Patents

Literature

71 results about "Fluid need" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Although you might be familiar with the drink eight, eight-ounce glasses of water per day rule, you may need slightly more throughout the day, advises the Mayo Clinic. Because your fluid needs increase with body size, men should drink about 13 cups of water per day while women should drink nine cups.

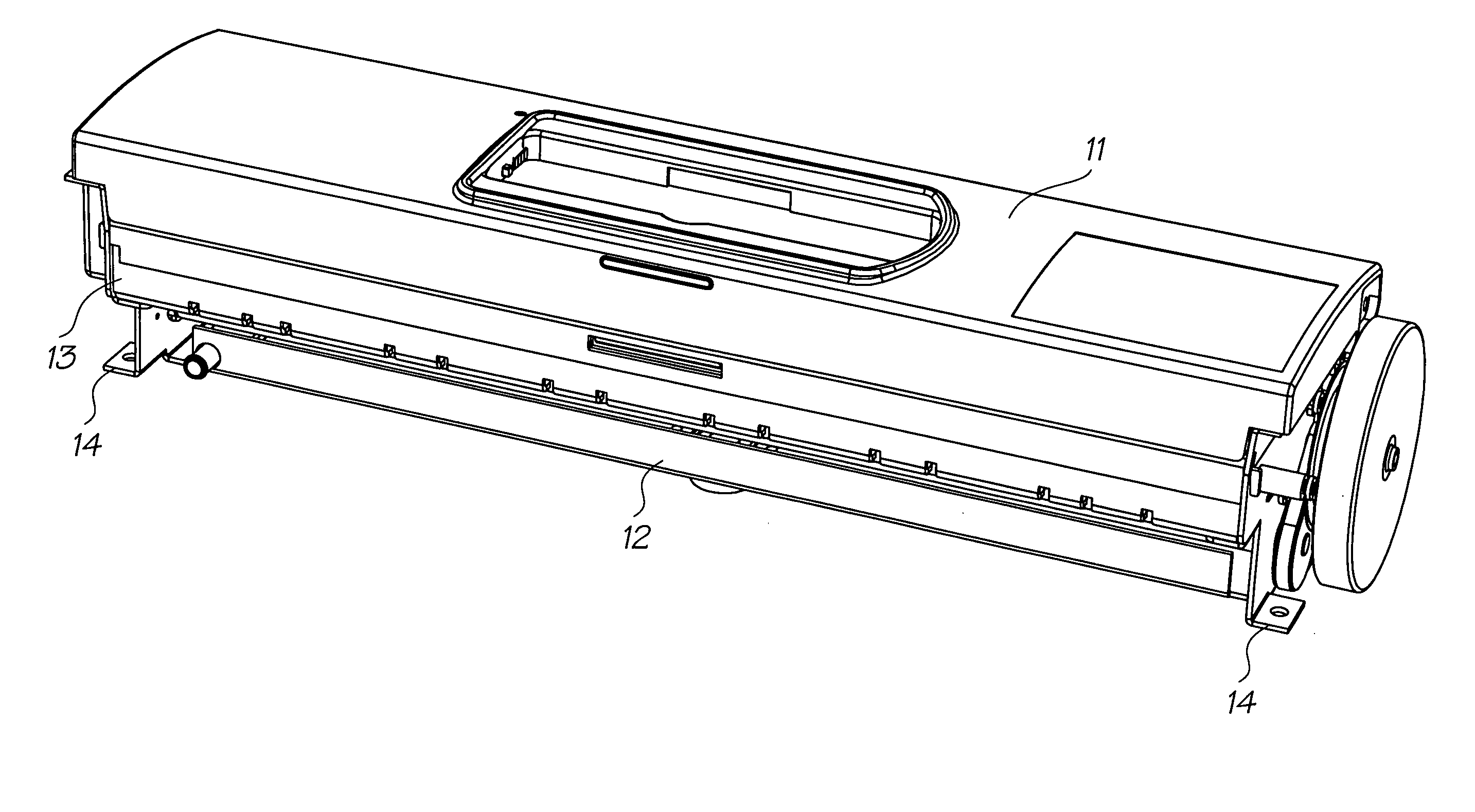

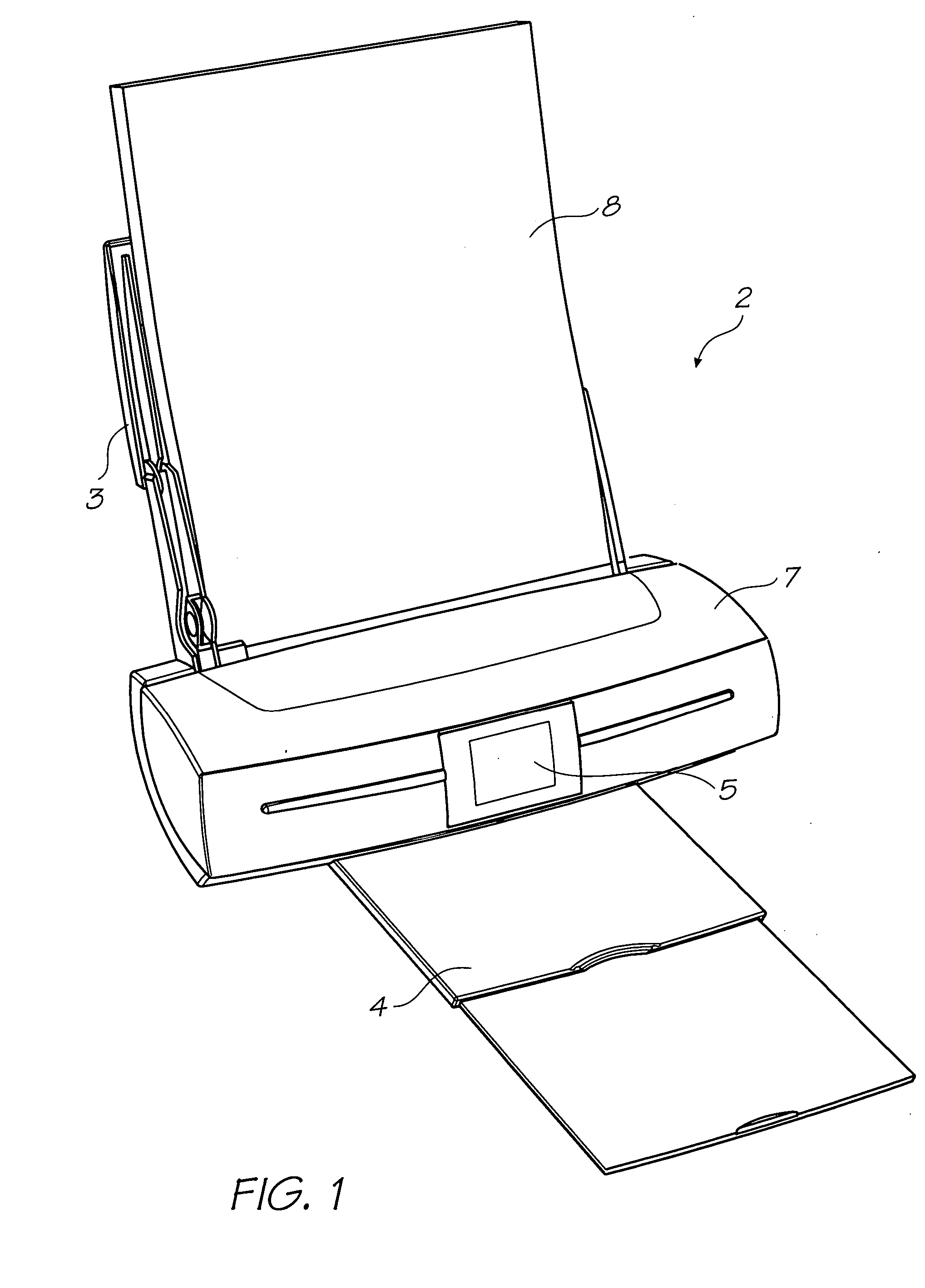

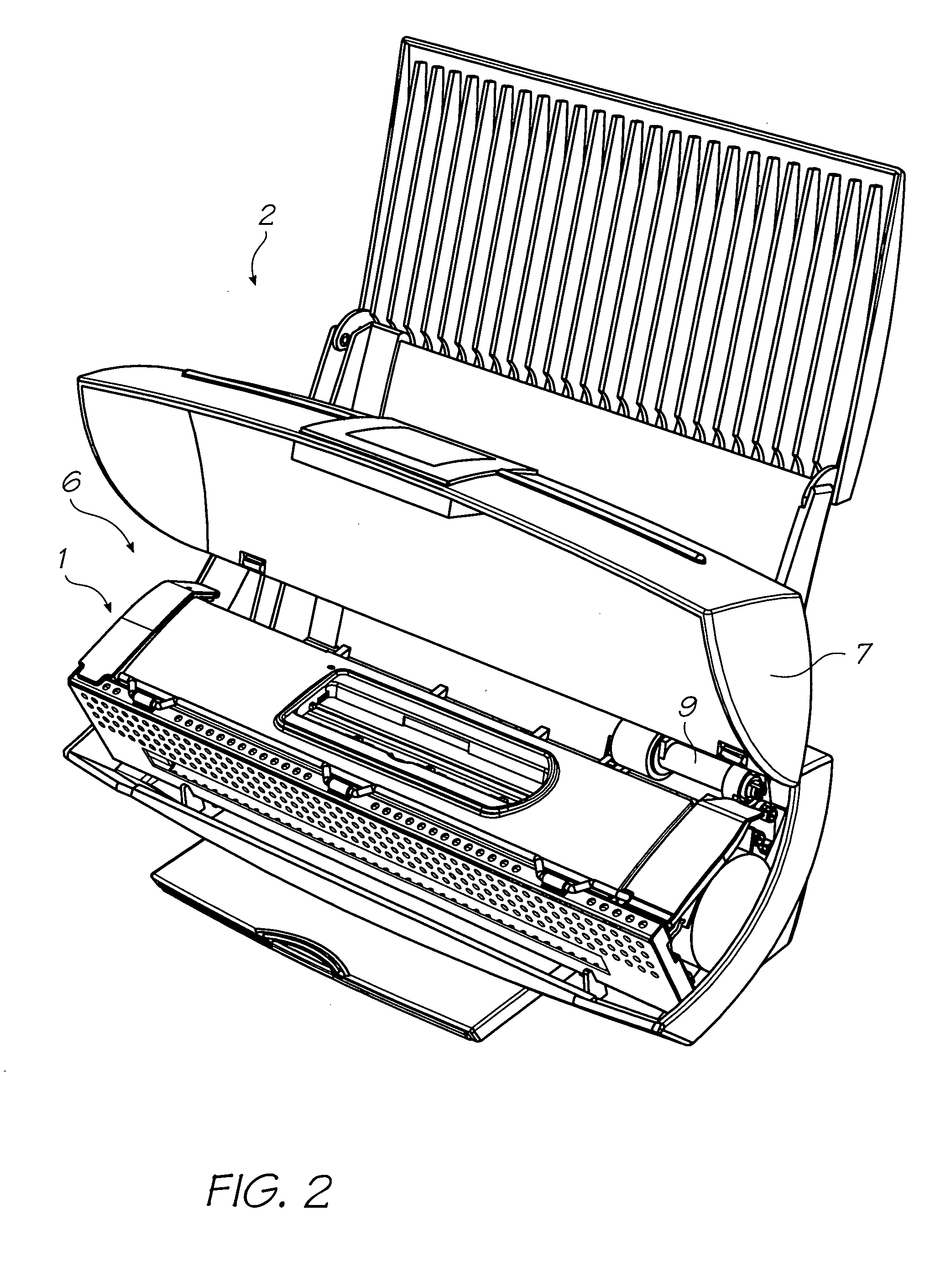

Method of refilling a high speed print engine

Owner:MEMJET TECH LTD +1

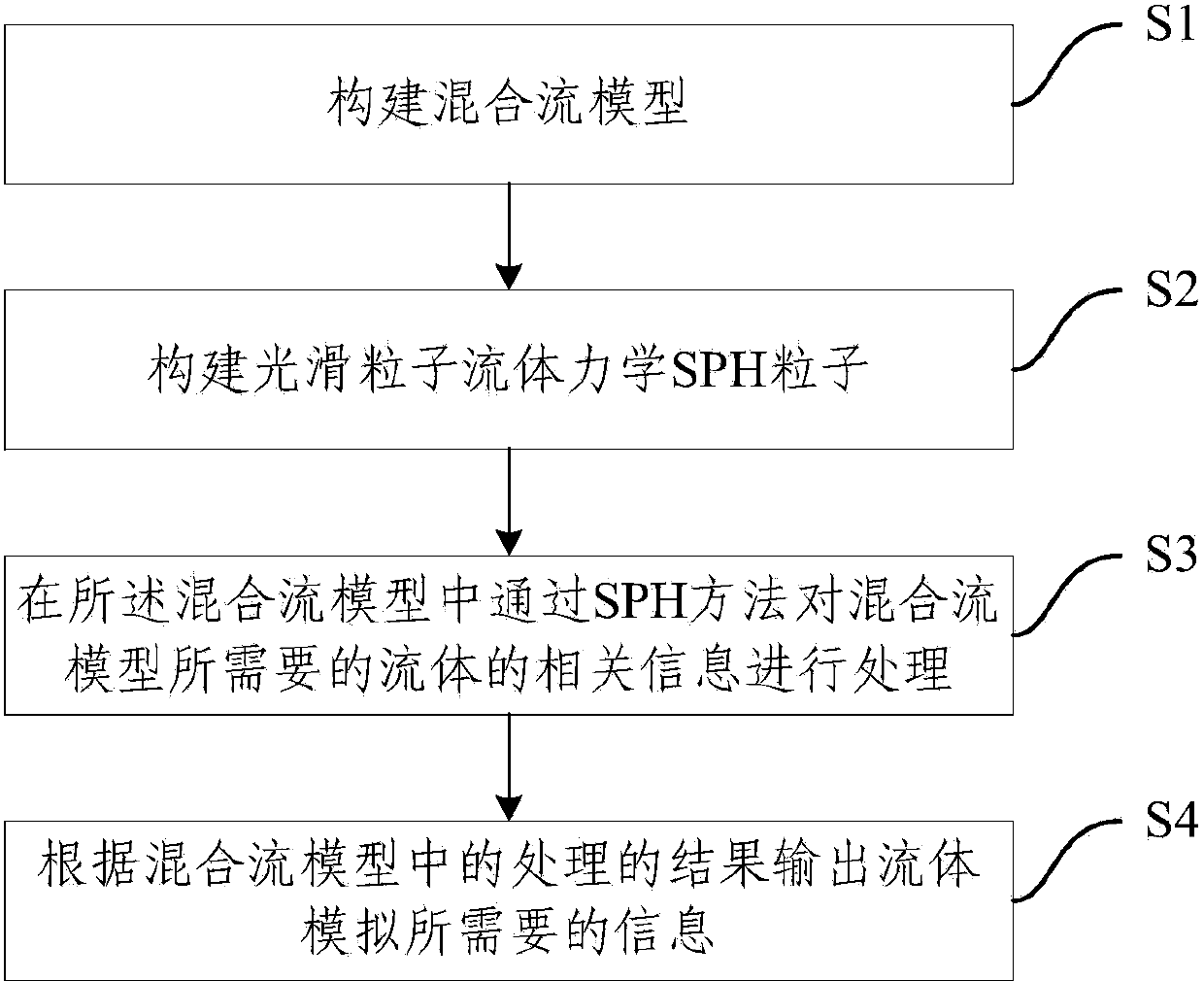

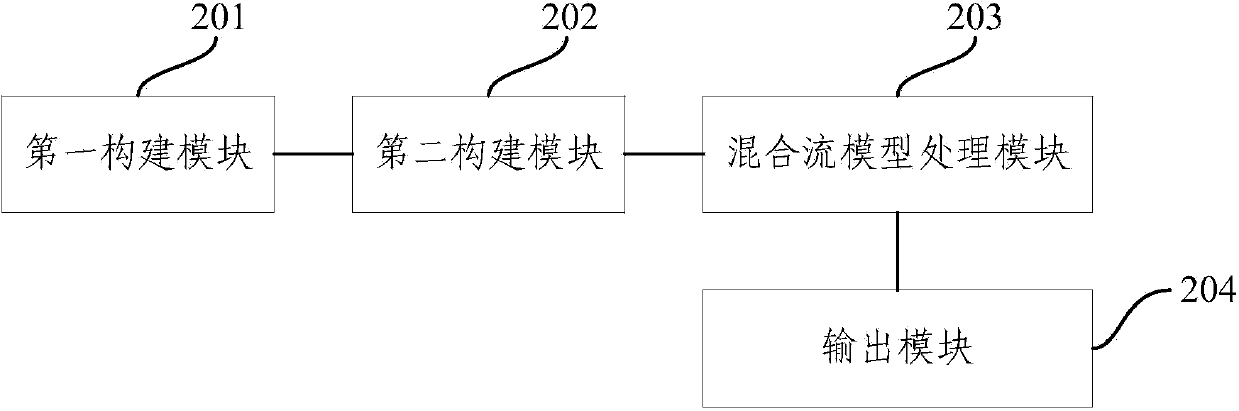

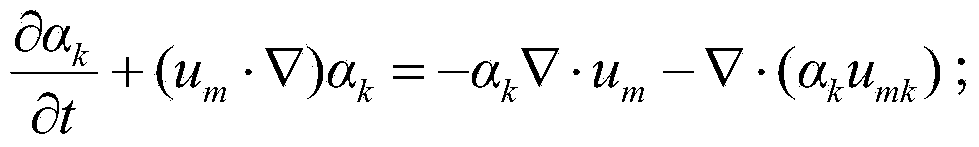

Fluid simulating method and device

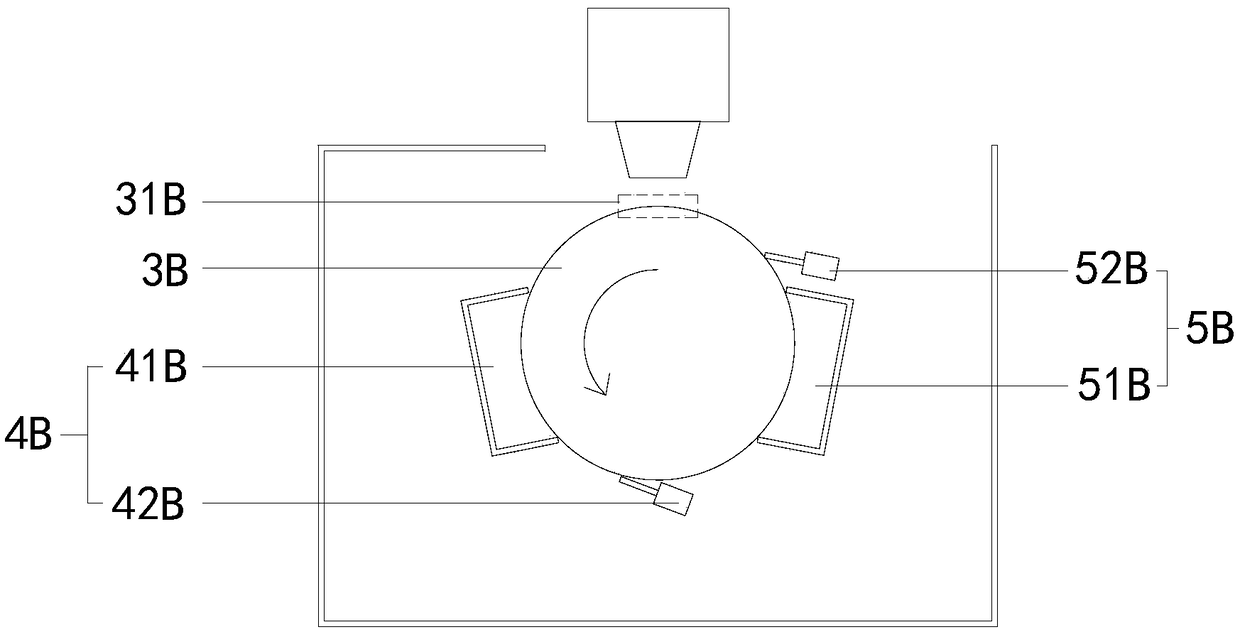

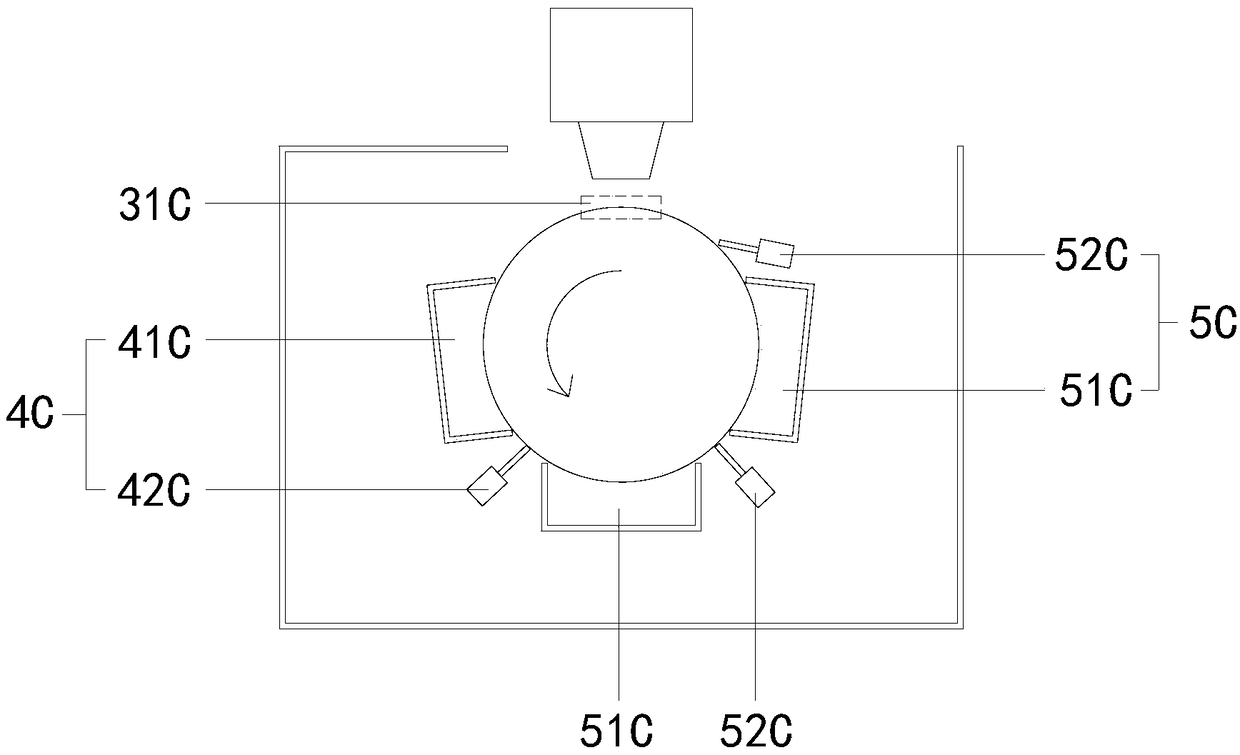

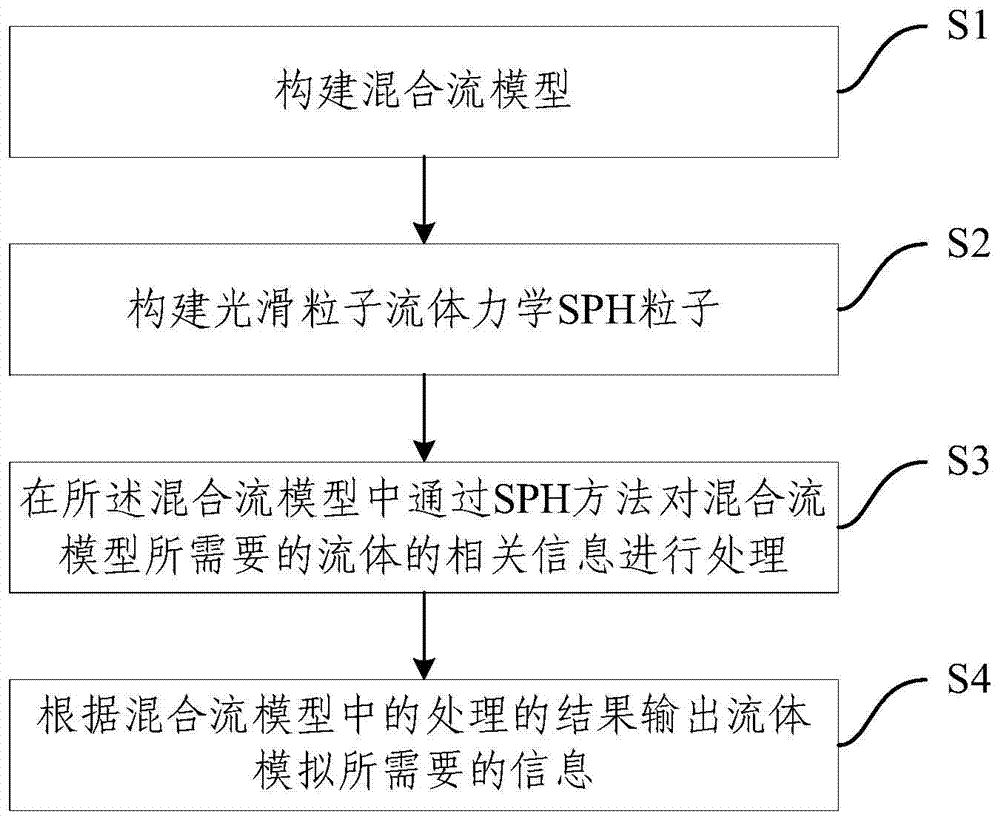

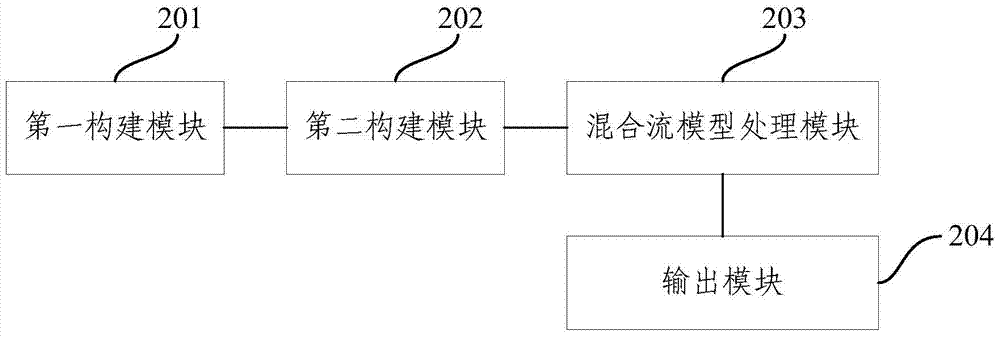

ActiveCN104200015ASimulate extensively and preciselyImprove numerical stabilitySpecial data processing applicationsSmoothed-particle hydrodynamicsRelevant information

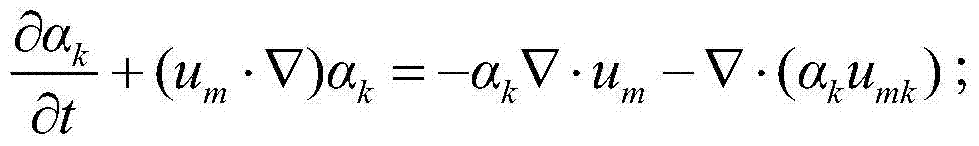

The invention provides a fluid simulating method and device. The method includes the steps that firstly, a mixed flow model is constructed; secondly, smoothed particle hydrodynamics (SPH) particles are constructed; thirdly, relevant information of fluid needed by the mixed flow model is processed in the mixed flow model through an SPH method; fourthly, information needed in fluid simulating is output according to a processing result in the mixed flow model. According to the fluid simulating method and device, the moving process of multi-component fluid can be widely and accurately simulated.

Owner:TSINGHUA UNIV

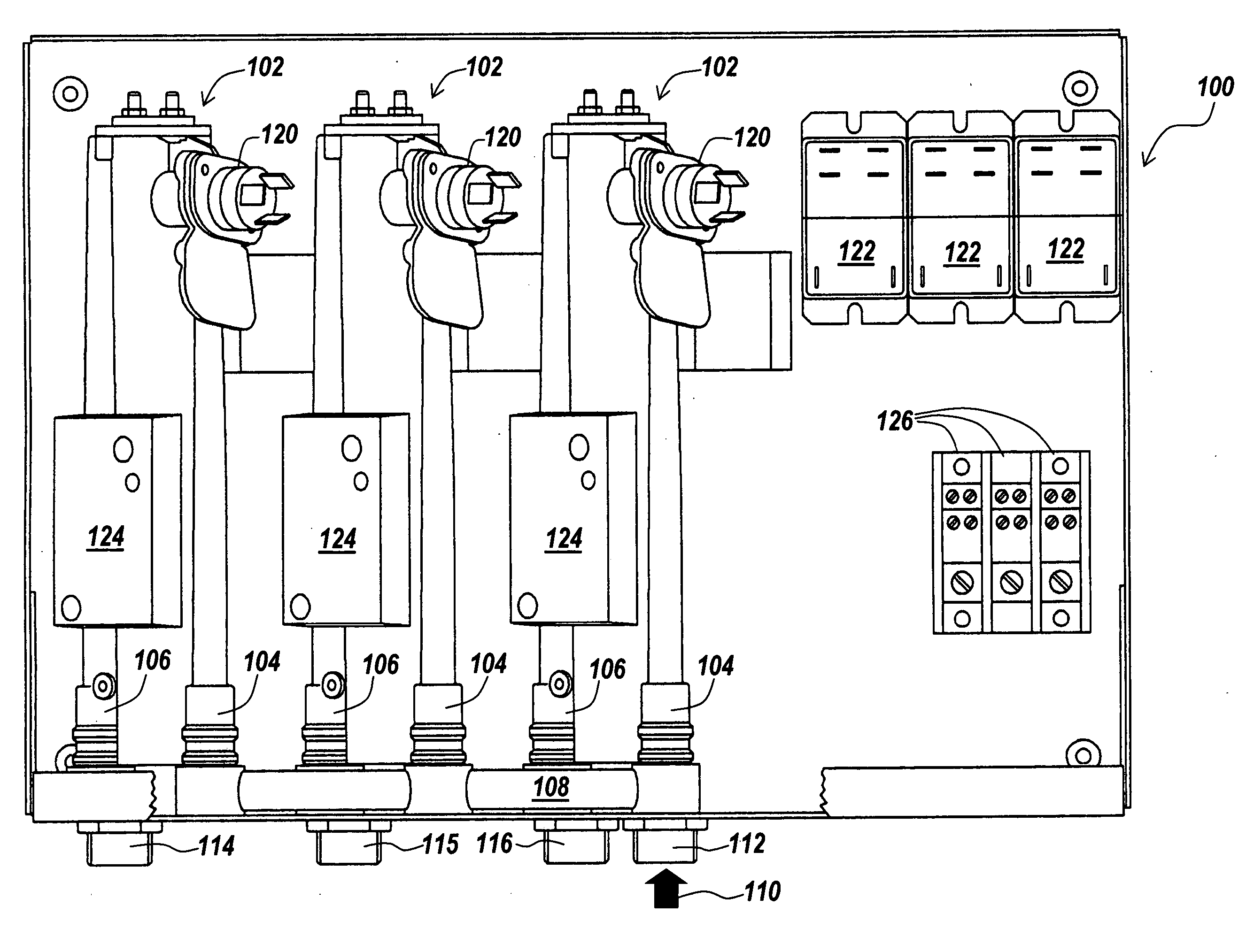

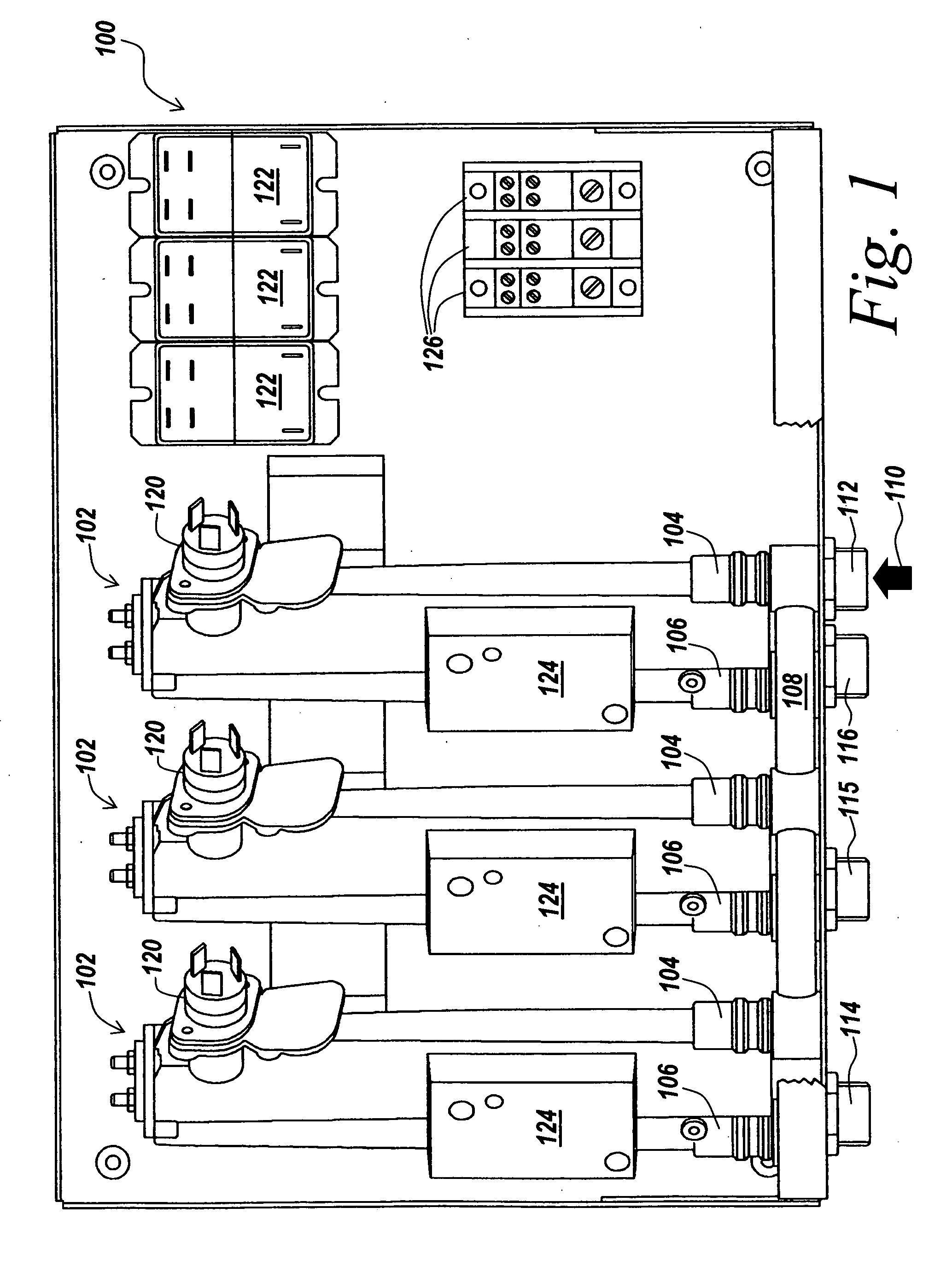

Electric tankless water heater

ActiveUS20060027673A1Increase temperatureAir-treating devicesVehicle heating/cooling devicesLiquid temperatureEngineering

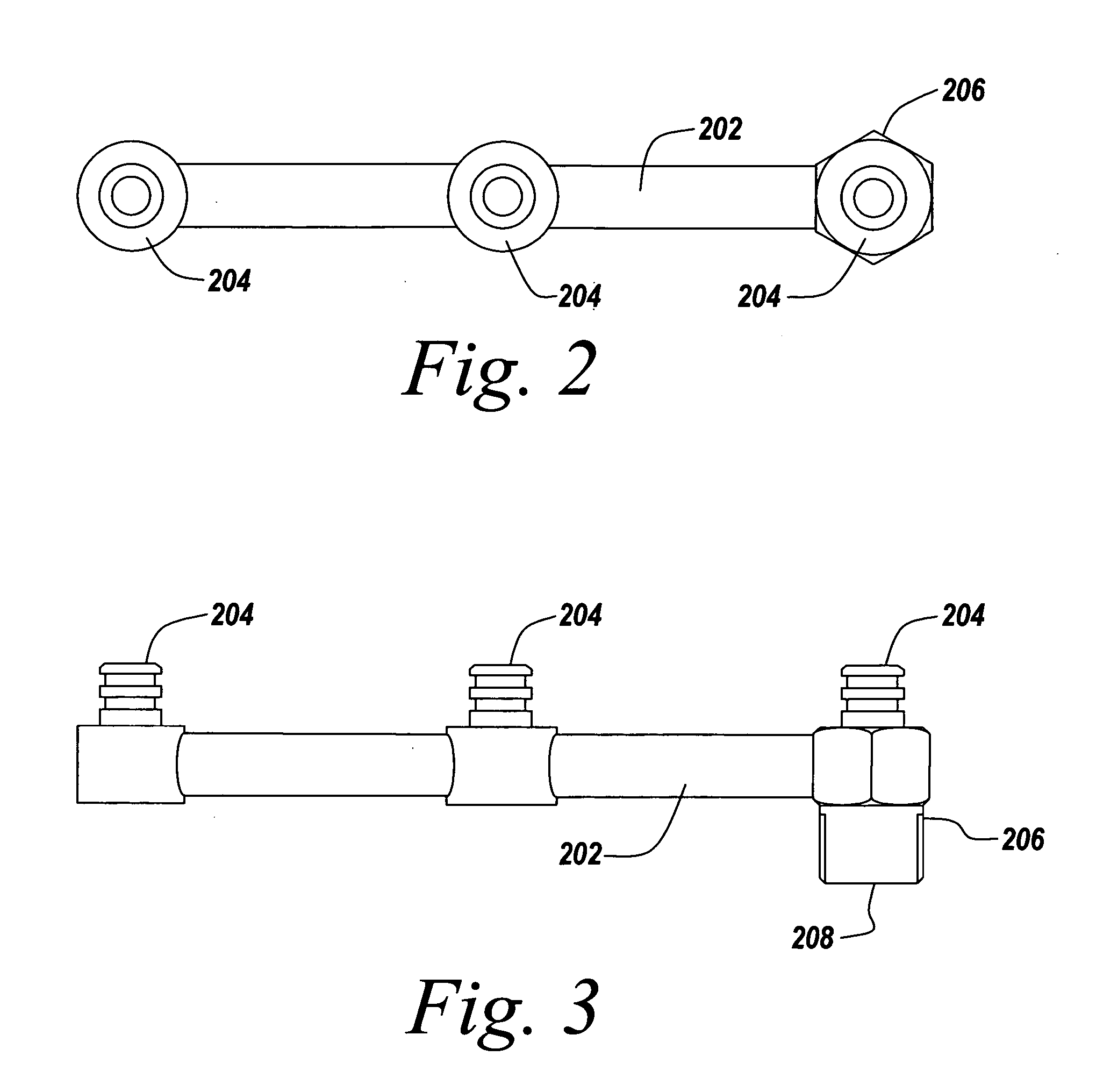

In various aspects, the present invention provides an electric tankless liquid heater system capable of delivering liquid, such as, for example, water, with an acceptable increase in output liquid temperature upon a sudden and substantial decrease in liquid demand. In various aspects, the electric tankless liquid heater comprises an inlet manifold and a plurality of liquid heaters the inlets of which are connected in a parallel flow relationship by the inlet manifold, and the outlets of which are each connected to a separate outlet conduit, and which is configured to provide water to a plurality of automatic water fixtures with a less than about 2° F. (about 1.1° C.) increase in output water temperature upon about a one-and-a-half-fold or greater decrease in water demand that occurs in less than about 500 milliseconds as measured by the increase time of the inlet liquid pressure.

Owner:RHEEM MFG CO

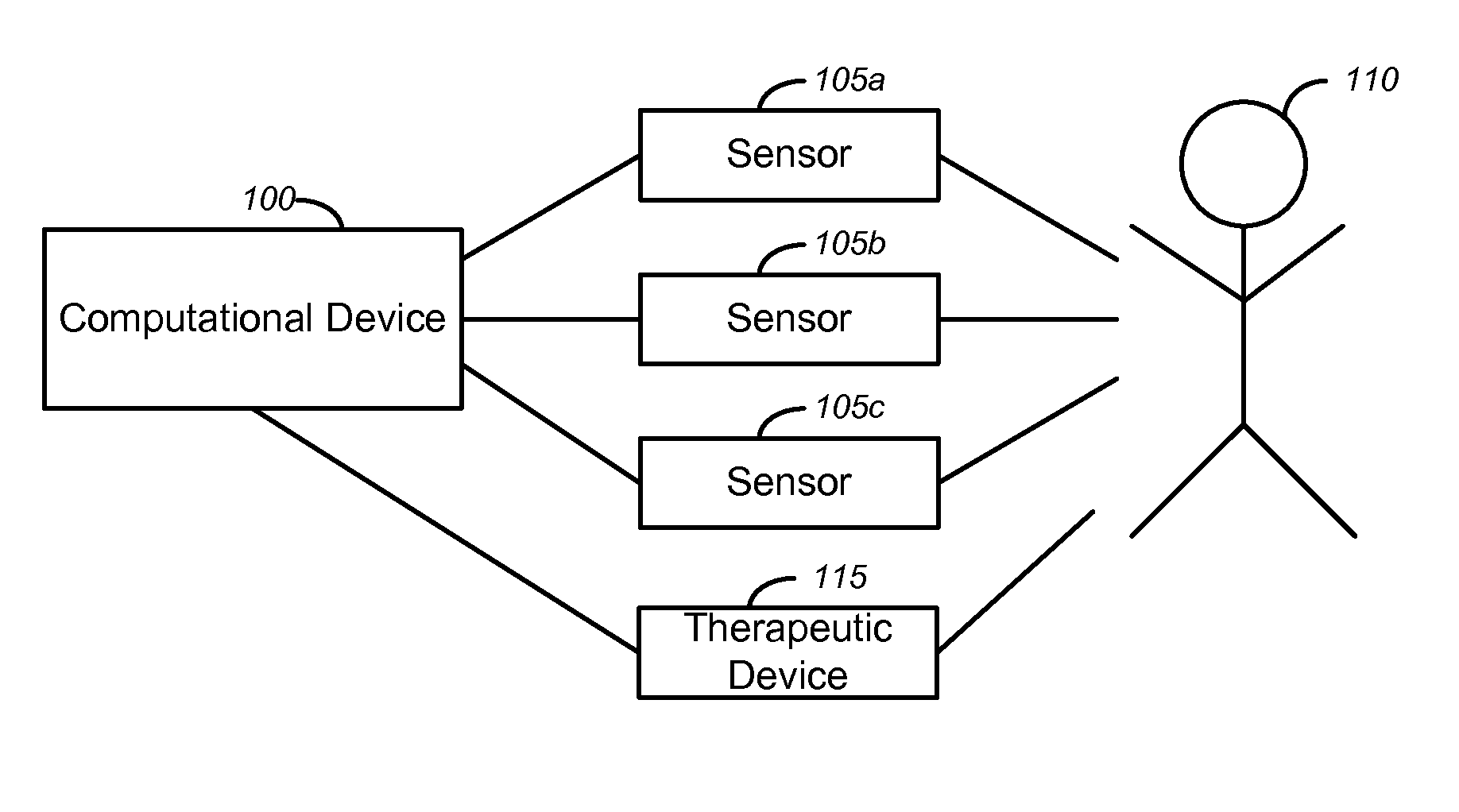

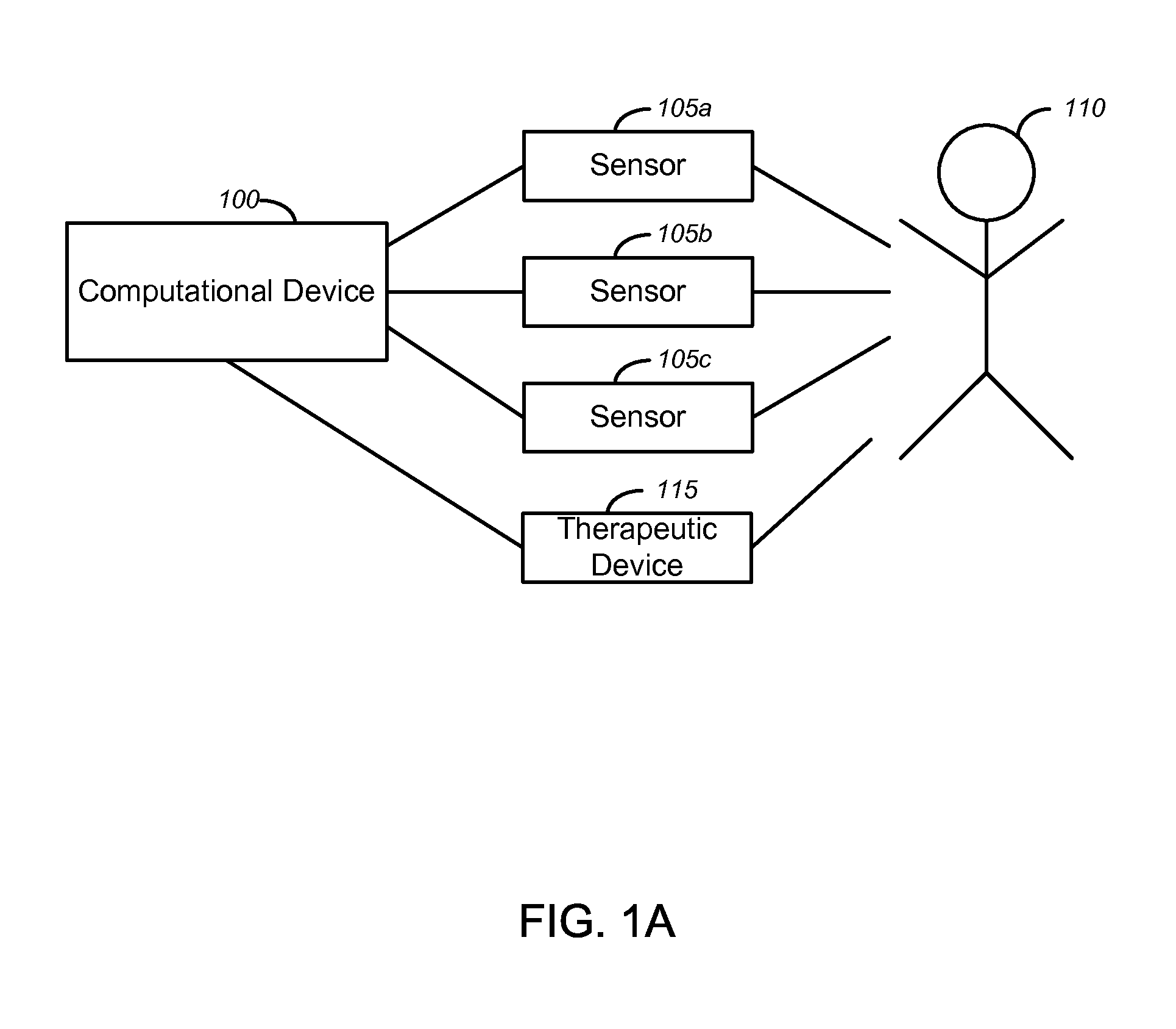

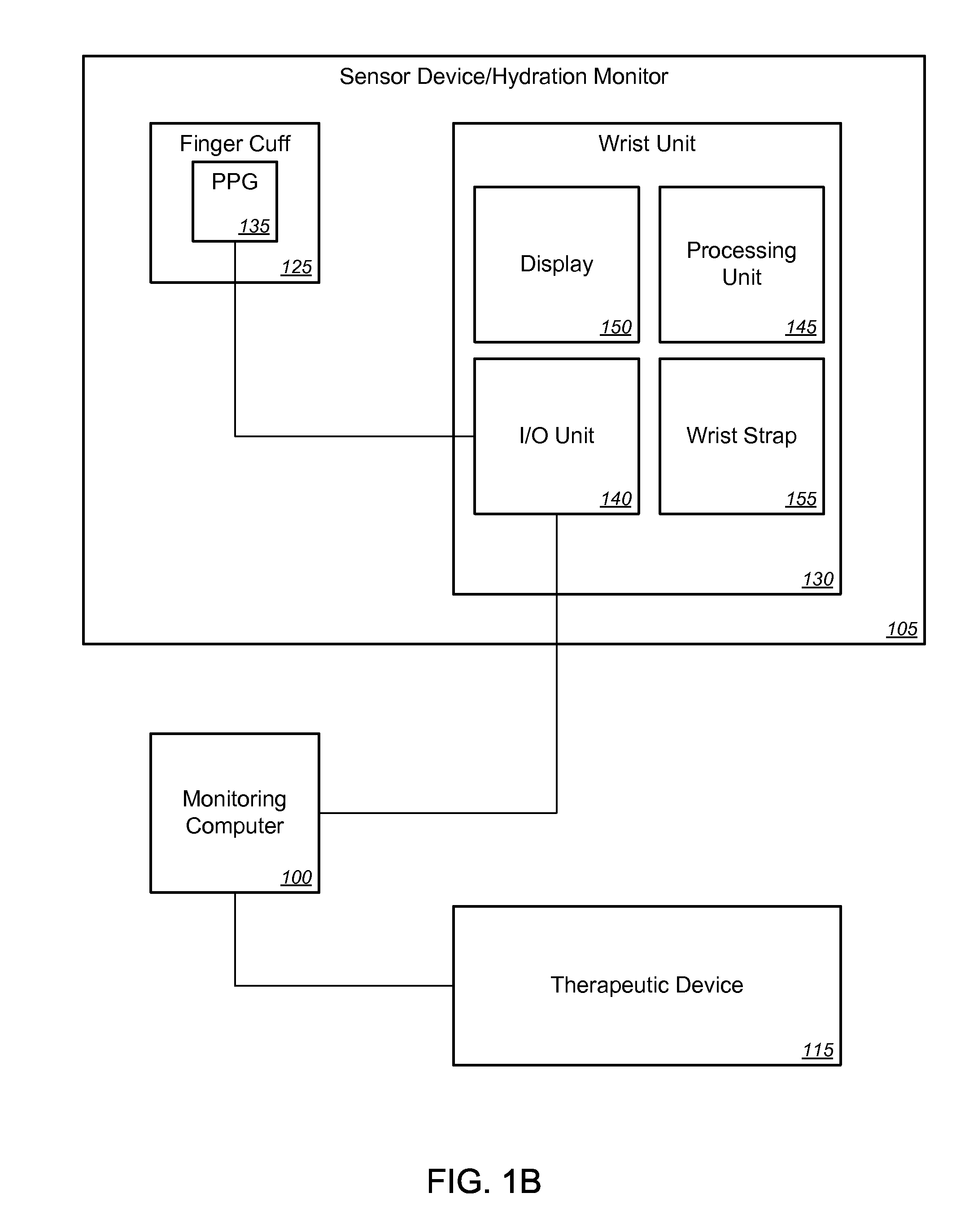

Noninvasive Hydration Monitoring

ActiveUS20150073723A1Good hydration statePerformance maximizationPhysical therapies and activitiesBioelectric signal measurementEmergency medicineNon invasive

Owner:FLASHBACK TECH +1

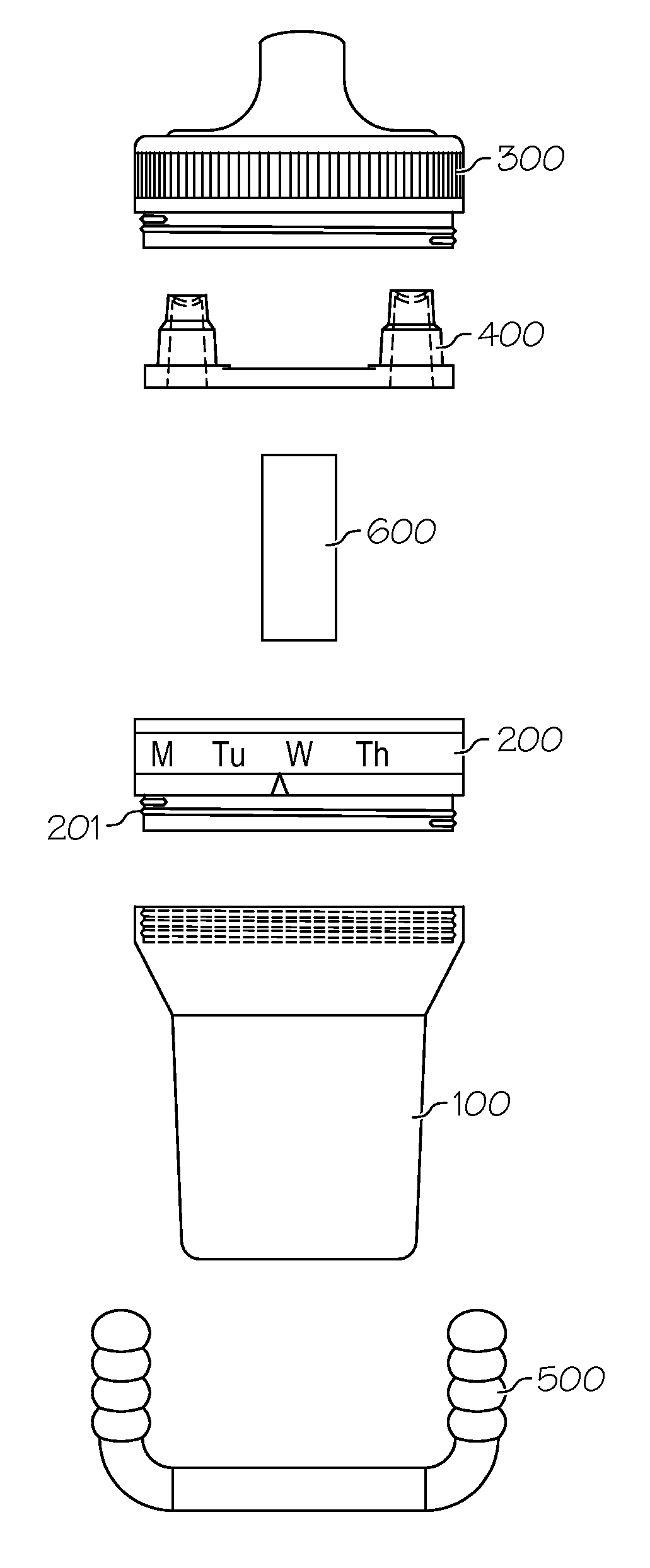

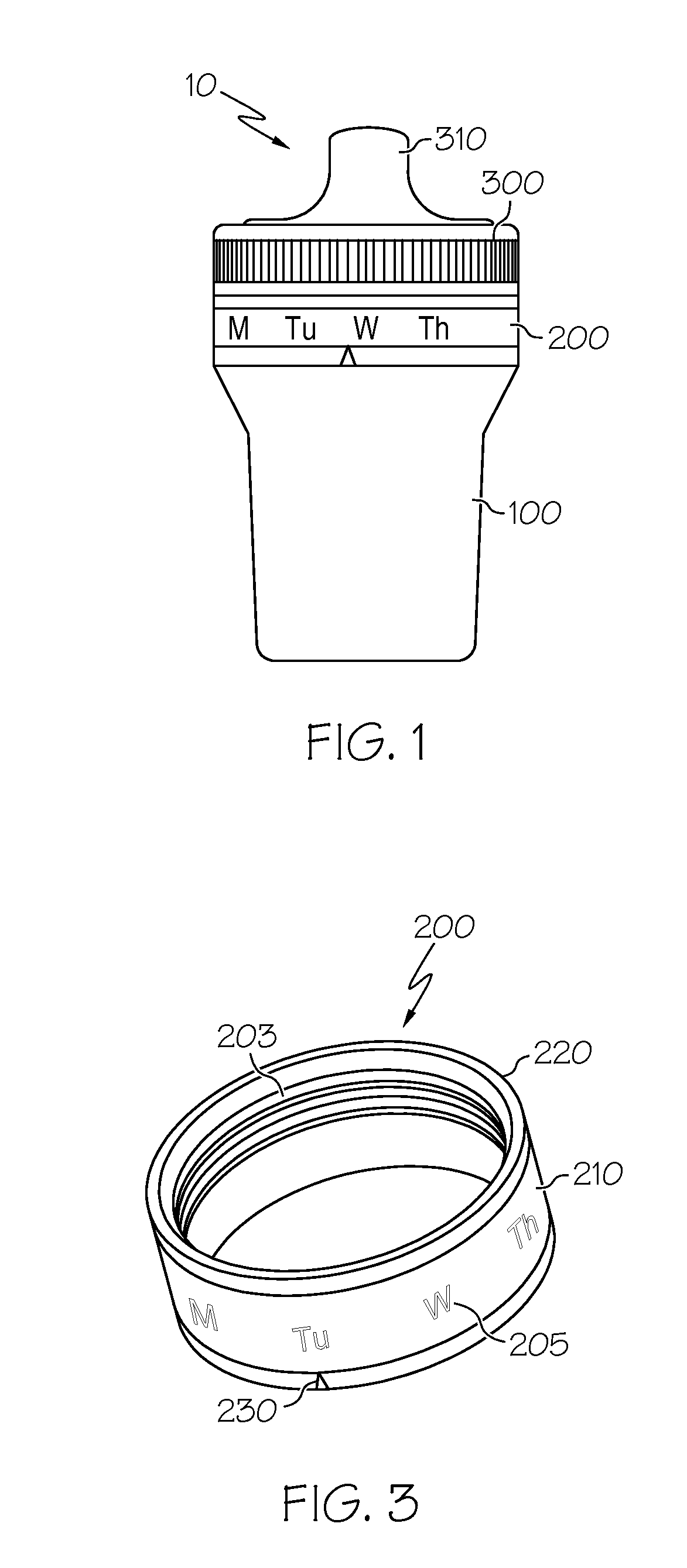

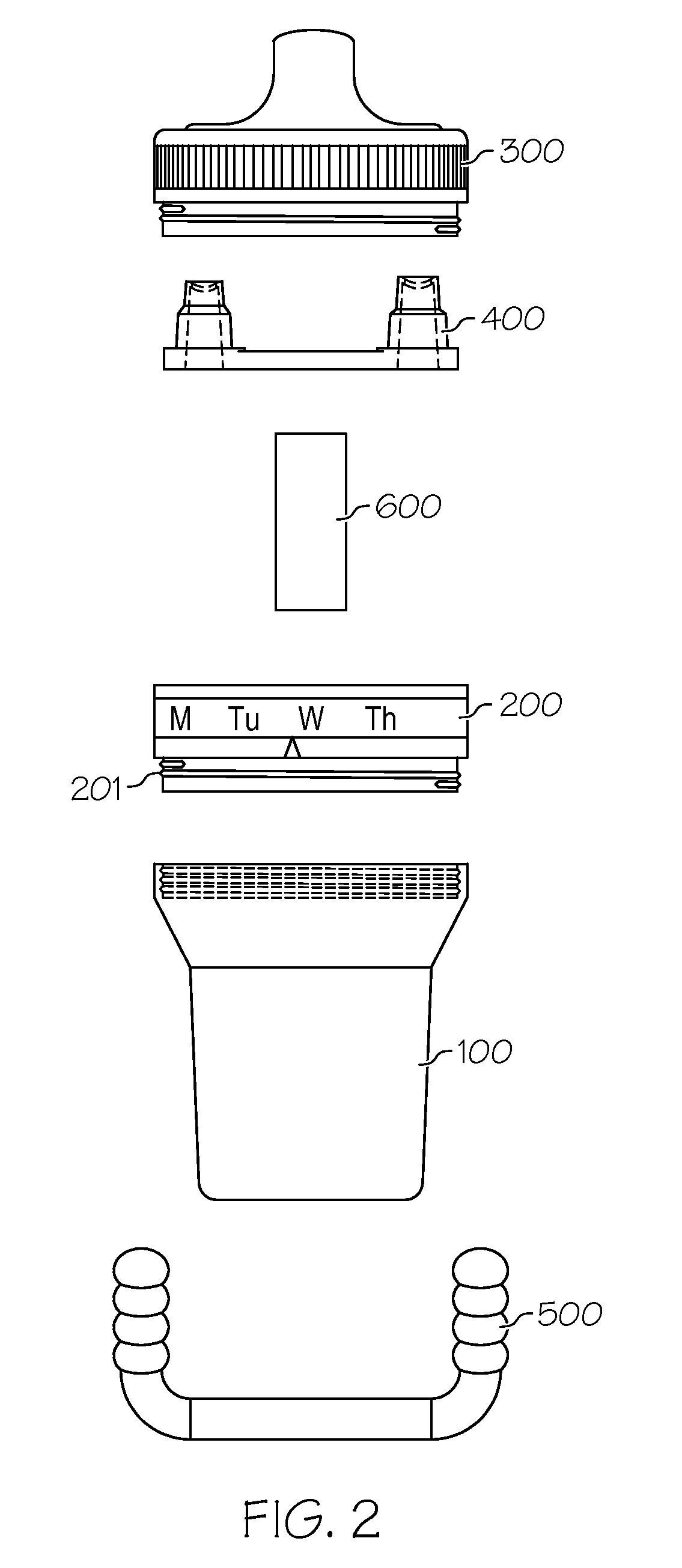

Fluid Intake and Content Management System

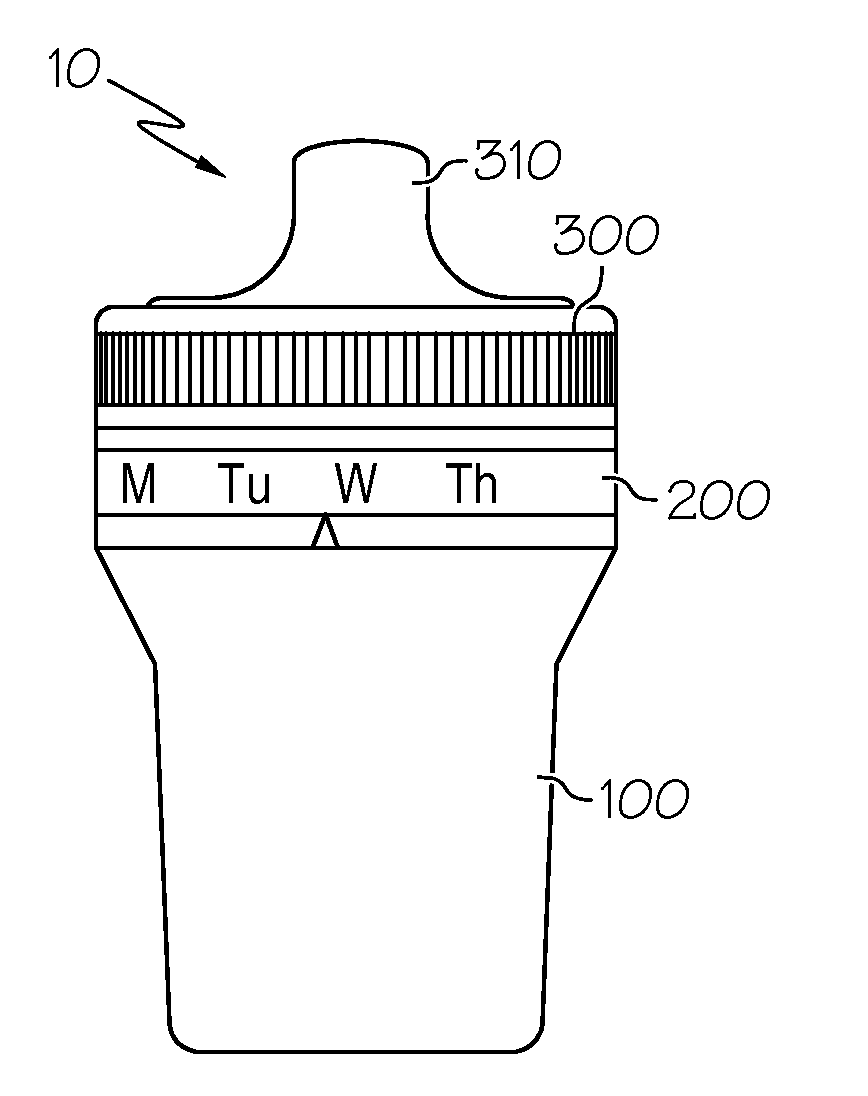

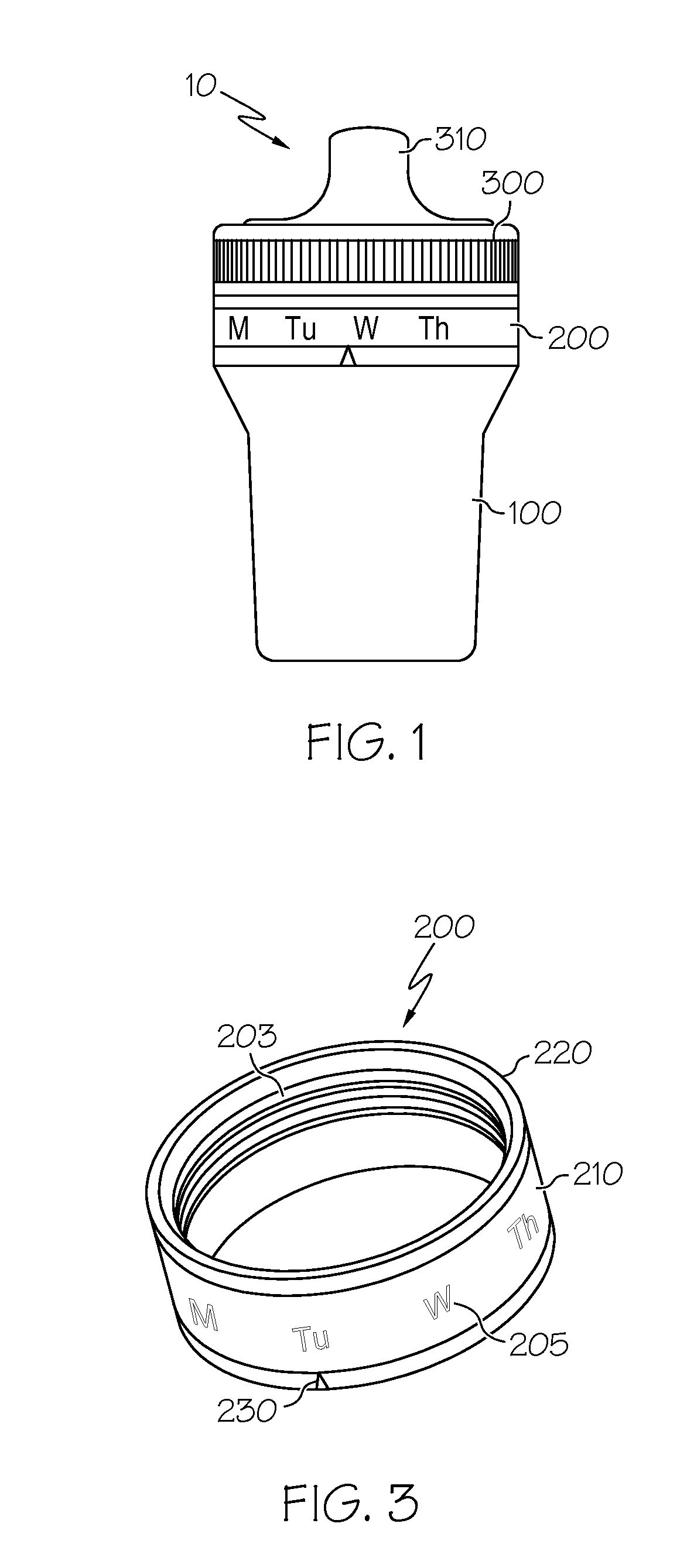

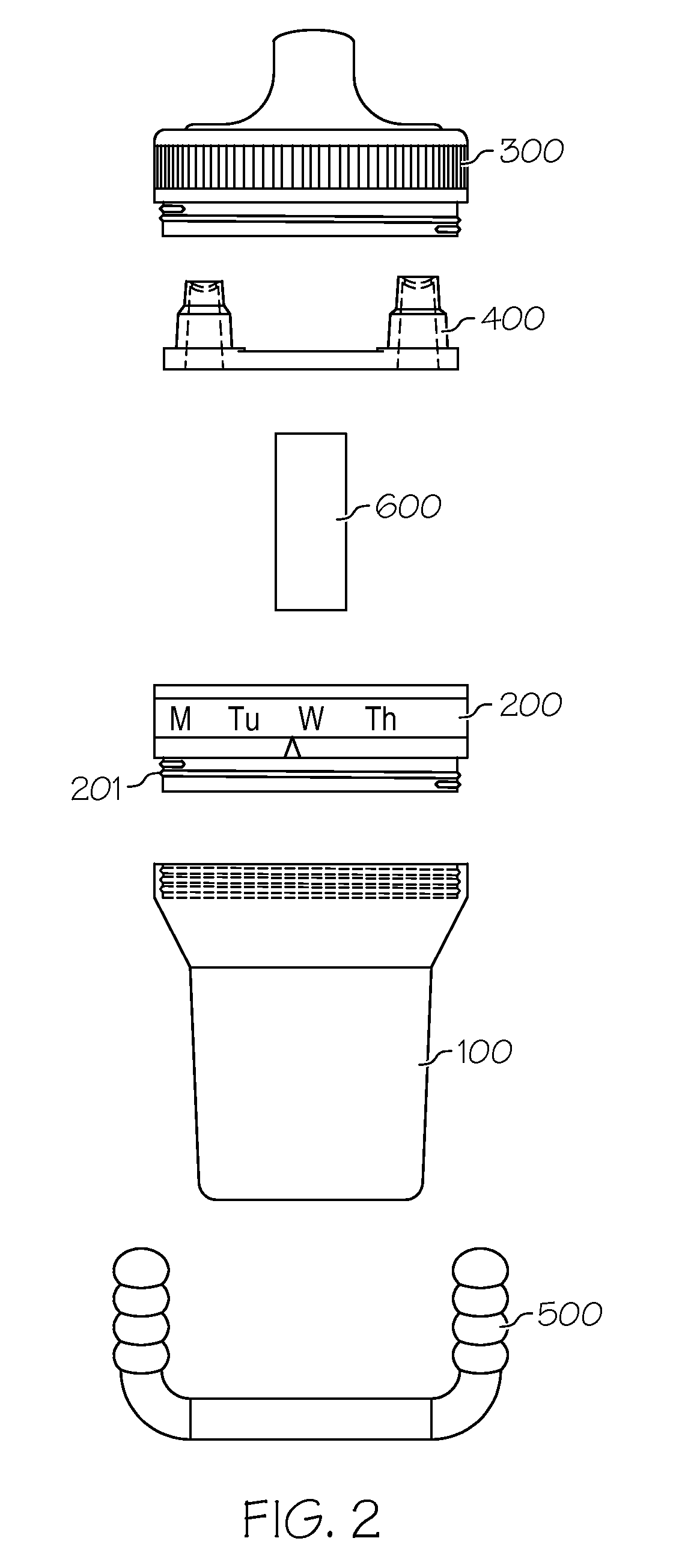

A system for managing the fluid intake of a person is disclosed. The system consists of multiple containers of various volumes, a common lid configured to incorporate a flow control valve, multiple flow control valves having varying flow rates, a date indicator ring incorporated circumferentially on said containers, a content indicator disposed on said lid, a chiller insert, and an optional slip on handle. The user selects a container based on the fluid needs of a person and a flow control valve based on the drinking ability of the person. The user fills the container with a drinkable fluid, and indicates the nature of the contents with the content indicator and the date of filling with the date indicator ring. The chiller insert allows the user to cool the contents without the possibility of dilution as with standard ice cubes.

Owner:YOUNG JONES DIANE

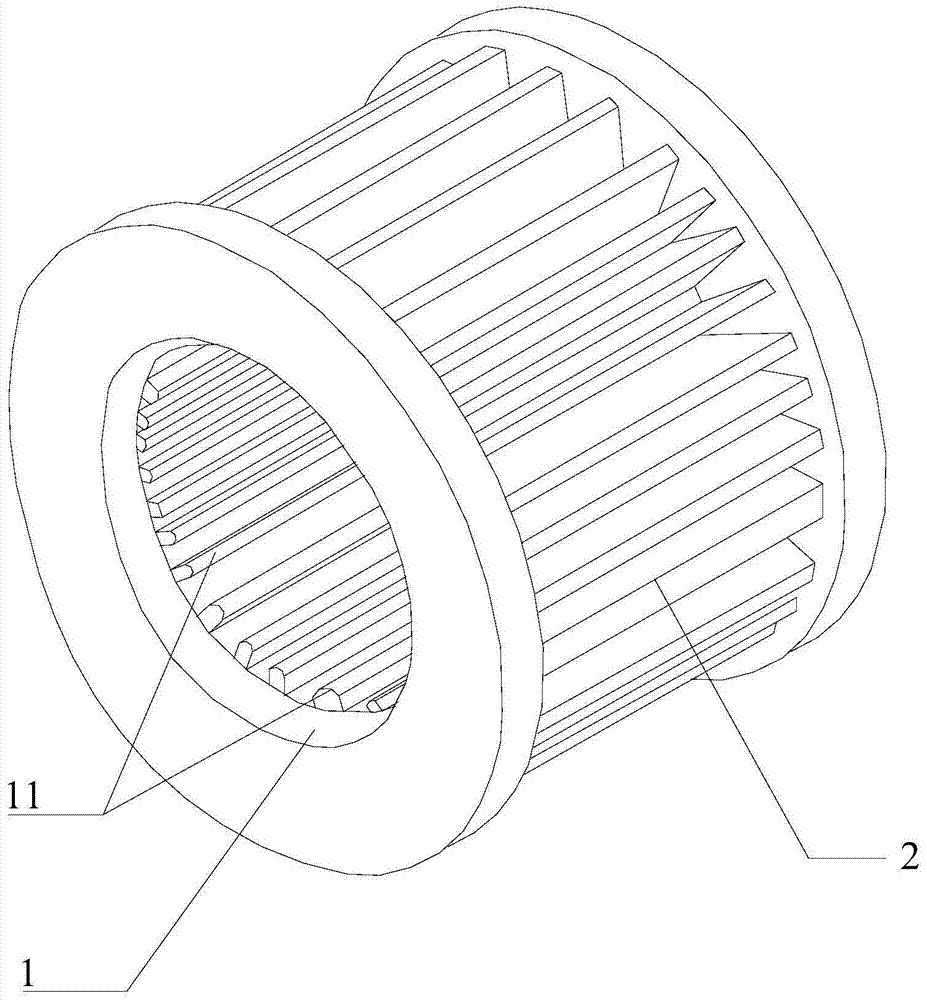

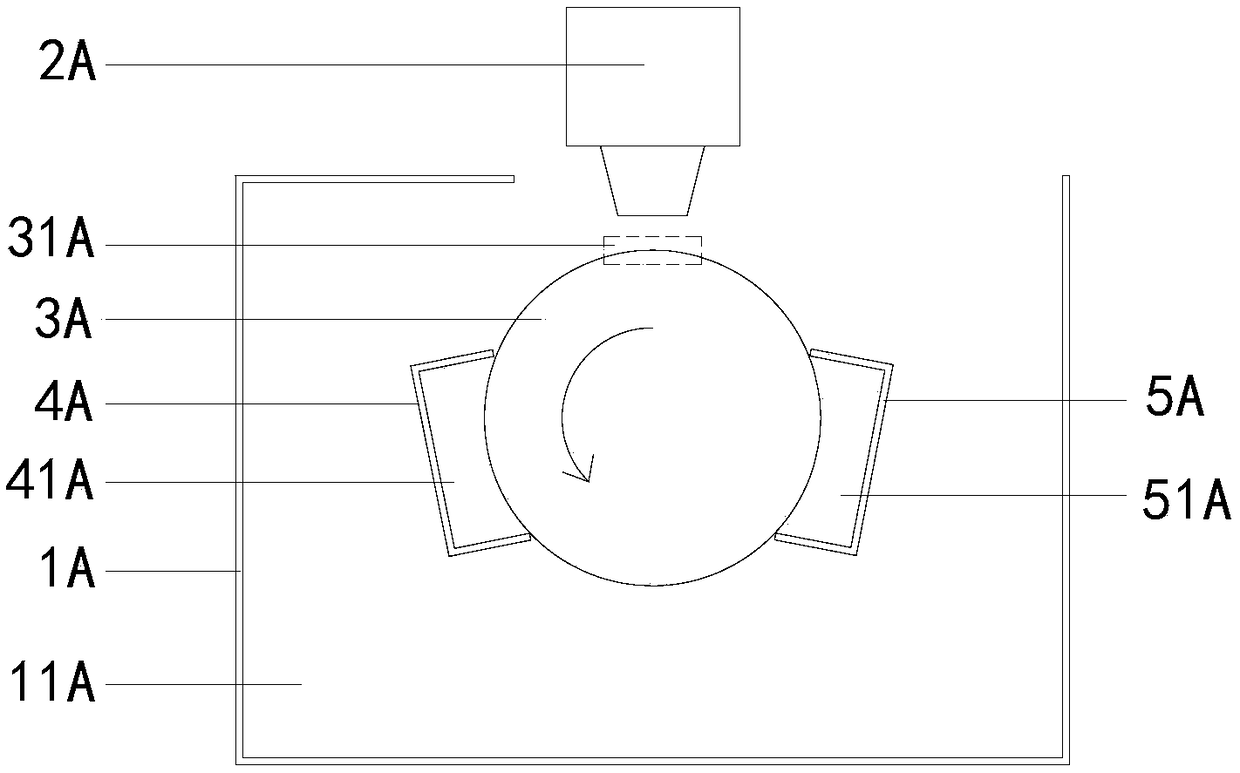

Adjustable fluid cooling fin

InactiveCN103673713AAdjust cooling efficiencyAdjust the cooling areaTubular elementsEngineeringHeat sink

The invention discloses an adjustable fluid cooling fin comprising a fluid pipe and cooling pieces arranged on the outer circumference of the fluid pipe, wherein grooves which are concave into a pipe cavity of the fluid pipe are formed in the pipe wall of the fluid pipe; one end of each cooling piece is arranged inside the corresponding groove; the other end of each cooling piece is arranged outside the corresponding groove; when fluid needs to increase the cooling area, the cooling pieces are outwards pulled out from the grooves, and the fluid flows through the fluid pipe and is cooled through the cooling pieces. As the grooves which are concave into the pipe cavity of the fluid pipe are arranged, the cooling pieces are arranged inside the grooves, and the cooling area of the cooling pieces outside the fluid pipe is adjusted through insertion and extraction, the cooling efficiency for the fluid is adjusted, and the application range of the single-fluid cooling fin is extended.

Owner:WUXI JIALONG HEAT EXCHANGER

Composite nano-grade silk fiber product and method for preparing the same

ActiveCN1837435AImprove microstructureGood dimensional stabilityFilament/thread formingConjugated cellulose/protein artificial filamentsElectrospinningNylon 6

This invention discloses a composite and nanometer-grade silk fibre, which is non-woven fabric composed of nanometer-grade silk element and nylon 6 composite fiber. The diameter of composite fiber is 50-300 nanometers, the weight ratio of nanometer-grade silk element and nylon 6 is in the range of 9:1-1:9. Its method for preparation is following: first preparing spinning fluid, obtaining non-woven fabric with electrostatic spinning method, then doing final treatment. Wherein said preparation of spinning fluid comprises the following steps: (1) preparing silk fibre solution and drying it into flim; liquefying the silk element flim into formic acid to get actified silk fibre solution; (2) liquefying nylon 6 section into into formic acid; (3) mixing equably the solution obtained from (1) and (2) to get spinning fluid needed. The invention improves the microstructure of fibre with composite method and final treatment, and the product obtained, with good dimensional stability which satisy the demand of performance and morphological stability of product in application, can be used as biological and medical material, protective material and filtering material and so on.

Owner:XINYUAN COCOON SILK GROUP +1

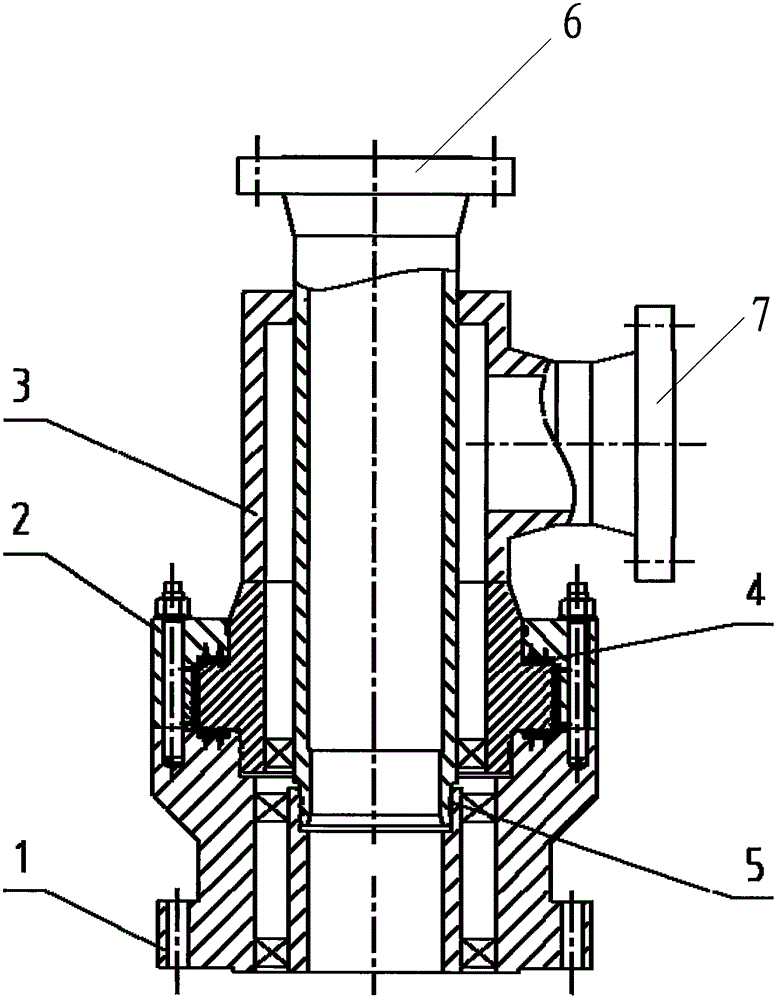

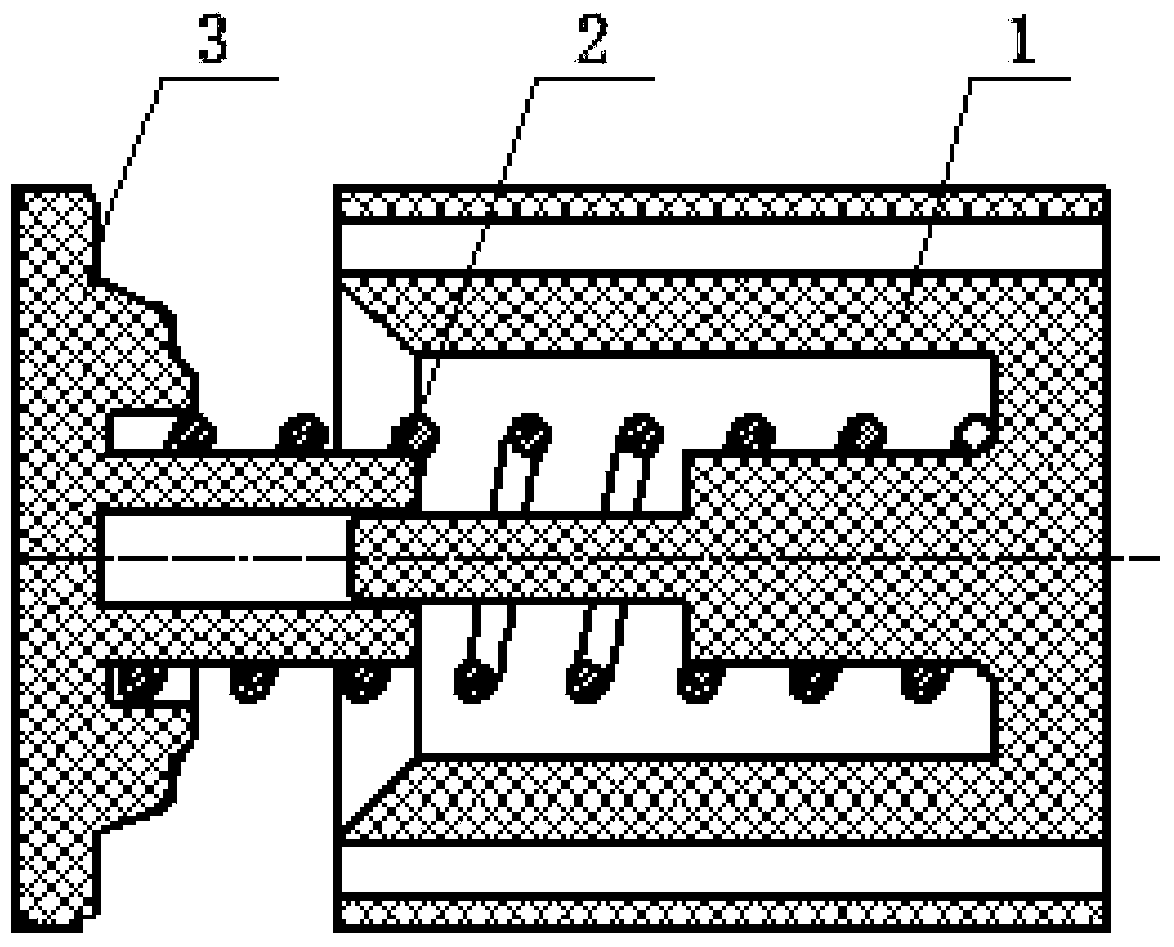

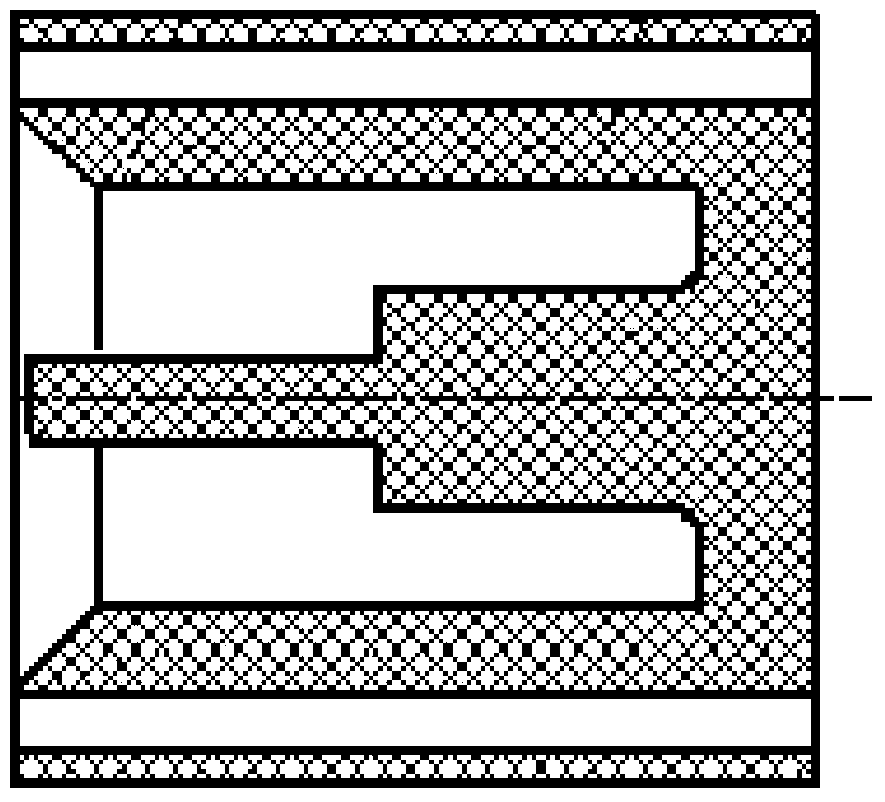

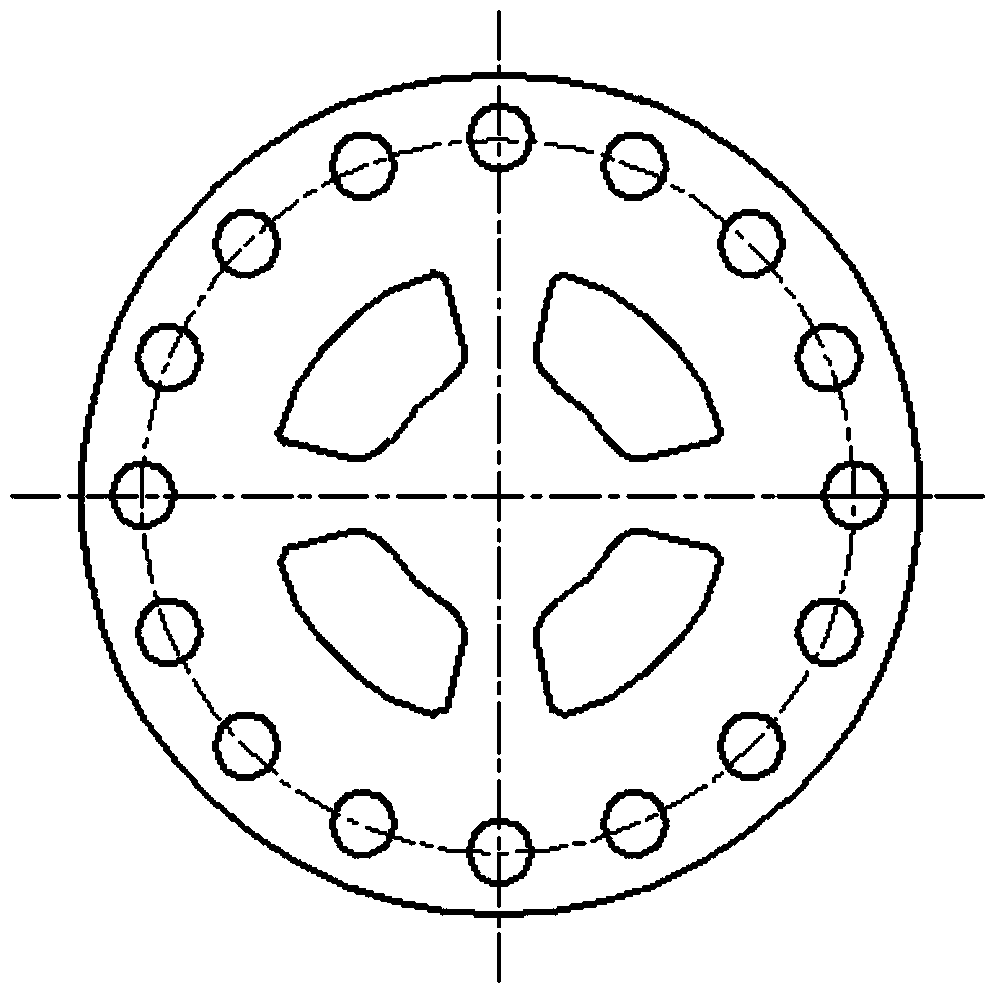

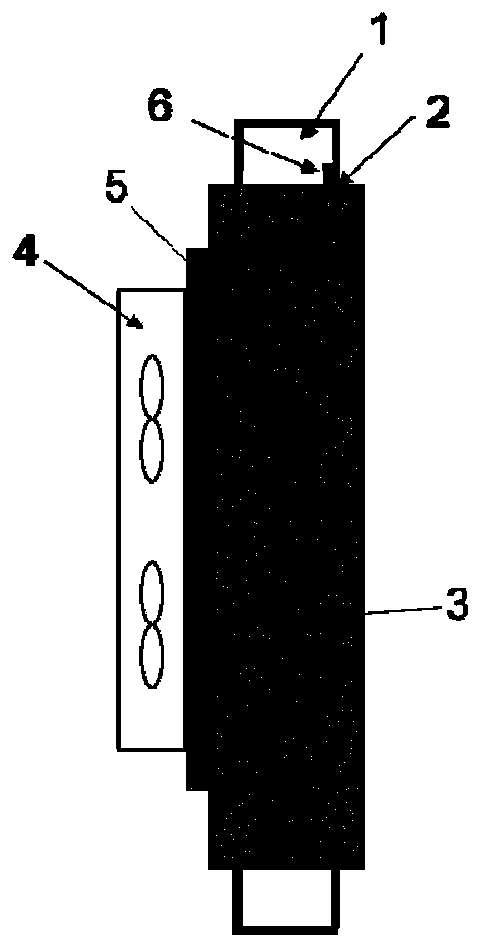

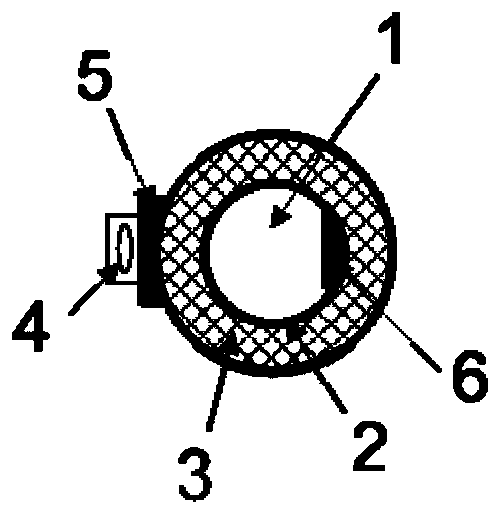

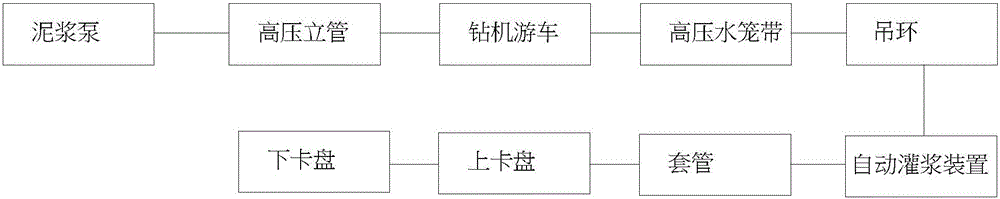

Fluid slip ring

ActiveCN106287077AIn line with the long-term development directionSolve delivery problemsDrilling rodsFluid removalNuclear powerGas phase

The invention discloses a fluid slip ring, relates to the technical field of slip rings and aims at solving the problem that in the prior art, in the severe sea condition, a high-temperature and high-pressure large-caliber fluid slip ring is poor in running reliability. The temperature of conveyed fluid of an inner runner of the fluid slip ring is 200 DEG C, the pressure is 11 Mpa, and the drift diameter is 250 mm; and the temperature of fluid of an outer runner is 70 DEG C, the pressure is 11 Mpa, and the drift diameter is 408 mm. The fluid slip ring receives fresh water conveyed by a user, and the fresh air is heated to 200 DEG C through an oversea nuclear power platform and conveyed to the user. The existing fluid conveying slip ring cannot reach the high-temperature and high-pressure conveying capability. According to the fluid slip ring, a coaxial inserting type structure is adopted according to the large-flow high-temperature and high-pressure fluid needed by the user, the multi-runner high-temperature and high-pressure rotation sealing is achieved, and the requirement for preventing washout of gas-phase media and liquid-phase media is met; and it is guaranteed that in the severe sea condition, the fluid slip ring runs safely and reliably. The temperature, pressure and flow parameter level of fluid conveying media can be improved to a new level.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND +1

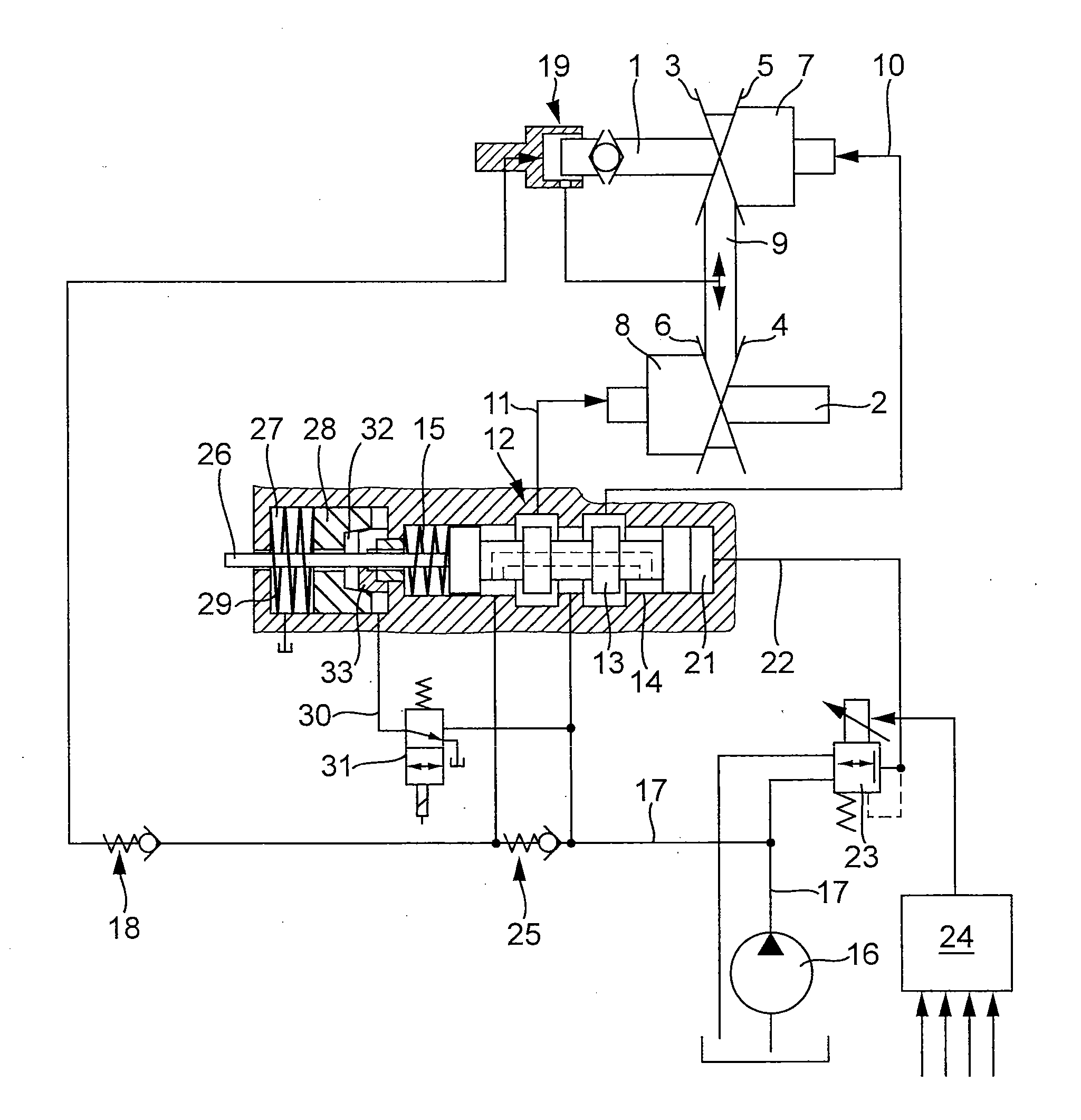

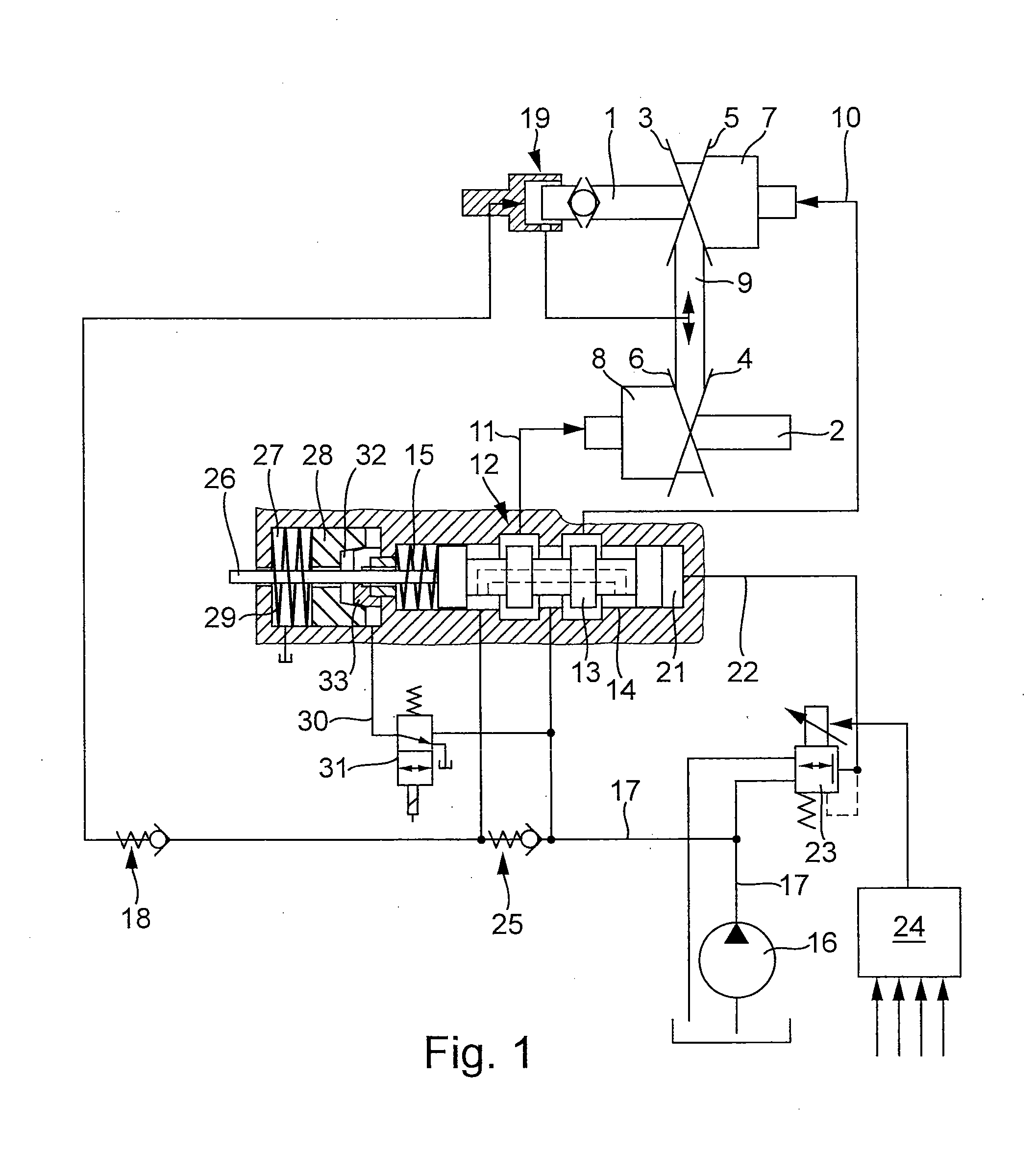

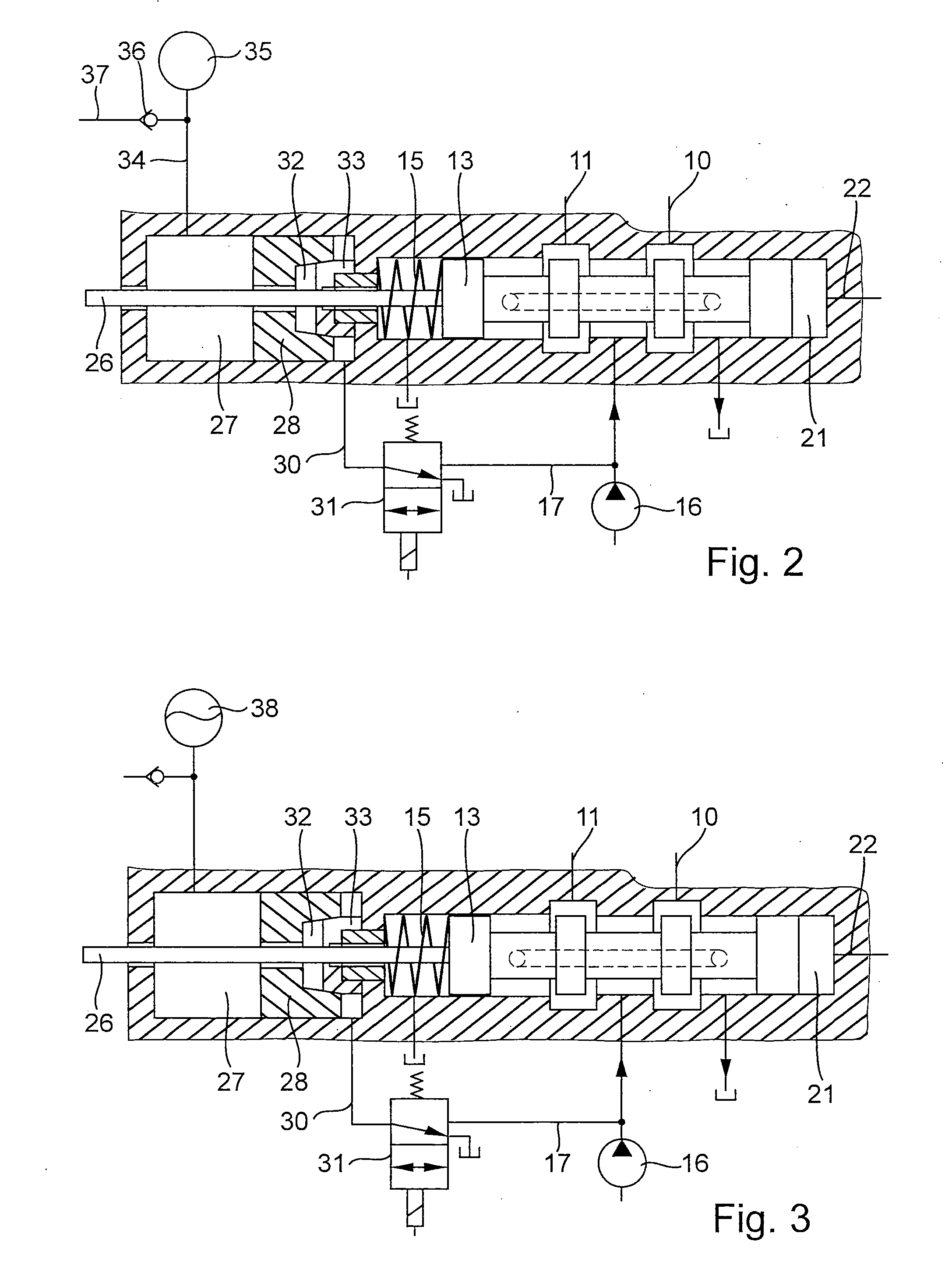

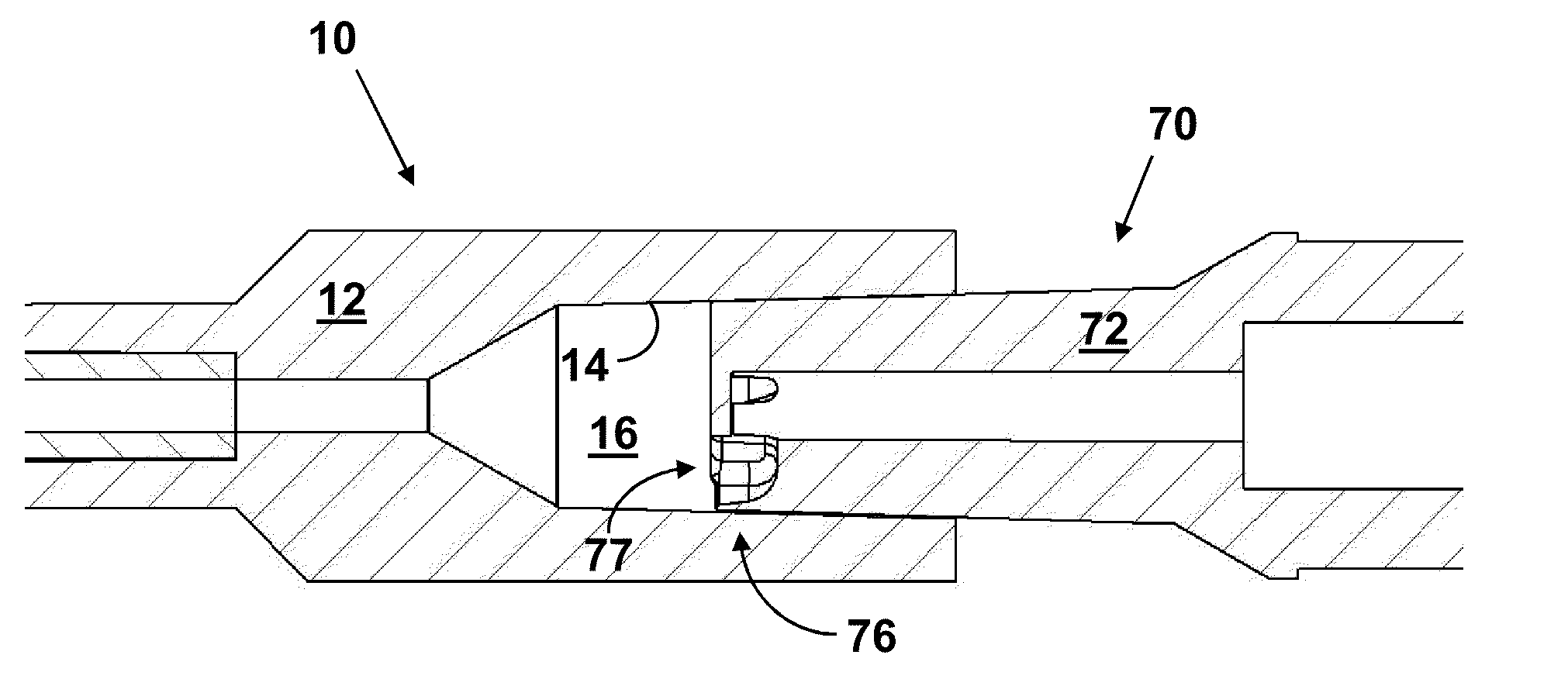

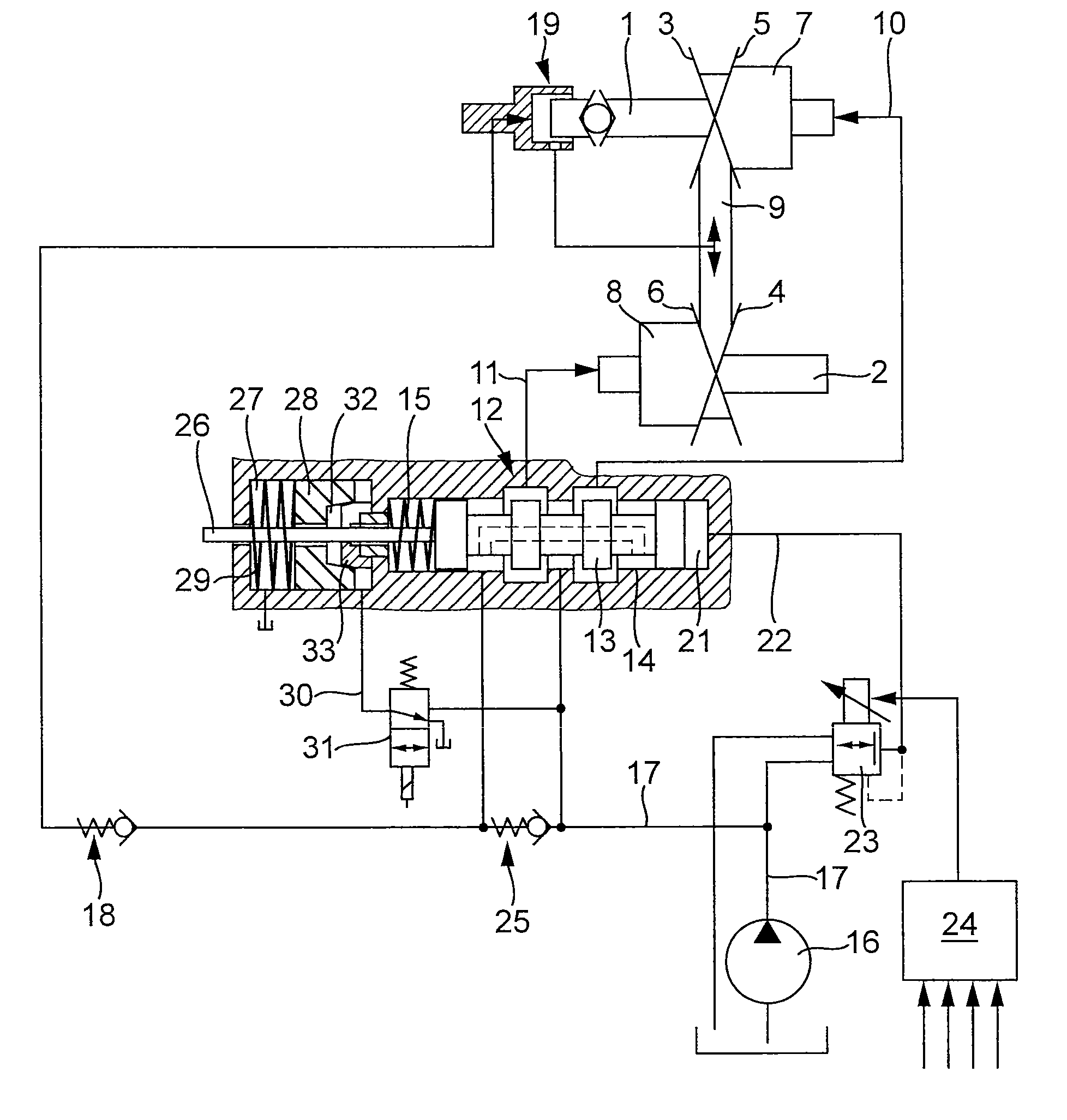

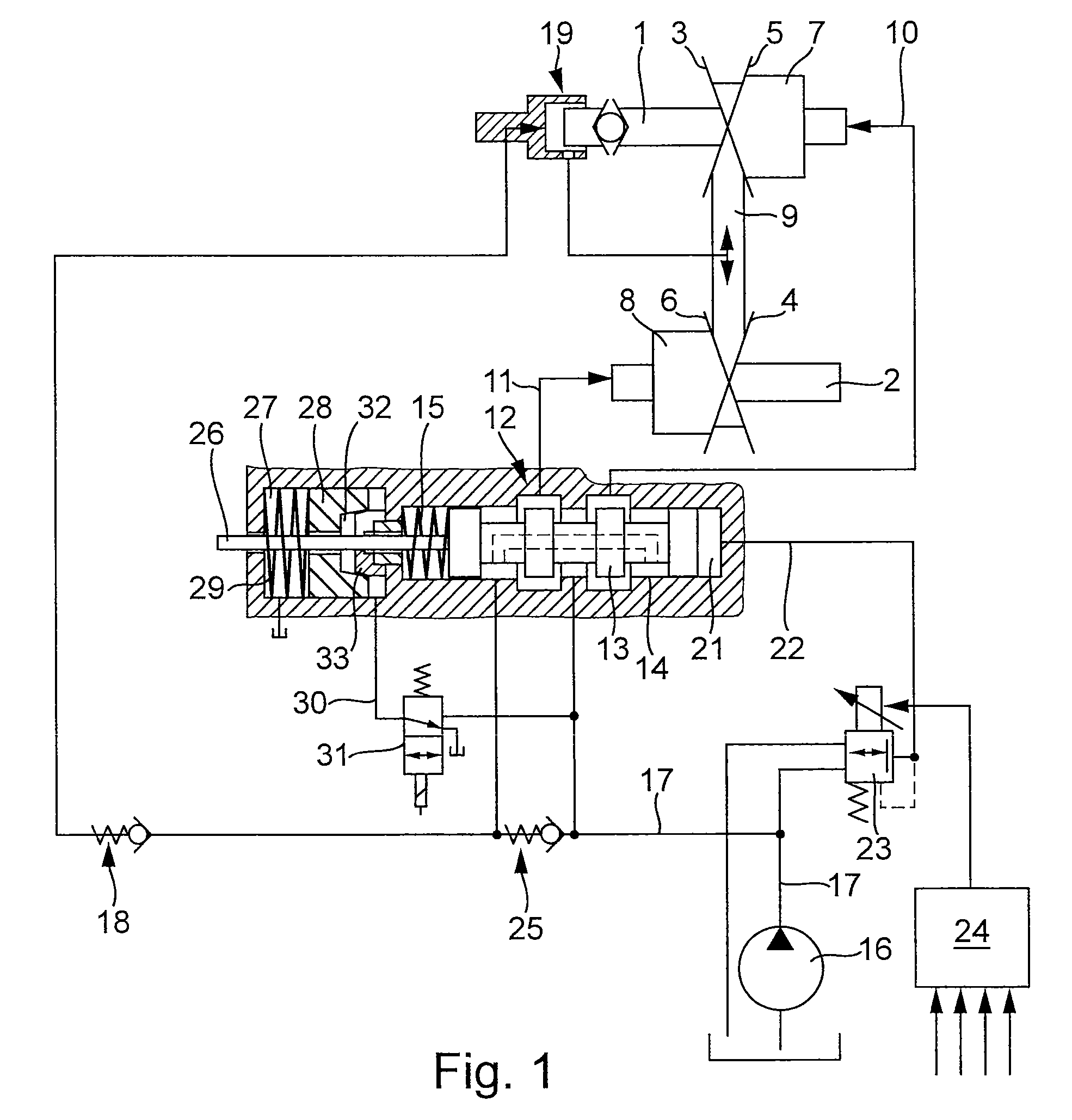

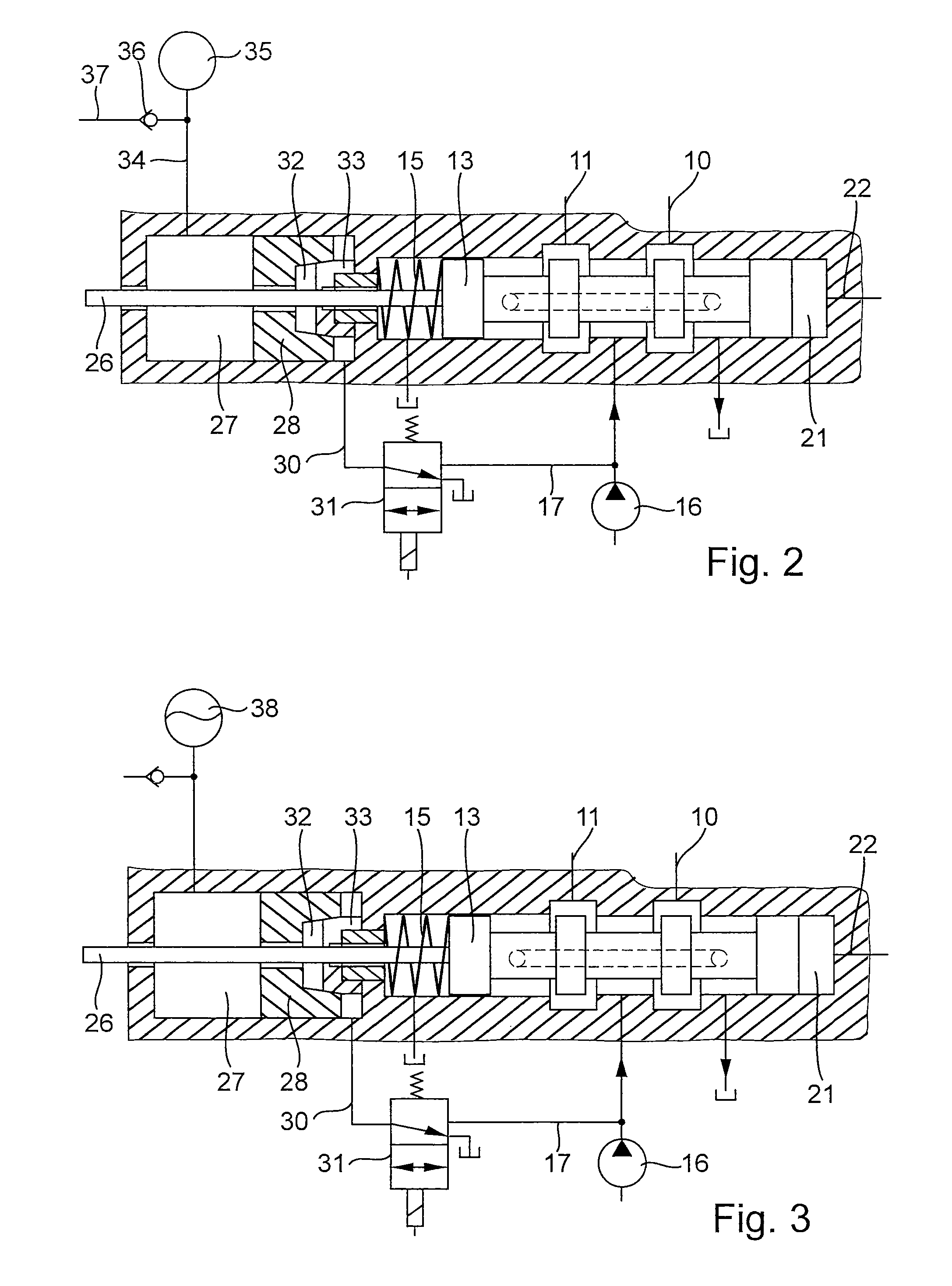

Hydraulically controlled cone disc continuously-variable transmission

InactiveUS20080026904A1Avoid sudden changesGuaranteed uptimeGearing controlEngine controllersDrive shaftEngineering

The invention concerns a continuously variable cone disc transmission with sets of discs mounted on drive and driven shafts. The sets of discs are each hydraulically adjustable axially in their distance from each other whereby the traction train circulating between them is able to adjust to different running circles and thereby enabling a continuously variable transmission. The pressure fluid needed for the hydraulic actuation is supplied to the pressure cylinders by a pump through a control valve. This control valve is actuated hydraulically by a pressure supply that is need-adjusted by a proportional-pressure reduction valve. In the event of a functional failure and consequent loss of the regulating pressure, the control valve is automatically arrested in position, so that the control valve is prevented from giving a command for the sudden change of the transmission ratio into an extreme position.

Owner:PIV DRIVES

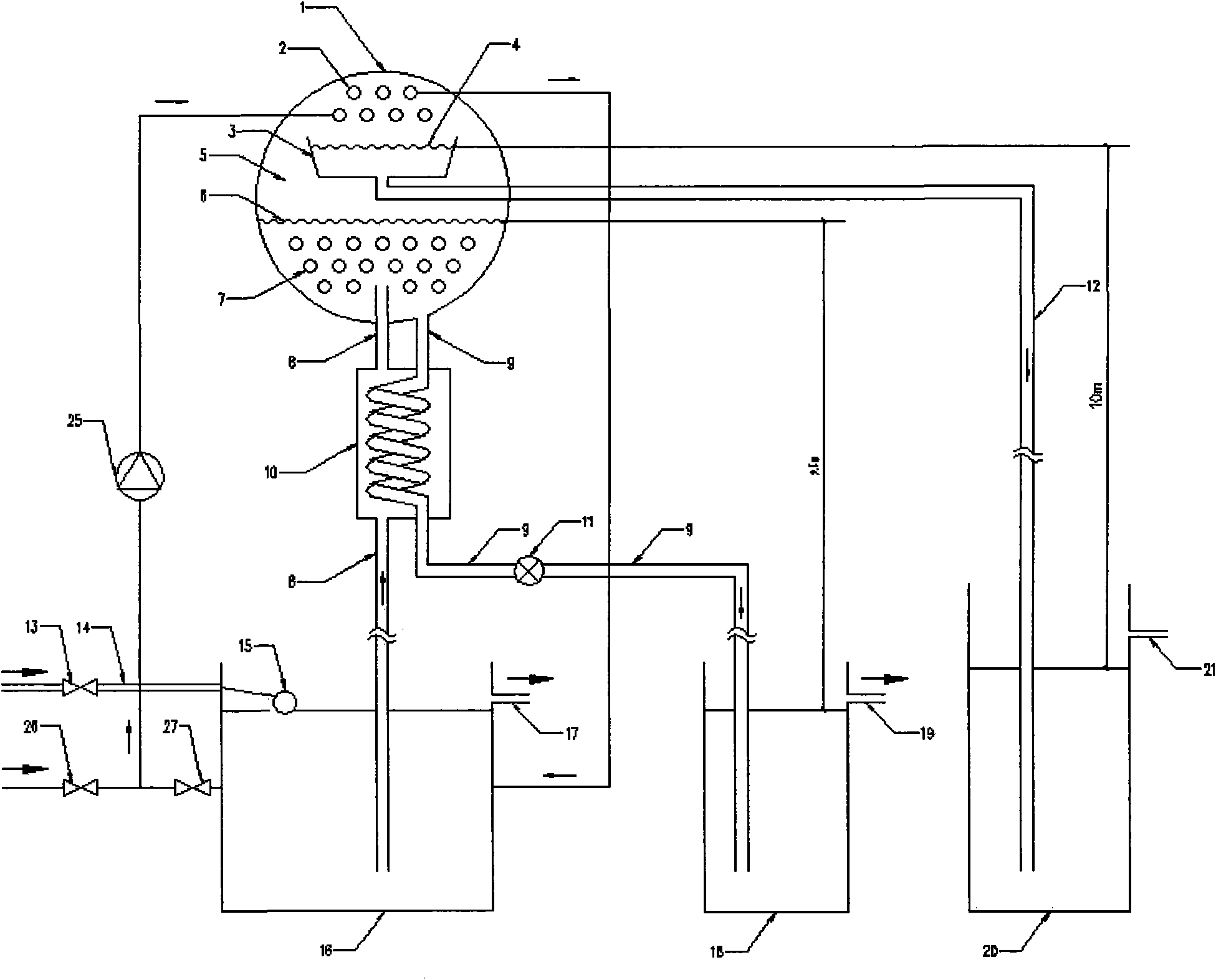

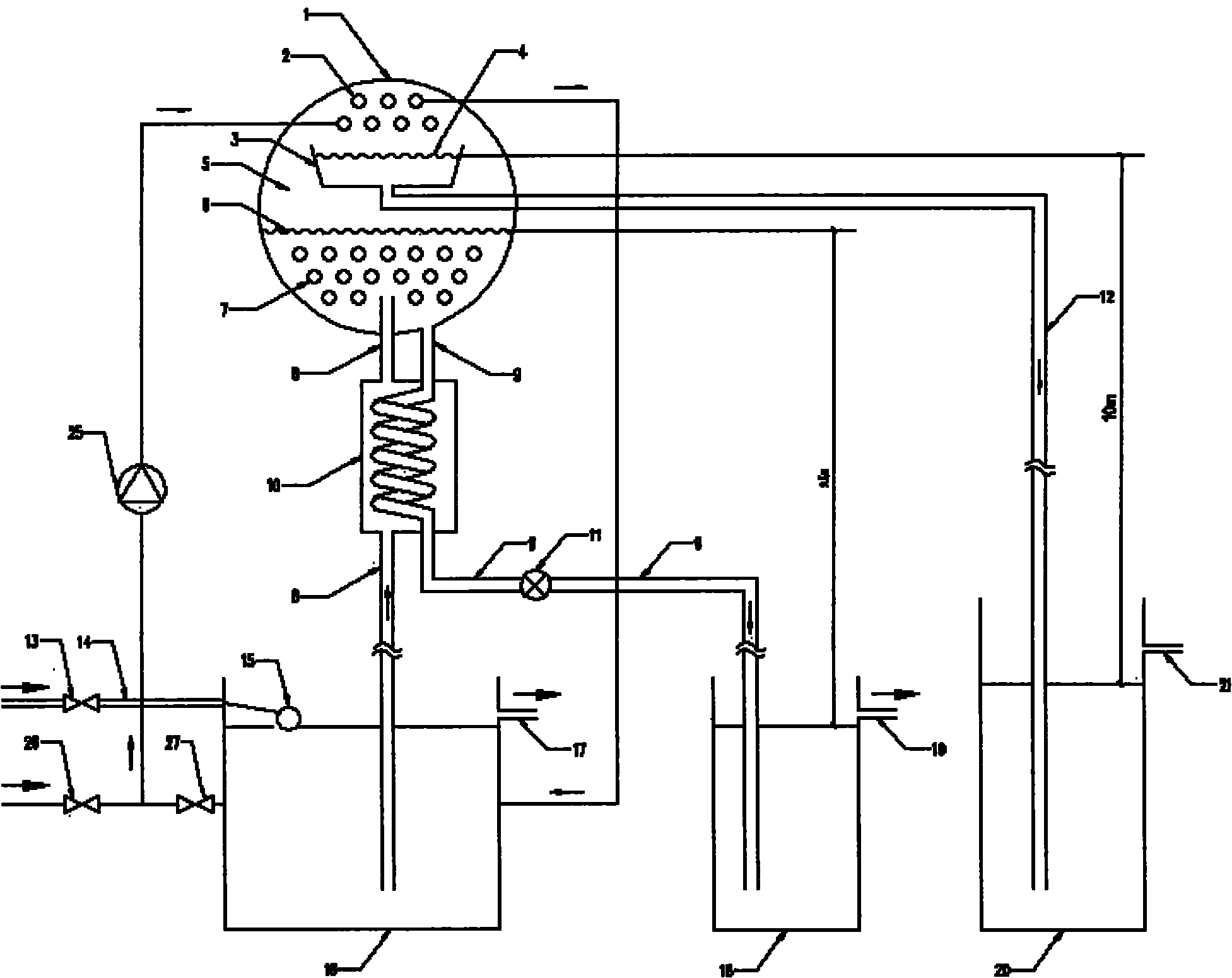

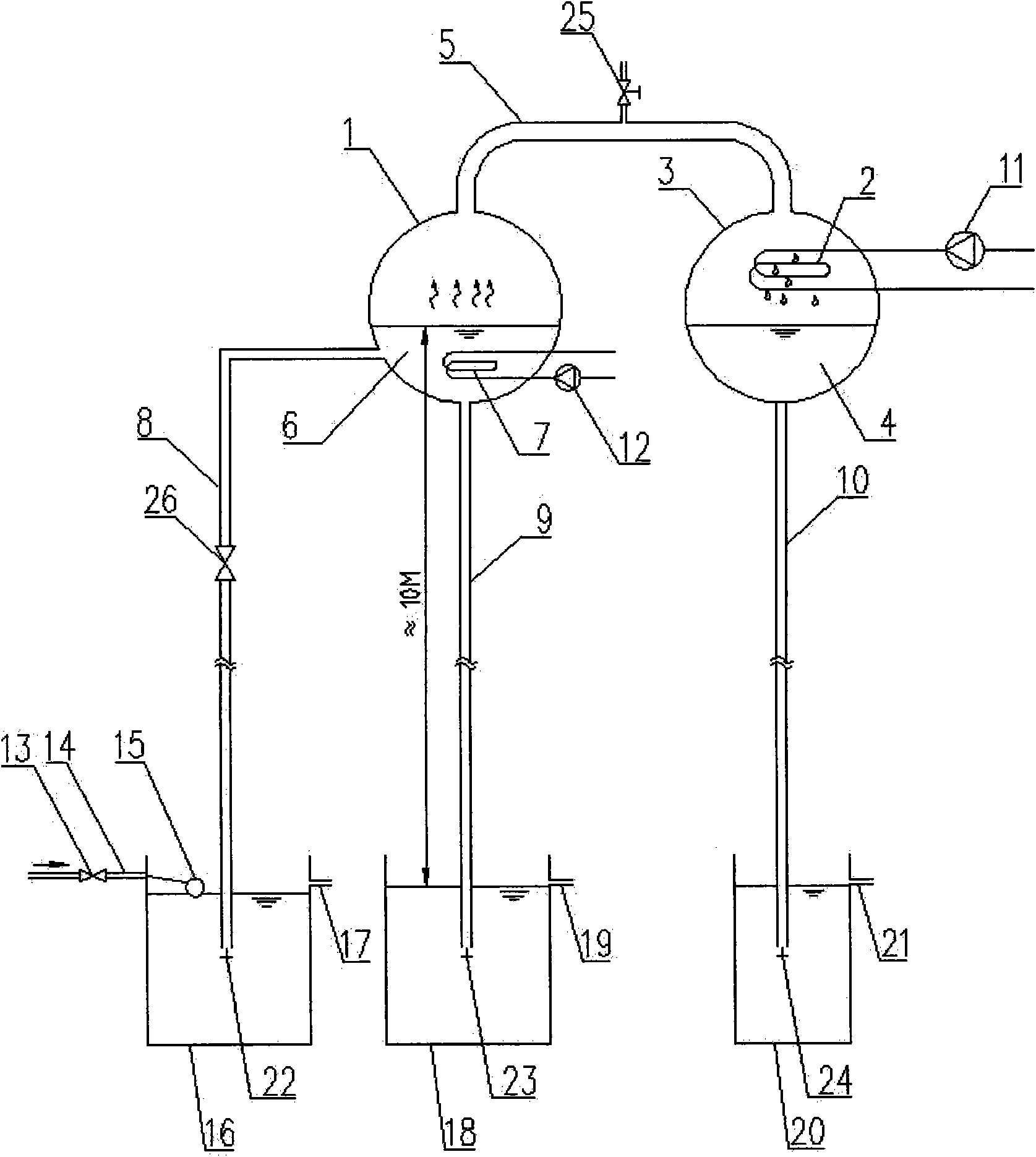

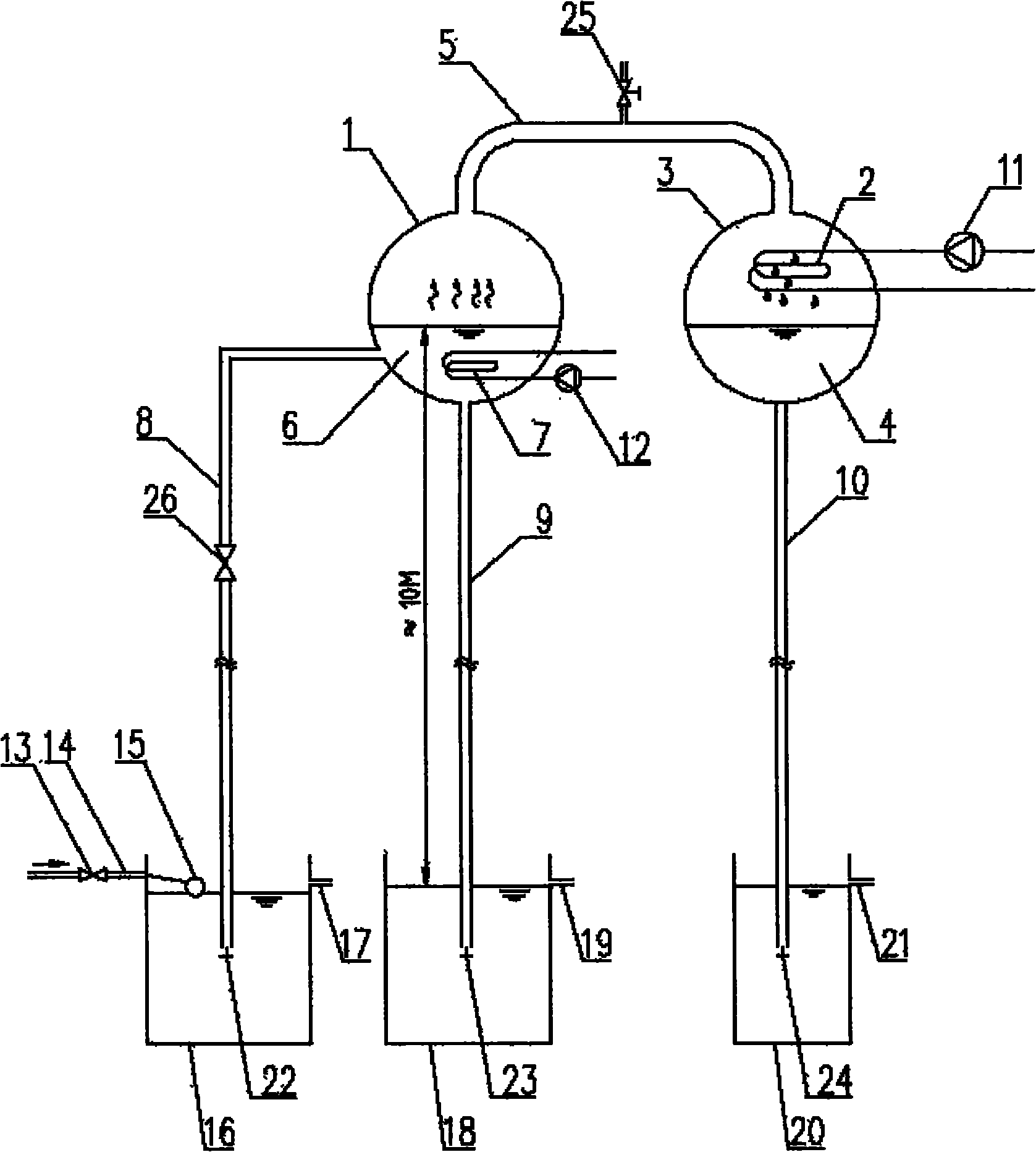

Low-temperature heat energy driven device for distilling and separating water evaporated under negative pressure

InactiveCN101993123AOvercome deficienciesOvercome defectsGeneral water supply conservationDistillation separationThermal energyEngineering

The invention aims to provide a device for distilling and separating water evaporated / boiled under negative pressure. The device has low heating temperature, high efficiency and low cost. The invention provides a scheme, which ensures that the needed negative pressure can be produced in the sea water desalinization systems without vacuum pumps, thus reducing the boiling temperature of the water solution to 30-50 DEG C. The water solution can be boiled as long as the temperature of the heating source is higher than 30-50 DEG C. The heating source for heating and evaporating the water solution in the invention can be water from solar heat collectors, tail water with higher temperature from the power plants, chemical plants, smelting plants and the like or water completing heat exchange with the residual heat from the power plants, chemical plants and smelting plants. The temperature of the heating fluid needed by the invention can be lower than 60 DEG C, preferably 37 DEG C, thus effectively utilizing the solar energy or largely recovering and utilizing the industrial residual heat and having great value in environmental protection and energy saving.

Owner:BEIHANG UNIV

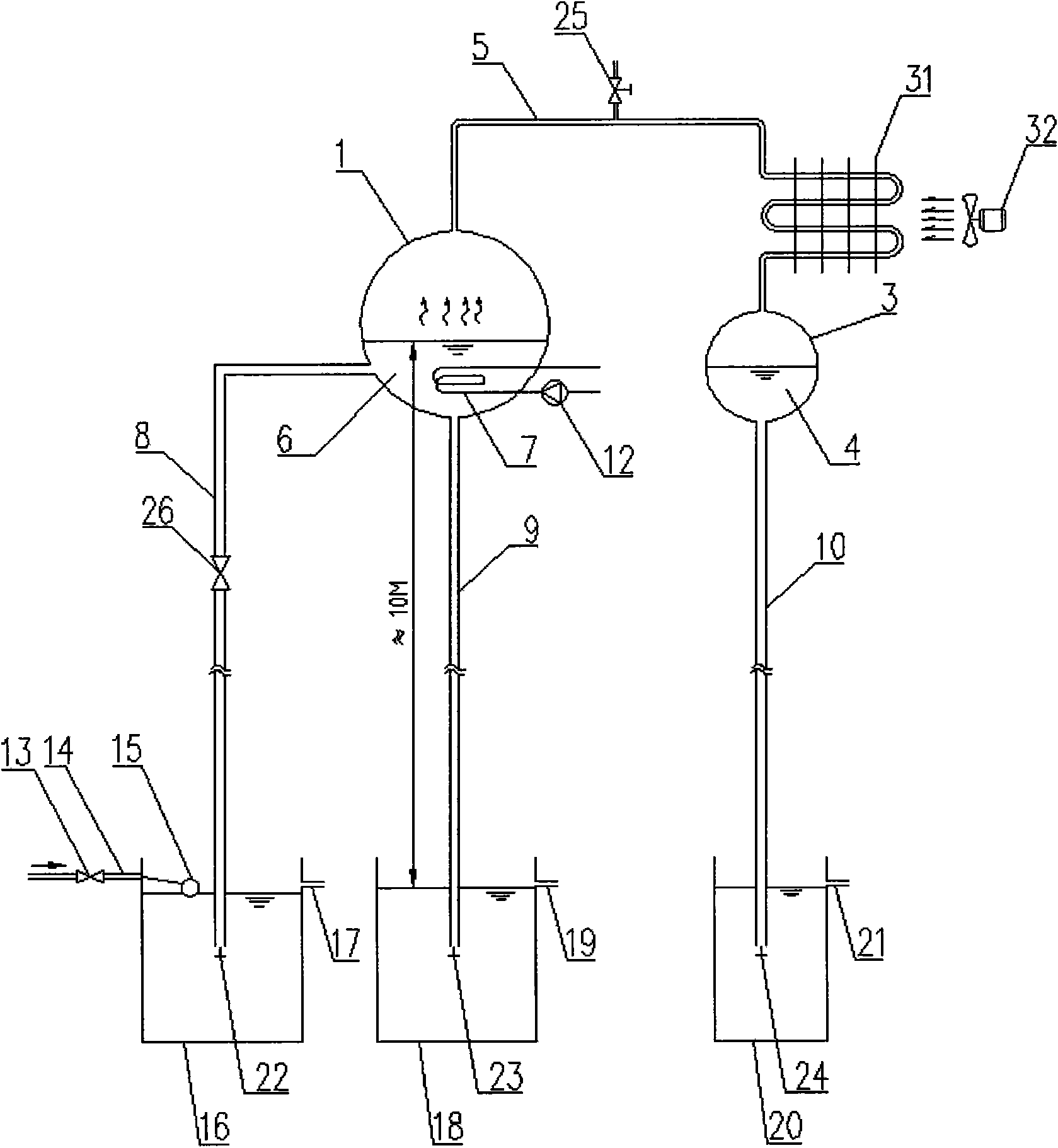

Low-temperature heat energy driven double-container device for distilling and separating water evaporated under negative pressure

InactiveCN101993122AOvercome deficienciesOvercome defectsGeneral water supply conservationWater/sewage treatment by heatingThermal energyDesalination

The invention aims to provide a device for distilling and separating water evaporated / boiled under negative pressure. The device has low heating temperature, high efficiency and low cost. The invention provides a scheme, which ensures that the needed negative pressure can be produced in the sea water desalinization systems without vacuum pumps, thus reducing the boiling temperature of the water solution to 30-50 DEG C. The water solution can be boiled as long as the temperature of the heating source is higher than 30-50 DEG C. The heating source for heating and evaporating the water solution in the invention can be water from solar heat collectors, tail water with higher temperature from the power plants, chemical plants, smelting plants and the like or water completing heat exchange with the residual heat from the power plants, chemical plants and smelting plants. The temperature of the heating fluid needed by the invention can be lower than 60 DEG C, preferably 37 DEG C, thus effectively utilizing the solar energy or largely recovering and utilizing the industrial residual heat and having great value in environmental protection and energy saving.

Owner:BEIHANG UNIV

Fluid intake and content management system

A system for managing the fluid intake of a person is disclosed. The system consists of multiple containers of various volumes, a common lid configured to incorporate a flow control valve, multiple flow control valves having varying flow rates, a date indicator ring incorporated circumferentially on said containers, a content indicator disposed on said lid, a chiller insert, and an optional slip on handle. The user selects a container based on the fluid needs of a person and a flow control valve based on the drinking ability of the person. The user fills the container with a drinkable fluid, and indicates the nature of the contents with the content indicator and the date of filling with the date indicator ring. The chiller insert allows the user to cool the contents without the possibility of dilution as with standard ice cubes.

Owner:YOUNG JONES DIANE

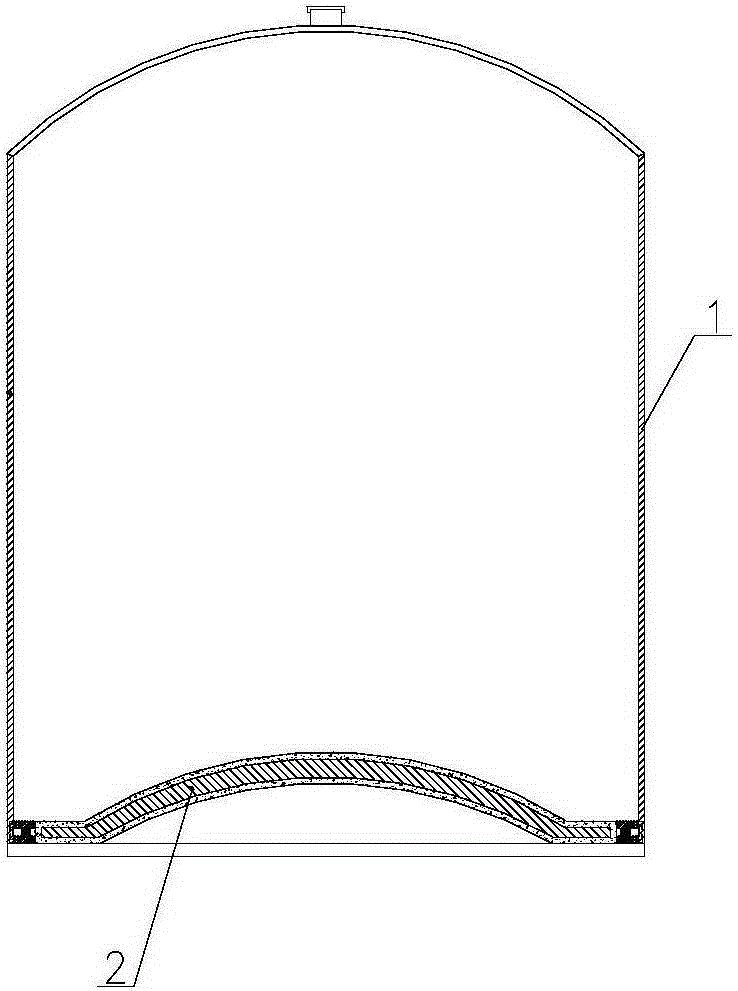

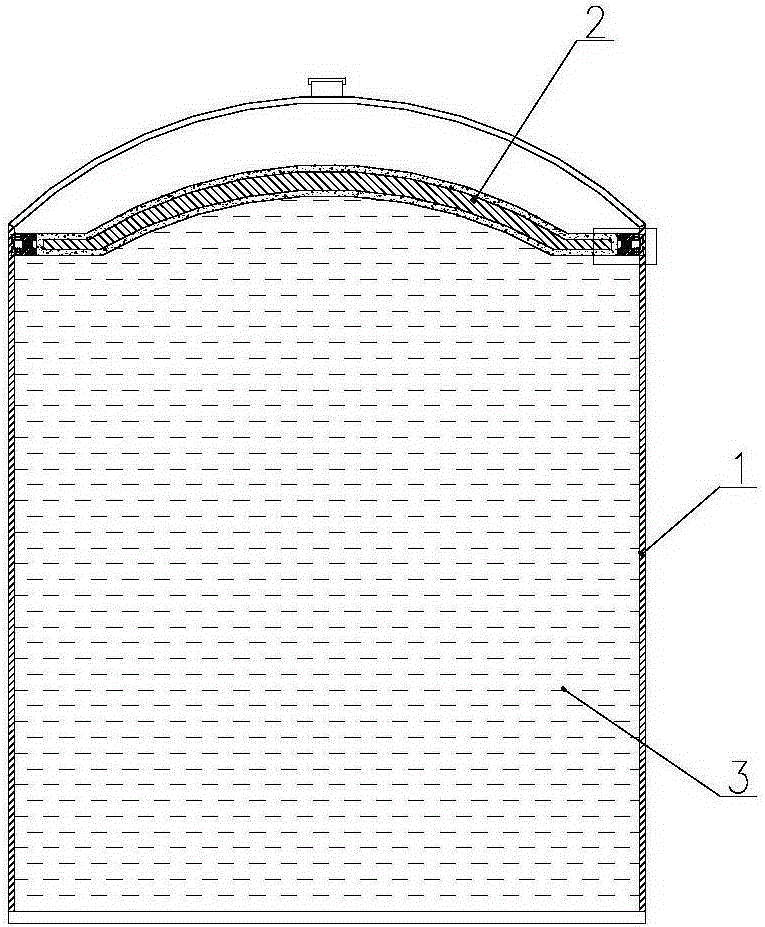

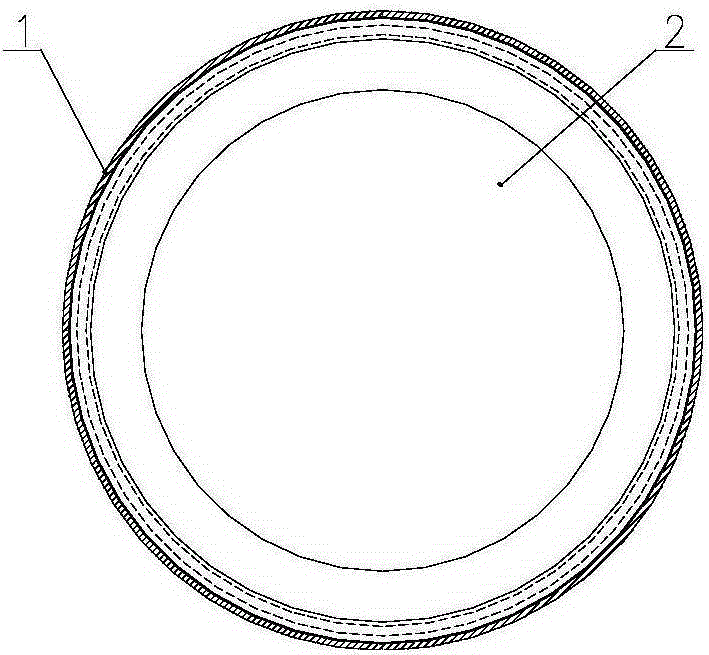

Magnetic fluid sealing device for gasholder

ActiveCN105351738AAdaptableMeet sealing requirementsVariable capacity gas holdersLower poleMagnetic liquids

The invention discloses a magnetic fluid sealing device for a gasholder. The magnetic fluid sealing device is installed between a piston of the gasholder and the inner wall of a holder body, and comprises an upper pole shoe, a lower pole shoe, a permanent magnet, pole teeth and a magnetic fluid, wherein the upper pole shoe and the lower pole shoe are of an annular structure respectively, and located on the upper part and the lower part of a disc edge of the piston respectively, and the upper pole shoe and the lower pole shoe are both magnetic conductors; the permanent magnet is clamped between the upper pole shoe and the lower pole shoe, is of an annular structure, and is out of touch with the piston; the plurality of pole teeth are provided, and arranged on the end parts of the upper pole shoe and the lower pole shoe, a certain gap is kept between the end part of each pole tooth and the inner wall of the holder body, and the magnetic fluid is injected in each gap; the holder body is made of a metal magnetic conductor material, the piston is made of a non-metal non-magnetic conductive material, and the magnetic fluid is a magnetic liquid. The sealing device disclosed by the invention is bidirectional, applicable to gas holders with various capacities, simple in structure, high in stability, and convenient to maintain because only the magnetic fluid needs to be regularly supplemented; and with the adoption of the sealing device, the invalid capacity of the gas holder is small, and the construction cost is greatly reduced.

Owner:WISDRI ENG & RES INC LTD

Medical luer fitting that promotes liquid mixing

InactiveUS20090143770A1Reduce of stagnant flowEasy to cleanMedical devicesCatheterPlenum chamberFluid need

A medical luer connection improves liquid mixing thereby reducing areas of low or stagnant flow within the plenum chamber formed between the male and female luer connectors. Stagnation or low flow areas in the plenum can be reduced by imparting a non-axial flow component to the fluid flow as it passes through the plenum. Improvement of the cleaning effectiveness of the luer connection reduces the amount of flushing fluid needed to clean the connection, reduces the residual blood matter at a fixed volume of fluid relative to a standard luer connection, or combinations of the above.

Owner:ROBINSON MARK RIES +2

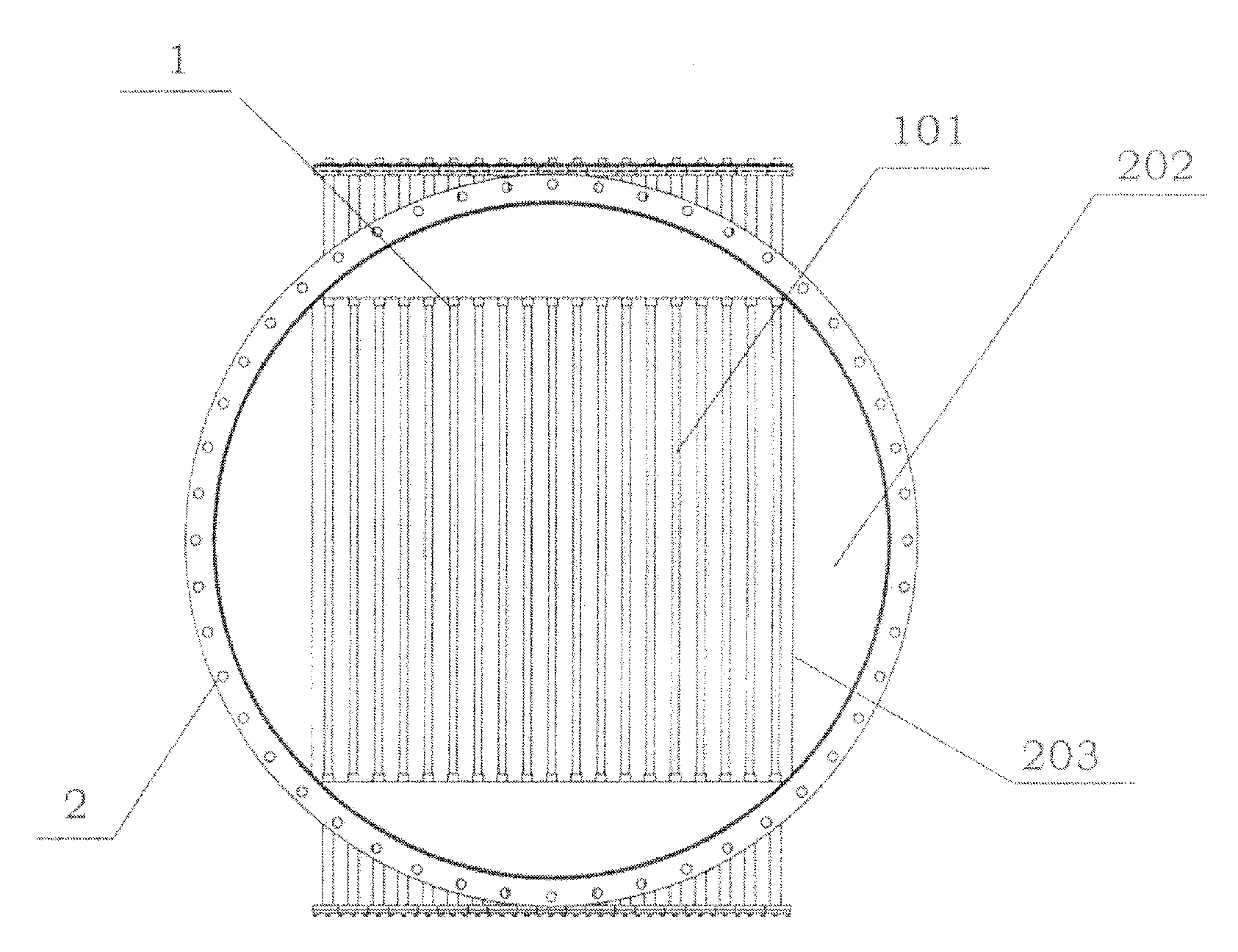

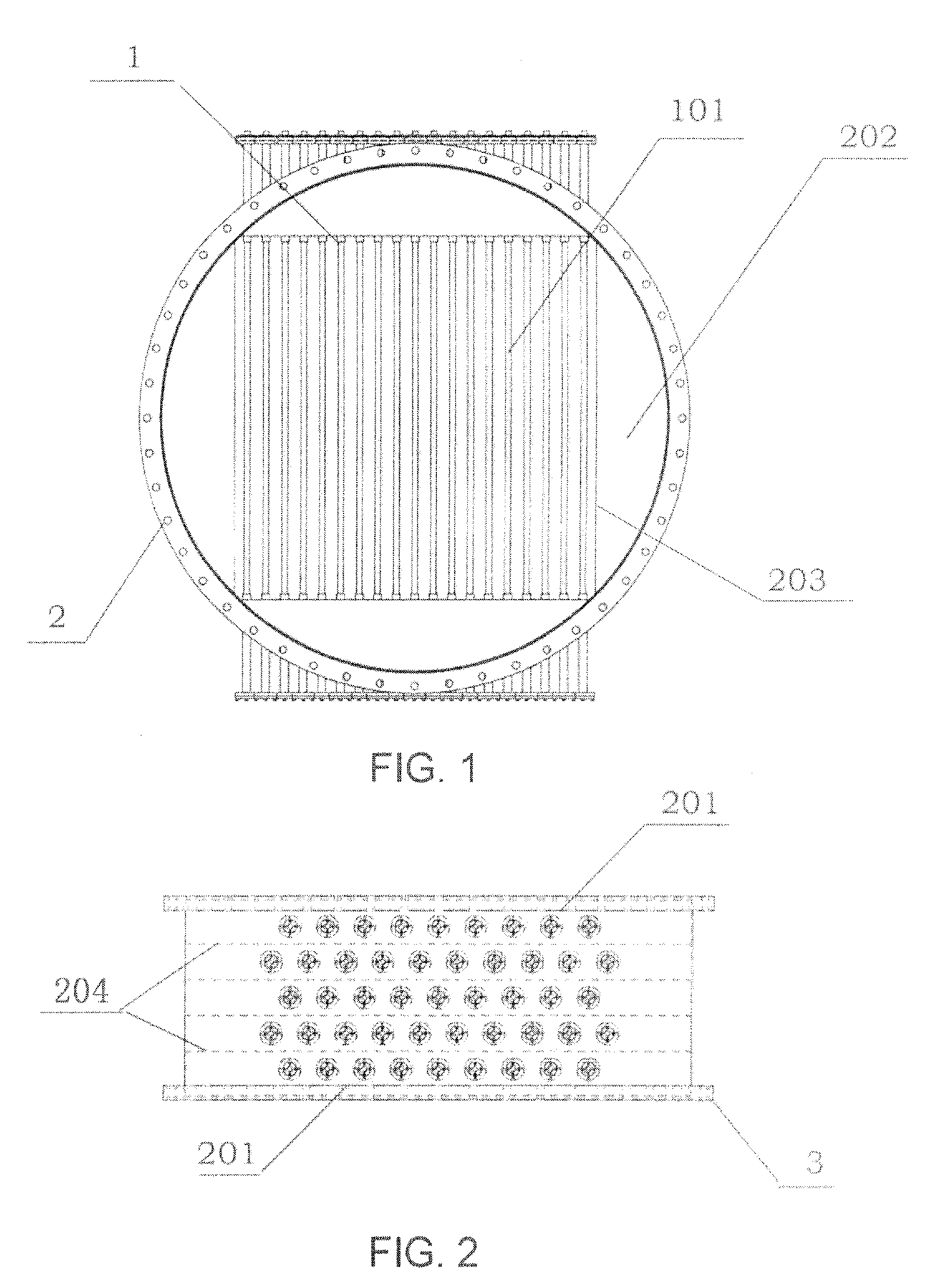

UV Sterilizer for Fluid of Large Flow Rate

InactiveUS20090291036A1Improve stress resistanceReduce system costEnergy based chemical/physical/physico-chemical processesWater/sewage treatment apparatusUv disinfectionEngineering

A UV sterilizer for fluid of large flow rate comprises at least one U V sterilization module and an mounting part for said module, each module comprising at least one UV lamp tube, said mounting part comprising a body in the form of a duct for the passage of fluid to be sterilized therethrough, with a number of mounting apertures for the UV sterilization module being provided on the wall of the duct, and on one or both end surfaces of the duct there being provided a baffle extending from the outer peripheral of said one or both end surfaces towards the center thereof, with a port being left on said one or both end surfaces with the baffle for the passage of fluid to be sterilized therethrough. The UV sterilizer for fluid of large flow rate of the present invention may be widely used in water supply plant, pharmaceutical plant, food plant, drink plant, or other plants or sites where fluid need to be sterilized.

Owner:FUJIAN NEWLAND ENTECH CO LTD

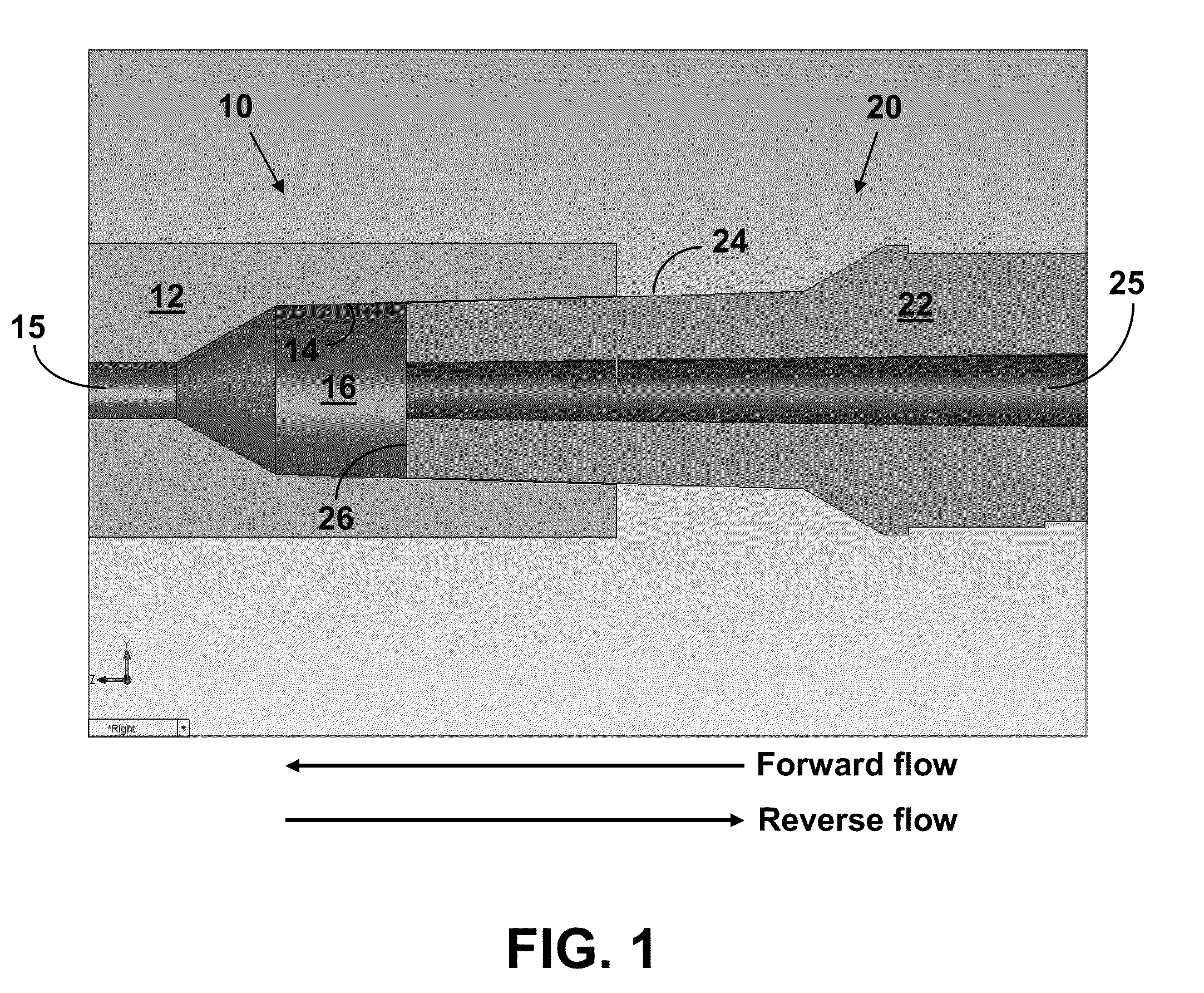

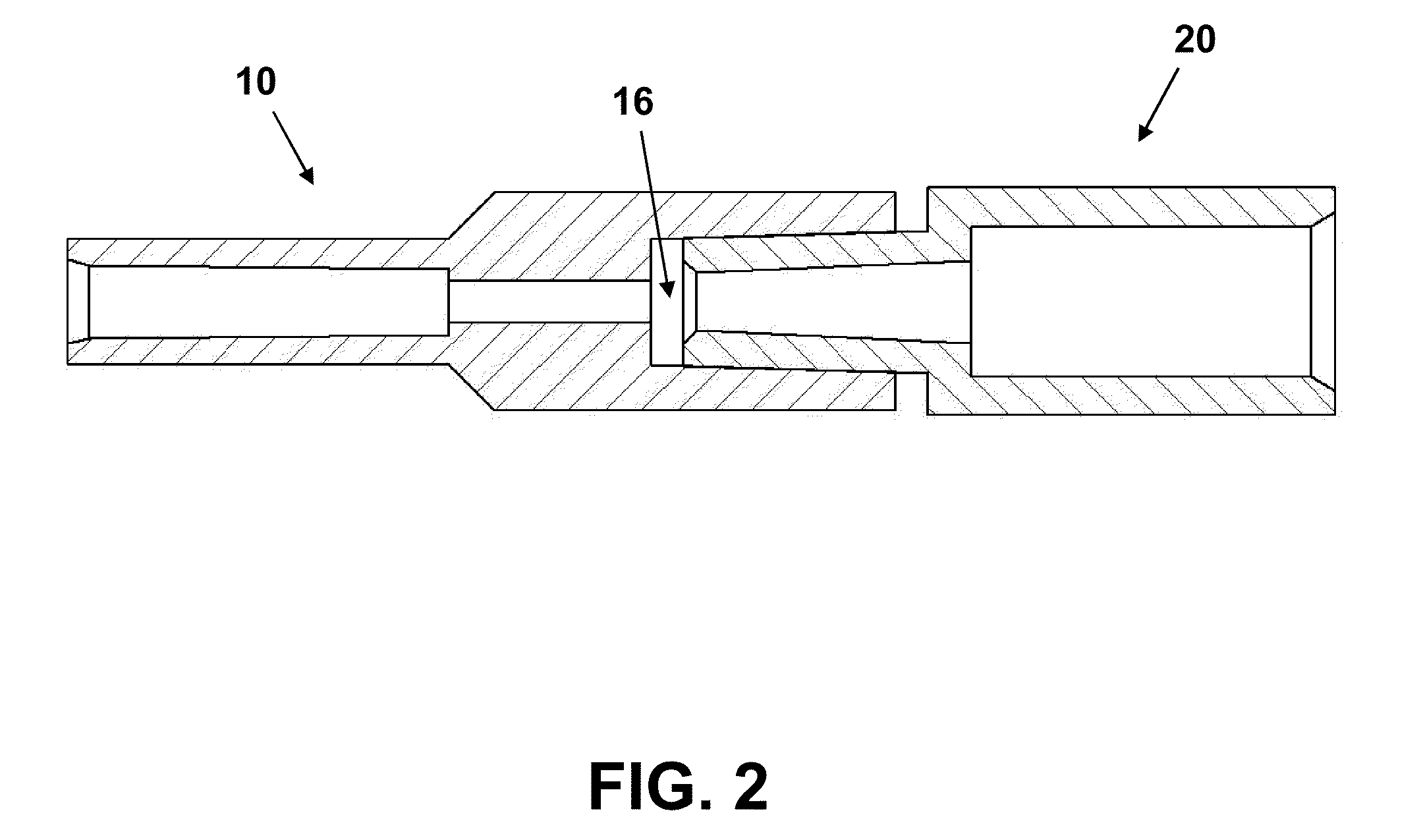

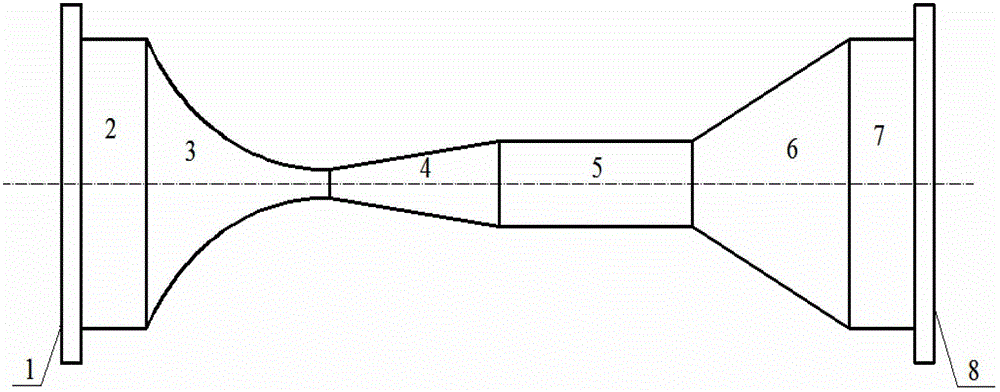

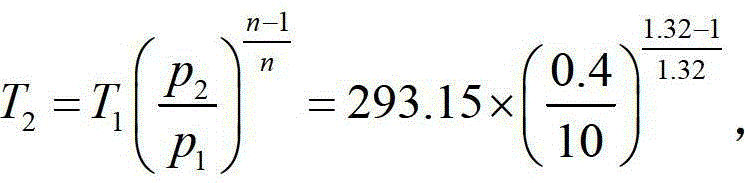

Pressure reducing device with temperature recovery function

InactiveCN102748332ALittle changeChange does not happenFluid-pressure convertersCompressed fluidEngineering

The invention relates to a pressure reducing device with a temperature recovery function. The pressure reducing device is applied to occasions where high-pressure compressible fluid needs to be converted into low-pressure fluid through throttling, and obvious temperature reduction is not allowed to occur, and belongs to the field of energy conservation and utilization. The pressure reducing device comprises an intake flange (1), an intake straight section (2), a laval nozzle taper section (3), a laval nozzle divergent section (4), a straight section (5), a diffusion section (6), a discharge straight section (7) and a discharge flange (8) which are connected continuously. The device has very broad pressure reduction range, has a compact structure and no moving parts, and is not easy to crack or leak.

Owner:BEIJING UNIV OF TECH

Fluid pressure stabilizing valve

ActiveCN103527829AConstant pressureProtect safe operationEqualizing valvesSafety valvesEngineeringFluid need

The invention relates to a fluid pressure stabilizing valve. The fluid pressure stabilizing valve comprises a valve body, a valve cover and a spring, wherein the valve body is composed of a valve seat, a valve element and stiffeners; the stiffeners connect the valve seat and the valve element; the valve seat is a hollow cylinder; through holes are formed in the solid part of the hollow cylinder in the axial direction; the valve element is composed of a spring seat and a locating needle; the stiffeners connect the bottom end of the spring seat and the bottom end of the valve seat; the valve cover is composed of a cover body and a locating column which is located in the middle of one side of the cover body and perpendicular to the cover body; the locating column is a hollow column; the inner diameter of the hollow part of the hollow column is greater than the outer diameter of the locating needle; guide protrusions are evenly distributed on the periphery of the cover body; one end of the spring is installed on the spring seat; the other end of the spring is installed on the locating column in a sleeved mode; the locating needle is inserted into the locating column. The fluid pressure stabilizing valve is ingenious in structure, reliable to operate and constant in water pressure output, and can be used on the various different occasions where pressure of fluid needs to be limited and stabilized, effectively prevent fluid pipelines from being cracked by over large pressure and also meet the requirement for pressure limiting and stabilizing in the conveying process of certain fluid.

Owner:项大利

Hydraulically controlled cone disc continuously-variable transmission

InactiveUS7955202B2Guaranteed uptimeAvoid the needGearing controlEngine controllersDrive shaftEngineering

Owner:PIV DRIVES

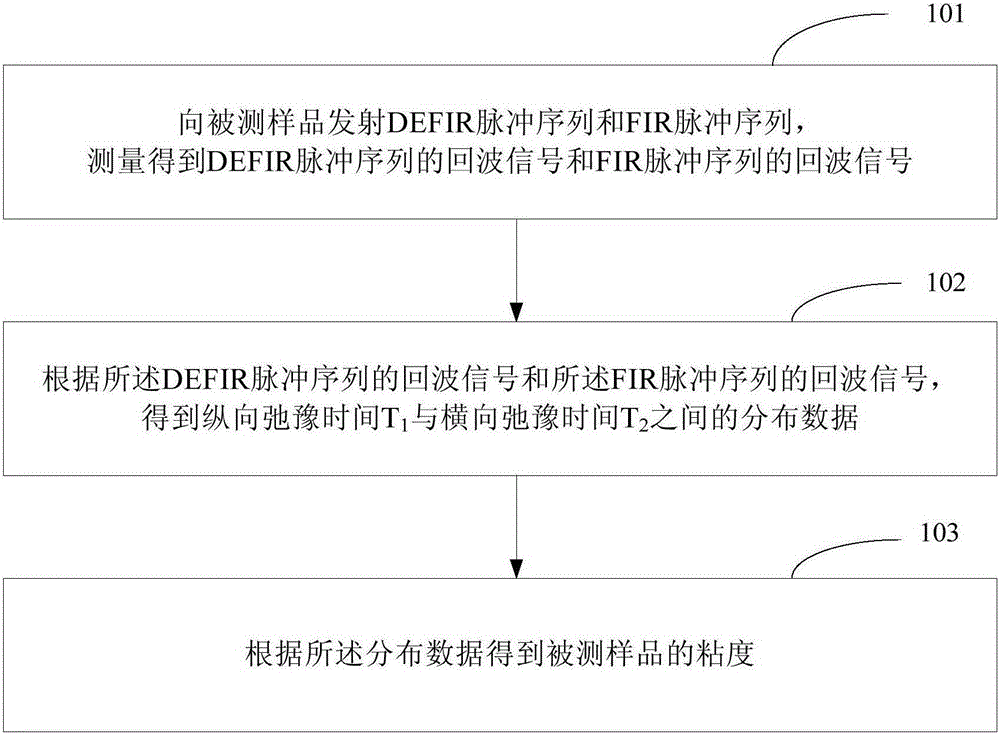

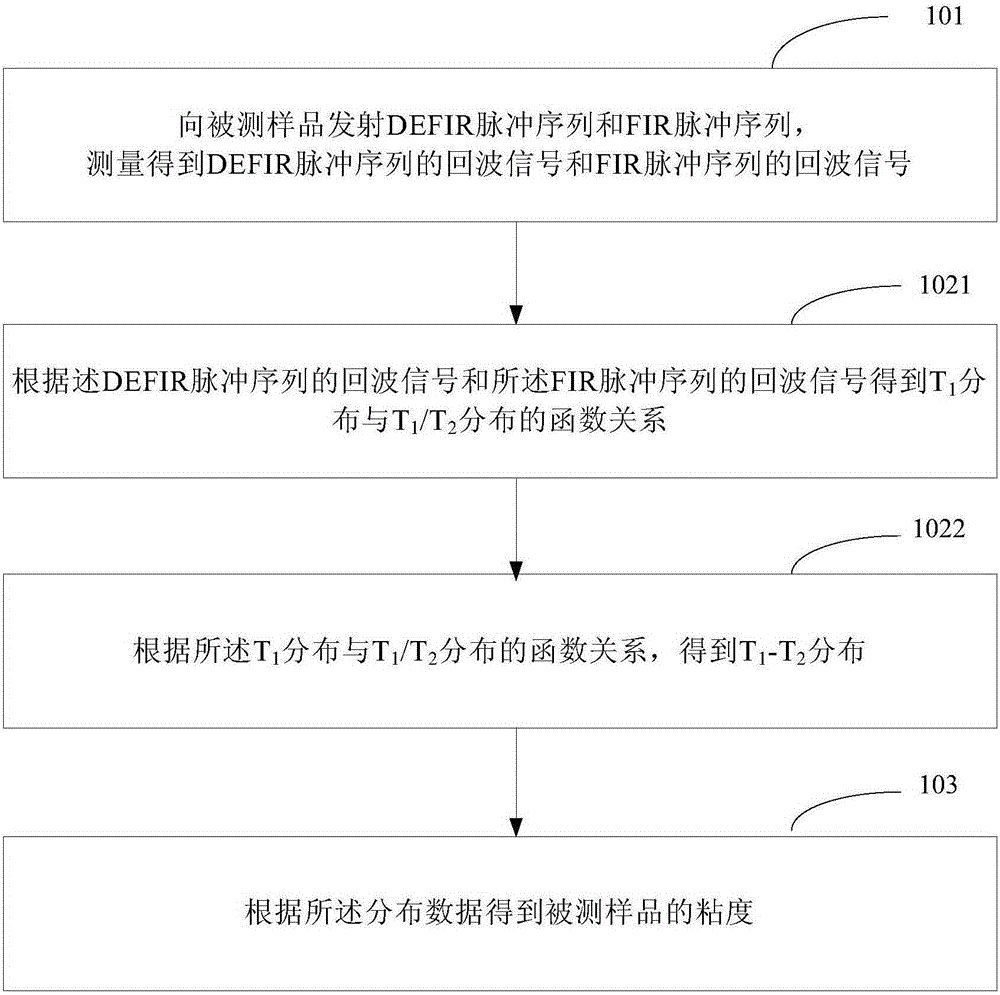

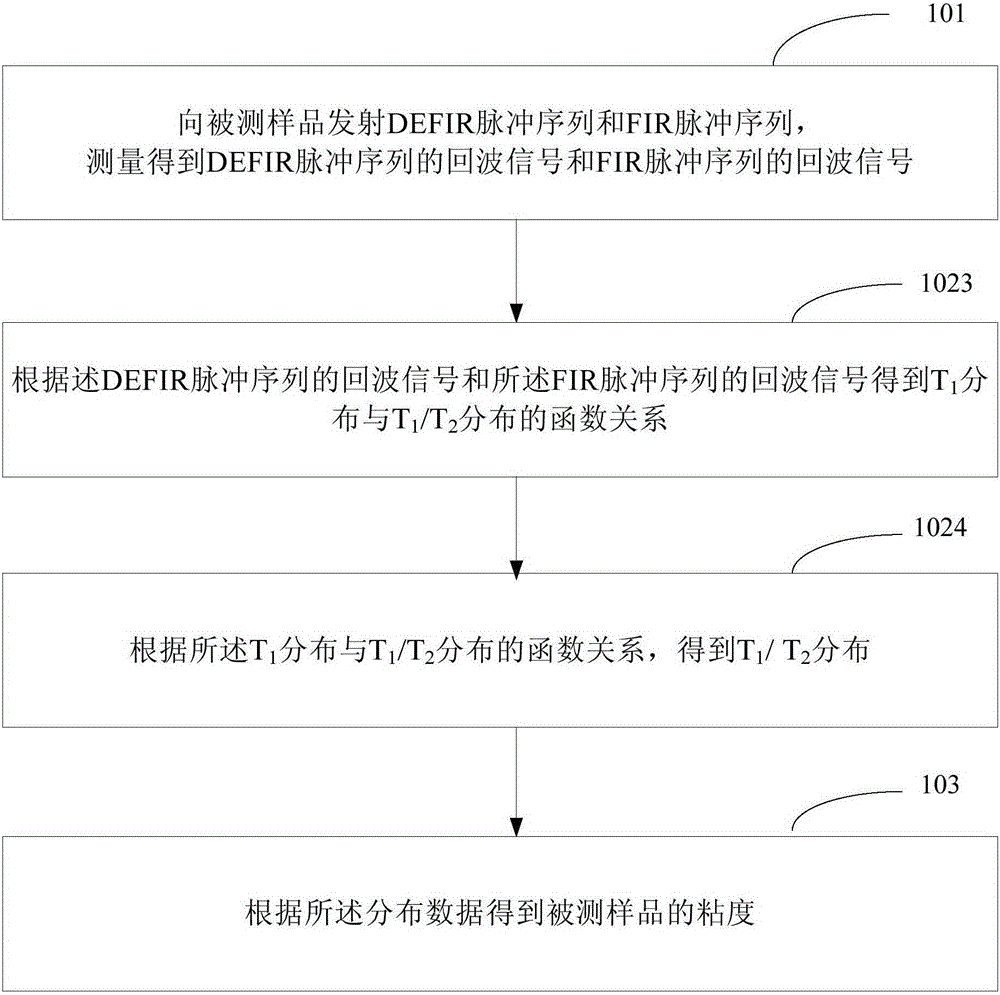

Fast crude oil viscosity measurement method

ActiveCN105352847AEnables real-time in situ viscosity measurementImprove detection efficiencyFlow propertiesAnalysis using nuclear magnetic resonancePulse sequenceEcho signal

The present invention discloses a fast crude oil viscosity measurement method which is as follows: a DEFIR pulse sequence and a FIR pulse sequence are transmitted to a to-be-tested sample, a DEFIR pulse sequence echo signal and a FIR pulse sequence echo signal are measured; longitudinal relaxation time T1 and transverse relaxation time T2 distribution data can be obtained according to the DEFIR pulse sequence echo signal and the FIR pulse sequence echo signal; and the viscosity of the to-be-tested sample can be obtained according to the distribution data. According to the method, real-time on-site viscosity measurement of a reservoir fluid can be achieved, the method makes up the defect that by the traditional fluid viscosity measurement method, the fluid needs to be collected from a reservoir to the ground, on the one hand the detection efficiency is improved; on the other hand viscosity changes caused by ambient temperature and pressure changes in the process of the delivery of the fluid from the reservoir to a ground laboratory can be avoided, and the viscosity measurement is more accurate.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Cleaning brush with cleaning fluid inside

InactiveCN103126292AEasy to useSolve the problem of pouring cleaning fluid into the cleaning brush multiple timesBrush bodiesBristle carriersBristleEngineering

The invention provides a cleaning brush with cleaning fluid inside. The cleaning brush with cleaning fluid inside comprises a storage tube, a handle, a brush head and an elastic part. The lower end of the handle is detachably connected with the upper end of the storage tube, the brush head is detachably connected with the lower end of the storage tube, the storage tube is provided with an air inlet hole, a sealing unit is arranged on the air inlet hole, and the elastic part is arranged between the brush head and the storage tube. Cleaning fluid is filled in the storage tube, flows into a hollow pipe in the brush head by extruding the elastic handle and moving the elastic part downwards under air pressure and flows to bristles from a cleaning fluid outlet on the hollow pipe. The cleaning brush with cleaning fluid is simple in structure and convenient to use, and solves the problem that cleaning fluid needs to pour to the cleaning brush multiple times during use of common cleaning brushes.

Owner:陈彦霖

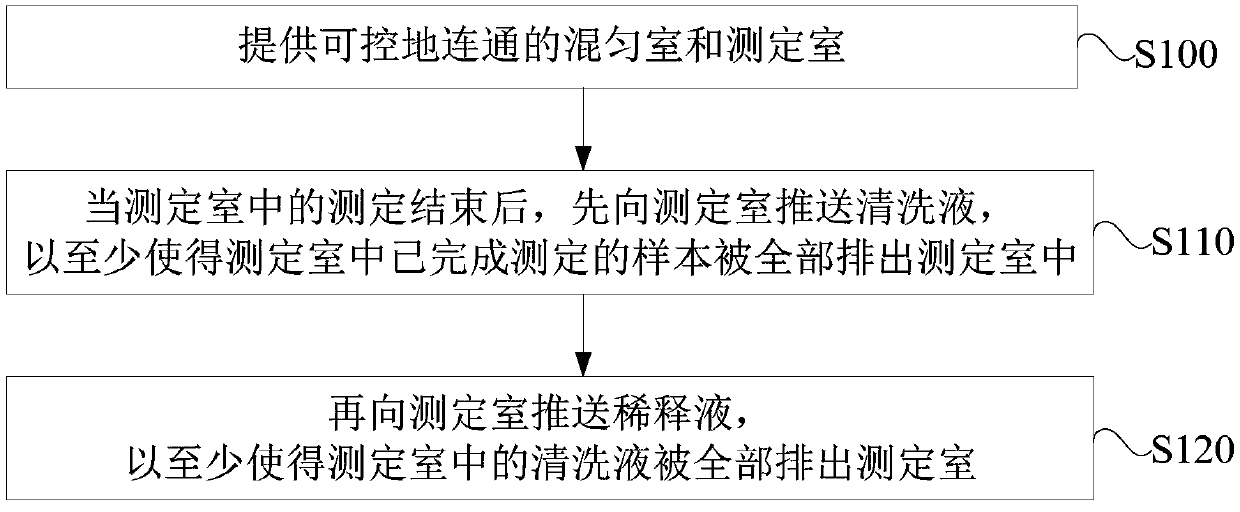

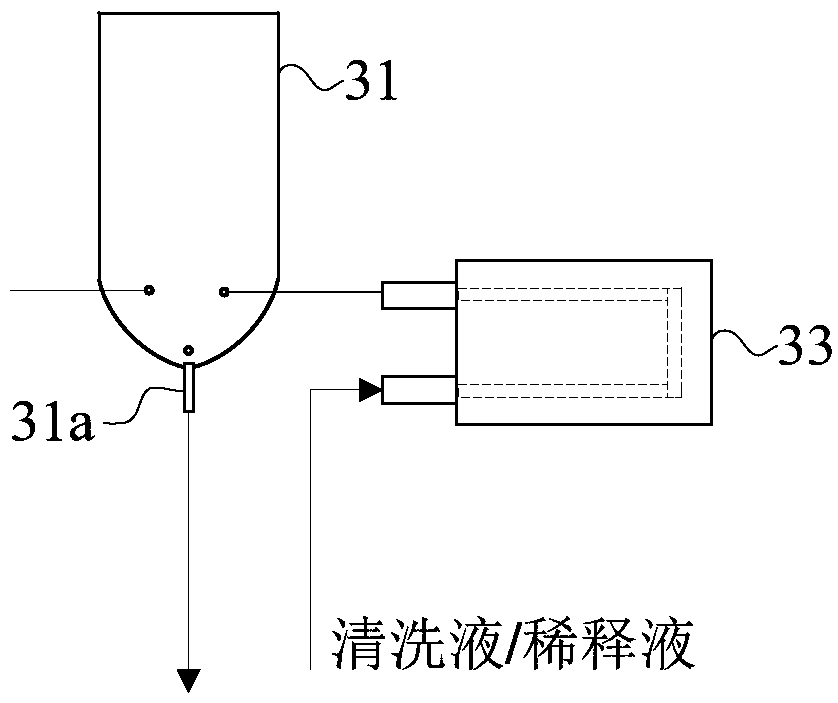

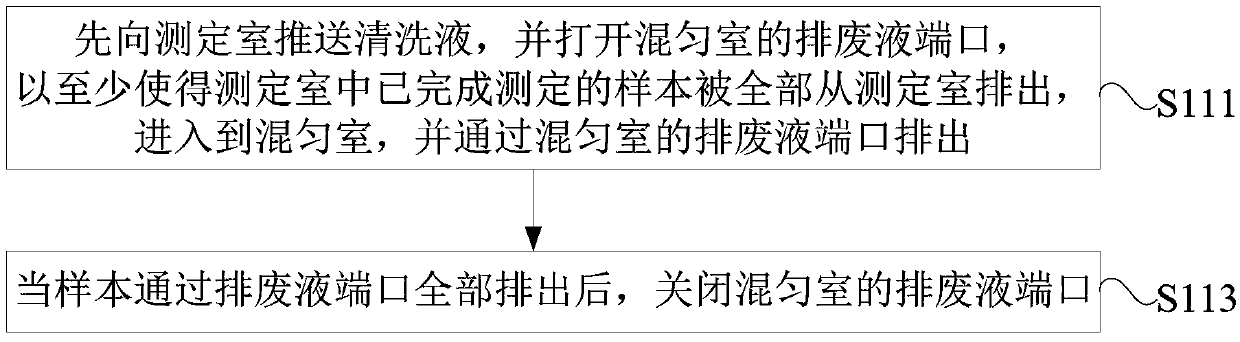

Method for cleaning reactants and sample analyzer

ActiveCN110270564AAvoid problems affecting cleaning resultsShort measurement periodHollow article cleaningBiological testingDiluentEngineering

The invention discloses a method for cleaning reactants and a sample analyzer. According to the method for cleaning the reactants, a mixing chamber and a measuring chamber which controllably communicate with each other are provided, when the measuring chamber and the mixing chamber are cleaned, a replacement type cleaning mode is adopted, so that a sample in the measuring chamber is replaced by a cleaning liquid firstly, and then the cleaning fluid in the measuring chamber is replaced by a diluent, so that cleaning is completed, the mixing chamber also has the similar condition, wherein a sample in the mixing chamber is replaced by the cleaning liquid firstly, and then the cleaning fluid in the mixing chamber is replaced by the diluent, so that cleaning is completed, therefore, the problem that the dilution concentration of the cleaning fluid needs to be accurately controlled so as to prevent the influence caused by the dilution concentration on the cleaning result is solved, accordingly, in the whole cleaning process of the method, the process of diluting the cleaning liquid is also avoided, so that the whole measuring period is directly shortened, and the measuring speed is increased.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

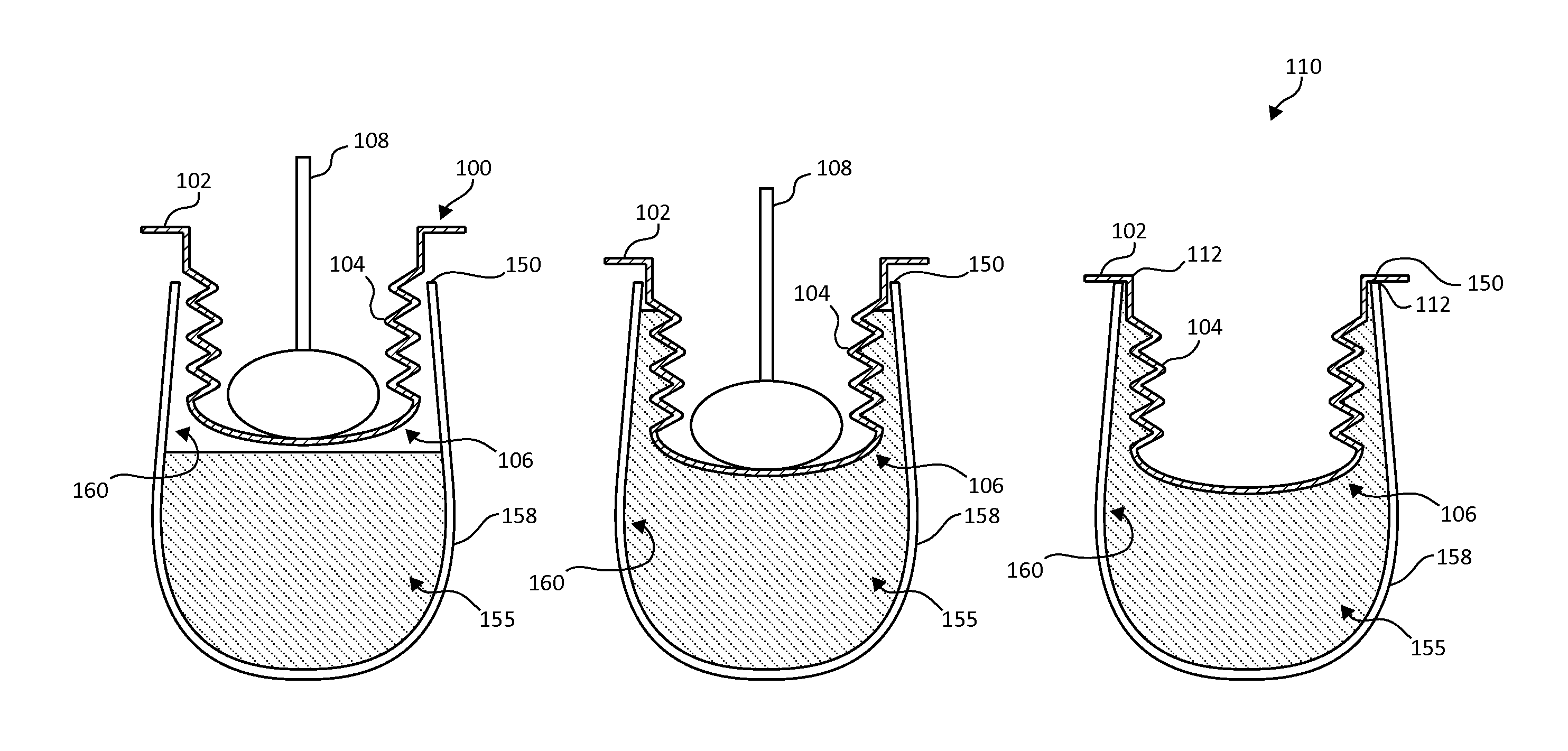

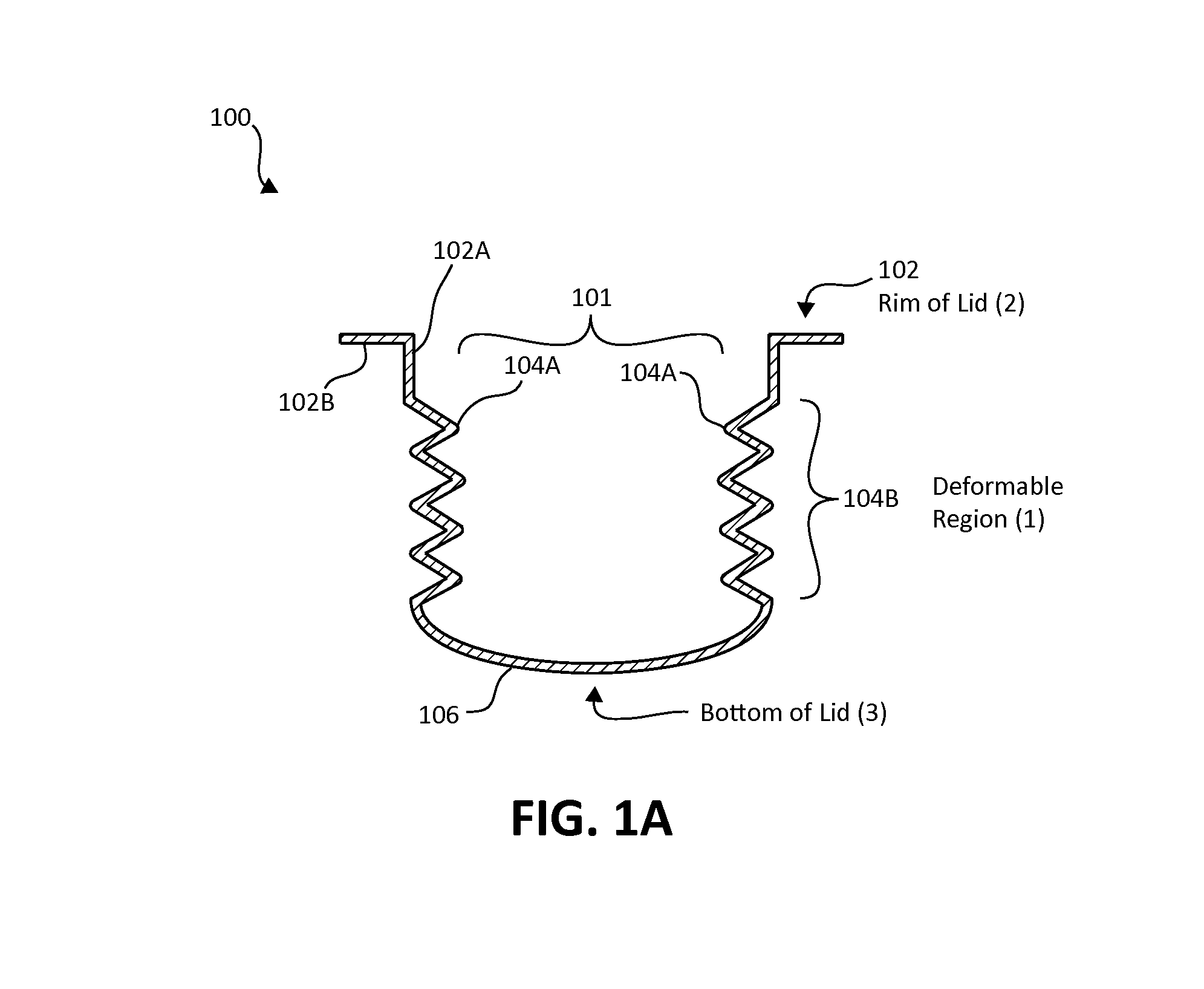

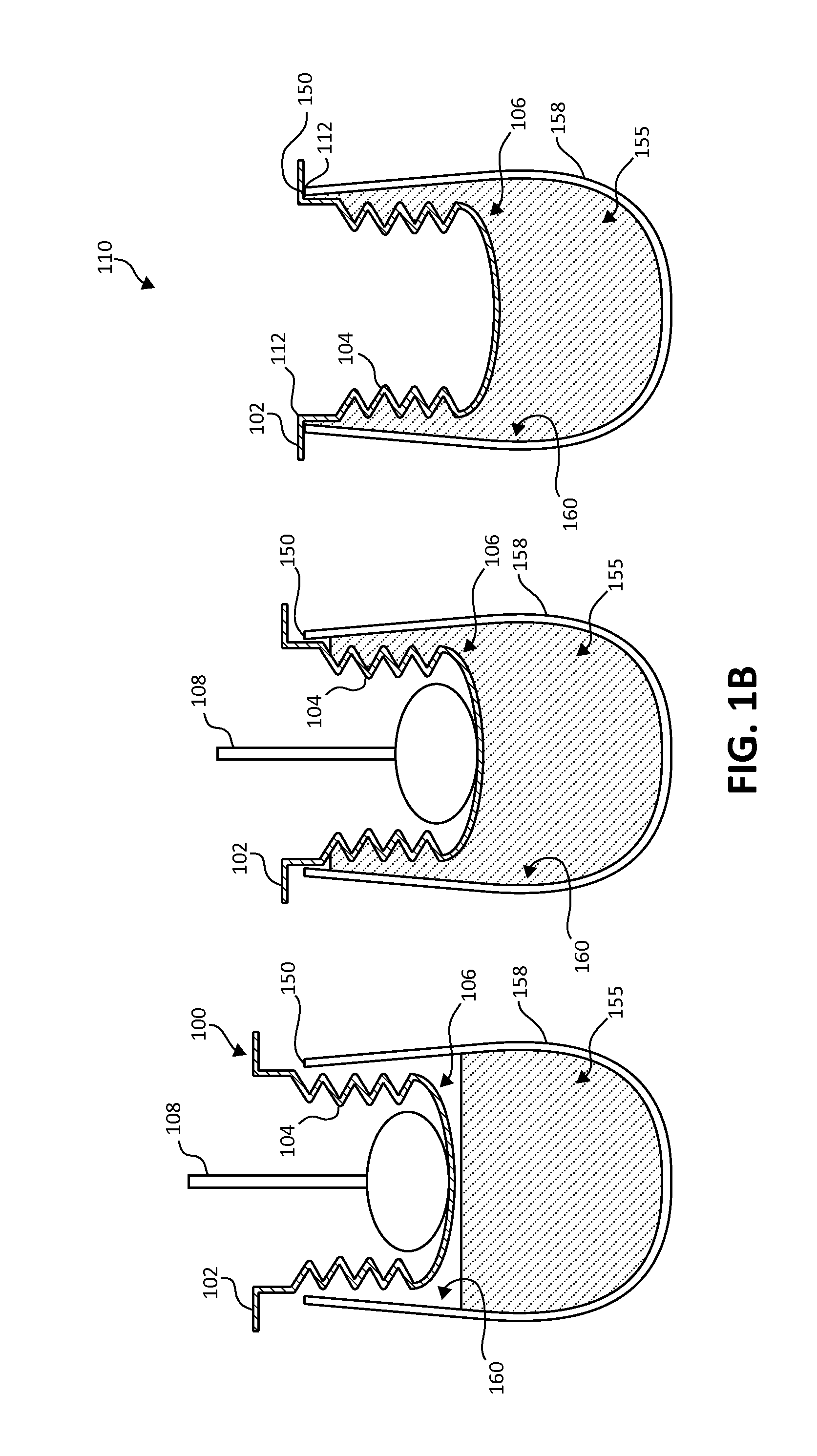

Air purging lid

A lid, having an opening area encased by one of the variety of shaped sidewalls with a flexible ribbed portion extending downwardly to one of the variety of shaped bases (e.g., a domed shaped base), is provided for completely purging of atmospheric gases out of a container upon installation so as to eliminate head space by forming an airtight barrier with the container and the lid. A lid rim, having an inside portion connected to the top of the one of the variety of shaped with the flexible ribbed portion and an outside portion is provided for sealing the lid to the container. The dome shaped base is connected to the bottom of the one of the variety of shaped sidewalls forming a circular base of the lid. The one of the variety of shaped sidewalls is provided for manipulating the lid from a relaxed state to an elongated state while being submerged into a liquid to displace an amount of fluid needed to raise the fluid level.

Owner:MATSCH GARY

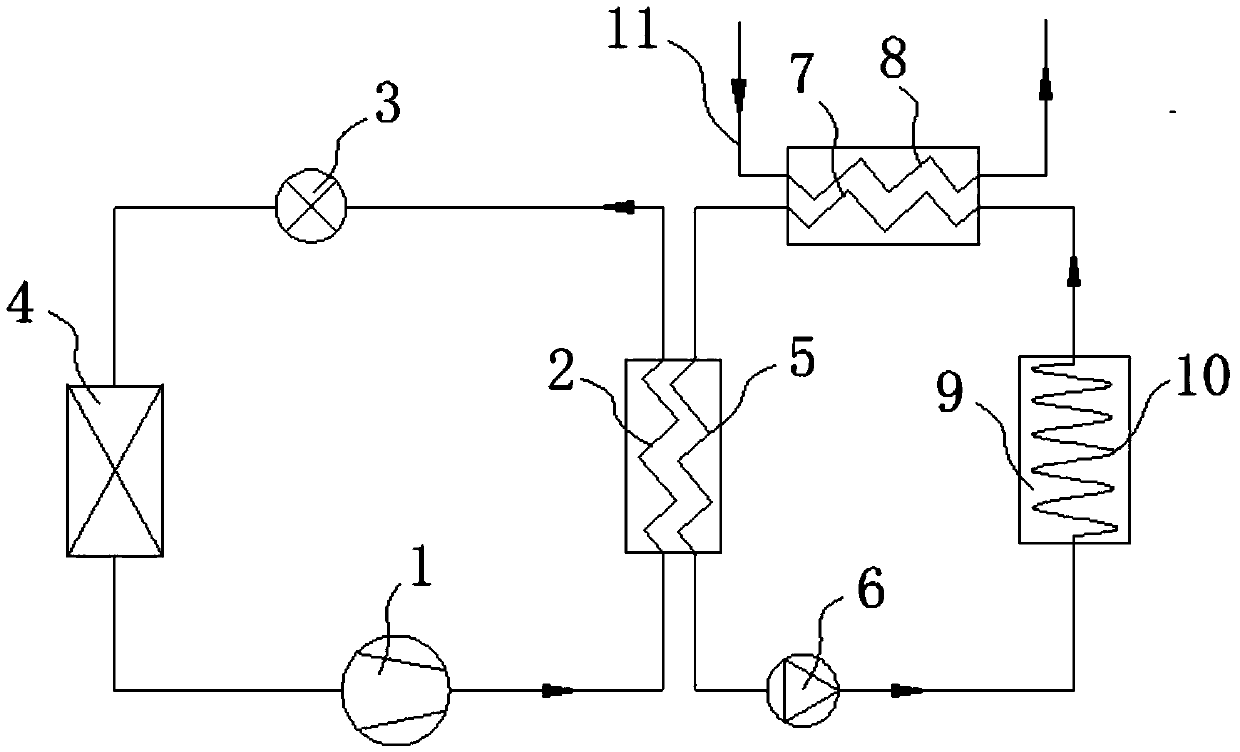

Temperature control device, method and system

PendingCN110513879AAdjust heating powerAvoid exceeding the set temperature phenomenonStorage heatersElectricityTemperature control

The invention provides a temperature control device, method and system and relates to the technical field of temperature control. The device is arranged on the outer side of a pipeline in a winding manner through a heating assembly. The portion between the heating assembly and the pipeline is filled with a phase change heat storage material. A first temperature sensor is arranged on the inner wallof the pipeline and used for measuring the temperature of fluid in the pipeline. A second temperature sensor is arranged on the outer wall of the heating assembly and used for measuring the outside environment temperature of fluid outside the pipeline. A control circuit is electrically connected with the heating assembly, a heat dissipating assembly, the first temperature sensor and the second temperature sensor. After the fluid needing temperature control enters the pipeline, when temperature rising or temperature lowering is needed, according to the set temperature and the fluid temperaturemeasured by the first temperature sensor, the control circuit can drive the heating assembly or the heat dissipating assembly to work, and by means of the assisting function of the second temperaturesensor and the phase change heat storage material, in the fluid temperature control process, the phenomenon that the actual temperature surpasses the set temperature can be avoided.

Owner:NANJING FORESTRY UNIV

High-efficiency environmental-friendly belt conveyor cleaning device

The invention discloses a high-efficiency environmental-friendly belt conveyor cleaning device which comprises an ultrasonic cleaning device arranged on a belt conveyor and used for cleaning, as well as a pollution discharge channel, wherein the ultrasonic cleaning device further comprises a transducer, an ultrasonic generator, a storage tank, a cleanout fluid ejection pipeline and a work head; the transducer converts electric energy into mechanical energy; the ultrasonic generator generates a high-frequency electric signal; the work head is arranged at one end of the cleanout fluid ejection pipeline. The high-efficiency environmental-friendly belt conveyor cleaning device disclosed by the invention is simple in structure, reasonable in design and high in practicality. Compared with a pure water pressure flushing device, the device disclosed by the invention does not need high water pressure, only cleanout fluid needs to be flushed onto the belt surface, extra friction obstruction is not produced to the belt conveyor so as not to cause damage, and the cleaning effect is good. Because the ultrasonic wave is high in frequency, short in wavelength and high in penetrating power, any tiny position of the belt can be completely cleaned, a striking effect can be achieved, the efficiency is high, the service life of the belt conveyor is greatly prolonged, and the environmental pollution is reduced.

Owner:HENGYANG CONVEYING MACHINERY

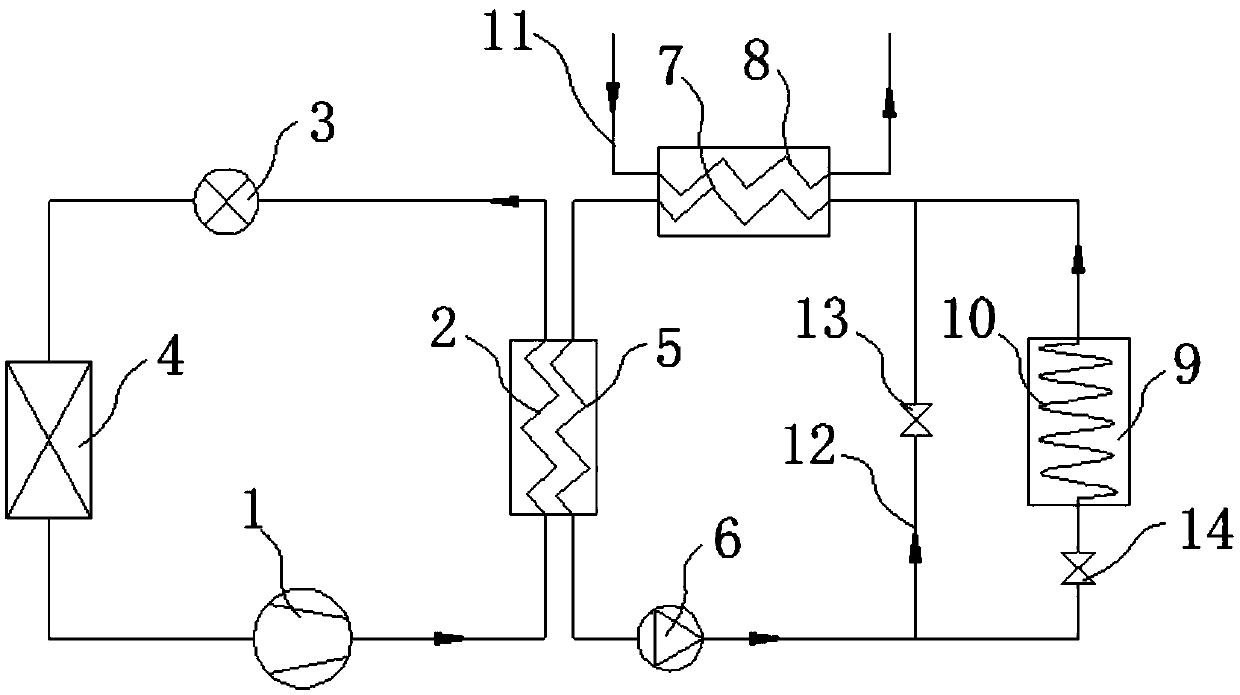

Temperature adjusting device and water heater

The invention relates to a temperature adjusting device and a water heater. The temperature adjusting device comprises a refrigerant loop, a medium loop and a third heater exchanger (8); the refrigerant loop comprises a compressor (1), a condenser (2) and an evaporator (4); the medium loop comprises a first heat exchanger (5) used for exchanging heat with the condenser (2) or the evaporator (4), an energy accumulator (9) communicating with an outlet of the first heat exchanger (5) and a second heat exchanger (7) communicating with an outlet of the energy accumulator (9); and the third heater exchanger (8) is configured to be capable of exchanging heat with the second heat exchanger (7) and used for allowing a fluid needing to be heated or cooled to circulate. By applying the technical scheme, the heat absorbing process and the heat releasing process of the energy accumulator both can be completed in the mode of exchanging heat with a medium in the medium loop, and therefore the problemthat in the prior art, heater exchangers in a heat accumulator can not fully exchange heat with a heat accumulation portion, and the water use safety problem caused by refrigerating agent leaking andheat accumulation material corrosion leaking are solved.

Owner:GREE ELECTRIC APPLIANCES INC

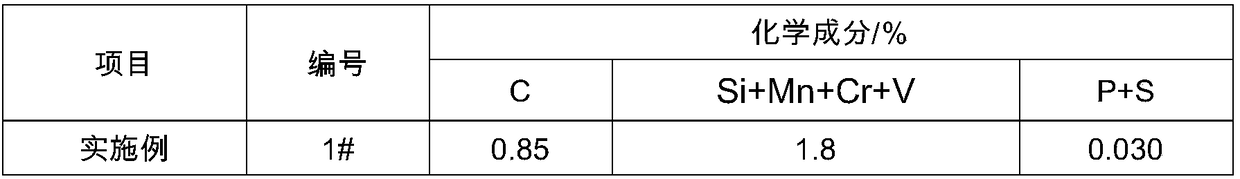

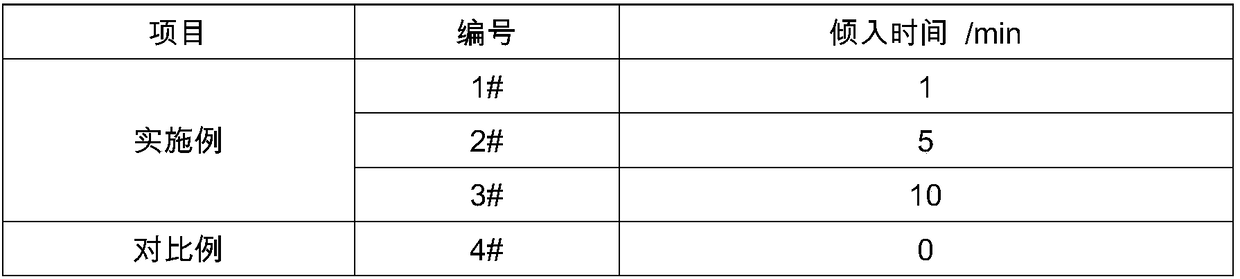

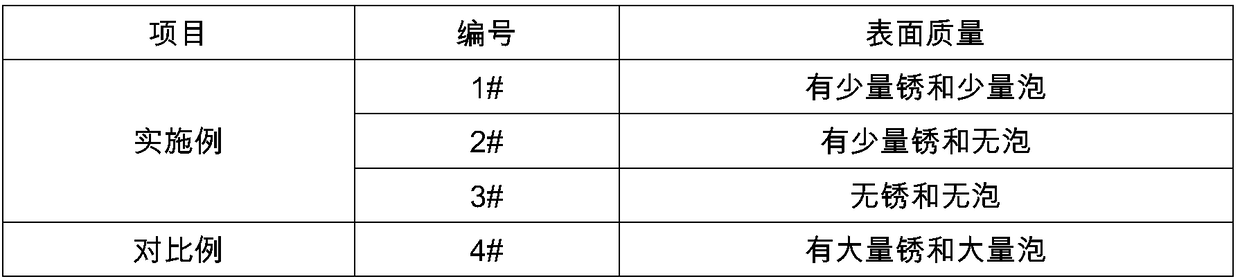

Production method of corrosion-resistant steel rails

InactiveCN109183014AImprove corrosion resistanceMetallic material coating processesSurface layerAnti freezing

The invention relates to the field of corrosion-resistant steel rail production, in particular to a production method of corrosion-resistant steel rails with excellent corrosion resistance. The production method comprises the step that after the steel rails are cooled and straightened, the steel rails are placed in a groove containing a trivalent chromium passivation solution for corrosion-resistant material attachment, wherein the adhesion time of a corrosion-resistant material ranges from 1 min to 10 min. After the steel rails are cooled and straightened, the steel rails are placed in the groove containing the trivalent chromium passivation solution to adhere the corrosion-resistant material, so that the corrosion resistant material is adhered to the surface layer of the rail bottom of each steel rail, and good corrosion resistance is achieved. Due to the fact that the real trivalent chromium passivation solution is adopted for treatment, the obtained corrosion resistance is excellent. The production method is particularly suitable for railway transportation occasions in which an anti-freezing fluid needs to be sprayed.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Circulating water anti-freezing system for solar heat collector

InactiveCN101846412AMake sure there is no waterImprove heat transfer efficiencySolar heat devicesSolar thermal energy generationAnti freezingEngineering

The invention provides a circulating water anti-freezing system for a solar heat collector, which relates to a solar circulating water system. The invention solves the problem that when the current solar circulating water system is operated in winter, heat tapes need to be additionally arranged on outdoor pipelines or anti-freezing fluid needs to be filled into the system, thus the operation energy consumption and cost of the system are higher, and the heat exchange efficiency is low. An input end of a first pipeline is connected with an insulating water tank; a first valve, a circulating pump, a second valve and a third valve are successively arranged on the first pipeline from the input end to the output end of the first pipeline; one end of a fourth pipeline is connected with a return water pipe on the plate solar heat collector and the other end is communicated with the insulating water tank; an air inlet and outlet pipe is arranged on the return water pipe of the plate solar heat collector, and the other end is communicated with atmosphere; the inner diameter of the fourth pipeline is the same as the inner diameters of the return water pipe and a water supply pipe in the plate solar heat collector; and the inner diameters of the first pipeline, the second pipeline and the third pipeline are smaller than the inner diameter of the fourth pipeline. The invention is suitable for use in winter in the north.

Owner:HARBIN DEGUANG NEW ENERGY

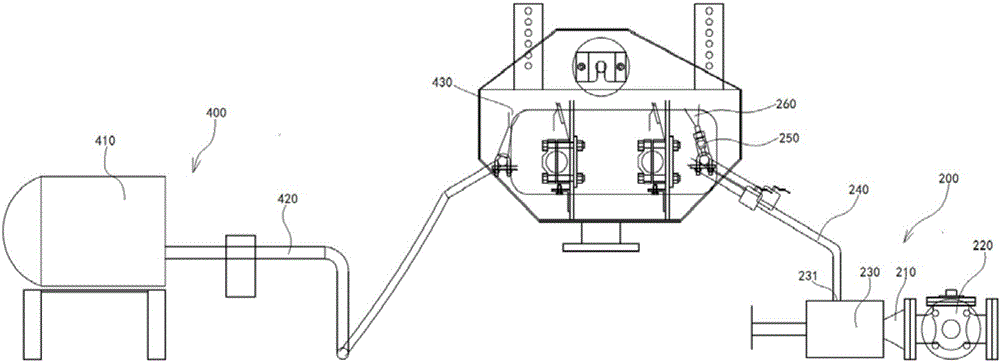

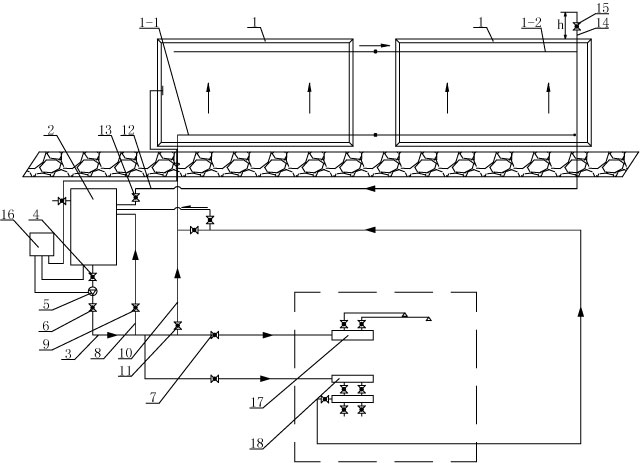

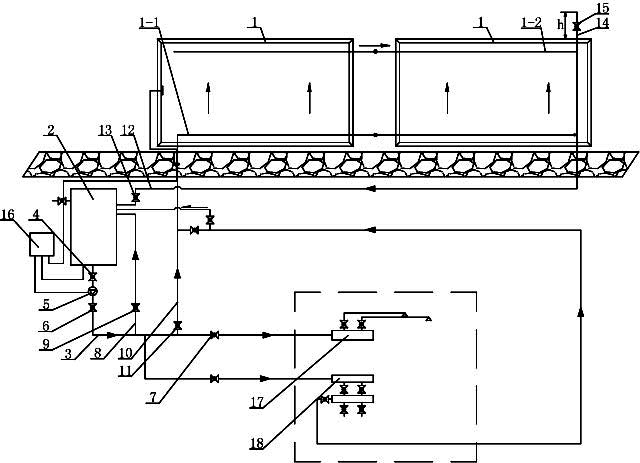

Operation method achieved through automatic grouting and drilling fluid circulating system

InactiveCN106014302ASolve obstaclesSolve problems such as encountering cardsFlushingDrilling machines and methodsHigh pressureFluid need

The invention discloses an operation method realized by an automatic grouting and circulating drilling fluid system, including the grouting operation process in the casing operation and the circulating drilling fluid operation process in the casing operation. When the drilling fluid needs to be poured after the buckling is completed, the mud pump is turned on, and the high-pressure drilling fluid enters the automatic grouting device through the high-pressure hose to realize the drilling fluid injection into the casing to balance the annular pressure inside and outside the casing; When stuck, insert the automatic grouting device into the casing, and when the drilling fluid pipe is full, the drilling fluid goes up to expand the sealing cup, closing the casing and the automatic grouting device, and completing the drilling fluid circulation operation.

Owner:CNPC BOHAI DRILLING ENG

Coating nozzle cleaning device

The invention discloses a coating nozzle cleaning device which comprises a roller, a main cleaning device and an auxiliary cleaning device. The area occupied by one part of the roller is a coating area; the roller can self-rotate; the main cleaning device is arranged outside the coating area and is provided with a main liquid holding cavity; one part of the roller is placed in the main liquid holding cavity; the auxiliary cleaning device is arranged outside the coating area and is internally provided with an auxiliary liquid holding cavity; one part of the roller is arranged in the auxiliary liquid holding cavity; the part, passing through the coating area, of the roller during self-rotating can pass through the main liquid holding cavity and the auxiliary liquid holding cavity along withthe self-rotation of the roller; and at the time, only a photoresistor cleaning fluid needs to be injected into the main liquid holding cavity so as to clean the a photoresistor, and only pure water needs to be injected into the auxiliary liquid holding cavity so as to clean a mixture of the photoresistor and the photoresistor cleaning fluid, so that the problem that the mixture of the photoresistor and the cleaning fluid cannot be effectively cleaned in the prior art can be solved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

A fluid simulation method and device

ActiveCN104200015BSimulate extensively and preciselyImprove numerical stabilitySpecial data processing applicationsSmoothed-particle hydrodynamicsMixed flow

The invention provides a fluid simulating method and device. The method includes the steps that firstly, a mixed flow model is constructed; secondly, smoothed particle hydrodynamics (SPH) particles are constructed; thirdly, relevant information of fluid needed by the mixed flow model is processed in the mixed flow model through an SPH method; fourthly, information needed in fluid simulating is output according to a processing result in the mixed flow model. According to the fluid simulating method and device, the moving process of multi-component fluid can be widely and accurately simulated.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com