Method for carrying out manufacturing by serving carbon fiber cloth as lithium ion battery cathode slice

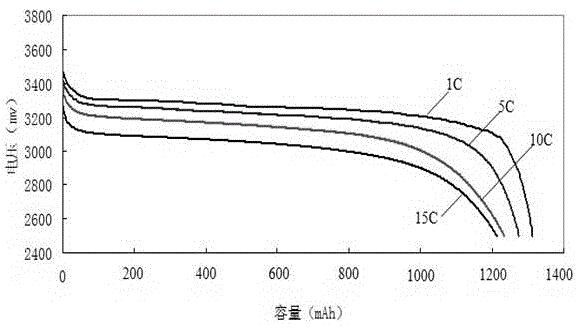

A lithium-ion battery, carbon fiber cloth technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as undisclosed carbon fiber tips, save auxiliary materials and production equipment, have good flexibility and toughness, and meet high current charge and discharge. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

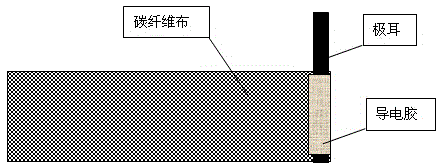

Image

Examples

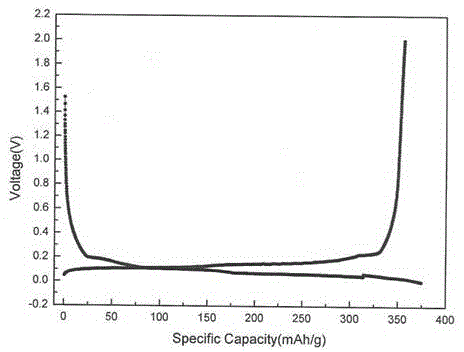

Embodiment 1

[0034] The carbon fiber spinnable pitch with a softening point of 250 ° C is heated to 280 ° C and melted into a liquid with a flowing state, the spinneret of the melt spinning machine is adjusted, and the pitch fiber precursor with a diameter of 20 ± 1 μm is collected. At a heating rate of 2 ℃ / min in the air, the temperature is raised to 230 ℃, and the oxidation treatment is carried out for 12 hours. The pre-oxidized silk cloth is obtained by drawing the oxidized raw silk, spinning and weaving, and the thickness is controlled at 140 ± 3 μm , the areal density is controlled at 31.3±0.5mg / cm2, the pre-oxygenated silk cloth is heated to 900°C at a heating rate of 10°C / min under the protection of inert gas, the high temperature is maintained for 2 hours, and then cooled to room temperature. The carbonized pre-oxidized silk cloth is then graphitized at high temperature, and the thickness of the finally obtained carbon fiber cloth is 130±3 μm, and the area density is 18.8±0.5 mg / cm2...

Embodiment 2

[0039]Heat the carbon fiber spinnable pitch with a softening point of 200°C to 250°C to melt it into a fluid liquid, adjust the spinneret of the melt spinning machine, and collect pitch fiber precursors with a diameter of 5±1 μm, and place the precursors in In the air, the temperature is raised to 200°C at a heating rate of 1.5°C / min, and the oxidation treatment is carried out for 10 hours. The pre-oxidized silk cloth is obtained by stretching, cutting, spinning and weaving the oxidized raw silk, and the thickness is controlled at 105±3μm. , the surface density is controlled at 23.5±0.5mg / cm2, the pre-oxidized silk cloth is under the protection of an inert gas, and the temperature is raised to 850 °C at a heating rate of 5 °C / min, kept at a high temperature for 1 hour, and then cooled to room temperature. Then the carbonized pre-oxidized silk cloth is subjected to high-temperature graphitization, and the thickness of the finally obtained carbon fiber cloth is 98±3μm, and the su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com