Semi-inverse construction method of super large diameter, ultra-burial depth storage pond

A technology with super large diameter and construction method, applied in excavation, artificial islands, water conservancy projects, etc., can solve the problems of waste of horizontal support of steel structure, large influence of building foundation, and high risk of water seepage, so as to save the cost of construction and demolition, Ensure safe excavation and good water stop effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] 1. General idea:

[0019] The enclosure structure adopts SMW construction method piles, and the manufacturing sequence is: pool roof, upper pool wall, pool floor, and lower pool wall.

[0020] During the construction of the upper section of the pool wall, the ring beam structure of the pool roof, cast-in-situ piles and steel lattice columns are used as the foundation pit support system.

[0021] After the construction of the upper pool wall is completed and before the construction of the pool floor, the middle support of the steel structure and the bottom ring beam support are fabricated in sequence.

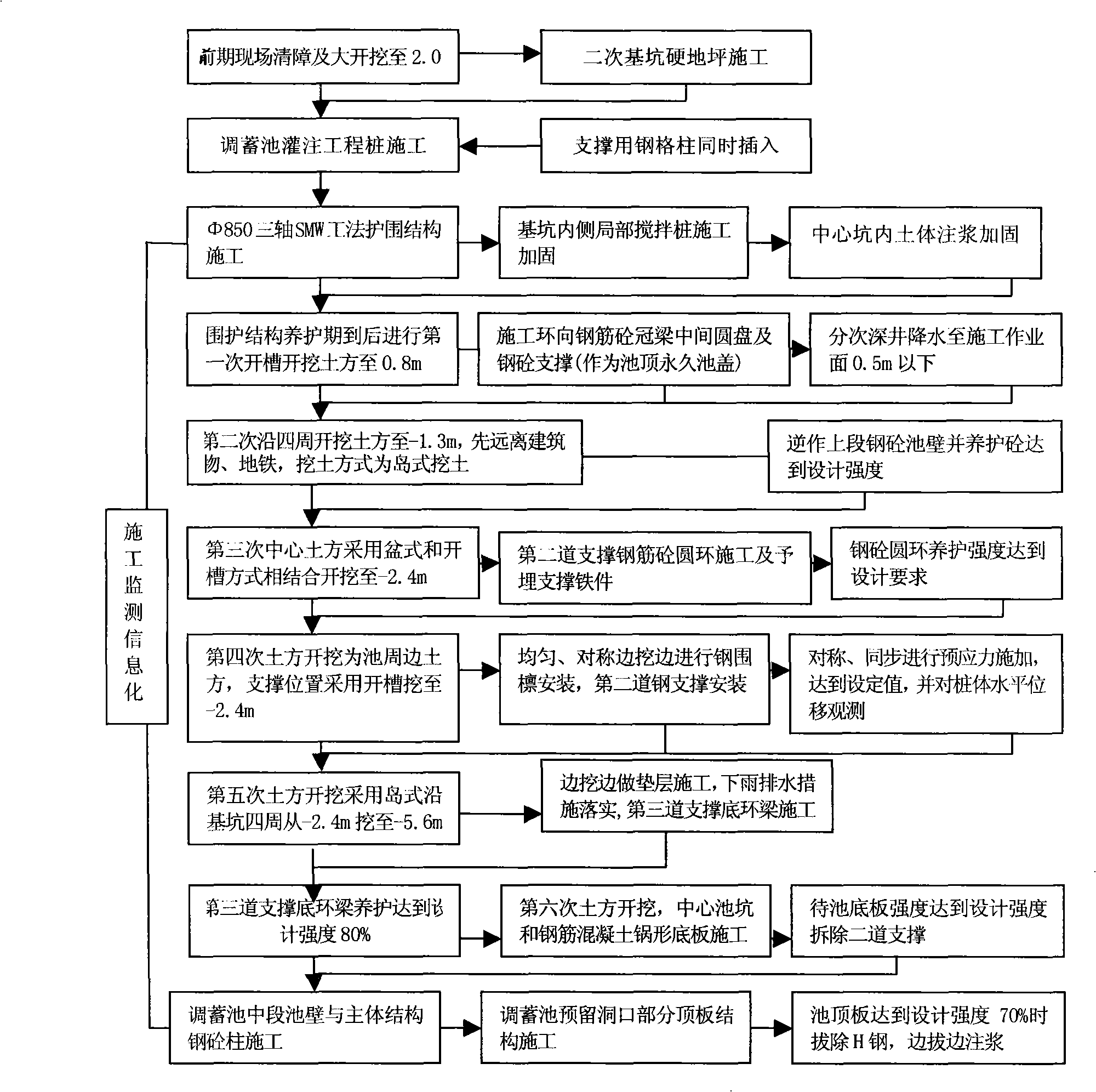

[0022] 2. Construction process:

[0023] See figure 1 .

[0024] 3. Key points of construction operation:

[0025] 1. Pool roof structure construction

[0026] The earthwork is excavated to the bottom of the pool roof structure, that is, the bottom of the supporting beams, and brick retaining walls and concrete cushion formwork are used in the construction.

[0027]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com