Manufacturing method for chinlon Dacron twill vertical strip fabric

A production method, the technique of nylon-polyester twill, which is applied in the field of production of nylon-polyester twill vertical strip fabrics, can solve the problems of poor dyeing effect, improper dyeing sequence adjustment, unsatisfactory texture, etc., and achieve the effect of good chroma and true color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

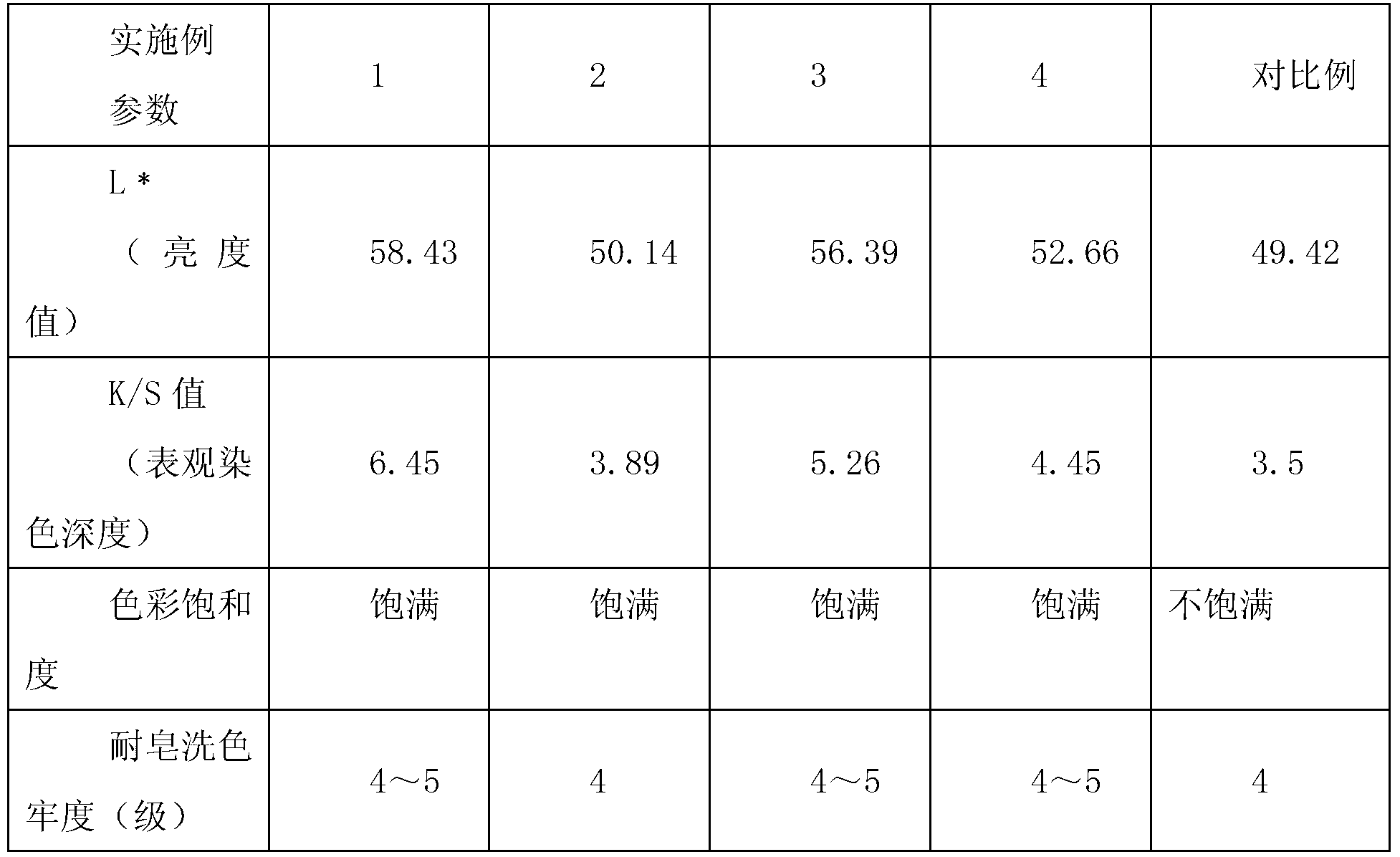

Embodiment 1

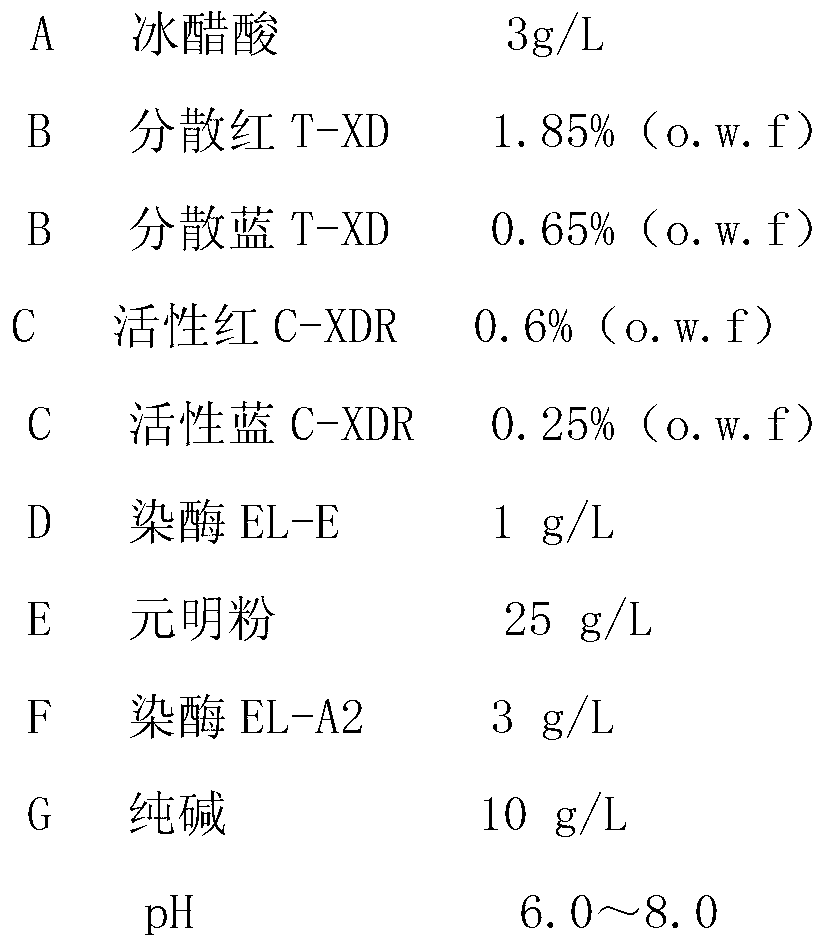

[0024] A method for making nylon and polyester twill vertical stripe fabrics, comprising raw material preparation, warping, weaving into twill vertical stripe blanks, alkali weight reduction, dyeing, color fixing, printing, shaping, and inspection steps, wherein the dyeing is a two-bath Method inclined tube staining, described two-bath method inclined tube staining comprises the following steps:

[0025] Step (1), one bath, first dyeing the polyester component in the twill vertical strip stock; it includes the following steps:

[0026] 101. Put the twill vertical bar stock into a pH regulator and a dye bath containing 2g / L leveling agent for pretreatment for 10 minutes, wherein the pH value of the pretreated dye bath is adjusted to 6.5 and the temperature is 55°C;

[0027] 102. Add dye, dispersant 841 and defoamer to the dye bath to make a dye solution, raise the temperature to 110°C, and keep the dyeing time at 30°C; wherein the dye includes Sumiclone dispersant produced by...

Embodiment 2

[0033] A method for making nylon and polyester twill vertical stripe fabrics, comprising raw material preparation, warping, weaving into twill vertical stripe blanks, alkali weight reduction, dyeing, color fixing, printing, shaping, and inspection steps, wherein the dyeing is a two-bath Method inclined tube staining, described two-bath method inclined tube staining comprises the following steps:

[0034] Step (1), one bath, first dyeing the polyester component in the twill vertical strip stock; it includes the following steps:

[0035] 101. Put the twill vertical bar stock into a pH regulator and a dye bath containing 4g / L leveling agent for pretreatment for 10 minutes, wherein the pretreated dye bath has a pH value of 6.8 and a temperature of 55°C;

[0036] 102. Add dye, dispersant 841 and defoamer to the dye bath to make a dye solution, raise the temperature to 110°C, and keep the dyeing time at 60°C; wherein the dyes include Sumiclon Disperse Red E-RPD (E) and Sumikaron ...

Embodiment 3

[0042] A method for making nylon and polyester twill vertical stripe fabrics, comprising raw material preparation, warping, weaving into twill vertical stripe blanks, alkali weight reduction, dyeing, color fixing, printing, shaping, and inspection steps, wherein the dyeing is a two-bath Method inclined tube staining, described two-bath method inclined tube staining comprises the following steps:

[0043] Step (1), one bath, first dyeing the polyester component in the twill vertical strip stock; it includes the following steps:

[0044] 101. Put the twill vertical bar stock into a pH regulator and a dye bath containing 3g / L leveling agent for pretreatment for 10 minutes, wherein the pretreated dye bath has a pH value of 7.0 and a temperature of 55°C;

[0045] 102. Add dye, dispersant 841 and defoamer to the dye bath to make a dye solution, raise the temperature to 110°C, and keep the dyeing time at 30-60°C; wherein the dye includes Sumiclon Disperse Red E-RPD (E ) and Sumika...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com