Formula of Amadori reactive flavor, preparation method of Amadori reactive flavor and use of Amadori reactive flavor

A technology of reaction and fragrance, applied in the application field of non-volatile flavor precursor substances in cigarettes, can solve the problems of low yield, long reaction time, cumbersome separation and purification treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

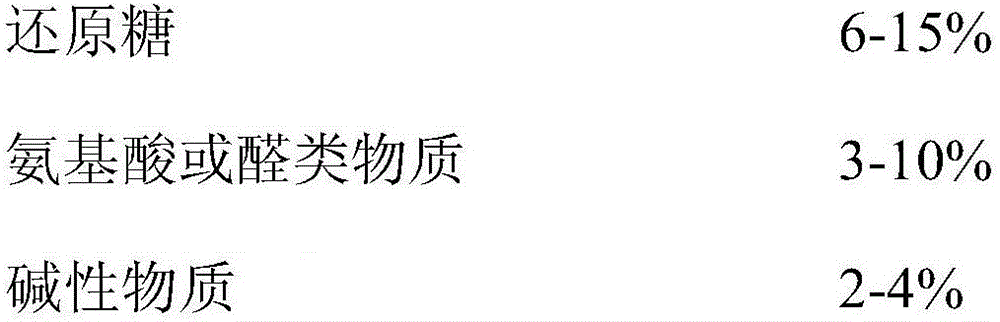

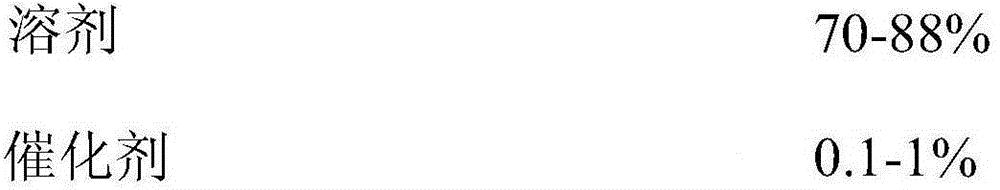

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1, a kind of preparation method of Amadori reaction perfume, concrete steps are as follows:

[0033] Add 5.4g of sodium methoxide and 8.9g of alanine to 250ml of anhydrous methanol and stir to dissolve until the solution is clear and transparent, add 18g of glucose, stir and heat to reflux at a heating temperature of 60°C, heat to reflux until the glucose is completely dissolved, then add excess anhydrous Sodium sulfate was heated to 40°C and refluxed for 20 minutes, the heating temperature was 40°C, the heating was stopped, the reaction was stirred at room temperature for 10 minutes, 1ml of acetic acid was added to stir the reaction for 10 minutes, filtered, the filtrate was concentrated under reduced pressure to remove the reaction solvent to obtain a crude product, and the crude product was washed with methanol-acetone solution After recrystallization, it is dissolved in water and then freeze-dried to obtain the reaction flavor.

Embodiment 2

[0034] Embodiment 2, a kind of preparation method of Amadori reaction perfume, concrete steps are as follows:

[0035] Add 5.6g of potassium hydroxide and 7.5g of glycine to 250ml of anhydrous methanol and stir to dissolve until the solution is clear and transparent. Add 15g of xylose, stir and heat to reflux at a heating temperature of 70°C. Heat sodium sulfate water to 50°C and reflux for 15 minutes, stop heating, stir and react at room temperature for 10 minutes, add 1ml oxalic acid to stir and react for 10 minutes, filter, and concentrate the filtrate under reduced pressure to remove the reaction solvent to obtain a crude product, which is recrystallized from methanol-acetone solution, water Freeze-dry after dissolving to obtain the reaction flavor.

Embodiment 3

[0036] Embodiment 3, a kind of preparation method of Amadori reaction perfume, concrete steps are as follows:

[0037] Add 5.4g of sodium methoxide and 10.5g of serine to 250ml of anhydrous methanol and stir to dissolve until the solution is clear and transparent, add 18g of glucose, stir and heat to reflux at a heating temperature of 65°C, heat to reflux until the glucose is completely dissolved, then add excess anhydrous sodium sulfate and heat to Reflux at 45°C for 25 minutes, stop heating, stir and react at room temperature for 10 minutes, add 1ml of acetic acid, stir and react for 10 minutes, filter, and concentrate the filtrate under reduced pressure to remove the reaction solvent to obtain a crude product, which is recrystallized from methanol-acetone solution, dissolved in water, and freeze-dried That is, reaction spices.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com