Excavator bucket tooth and preparation process of excavator bucket teeth

A technology of excavator bucket teeth and tooth tips, which is applied in the preparation process of excavator bucket teeth and bucket teeth, and the field of excavator accessories. It can solve the problems of slow manual construction progress, tooth tip damage, loss of function, etc., and achieve bonding strength. The possible effect of improving, increasing the service life, and reducing the possibility of tooth tip falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

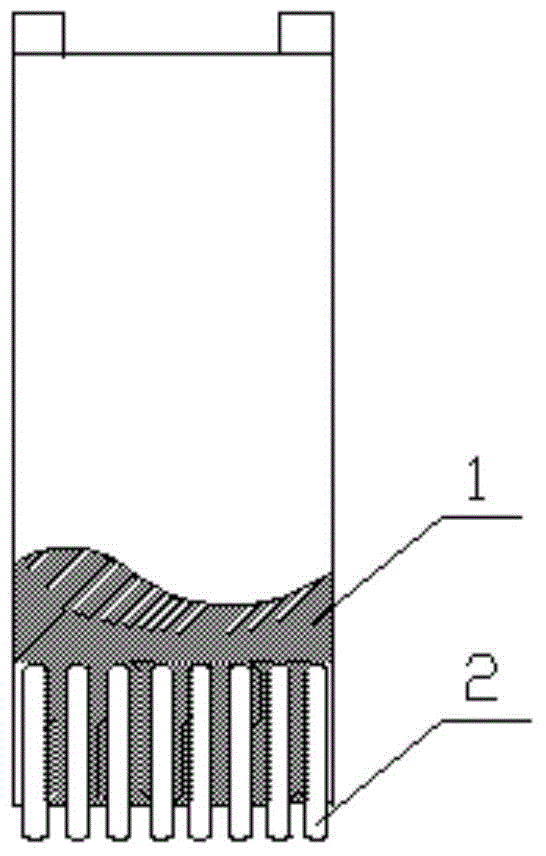

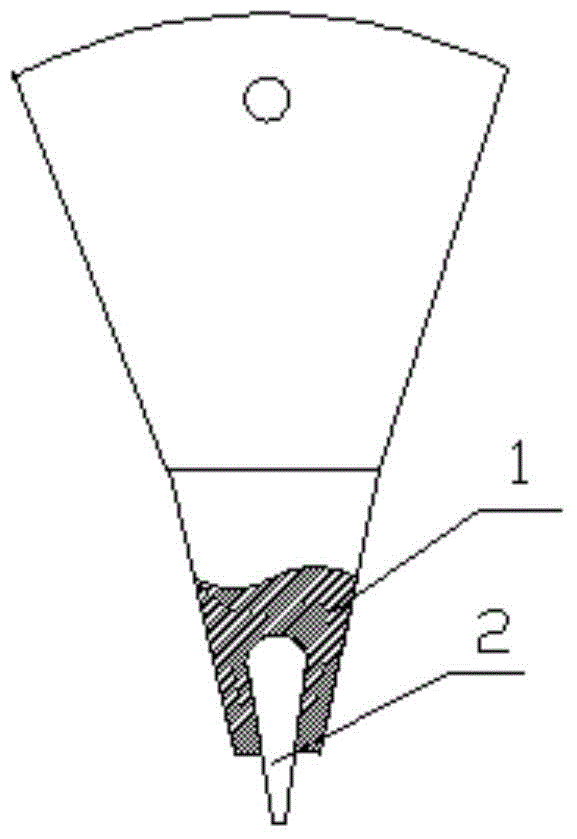

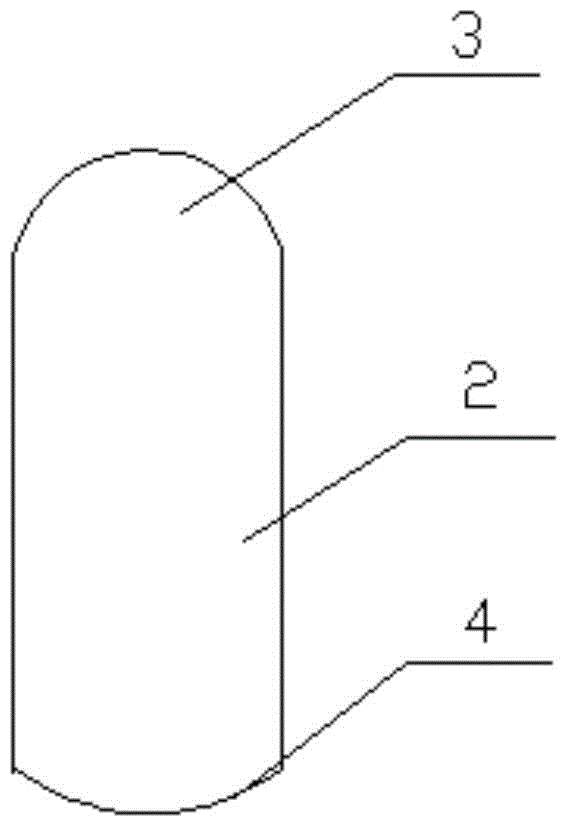

[0026] A bucket tooth of an excavator, which consists of two parts, the tooth base 1 and the tooth tip 2, which are cast separately. The tooth tips 2 are fixed side by side on the front end of the tooth base 1. There is a gap between the tooth tips 2. The part 4 is arc-shaped, the thickness of the tooth tip gradually decreases from the root 3 to the head 4, the tip of the tooth tip 2 remains sharp, the overall length of the tooth tip 2 is 11cm, and the front end of the tooth seat 1 is exposed by 3cm, and the gap between the tooth tips 2 is 0.8cm, and the thickness of the arc-shaped part is 0.9cm.

[0027] The mass percentages of the components of the tooth tips of the bucket teeth described in this embodiment are: carbon: 0.5%, silicon: 1.9%, manganese: 1.3%, molybdenum: 0.18%, chromium: 0.5%, boron: 0.006%, rhenium: 0.49%, aluminum: 0.03%, sulfur: 0.015%, phosphorus: 0.022%, and the rest is iron; the mass percentage of each component of the tooth seat part is: carbon: 3.38%, ...

Embodiment 2

[0039] A bucket tooth of an excavator, which consists of two parts, the tooth base 1 and the tooth tip 2, which are cast separately. The tooth tips 2 are fixed side by side on the front end of the tooth base 1. There is a gap between the tooth tips 2. The part 4 is arc-shaped, and the thickness of the tip 2 gradually decreases from the root 3 to the head 4 .

[0040]Preferably, the overall length of the tooth tip 2 is 10 cm, 3 cm is exposed from the front end of the tooth holder 1, the gap between the tooth tips 2 is 0.5 cm, and the thickness of the arc-shaped part is 0.5 cm.

[0041] The mass percentages of the components of the tooth tips of the bucket teeth described in this embodiment are: carbon: 0.4%, silicon: 1.8%, manganese: 1.1%, molybdenum: 0.15%, chromium: 0.4%, boron: 0.004%, rhenium: 0.45%, Aluminum: 0.015%, Sulfur: 0.01%, Phosphorus: 0.01%, and the rest is iron; the mass percentage of each component of the tooth seat part is: Carbon: 3.25%, Silicon: 2.1%, Mangane...

Embodiment 3

[0053] A bucket tooth of an excavator, which consists of two parts, the tooth base 1 and the tooth tip 2, which are cast separately. The tooth tips 2 are fixed side by side on the front end of the tooth base 1. There is a gap between the tooth tips 2. The part 4 is arc-shaped, and the thickness of the tip 2 gradually decreases from the root 3 to the head 4. The overall length of the tip 2 is 12 cm, exposing the front end of the tooth seat 1 by 4 cm, and the gap between the tip 2 is 2 cm. The thickness of the arc-shaped part It is 1cm.

[0054] The mass percentages of the components of the tooth tips of the bucket teeth described in this embodiment are: carbon: 0.6%, silicon: 2.0%, manganese: 1.4%, molybdenum: 0.2%, chromium: 0.6%, boron: 0.008%, rhenium: 0.54%, Aluminum: 0.035%, Sulfur: 0.02%, Phosphorus: 0.03%, and the rest is iron; the mass percentage of each component in the tooth seat part is: Carbon: 3.55%, Silicon: 2.3%, Manganese: 0.4%, Chromium: 0.45 %, magnesium: 0.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com