Patents

Literature

35results about How to "With drainage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

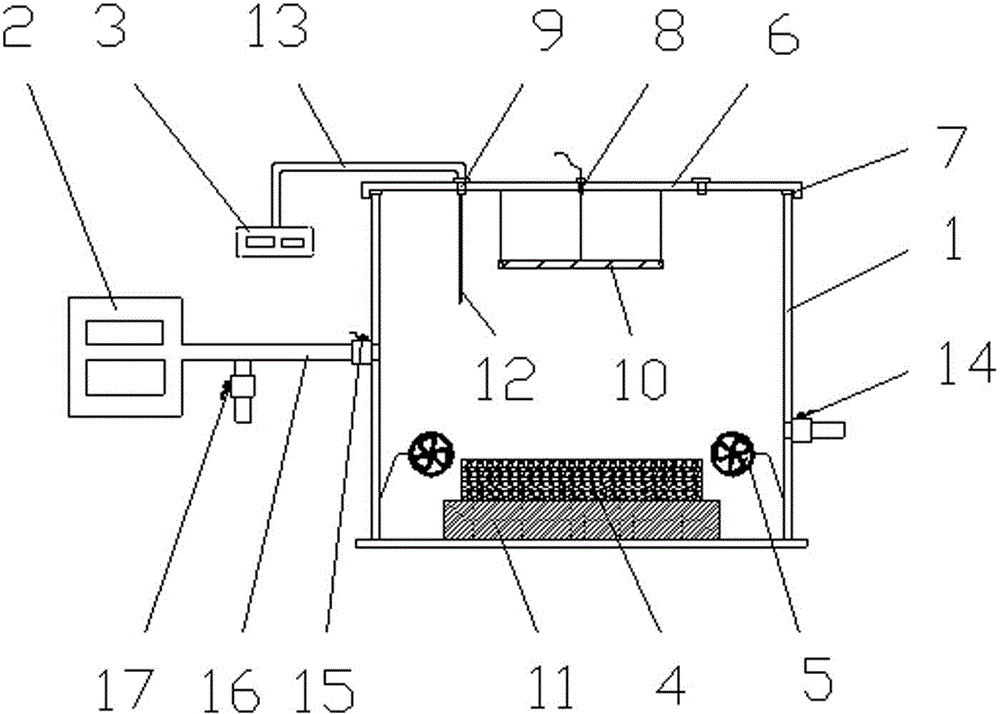

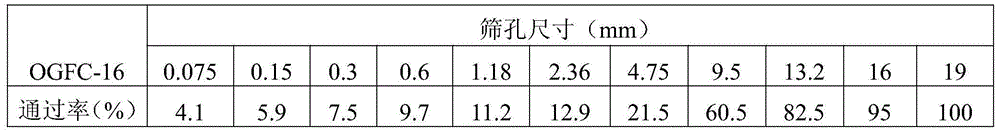

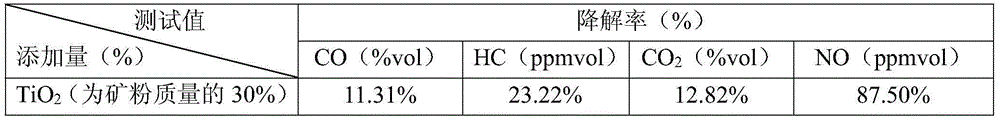

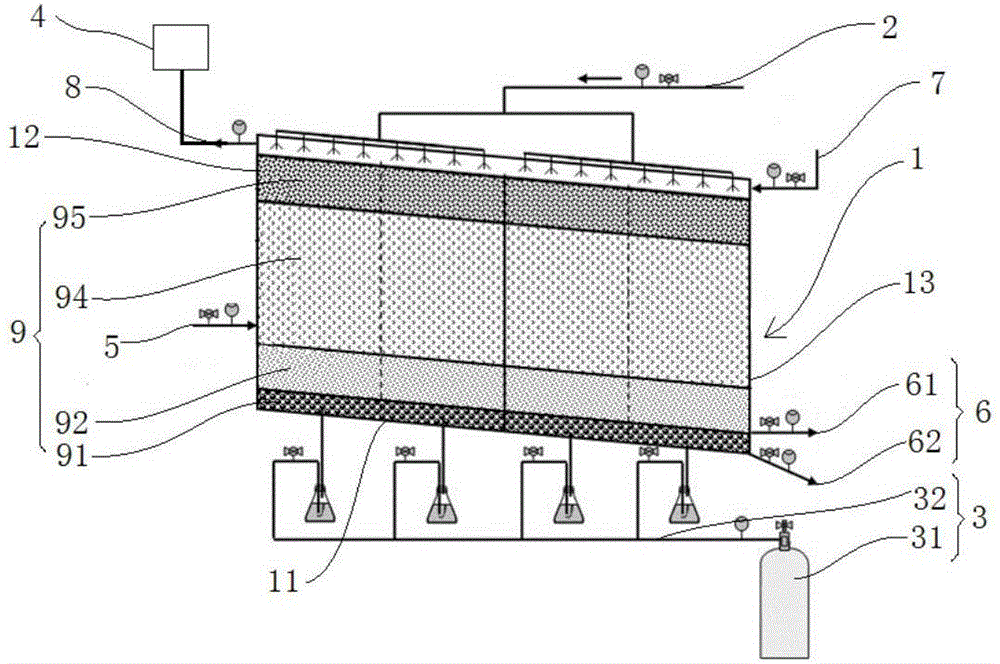

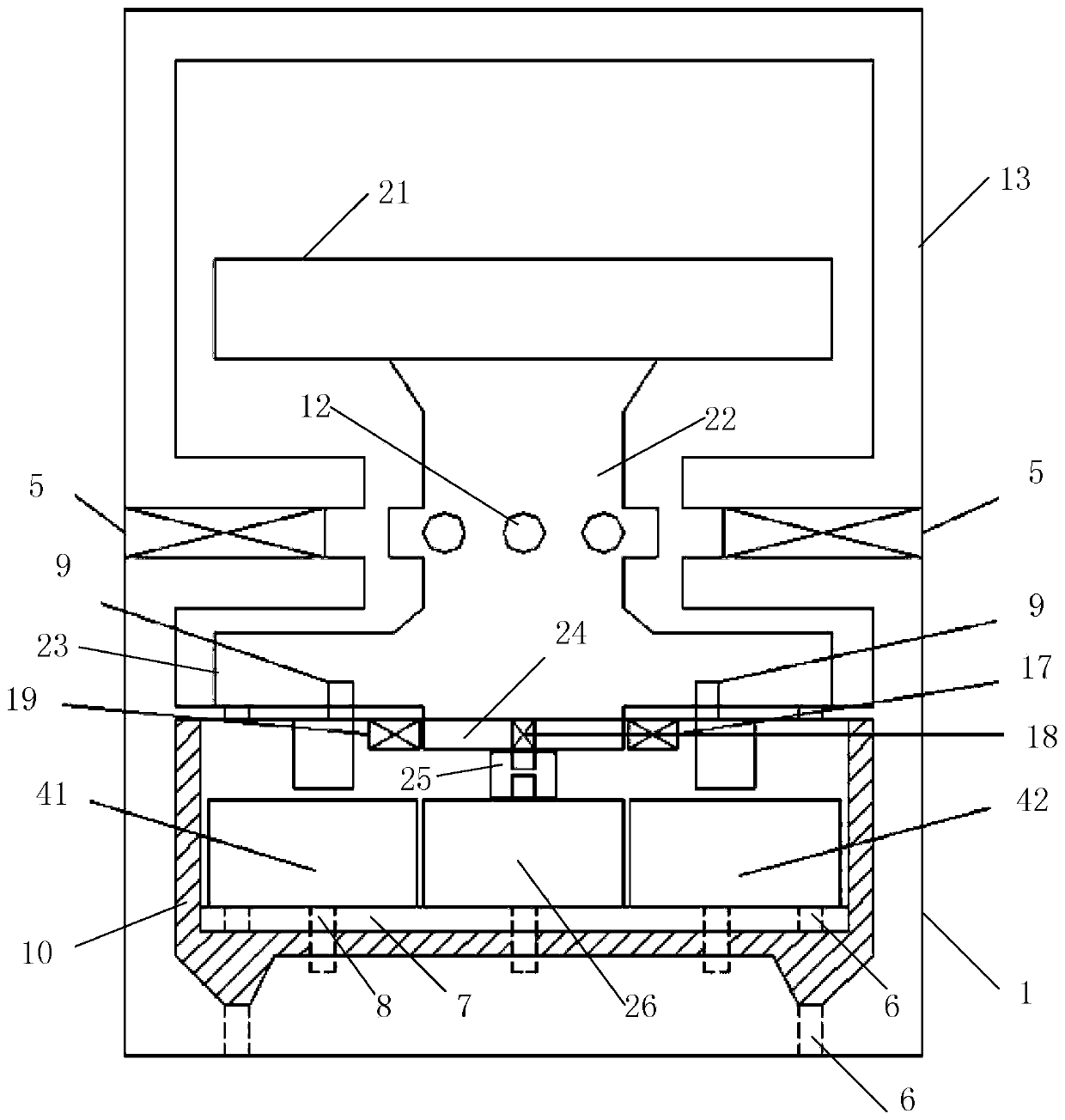

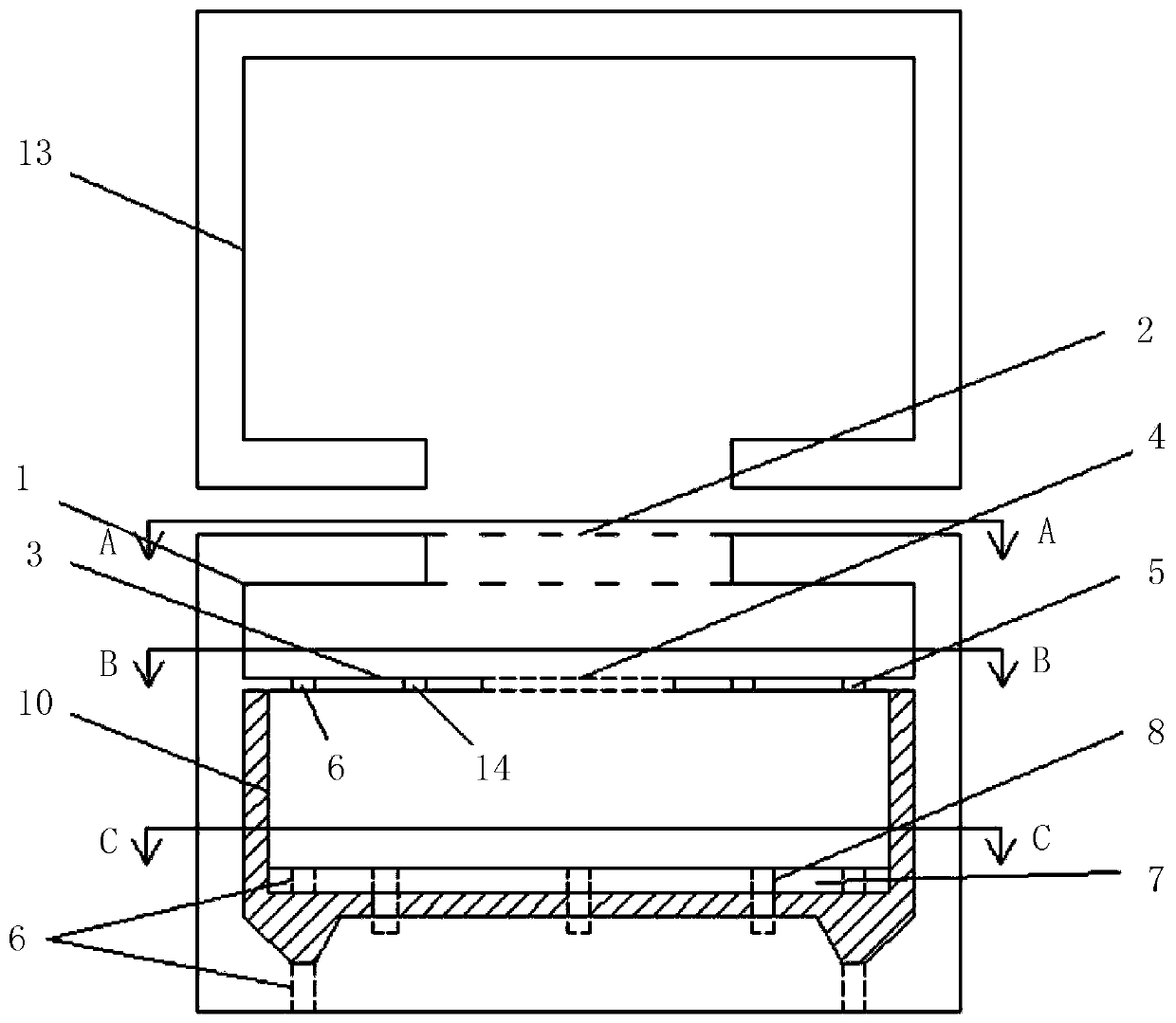

Device and method for evaluating automobile exhaust degradation effect of OGFC mixture

InactiveCN104807950ASimple structureEasy to operateChemical analysis using catalysisRoad surfaceData treatment

The invention discloses a device for evaluating the automobile exhaust degradation effect of an OGFC mixture. The device comprises a closed container, an automobile engine, an automobile exhaust analyzer, a track board test piece, and air supplying devices, wherein the air supplying devices are arranged in the closed container. The invention further discloses an evaluation method which comprises the following steps in sequence: preparing the track board test piece, and generating automobile exhaust; simulating the degradation of automobile exhaust on a pavement and testing the concentration of each gas in the automobile exhaust; processing data. The track board test piece is prepared from the OGFC mixture which is added with a photocatalytic material; the evaluation index, used for evaluating the automobile exhaust degradation effect, of the OGFC mixture is taken as the degradation rate. The evaluation device can simulate the automobile exhaust degradation processes of the OGFC mixture in different illumination conditions by controlling the number of ultraviolet lamp tubes. The evaluation method is accurate and reliable, and coincides with the automobile exhaust degradation situation on a real pavement.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

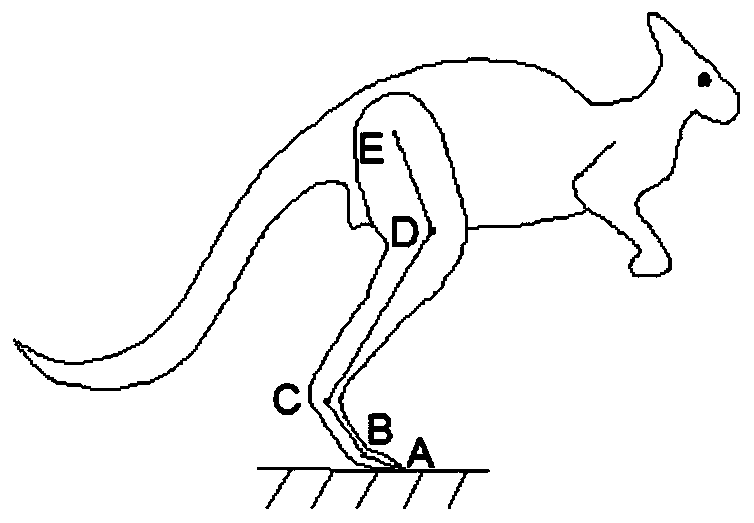

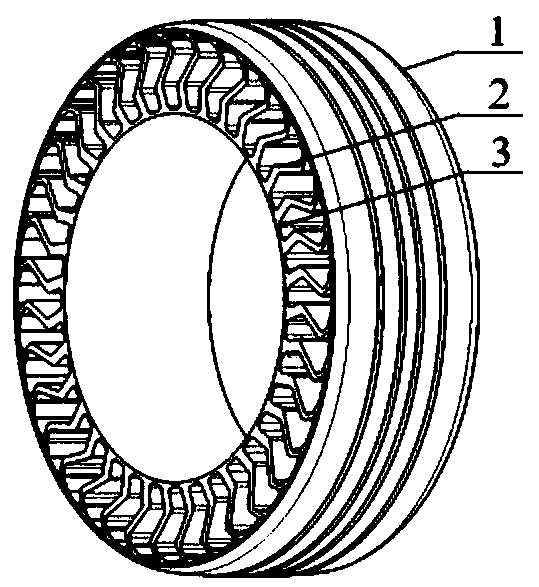

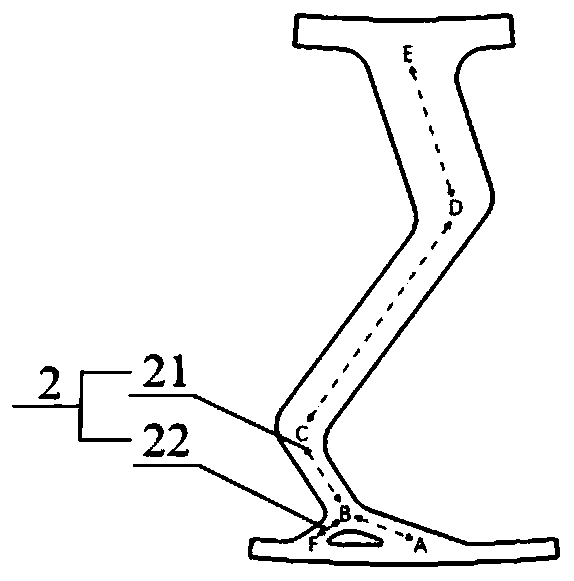

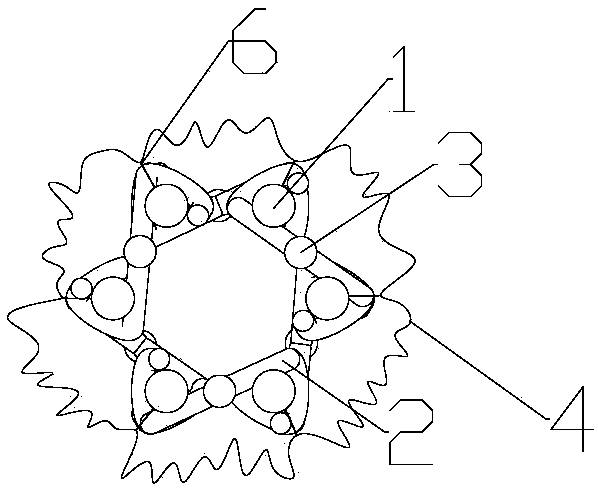

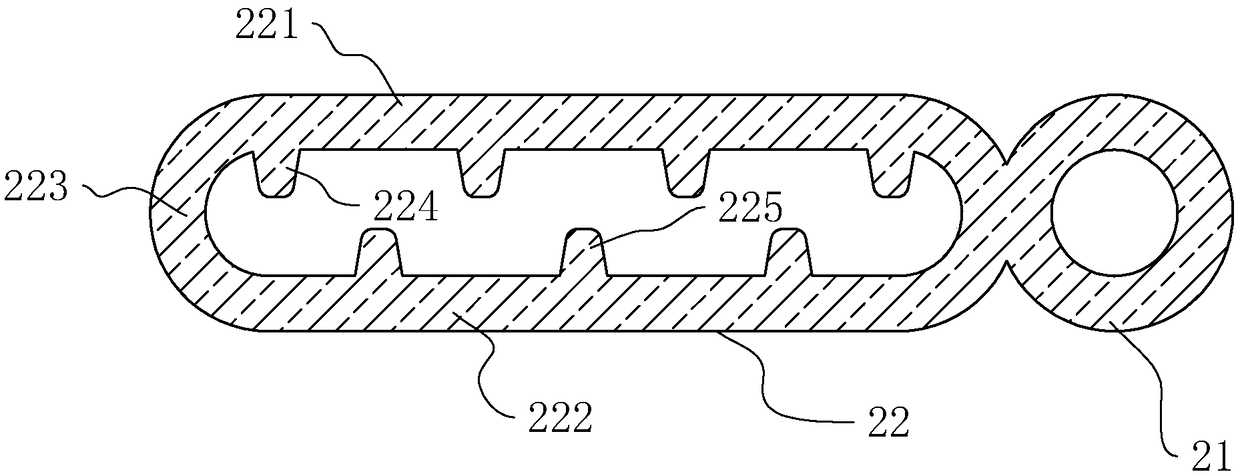

Bionic non-pneumatic tire

PendingCN110682741AHigh strengthImprove carrying capacityNon-inflatable tyresTyre tread bands/patternsControl theoryMechanical engineering

The invention discloses a bionic non-pneumatic tire. The bionic non-pneumatic tire comprises a crown, a bionic spoke plate support body and a spoke plate inner ring, wherein the crown, the bionic spoke plate support body and the spoke plate inner ring are sequentially arranged from outside to inside according to the radial direction of the tire; the crown comprises a tread, a cap ply and belt plies, wherein the tread, the cap ply and the belt plies are sequentially arranged from outside to inside according to the radial direction of the tire; the belt plies comprise a # 1 belt ply and a # 2 belt ply which are sequentially arranged from outside to inside according to the radial direction of the tire; and the bionic spoke plate support body is designed by imitating a kangaroo lower limb structure, and the bionic spoke plate support body comprises a kangaroo lower limb-imitated main spoke plate and a supporting auxiliary spoke plate. According to the bionic non-pneumatic tire, shock absorption, drainage and heat dissipation capability of the non-pneumatic tire are remarkably improved, and the overall mass is remarkably reduced; and the bionic spoke plate support body adopts a high-modulus polyurethane material, and thus high hardness, fatigue resistance, cutting resistance and green and environmental protection performance are achieved.

Owner:SHANDONG UNIV OF TECH

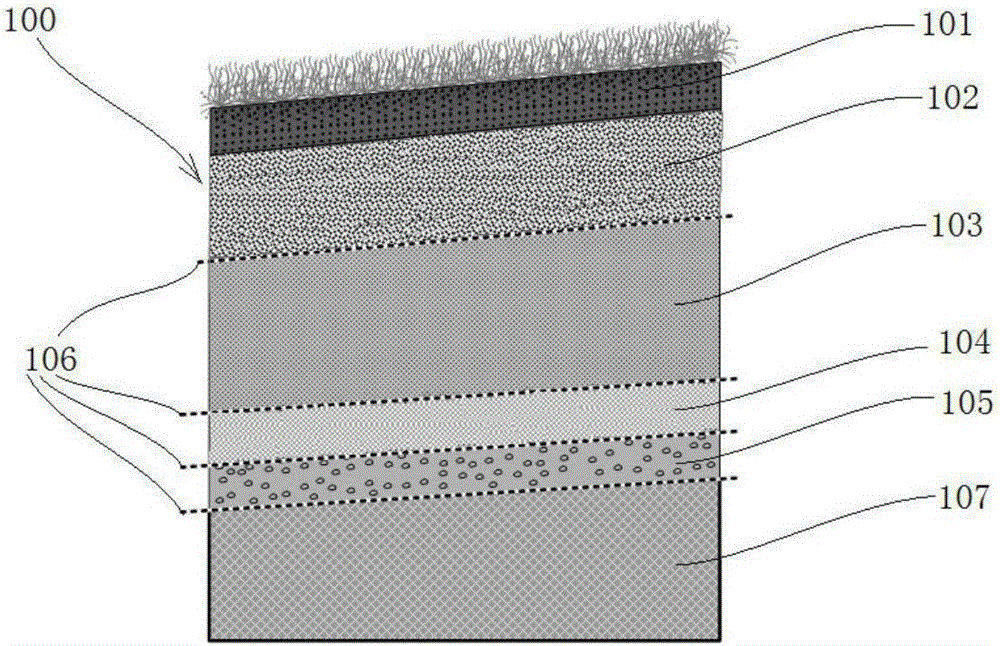

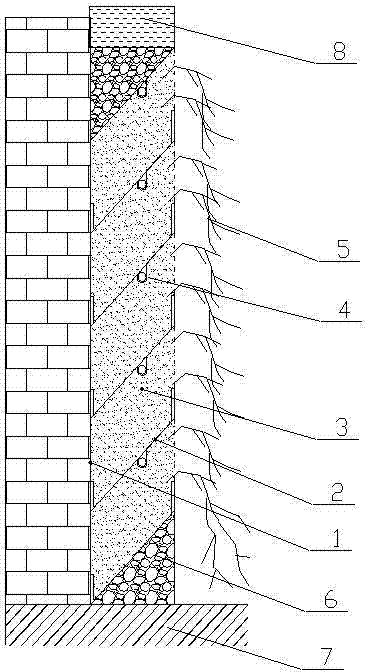

Final covering layer for semi-aerobic landfill

The invention relates to the field of garbage treatment, in particular to a final covering layer for household refuse semi-aerobic landfill. The final covering layer covers the surface layer of a household refuse semi-aerobic landfill and comprises a vegetation layer, a biological covering layer, a reservoir layer, a capillary barrier layer and a drainage layer sequentially from top to bottom. Methane-oxidizing bacteria exist in the biological covering layer. According to the actual situation of the household refuse semi-aerobic landfill process, the covering layer provided by the invention has good air permeability, and it can be guaranteed that external air is diffused into a landfill pile body; and meanwhile, the landfill gases including methane and the like generated when pile body landfill is conducted are diffused outside the pile body from the inside, so that an appropriate oxidation removing environment is provided for the methane released into the air through the covering layer. By adoption of the final covering layer for household refuse semi-aerobic landfill, the methane oxidation efficiency of the final covering layer is improved through optimization design of all the layers.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Hollow planting brick and vertical greening structure

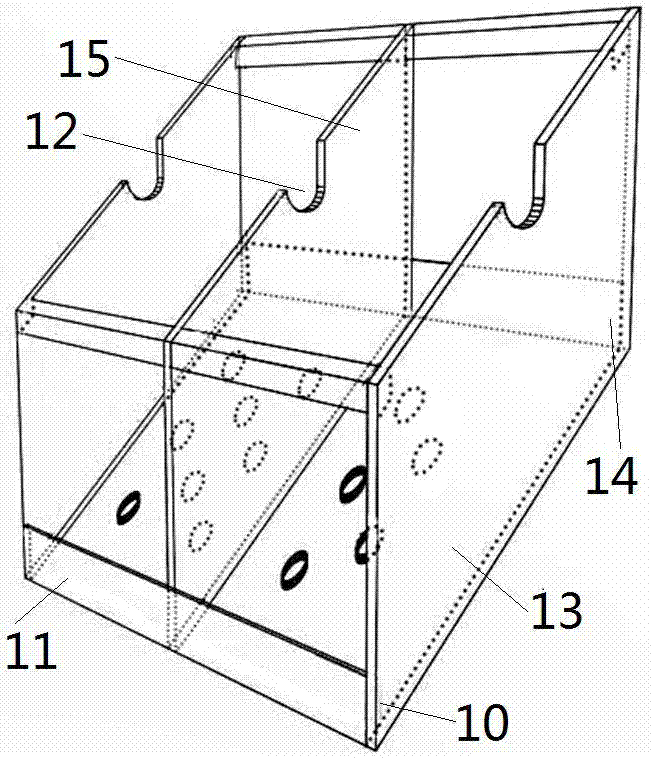

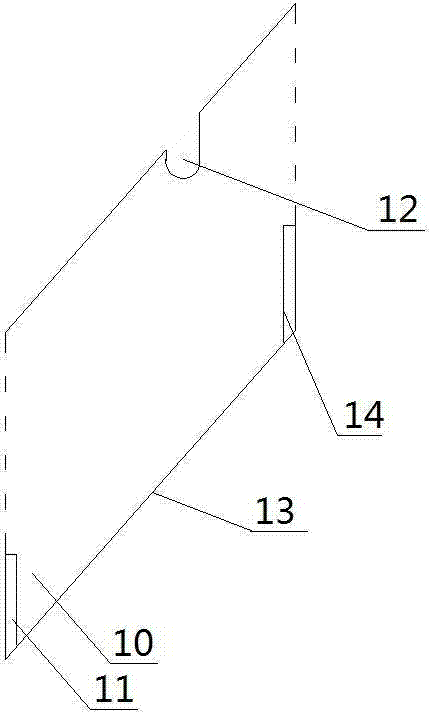

InactiveCN103883066APrevent wash awayWith water storage functionArtificial islandsBuilding componentsSocial benefitsEcological environment

The invention discloses a hollow planting brick which is characterized in that an overall framework of a brick body is in the shape of a quadrangular prism with rectangular upper, lower, left and right end surfaces and parallelogram front and rear end surfaces; a right baffle edge with a non-completely sealed gap is arranged on the right end surface of the brick body; irrigation pipe holes are formed in the front end surface and the rear end surface of the brick body; a water outlet is formed in the lower end surface of the brick body; the included angle between the lower end surface and the left end surface forms a water storage tank angle. Meanwhile, the invention provides a vertical greening structure. The vertical greening structure can solve the problem that plants cannot grow on vertical or steep slopes, can be widely used in the fields of city wall body greening, rock side slope greening, soil retaining wall greening and the like, has important practical and far-reaching significances on ecological environment, green area enlargement, PM2.5 reduction and the like, and has remarkable economic and social benefits.

Owner:湖南天泉生态草业工程有限公司

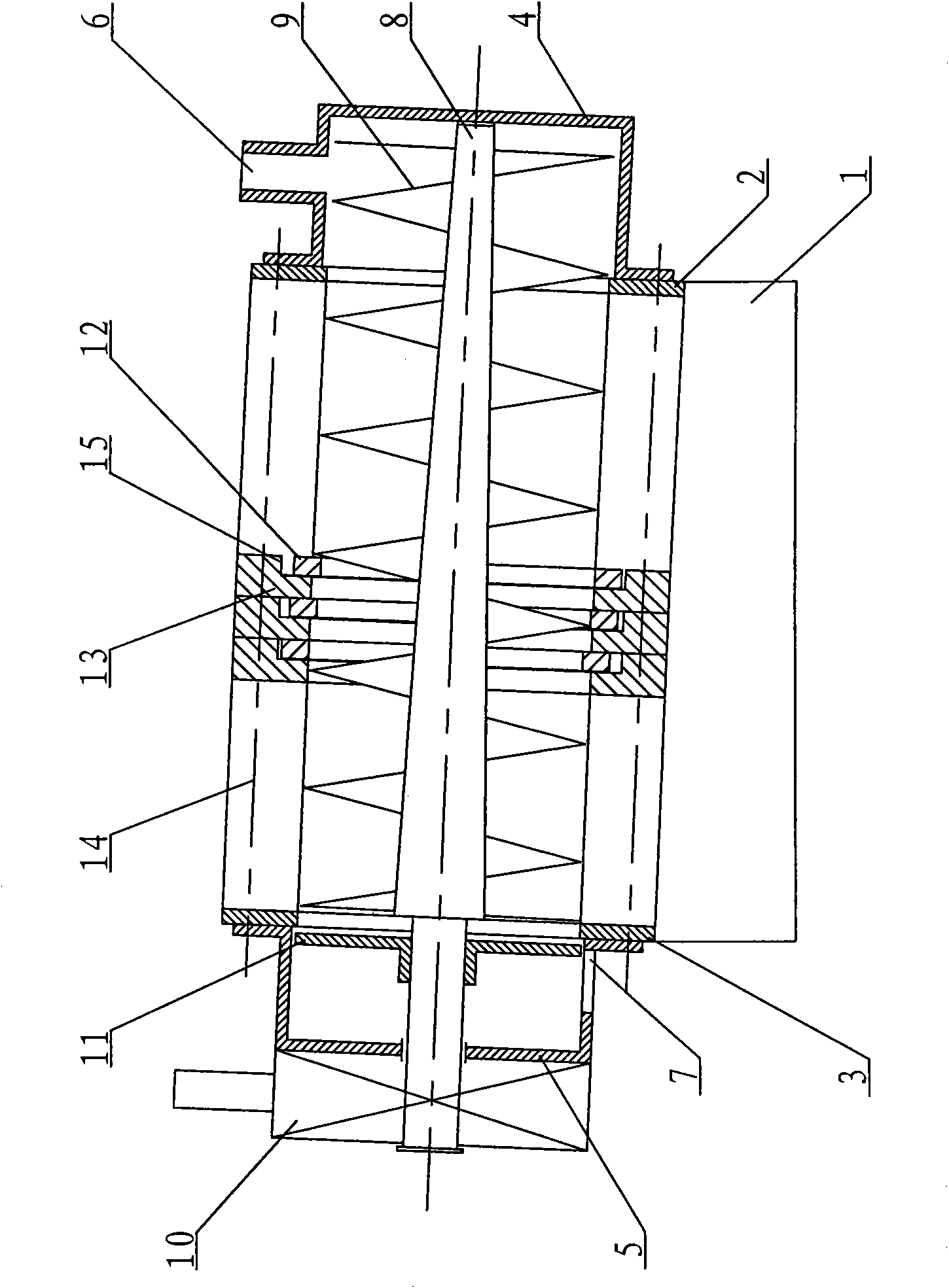

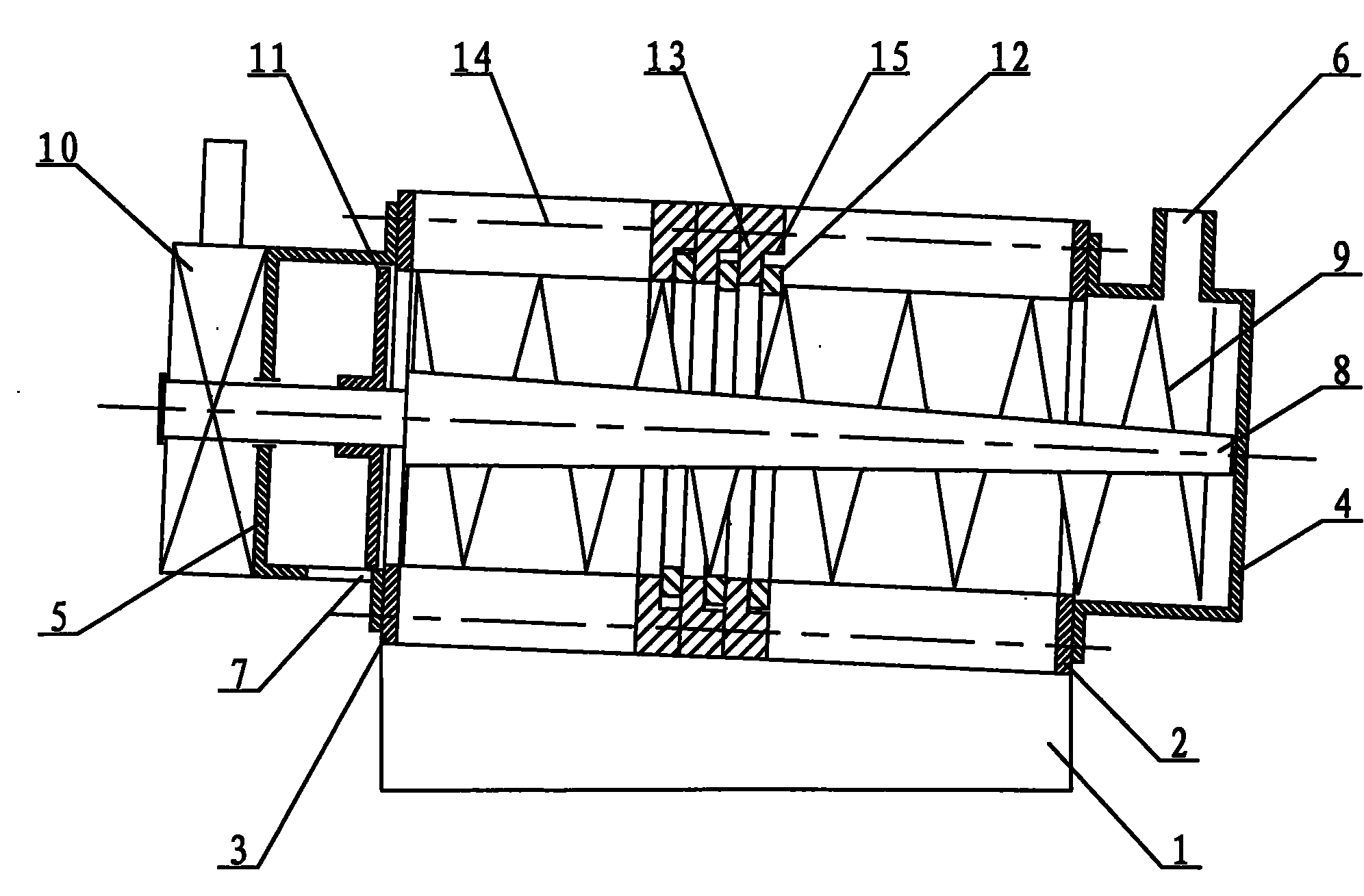

Dynamic gap type screw press

The invention relates to a dynamic gap type screw press comprising a spiral auger driven by a speed reducer and front and rear flange sleeves for supporting the spiral auger, wherein moving and static sheet groups matched with the spiral auger are arranged between the front flange sleeve and the rear flange sleeve; the front flange sleeve is provided with a feed opening; the rear flange sleeve is provided with a discharge opening; the spiral auger consists of a tapered shaft and blades; the outside diameters of the blades are equal; the screw pitches of the blades are equal; the inside diameters of the moving and the static sheet groups are greater than the outside diameter of the blades of the spiral auger; and the inside diameters of moving blades of the moving and the static sheet groups are smaller than the outside diameter of the blades of the spiral auger. According to the invention, sludge is propelled and extruded in the moving and the static sheet groups by the spiral auger consisting of the tapered shaft and the equidistant blades so as to realize the solid-liquid separation. The dynamic gap type screw press has simple structure and is convenient to process and stable for dehydration and has long service life; the equidistant blades have high rigidity; and the moving and the static sheet groups have the functions of draining, automatically cleaning, preventing blockage and the like.

Owner:周明泉

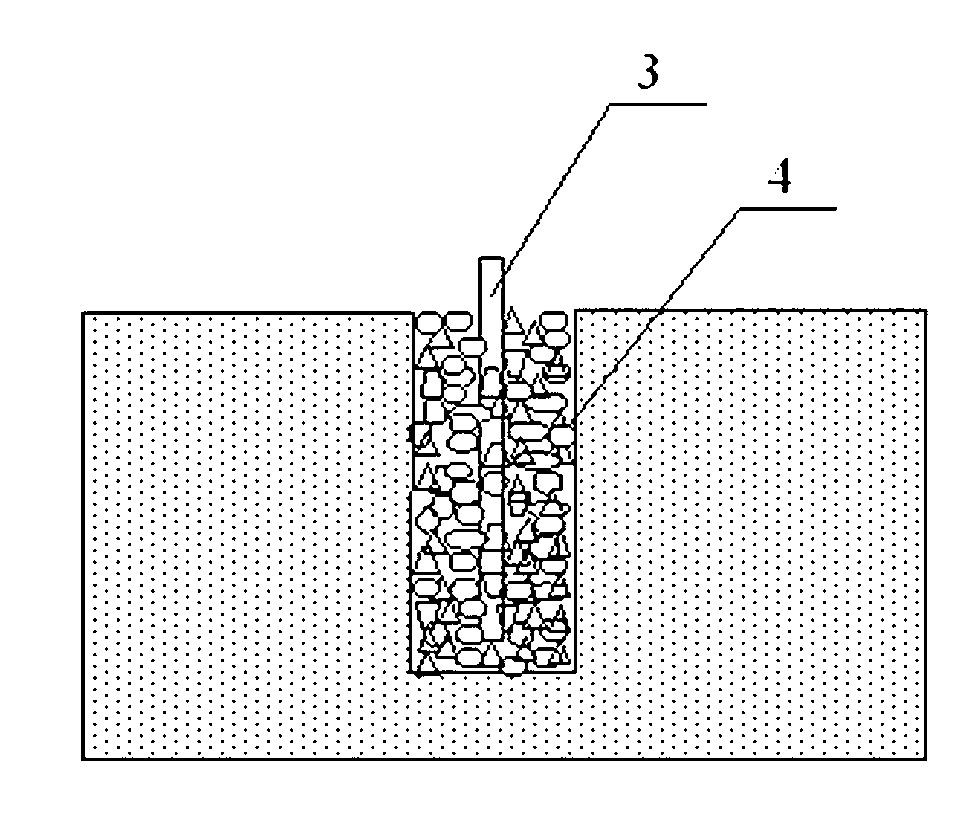

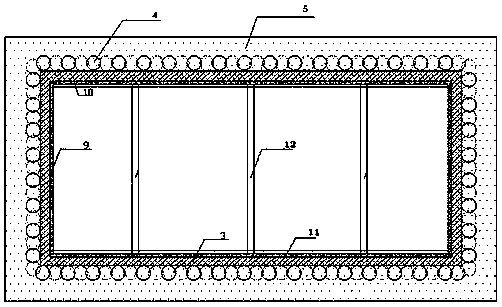

Polymer gravel pile grouting method

Owner:HENAN POLYTECH INFRASTRUCTURE REHABILITATION

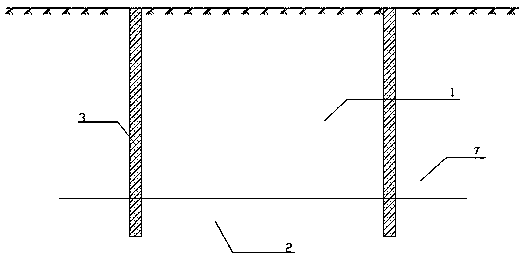

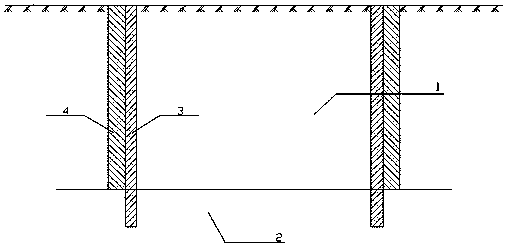

Reverse construction method of deep foundation pit in upper soft and lower hard water-rich stratum

The invention discloses a reverse construction method of a deep foundation pit in upper soft and lower hard water-rich stratum. The reverse construction method comprises the following steps that step(1) underground continuous wall construction is carried out; step (2) construction of split-type hole drilling cast-in-place piles in row is carried out; step (3) grouting curtain construction at theinterface of soft and hard stratum is carried out; step (4) the small foundation pit of a first floor is excavated, and core soil is pre-reserved; step (5) a water drainage resistance structure layeris arranged, and initial supporting and protecting are carried out; step (6) the reserved core soil in the first layer foundation pit is excavated; step (7) a first support system is arranged; and step (8) the stability of the protecting structure is determined through monitoring measurement results, if the monitoring measurement results are normal, then the next cycle is carried out, the step (4)to the step (7) are repeated until the foundation pit is closed. Through the combined action of the inner and outer protecting structure of the foundation pit and the rational design of the excavation method, and the deep foundation pit engineering in the upper soft and lower hard water-rich stratum can achieve effective water-stopping and deformation control effects on the basis of safe and efficient excavation.

Owner:FUJIAN UNIV OF TECH

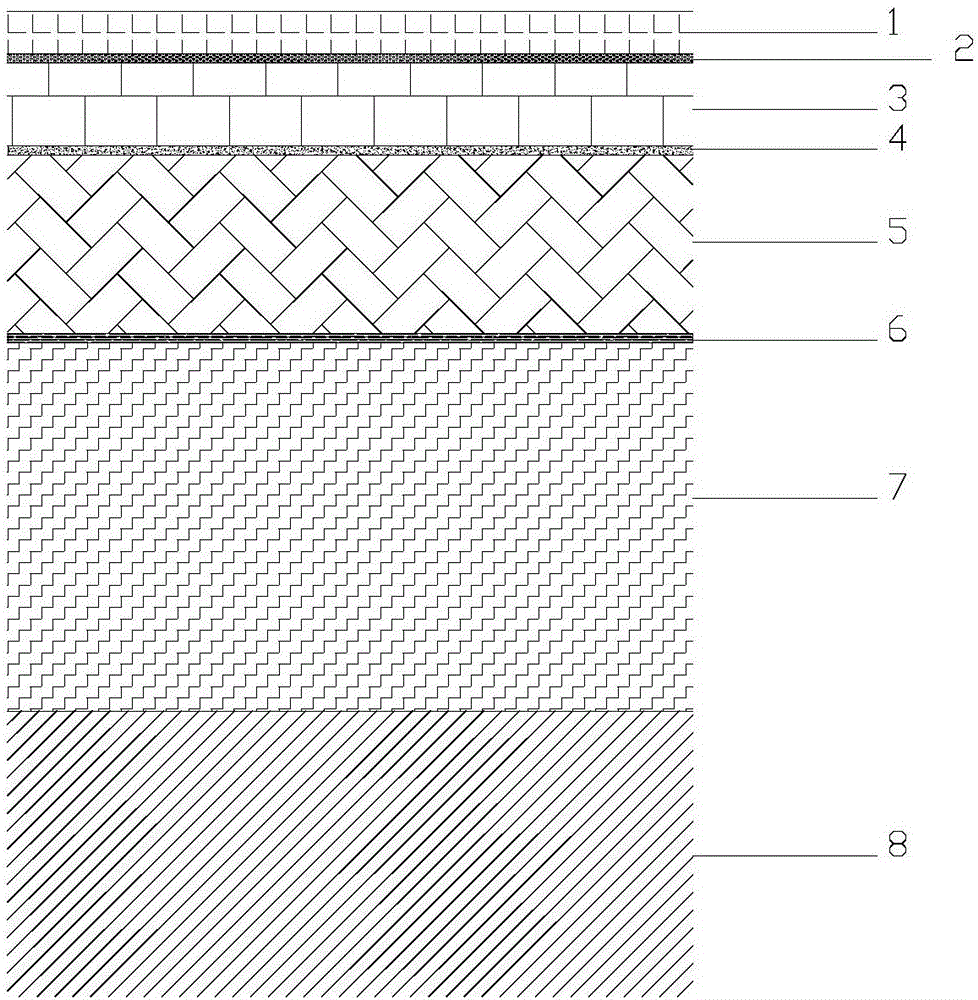

Pavement structure with low cost, environmental friendliness and long service life

PendingCN106702844AImprove driving comfort and safetyLow costIn situ pavingsEnvironmentally friendlyThin layer

The invention discloses a pavement structure with the low cost, environmental friendliness and long service life and relates to a road engineering pavement structure. The pavement structure is provided with a surface layer, an upper sealing layer, a middle face layer, a viscous layer, a lower face layer, a lower sealing layer, a semi-rigid base layer and a graded crushed stone base layer from top to bottom. The surface layer adopts an OGFC-10 thin layer; the upper sealing layer adopts a rubber asphalt fiber synchronized gravel sealing layer; the middle face layer adopts a rubber powder modified asphalt limestone SMA-20 mixed material without adding fibers; the viscous layer adopts SBR modified emulsified asphalt; the lower face layer adopts an ATB-30 ordinary mixed material; the lower sealing layer adopts a rubber asphalt fiber synchronized gravel sealing layer; the semi-rigid base layer adopts a cement stable crushed stone mixed material; and the graded crushed stone base layer is laid on the road bed surface. According to the pavement structure, the service life and the maintenance period of a road can be effectively prolonged, the cost is relatively low, the environmentally friendly function is achieved, environmental, economic and social benefits are significant, and good application prospects are achieved.

Owner:建发合诚工程咨询股份有限公司 +1

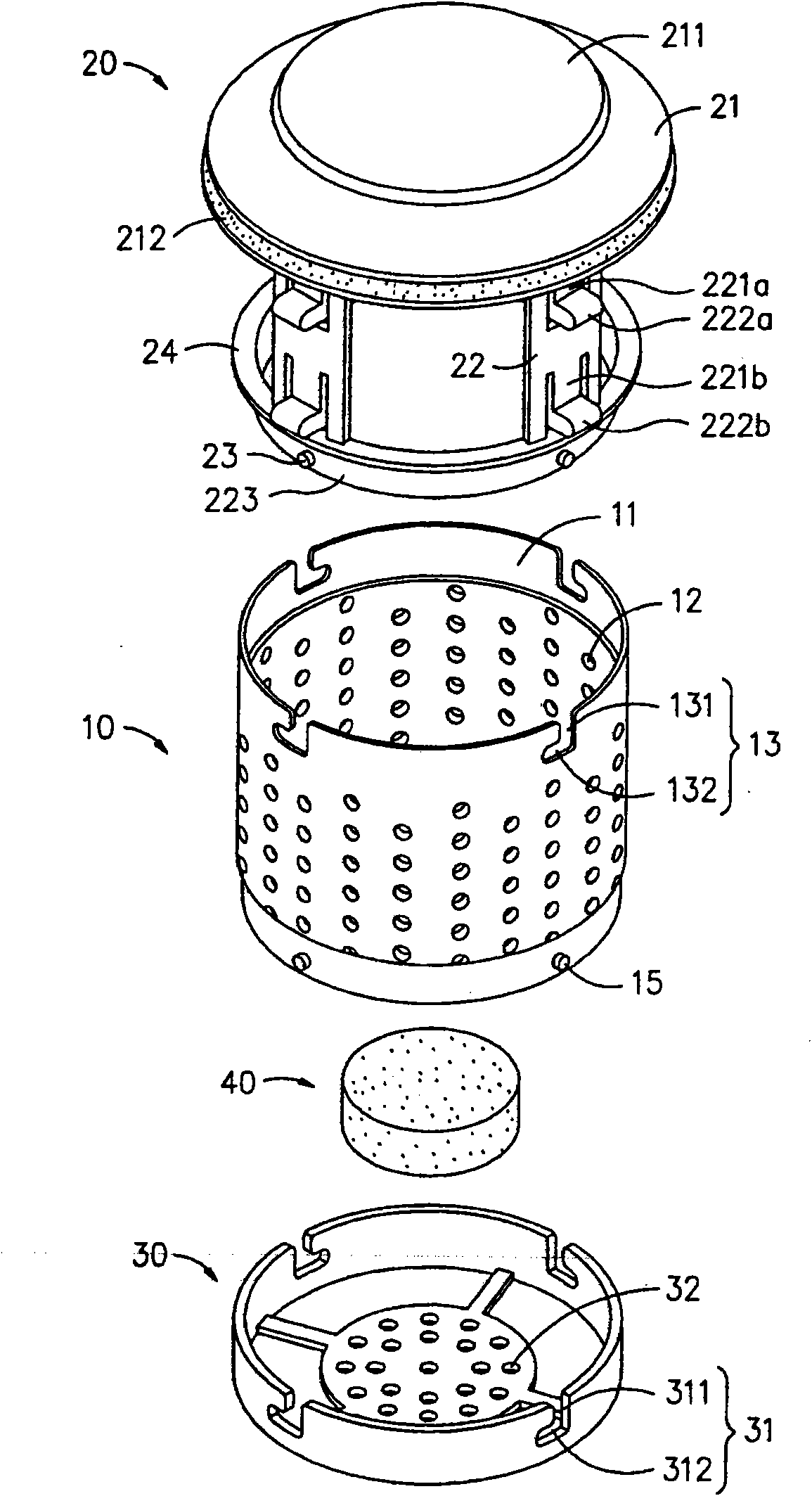

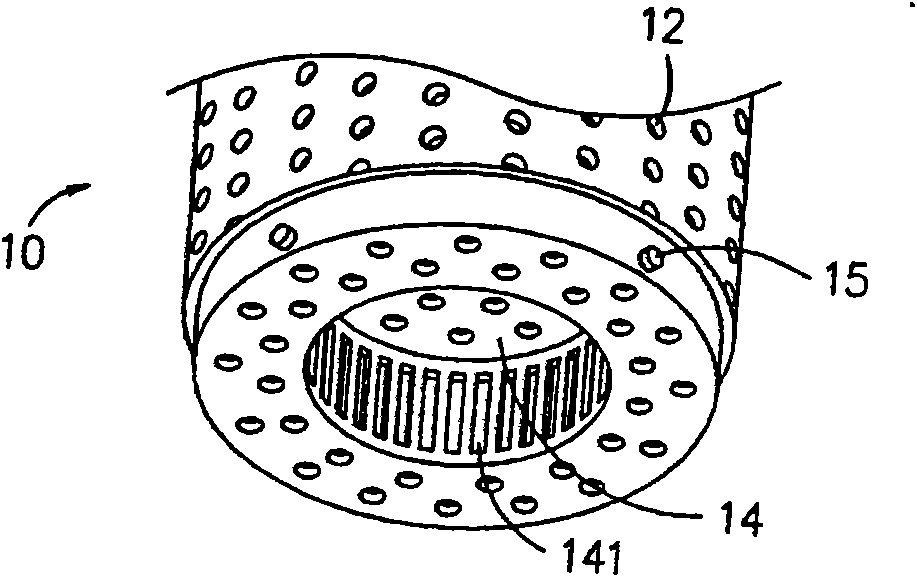

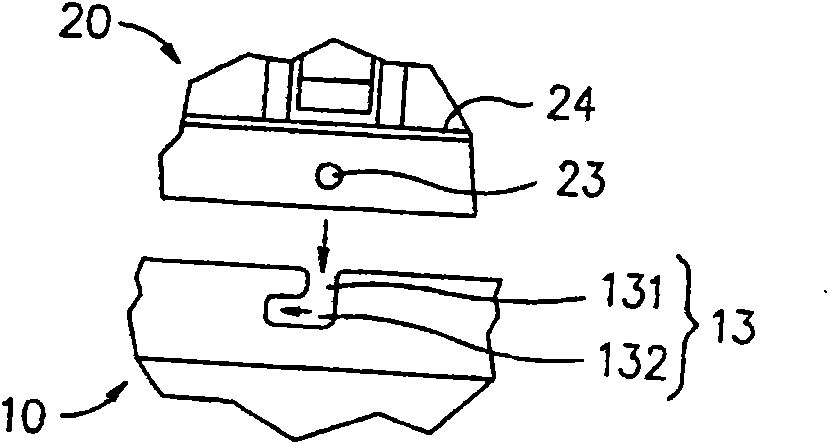

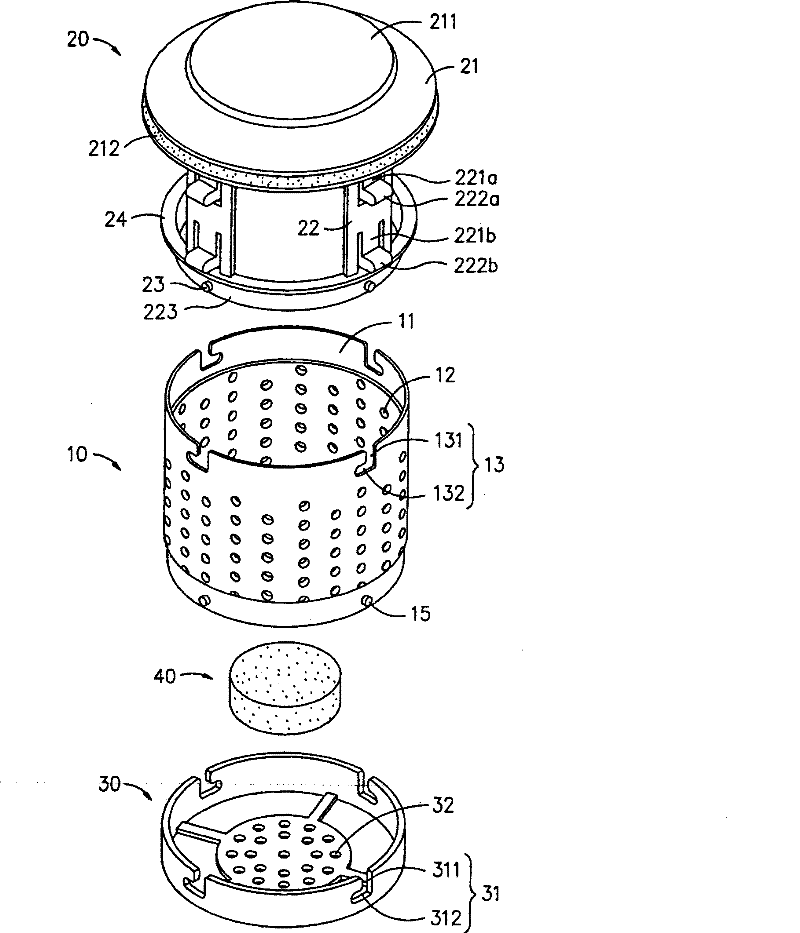

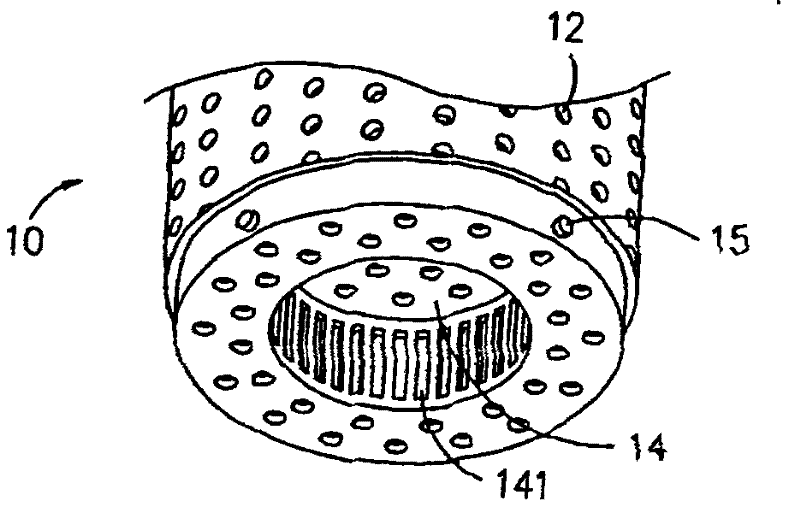

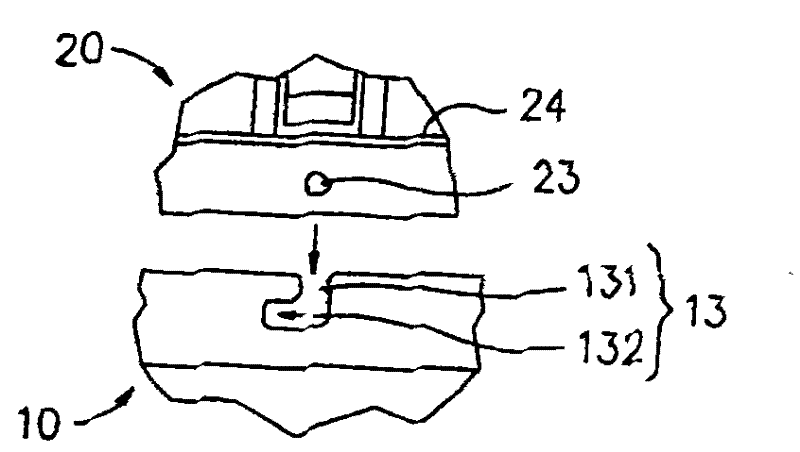

Drain device

The invention relates to a drain device, which comprises a body, a top cover assembly and a bottom cover. The body is provided with an inner space, and a plurality of permeable parts running through the inner space. The top cover assembly is separably arranged on the top of the body and comprises a top cover and a plurality of connecting pieces. The connecting pieces extend a certain length from the bottom of the top cover. The bottoms of the connecting pieces are connected with each other. Each connecting piece is provided with an upper elastic sheet and a lower elastic sheet. The elastic sheets are provided with convex parts towards the outside of the top cover. The bottom cover is separably arranged on the bottom of the body. A certain space is formed between the bottom cover and the body. The bottom cover is provided with a permeable part. Due to the combination of the components, an outer edge of each convex part protrudes out of the body and an outer side wall of the bottom cover, and can be applied with a force so that the convex part inwards contracts toward the inside of the top cover, and the convex part can be automatically popped up when the external force is eliminatedso that the outer edge of the convex part protrudes out of the body and the outer side wall of the bottom cover again.

Owner:THANK GOD ENTERPRISE

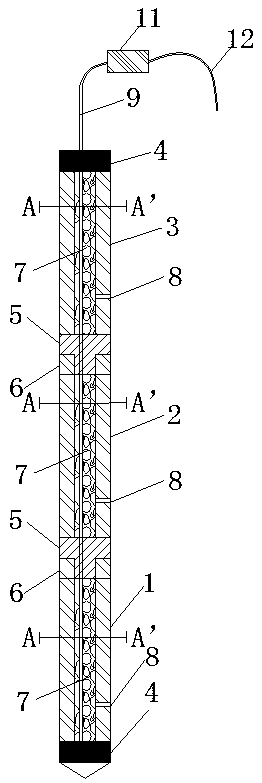

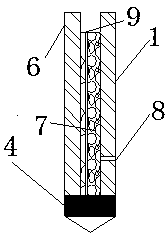

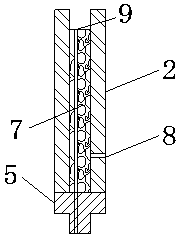

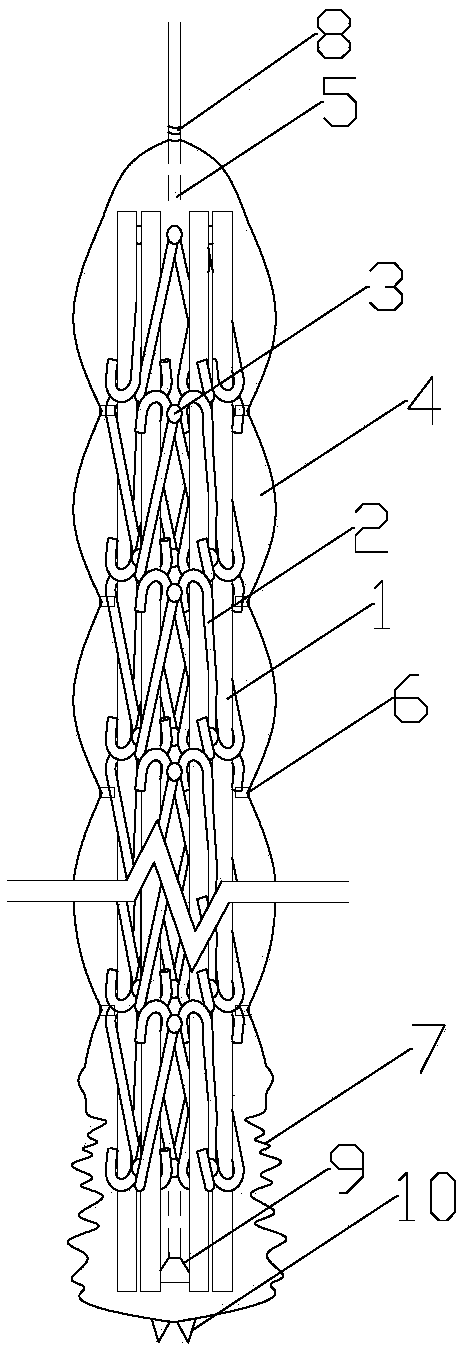

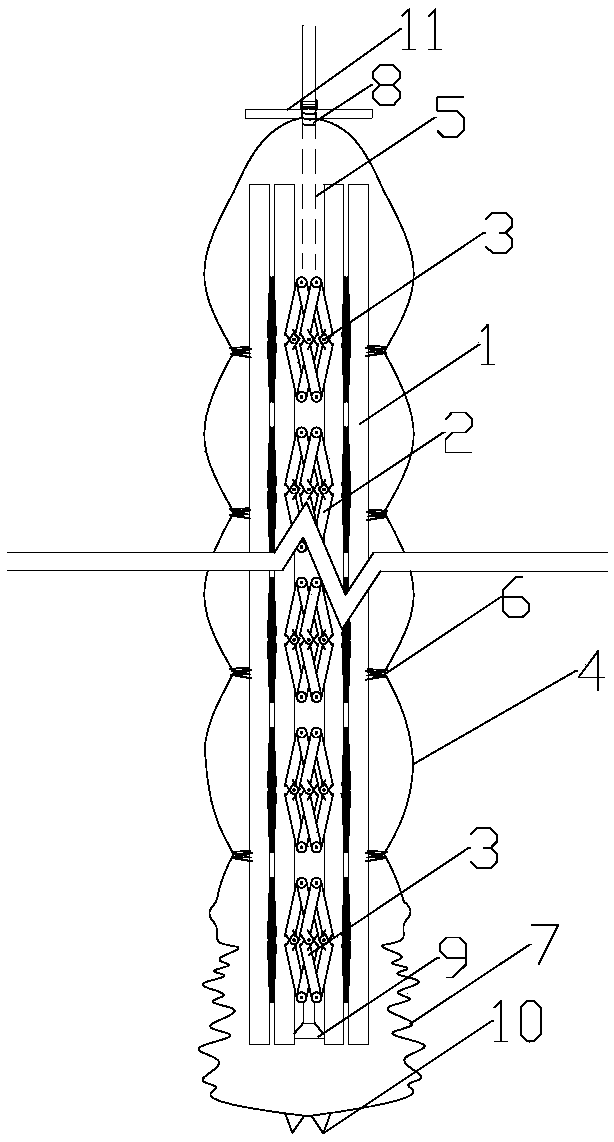

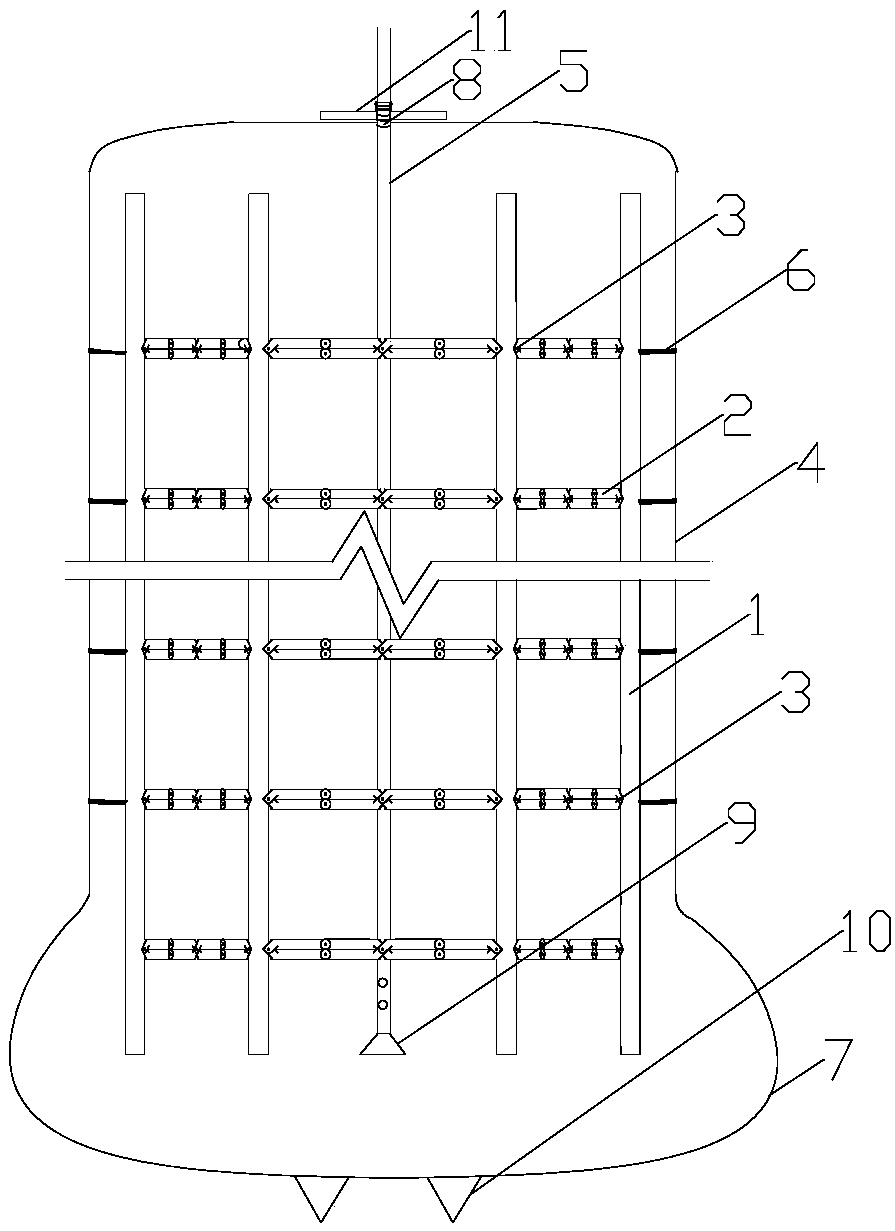

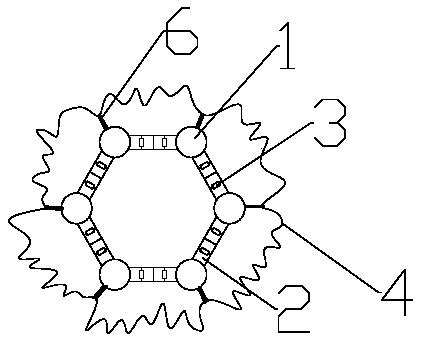

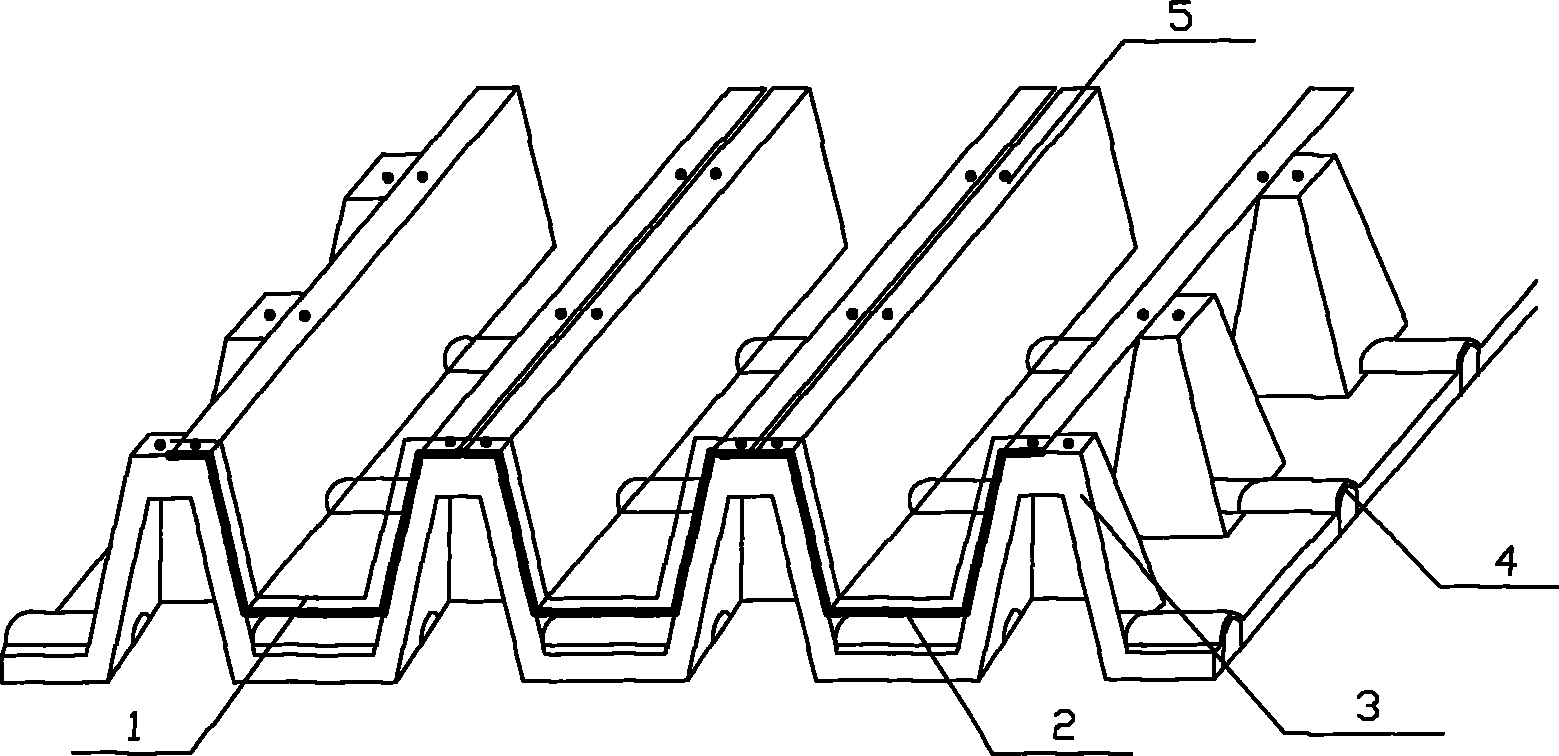

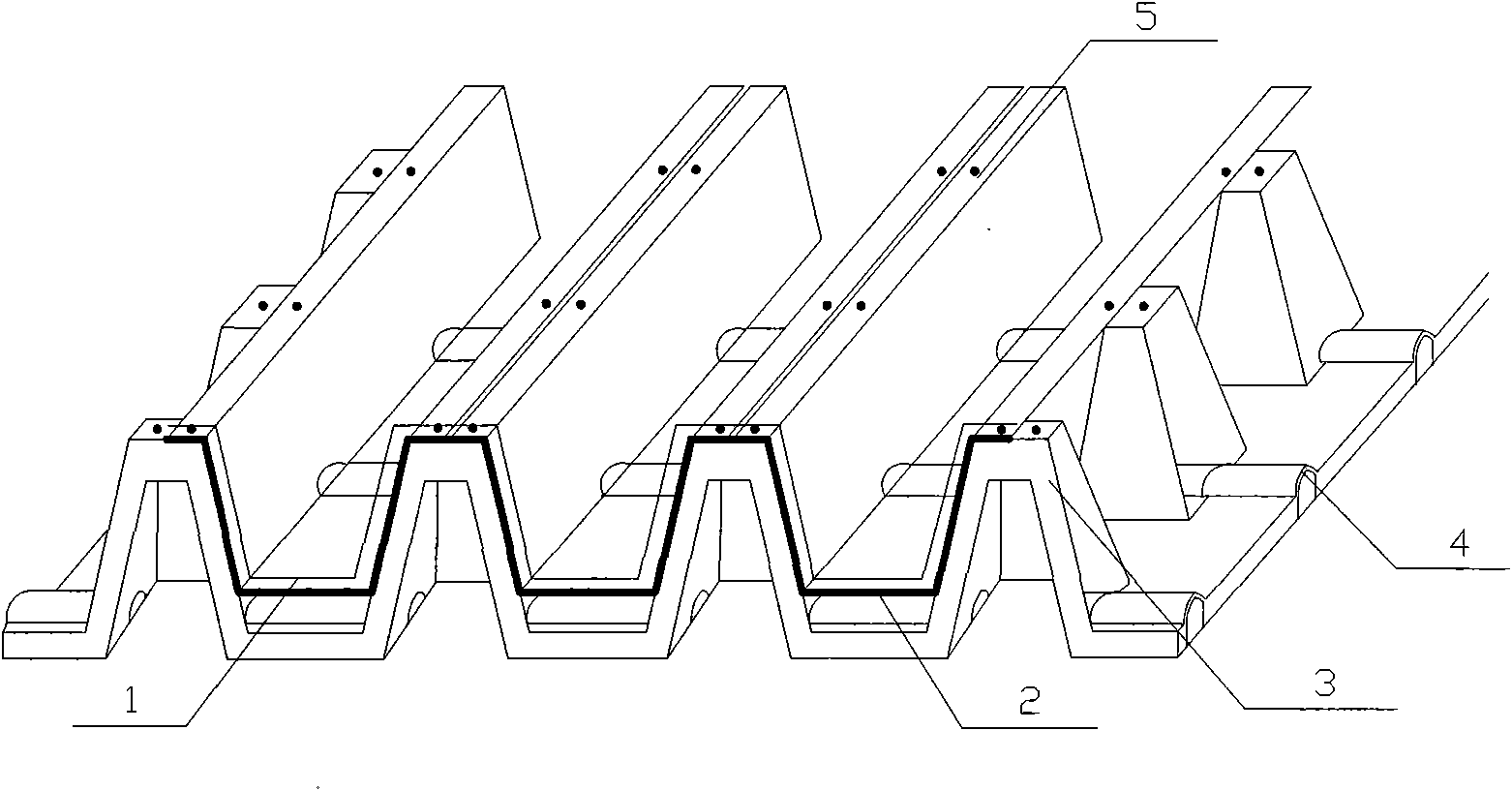

Prefabricated drainage prestressed anti-slide pile structure and construction process thereof

PendingCN109113081AImprove carrying capacityActive promotionExcavationsSoil preservationEmergency rescuePre stress

The invention discloses a prefabricated drainage prestressed anti-slide pile structure and a construction process thereof. The anti-slide pile structure comprises pipe piles, and the pipe piles comprise the I type steel concrete pipe pile, the II type steel concrete pipe pile and the III type steel concrete pipe pile which are sequentially connected, a tip plate is arranged at the bottom of the Itype steel concrete pipe pile, a connecting end disc is arranged at the upper end of the I type steel concrete pipe pile, the lower end of the II type steel concrete pipe pile is provided with a threaded end disc, the upper end of the II type steel concrete pipe pile is provided with a connecting end disc, the top of the III type steel concrete pipe pile is provided with a tip plate, the lower endof the III type steel concrete pipe pile is provided with a threaded end disc, and every two adjacent pipe piles are connected through the corresponding connecting end disc to the corresponding threaded end disc. The prefabricated drainage prestressed anti-slide pile structure and the construction process are applicable to a landslide disaster rapid treatment project or an emergency rescue project which is in progressive damage or accelerated damage state, have the characteristics of the short construction period, simple and convenient construction, small economic input, large landslide loads, drainage capacity and the like, and have the disaster prevention, disaster mitigation and emergency rescue attributes.

Owner:INST OF EXPLORATION TECH OF CHINESE ACAD OF GEOLOGICAL SCI

Intelligent lock used for container platform lorry and locking method of intelligent lock

PendingCN109733272AAchieve vibration reductionRealize drainageLoad securingRemote controlEngineering

The invention provides an intelligent lock used for a container platform lorry. The intelligent lock is connected with a corner fitting at the vertex angle of the bottom of a container and comprises alock seat, a motor, a sensor unit and a unit controller, wherein the lock seat comprises a lock seat body and a lock body, and the lock seat body is fixed to the platform lorry and corresponds to thecorner fitting in position; the lock body is of an I-shaped structure, and the two ends of the lock body penetrate through the bottom of the corner fitting and the top of the lock seat and are located in an inner cavity of the corner fitting and an inner cavity of the lock seat; the motor is arranged in the lock seat and drives the lock body to rotate; the sensor unit is connected with the lock seat and obtains container bearing information and lock body on-off state information; and the unit controller is arranged in the lock seat, wirelessly sends the information acquired by the sensor unitto a vehicle-mounted integrated controller and a remote control center, receives commands of the vehicle-mounted integrated controller and the remote control center to drive the motor to work and achieves automatic unlocking and locking functions. The invention further provides a method for locking the container and the platform lorry. The intelligent lock is reliable in use, a container fasteneris intelligent, and work efficiency is improved.

Owner:SHANGHAI MARITIME UNIVERSITY

Water-logging fire-flooding oil reservoir combustible blocking method

ActiveCN109505575ANo pollution in the processBurn fullyFluid removalSealing/packingCombustionOrganic matter

The invention discloses a water-logging fire-flooding oil reservoir combustible blocking method. The method comprises the steps that oil or water is used for carrying a combustible blocking agent anda combustion improver to be injected into an injection well to conduct profile control and plugging. The water-logging fire-flooding oil reservoir combustible blocking method mainly aims at multi-turnsteam huff and puff blocks, water logging exists, stratum deficits are serous, the oil saturation of immediate vicinity of wellbore is low (95% or above of water is contained), and a fire-flooding injection well is prepared. Accordingly, the combustible blocking agent and the combustion improver are carried through the oil or the water, combustible organic matter is provided while profile controland plugging re conducted on the immediate vicinity of wellbore, ignition is uniform, and combustion is sufficient.

Owner:PETROCHINA CO LTD

Large karst stratum partial filling reinforced concrete bag pile structure and process

PendingCN108411904AAvoid damageImprove construction work safetyBulkheads/pilesReinforced concreteKarst

The invention provides a large karst stratum partial filling reinforced concrete bag pile structure and a process. The structure comprises a geofabric bag; a folding reinforcement frame connected withthe geofabric bag is arranged in the geofabric bag and used as an inner support; concrete is poured into the geofabric bag; and the filing boundary of concrete is limited through the geofabric bag, then pouring is conducted, and partial filling of a karst cave is achieved. The adopted high-strength geofabric bag has the characteristics of isolation and water drainage, and a pile is easy to form.

Owner:中铁十四局集团建筑工程有限公司 +3

Semen pharbitidis healthy tea for preventing edema

The invention relates to semen pharbitidis healthy tea for preventing edema. The semen pharbitidis healthy tea is prepared by adopting the steps of: washing 26 parts of semen pharbitidis, 13 parts of semen coicis, 15 parts of leonurus heterophyllus sweet, 15 parts of semen plantaginis and 13 parts of saururus chinensis, then airing and crushing, wherein the particle size of crushed materials is 1-3mm; mixing the crushed powder with 18 parts of green tea powder; and after drying, sub-packaging into small bags by using an automatic packaging machine, thus obtaining the semen pharbitidis healthy tea for preventing edema. The semen pharbitidis healthy tea for preventing edema is simple in preparing method, is convenient to carry, is good in effect, has the effects of promoting fluid metabolism and eliminating swelling and can promoting fluid metabolism and prevent edema after being taken for a long time.

Owner:潘亚琴

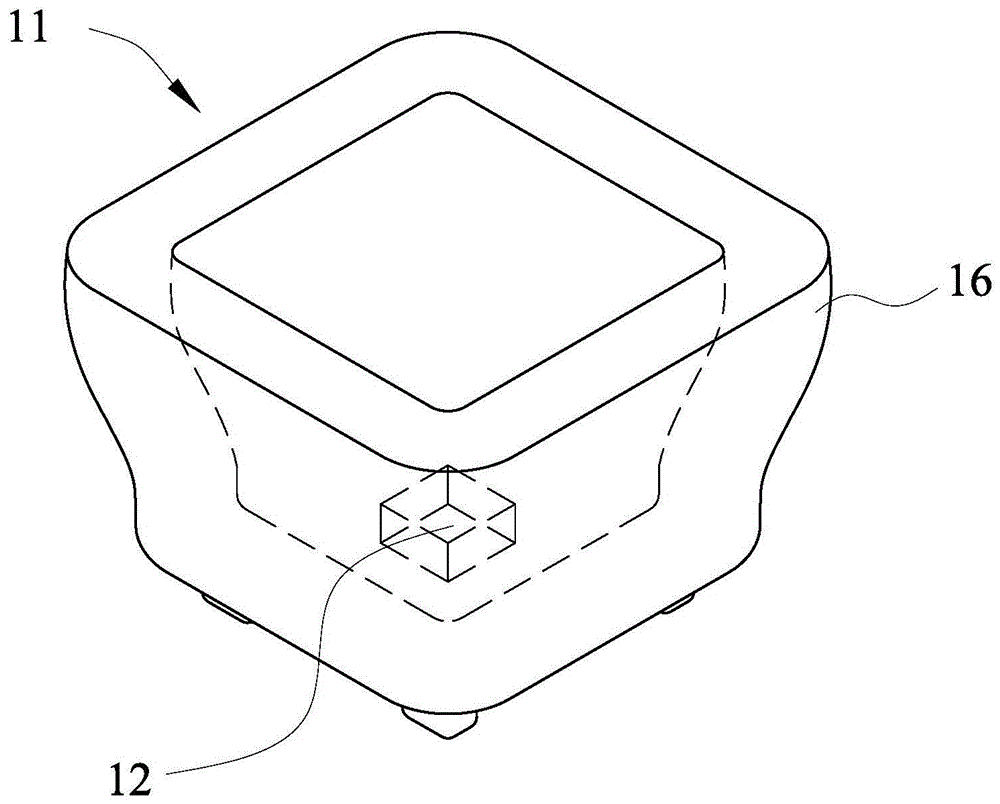

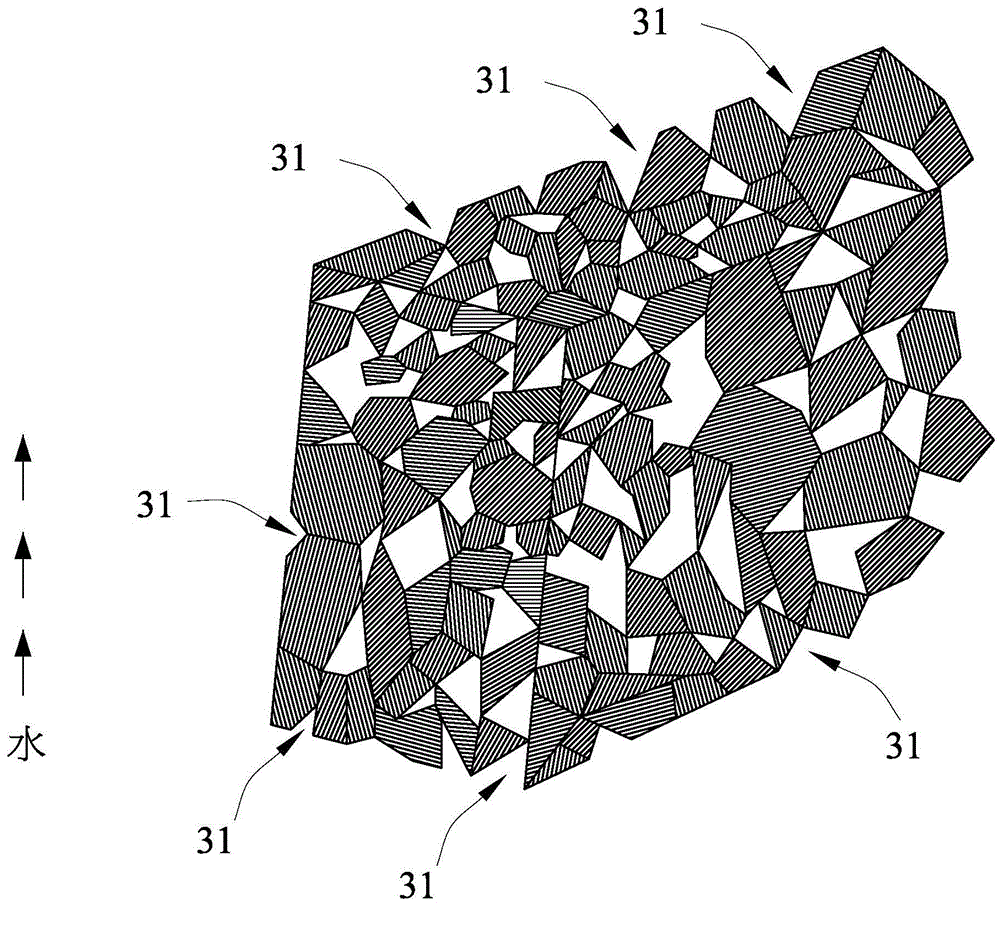

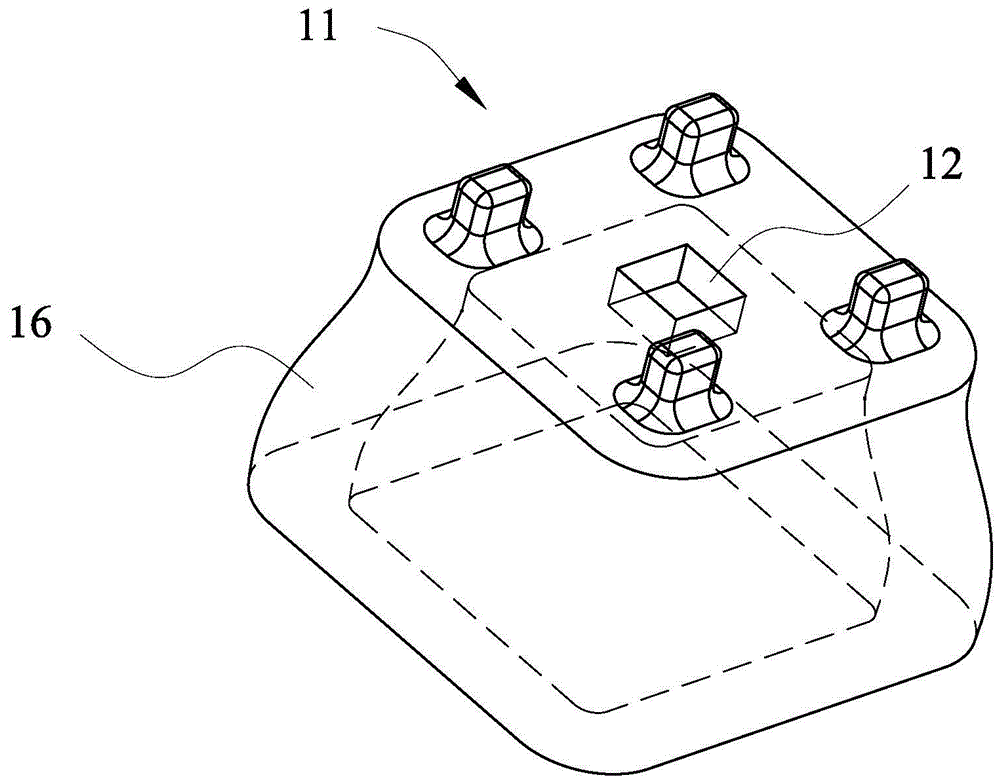

Breathable Planting Device

InactiveCN104054528AOvercome the effect of non-drainageHigh Ventilation EfficacyReceptacle cultivationPlant soilMaterials science

The inventin provides a breathable planting device with a sintering structure capable of ventilation, moisturizing and water drainage and comprsing a flower pot body in a hollow pot structure and further a sintering ball made from recycle glass and formed via sintering. The flower pot body is made from environment-friendly recovery recycle glass and formed via sintering; the hollow flower pot structure carries planting soil; and the sintering ball is arranged on the inner side of the hollow flower pot structure of the flower pot body or in the flower pot.

Owner:邱大展

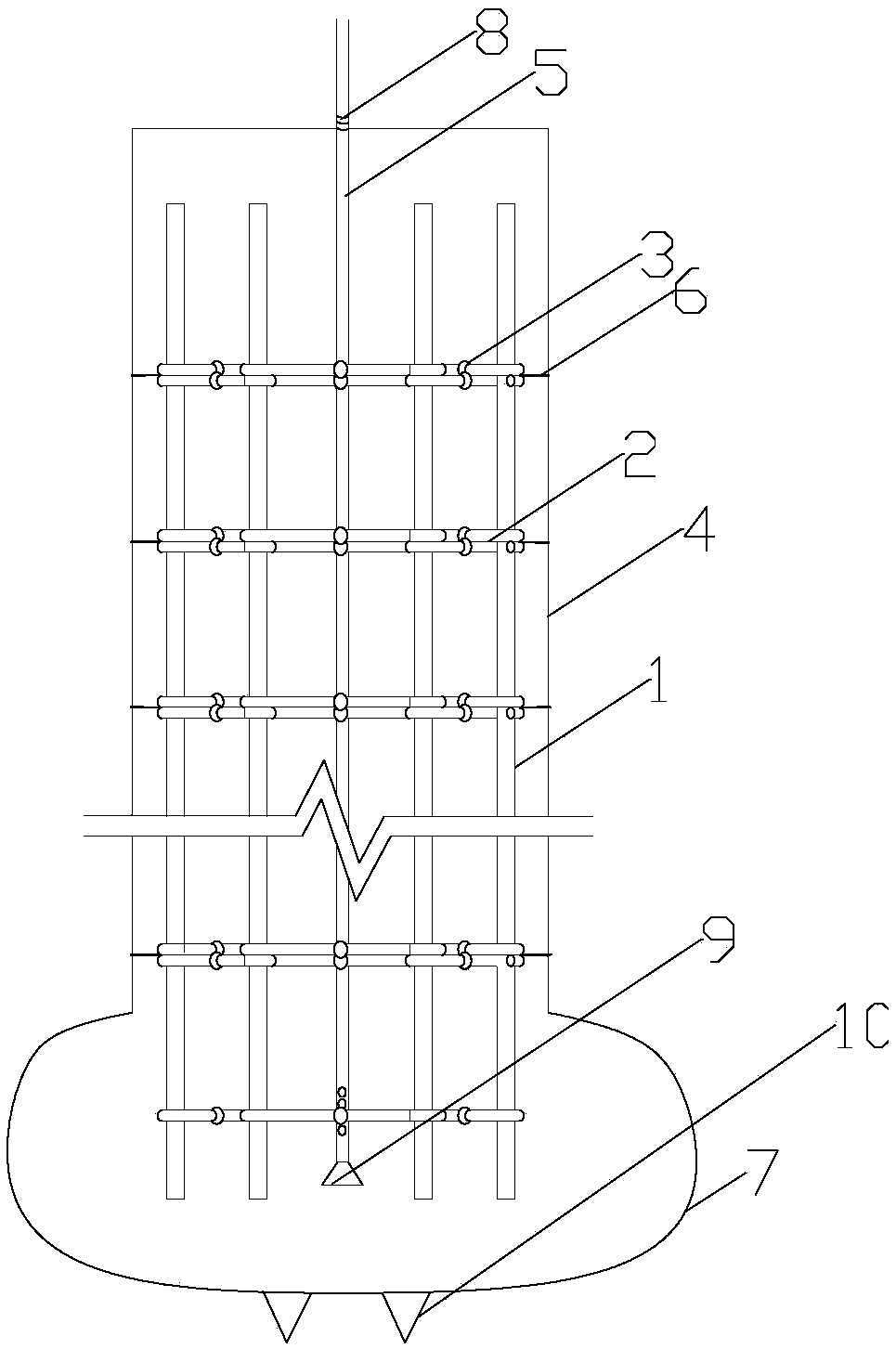

Cloth bag pile structure equipped with unfoldable steel bar framework and construction process thereof

The invention discloses a geotextile bag pile structure equipped with an unfoldable steel bar framework and a construction process thereof. A folded steel bar framework structure is adopted; the structure is shrinkable; a group of telescopic frames are arranged between two vertical bars at intervals; the telescopic frames are in articulated connection with the vertical bars through rotating headsto form a structure similar to a telescopic door; when the spacing between the vertical bars is reduced, the telescopic frames can rotate along the rotating heads and own rotating shafts; the diameterof the structure is reduced; when the cloth bag is pulled, the spacing between the vertical bars is increased, the telescopic frames are stretched until the steel bar framework is unfolded, and the diameter of the structure is increased. According to the geotextile bag pile structure equipped with the unfoldable steel bar framework and the construction process thereof, the geotextile bag is connected with the folded steel bar frame structure through composite fiber bars; when the pile structure is constructed, the pile body is firstly placed down, then the concrete is poured, the cloth bag isexpanded to generate pressure; the composite fiber bars are used for pulling the steel bar frame structure to be unfolded, and a high-strength reinforced concrete cloth bag pile structure is automatically formed.

Owner:SHANDONG JIANZHU UNIV +3

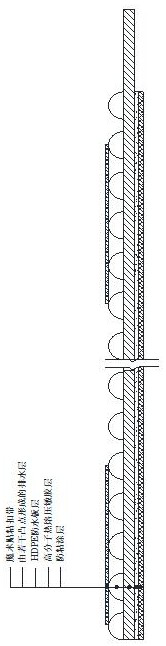

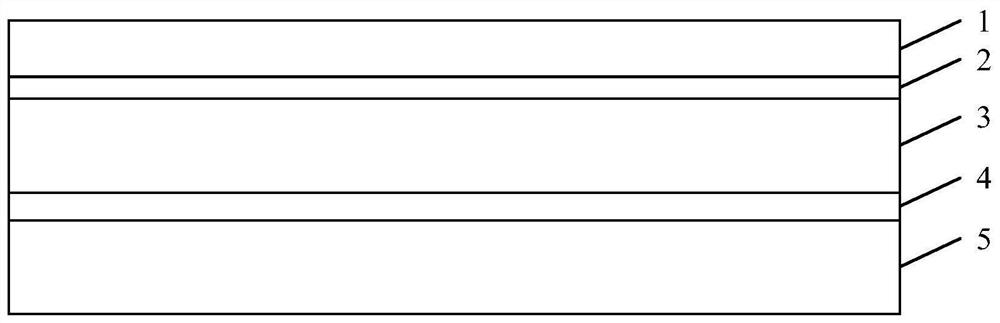

Drainage prevention combined self-adhesion waterproof plate for mining method underground tunnel and construction method of drainage prevention combined self-adhesion waterproof plate

PendingCN112228122AAvoid poor drainageAvoid scourUnderground chambersDrainageUnderground tunnelArchitectural engineering

The invention discloses a drainage prevention combined self-adhesion waterproof plate for a mining method underground tunnel. The drainage prevention combined self-adhesion waterproof plate comprisesa hook-and-loop fastener band, a drainage layer formed by multiple convex points, an HDPE waterproof plate layer, a macromolecule hot-melt pressure-sensitive adhesive layer and an anti-adhesion coating. The invention further provides a construction method of the drainage prevention combined self-adhesion waterproof plate. The waterproof plate can guide drainage, and unsmooth drainage of surrounding rock water or scouring to anchoring and shotcreting concrete is avoided. In addition, the waterproof plate can sufficiently adhere to secondary lining concrete, water channeling is avoided, the secondary lining concrete is sufficiently protected while the hidden danger of leakage is greatly reduced, the service life of the tunnel is prolonged, and the driving safety is greatly improved; and dueto the fact that the drainage effect is good, circumferential and longitudinal drainage blind pipes in a conventional method can be omitted, the construction period can be shortened, and the manufacturing cost can be reduced.

Owner:苏州凯伦高分子新材料科技有限公司

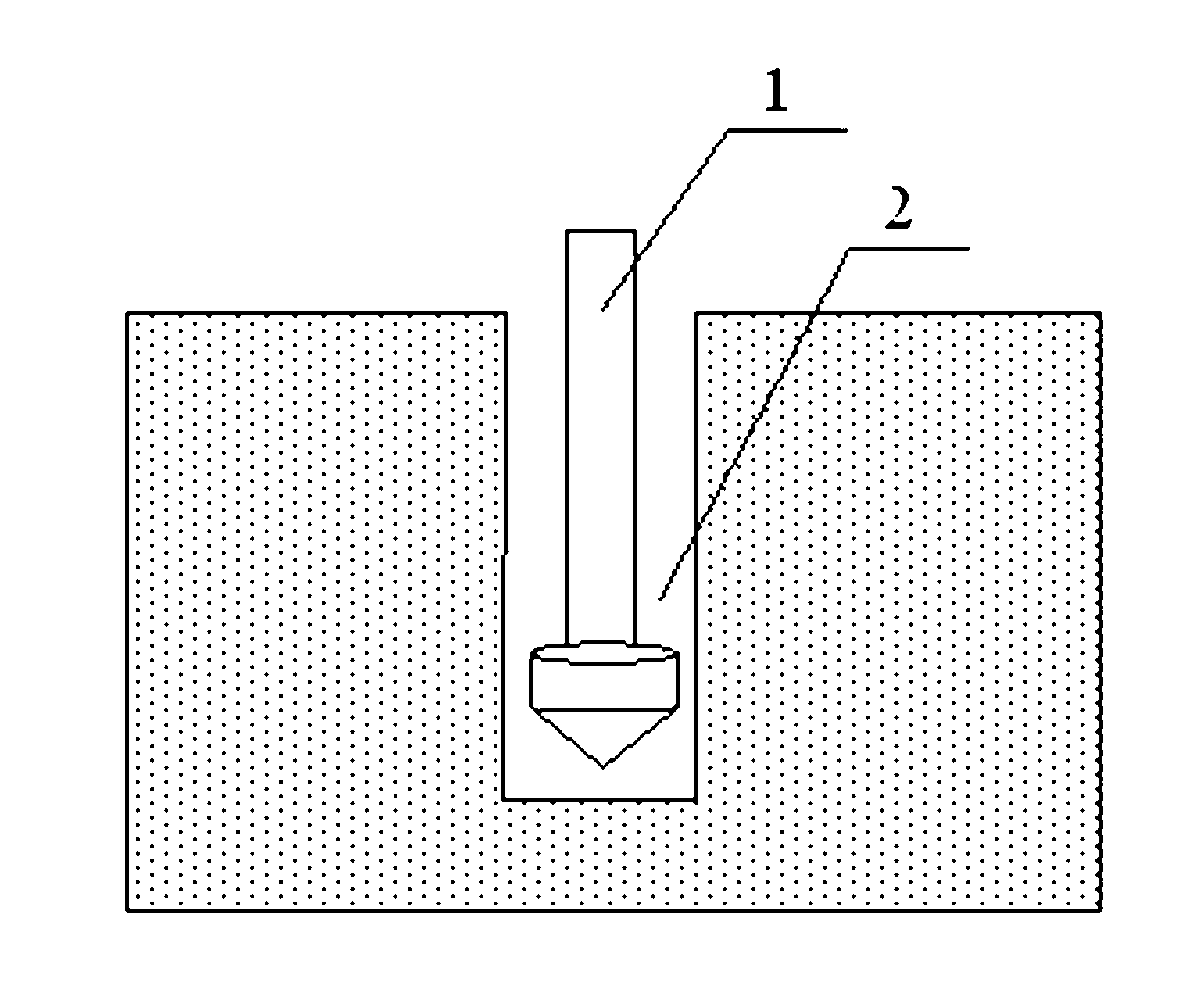

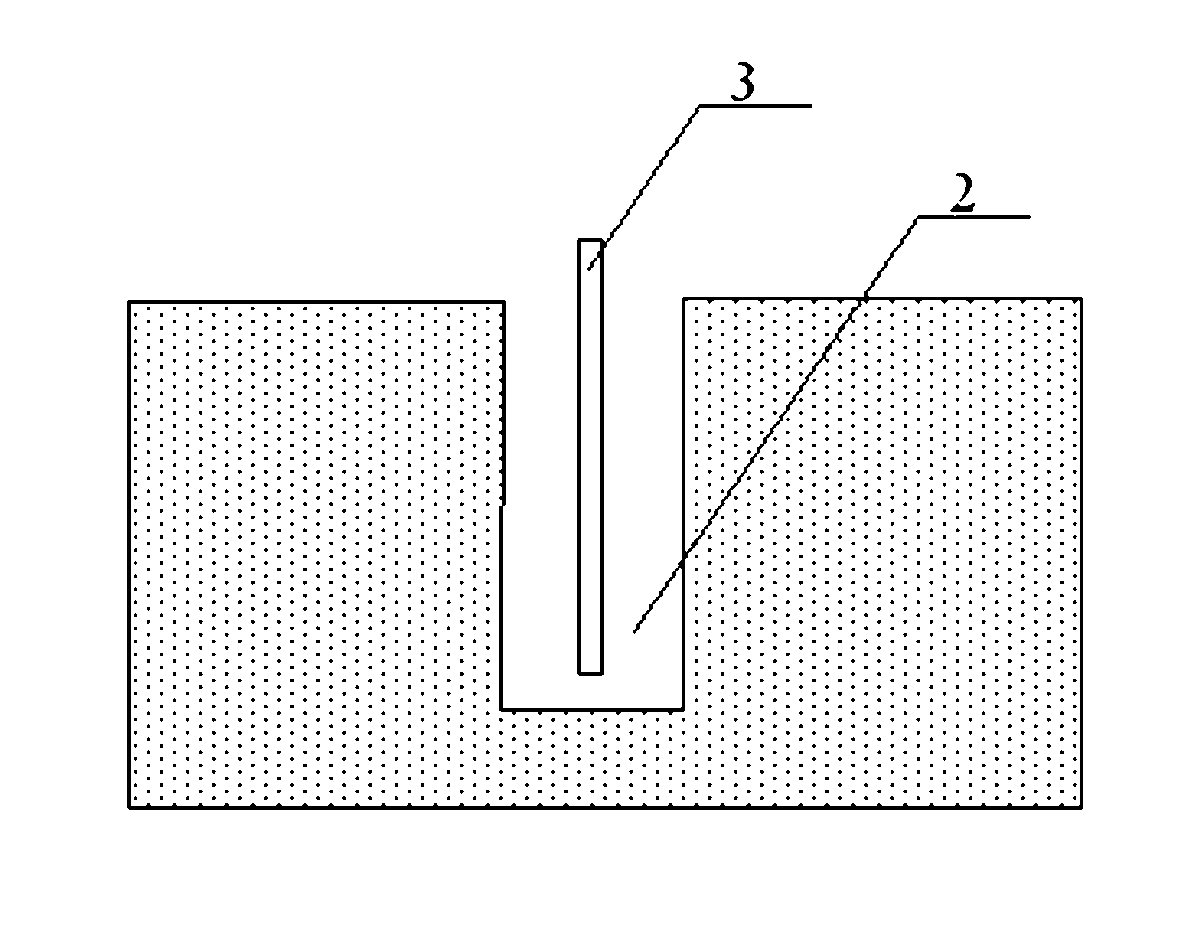

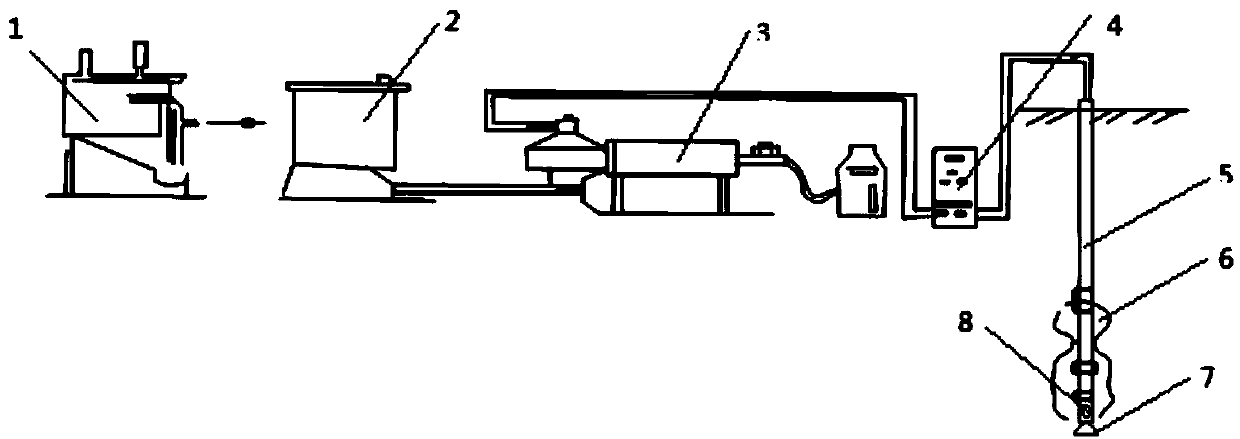

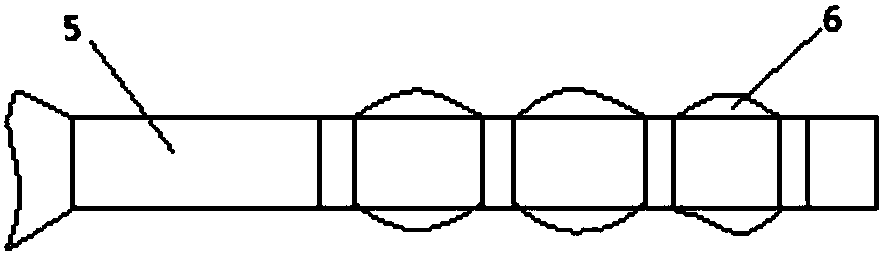

Application method of bag grouting pile in soft soil foundation of railway

InactiveCN107780308AWith drainageWaterproofRailway tracksFoundation engineeringSoil massCement grout

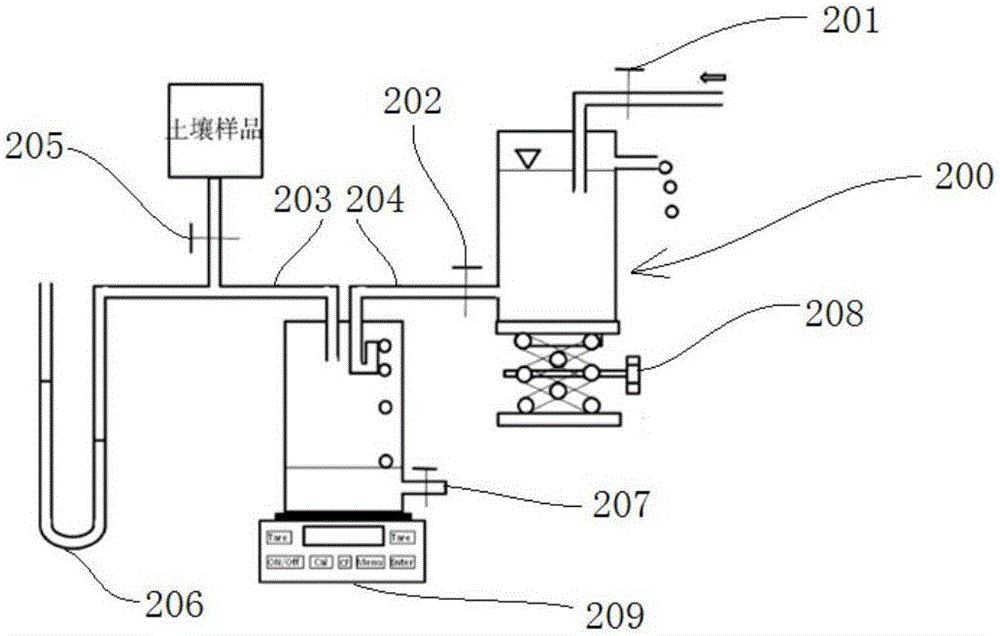

The invention discloses an application method of a bag grouting pile in a soft soil foundation of a railway. A grout mixing and storing system, a mud jacking pump and a grouting pipe applicable to high pressure are contained, wherein the grout mixing and storing system comprises a grout mixing barrel and a grout storing barrel, one end of the mud jacking pump is connected with the grout storing barrel, and the other end of the mud jacking pump is connected with the grouting pipe through a sprinkler recorder, and a geotextile bag is tied outside the grouting pipe. Cement grout is injected to form the pile under high pressure by use of the mud jacking pump and the grouting pipe, the swollen geotextile bag plays a role in compaction on peripheral soil mass through extrusion, a pile body obtained after the geotextile bag is hardened and pile space soil form a manual composite foundation, so that the stability and the bearing force of the foundation are greatly improved, defects that diffusion is easily caused during conventional grouting, the pile forming property is poor, the reinforcing range is not clear and the like are overcome, the flow direction of grout can be controllable instead of out of control, the strength of a reinforcing composite body is turned to be measurable instead of difficult to measure, engineering waste can be reduced, and grout loss and environmental pollution are avoided.

Owner:CR10BG NO 3 CONSTR

Plant cultivation method based on assembly type greening

PendingCN113133372AReduced survival rateReduced service lifeHops/wine cultivationTurf growingAgricultural engineeringGene technology

The invention discloses a plant cultivation method based on assembly type greening, and aims to solve the urgent problem about how to quickly and efficiently realize urban greening and ensure the survival rate of plants along with the increasing demands on greening of urban construction. The method comprises the following steps: determination of a cultivated plant, cultivation and shaping, transplanting and installation and later maintenance. The Lianggu assembly type greening is proposed for the first time, green plants are cultivated through a factory cultivator and planted in a customized mode according to a design drawing, and the plants such as flowers, shrubs and arbors can be selected and freely matched to achieve the needed landscape effect. The green plants planted through factory cultivation and soil layers of the green plants are integrally transplanted and installed on site, later maintenance is reduced, and therefore, a five-step integrated assembly mode including Lianggu customized design, Lianggu gene technology cultivation, Lianggu greening installation, Lianggu online detection and Lianggu operation maintenance is formed. With the adoption of the method, the greening coverage rate needed by buildings can be increased, and the building assembly rate is increased to the maximum extent.

Owner:MIANYANG LIANGGU TECH

A treatment process for high-concentration organic wastewater from a liquor factory

ActiveCN103739140BHave a reactionWith precipitationWater contaminantsMultistage water/sewage treatmentHigh concentrationTherapeutic effect

Owner:ANHUI GREEN TITAN ENVIRONMENTAL TECH

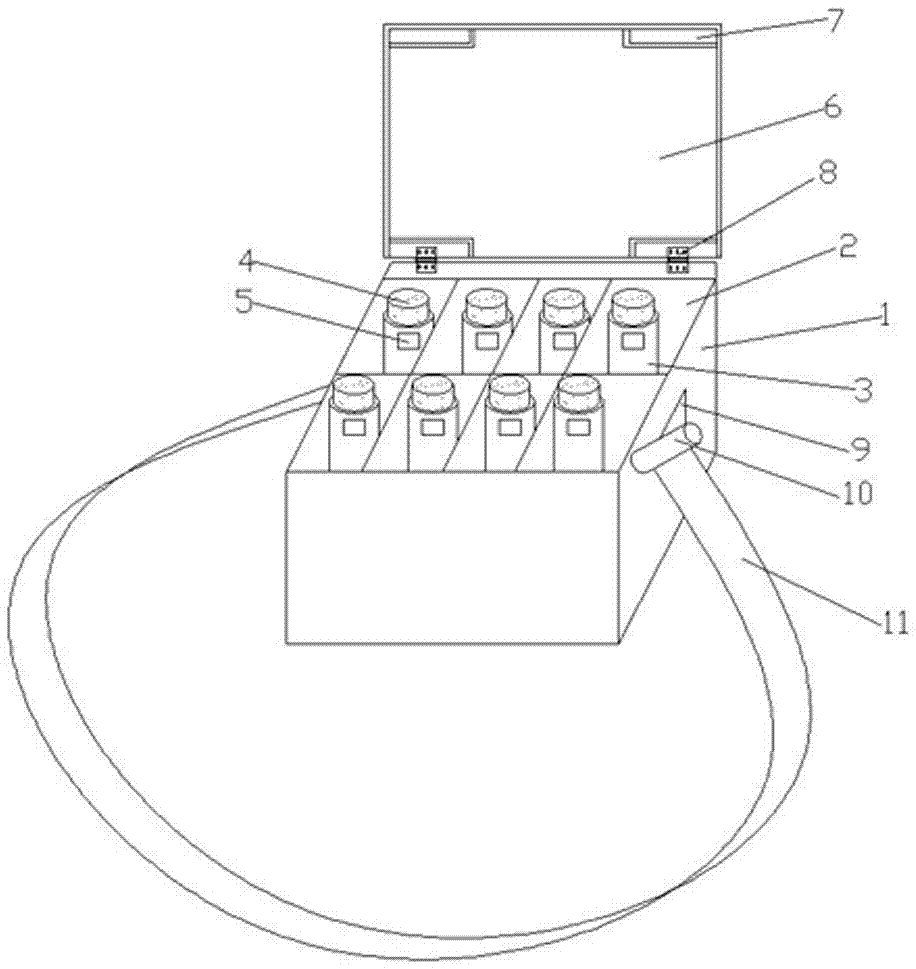

Multifunctional long-term storage bottles for seeds

InactiveCN107187709AErase anytimeWith air barrierClosure using stoppersNon-removalbe lids/coversClamp connectionEngineering

The invention discloses multifunctional long-term storage bottles for seeds. The multifunctional long-term storage bottles are characterized in that a storage box is included, wherein the storage box is horizontally placed on the ground; the inner part of the storage box is partitioned by partition plates to form separate bins; the storage bottles are placed in the separate bins separately; each of the storage bottles is hollow and cylindrical; one end of each of the storage bottles is opened; a bottle plug is inserted in one end of each of the storage bottles; a frosted piece is adhered onto the side wall of each of the storage bottles; a box cover is arranged at the end, away from the ground, of the storage box; the box cover is rectangular; a shockproof pad is adhered onto each of the four corners of the box cover; each of the connecting parts of the box cover and the storage box is fixed through a hinge; a pin hole is formed in one side wall of the storage box; the pin hole is in clamping connection with a clamping head; and the clamping head is fixedly connected with a backstrap. The multifunctional long-term storage bottles for seeds have the advantages that the operation is simple, the utilization rate is high and multiple functions are achieved; besides, the multifunctional long-term storage bottles for seeds are suitable for storing seeds for a long time, particularly suitable for storing seeds in a classified and concentrated manner, and meanwhile the bottle plugs are made from oak wood, thereby being air-permeable and excellent in the water retention property.

Owner:安徽富牧通生物科技有限公司

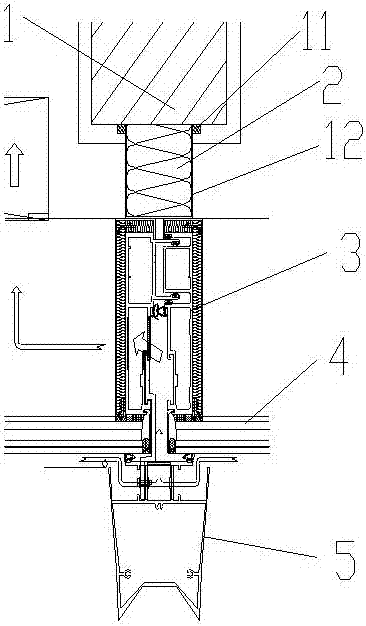

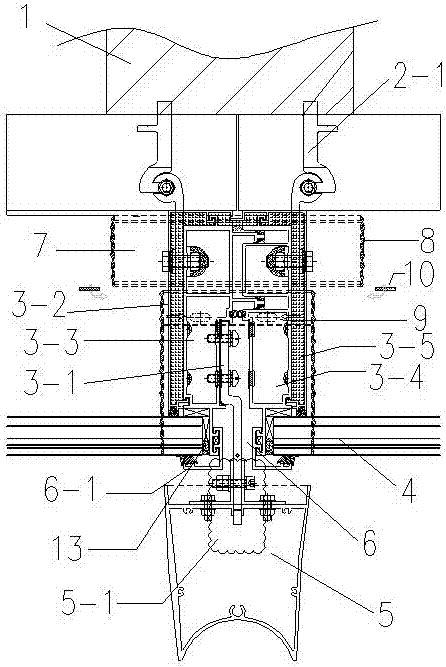

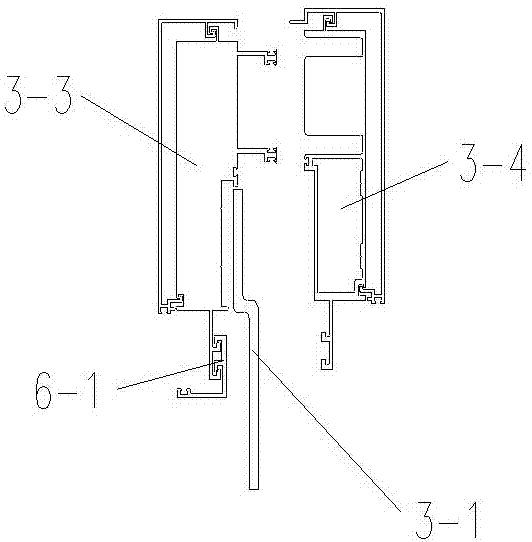

Fireproof joint structure of tower curtain wall floor plate

ActiveCN107119838AImplement fire compartmentsWith drainageWallsClimate change adaptationFloor slabEngineering

The invention discloses a fireproof joint structure of a tower curtain wall floor plate. The fireproof joint structure comprises a wall, a fireproof rock wool plate, an aluminum alloy transverse and vertical frame, double-layer tampered glass and an aluminum alloy decorative strip from inward to outward. Anodized aluminum alloy hanging weights are arranged in the fireproof rock wool plate. One sides of the anodized aluminum alloy hanging weights are fixed to the wall through embedded lines arranged on the wall, and other sides of the anodized aluminum alloy hanging weights are fixed to the interior of the aluminum alloy transverse and vertical frame. The double-layer tampered glass is arranged between the aluminum alloy transverse and vertical frame and the aluminum alloy decorative strip. A channel for connecting the aluminum alloy transverse and vertical frame with the aluminum alloy decorative strip is formed in the double-layer tempered glass. A fixing piece used for fixing the aluminum alloy transverse and vertical frame on the double-layer tempered glass is arranged in the channel. Aluminum alloy decorative strip fixing pieces are arranged in the aluminum alloy transverse and vertical frame, and the bottom ends of the aluminum alloy decorative strip fixing pieces are fixed to the aluminum alloy decorative strip through bolts. The fireproof joint structure of the tower curtain wall floor plate is fireproof, can sluice water and has good heat retaining property.

Owner:THE SECOND CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU

Drain device

The invention relates to a drain device, which comprises a body, a top cover assembly and a bottom cover. The body is provided with an inner space, and a plurality of permeable parts running through the inner space. The top cover assembly is separably arranged on the top of the body and comprises a top cover and a plurality of connecting pieces. The connecting pieces extend a certain length from the bottom of the top cover. The bottoms of the connecting pieces are connected with each other. Each connecting piece is provided with an upper elastic sheet and a lower elastic sheet. The upper and lower elastic sheets are provided with corresponding convex parts towards the outside of the top cover. The bottom cover is separably arranged on the bottom of the body. A certain space is formed between the bottom cover and the body. The bottom cover is provided with a permeable part. Due to the combination of the components, an outer edge of each convex part protrudes out of the body and an outer side wall of the bottom cover, and can be applied with a force so that the convex part inwards contracts toward the inside of the top cover, and the convex part can be automatically popped up when the external force is eliminated so that the outer edge of the convex part protrudes out of the body and the outer side wall of the bottom cover again.

Owner:THANK GOD ENTERPRISE

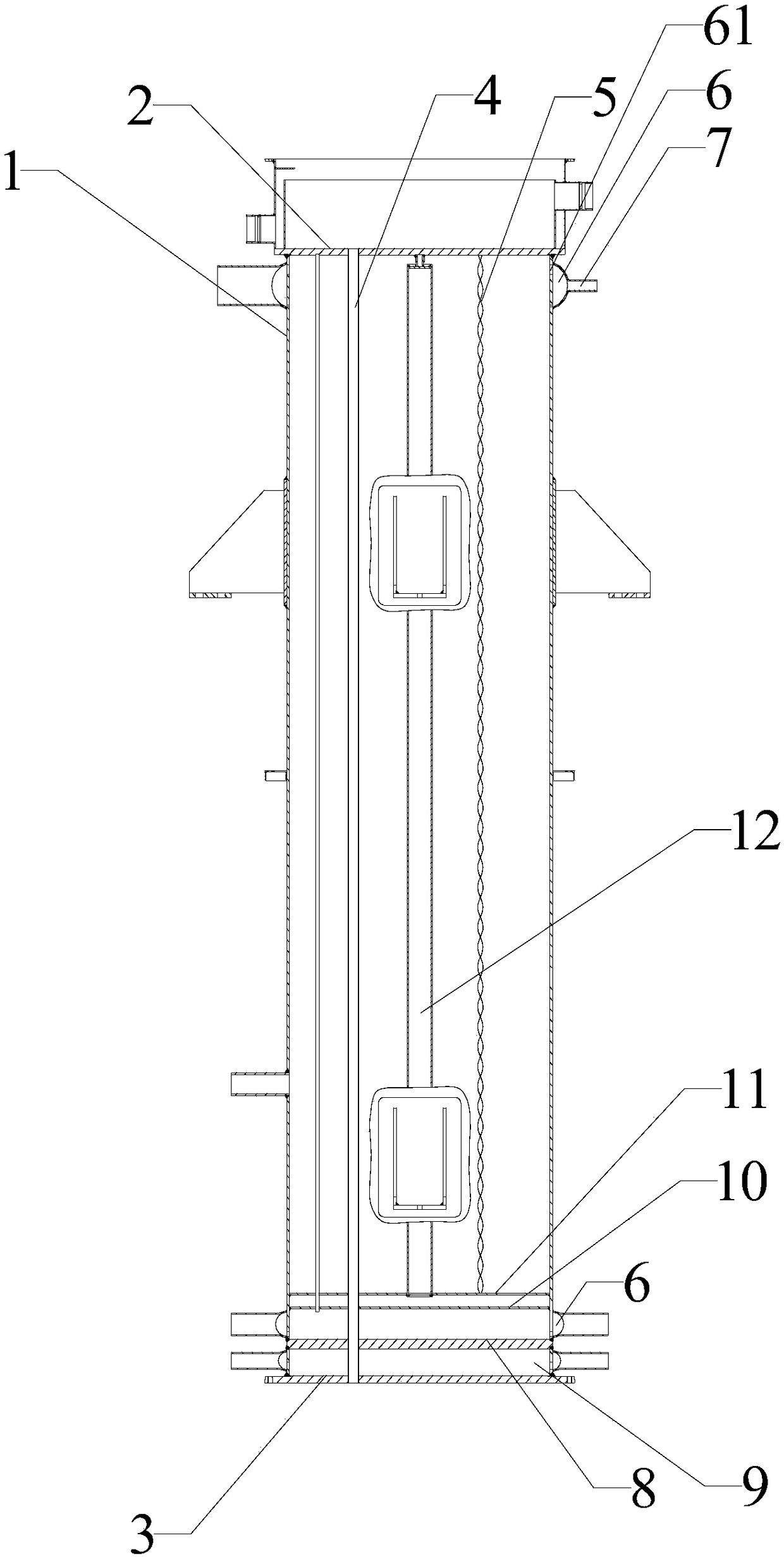

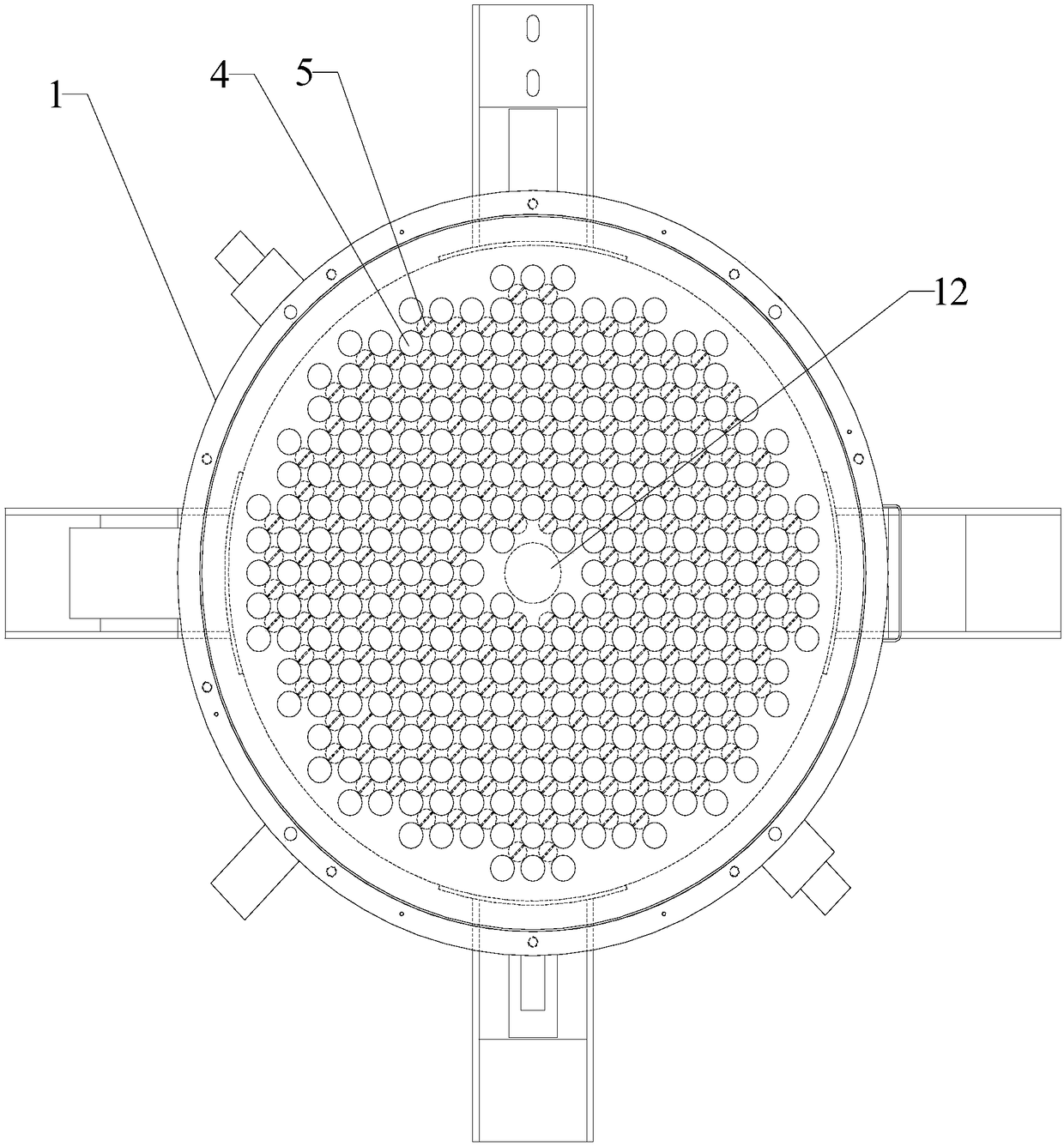

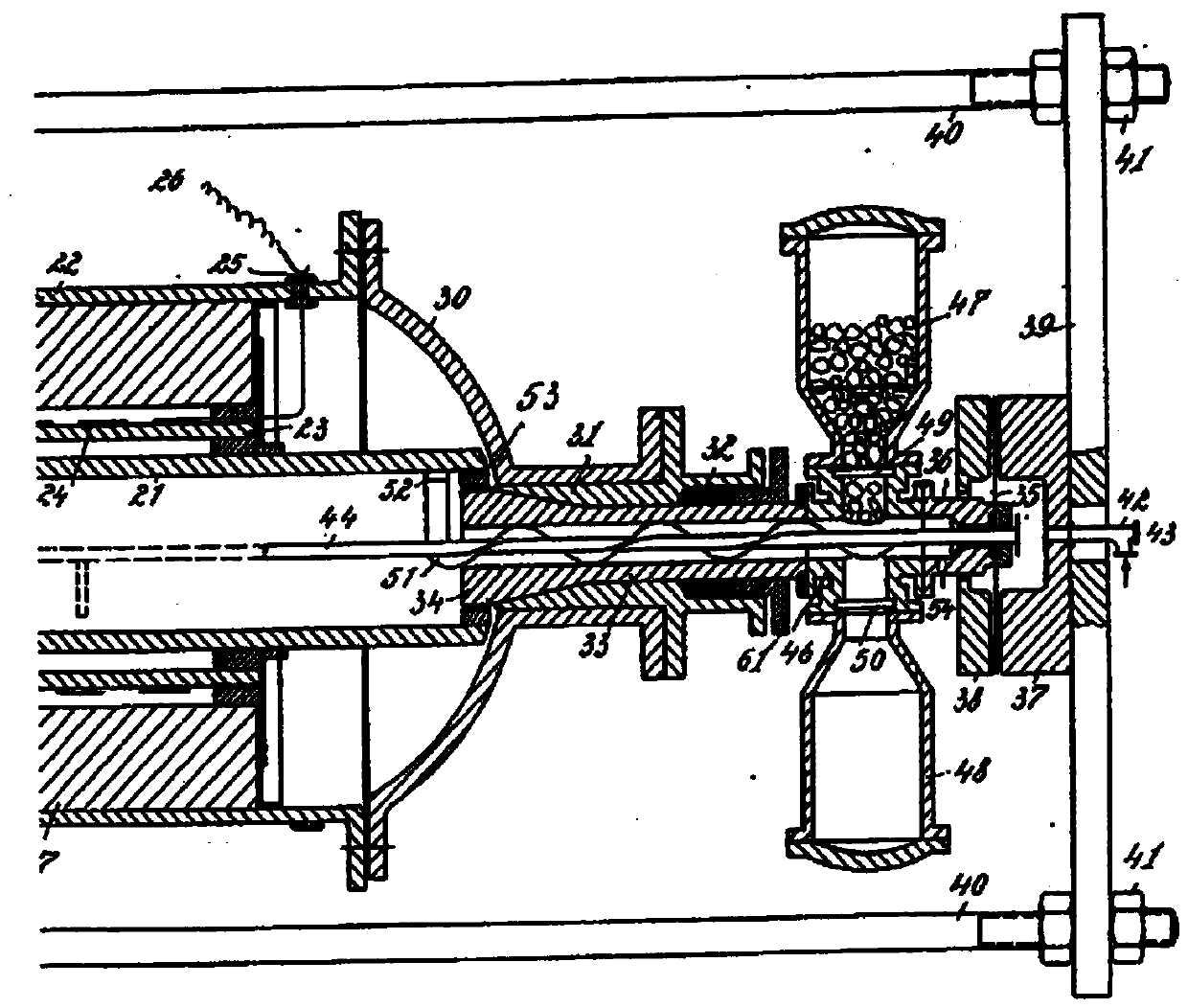

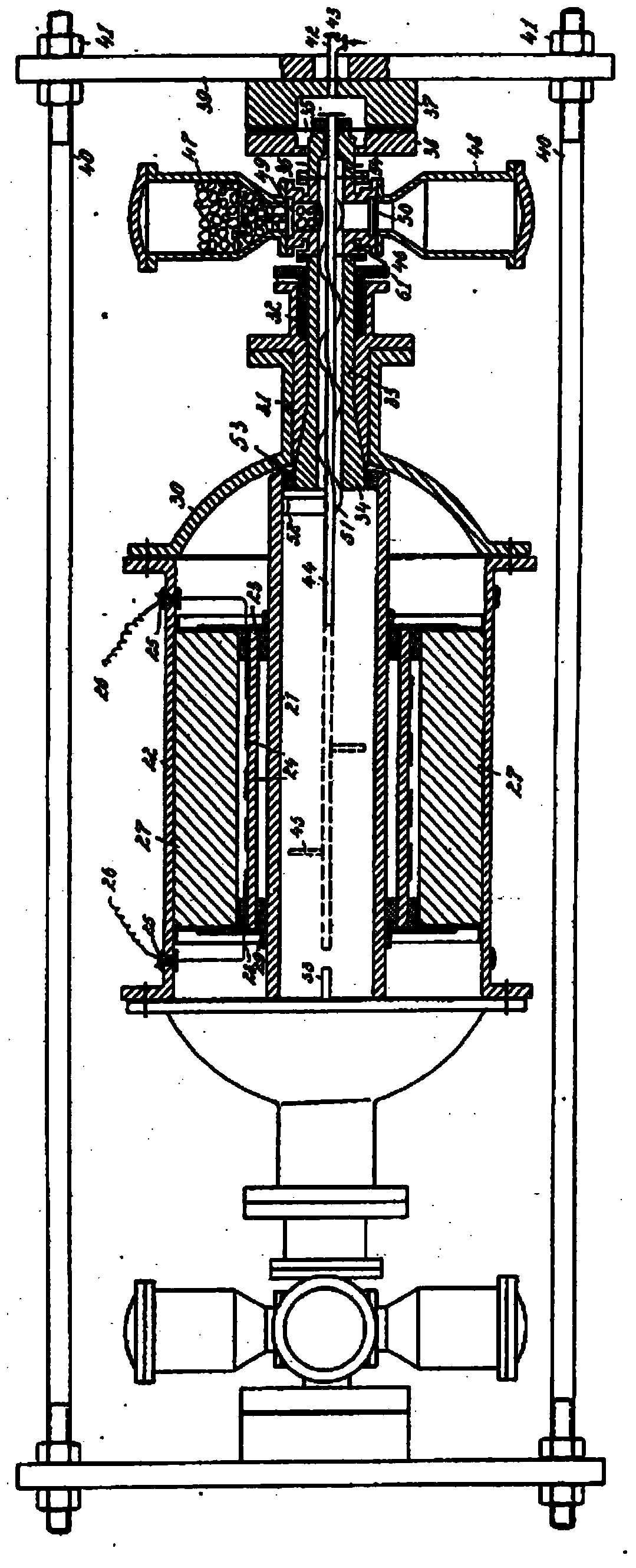

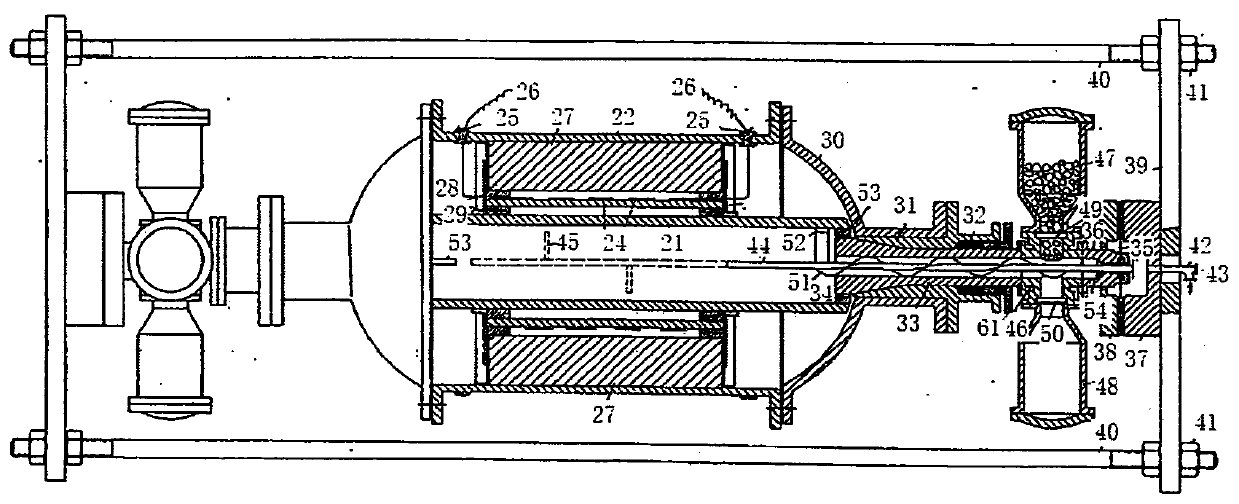

Dry type tube ice evaporator

The invention relates to the technical field of refrigeration equipment, in particular to a dry type tube ice evaporator, which comprises a barrel body. An upper pipe plate and a lower pipe plate arearranged at two ends of the barrel body; multiple heat exchange pipes in a vertical direction are uniformly distributed in the barrel body; two ends of the heat exchange pipes penetrate through and are connected onto the upper pipe plate and the lower pipe plate; a spoiler plate is arranged between each two adjacent heat exchange pipes and spirally rise around a middle axis; and two sides of eachspoiler plate are connected onto the side surfaces of each two adjacent heat exchange pipes. The dry type tube ice evaporator provided by the invention has the beneficial effects that the spoiler plates of the dry type tube ice evaporator provided by the invention have flow guiding and disturbing functions, a refrigerating fluid needs to circularly flow around the heat exchange pipes according toa set flowing direction, and the evaporation of the refrigerating fluid is accelerated, so that a heat exchange effect of the evaporator is improved.

Owner:FUJIAN SNOWMAN

High-activity nanoscale tricalcium phosphate production reaction kettle and using method thereof

PendingCN111003698AWith rotation functionDoes not affect reaction productionMaterial nanotechnologyPhosphorus compoundsTemperature controlPhosphoric acid

The invention discloses a high-activity nanoscale tricalcium phosphate production reaction kettle, and belongs to the technical field of nanoscale tricalcium phosphate preparation devices, wherein theproduction reaction kettle comprises a frame body part composed of a supporting plate, a supporting profile and a connecting piece, and a reaction part composed of a first reaction container, a second reaction container and a third reaction container. The reaction kettle has a rotating function, can realize full reaction, and also has the functions of drainage, drying, temperature control and thelike to improve the reaction precision; when the two groups of reaction containers work simultaneously, the yield can be effectively improved, and when one group of reaction containers work, the other group of idle reaction containers can be maintained or overhauled; and when a single container is damaged, the reaction production of the other group of containers is not influenced.

Owner:江阴市星宇化工有限公司

Roof board for planted sloping roof

InactiveCN101696592BUndamagedImprove drainageRoof covering using slabs/sheetsReceptacle cultivationElectricitySEMI-CIRCLE

The invention discloses a roof board for a planted sloping roof. The bottom surface of an inverse echelon-shaped electricosmotic board is 25 to 35cm away from a bottom board of a prismatic support, and an air sandwich layer is formed between the inverse echelon-shaped electricosmotic board and the bottom board of the prismatic support. The bottom board of the prismatic support is provided with a seepage hole which is of a semi-circle shape and forms a penetration pore channel along the gradient direction of the roof. During the drainage, the inverse echelon-shaped electricosmotic board is connected with a DC power supply, an interface in an uphill direction is connected with an anode of the power supply, and an interface in a downhill direction is connected with a cathode of the power supply. During the electroosmosis, the voltage is controlled to be between 30 and 45V. The roof board has the characteristics of simple structure and convenient construction.

Owner:朱奎

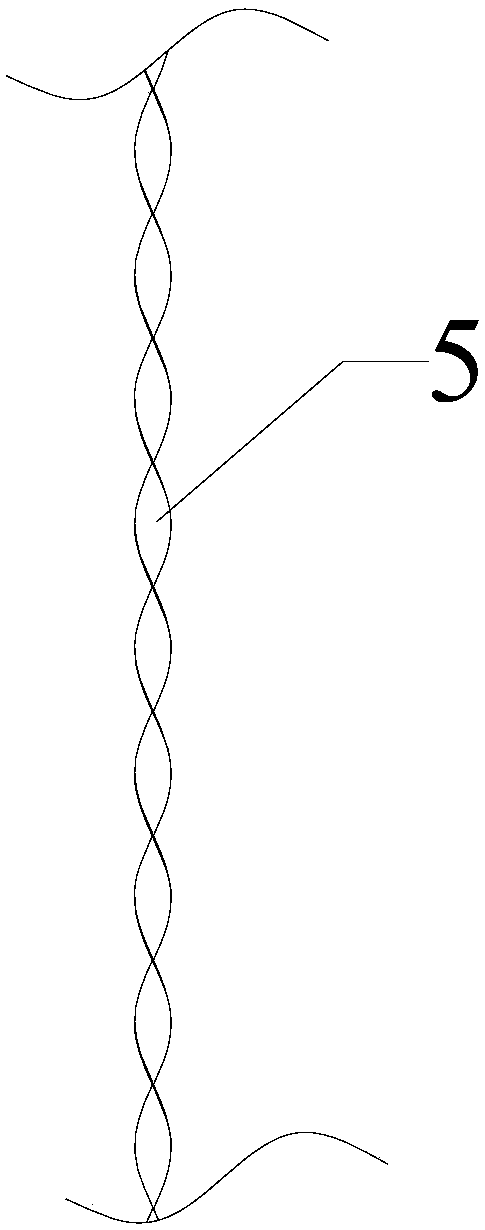

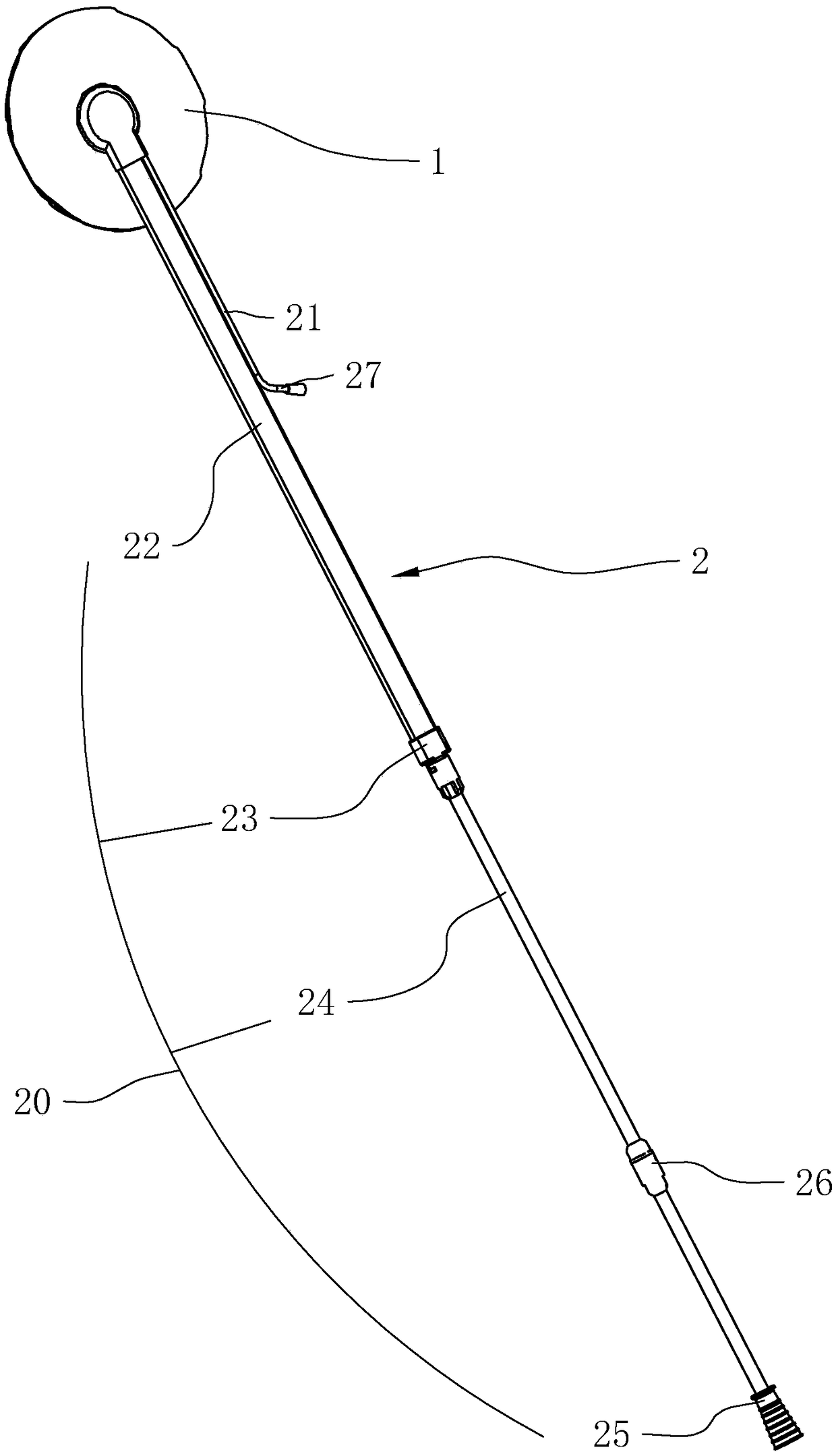

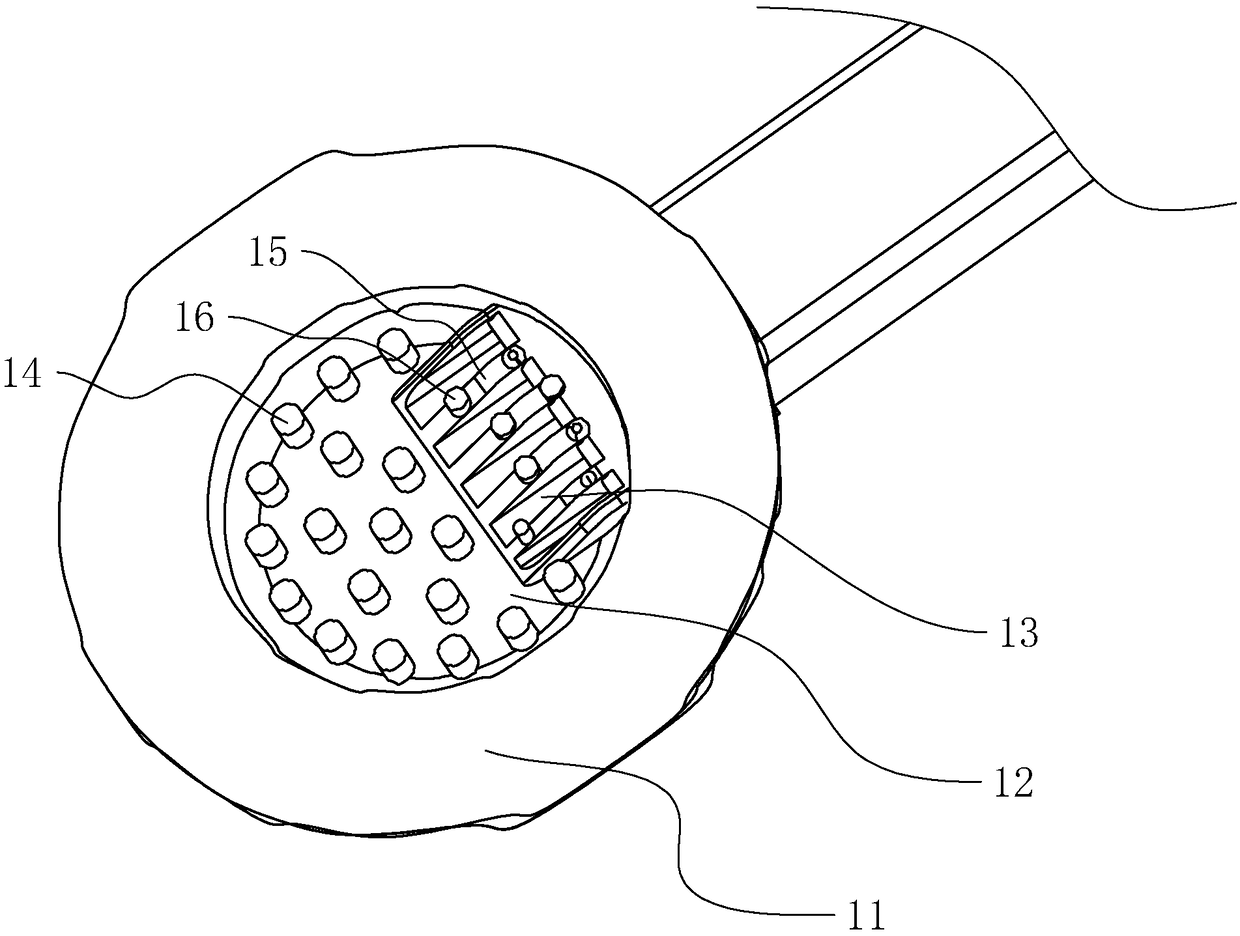

Sucker line device

PendingCN109481749APrevent air leakageExtended use timeIntravenous devicesSuction drainage systemsIn planeStructural engineering

The invention discloses a sucker line device and relates to the technical field of medical instruments. The sucker line device is technically characterized by comprising a sucker and a guide-out lineconnected to the sucker; the guide-out line includes a flat tube connected at one end to the sucker; an upper flat wall in plane form, a lower flat wall parallel to the upper flat wall and a connection wall to connect the upper and lower flat walls are arranged in the flat tube; ribs are arranged between the upper flat wall and the lower flat wall along the length direction; the ribs on the lowerflat wall and the ribs on the upper flat wall are staggered. The sucker line device has the advantages that a patient feels more comfortable after lying down and ventilation is stabilized.

Owner:SUNEETEK XIAMEN MEDICAL EQUIP CO LTD

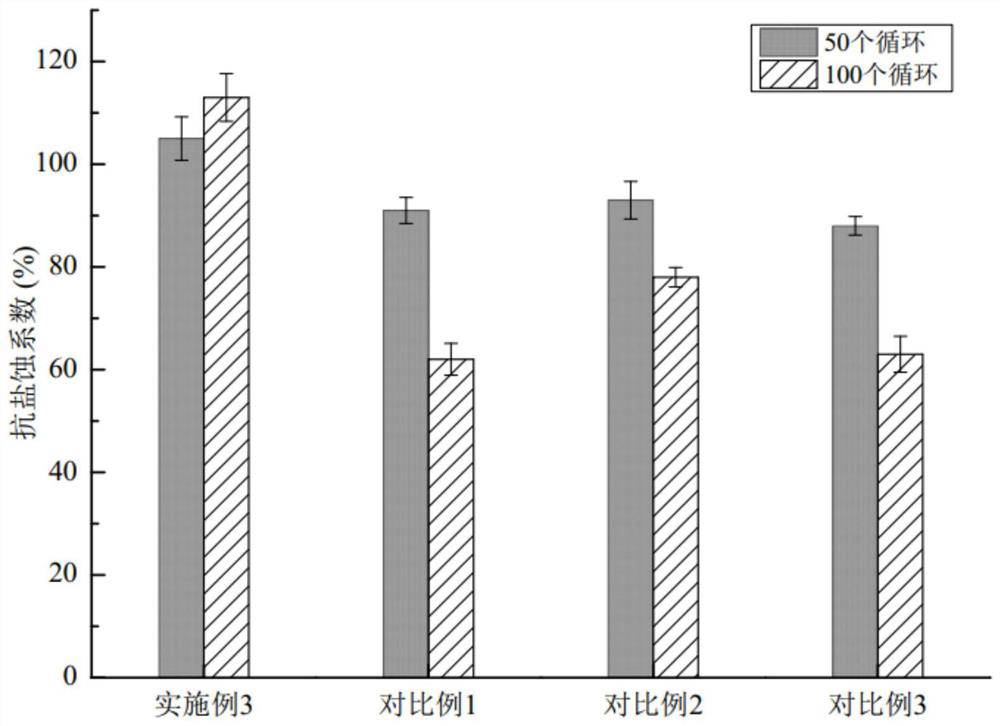

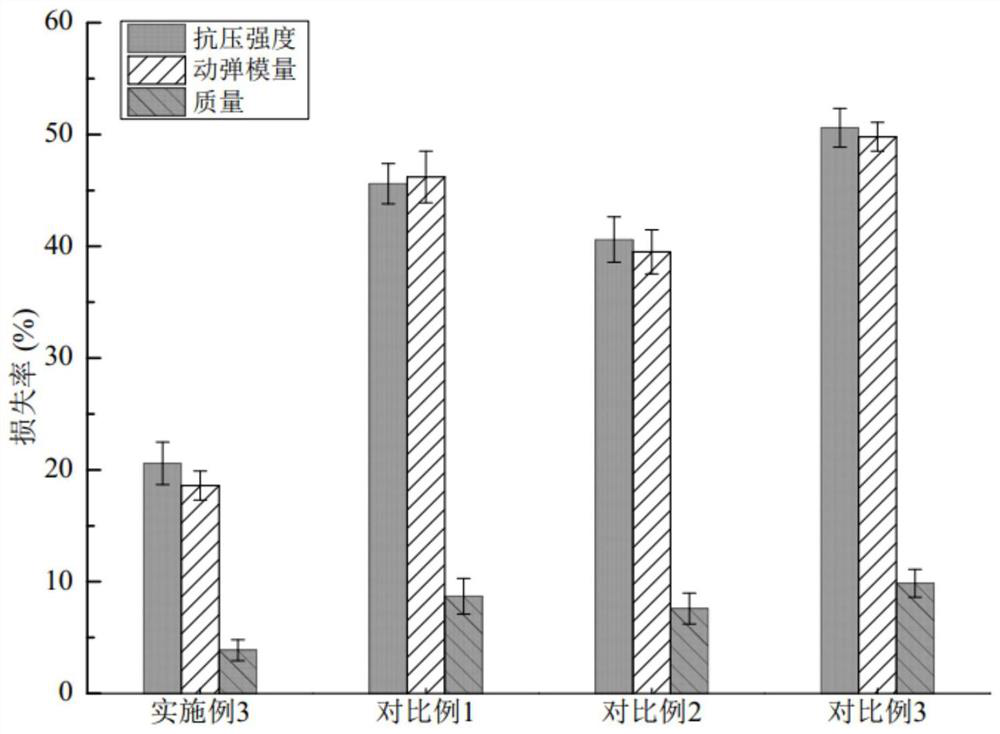

Preparation method of trench with anti-seepage function

The invention provides a preparation method of a trench with an anti-seepage function, and belongs to the technical field of constructional engineering.The preparation method comprises the steps that a U-shaped foundation trench is provided, and a concrete layer is laid at the bottom of the U-shaped foundation trench; providing an anti-seepage film, and laying the anti-seepage film on the surface of the concrete layer; providing a lime soil cushion layer, and paving the lime soil cushion layer on the surface of the impermeable film; providing concrete slurry, and pouring the concrete slurry into the U-shaped mold bound with the U-shaped reinforcing ribs to form a concrete layer; the concrete slurry contains 2-5 wt% of an additive, and the additive comprises calcium lignosulphonate, short carbon fibers, triethylene glycol monomethyl ether and n-propyl thiophosphoric triamide. The preparation method provided by the invention can effectively solve the problems of leakage and corrosion of a foundation caused by waste liquid, leaked liquid and the like, improves the stability and strength of the trench structure, improves the anti-leakage effect, remarkably enhances the corrosion (salt corrosion) resistance and low-temperature anti-freezing and anti-cracking performance, is easy to construct and maintain in the later period, and effectively prolongs the service life of the trench.

Owner:宁夏兴昊永胜盐业科技有限公司

An enhanced composite functional pavement structure and its laying method

ActiveCN113338107BImprove structural performanceWith drainageIn situ pavingsCeramicwarePolymer sciencePolyurethane adhesive

The invention provides an enhanced composite functional pavement structure and a laying method thereof. The pavement structure comprises: an upper layer of a mixture, a first polyurethane bonding layer, a middle surface layer of a mixture, and a second polyurethane bonding layer arranged sequentially from top to bottom. layer, the lower layer of the mixture; the upper layer of the mixture is PERS-13, the upper layer of the anti-scattering polyurethane porous elastic mixture; the first polyurethane adhesive layer is a slow-reaction two-component polyurethane adhesive layer; the middle layer of the mixture is The surface layer of the polyurethane porous elastic mixture is PERS‑20; the second polyurethane adhesive layer is a slow-response two-component polyurethane stress absorption layer; the lower layer of the mixture is the lower layer of the polyurethane porous elastic mixture PERS‑25. The pavement structure provided by the invention has strong compound functions such as drainage, deicing, noise reduction, etc., can effectively prevent the problem of debonding of the porous elastic mixture surface layer, and prolong the service life of the pavement structure.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT

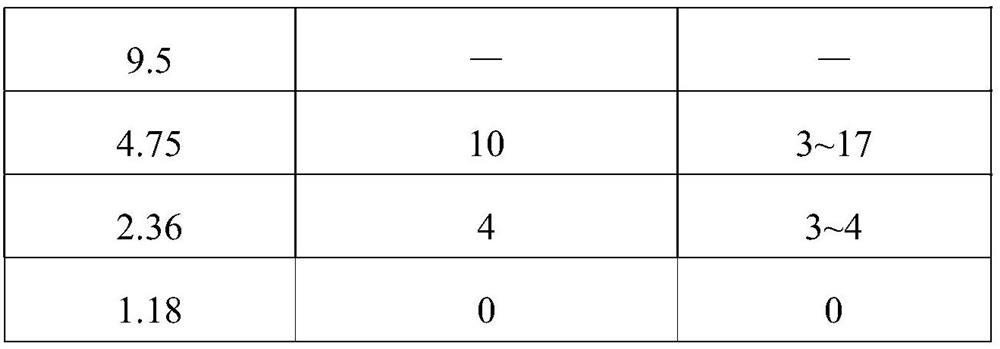

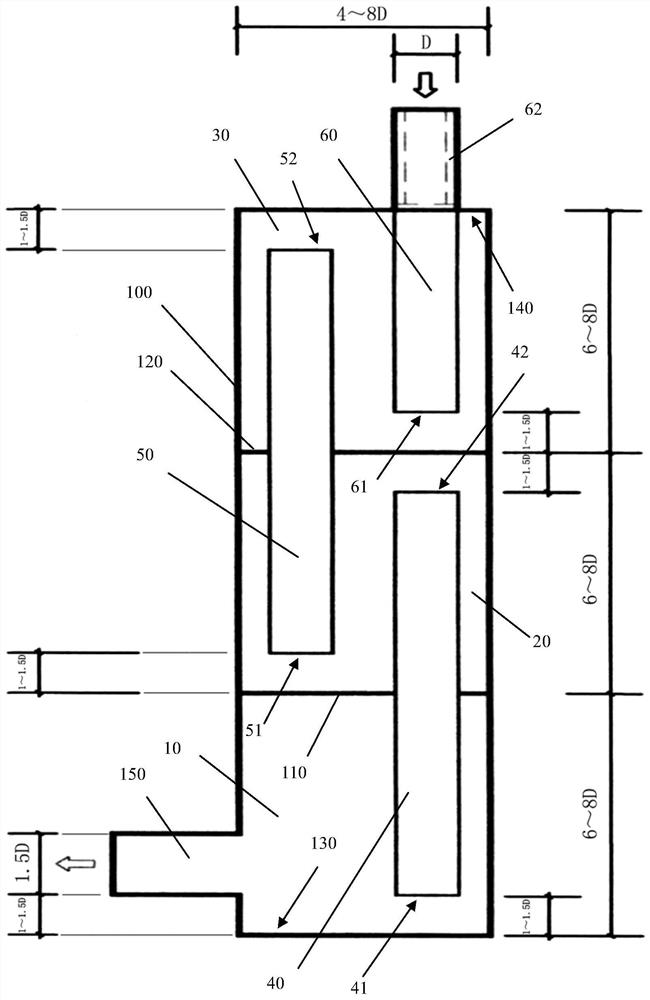

Multi-stage compressed air silencer and application

PendingCN114876882ASimple structureReduce volumeInternal combustion piston enginesPump componentsMufflerMechanics

The invention discloses a multi-stage type compressed air silencer and application, the multi-stage type compressed air silencer comprises a shell and an air inlet pipeline, and at least three continuous cylindrical cavities are formed in the shell in the axial direction; the adjacent chambers are separated by chamber walls and are communicated through a connecting pipeline; the adjacent connecting pipelines are arranged in a staggered mode in the radial direction. One end of the air inlet pipeline extends into the first cavity; in the airflow direction, the chambers are used as a first-stage chamber, a second-stage chamber,... and a final-stage chamber, and an air outlet pipeline is arranged in the final-stage chamber; along the radial direction, the air inlet pipeline and the connecting pipeline for connecting the first-stage chamber and the second-stage chamber are arranged in a staggered manner; the inner diameter of the air inlet pipeline is D, the inner diameters of the first-stage cavity, the second-stage cavity,... and the last-stage cavity are 4-8D, and the depth of the cavity is 6-8D; the inner diameters of the connecting pipeline and the air inlet pipeline are equal; the distance between the end of the air inlet pipeline and the chamber wall of the first-stage chamber opposite to the end of the air inlet pipeline is 1-1.5 D; the distance between the end heads on the two sides of each connecting pipeline and the chamber wall of the corresponding chamber right opposite to the connecting pipeline is 1-1.5 D.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com