Horizontal steel tube occluding water blocking tube curtain and construction method thereof

A technology for water-stop pipes and steel pipes, which is used in infrastructure engineering, construction, etc., can solve the problems of soil that cannot be consolidated, water-stop enclosures, and fully-closed enclosures cannot be formed, and achieves the effect of reducing construction procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

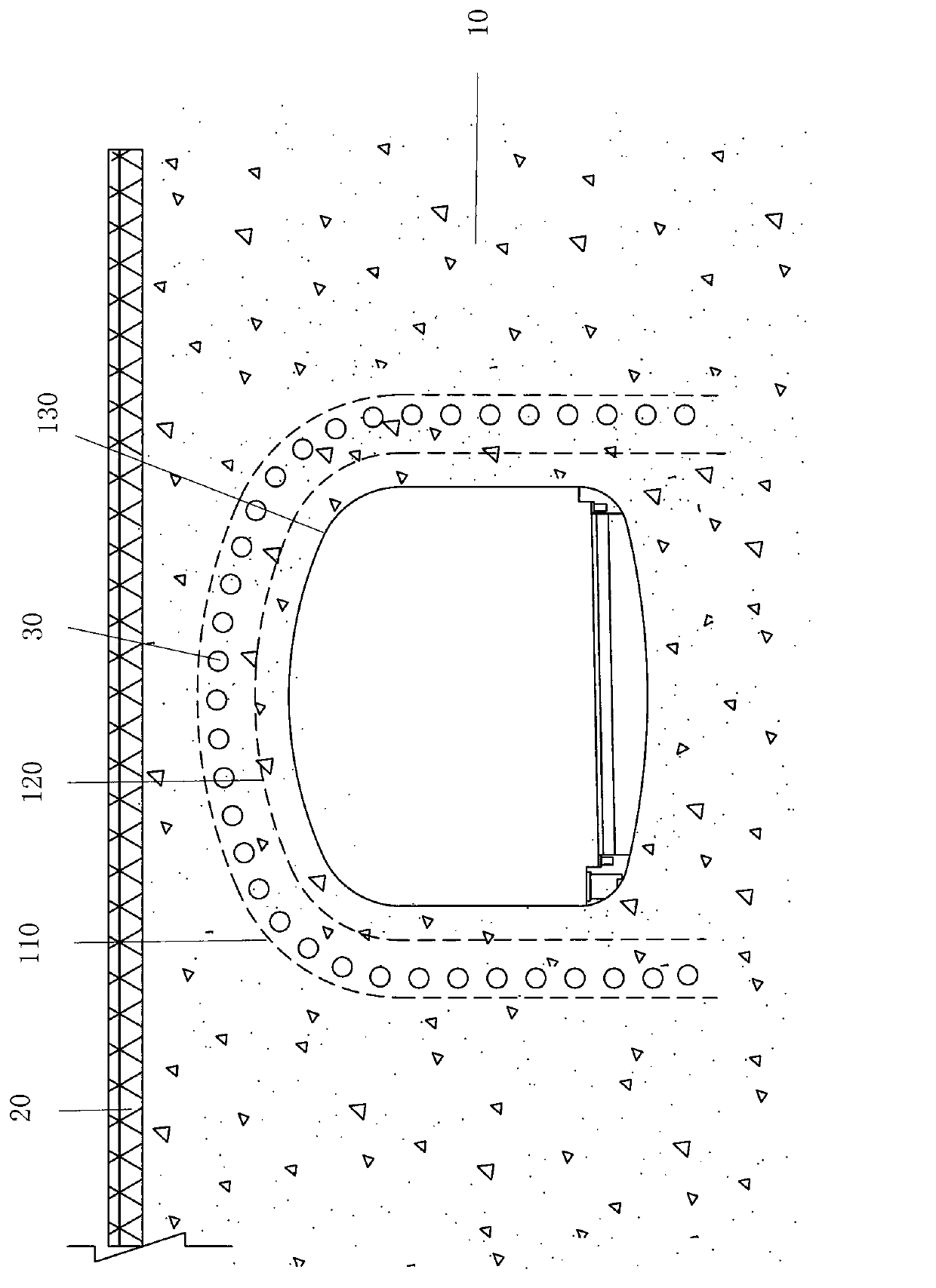

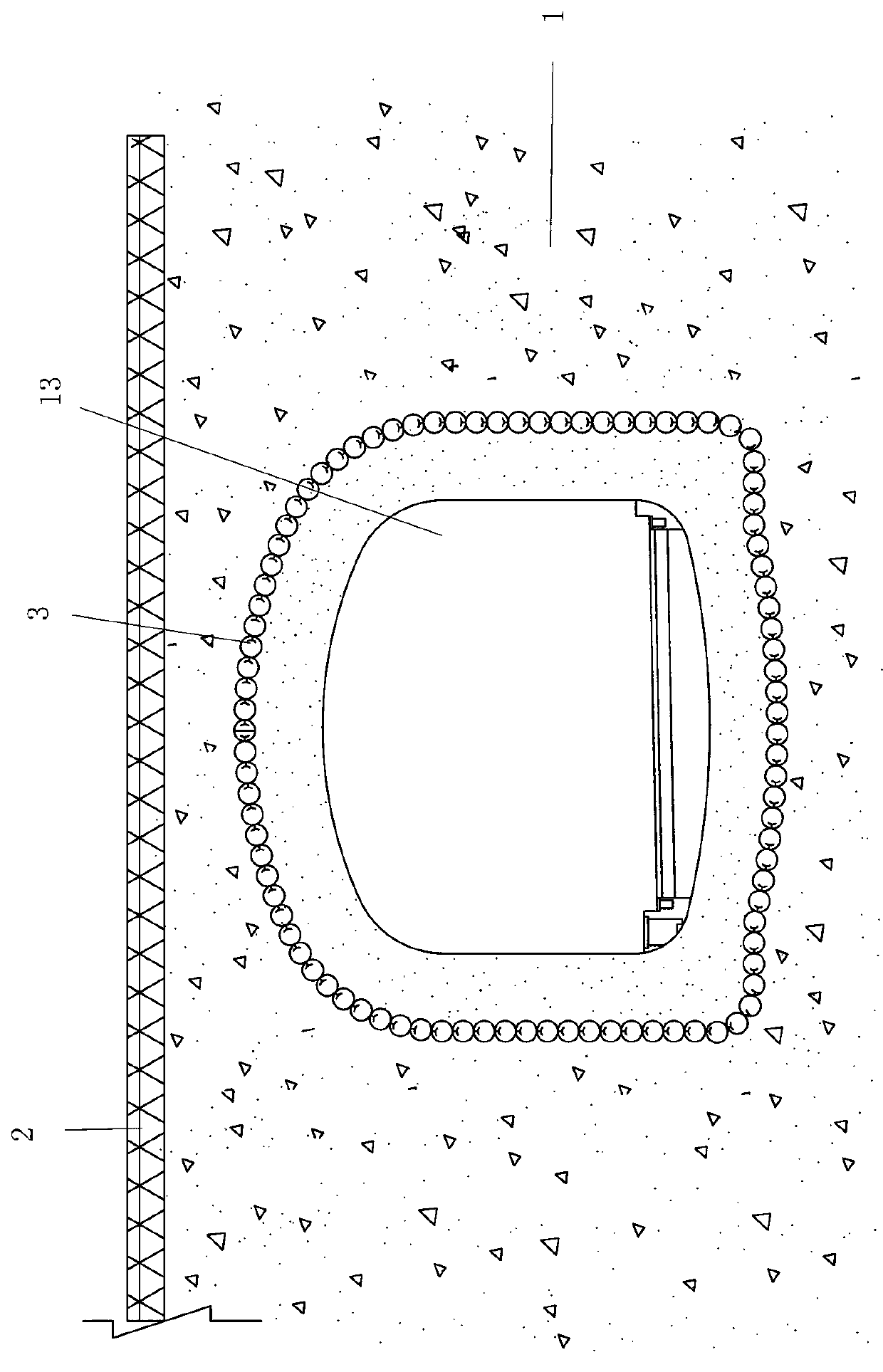

[0042] The cross-sectional structure of an embodiment of the horizontal steel pipe interlocking water-stop pipe curtain of the present invention, as figure 2 Shown: the sand and gravel formation 1 below the municipal road 2 surrounds the channel 13 and builds a horizontal steel pipe interlocking water-stop pipe curtain 3 composed of a plurality of horizontal steel pipes. Among these horizontal steel pipes, there is a reference occlusal steel pipe 31, a plurality of unidirectional occlusal steel pipes 32 and a two-way occlusal steel pipe 33, which are connected in turn to form an annular enclosure that can surround the underpass 13 of the road; The spaces on the left and right sides and the inner holes of all the one-way occlusal steel pipes 32 are filled with cement mortar.

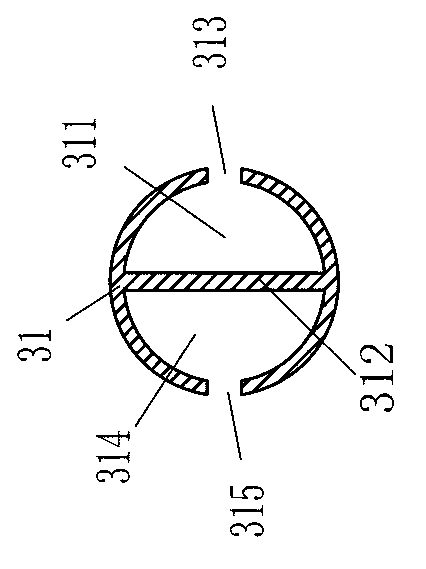

[0043] Please see image 3 , the inner hole of the standard interlocking steel pipe 31 is provided with a vertical plate 312 connecting the upper and lower surfaces of the inner wall, and the vertical p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com