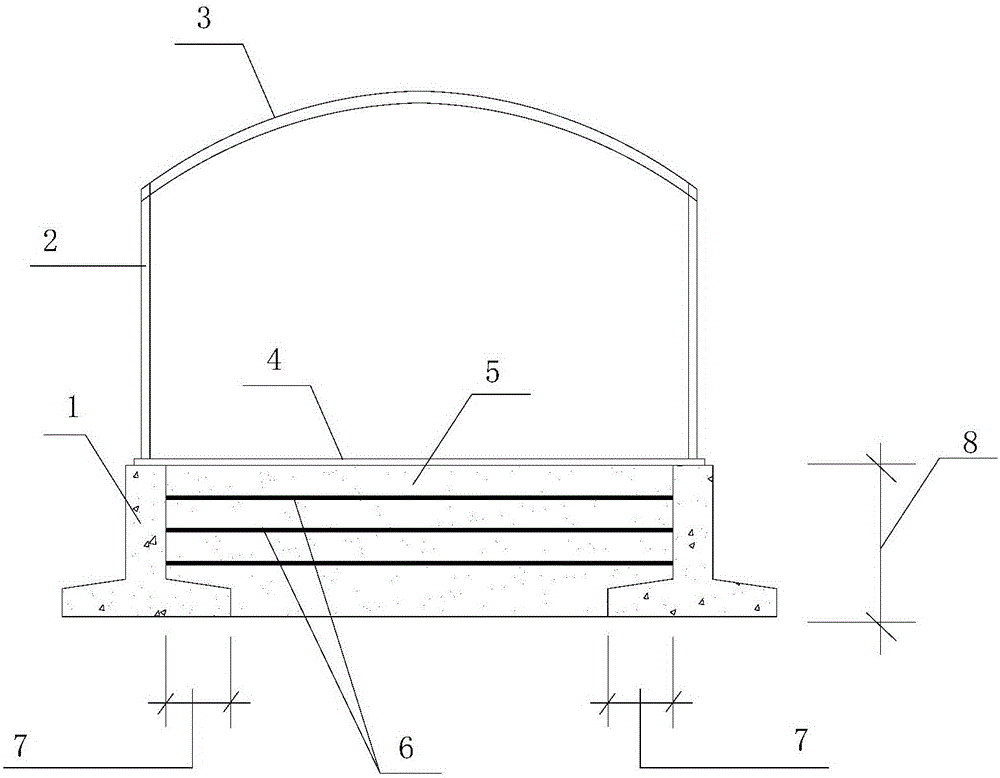

Low Pressure Vaulted Steel Storage Tank Foundation

A technology for steel storage tanks and vaults, applied in infrastructure engineering, construction, etc., can solve the problems of troublesome construction, poor economy, and high construction costs, and achieve the effects of simple construction, reduced construction costs, and improved shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The foundation of a low-pressure vaulted steel storage tank adopts a ring-wall-type extension foundation, which is a reinforced concrete structure. Three-layer reinforced body, the filler layer is coarse sand, the inner expansion width of the ring wall type extended foundation is 0.8 meters, the lap length of the reinforced body is 0.8 m, and the height of the ring wall type extended foundation is 1.0 m. The material of the reinforced body is conventional geotextile, and each layer of reinforced body needs to be overlapped with each other to form a continuous and complete layer of reinforced body, but there is no overall reinforced concrete raft at the bottom.

[0019] The storage tank foundation can achieve the technical and economic rationality of the low-pressure storage tank foundation design scheme.

Embodiment 2

[0021] The foundation of a low-pressure vaulted steel storage tank adopts a ring-wall-type extension foundation, which is a reinforced concrete structure. One layer of reinforced body, the filling layer is stone chips, the inner expansion width of the ring wall type expansion foundation is 1.2 meters, the lap length of the reinforcement body is 1.2 meters, and the height of the ring wall type expansion foundation is 1.4 meters. The material of the reinforced body is conventional geogrid, and each layer of reinforced body needs to be overlapped with each other to form a continuous and complete layer of reinforced body, but there is no overall reinforced concrete raft at the bottom.

[0022] The storage tank foundation can achieve the technical and economic rationality of the low-pressure storage tank foundation design scheme.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com