A method and device for increasing the pull-out force of a bolt

A pull-out force and bolt technology, which is applied in construction, infrastructure engineering, sheet pile walls, etc., can solve the problems of inability to resist the extrusion of retaining walls, insufficient shear strength of silt, and excessive deformation. Achieve the effect of increasing self-supporting stability, increasing height and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0028] (1) Prepare the geogrid, cut it to the length of the anchor body, and the width to the sum of the width of the upper surface of the anchor body and the width of both sides, and prepare some crushed stones with a particle size of 3 to 5 cm.

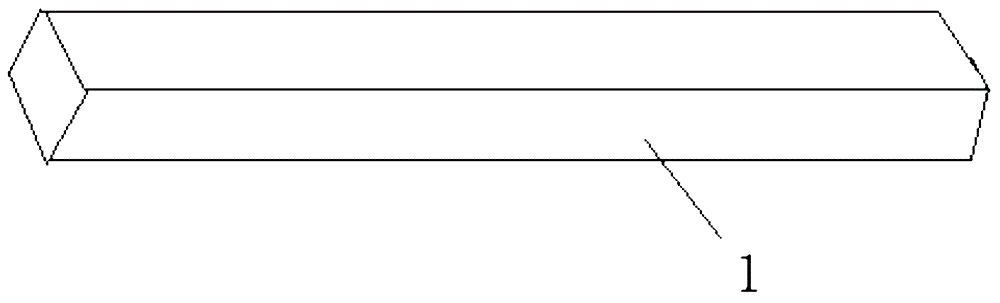

[0029] (2) After the installation of the anchor rods is completed, the support formwork shall be poured into the anchor body to ensure that the width and height of the anchor body are not less than 40cm. figure 1 shown.

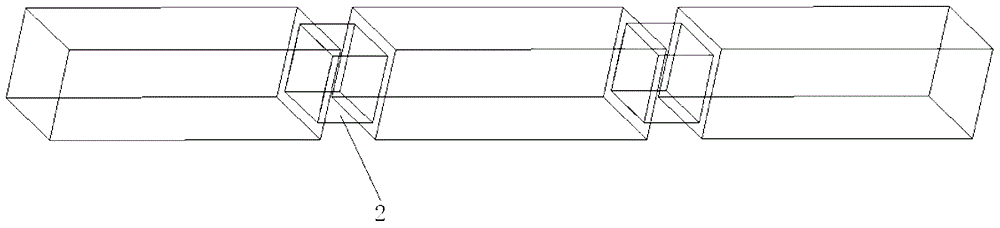

[0030] (3) The formwork shall be removed after 7 days of pouring of the anchor body, and the top and both sides of the anchor body shall be chiseled down by 3 cm. figure 2 shown.

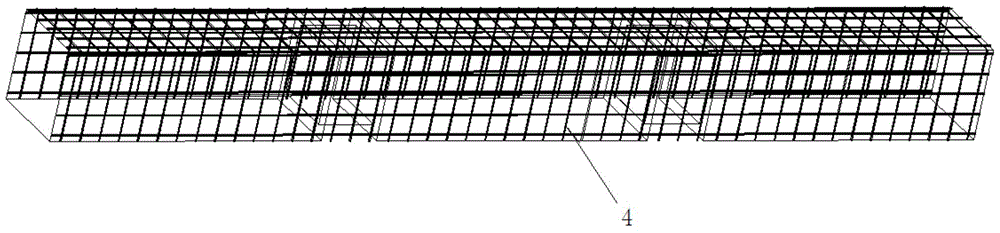

[0031] (4) Arrange the prepared geogrid on the top and both sides of the anchor along the length direction of the anchor, as attached image 3 As shown, the main stress direction of the laid geogrid is preferably full-length without joints, and the connection between the webs can be manually tied and lapped, and the lap width is not l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com