Full aluminum alloy spliced car

An aluminum alloy and carriage technology, applied in the superstructure, superstructure of trucks, vehicle parts, etc., can solve the problems of few recyclable items, long production preparation period, high manufacturing cost, and easy assembly process. Fast, improve resource utilization, reduce the effect of manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

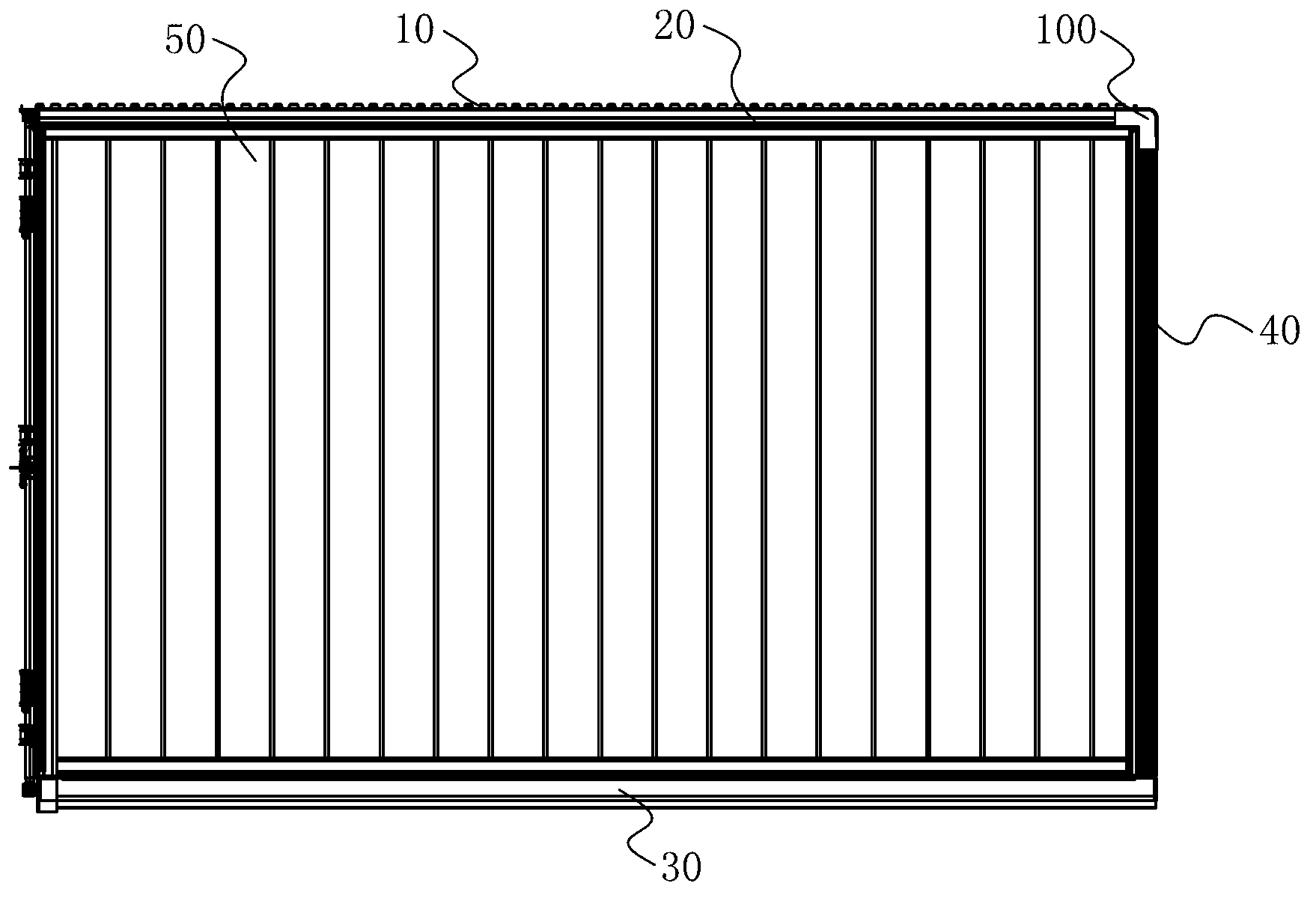

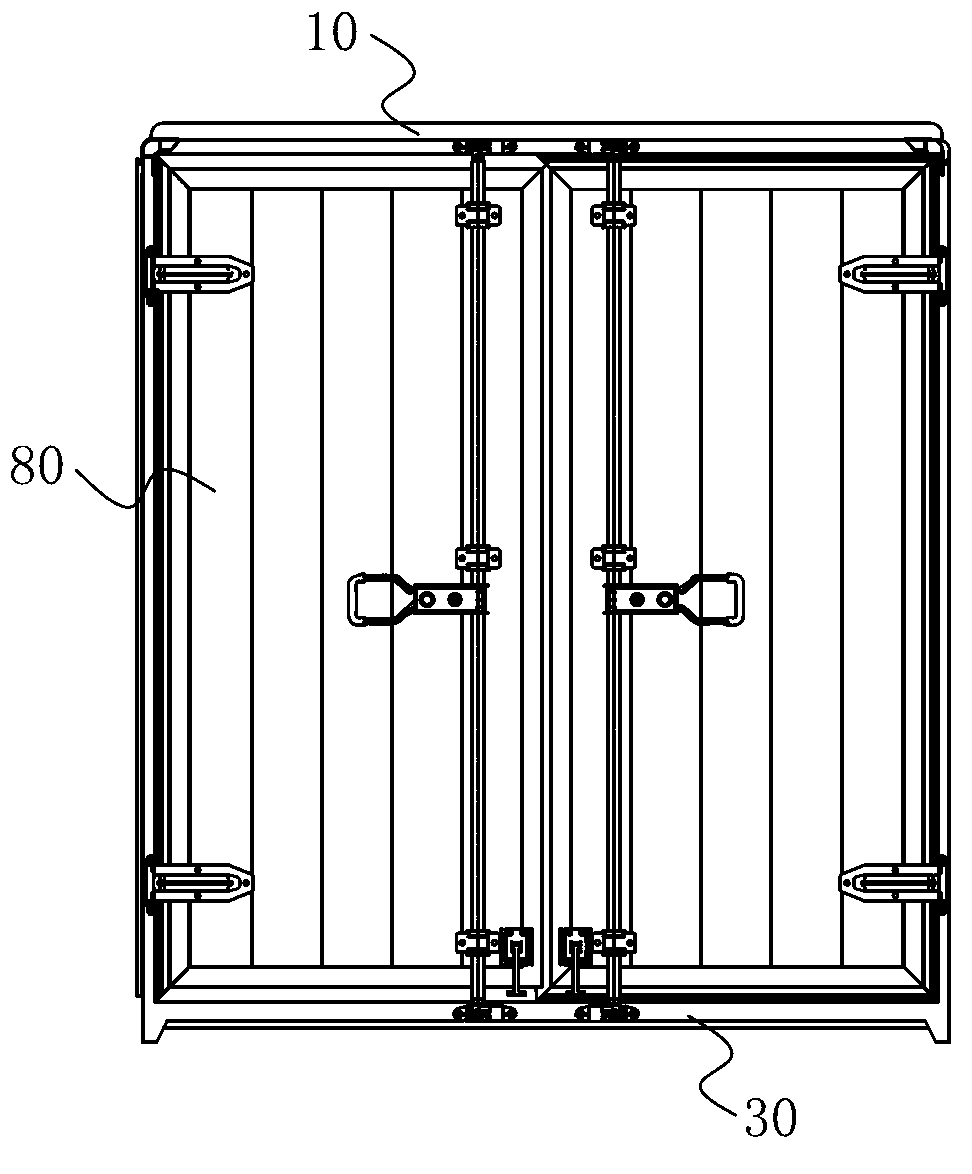

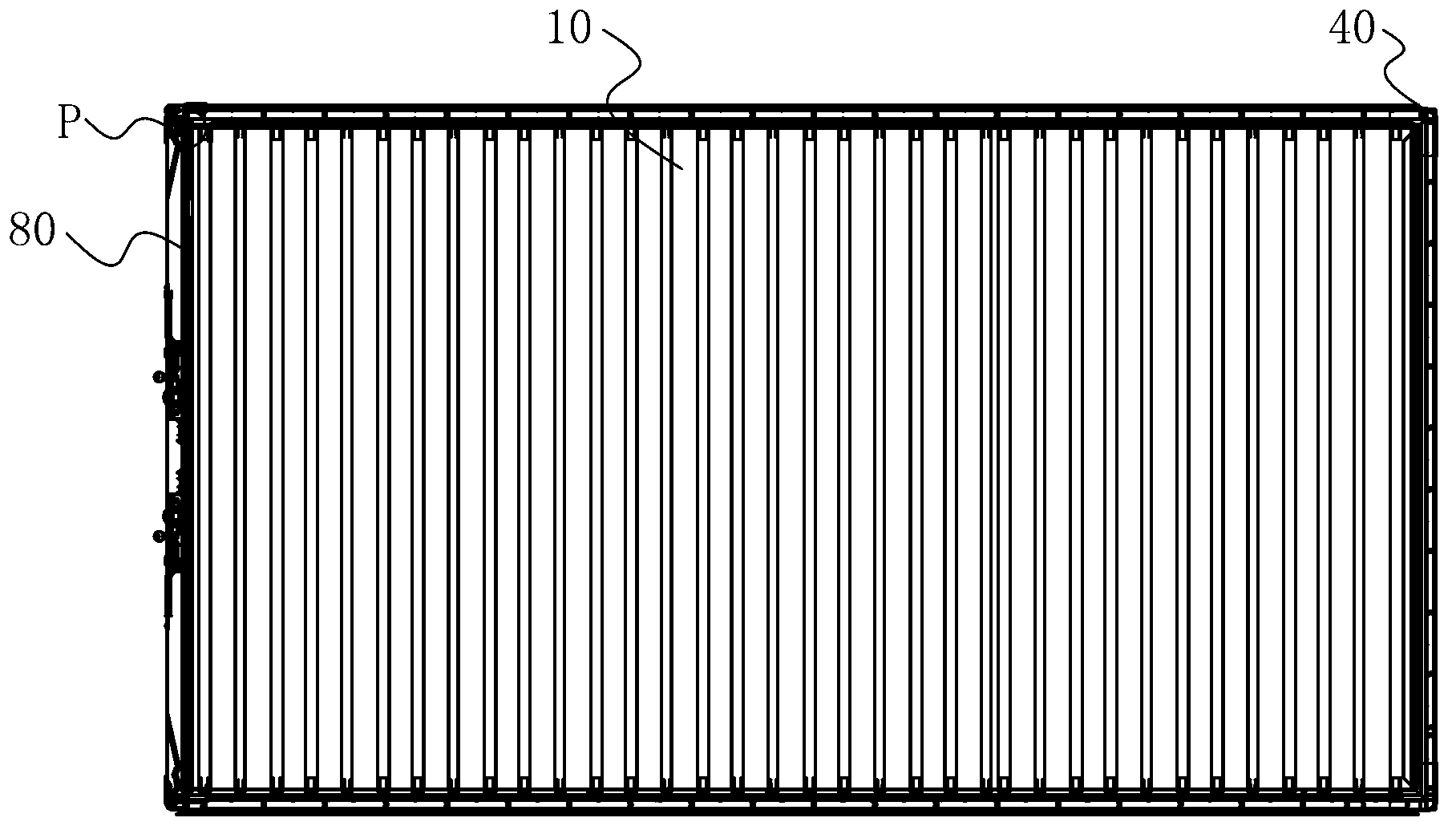

[0044] a kind of like Figure 1-7 The shown all-aluminum alloy assembly structure compartment includes a top panel 10, a bottom panel 30, a side panel 50, a dash panel 70, and a rear door panel 80. The L-shaped upper profile 20 and the front profile 60 are used as connectors; the joints of the side panels 50 with the dash panel 70 and the rear door panel 80 are respectively provided with L-shaped column profiles 40 as connectors or adjacent parts; An L-shaped lower profile 90 is provided at the junction of the side panel 50, the dash panel 70 and the bottom panel 30, wherein the top panel 10 is spliced by several top panel profiles 101, and each top panel profile 101 is close to two sides. The edge of the side is provided with a base 103 and a buckle 102 along its axial direction, and each roof profile 101 is fastened and connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com