Flame-retardant anti-dripping high-moisture-permeability artificial leather and preparation method thereof

An artificial leather and anti-droplet technology, applied in the field of artificial leather, can solve the problems of poor flame retardant effect, uncomfortable wearing, easy to produce molten droplets, etc., achieve good flame retardant effect, improve moisture permeability and wearing comfort, and reduce smoke Small amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

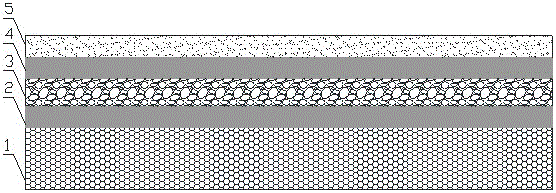

[0027] The artificial leather is compounded by a film surface layer 1, an adhesive layer I2, a foam layer 3, an adhesive layer II4 and a base cloth layer 5.

[0028] The manufacture method of the artificial leather of the present embodiment, concrete steps are as follows:

[0029] (1) Preparation of film surface layer 1:

[0030] Put 100 parts of TPU resin, 1 part of porogen, 1 part of "nitrogen-phosphorus" halogen-free intumescent flame retardant, 1 part of PTFE powder, 1 part of colorant, and 1 part of anti-aging agent into a high-speed mixer for mixing Evenly, the stirring temperature is 100°C; put the stirred material into the casting machine and cast it into a film to form the film surface layer 1, and the temperature of the casting machine does not exceed 230°C;

[0031] (2) Preparation of adhesive layer I2 and adhesive layer II4:

[0032] Put 100 parts of TPU hot-melt adhesive resin with a softening point of 105°C, 1 part of superfine protein powder, 1 part of "nitrog...

Embodiment 2

[0046]The artificial leather is compounded by a film surface layer 1, an adhesive layer I2, a foam layer 3, an adhesive layer II4 and a base cloth layer 5.

[0047] The manufacture method of the artificial leather of the present embodiment, concrete steps are as follows:

[0048] (1) Preparation of film surface layer 1:

[0049] In parts by weight, put 100 parts of TPU resin, 10 parts of porogen, 10 parts of "nitrogen-phosphorus" halogen-free intumescent flame retardant, 3 parts of PTFE powder, 3 parts of colorant, and 1 part of anti-aging agent into a high-speed mixer for mixing Evenly, the stirring temperature is 110°C; the stirred material is added to the casting machine and cast to form a film to form the film surface layer 1, and the temperature of the casting machine does not exceed 230°C;

[0050] (2) Preparation of adhesive layer I2 and adhesive layer II4:

[0051] Put 100 parts of TPU hot-melt adhesive resin with a softening point of 105°C, 10 parts of ultrafine pro...

Embodiment 3

[0060] The artificial leather is compounded by a film surface layer 1, an adhesive layer I2, a foam layer 3, an adhesive layer II4 and a base cloth layer 5.

[0061] The manufacture method of the artificial leather of the present embodiment, concrete steps are as follows:

[0062] (1) Preparation of film surface layer 1:

[0063] In parts by weight, put 100 parts of TPU resin, 20 parts of porogen, 10 parts of "nitrogen-phosphorus" halogen-free intumescent flame retardant, 5 parts of PTFE powder, 5 parts of colorant, and 2 parts of anti-aging agent into a high-speed mixer for mixing Evenly, the stirring temperature is 120°C; put the stirred material into the casting machine and cast it into a film to form the film surface layer 1, and the temperature of the casting machine does not exceed 230°C;

[0064] (2) Preparation of adhesive layer I2 and adhesive layer II4:

[0065] Put 100 parts of TPU hot-melt adhesive resin with a softening point of 105°C, 20 parts of ultrafine prot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com