LED light cured aqueous woodenware paint and preparation method thereof

A water-based wood paint, light-curing technology, applied in the field of coatings, can solve the problems of complex construction process, long drying time, safety and other problems, and achieve the effects of good storage stability, convenient preparation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

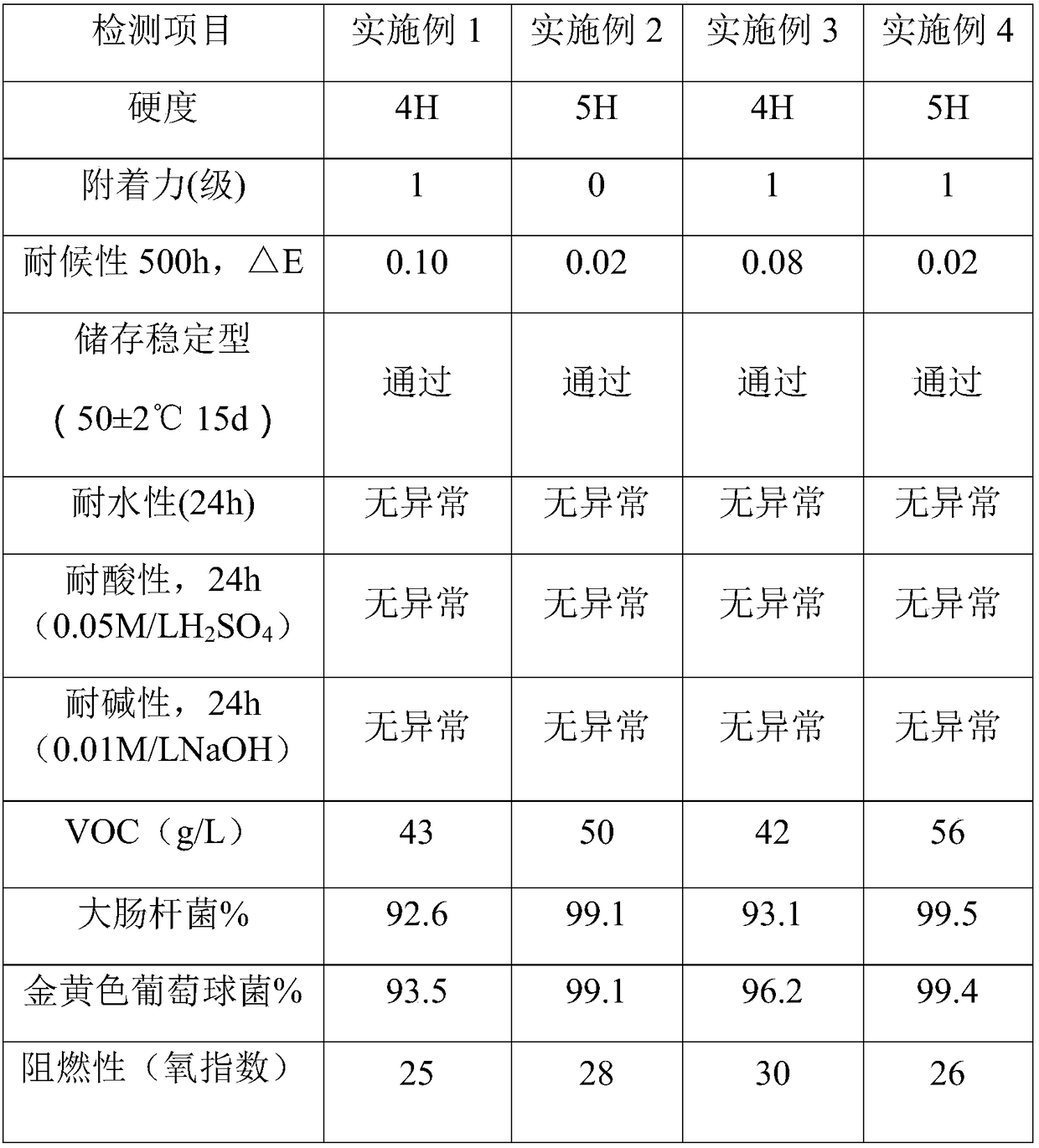

Examples

Embodiment 1

[0037] The embodiment of the present invention provides a kind of LED photocurable water-based wood varnish, and described wood ware varnish specifically comprises the following components by weight:

[0038] 95 parts of polyurethane acrylate emulsion, 2 parts of carbon nanotube modified polyphosphazene-polyethersulfone block copolymer, 8 parts of composite photoinitiator, 2 parts of 4-dimethylamino-ethyl benzoate, water-soluble active monomer 1 part of body, 4 parts of silver nanoparticles, 0.5 parts of Ag-bisphenylpyrazolylpyridine-p-phenylacetic acid complex, 10 parts of matting agent, 5 parts of preservative, 8 parts of wetting and dispersing agent, 4 parts of defoaming agent, 13 parts of thickener, 2 parts of film-forming aid, 0.2 part of pH regulator, 8 parts of filler, 8 parts of coloring agent, 25 parts of deionized water.

[0039] Wherein the composite photoinitiator is: 2-methyl-1-(4-methylthiophenyl)-2-morpholino-1-acetone accounts for 17wt% of the initiator total a...

Embodiment 2

[0052] The embodiment of the present invention provides a kind of LED photocurable water-based wood varnish, and described wood ware varnish specifically comprises the following components by weight:

[0053] 100 parts of silicone modified acrylic emulsion, 5 parts of carbon nanotube modified polyphosphazene-polyethersulfone block copolymer, 6 parts of composite photoinitiator, 2 parts of 4-dimethylamino-ethyl benzoate, water-soluble 3 parts of active monomer, 5 parts of silver nanoparticles, 0.2 parts of Ag-bisphenylpyrazolylpyridine-p-phenylacetic acid complex, 6 parts of matting agent, 3 parts of preservative, 13 parts of wetting and dispersing agent, 6 parts of defoaming agent 8 parts, 8 parts of thickener, 2 parts of film-forming aid, 0.4 parts of pH regulator, 7 parts of filler, 6 parts of colorant, 30 parts of deionized water.

[0054]Wherein the composite photoinitiator is: 2-methyl-1-(4-methylthiophenyl)-2-morpholino-1-acetone accounts for the total 15wt% of initiator...

Embodiment 3

[0062] The embodiment of the present invention provides a kind of LED photocurable water-based wood varnish, and described wood ware varnish specifically comprises the following components by weight:

[0063] 110 parts of organic fluorine modified acrylic emulsion, 4 parts of carbon nanotube modified polyphosphazene-polyethersulfone block copolymer, 5 parts of composite photoinitiator, 1 part of 4-dimethylamino-ethyl benzoate, water-soluble 2 parts of active monomer, 2 parts of silver nanoparticles, 0.3 parts of Ag-bisphenylpyrazolylpyridine-p-phenylacetic acid complex, 8 parts of matting agent, 1 part of preservative, 20 parts of wetting and dispersing agent, 1 part of defoamer 5 parts, thickener 5 parts, film-forming aid 3 parts, pH adjuster 0.4 parts, filler 6 parts, coloring agent 5 parts, deionized water 28 parts.

[0064] Wherein the composite photoinitiator is: 2-methyl-1-(4-methylthiophenyl)-2-morpholino-1-acetone accounts for 25wt% of the initiator total amount, 2,4,6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com