Grouting technology for controlling water-stop curtain of dolomite vertical shaft of large-thickness water-rich lamp shadow group

A water-stop curtain and grouting technology, which is applied in shaft lining, shaft equipment, mining equipment, etc., can solve the problems of wasting grouting materials, increasing the cost of preventing and controlling water in the shaft, and failing to form an effective grouting curtain, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

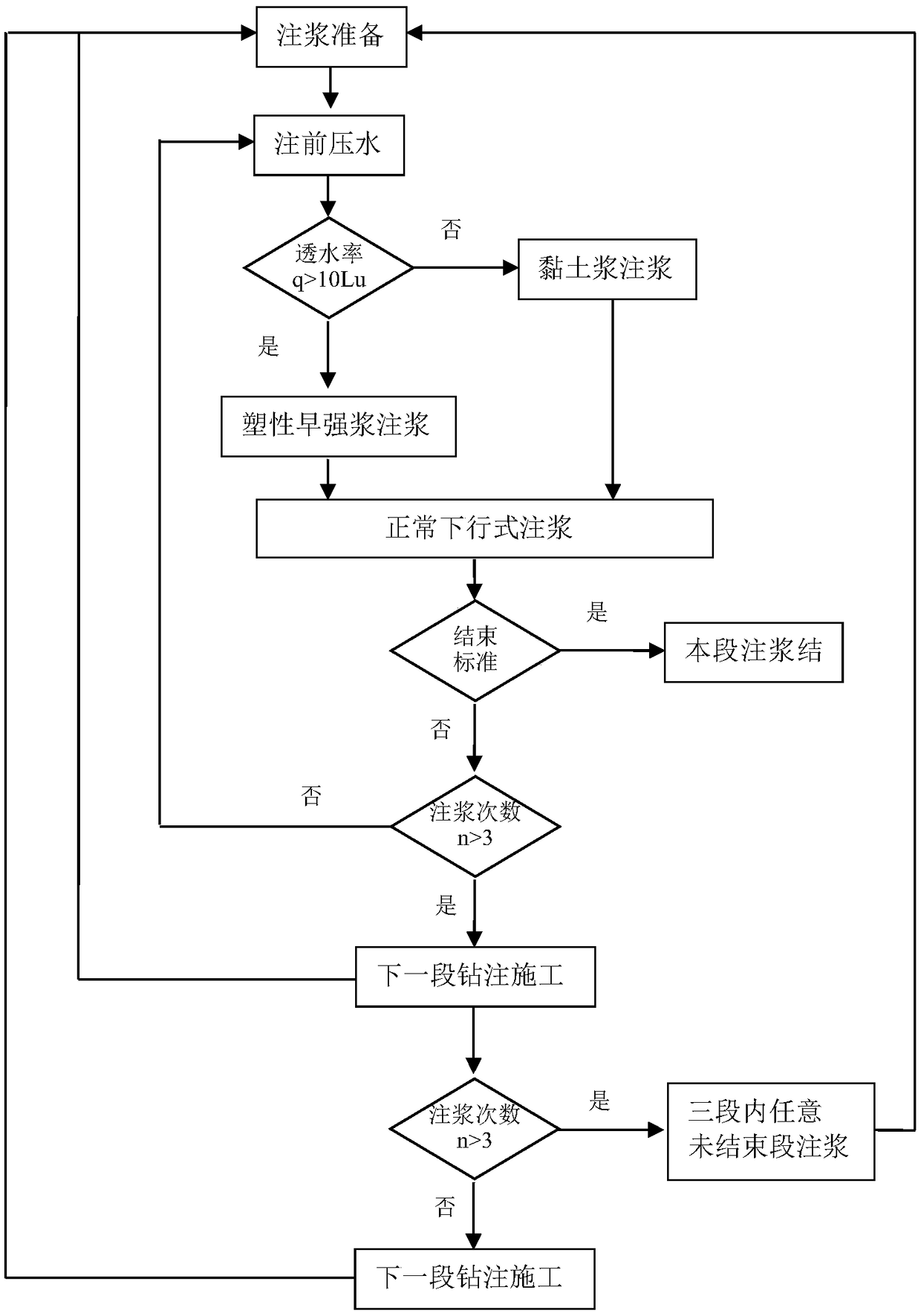

[0034] This embodiment is a test of pre-grouting on the surface of the shaft shaft of the return air shaft of the Laohudong Phosphate Mine in Guizhou Laohudong Phosphate Mine by the water-stop curtain control grouting process of the dolomite vertical shaft shaft of the Juhou Fushui Dengying Formation, including the following steps:

[0035] (1) Use a water source drilling rig to drill holes on the ground and drill grouting holes;

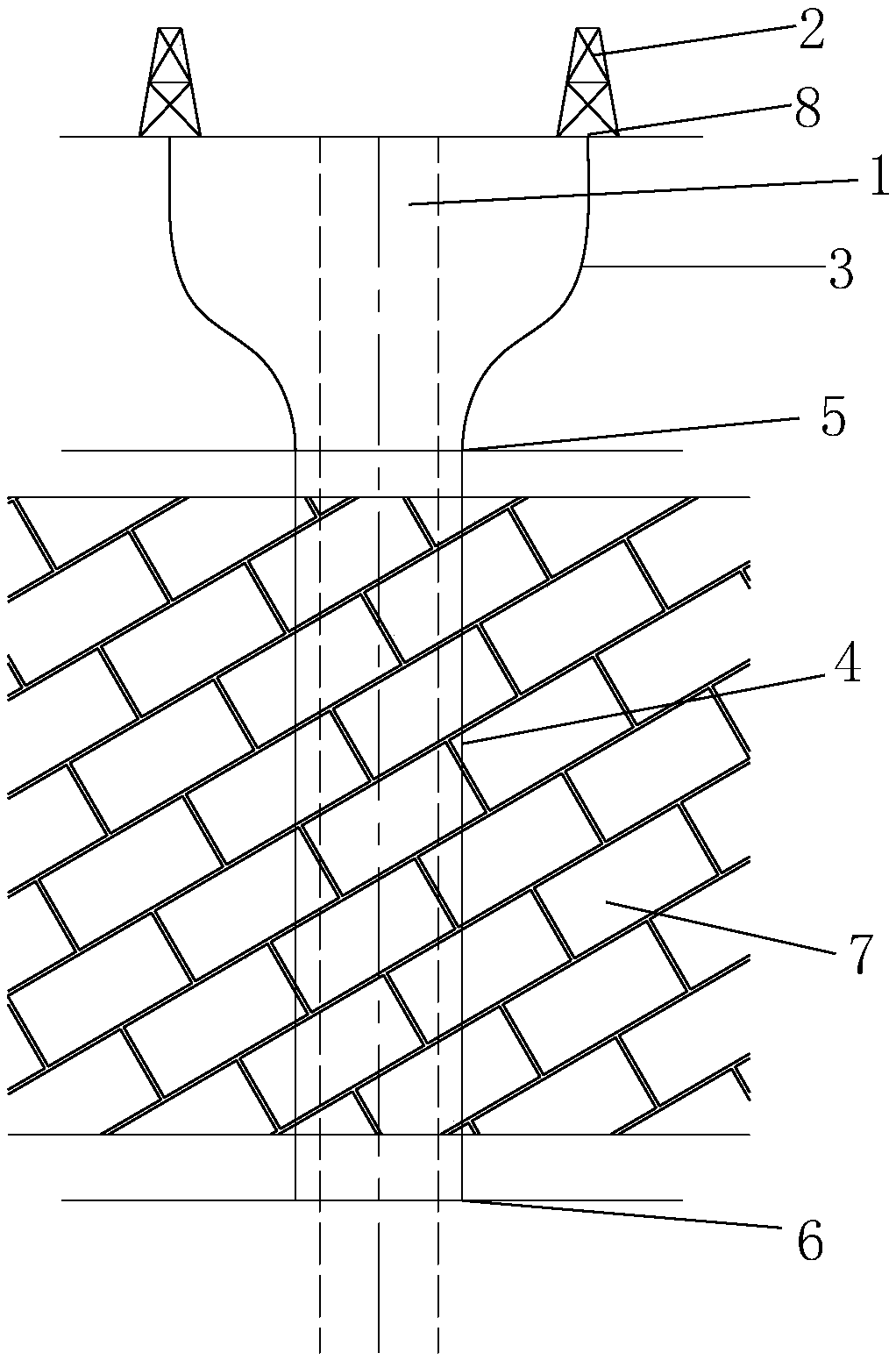

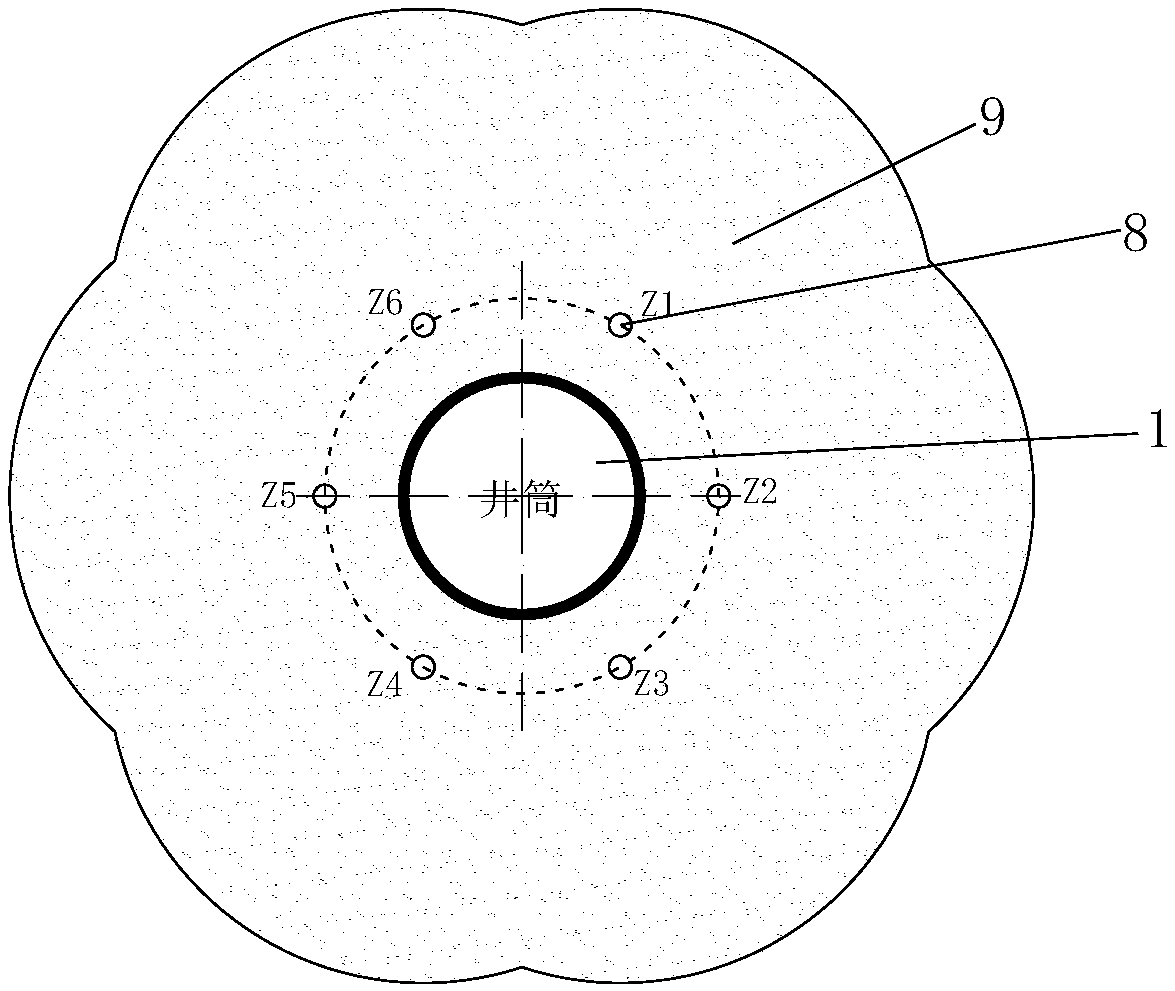

[0036] In step (1), the grouting holes are 6 grouting holes evenly distributed in the shaft shaft, and the center of the grouting holes is 8 meters away from the center of the shaft shaft. like figure 1 and figure 2 shown.

[0037] In step (1), the grouting hole includes a casing section and a grouting section, the grouting section is located in the dolomite layer of the extremely thick water-rich Dengying Formation, and the casing section is from the upper end of the grouting section to the ground; the hole diameter of the casing section is for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com