Dry type tube ice evaporator

An evaporator and dry technology, applied in the field of dry tube ice evaporators, can solve the problems of unstable heat exchange performance, large refrigerant charge, uneven distribution of refrigerant, etc. The effect of reducing the amount of ice and shortening the freezing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

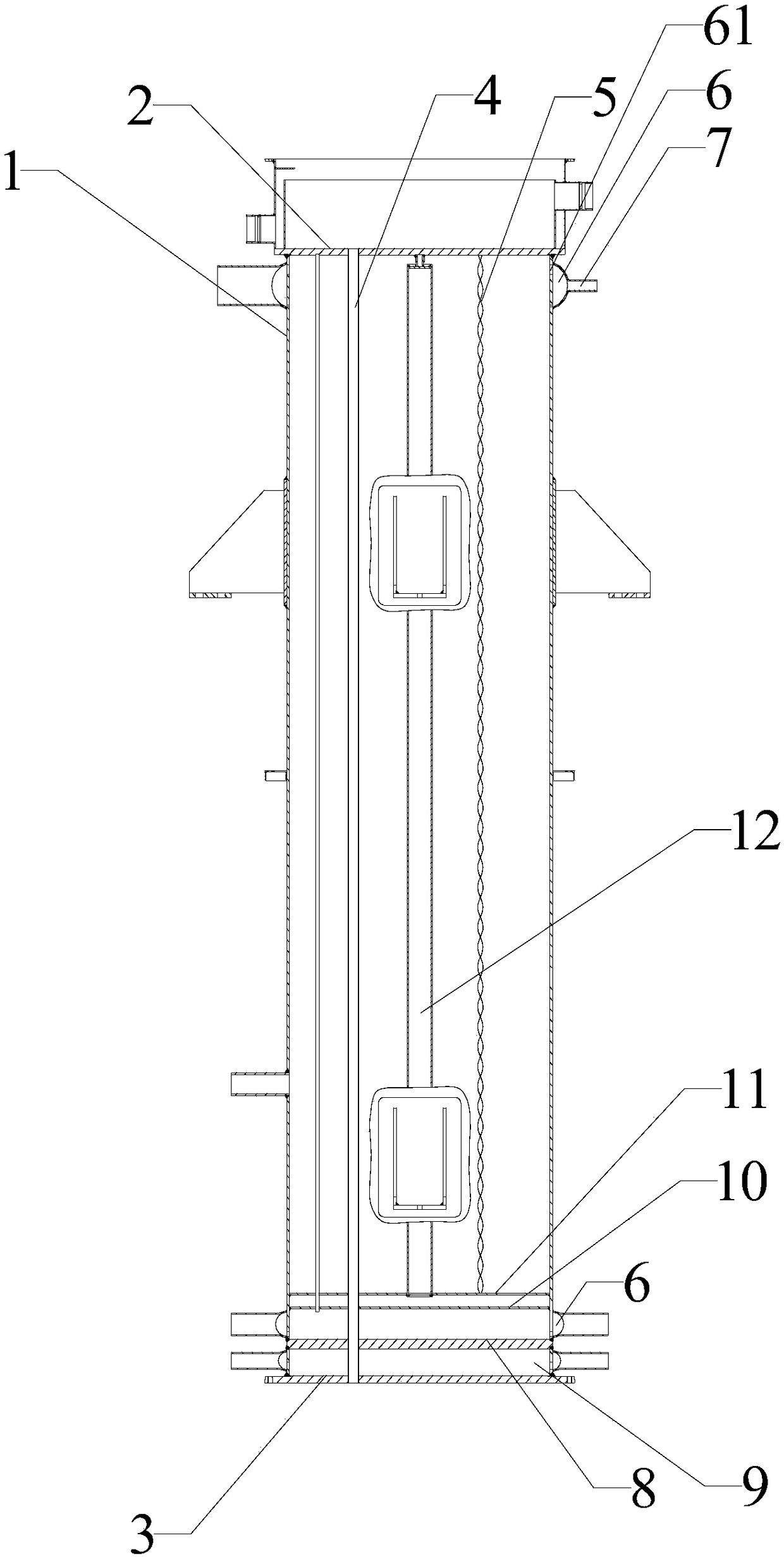

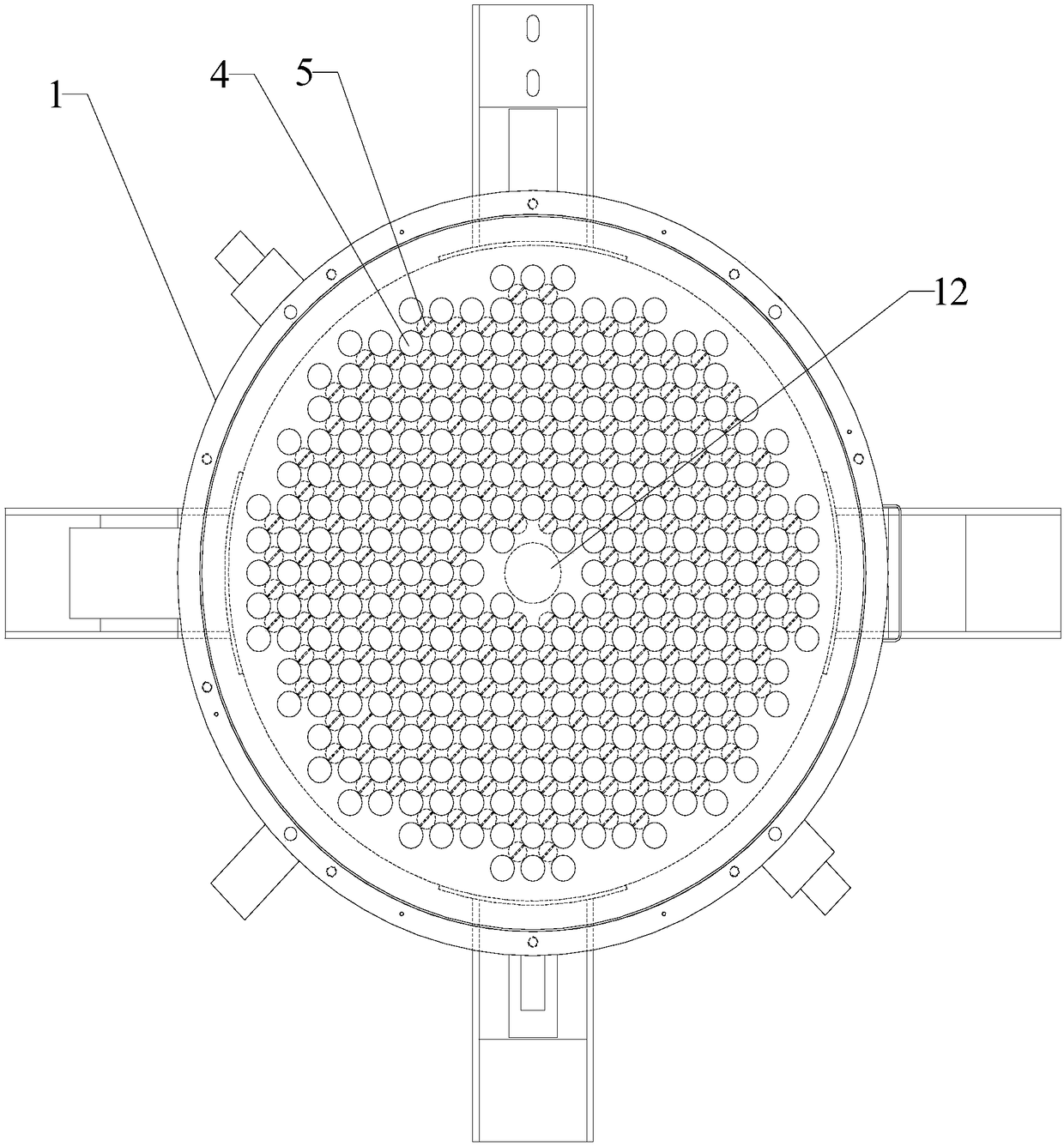

[0030] A dry tube ice evaporator, the dry tube ice evaporator includes a cylinder 1, the two ends of the cylinder 1 are respectively provided with an upper tube plate 2 and a lower tube plate 3, and the inside of the cylinder 1 is uniform A plurality of heat exchange tubes 4 in the vertical direction are distributed, and the two ends of the heat exchange tubes 4 pass through and connect to the upper tube sheet 2 and the lower tube sheet 3 respectively;

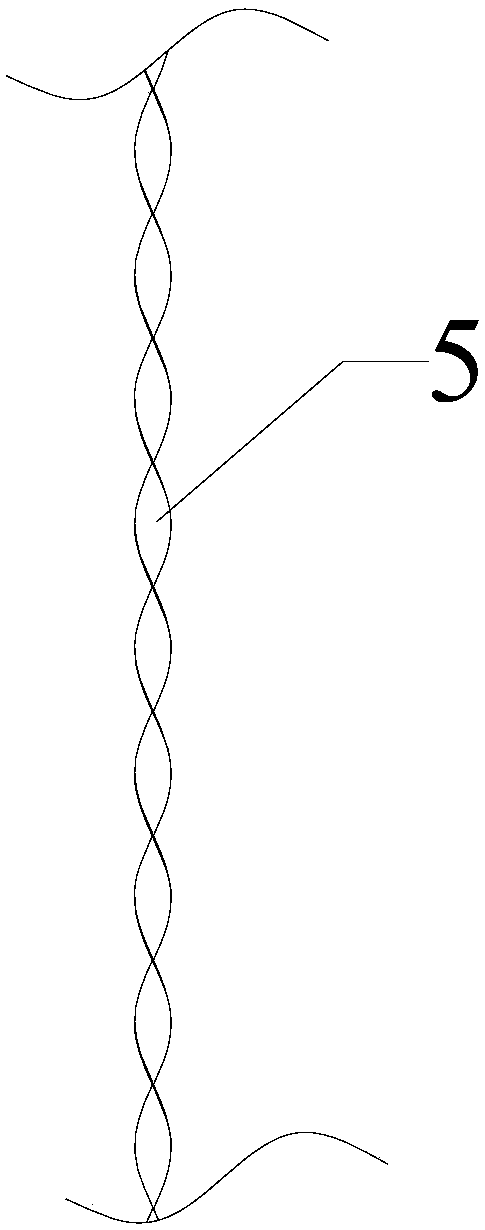

[0031] A spoiler 5 is arranged between the adjacent heat exchange tubes 4, and the spoiler 5 spirally rises around the central axis, and the two sides of the spoiler 5 are respectively connected to the side surfaces of the adjacent heat exchange tubes 4 .

[0032] The cylinder body 1 is respectively provided with a coil 6 horizontally surrounding the cylinder body 1 near the upper tube plate 2 and the lower tube plate 3, and the coil tube 6 is provided with a through hole communicating with the inside of the cylinder body 1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com