High magnetic permeability soft magnetic alloy powder, inductance part and preparation method thereof

A soft magnetic alloy, high permeability technology, used in transformer/inductor parts, electrical components, circuits, etc., can solve the problem that the magnetic permeability cannot reach a higher level, the hysteresis loss and eddy current loss are high, and problems such as large pressing pressure, to achieve the effect of fast diffusion, low power loss, and improved magnetic permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

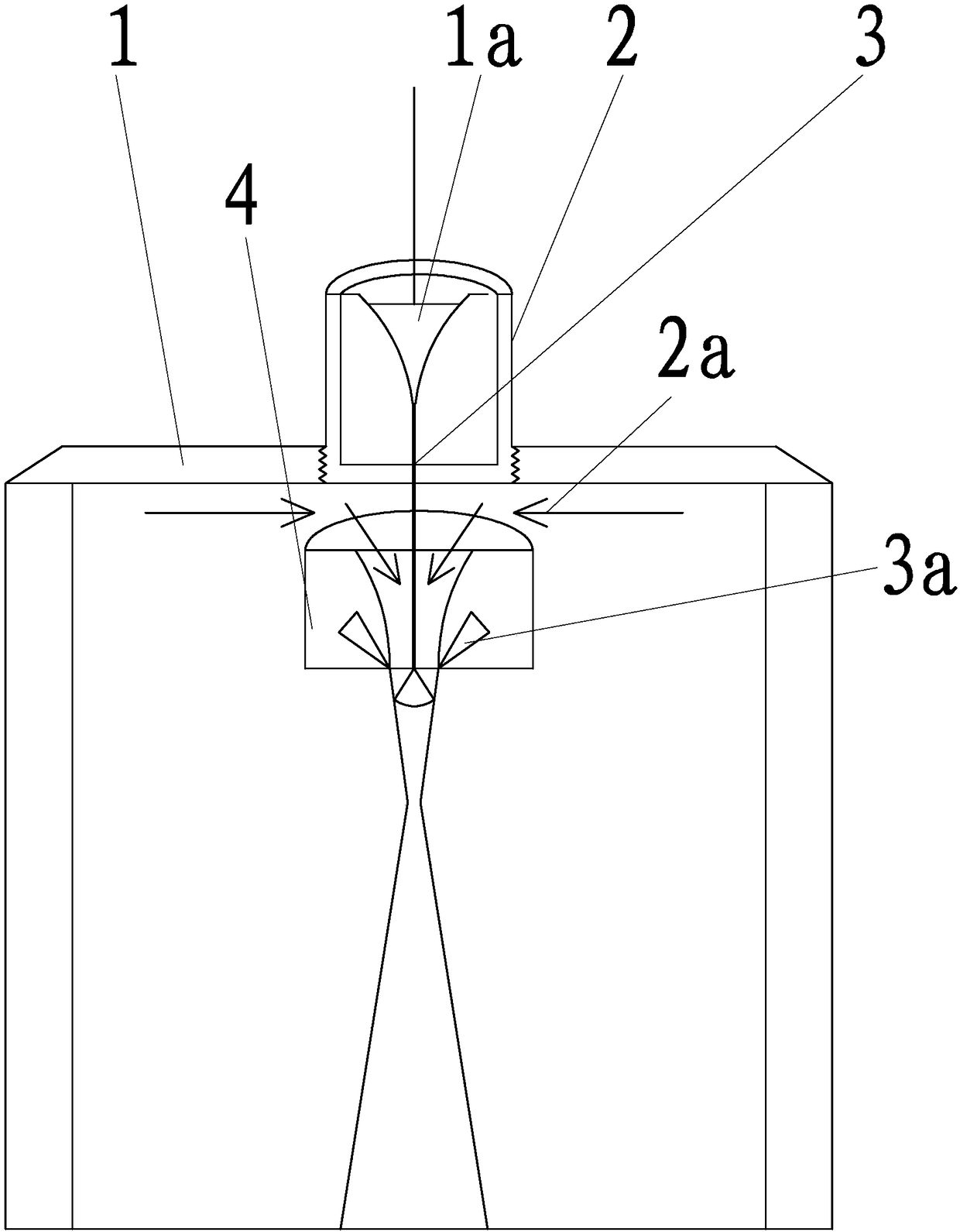

Image

Examples

Embodiment 1

[0038] (1) Add the high-purity materials of iron, nickel, silicon, phosphorus and boron into the intermediate frequency furnace and the intermediate frequency induction furnace, and carry out atmospheric smelting; in the present embodiment, the composition ratio of the soft magnetic alloy is: Fe=35-65 mass parts, Si=3.0-6.5 parts by mass, Ni=20-35 parts by mass, P=1.0-1.5 parts by mass, B=1.0-1.5 parts by mass.

[0039] (2) During the smelting process, control the smelting power to 300-350KW; the time and order of adding alloy elements, first add pure iron and pure nickel, and then add pure silicon during the melting process of raw materials. Add low-carbon iron phosphorus and low-carbon iron boron in turn.

[0040] (3) The molten metal is cooled and solidified into alloy powder after passing through the ultra-high pressure water-gas combined atomization process. A surfactant solution is added to the atomized water, and the surfactant is referred to as activity. Surfactant A...

Embodiment 2

[0048] The difference between this implementation and Example 1 is: the addition amount of surfactant A is different in the process of preparing Fe-Si-Ni-P-B soft magnetic alloy powder in the present embodiment, and the addition amount of this surfactant A in the present embodiment is 2wt‰ of the total amount of atomized water, that is, 2 per thousand.

[0049] After testing, the bulk density of the FeSiCr soft magnetic alloy powder is 2.95g / cm 3 , the tap density is 4.4g / cm 3 , the oxygen content is lower than 1500ppm. Under the pressing pressure of 600MPa, the green body density of the ring inductor is 6.33g / cm 3 , the magnetic permeability is 61, and the loss Ps is 108kW / m 3 , or even lower, reaching 100kW / m 3 Below, 100kW / m 3 Around, 105kW / m 3 about.

Embodiment 3

[0051] In this embodiment, the preparation method of sintered inductance and inductance is according to the conventional method, and the above-mentioned high magnetic permeability soft magnetic alloy powder is used as raw material to make integrally formed wire wound inductors, patch laminated inductors, magnetic core inductors, and filter inductors. , High-frequency transformers for LED circuits. The above-mentioned high magnetic permeability soft magnetic alloy powder may also be referred to as soft magnetic alloy powder.

[0052] In addition, microelectronic products, miniature inductors, etc. can also use the above-mentioned high magnetic permeability soft magnetic alloy powder as a raw material and prepare them according to conventional processes.

[0053] The applications in this embodiment can all meet the indicators in the above embodiments.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bulk density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com