Block assembling type bottomless single-wall steel bushing box cofferdam and construction method thereof

A steel casing and assembled technology, which is applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve the problems that the overall sinking cannot be realized, and achieve the effect of simple and convenient dismantling operation, cost saving, and simple lifting and sinking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

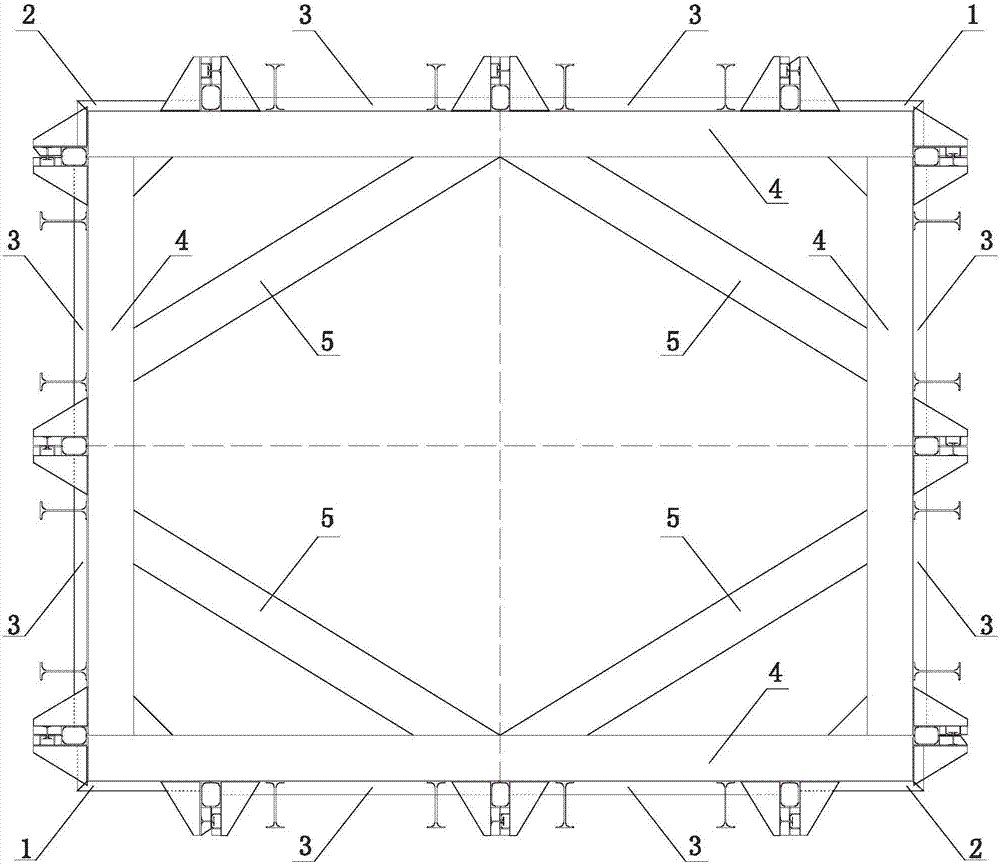

[0037] Such as figure 1 As shown, a block-assembled bottomless single-wall steel casing cofferdam includes A-shaped side panels 1, B-shaped side panels 3, C-shaped side panels 2, inner guide beams 4, and inner supports 5.

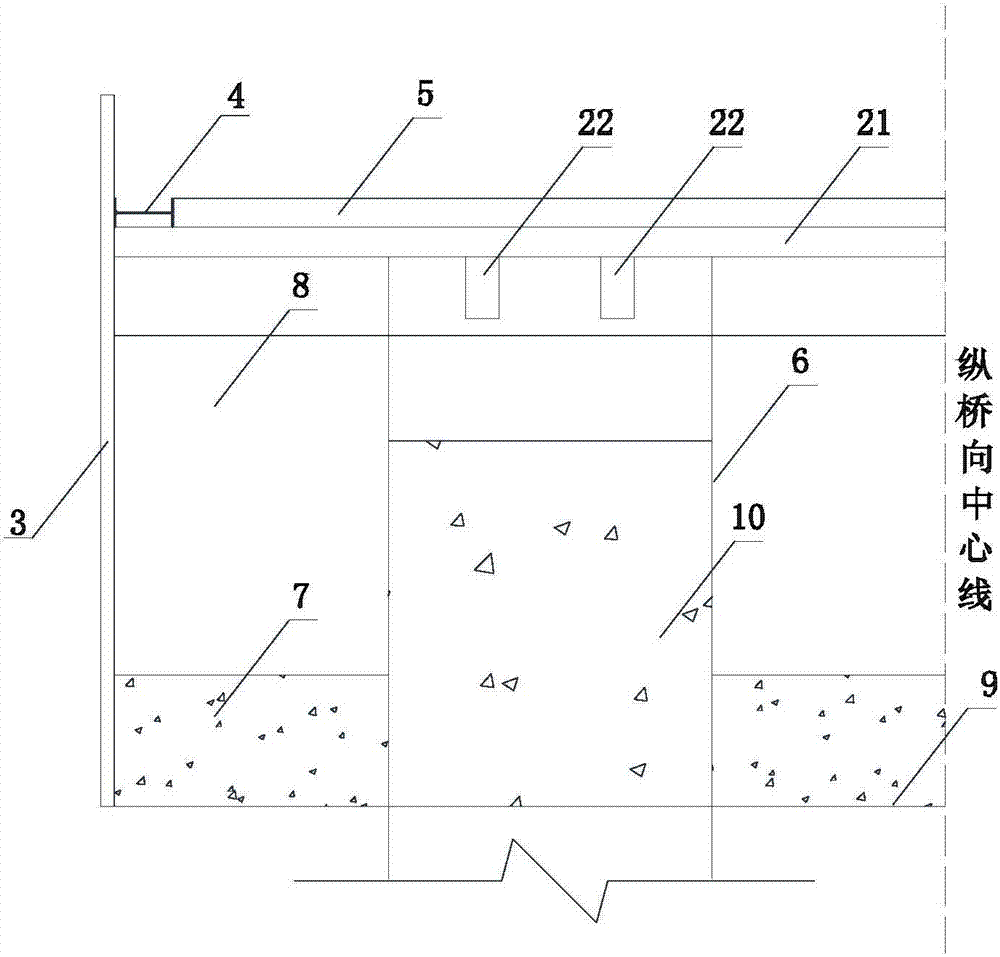

[0038] Such as figure 2 Shown is a schematic diagram of the elevation of the steel casing cofferdam.

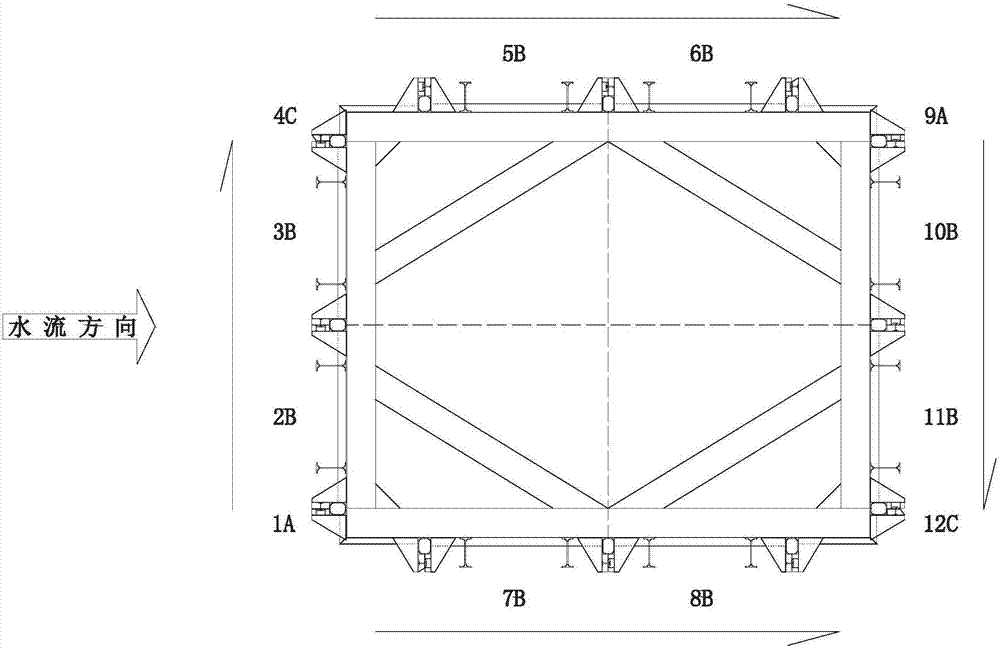

[0039] Such as image 3 As shown, it is the installation sequence of the side panels of the steel box. The installation starts from the upstream side, and the A-type side panel 1 is installed first, and then follows 1A→2B→3B→4C→5B→6B→7B→8B→9A→10B→11B→ In the order of 12C, the installation of the steel box side plates around the platform 8 is completed successively.

[0040] Such as Figure 4~5 The steel box cofferdam shown, the structure of A-type side plate 1 and C-type side plate 2 includes: I10a I-beam 11, L75×50×6 mm angle steel 13, [20a channel steel 12, a-type horizontal stiffening plate 16 , b-type horizontal stiffener 17, c-type horizontal stif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com