Engineering rock mass mechanical parameter rapid automatic measuring device and application method

A technology of rock mechanics and automatic measurement, applied in the direction of measuring devices, using stable tension/pressure to test material strength, scientific instruments, etc., can solve problems such as unfavorable tunnel surrounding rock mechanics parameters, long construction time, unfavorable TBM construction, etc. , to achieve a wide range of engineering application prospects, high degree of automation, and achieve the effect of unmanned testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

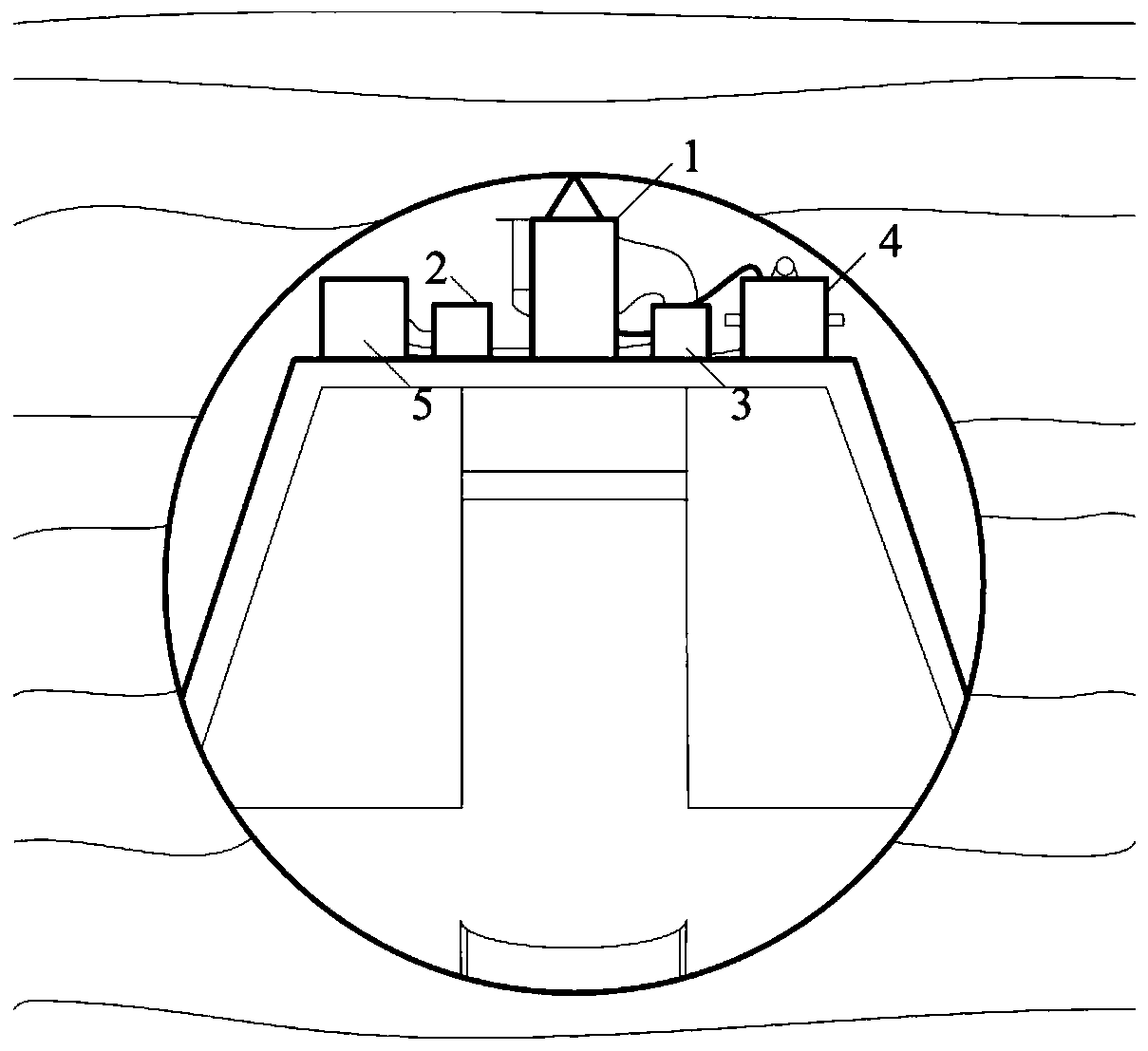

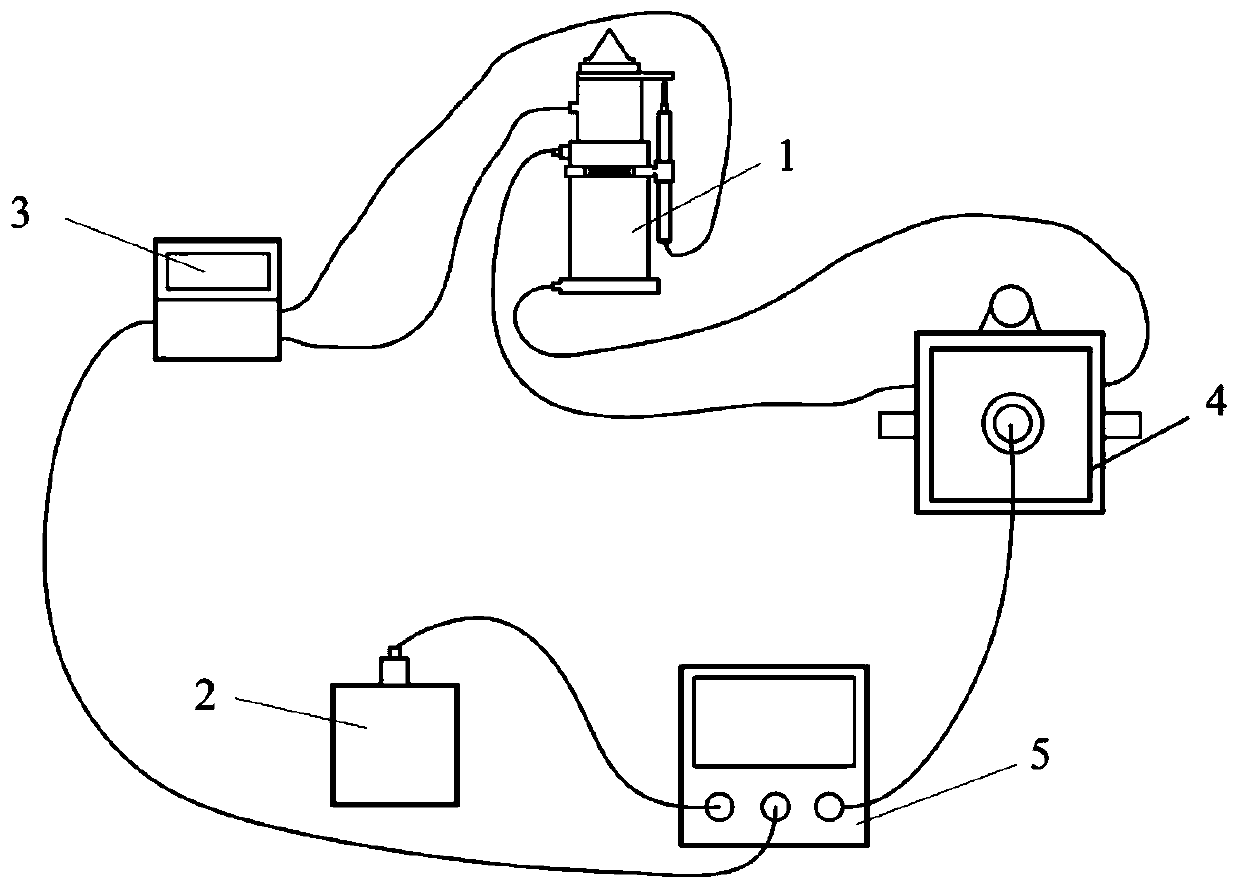

[0069] Such as figure 1 As shown, a rapid automatic measurement device for mechanical parameters of engineering rock mass is mounted on a position where the TBM equipment is relatively rigid and does not affect normal construction (between the rock wall and the outer wall of the TBM), including a penetrometer 1, real-time positioning sensing System 2, display 3, hydraulic loading system 4 and control system 5;

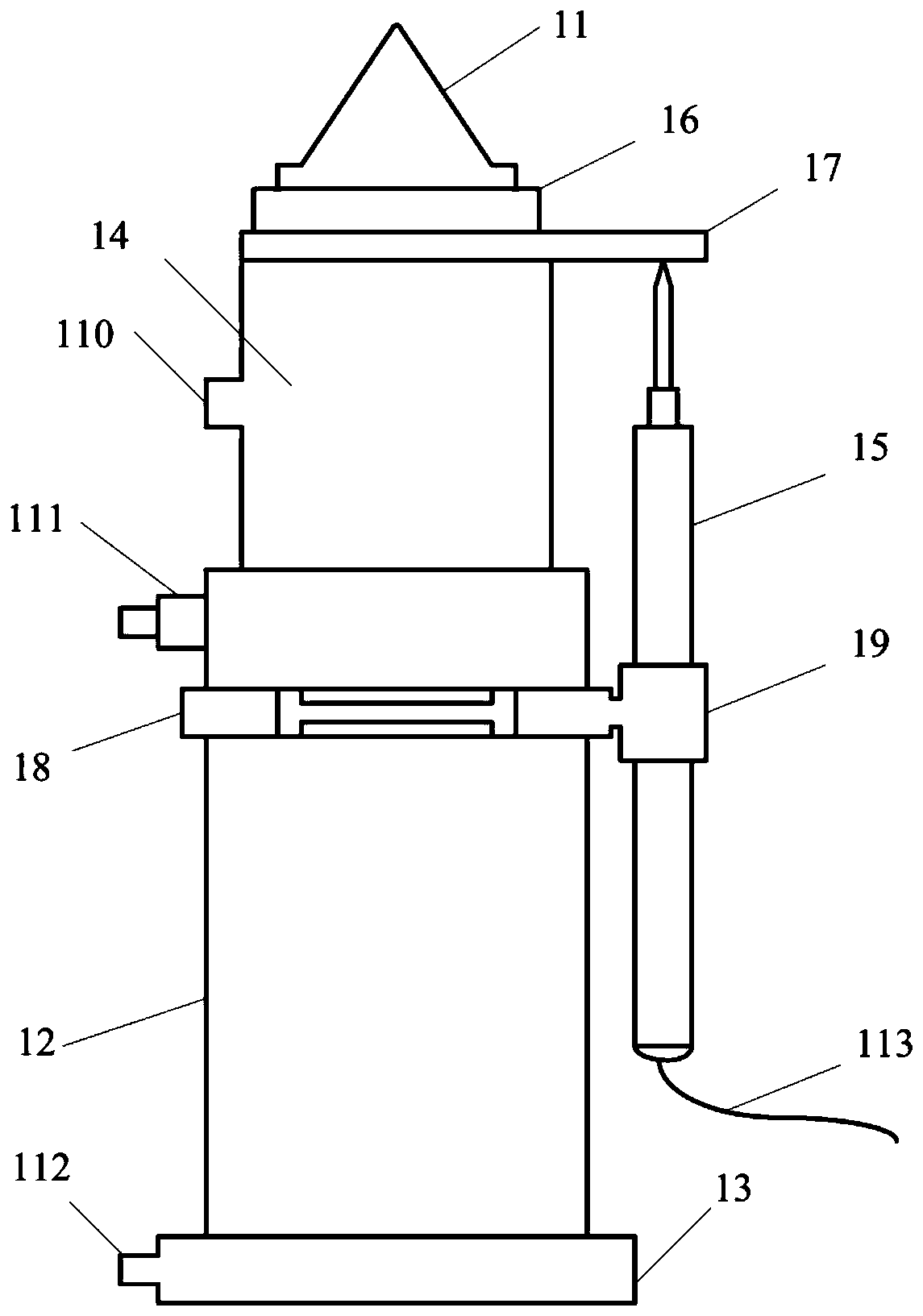

[0070] 1. Penetrometer 1, as shown in Figures 3 and 4

[0071] The penetrometer 1 includes a conical indenter 11, a jack 12, a load-bearing base 13, a pressure sensor 14 and a displacement sensor 15;

[0072] The jack 11 includes an upper and lower frame, which is arranged on a load-bearing base 13 , and the top surface is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com