Preparation method of chlorophenyl acetic acid

A manufacturing method and chlorobenzene technology, which are applied in the preparation of nitrile, organic chemistry, etc., can solve the problems of high labor intensity of operators, many equipment and sites, etc., and achieve the effects of less pollution of three wastes, high efficiency, and simple process operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

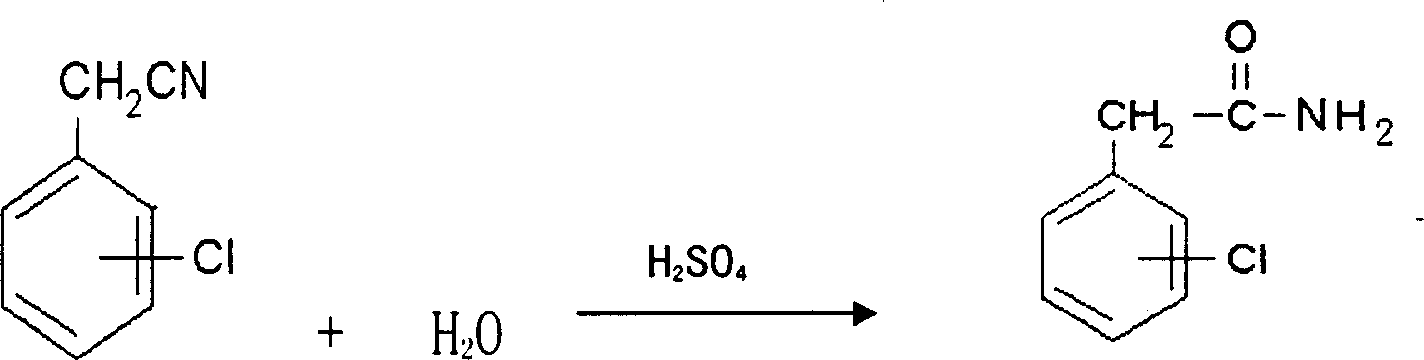

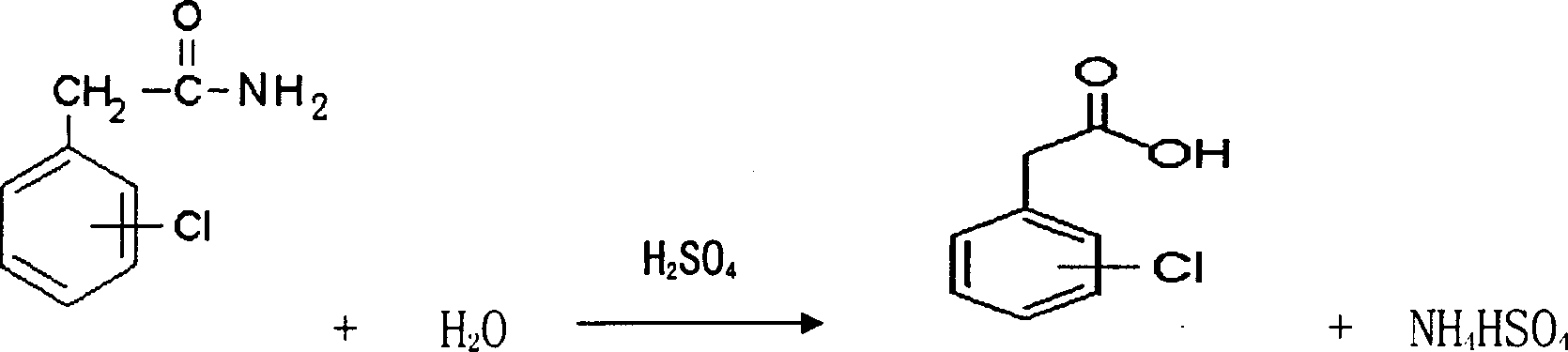

Method used

Image

Examples

Embodiment 1

[0023] Put 707g (7.07mol) of 98% concentrated sulfuric acid and 471g of water into a 2000ml four-necked flask, and slowly add 693g (4.53mol) of 99.0% o-chlorophenylacetonitrile dropwise at 90 to 130°C. After the heat preservation reaction for 1 hour, About 260g of water was distilled off, and the reaction was further incubated at 130-150°C for 3 hours to stop (sampling and analysis by GC, o-chlorophenylacetic acid: 99.74%, o-chlorophenylacetonitrile: 0.12%). Add 500ml of water to make it miscible and then cool and crystallize to 35°C. Suction filtration, and the obtained crystals were washed once with 500ml of warm water; the crystals were dried at 30-40°C to obtain 738.0g of finished o-chlorophenylacetic acid. Content (GC): 99.94%; Ash: 0.10%; Moisture: 0.12%; Melting point: 94.8-95.8°C (literature value: 94-97°C); Yield: 95.4%.

Embodiment 2

[0025] 11.9kg (0.119kmol) of 98% concentrated sulfuric acid and 8kg of clear water were dropped into a 50L enamel reaction kettle; 13.0kg (0.085kmol) of 99.0% p-chlorophenylacetonitrile was slowly added dropwise, and the operation was the same as above. Sampling analysis (GC) at the end of the reaction: p-chlorophenylacetic acid 99.82%; p-chlorophenylacetonitrile 0.07%. Keep warm at 100-110°C, settle for 10-15 minutes, and release acid water. Add 10-15kg of clear water, stir and heat up to 90-100°C, cool to crystallize, and other operations are the same as above. The obtained wet acid is dehydrated and dried under vacuum at 90-100°C to obtain 13.8Kg of p-chlorophenylacetic acid as a finished product. Product analysis: content (GC) 99.96%; ash content 0.03%; moisture content 0.07%; melting point 91.5-92.5°C (documentation value: 90-93°C); yield: 95.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com