Undermining method for three-dimensional pipe-roof

A three-dimensional pipe curtain and underground excavation technology, which is applied in wellbore lining, tunnel lining, underground chamber, etc., can solve problems such as high safety risks, achieve broad market promotion value, avoid excavation, and reduce life interference.

Active Publication Date: 2008-10-15

WUHAN ZHONGJIAO TRAFFIC ENG CO LTD

View PDF0 Cites 35 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

When the geological conditions are poor and the burial depth is deep, if the underground excavation method is used for construction, the safety risk will be greater. Once a construction accident occurs, the social impact will be significant.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

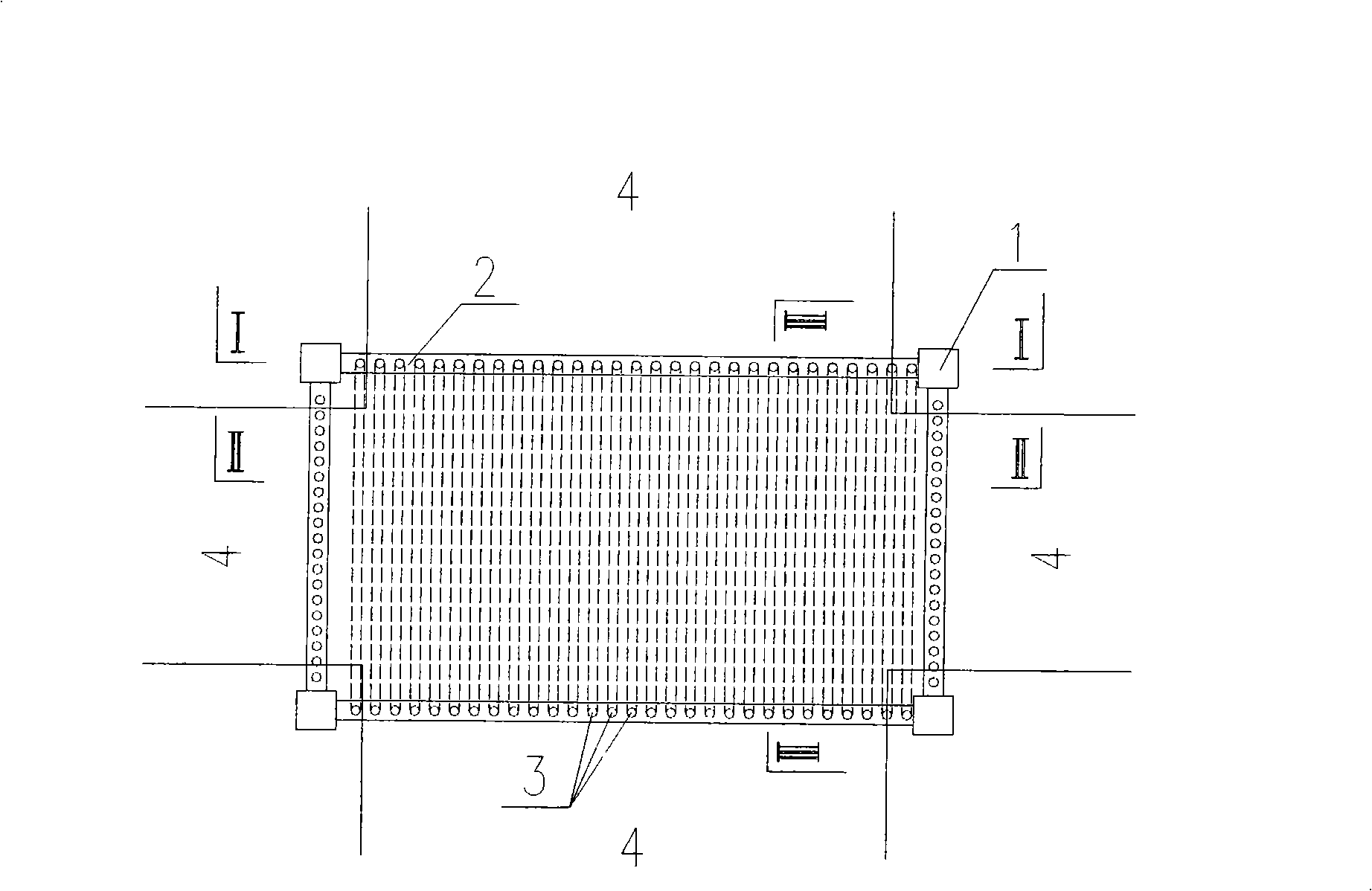

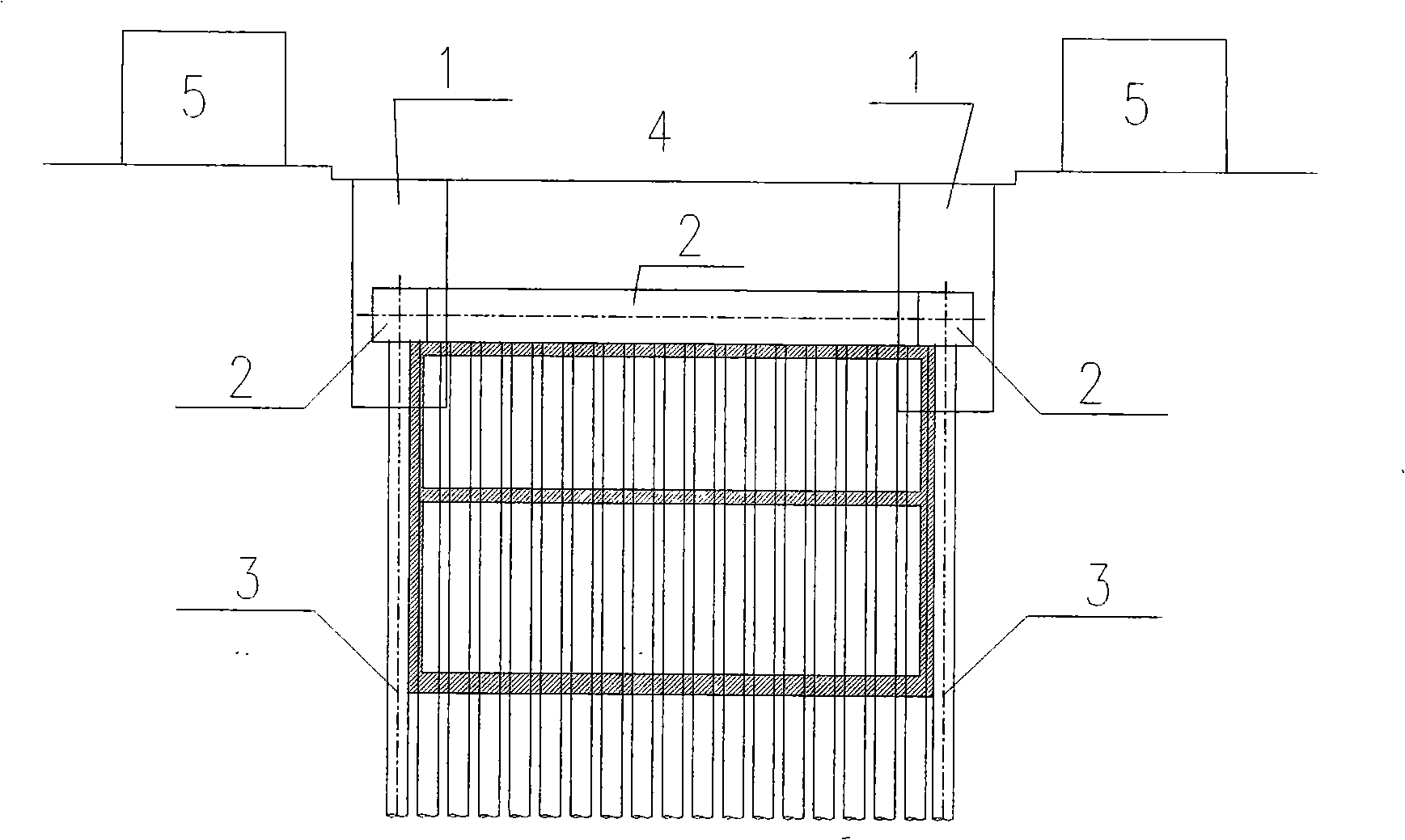

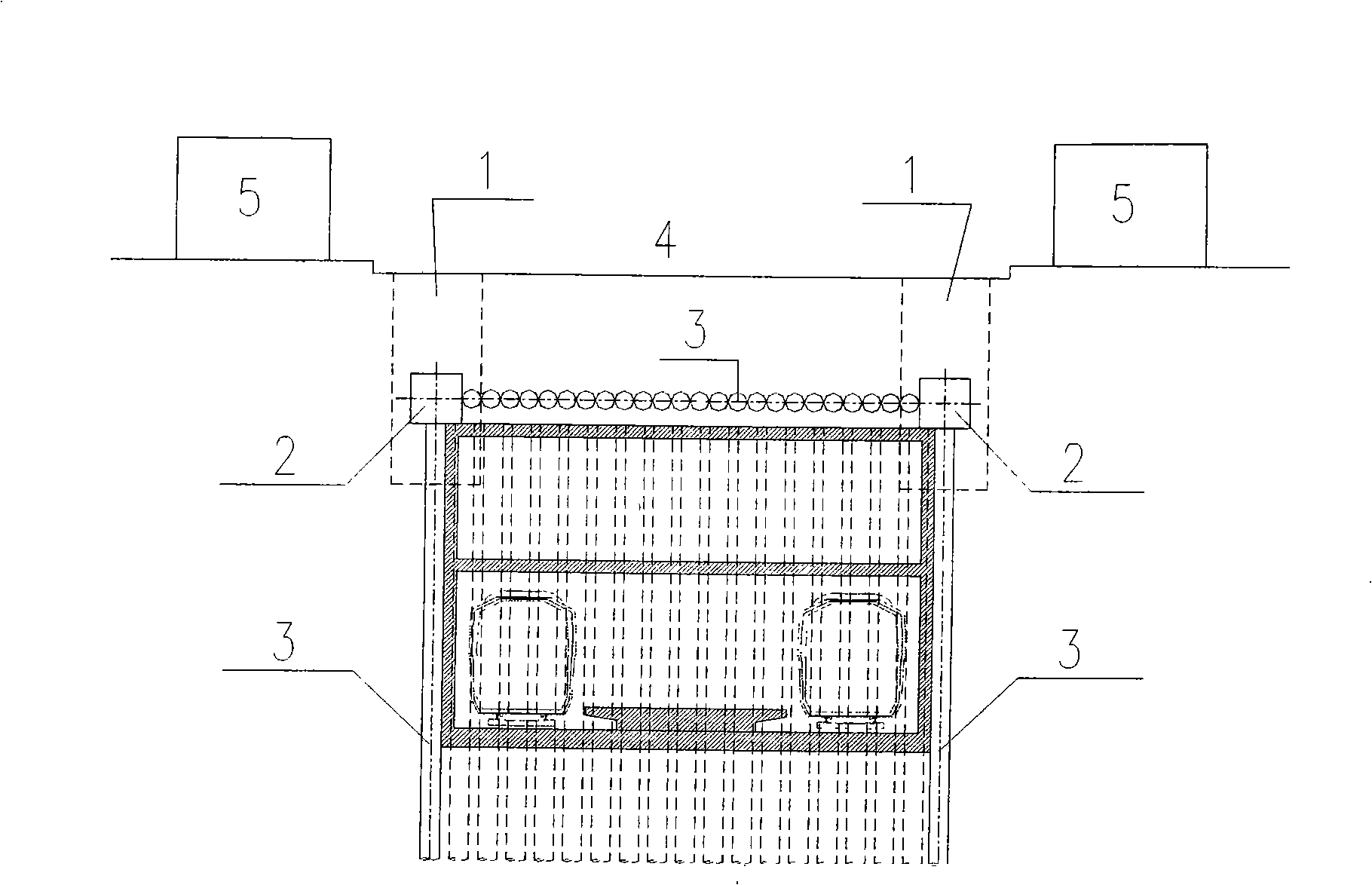

The invention discloses a three-dimensional pipe-curtain subsurface excavation method. The steps of the method are as follows: A. a vertical working well is formed at the circumference of an underground structure; B. a horizontal working channel is formed on the outer surface of the underground structure; C. a pipe roofing support is formed at the outer surface and a pipe roofing curtain is constructed inside the horizontal working channel; D. grouting and reinforcement are carried out by using pipe roofing steel pipes, and the grouting is carried out by pipe roofing to form a curtain after the pipe roofing construction inside the horizontal working channel is finished; E. digging is started; when the pipe roofing grouting curtain reaches the strength, the digging construction of soil mass inside the three-dimensional curtain is carried out; afterwards, the construction of the underground structure is carried out. The method is simple and convenient, and safe and convenient in construction. Particularly, for a large span underground structure under a crossroad, the method only digs half of one side of a certain road, thus the method can ensure that the road is unblocked in the construction process. Accordingly, the method can be widely applied to projects with roads and other buildings, etc., such as subway stations of a city, road tunnels with large span, underground parking areas with large span and down-traversing tunnels under main roads of the city.

Description

Three-dimensional pipe screen underground excavation method technical field The invention relates to a three-dimensional pipe curtain underground excavation method, which is suitable for the construction of shallow-buried large-span underground structures. Background technique With the acceleration of China's urbanization process, more and more large-scale underground structures are built under urban roads, such as subway stations, urban underground roads, underground parking lots and so on. At present, the construction of urban subway stations, urban underground roads, underground parking lots and other projects under existing roads mainly includes open-cut method, under-cut method and trenchless pipe curtain method. The open and cut method not only destroys the environment, but also excavates the original roads, which hinders the smooth flow of traffic and greatly interferes with urban production and life. When the geological conditions are poor and the burial depth is ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E21D9/00E21D11/04E21D21/00

Inventor 郭小红程勇刘继国

Owner WUHAN ZHONGJIAO TRAFFIC ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com