Reverse construction method of deep foundation pit in upper soft and lower hard water-rich stratum

A technology for water-rich strata and construction method, which is applied in basic structure engineering, excavation, construction, etc., can solve problems such as water seepage and leakage between piles or at the junction of pile bottoms, poor splicing of supporting structures, and large deformation of soft soil foundation pits. To achieve the effect of good foundation pit stability, good anti-seepage and water-stop effect, and good water-stop effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

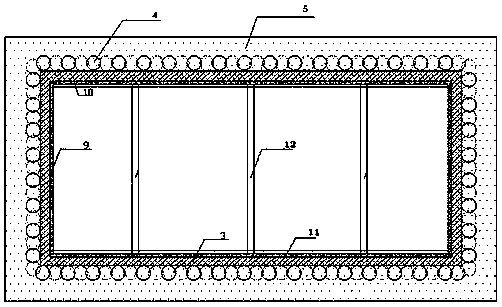

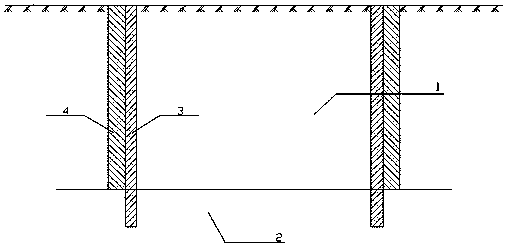

[0036] Such as figure 1 As shown, a deep enclosure structure for upper soft and lower hard water-rich strata, including underground diaphragm wall 3, intersecting bored piles 4, grouting curtain 5 at the interface between soft and hard stratum, waterproof and drainage structure layer 9, initial stage The support 10 and the support system, the support system includes horizontal purlins 11 and steel cross braces 12 .

[0037] The construction method of the above-mentioned upper soft and lower hard water-rich formation deep enclosure structure comprises the following steps:

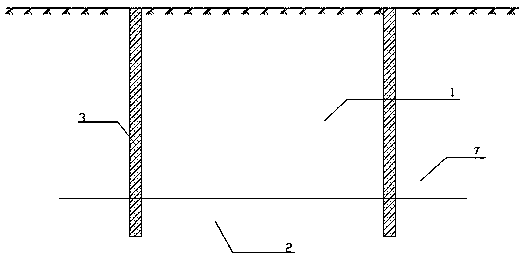

[0038] Such as figure 2 As shown, step 1) construction of the underground diaphragm wall 3, the underground diaphragm wall 3 is constructed outside the excavation line of the foundation pit, and the depth of the underground diaphragm wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com