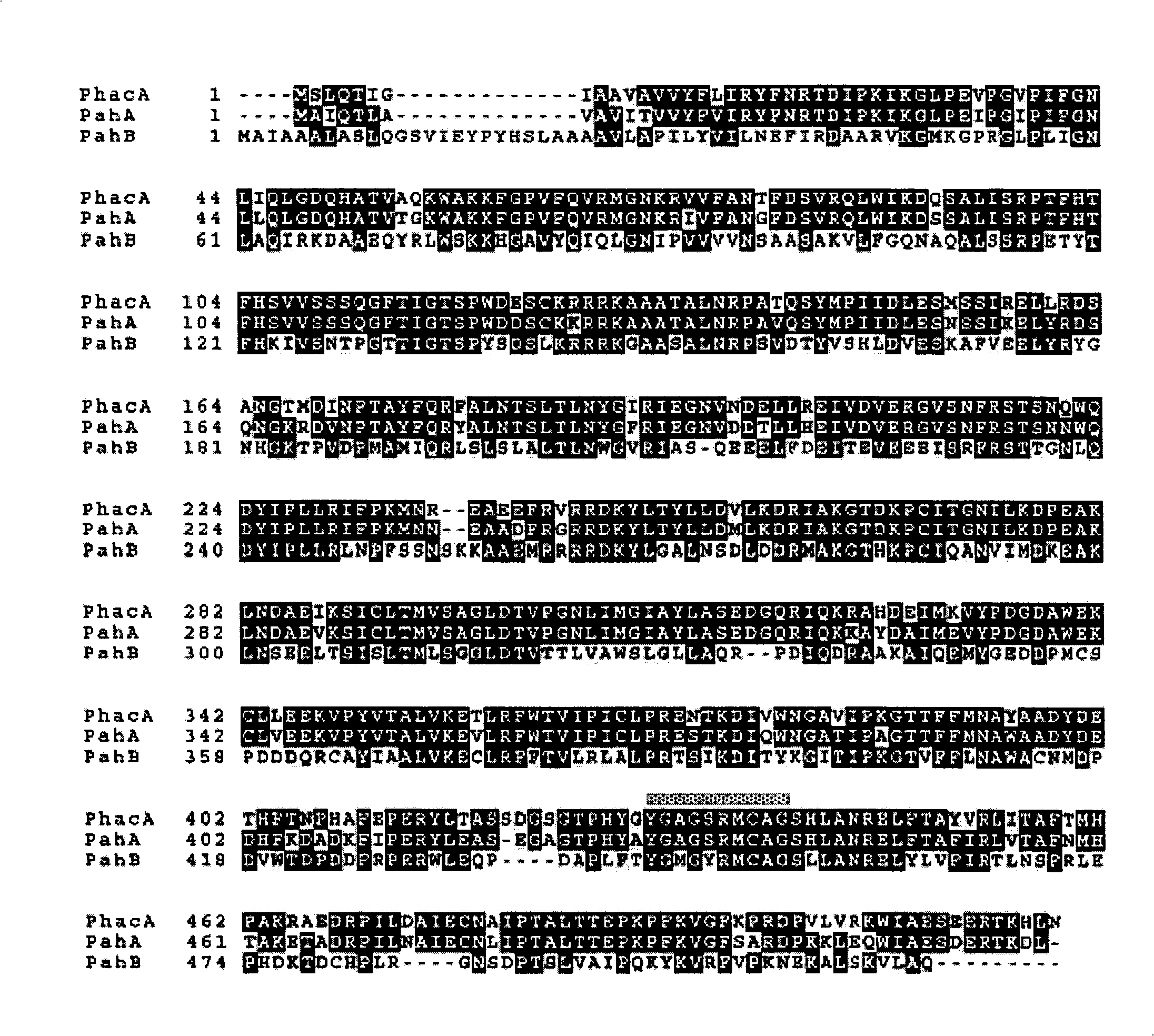

Gene for coding penicillium chrysogenum phenylacetic acid hydroxylase and its use

This invention involves the new encoding hydroxylase gene (pahB) from Penicillium chrysogenum, the gene encoding the peptide and containing the gene expression vector. It also demonstrated that the phenyl acetic acid can significantly induce the expression of pahB. The invention also provides a direction and target for increasing the production of penicillin from genitic modified Penicillium Chrysogenum, and is of great importance to the production of penicillin.

Owner:NORTH CHINA PHARMA COMPANY

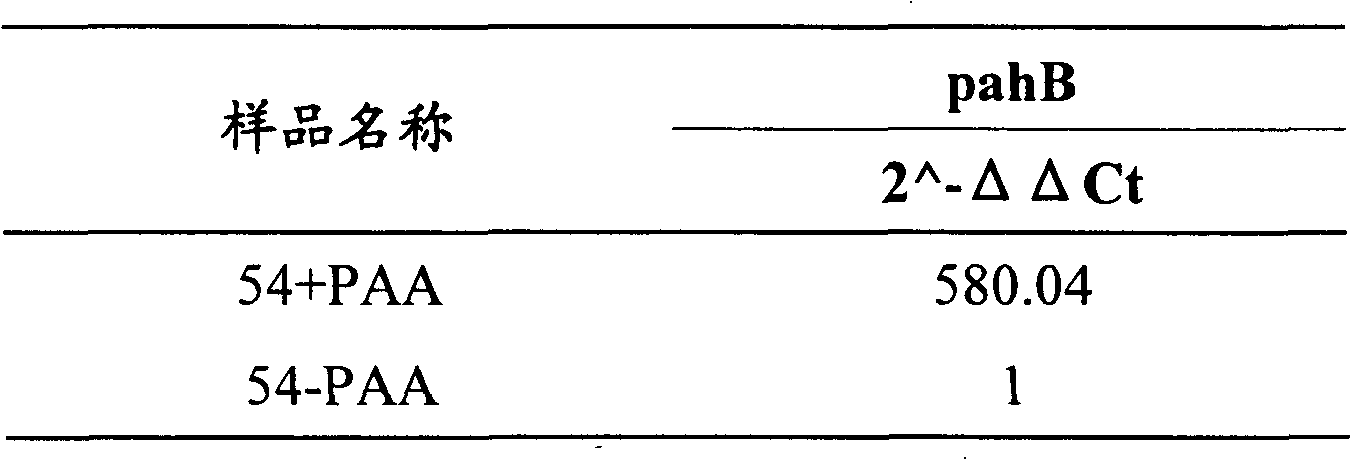

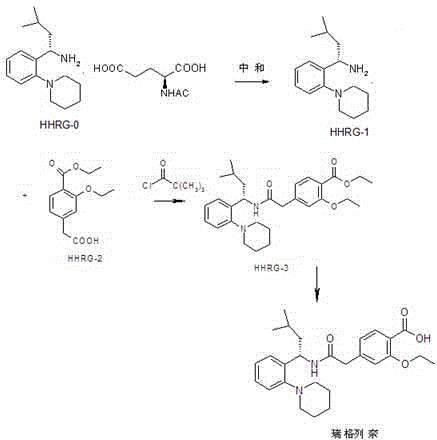

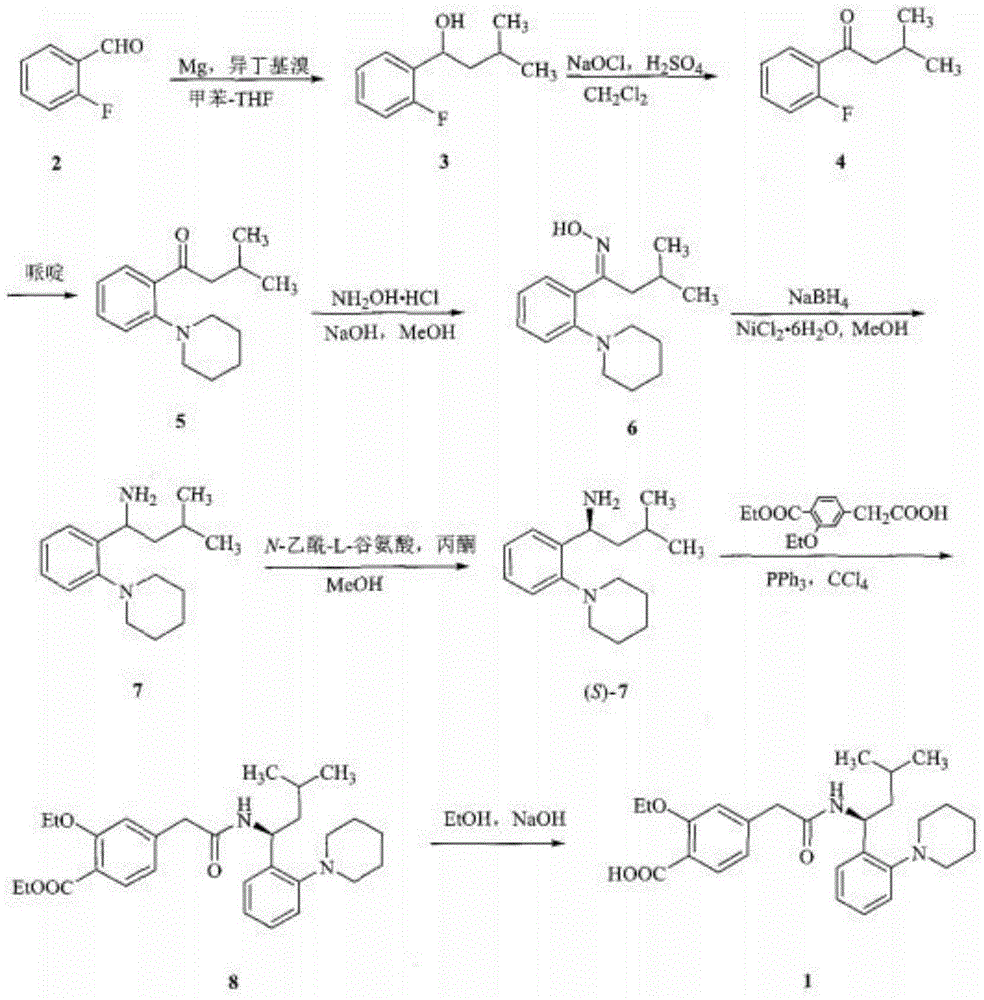

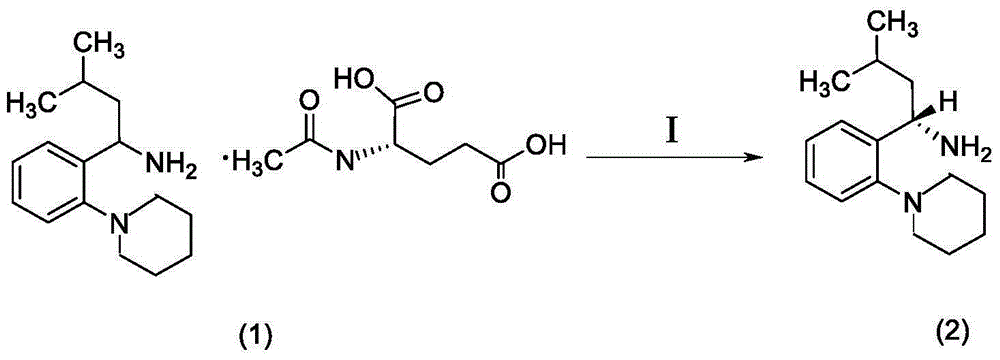

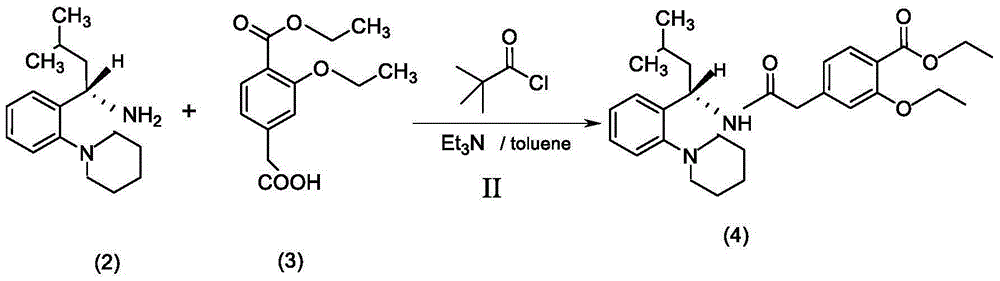

Preparation method and application of repaglinide

InactiveCN104557778AReduce riskEasy to operateOrganic chemistryMetabolism disorderPhenyl acetic acidRepaglinide

The invention provides a preparation method and application of repaglinide. The preparation method comprises the following steps of neutralizing repagamine.N-acetyl-L-glutamic acid and alkali to obtain repagamine, acylating repagamine, condensing acylated repagamine and ethoxy-4-ethoxycarbonyl phenyl acetic acid to obtain an intermediate and hydrolyzing the intermediate to obtain the repaglinide. The preparation method has the advantages of low cost, high yield, simple process and the like and is more suitable for industrial production.

Owner:蔡伦

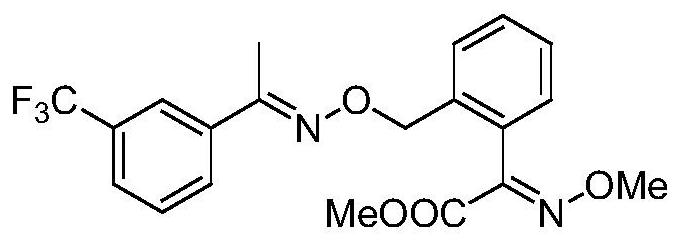

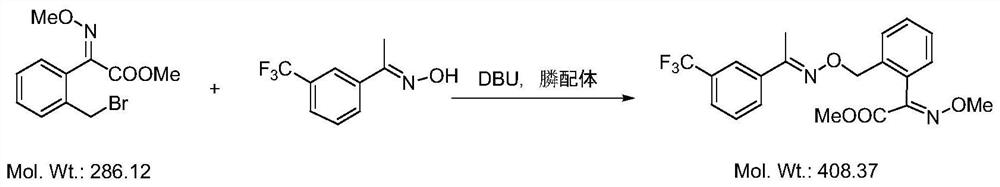

Green synthesis method for high-yield preparation of trifloxystrobin

PendingCN112538029ANo alkaline hydrolysisAlkaline hydrolysis does not occurOrganic chemistry methodsChemical/physical/physico-chemical microreactorsPhenyl acetic acidPtru catalyst

The invention discloses a green synthesis method for high-yield preparation of trifloxystrobin. The method comprises the following steps that methyl 2-bromomethyl-(alpha E) methoxyiminobenzene acetateis condensed with m-trifluoromethyl acetophenone oxime under the dual catalytic action of a phosphine-containing ligand catalyst and DBU serving as alkali to generate the high-yield trifloxystrobin.The reaction conditions for preparing trifloxystrobin are milder, the reaction time is short, the use amount of the solvent is small, inorganic base is adopted, and the amount of waste salt is reduced. And the fully-dissolved state of the material can be used for a micro-channel reactor. The method has the advantages of simple steps, environmental protection, suitableness for industrial production, high yield and high content of the final product, and production cost reduction.

Owner:利民化学有限责任公司

2-carbonyl-2-phenyl acetic acid p-nitrobenzoylhydrazone bis(2,4-dichlorobenzyl)tin complex and preparation method and application thereof

ActiveCN106336427AHas a thermally stable rangeFriendly and beneficialTin organic compoundsOrganic chemistry methodsPhenyl acetic acidAcetic acid

The invention discloses a 2-carbonyl-2-phenyl acetic acid p-nitrobenzoylhydrazone bis(2,4-dichlorobenzyl)tin complex, which is shown in a following structural formula (I), wherein Ph is phenyl, and R is 2,4-dichlorobenzyl. The invention also discloses a preparation method of the 2-carbonyl-2-phenyl acetic acid p-nitrobenzoylhydrazone bis(2,4-dichlorobenzyl)tin complex and an application of the complex in preparation of anticancer medicines.

Owner:HENGYANG NORMAL UNIV

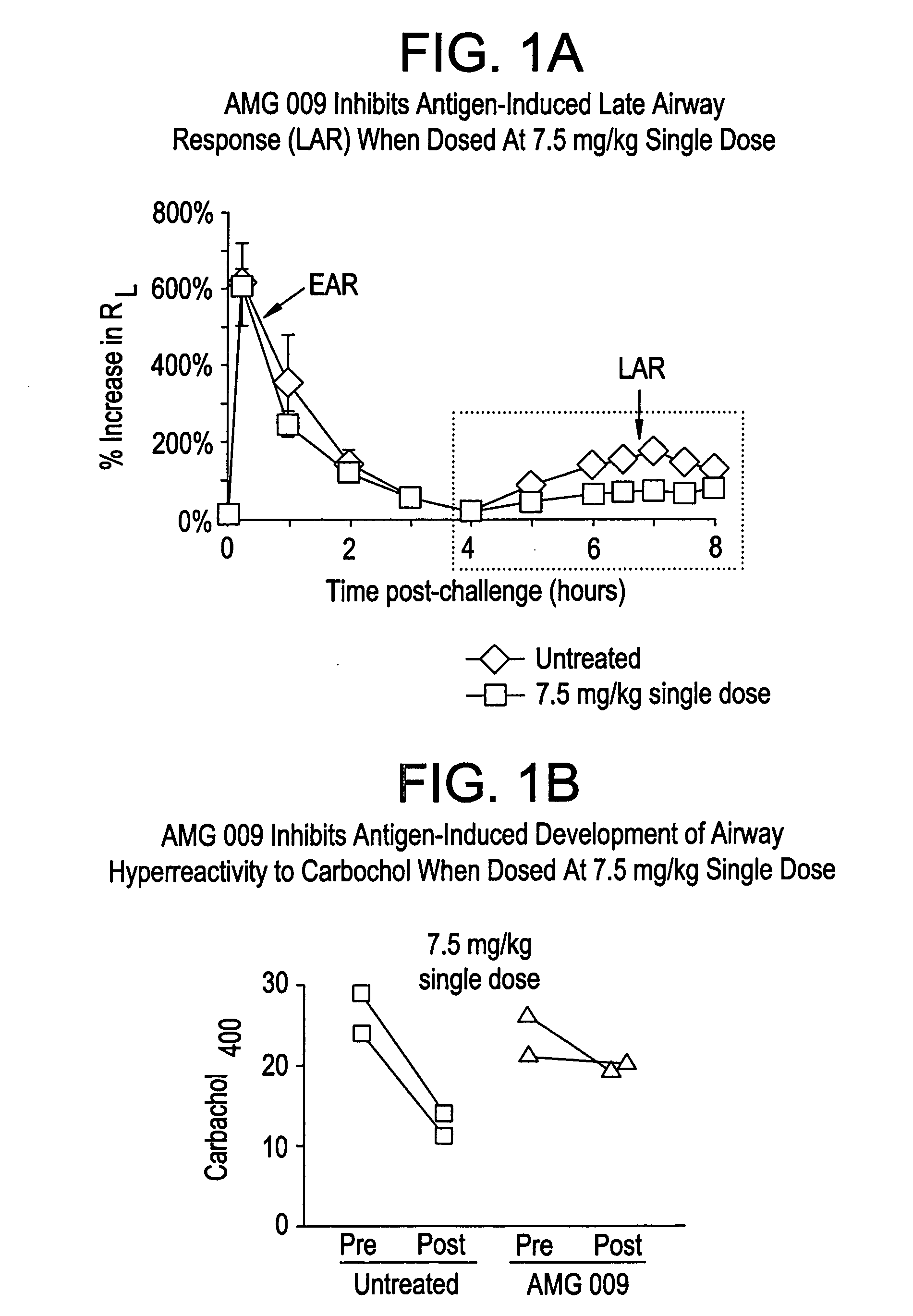

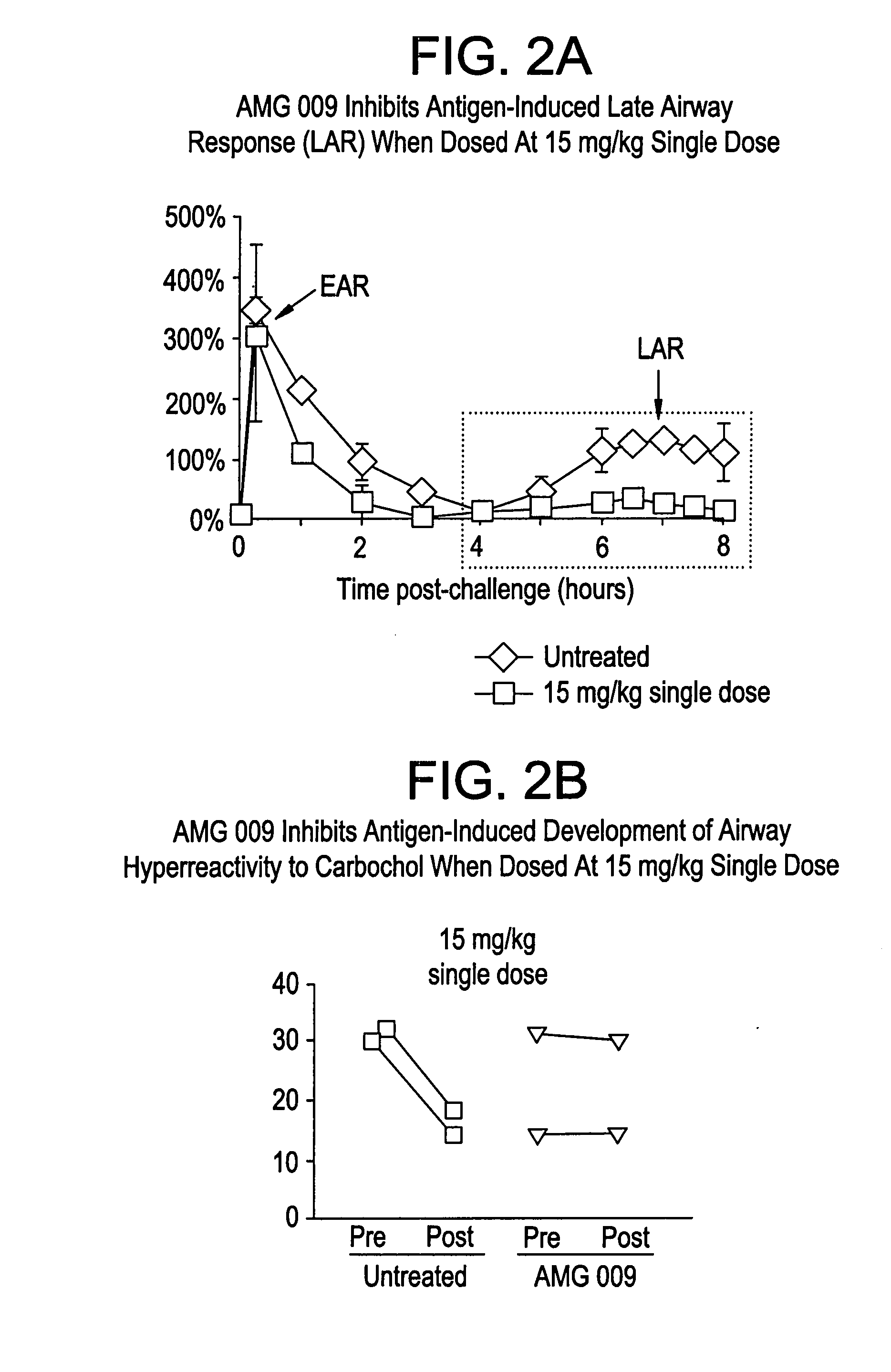

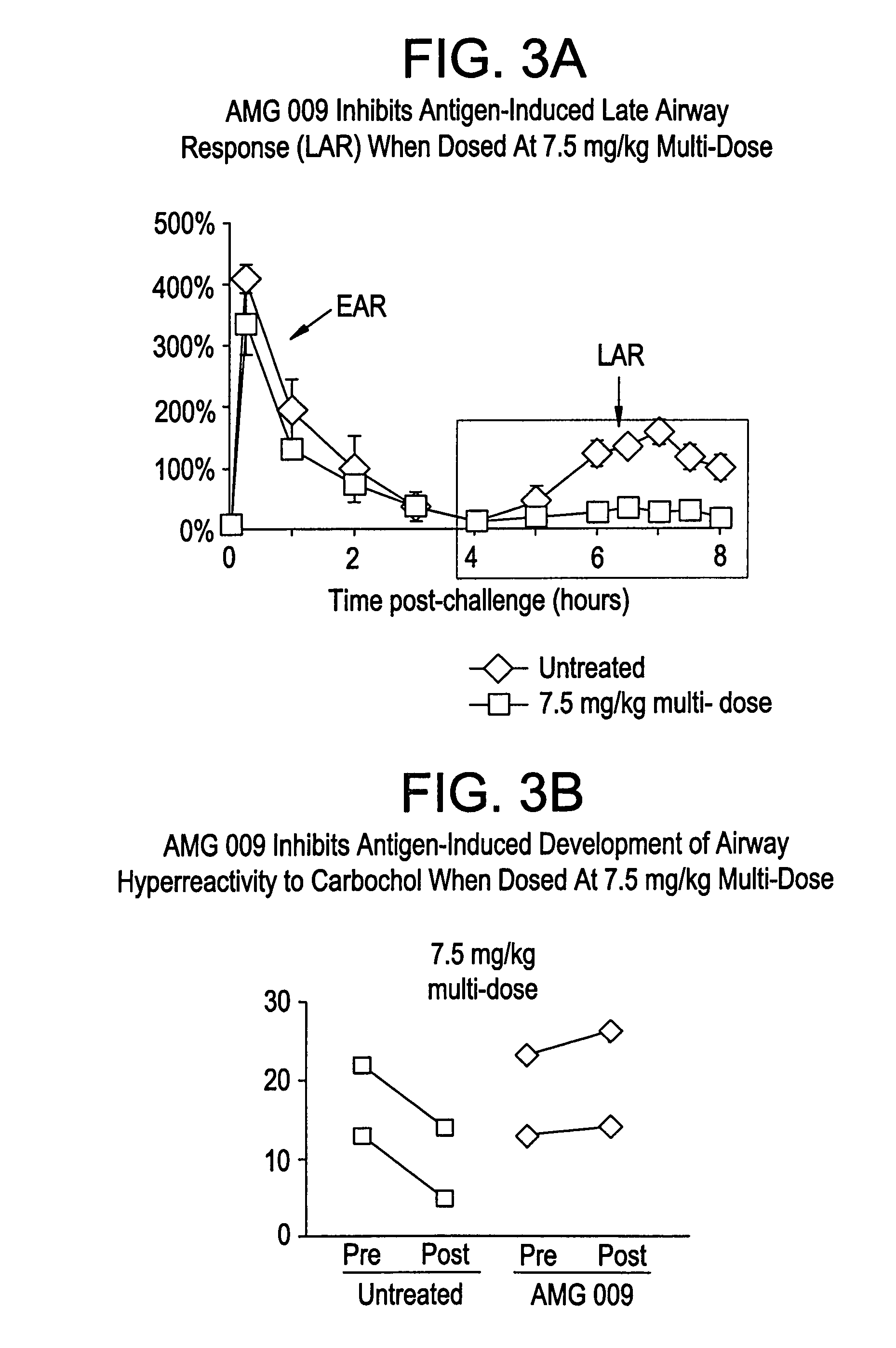

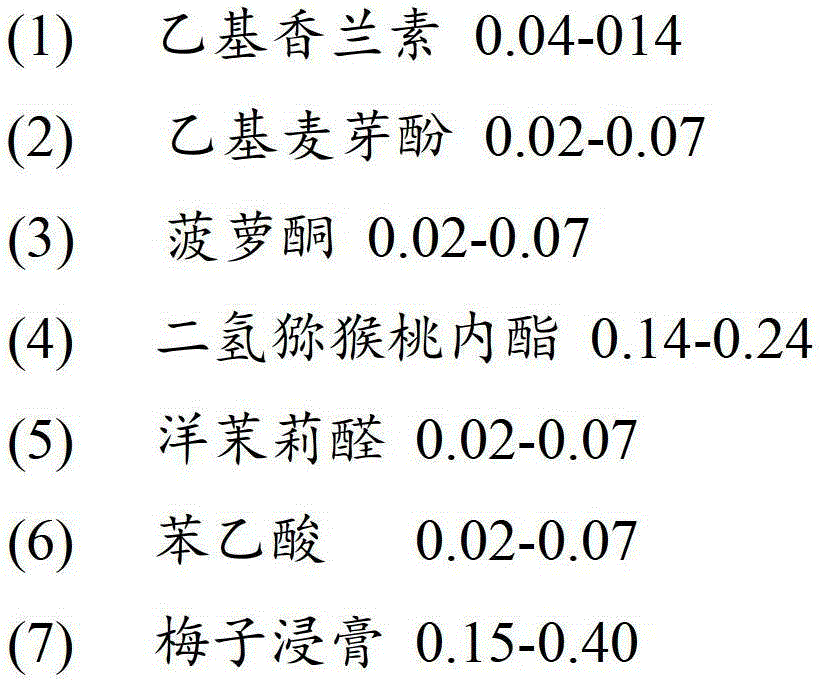

Phenyl acetic acid derivatives

Compounds, pharmaceutical compositions and methods are provided that are useful in the treatment of inflammatory and immune-related diseases and conditions. In particular, the invention provides compounds which modulate the function and / or expression of proteins involved in atopic diseases, inflammatory conditions and cancer. The subject compounds are carboxylic acid derivatives.

Owner:AMGEN INC

Method for producing entacapone

InactiveCN104744301ASimplify the manufacturing processReduce manufacturing costCarboxylic acid nitrile preparationOrganic compound preparationTolueneEntacapone

The invention relates to a method for producing entacapone. The method comprises the following specific steps: dissolving 1.83g of 3,4-dihydroxy-5-nitrobenzaldehyde and 1.5g of N,N-diethyl cyanoacetamide and a catalytic amount of piperidine acetate in 40mL in dry ethanol, and stirring overnight to obtain 2.23g of a crude product; heating at 90 DEG, dissolving 3.0kg of the crude product in 8.0kg of acetic acid (or formic acid) containing 80g of HBr (or 40g of HCl), slowly cooling to 20 DEG C, and stirring at the temperature for 20 h, then stirring at 15 DEG C for 6 h, filtering, collecting precipitated crystal; and carefully washing the crystal with 1L of a cold mixed liquid (4 DEG C) of toluene-acetic acid (volume ratio of 1:1), then washing the crystal with 1L of cold toluene, and drying in vacuum at 45 DEG C to obtain 2.4kg of crystalline pure entacapone. The method for producing entacapone has the advantages of simple manufacture process, low production cost and high output.

Owner:李磊

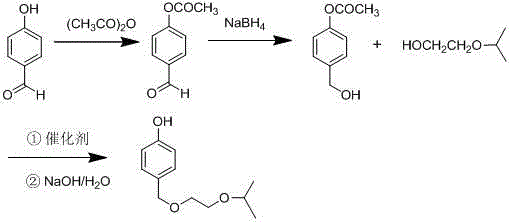

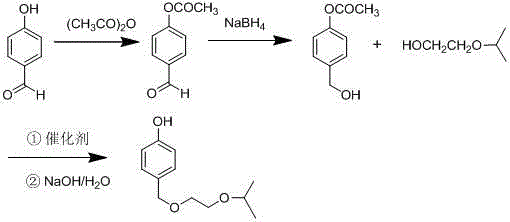

Novel method for synthesizing bisoprolol importance intermediate

InactiveCN104876806AMild reaction conditionsEasy to operateOrganic compound preparationCarboxylic acid esters preparationPhenyl acetic acidAcetic anhydride

The invention discloses a novel method for synthesizing a bisoprolol importance intermediate. The novel method has the following steps: carrying out a reaction between hydroxy benzaldehyde which is taken as a raw material and acetic anhydride to obtain 4-acetoxybenzaldehyde; conducting reduction on 4-acetoxybenzaldehyde with sodium borohydride to obtain 4-acetoxyl benzyl alcohol; carrying out a reaction between 4-acetoxyl benzyl alcohol and 2-isopropoxyethanol to obtain 4-[(2-isopropoxyethanol)methyl]phenyl acetic acid, thereby avoiding side reactions such as phenolic hydroxyl etherification; under an alkaline condition, directly hydrolyzing 4-[(2-isopropoxyethanol)methyl]phenyl acetic acid without separation to recover 2-isopropoxyethanol, thereby obtaining the required intermediate, namely 4-isopropoxyethoxymethylphenol. The novel method is mild in reaction and safe to operate; impurities generated due to self-polymerization of raw materials, phenolic hydroxyl etherification and the like are reduced; the product purity and yield are relatively high; as a novel way for obtaining the bisoprolol importance intermediate, the novel method can be applied to large-scale industrialized production.

Owner:UNIV OF JINAN

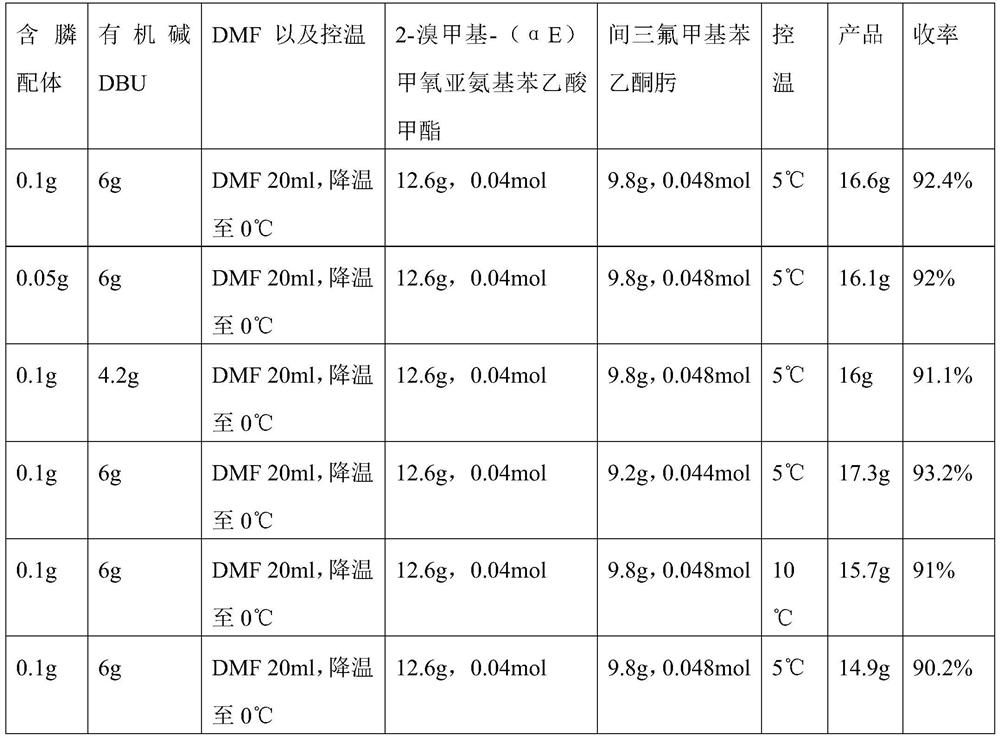

Improved production process for repaglinide

InactiveCN105175361AChange the status quo of low puritySimplified synthesis stepsOrganic chemistry methodsPhenyl acetic acidButylamines

The invention provides an improved production process for repaglinide. The process is characterized by comprising the following steps: with (S,S')-3-methyl-1-(2-(1-piperidinyl)phenyl)butylamine, N-acetyl-glutamate as a main material, adding ammonia water to prepare chiral amine (S)-(+)-3-methyl-1-(2-piperidinyl-phenyl)butyl amine; then adding triethylamine and adding a mixed liquid of pivaloyl chloride and toluene drop by drop; subjecting a product obtained in the previous step and 3-ethoxy-4-ethoxycarbonyl phenyl acetic acid to a condensation reaction so as to prepare a compound (S)-2-ethoxy-4[2-[3-methyl-1-[2-(1-piperidinyl)-phenyl]-butyl]-amino]-2-carbonylehtyl ethyl benzoate; hydrolyzing the compound in ethanol and a sodium hydroxide solution so as to obtain a crude repaglinide product; and dissolving the obtained crude repaglinide product in a mixed solution of ethanol and water for purification so as to prepare a refined repaglinide product. The improved production process provided by the invention further simplifies synthesis and purification steps, has the advantages of high efficiency, low toxicity, low danger, easy operation, etc. and has the characteristics of simplicity and easiness in control and industrial production.

Owner:TIANJIN PHARMA GROUP GENCOM PHARMA

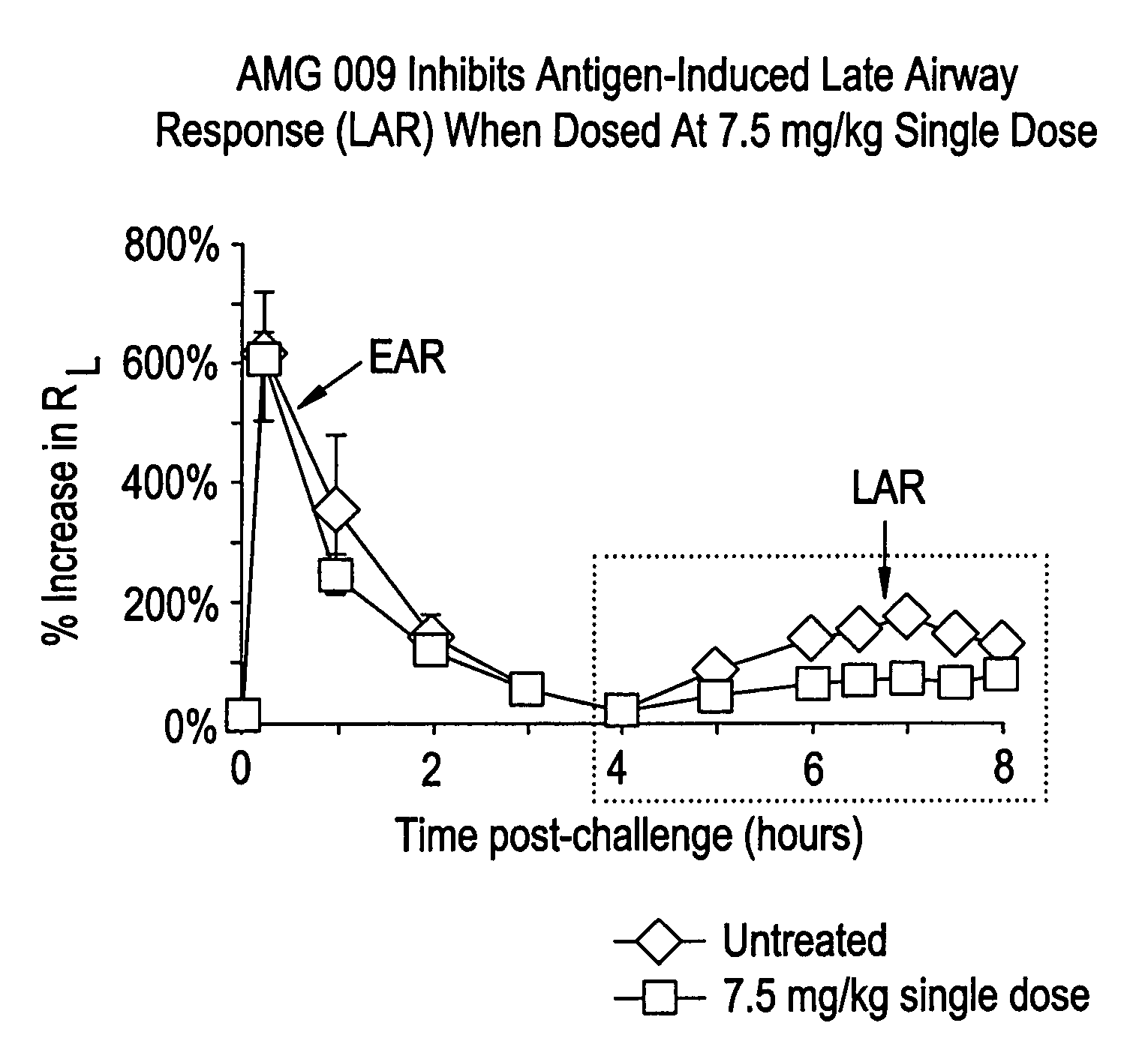

Phenyl acetic acid derivatives as inflammation modulators

Compounds, pharmaceutical compositions and methods are provided that are useful in the treatment of inflammatory and immune-related diseases and conditions. In particular, the invention provides compounds which modulate the function and / or expression of proteins involved in atopic diseases, inflammatory conditions and cancer. The subject compounds are carboxylic acid derivatives.

Owner:AMGEN INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

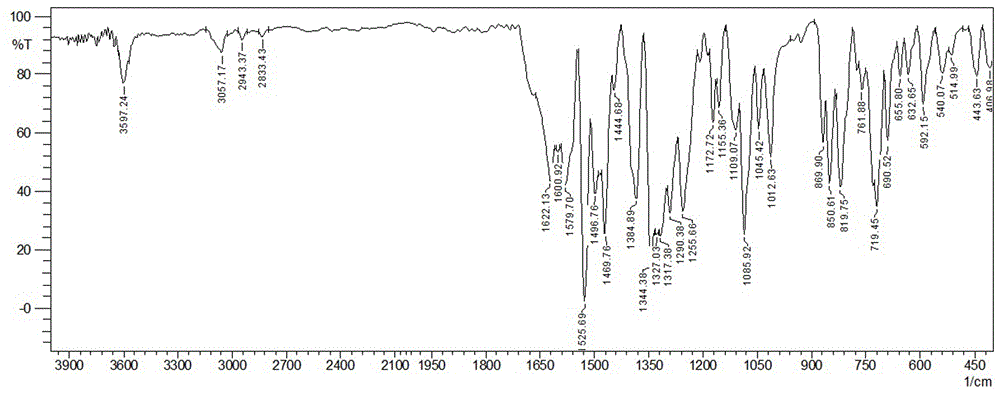

![Novel crystalline forms of 4-[4-[4-(hydroxydiphenylmethyl)-1- piperidinyl]-1-hydroxybutyl]-$g(a)-dimethylbenzene acetic acid and its hydrochloride Novel crystalline forms of 4-[4-[4-(hydroxydiphenylmethyl)-1- piperidinyl]-1-hydroxybutyl]-$g(a)-dimethylbenzene acetic acid and its hydrochloride](https://images-eureka.patsnap.com/patent_img/d0b45a86-06d0-4b68-ba02-3e752722a29b/US20040077683A1-20040422-C00001.png)

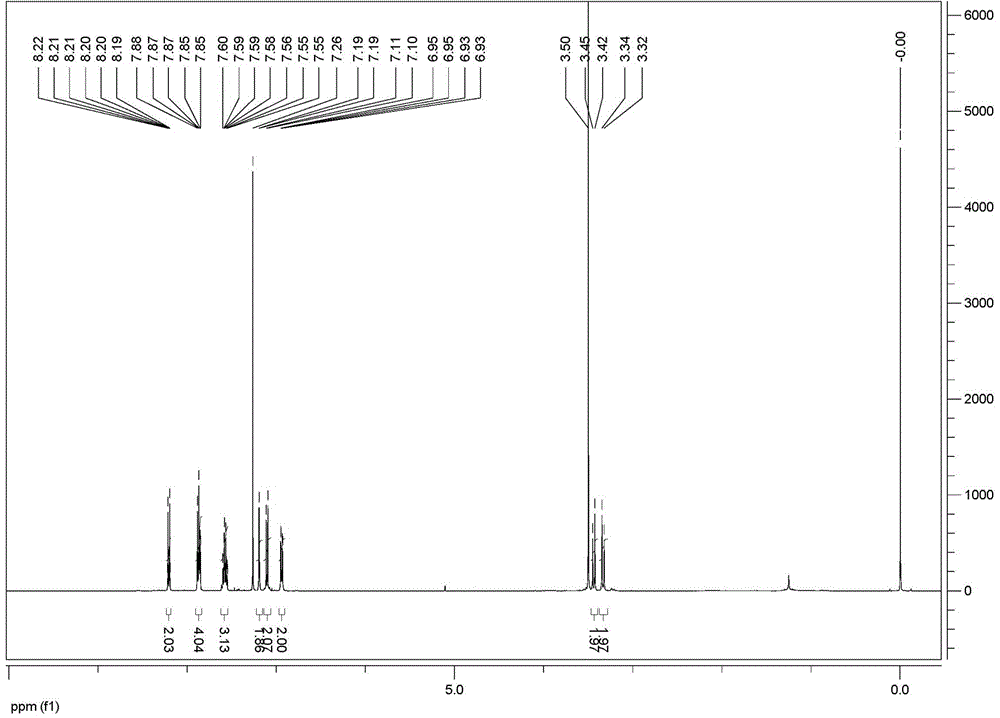

![Novel crystalline forms of 4-[4-[4-(hydroxydiphenylmethyl)-1- piperidinyl]-1-hydroxybutyl]-$g(a)-dimethylbenzene acetic acid and its hydrochloride Novel crystalline forms of 4-[4-[4-(hydroxydiphenylmethyl)-1- piperidinyl]-1-hydroxybutyl]-$g(a)-dimethylbenzene acetic acid and its hydrochloride](https://images-eureka.patsnap.com/patent_img/d0b45a86-06d0-4b68-ba02-3e752722a29b/US20040077683A1-20040422-D00001.png)

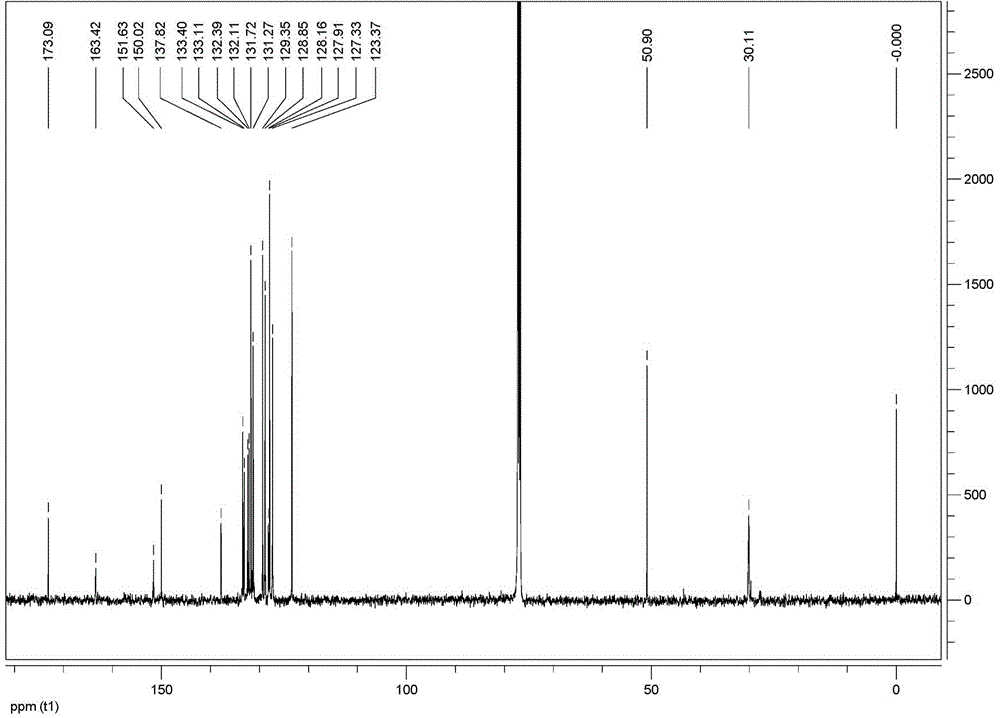

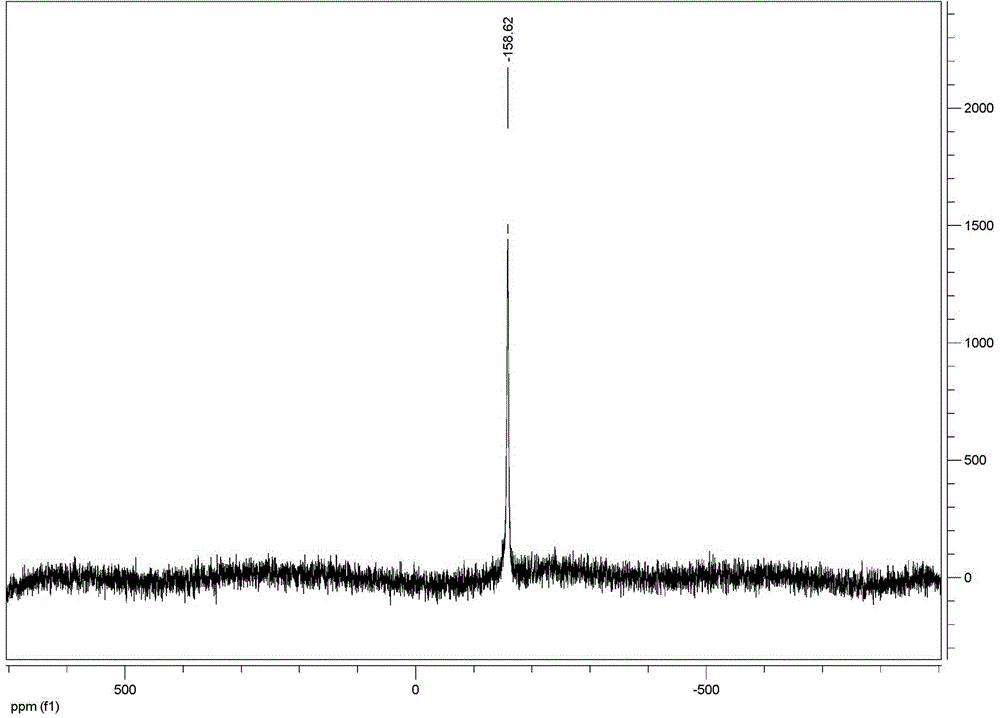

![Novel crystalline forms of 4-[4-[4-(hydroxydiphenylmethyl)-1- piperidinyl]-1-hydroxybutyl]-$g(a)-dimethylbenzene acetic acid and its hydrochloride Novel crystalline forms of 4-[4-[4-(hydroxydiphenylmethyl)-1- piperidinyl]-1-hydroxybutyl]-$g(a)-dimethylbenzene acetic acid and its hydrochloride](https://images-eureka.patsnap.com/patent_img/d0b45a86-06d0-4b68-ba02-3e752722a29b/US20040077683A1-20040422-D00002.png)

![Polymorph of acid 4-[2-[4-[1-2-ethoxyethyl)-1h-benzimidazole-2-il]-1-piper idinyl]ethyl]-dollar G (A), dollar G (A)-dimethyl-benzeneacetic Polymorph of acid 4-[2-[4-[1-2-ethoxyethyl)-1h-benzimidazole-2-il]-1-piper idinyl]ethyl]-dollar G (A), dollar G (A)-dimethyl-benzeneacetic](https://images-eureka.patsnap.com/patent_img/fa3f2371-d99d-4c66-82f0-fb9a7e006a59/A0282898700121.PNG)

![Polymorph of acid 4-[2-[4-[1-2-ethoxyethyl)-1h-benzimidazole-2-il]-1-piper idinyl]ethyl]-dollar G (A), dollar G (A)-dimethyl-benzeneacetic Polymorph of acid 4-[2-[4-[1-2-ethoxyethyl)-1h-benzimidazole-2-il]-1-piper idinyl]ethyl]-dollar G (A), dollar G (A)-dimethyl-benzeneacetic](https://images-eureka.patsnap.com/patent_img/fa3f2371-d99d-4c66-82f0-fb9a7e006a59/A0282898700131.PNG)

![Polymorph of acid 4-[2-[4-[1-2-ethoxyethyl)-1h-benzimidazole-2-il]-1-piper idinyl]ethyl]-dollar G (A), dollar G (A)-dimethyl-benzeneacetic Polymorph of acid 4-[2-[4-[1-2-ethoxyethyl)-1h-benzimidazole-2-il]-1-piper idinyl]ethyl]-dollar G (A), dollar G (A)-dimethyl-benzeneacetic](https://images-eureka.patsnap.com/patent_img/fa3f2371-d99d-4c66-82f0-fb9a7e006a59/A0282898700141.PNG)