Patents

Literature

304 results about "Fluid warmer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A fluid warmer is a medical device used in healthcare facilities for warming fluids, crystalloid, colloid, or blood product, prior to being administered (intravenously or by other parenteral routes) to body temperature levels in order to prevent hypothermia in physically traumatized or surgical patients. Infusion Fluid Warmers are FDA regulated medical devices, product code LGZ. They are unclassified devices with special considerations and require 510(k) clearance to be legally marketed in the United States. There are two primary categories of fluid warmers- those that warm fluids before use, typically warming cabinets, and those that actively warm fluids while being administered, in-line warming.

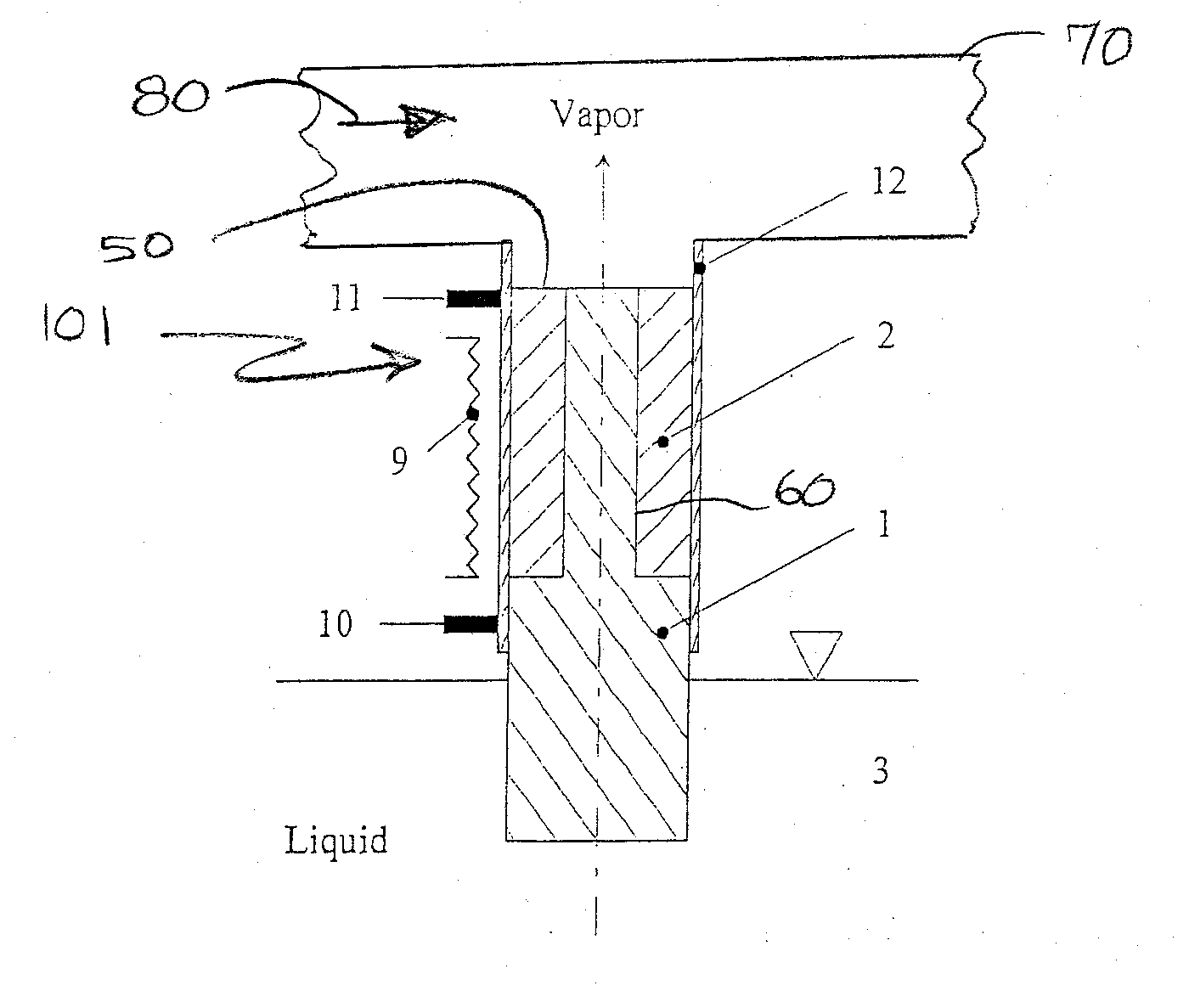

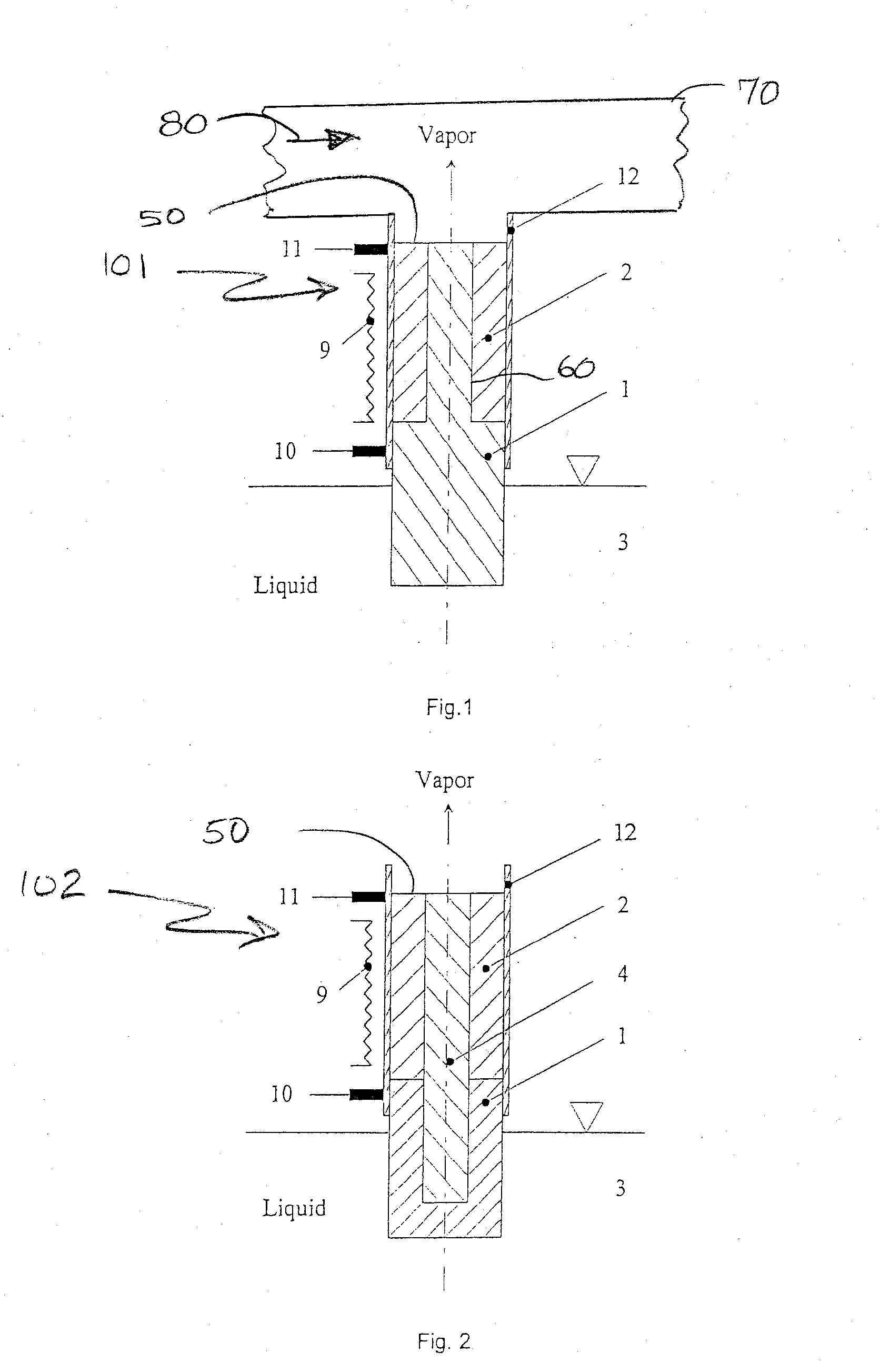

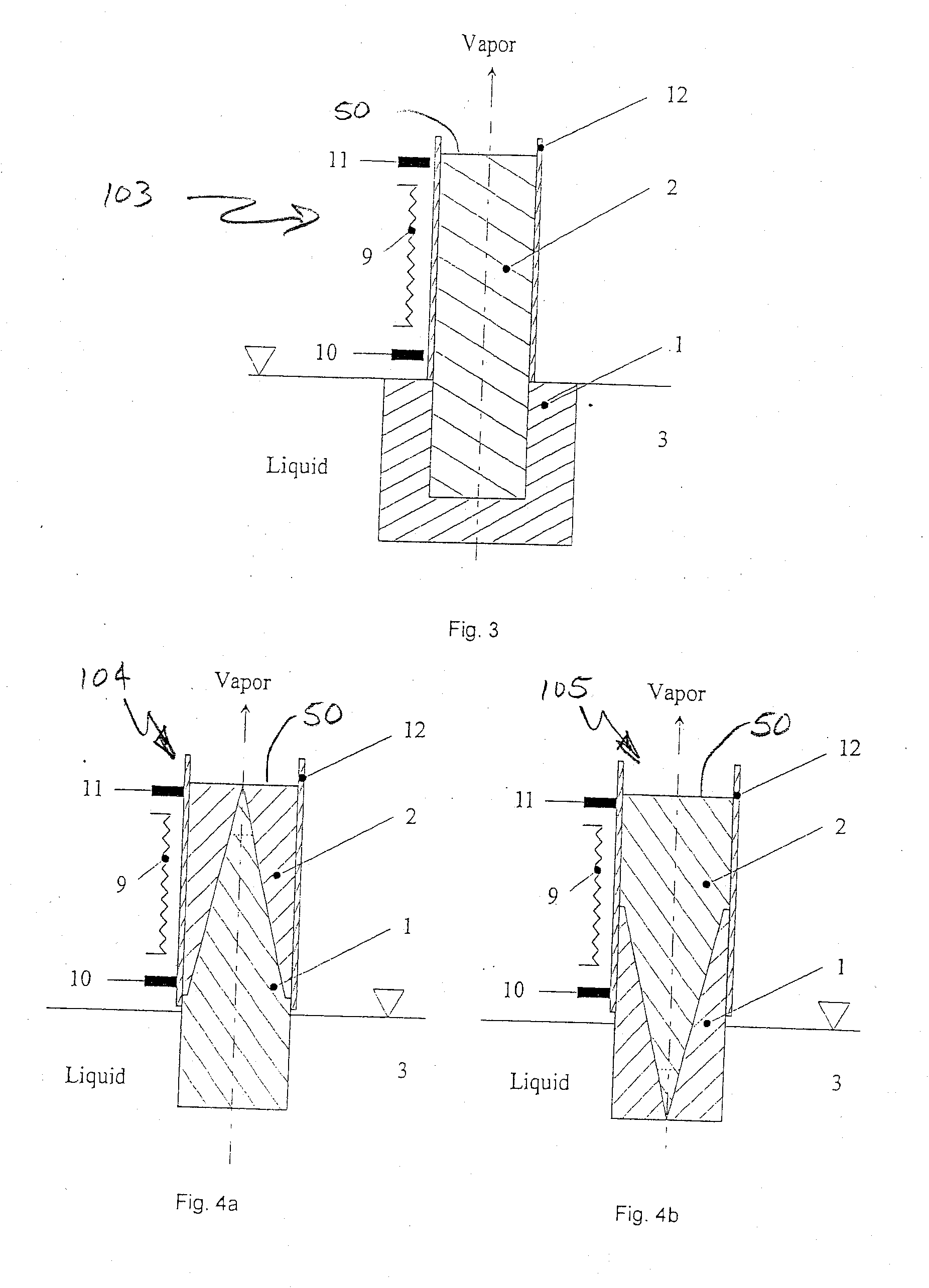

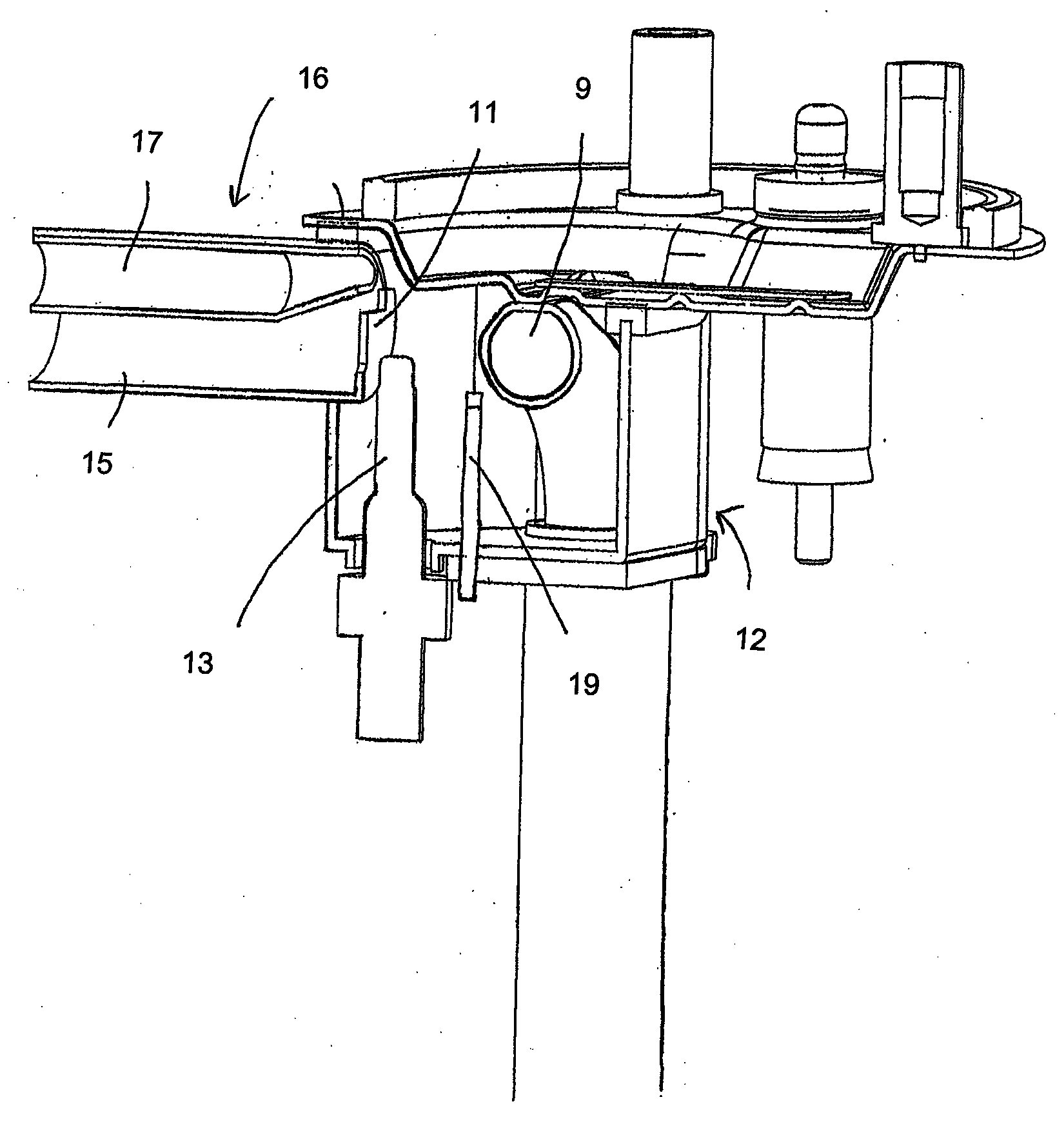

Liquid evaporator

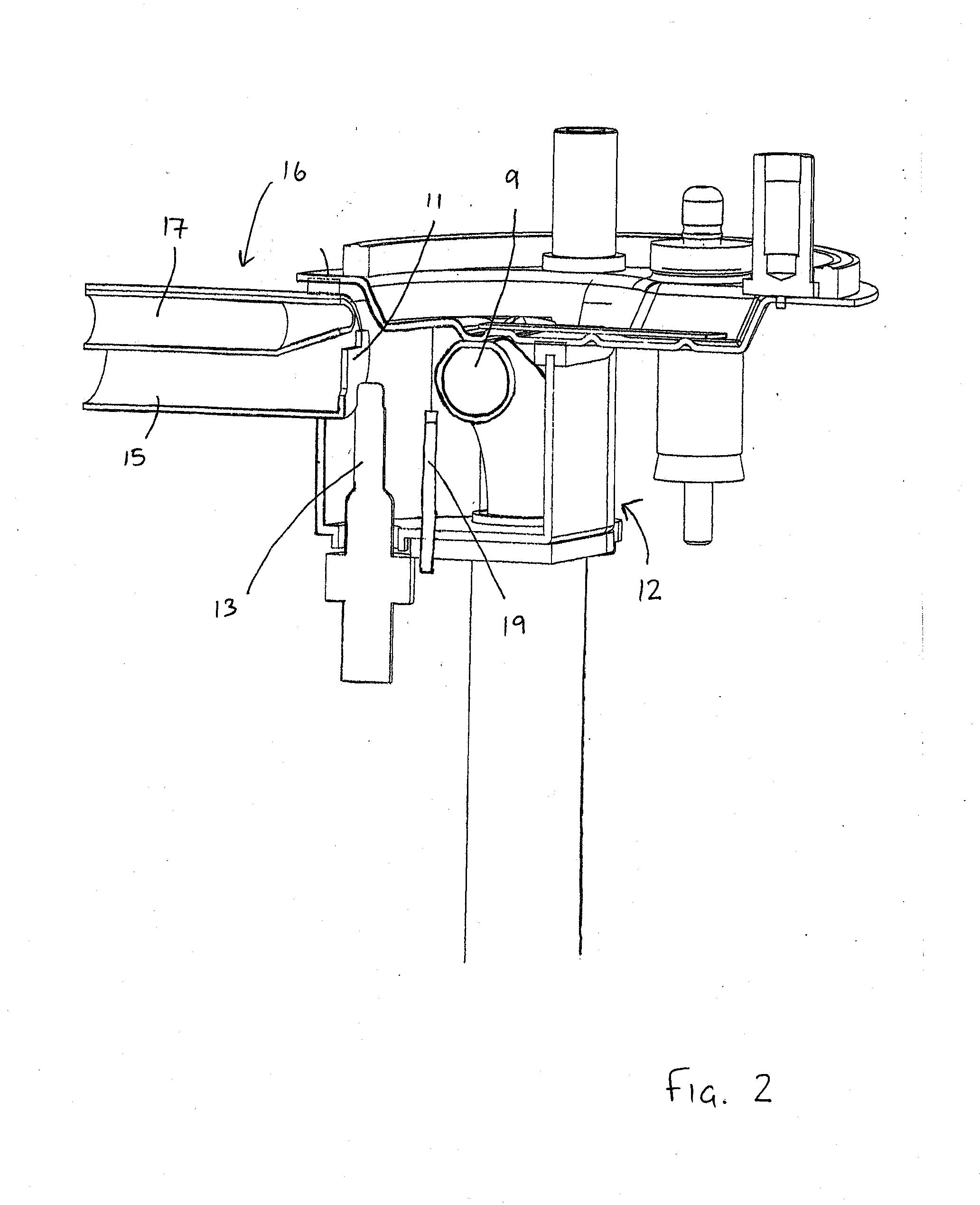

ActiveUS20070107879A1Simple designImprove evaporation effectBurnersSpace heating and ventilationPorosityEngineering

A liquid evaporator includes a liquid reservoir (3) with a liquid to be evaporated, a heater (9) and an evaporator tube (12). The evaporator tube (12) has a first porous element (1) having a first porosity and with an area in contact with the liquid in the liquid reservoir (3) and a second porous element (2) with a second porosity and with an area present on an evaporator side (50) used to dispense the evaporated liquid, and an area outside the liquid reservoir heated by the heater (9) which is not directly in connection with the liquid. The first porous element and the second porous element are in contact in contact areas with the first porous element forming a wick delivering liquid from the reservoir to the contact area.

Owner:DRAGERWERK AG

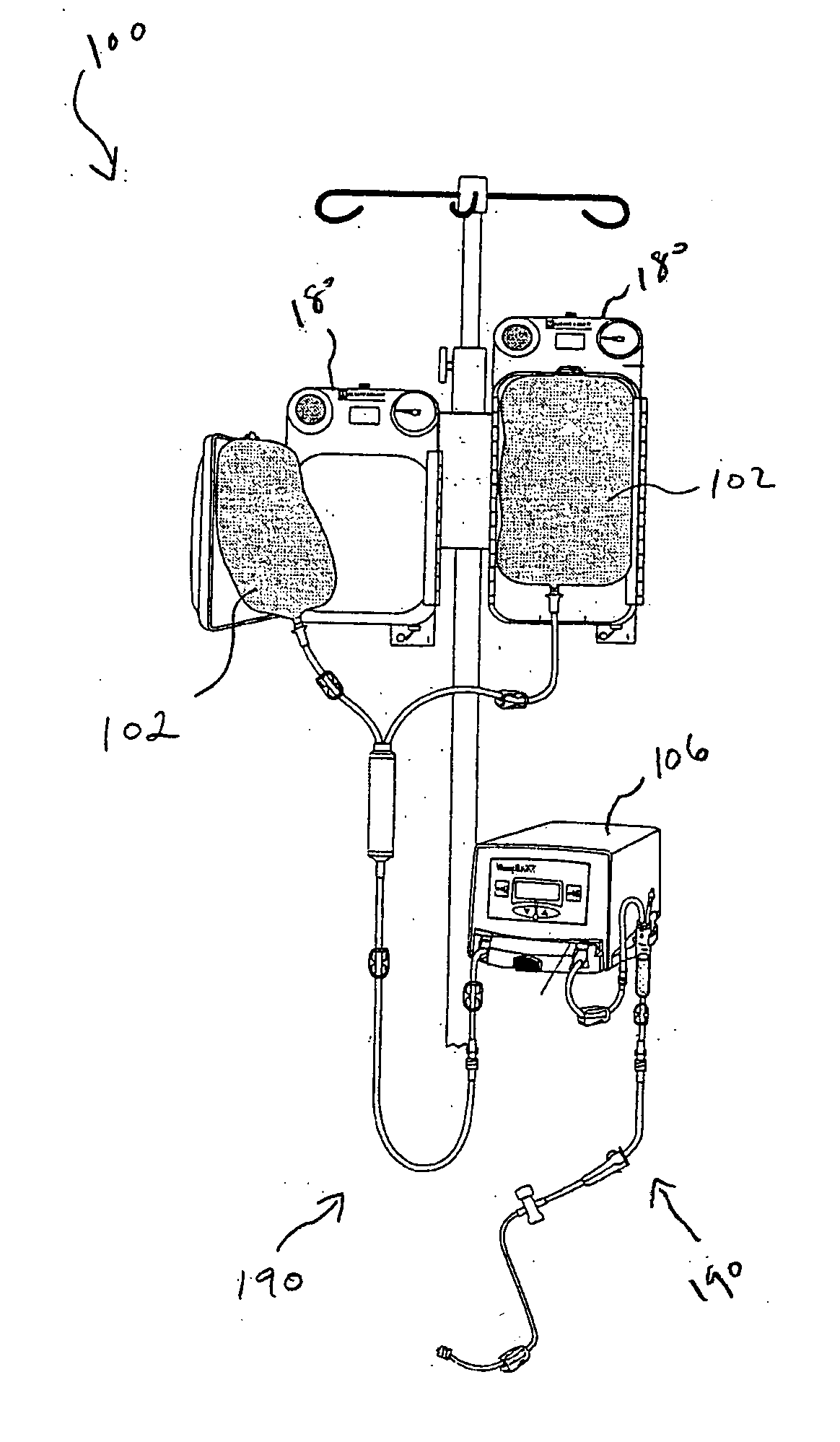

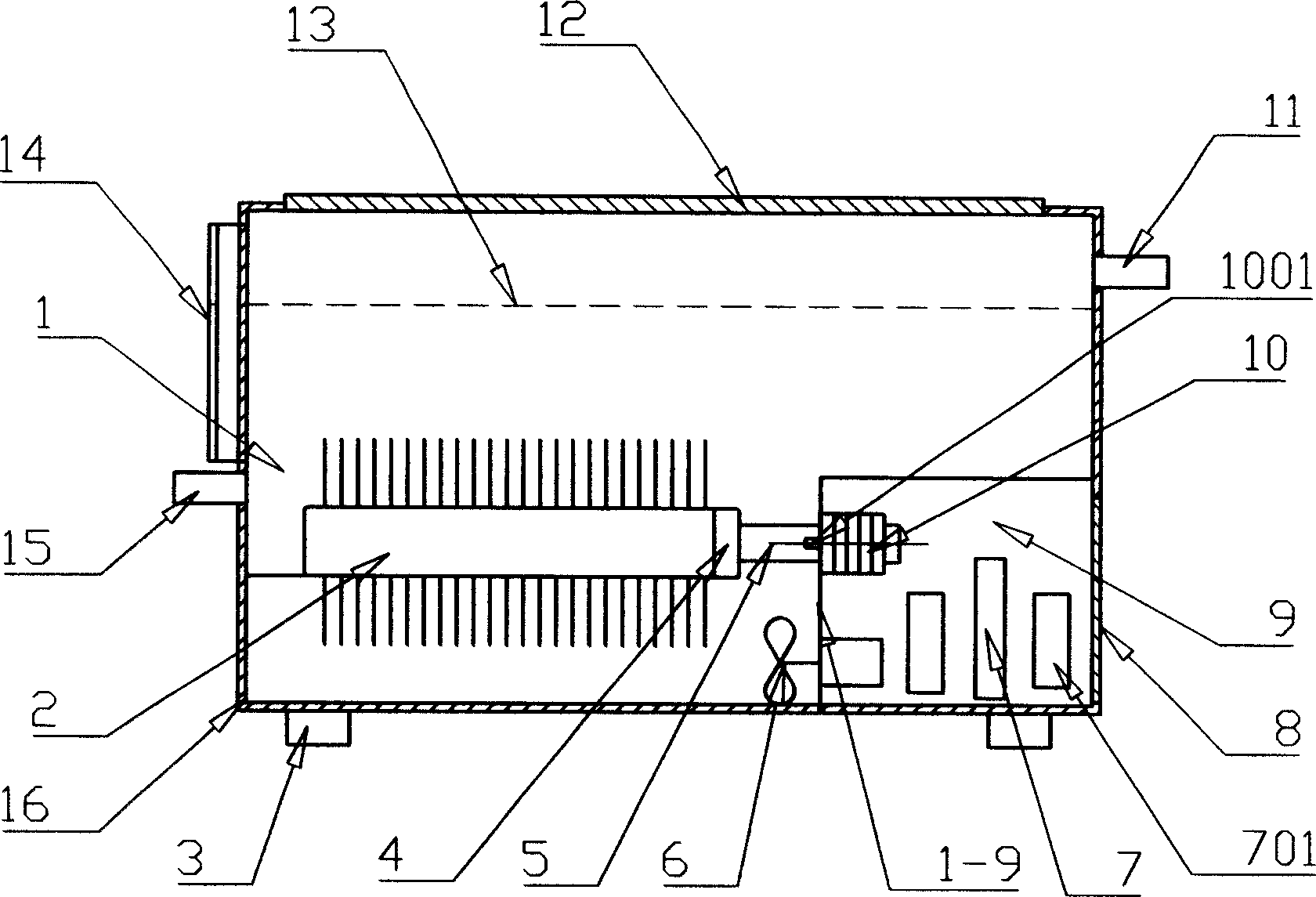

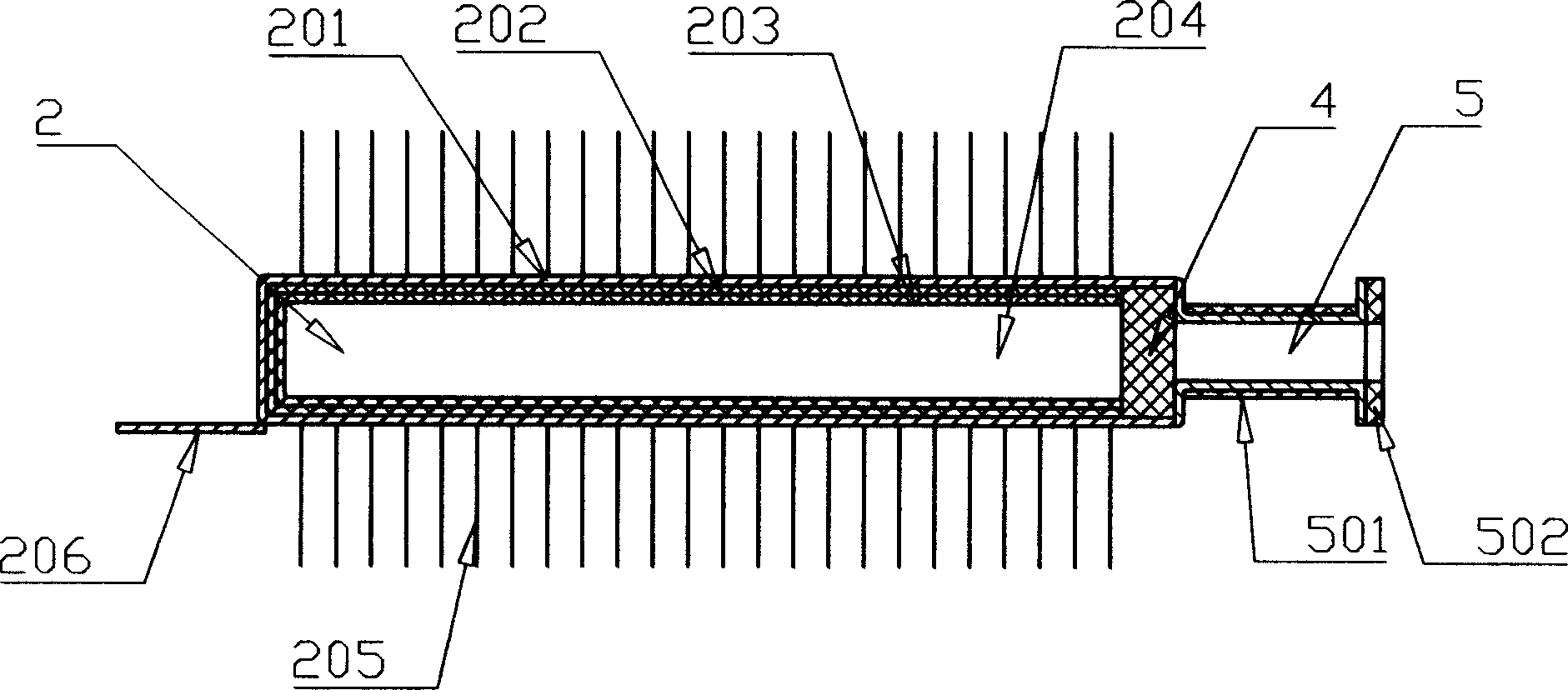

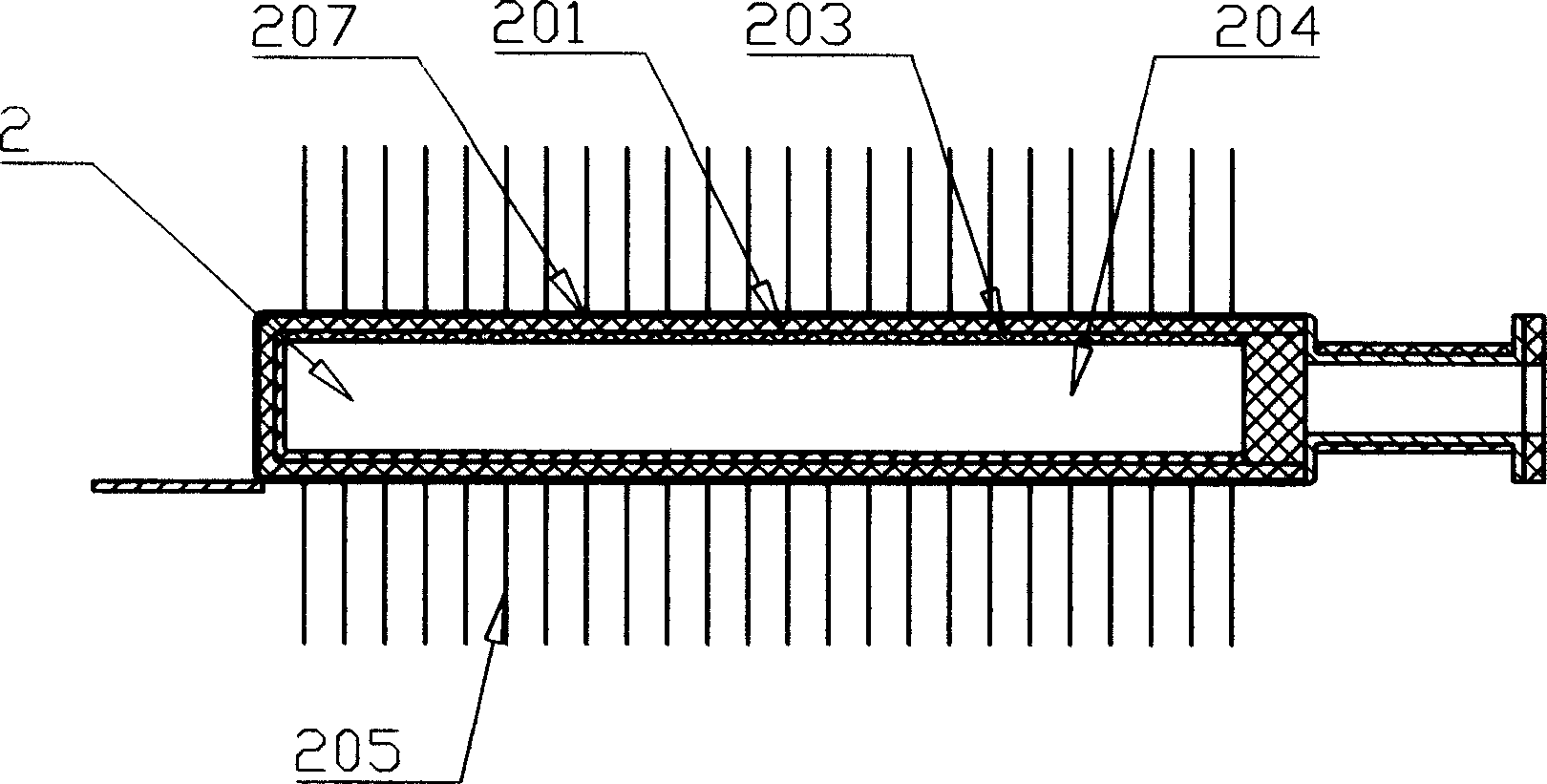

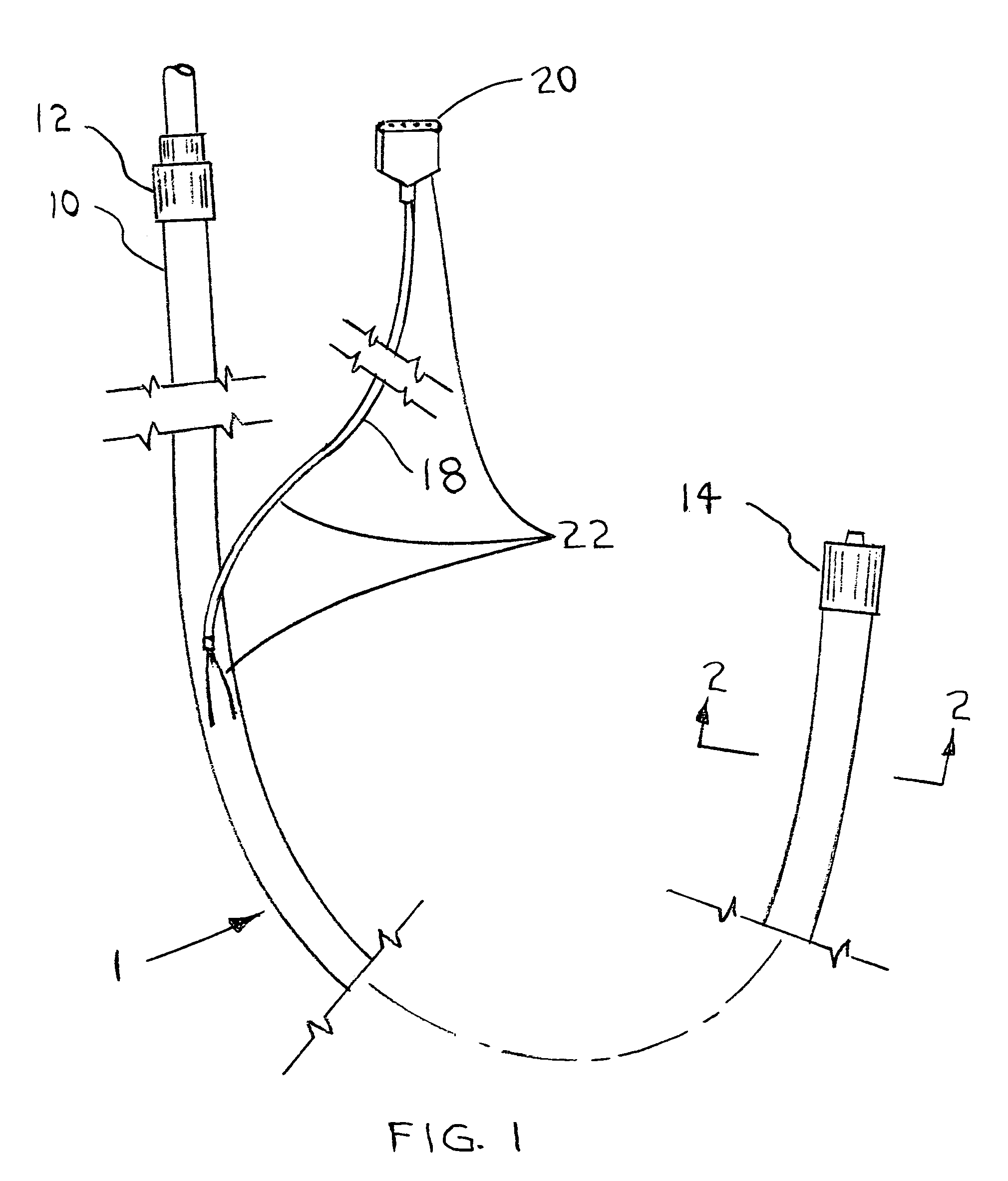

Fluid infusion apparatus with an insulated patient line tubing for preventing heat loss

InactiveUS20050148934A1Large amount of heatEnhancing infusionMedical devicesIntravenous devicesLine tubingFluid infusion

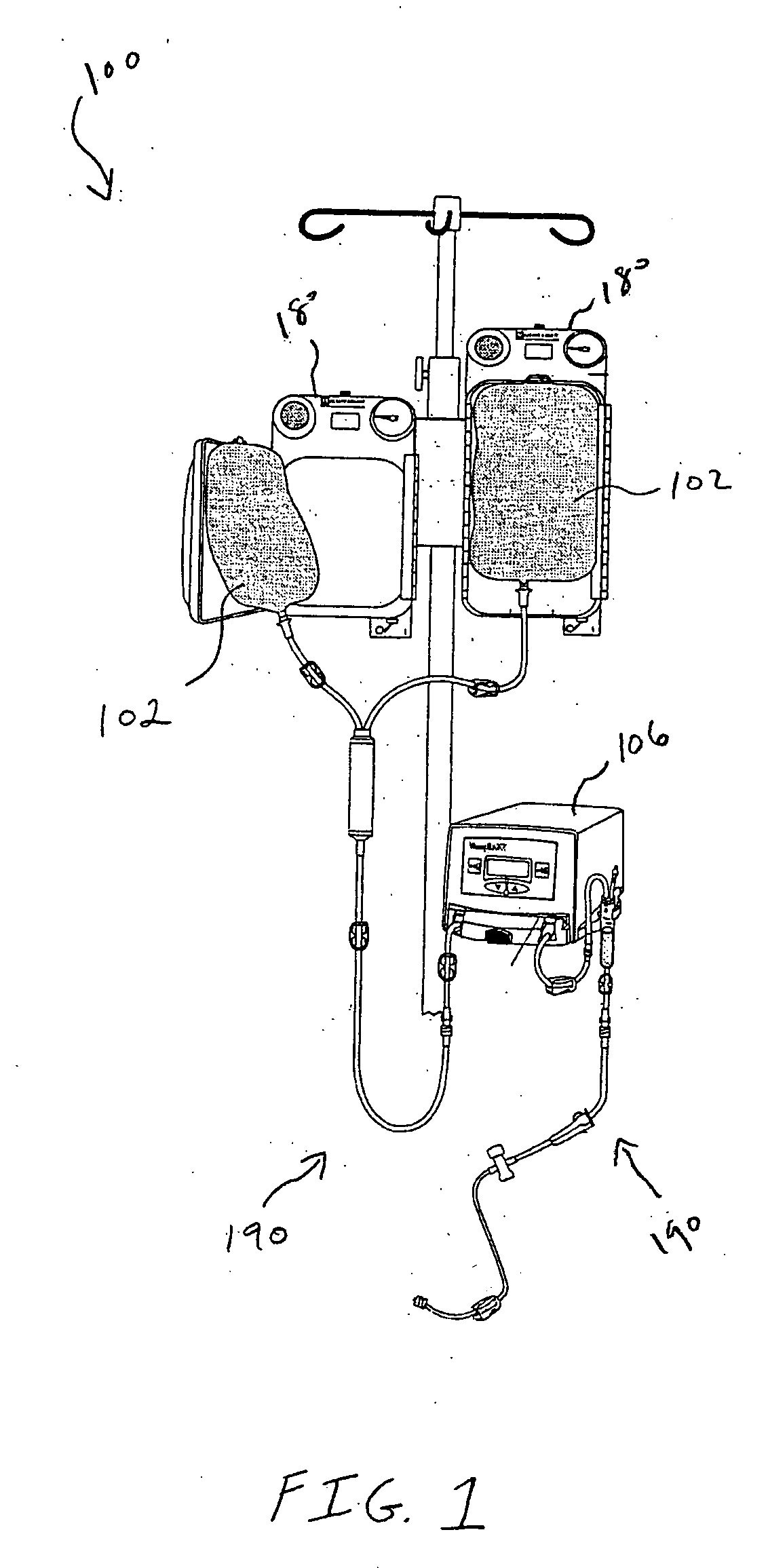

A fluid warming and infusion system. According to one embodiment, the fluid warming and infusion system includes a container for storing a fluid to be infused into a patient, a fluid warmer for warming the fluid prior to the fluid being infused into the patient, a tubing for delivering the fluid to the patient after the fluid has been warmed by the fluid warmer, and a patient insertion device (e.g., a needle, or the like), which is connected to a distal end of the tubing, for insertion into the patient. After being warmed by the fluid warmer, the fluid flows through the tubing and is delivered into the patient by the insertion device. The tube includes a substantially thermally insulating component that prevents the warmed fluid from losing a substantial amount of heat as the fluid flows through the tube.

Owner:MALLINCKRODT INC

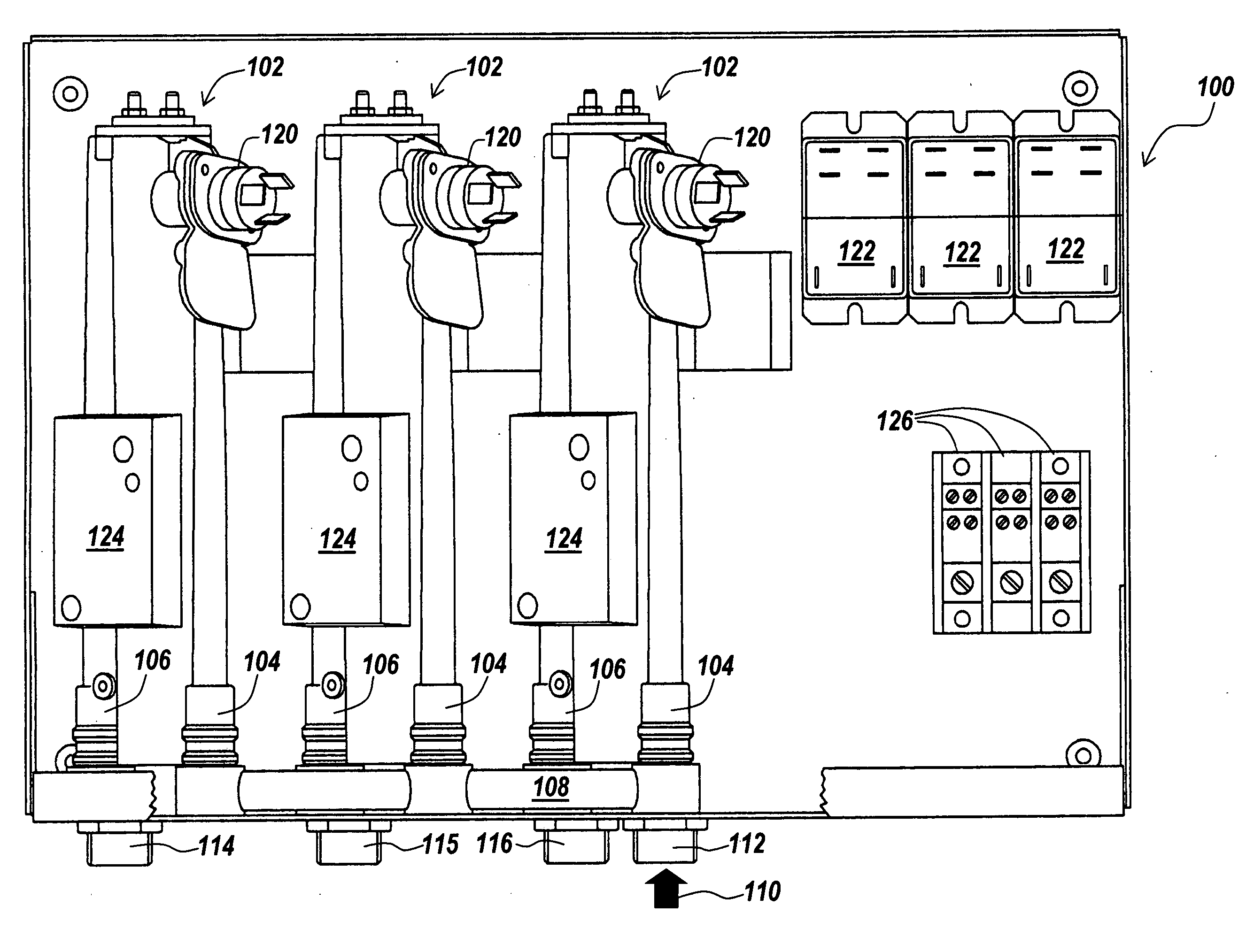

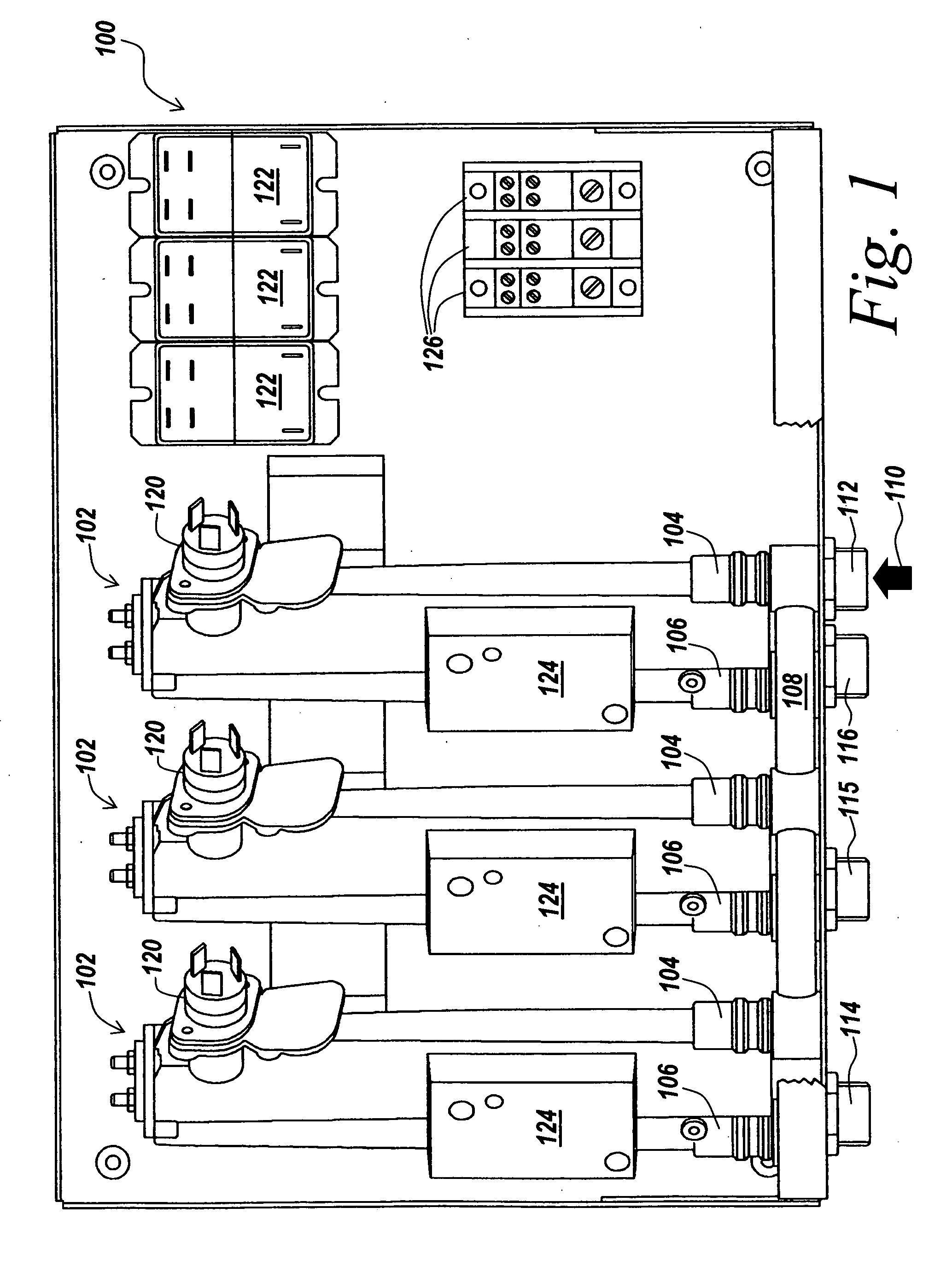

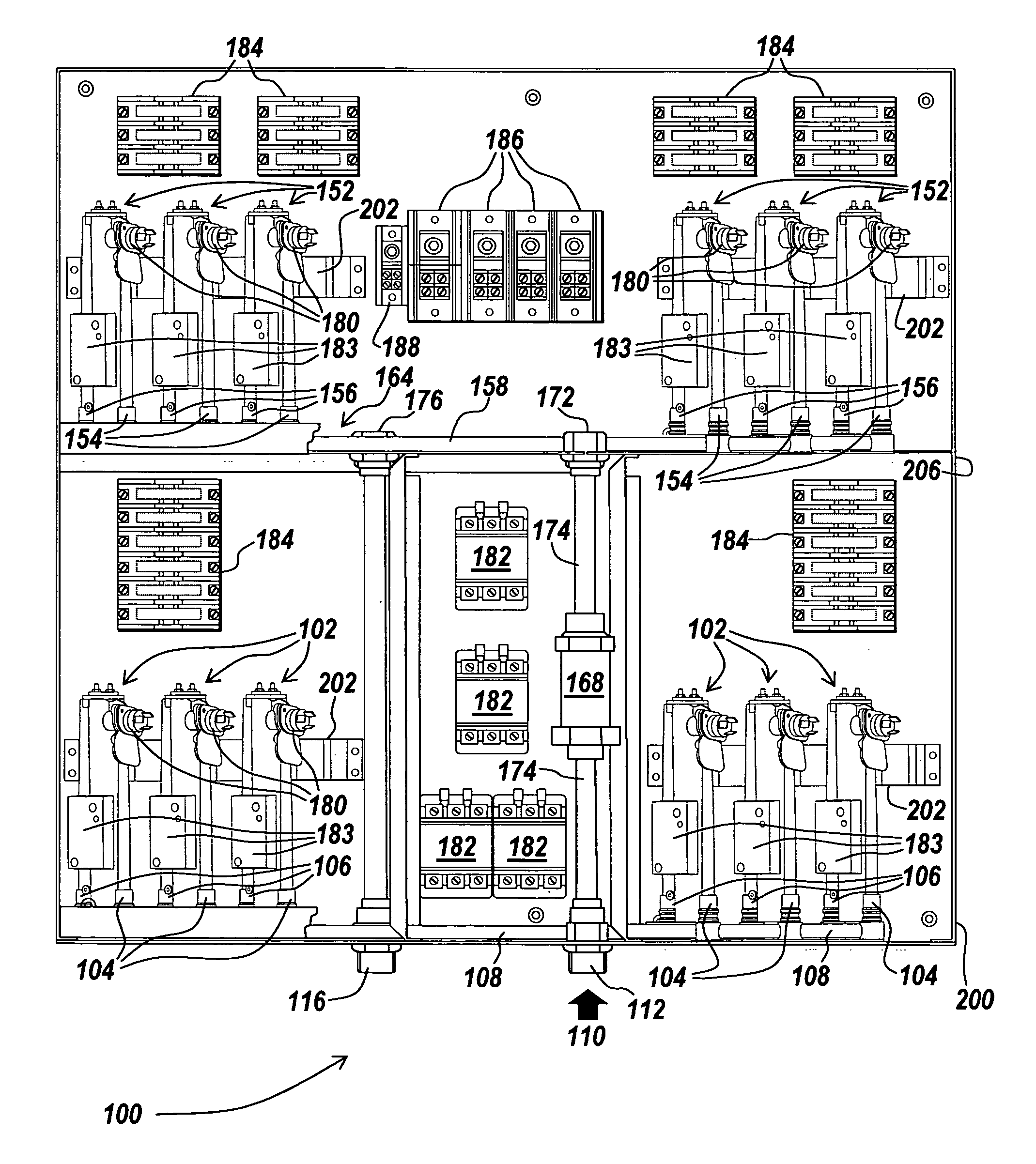

Electric tankless water heater

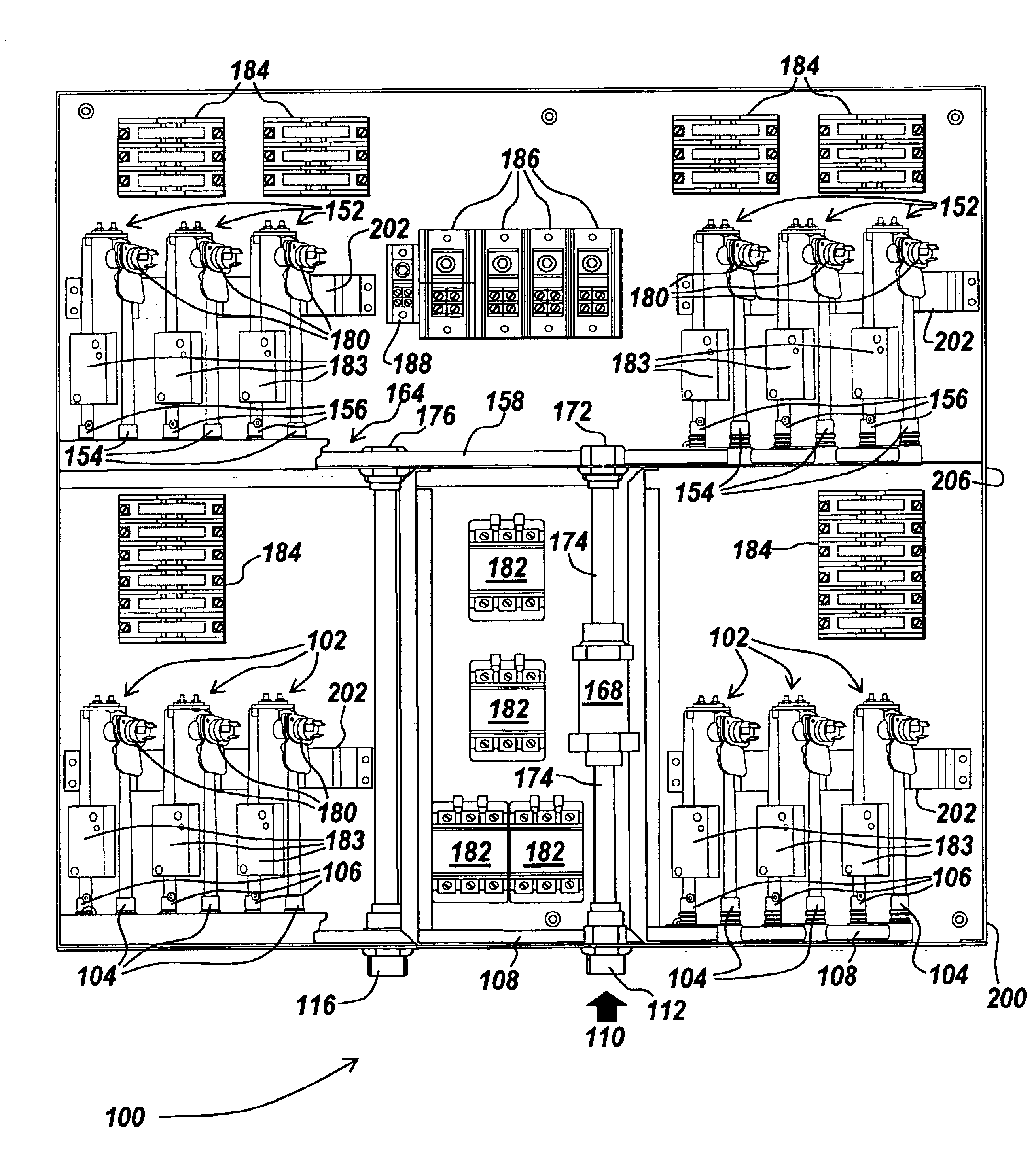

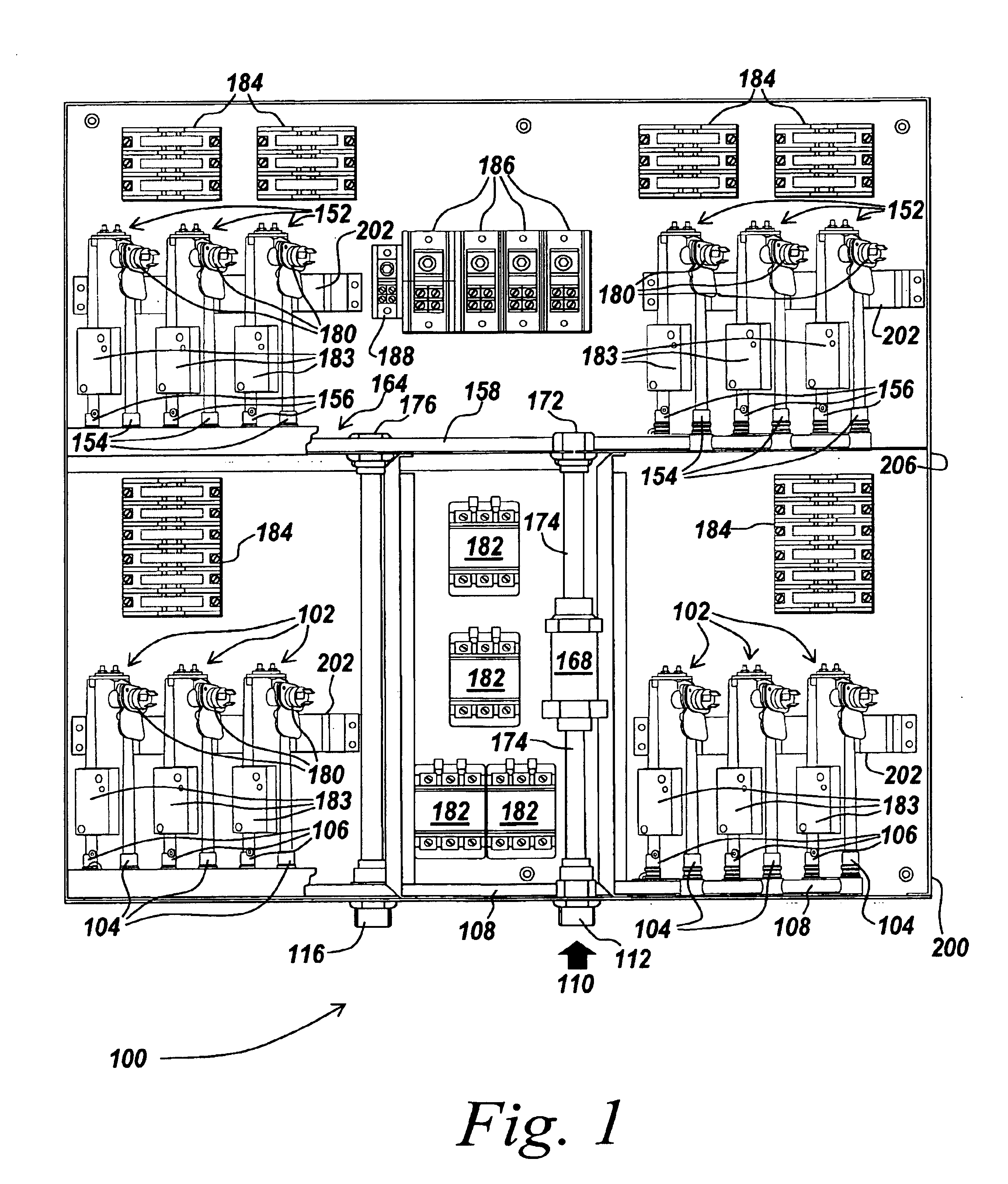

In various embodiments, the invention provides a system for heating a liquid, such as, for example, water, comprising a plurality of liquid heaters, the inlets and outlets of which are respectively connected in a parallel flow relationship by respective manifolds, and configured to provide liquid having a temperature of greater than about 90 degrees Fahrenheit at a flow rate of greater than about 10 gallons per minute. In various embodiments, the present invention provides an electric tankless liquid heater system capable of delivering hot liquids, and in particular water, at even higher flow rates and or temperatures, including, but not limited to, flow rates greater than about: (1) 12 gpm; (2) 18 gpm; (3) 20 gpm; and (5) 20 gpm; and / or temperatures of greater than about: (1) 100° F.; (2) 120° F.; (3) 140° F.; and (4) 180° F.

Owner:RHEEM MFG CO

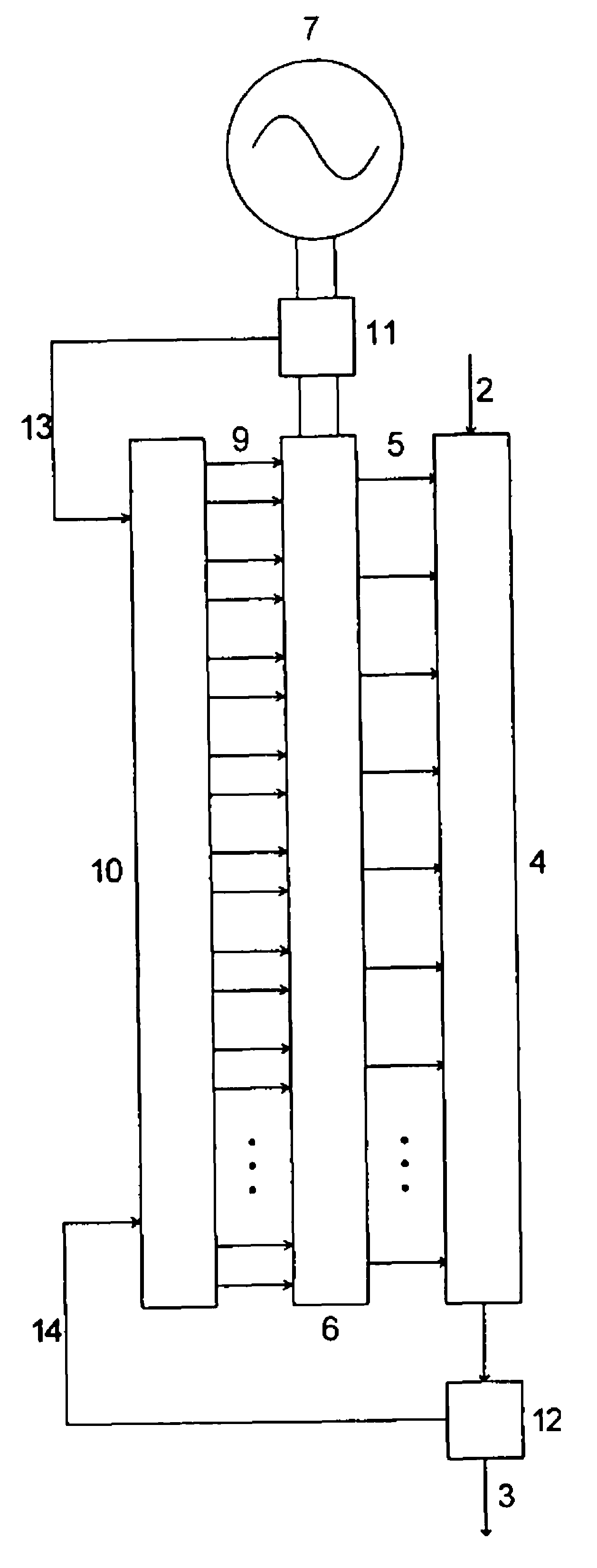

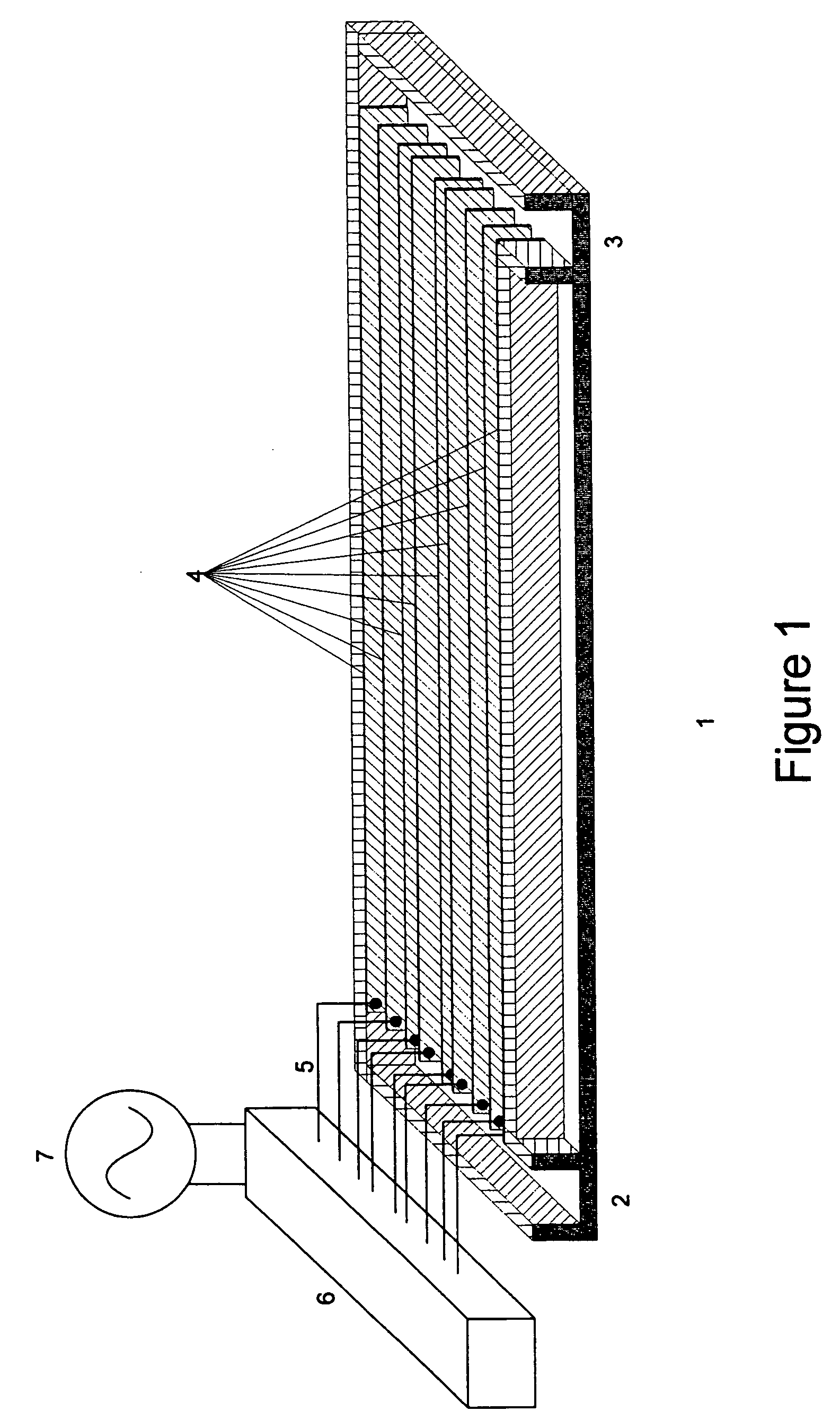

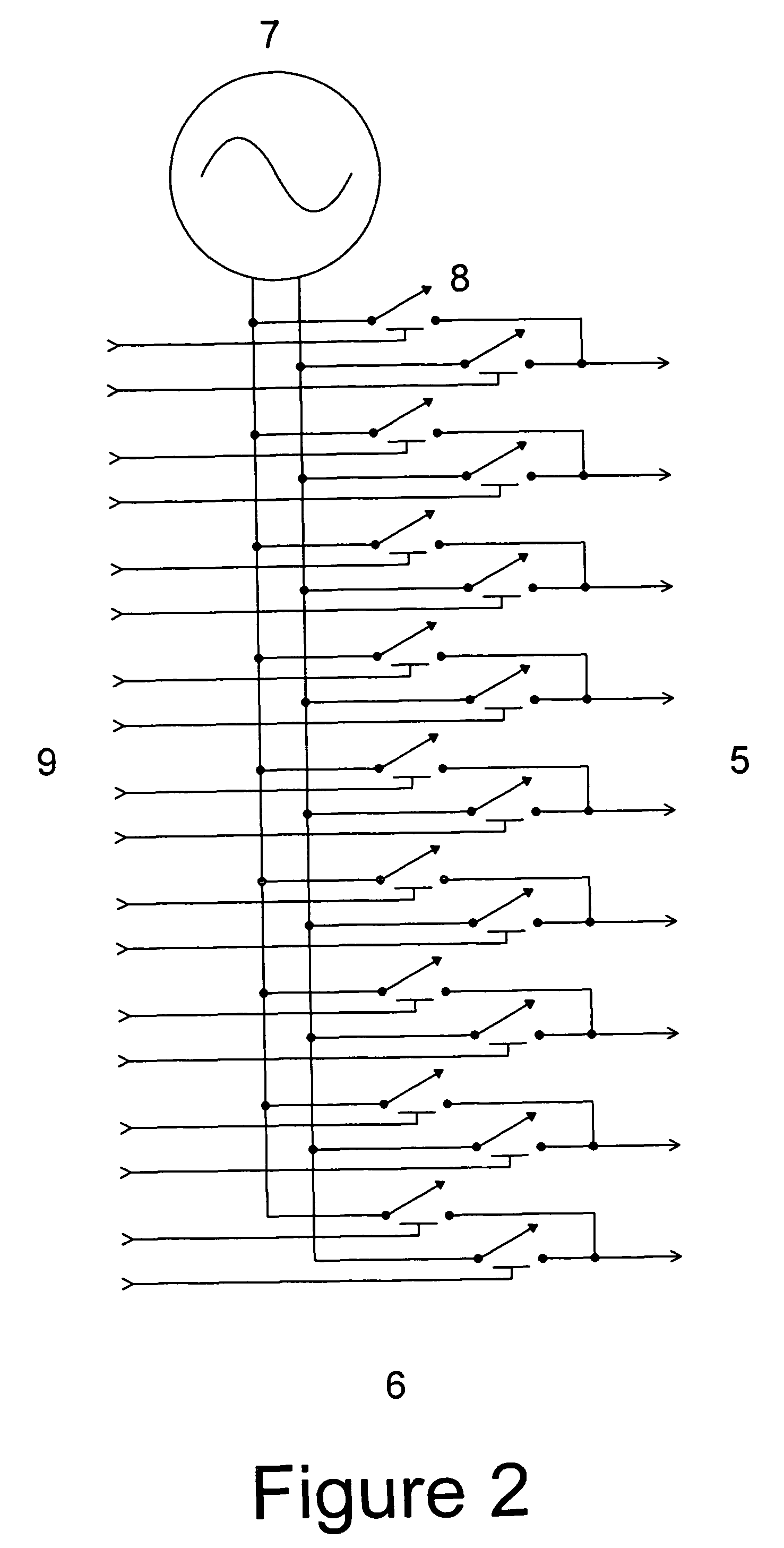

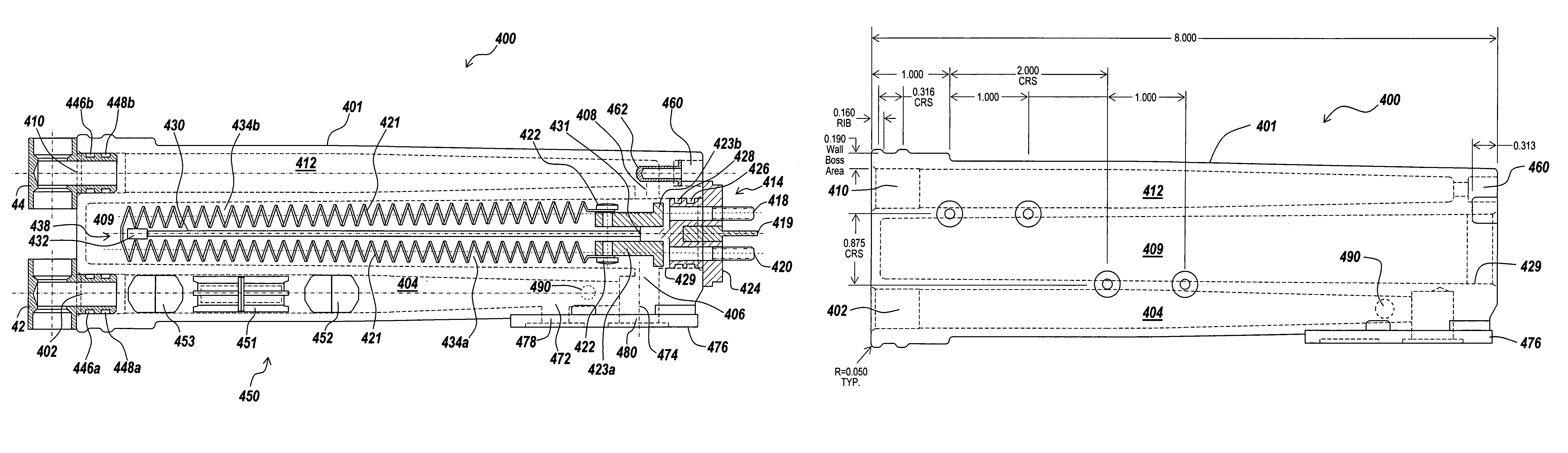

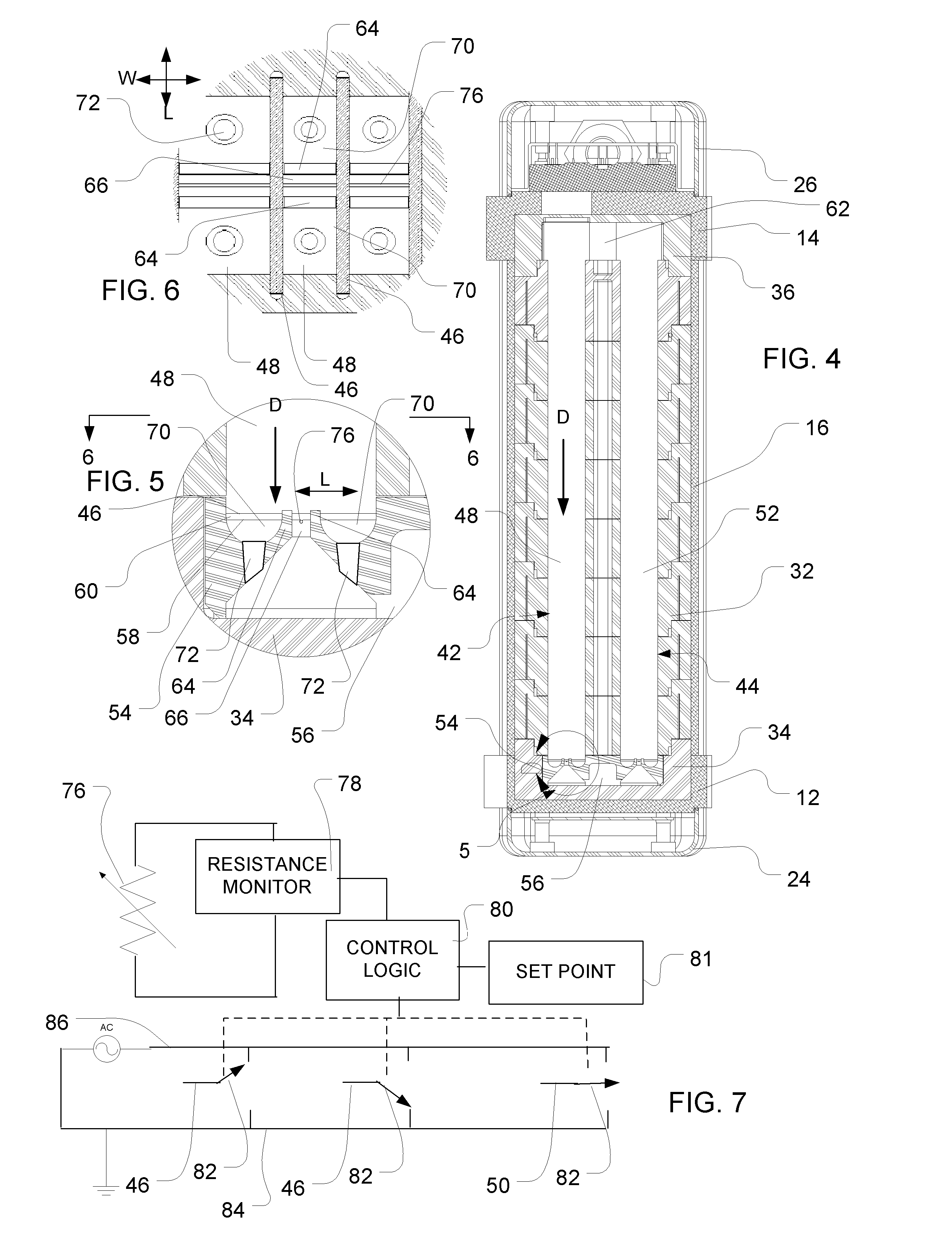

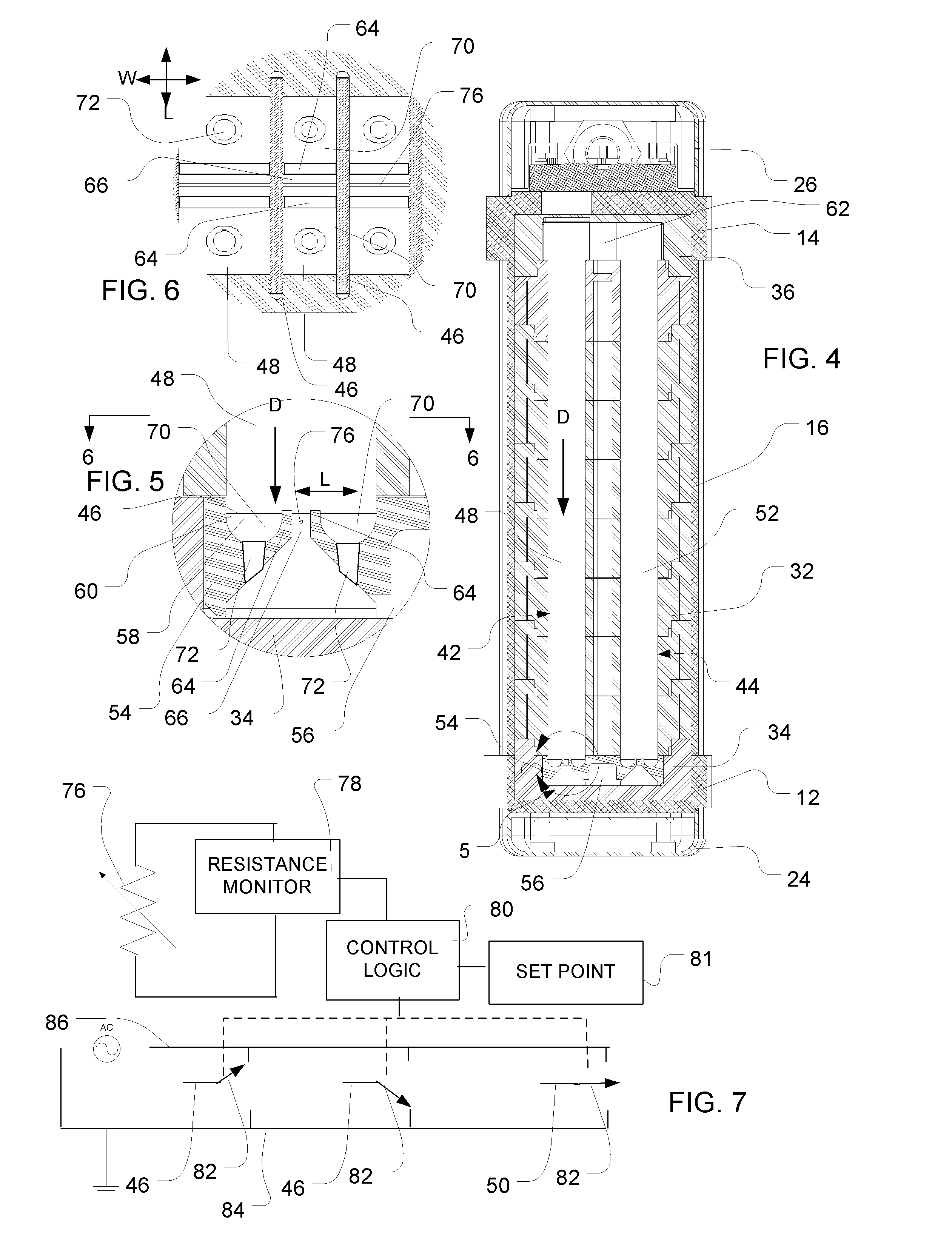

Direct electric resistance liquid heater

ActiveUS7817906B2Minimize response timeOvercome difficultiesSteam generation heating methodsElectric discharge heatingElectrical resistance and conductanceFluid warmer

The Direct Electric Resistance Liquid Heater comprises a liquid heating chamber containing a plurality of electrodes. The electrodes are spaced apart to create a plurality of channels through which the liquid to be heated passes. The electrodes are each connected to a power supply by one or more switches. A controller controls the switches based upon data received from a temperature sensor, sensing the temperature of the liquid, and / or an electric current sensor, sensing the current utilized by the liquid heater. Selection of the number and spacing of the electrodes, and the number of switches, provides the controller with various current levels options to apply to the liquid to be heated. The current levels available due to the number and spacing of the electrodes and the number of switches, span the range from minimum current to maximum current such that the controller can incrementally increase or decrease the current applied to the liquid to be heated without disrupting other users of the same power source.

Owner:OHMIQ INC

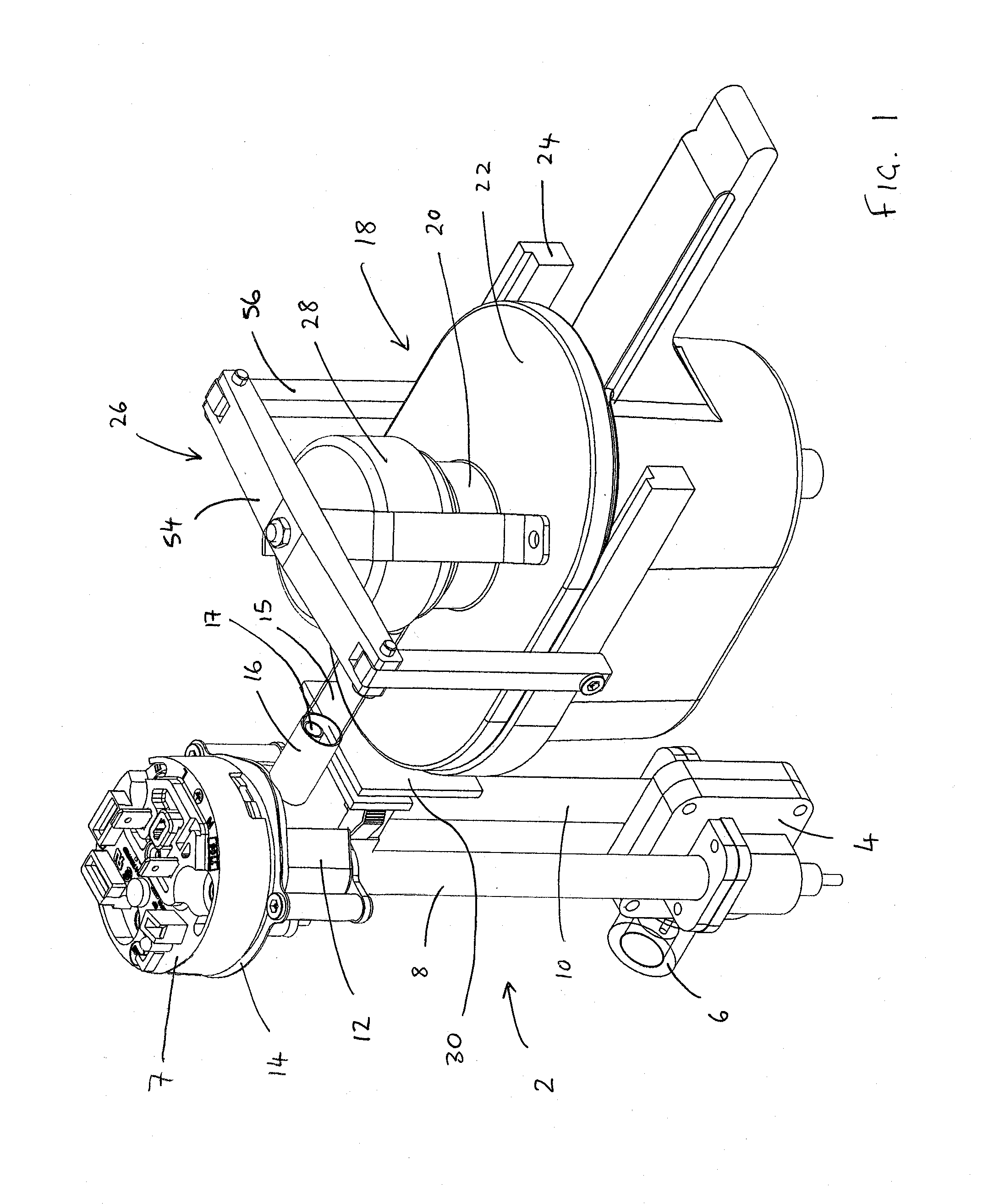

Flow control in an intravenous fluid delivery system

InactiveUS20060020255A1Improve electrical isolationLeakage current is lowInfusion devicesMedical devicesControl systemClosed loop

An intravenous flow control system provides closed loop control to maintain a desired flow rate. The actual flow rate is determined by two techniques, a geometrically based technique that uses geometric parameters of the IV system, and a thermally based technique that uses the power input to an IV fluid warmer and the temperature of the IV fluid entering and exiting the warmer.

Owner:VITAL SIGNS INC

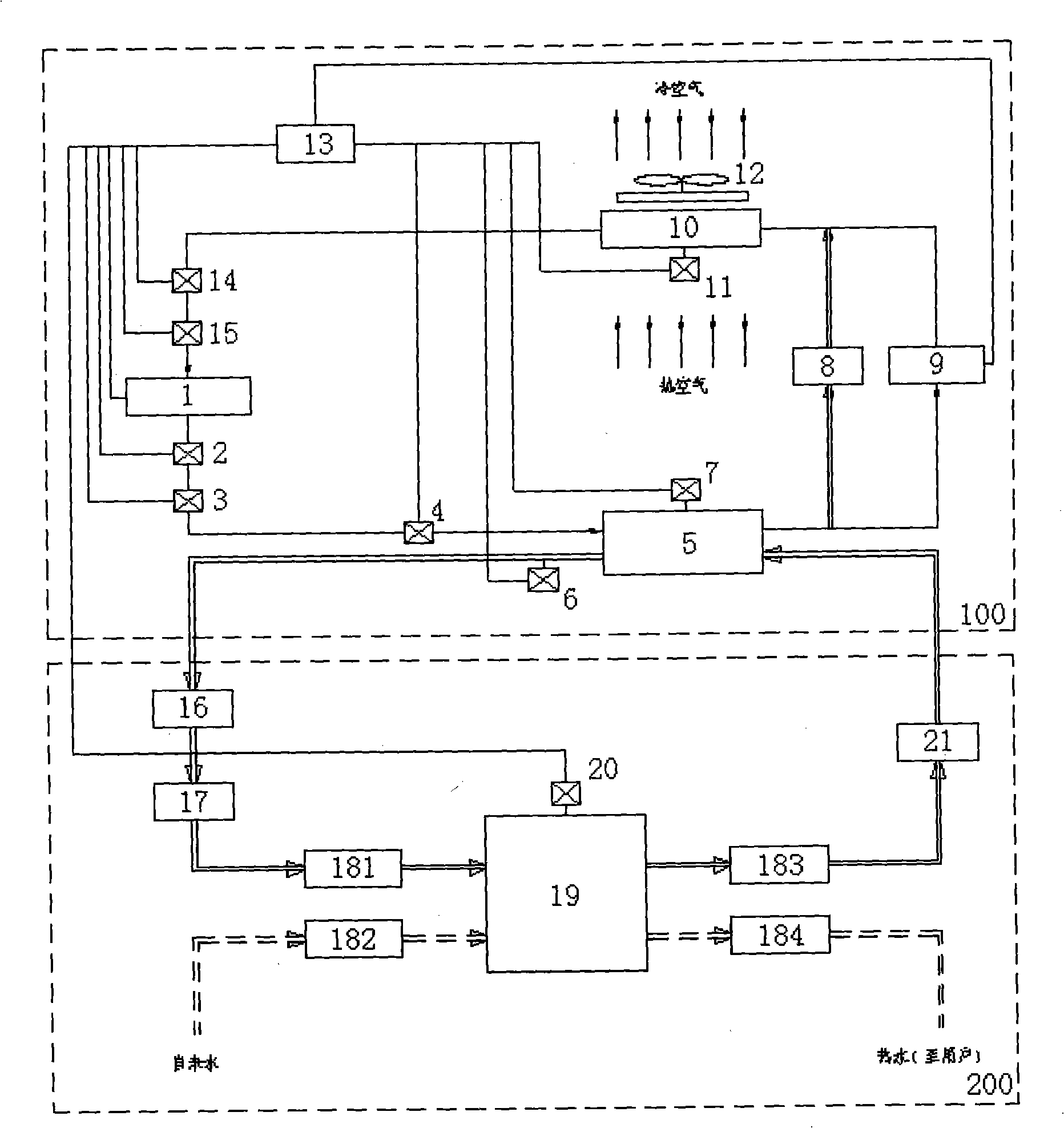

Frequency-variable flux-changing heat pump water heater

InactiveCN101319818AGood performance parametersFestive stream statusFluid heatersFuel oilEngineering

The invention provides a frequency and flow changing heat pump water heater, relates to a liquid heater with a heat generation device by using a heat pump. The frequency and flow changing heat pump water heater comprises a unit part, a water circulating part, water tubes and communication lines connected inside the water circulating part. The unit part comprises a frequency-changing compressor, a cross tee change valve, a double pipe condenser, an unloading valve, an electronic expansion valve, an evaporator, a fan, a controller, various temperature sensors and pressure sensors. The water circulating part comprises a pump, an outlet valve, a ball valve, a water tank, a water temperature sensor and a filter. The frequency and flow changing heat pump water heater takes the frequency-changing compressor as the power source of the system, takes the electronic expansion valve as a throttling device and uses the water temperature sensor to prevent freezing. Compared with combustion gas, fuel oil, coal or electronic water heater, the frequency and flow changing heat pump water heater has safety, environmental protection and energy saving properties. Compared with the heat pump hot water units, the throttling of which uses rated frequency compressor and thermostatic expansion valve or capillary tubes, the frequency and flow changing heat pump water heater has high heating output power, good heating effect and good environmental adaptability.

Owner:SHANGHAI MO & ELECTRICAL APPLIANCE

Tankless liquid heater using a thermostatic mixing valve

InactiveUS20120057857A1Temperature control with auxillary non-electric powerElectric heatingThermostatic mixing valveEngineering

In various aspects, the present application describes a tankless liquid heater receiving liquid at an inlet and providing heated liquid at an outlet. The tankless liquid heater may include a heating element for heating liquid received from the inlet. A flow sensor indicates the flow rate of the liquid received by the heating element. The heater includes a temperature sensor measuring the temperature of liquid exiting the heating element. A controller of the heater regulates the amount of electrical current energizing the heating element responsive to the flow sensor and the temperature sensor, energizes the heating element when the flow rate of the liquid exceeds a predefined value and prevents energizing the heating element when the heated liquid exceeds a predefined temperature. The heater may also include a thermostatic mixing valve for mixing the heated liquid with liquid diverted from the inlet responsive to the temperature of the heated liquid.

Owner:EEMAX

Electric tankless water heater

ActiveUS7779790B2Increase temperatureSteam generation heating methodsImmersion heating arrangementsLiquid temperatureEngineering

Owner:RHEEM MFG CO

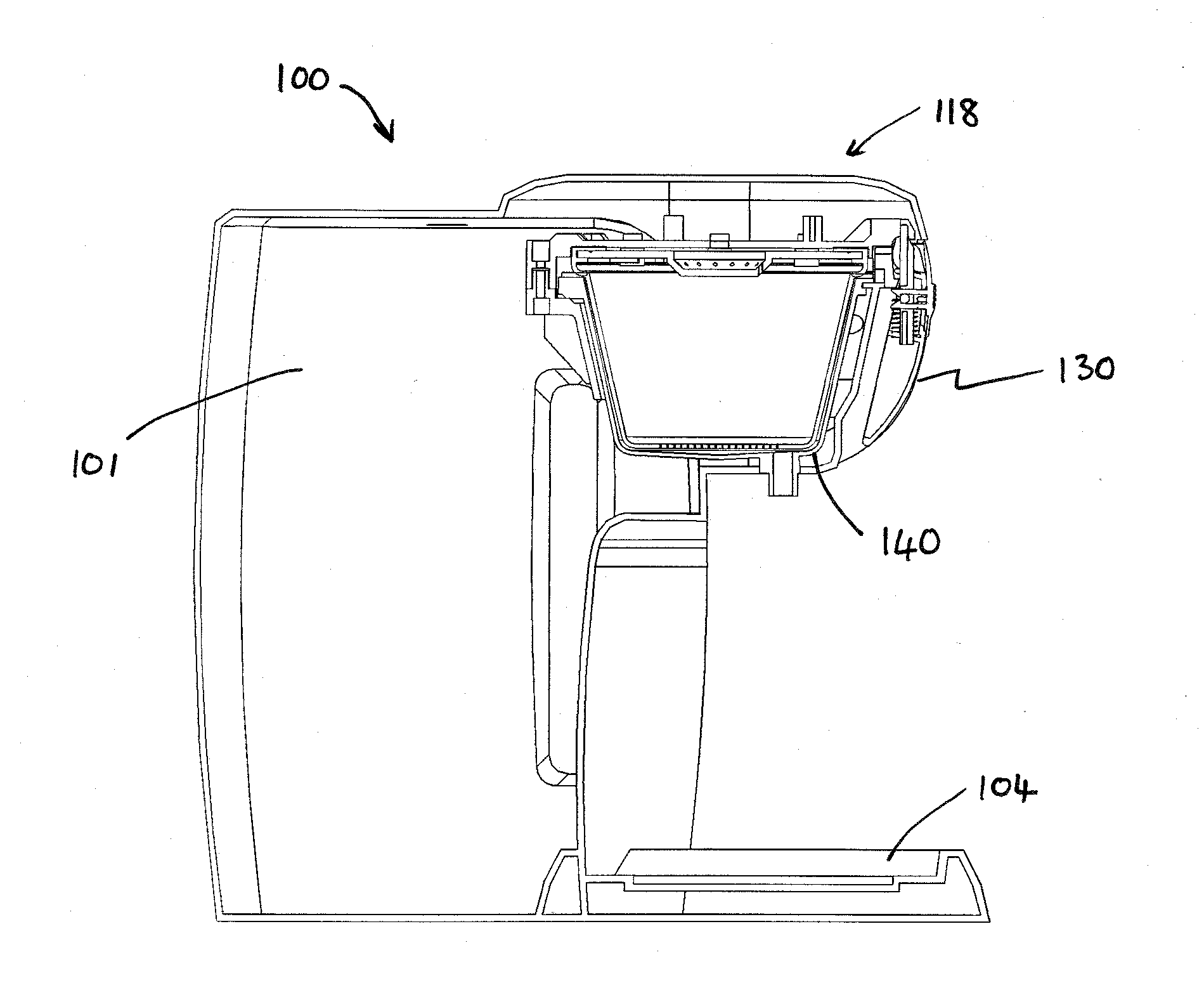

Liquid heating apparatus

InactiveUS20130337132A1Avoid passingFunction increaseBeverage vesselsFood preparationSteam pressureEngineering

An infusion beverage making apparatus (100) comprises a liquid heater, an infuser (140) for receiving beverage solid and conveying means for conveying heated liquid from the liquid heater onto the beverage solids. The apparatus (100) is configured to operate in at least one phase in which heated liquid is passed from the liquid heater through the beverage solids and in another phase in which steam is passed through at least a portion of the conveying means. A quantity of water is heated to boiling by the liquid heater and a steam pressure allowed to develop as a result which is sufficient to force steam through at least a portion of the conveying means.

Owner:STRIX LTD

Microwave heater for liquid

A microwave liquid heater relates to a liquid heating implement technology field. The invention is design of an assembly, a microwave heating body which absorb microwave and generates heat utilizing microwave heating body as heating source, microwave heating body absorbing microwave and generate heat to heat water oil etc and various liquids.

Owner:张敬胜

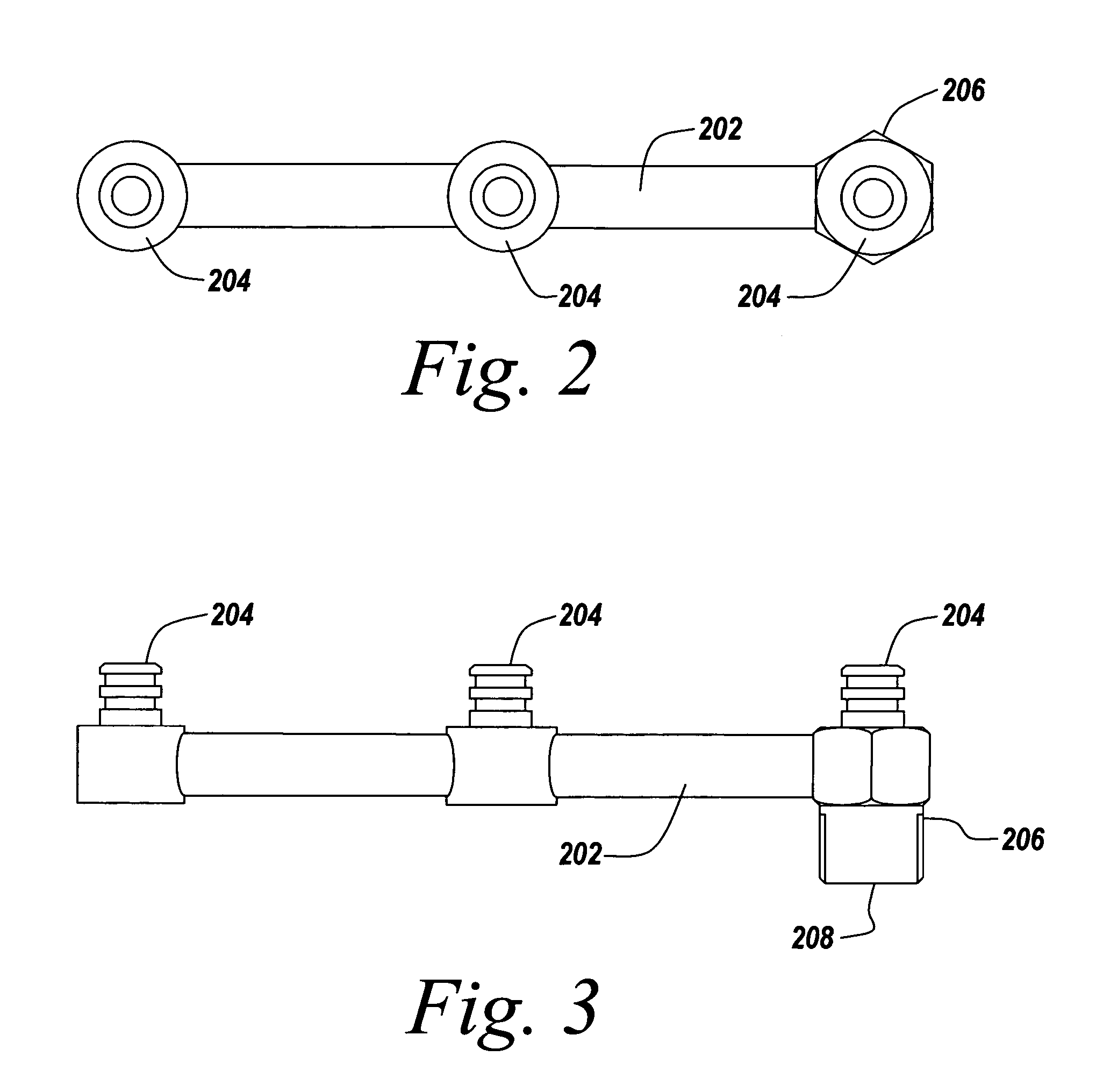

Heating element assembly for electric tankless liquid heater

ActiveUS8577211B2Minimize overall cost and maintenanceReduce vulnerabilityWashersWater heatersEngineeringFluid warmer

Owner:RHEEM MFG CO

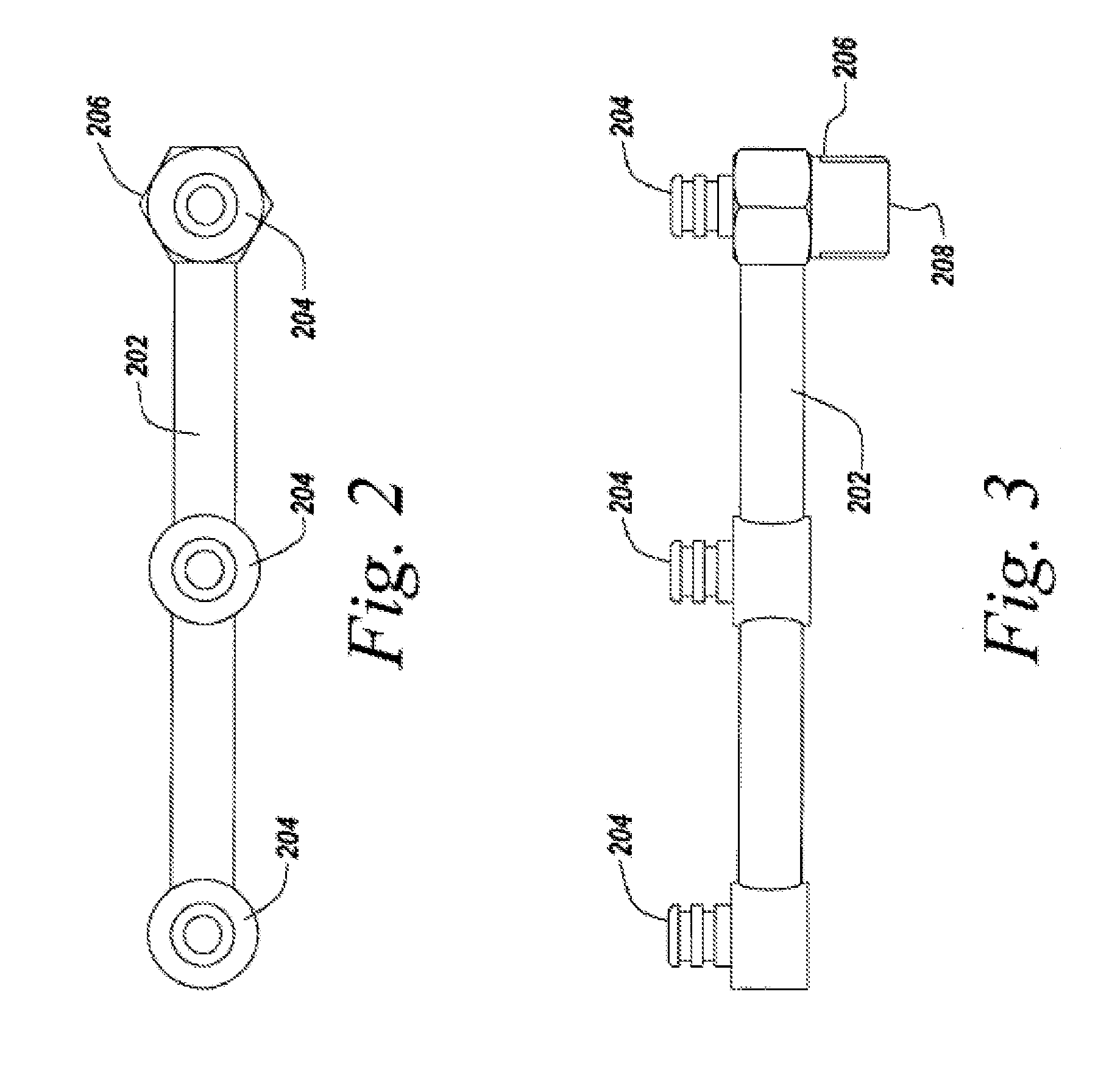

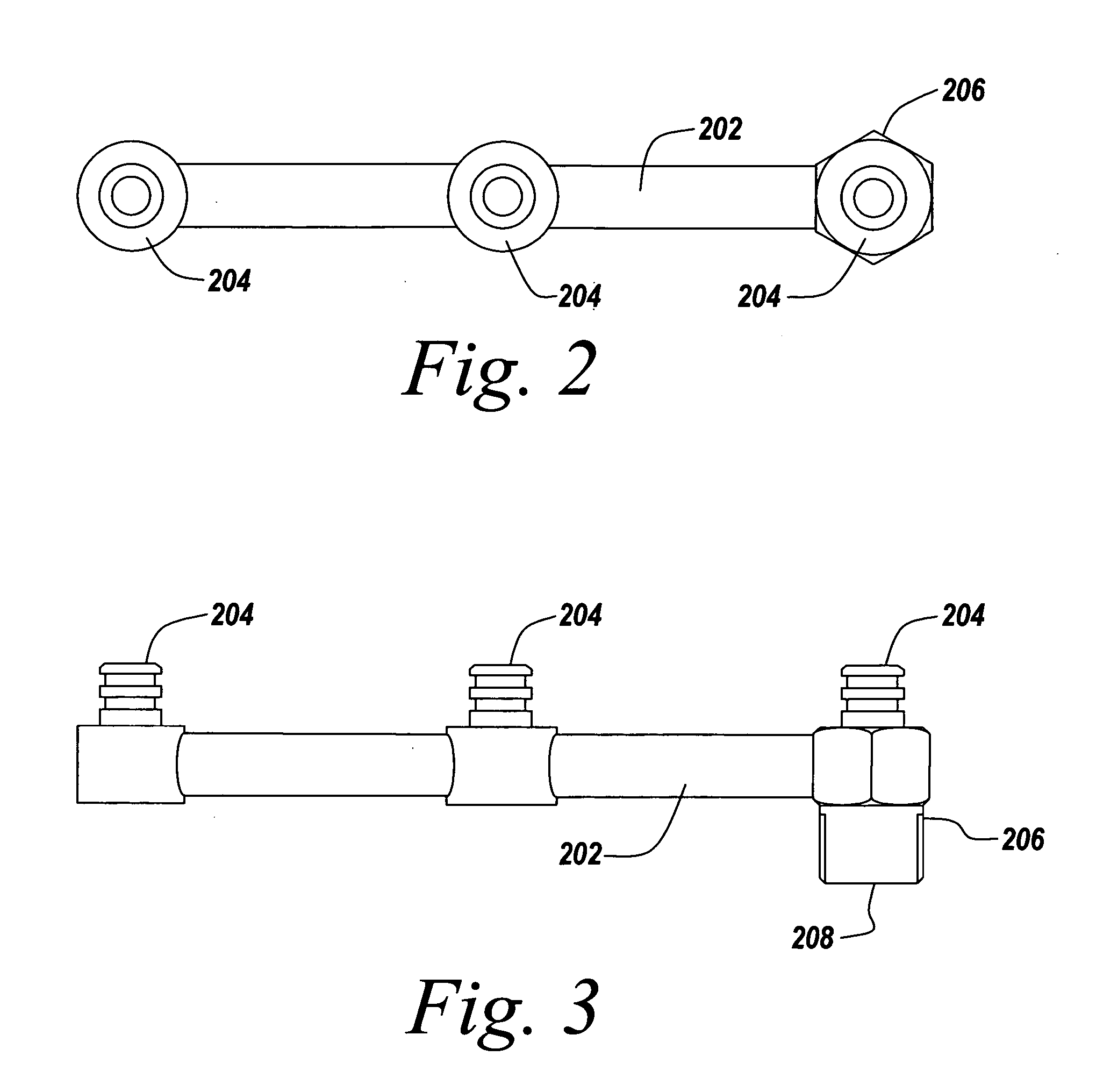

Heating element assembly for electric tankless liquid heater

ActiveUS20120063755A1Low costMinimize maintenanceWater heatersControl of fluid heatersFluid warmerElectrical contacts

In various aspects, the present application describes a heating element assembly for a liquid heater, embodiments of which may include an electrically conductive termination rod with a base portion defining a securement opening. An electrically conductive fastener may include a shank portion for fitting into the securement opening. The heating element assembly may have a head portion larger than the securement opening, and an electrical resistance heating element comprising a continuous coil. An end portion of the continuous coil may be formed to loop around the fastener shank portion. The end portion may be in electrical contact with the fastener head portion and the termination rod base portion. An adjacent portion of the continuous coil may be formed to clear the fastener head portion as the adjacent portion extends from the end portion. The continuous coil may have a coil axis substantially aligned with a lengthwise axis of the fastener.

Owner:RHEEM MFG CO

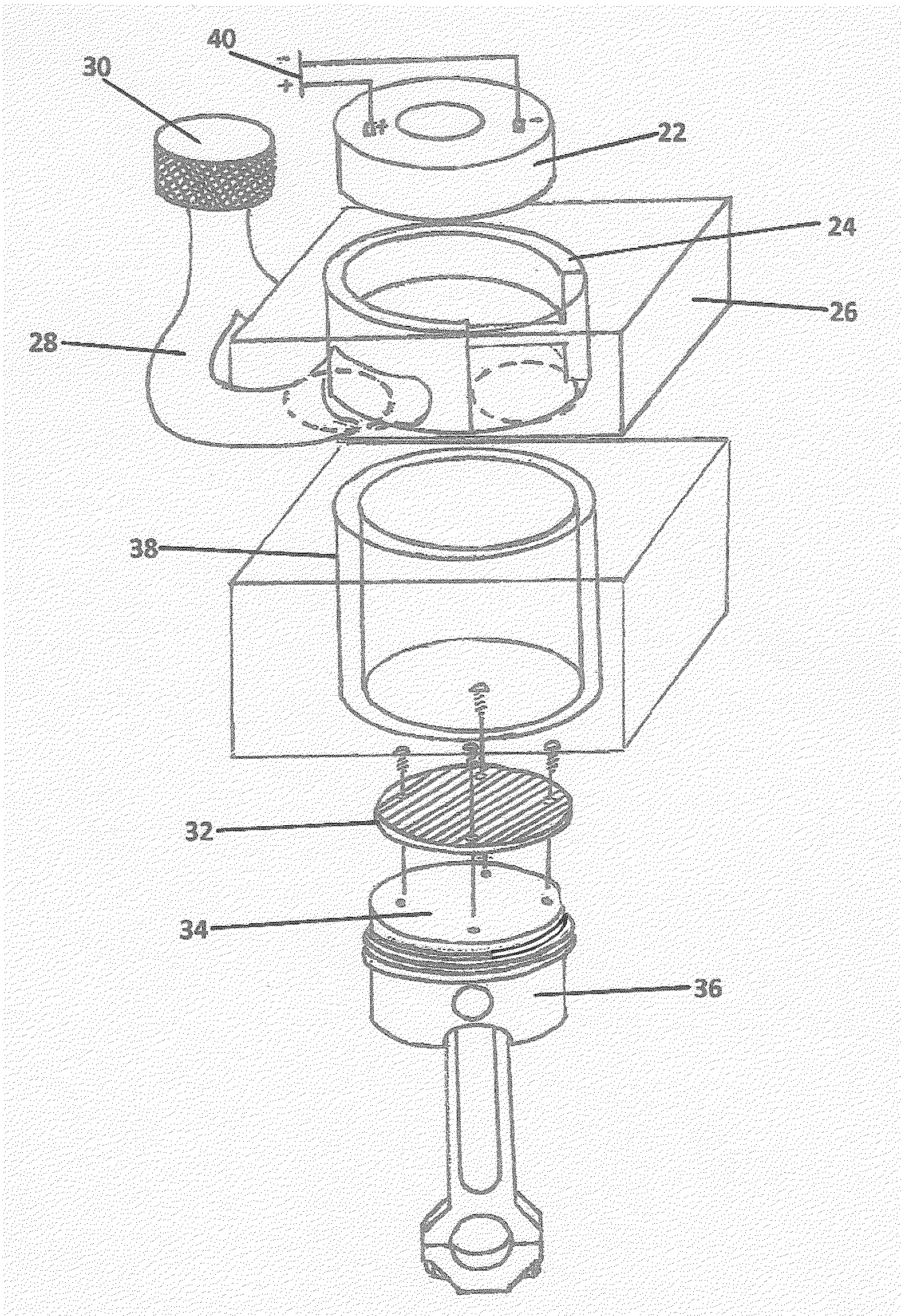

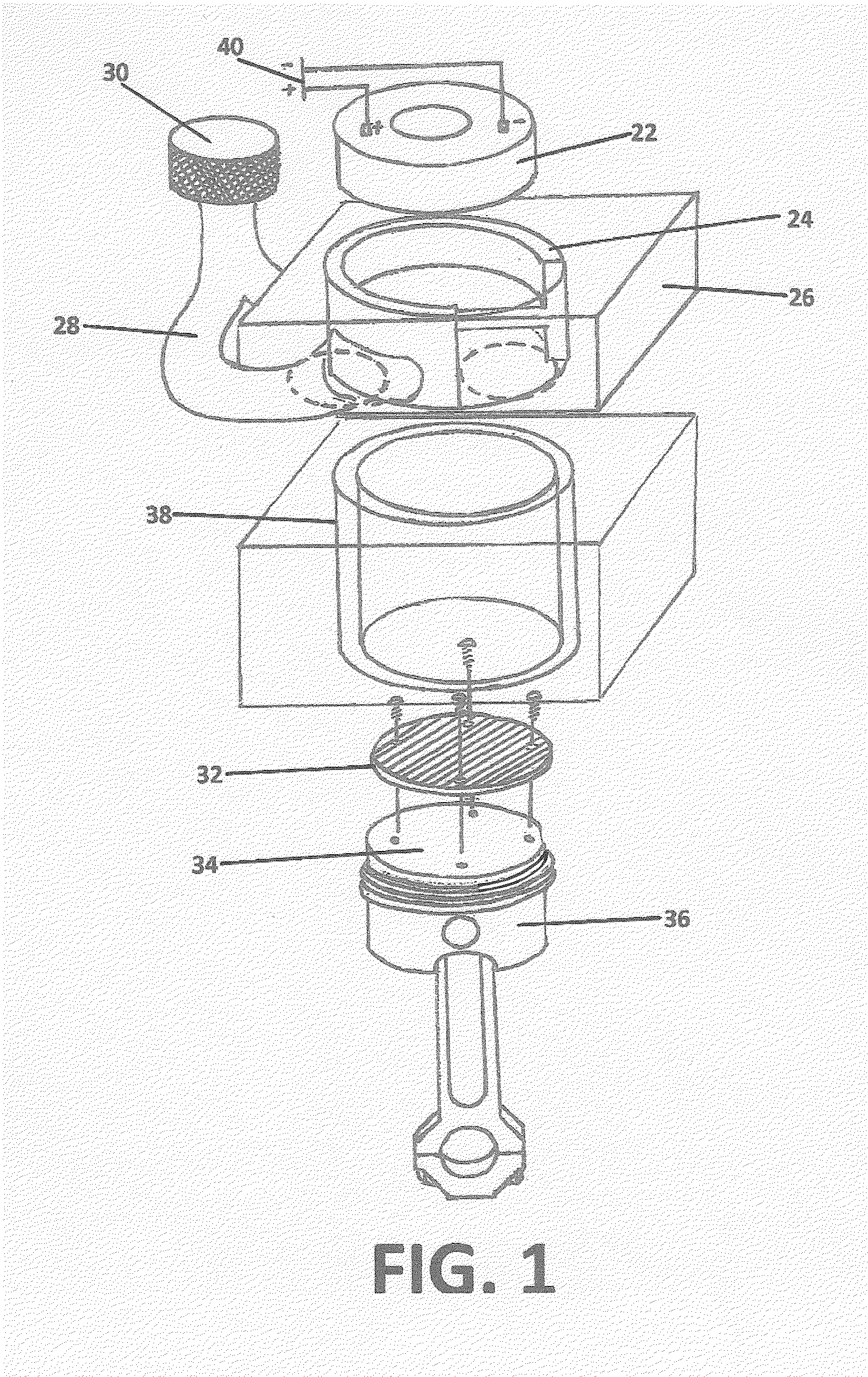

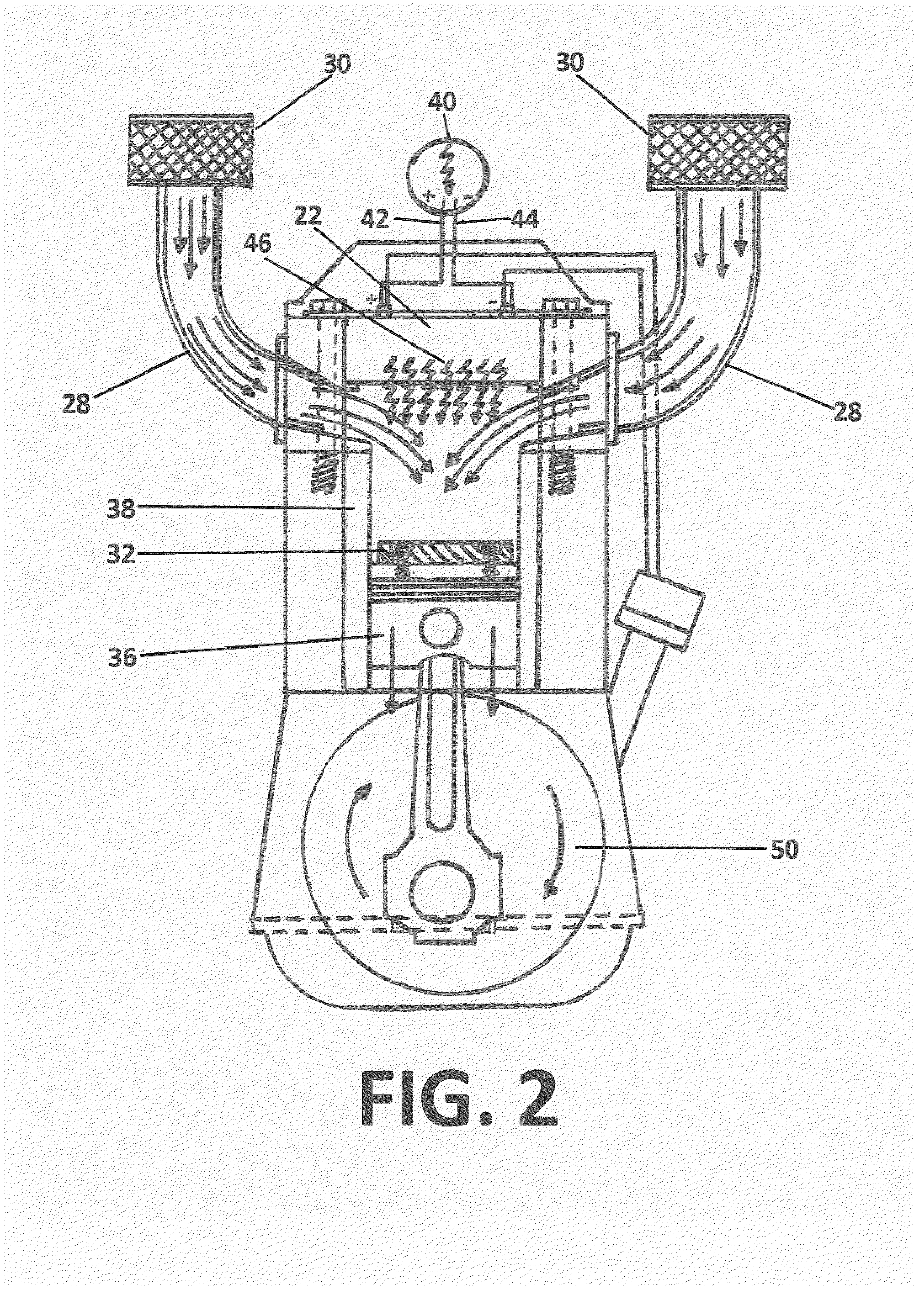

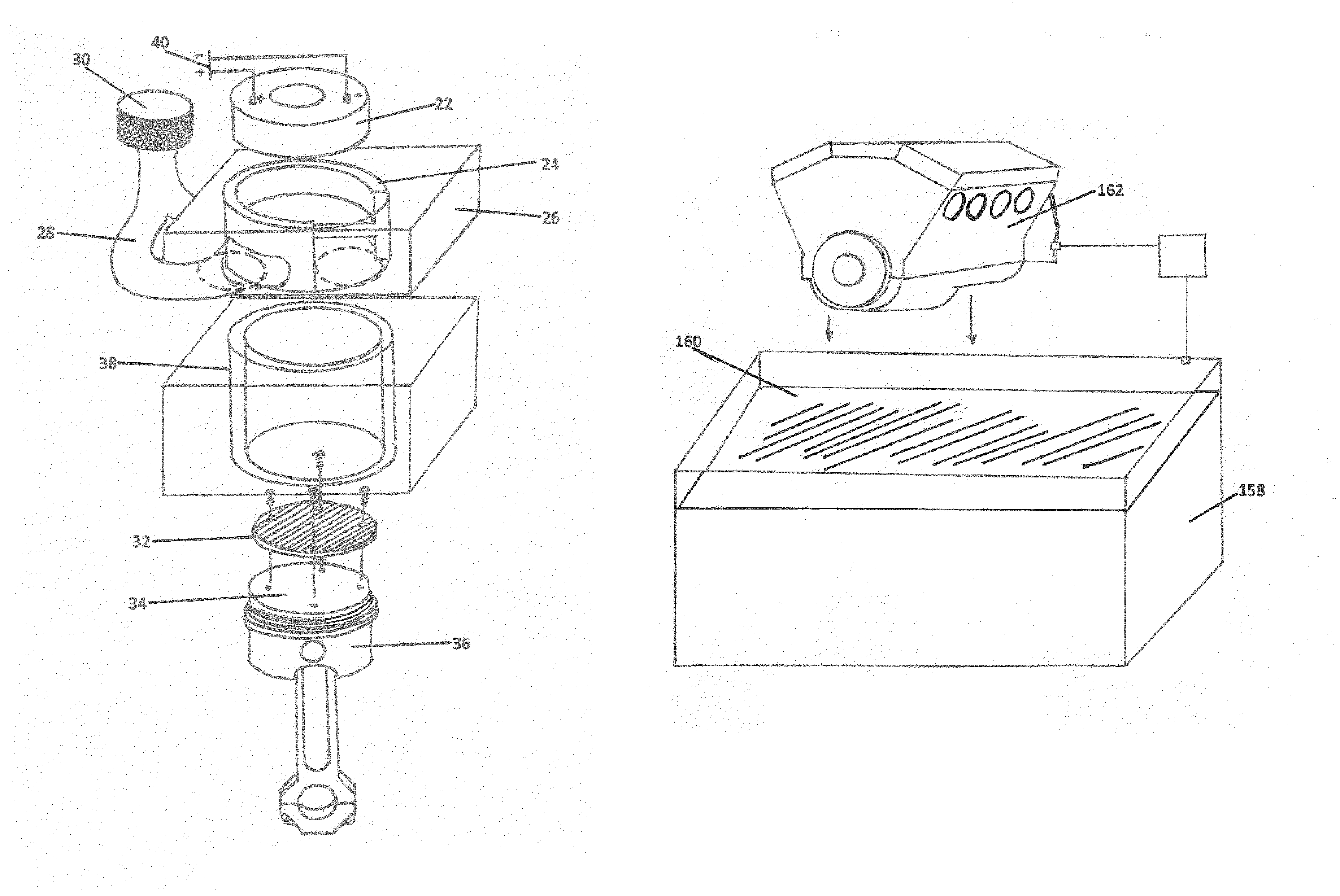

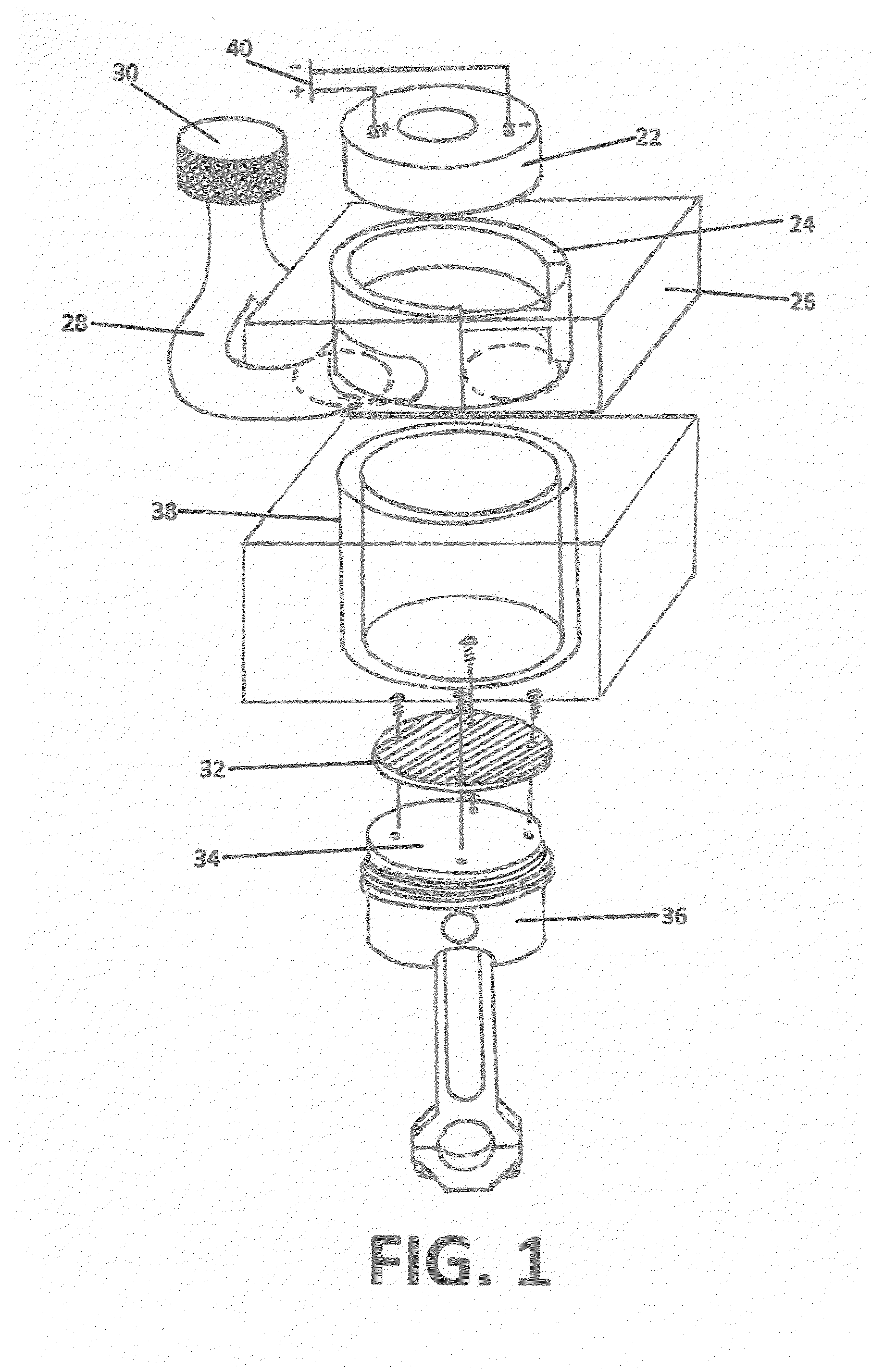

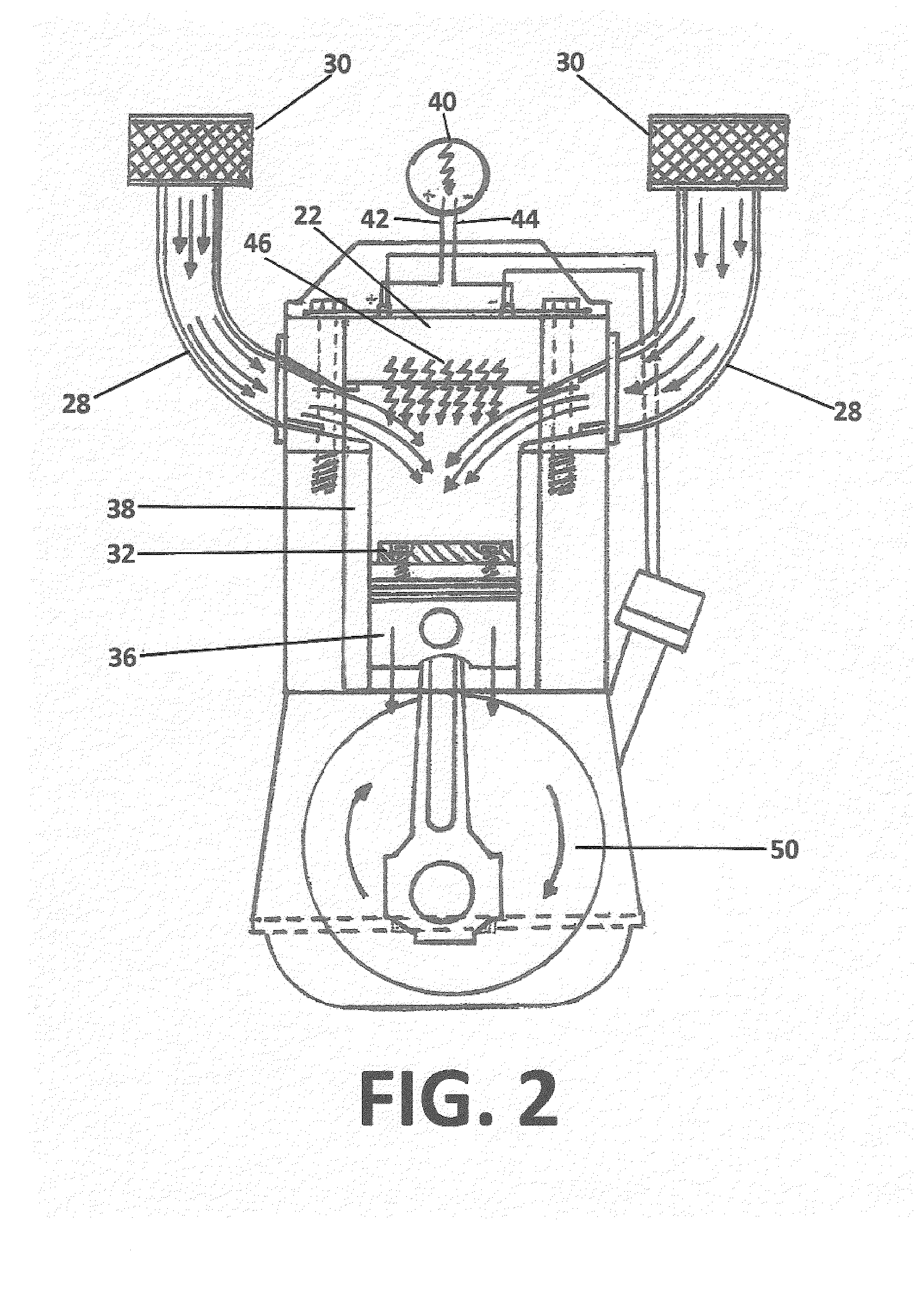

Magnetically Propelled Engine That Does Not Require Fuel

ActiveUS20100066181A1Reduce and block magnetic field(s)Simple designMechanical energy handlingAtmospheric airEngine power

An engine powering device with magnetic components that aid in the operation of piston propelled engines by attaching the device individually to the pistons, causing the pistons to perform the up and down thrusts without the use of fuel combustion thereby mobilizing the engine, eliminating the necessity of fuel and preventing pollution exhausting into the atmosphere. An exemplary system for a magnetically controlled propelled engine that uses exhausted clean air from the engine that flows through an electric generating turbo or turbine to charge the battery to power the engine. Passenger compartment comfort heating is supplied by and electric liquid boiler or liquid heater with a circulation pump. A fuel door mounted universal electrical connector to aid in charging engine battery. This engine has magnetic shielding safety components to protect people and other electronic devices from strong rare earth magnets and electromagnets.

Owner:KELLER MR CHRISTIAN HARVEY

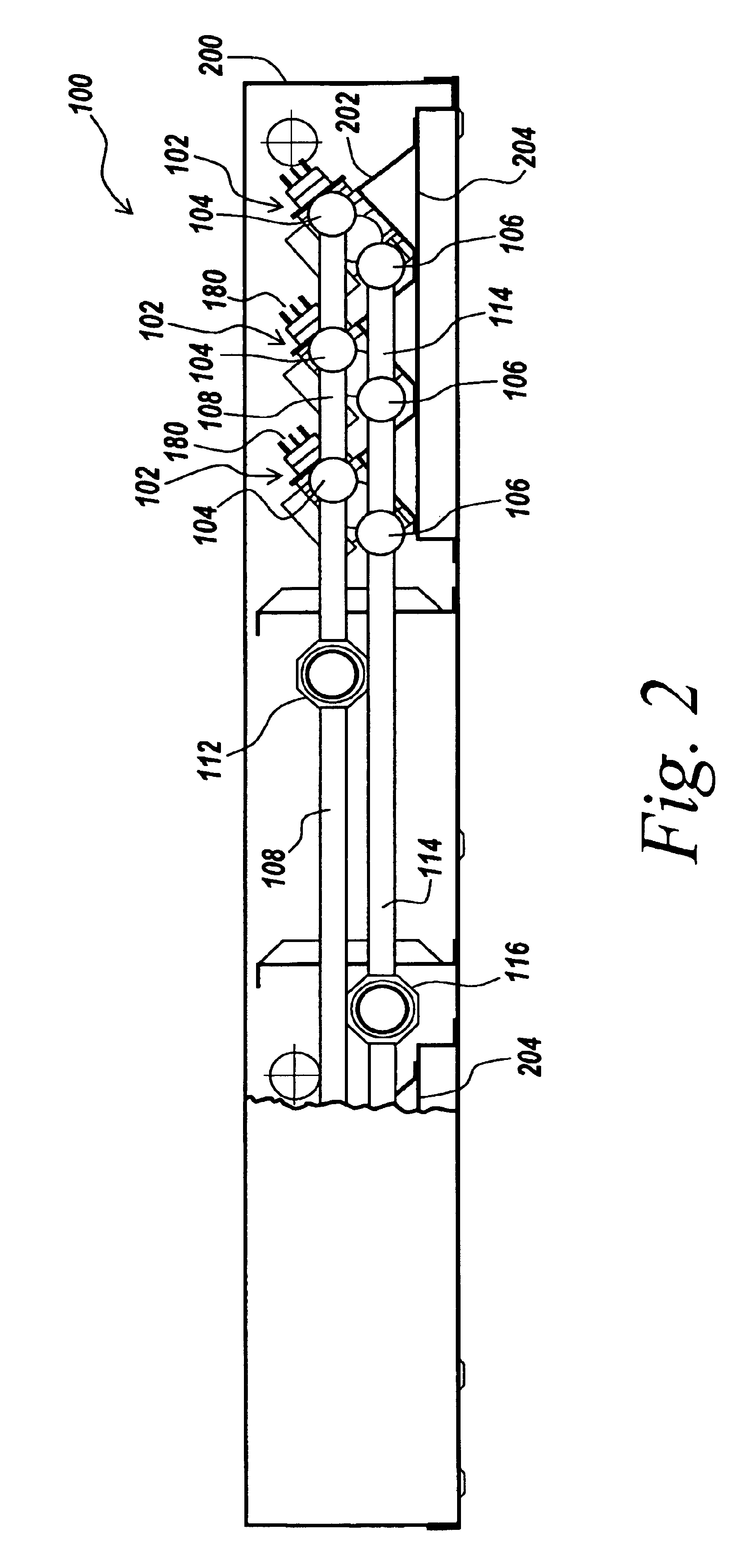

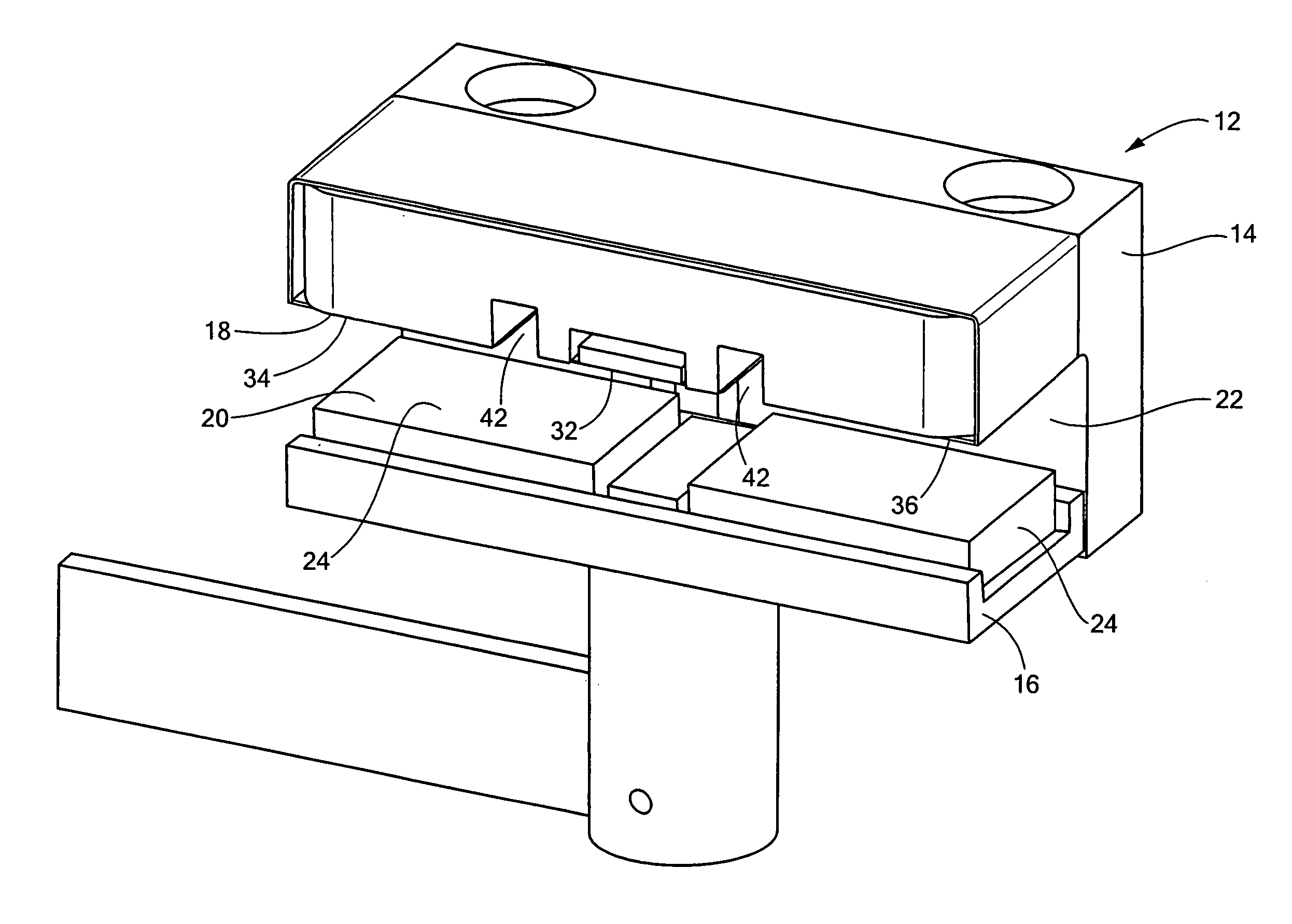

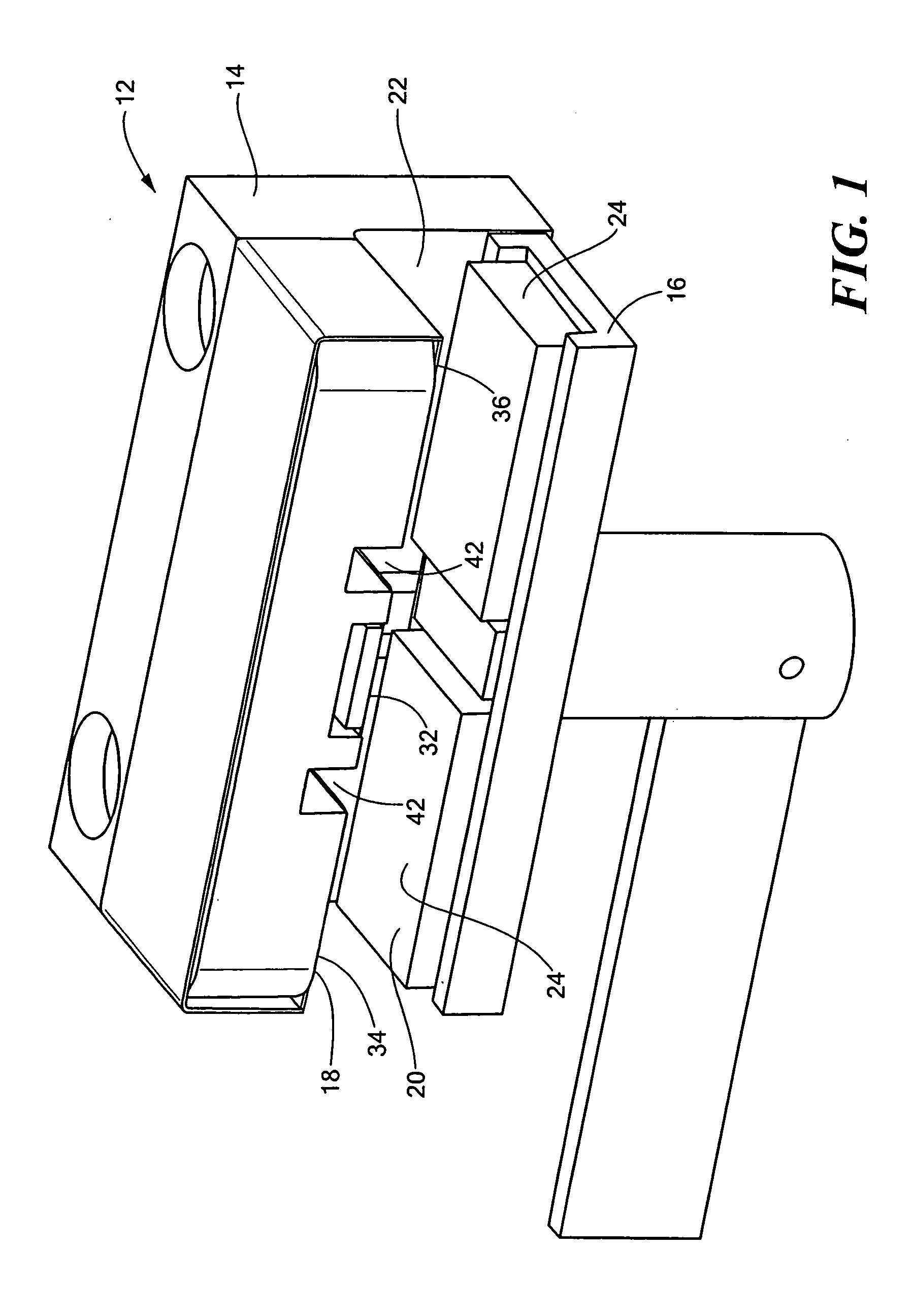

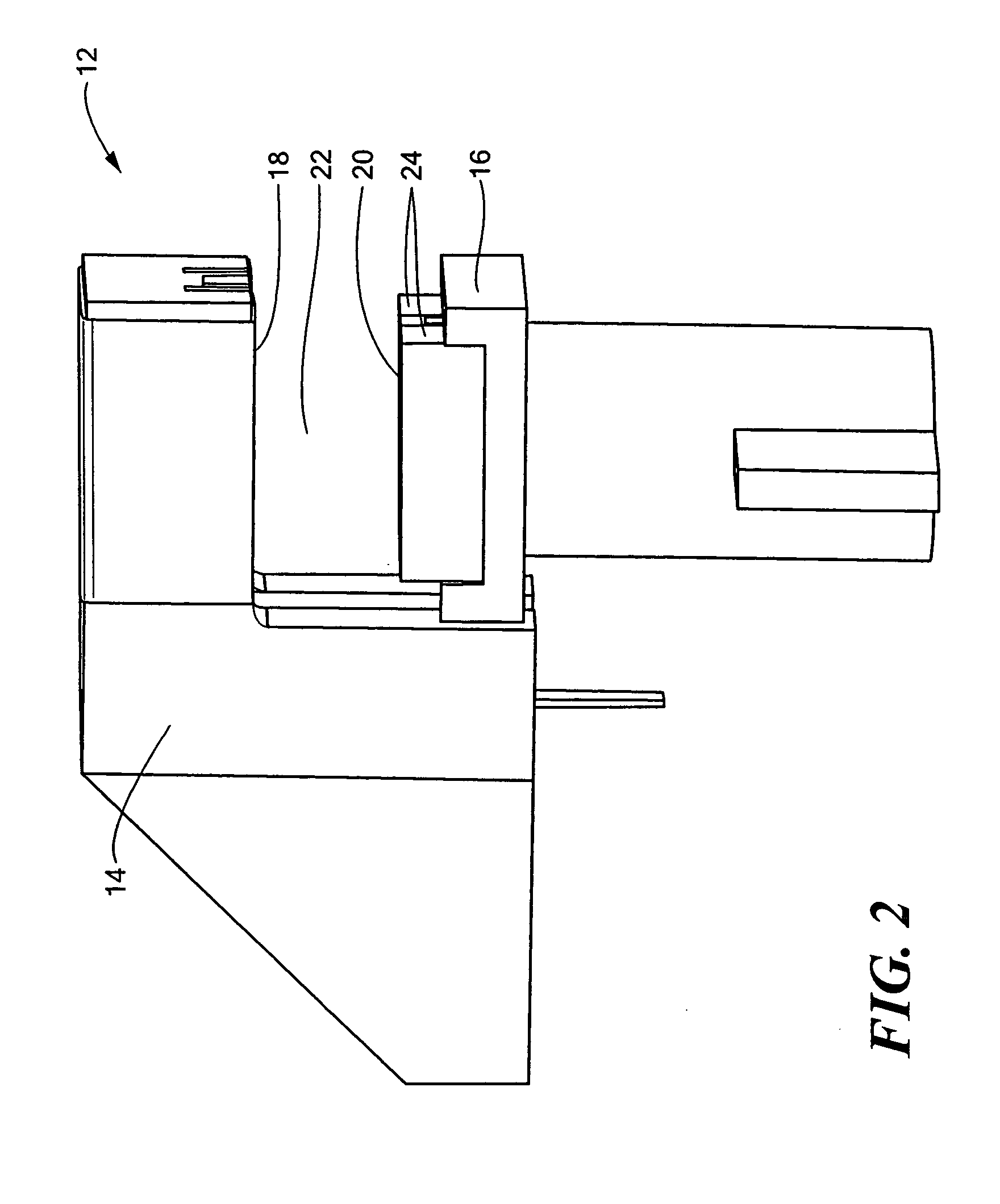

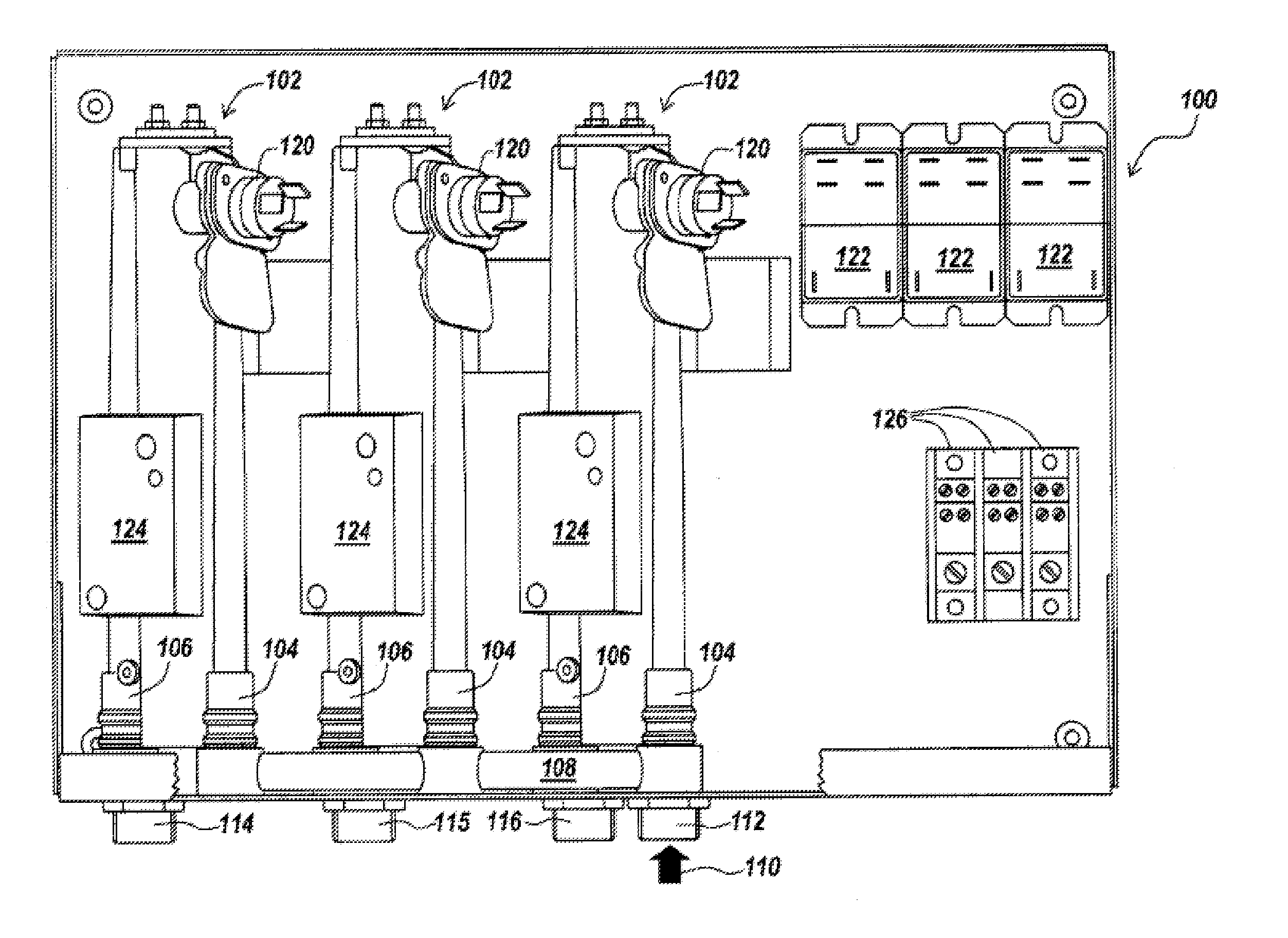

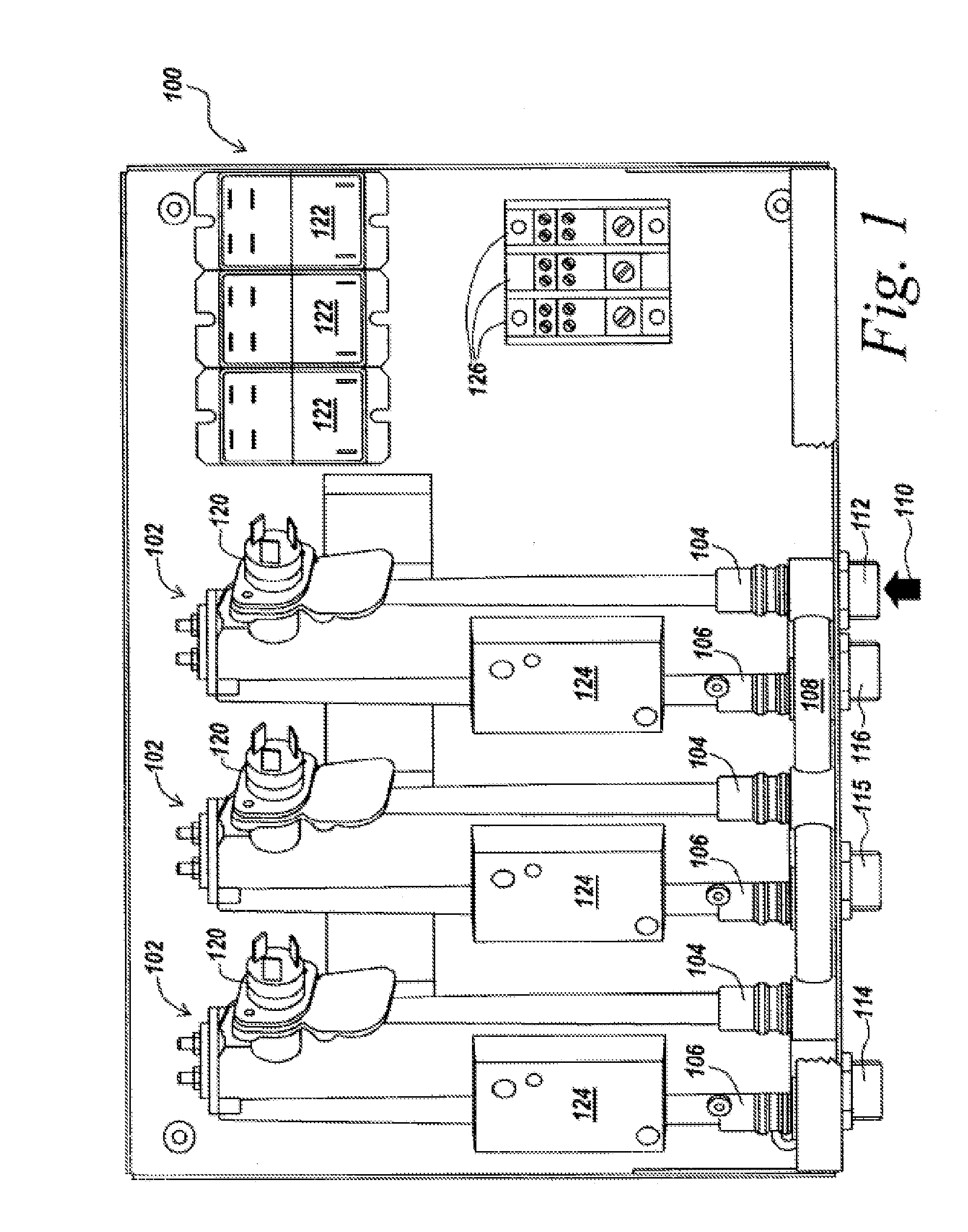

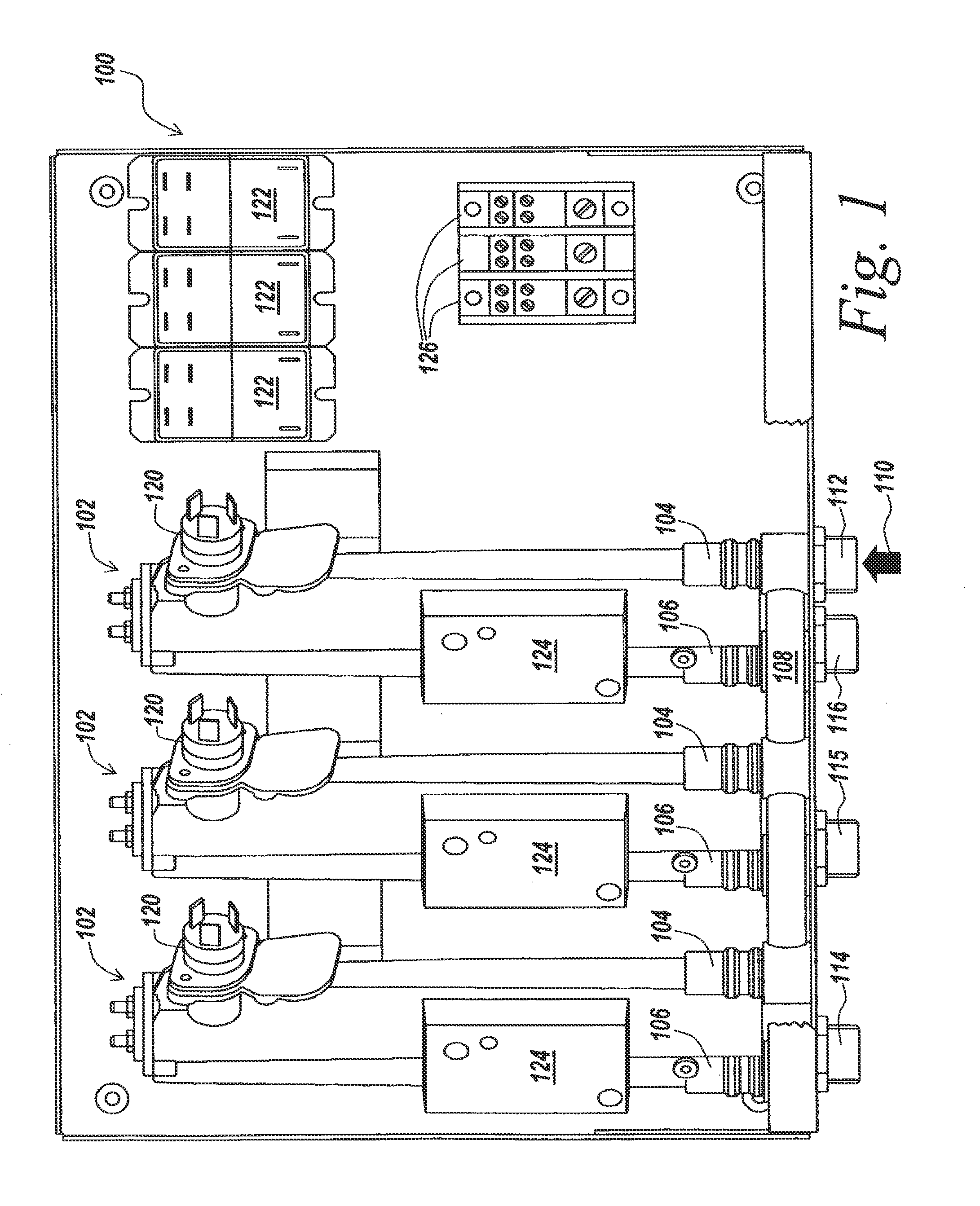

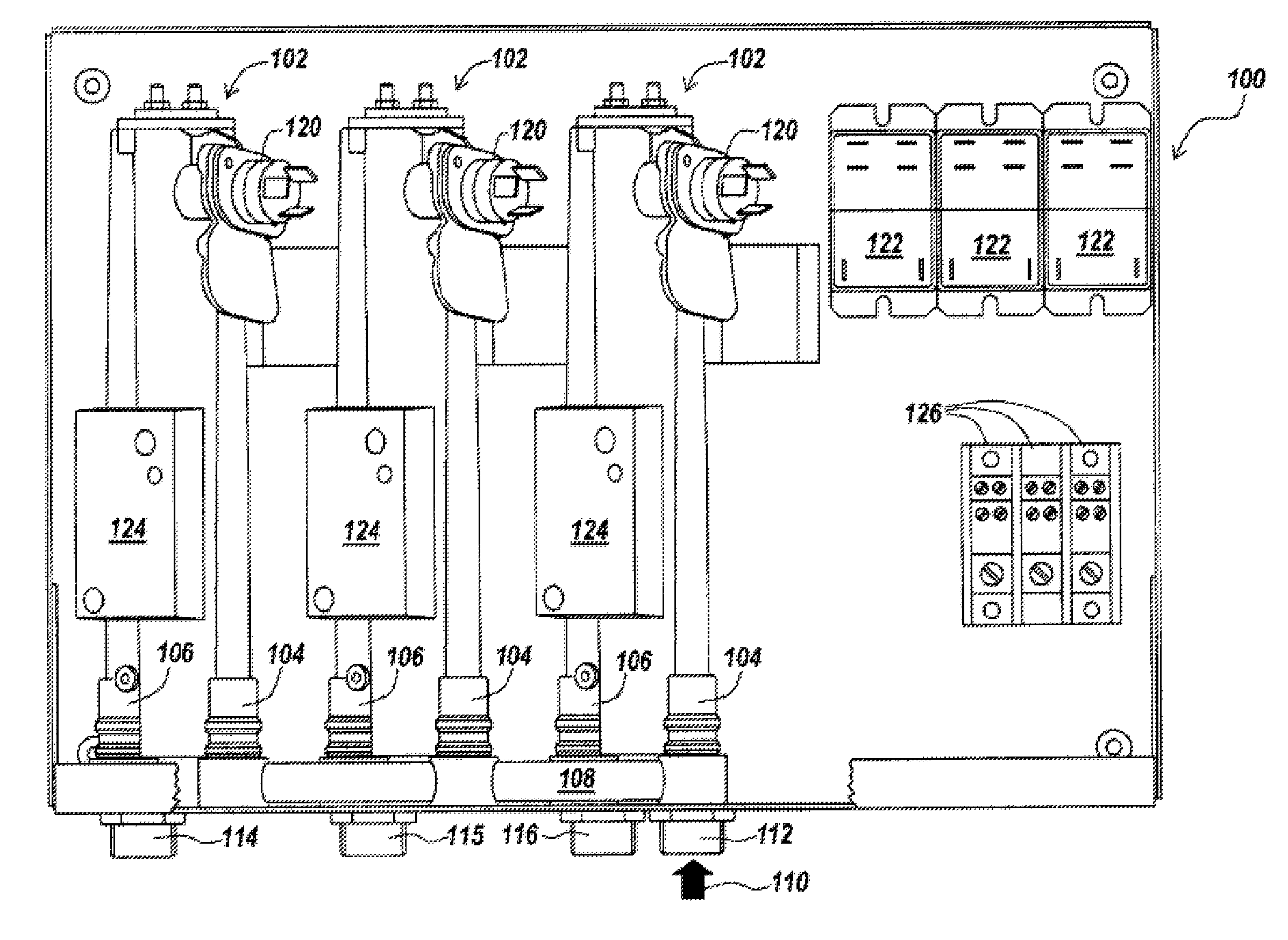

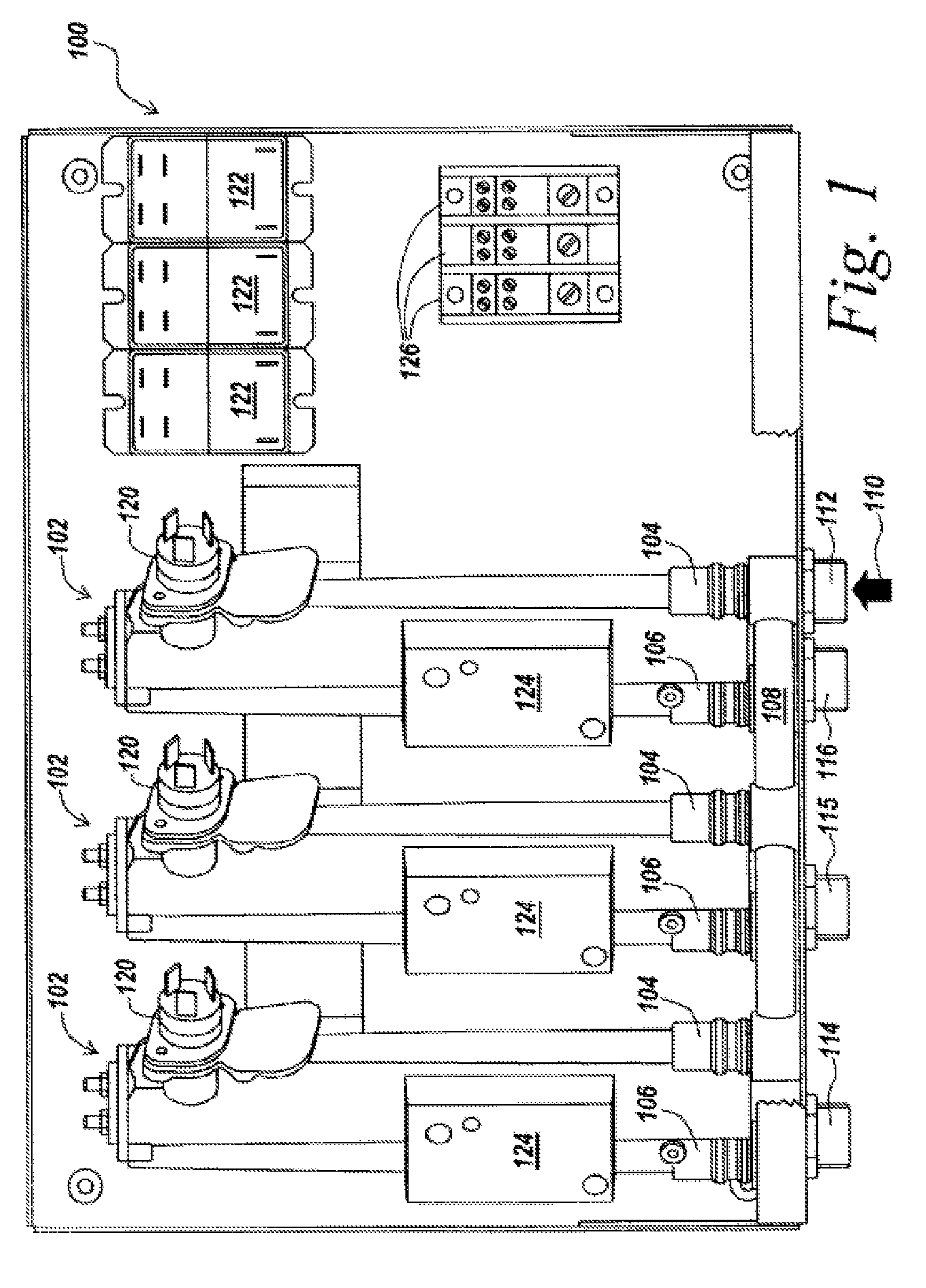

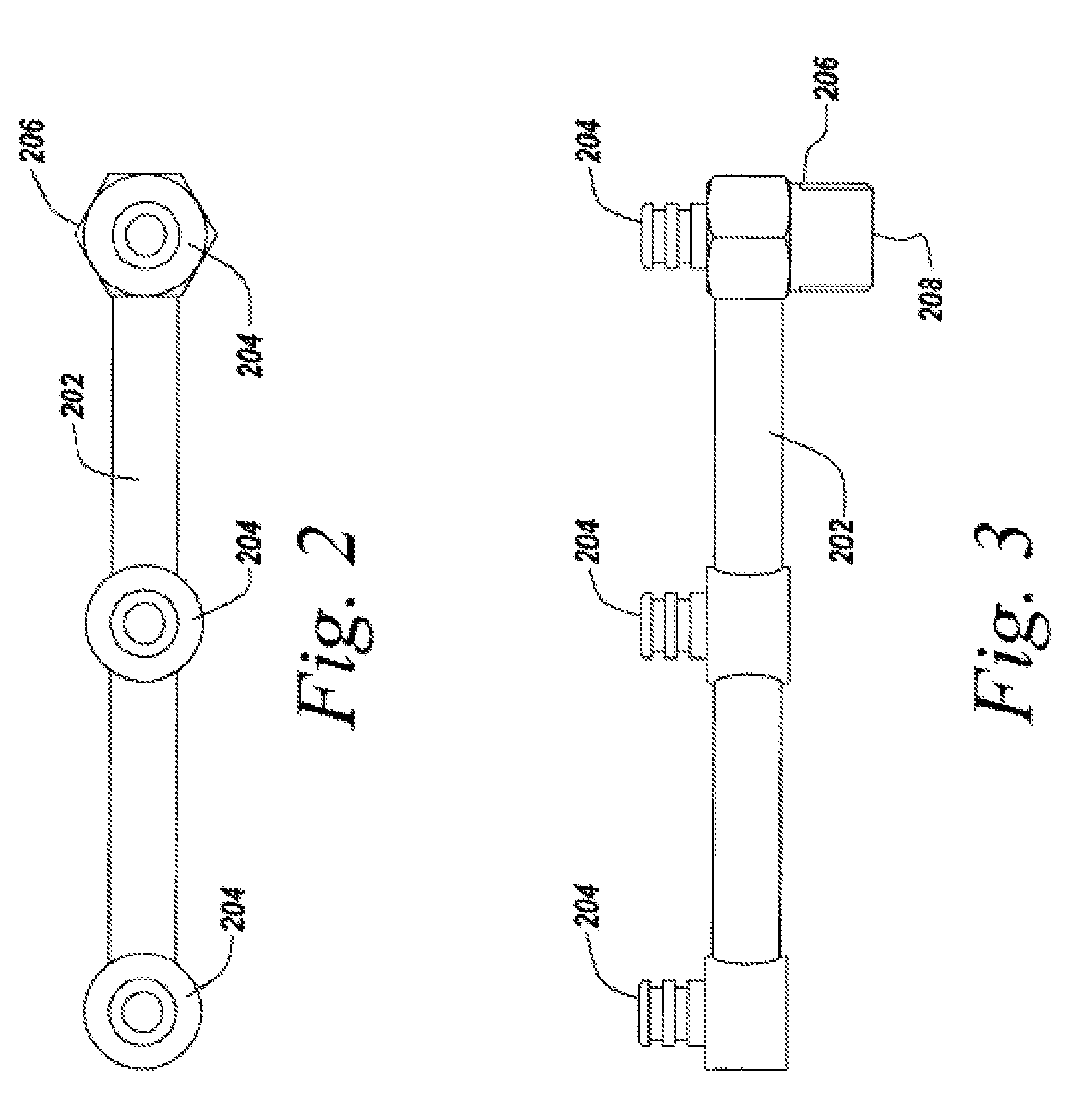

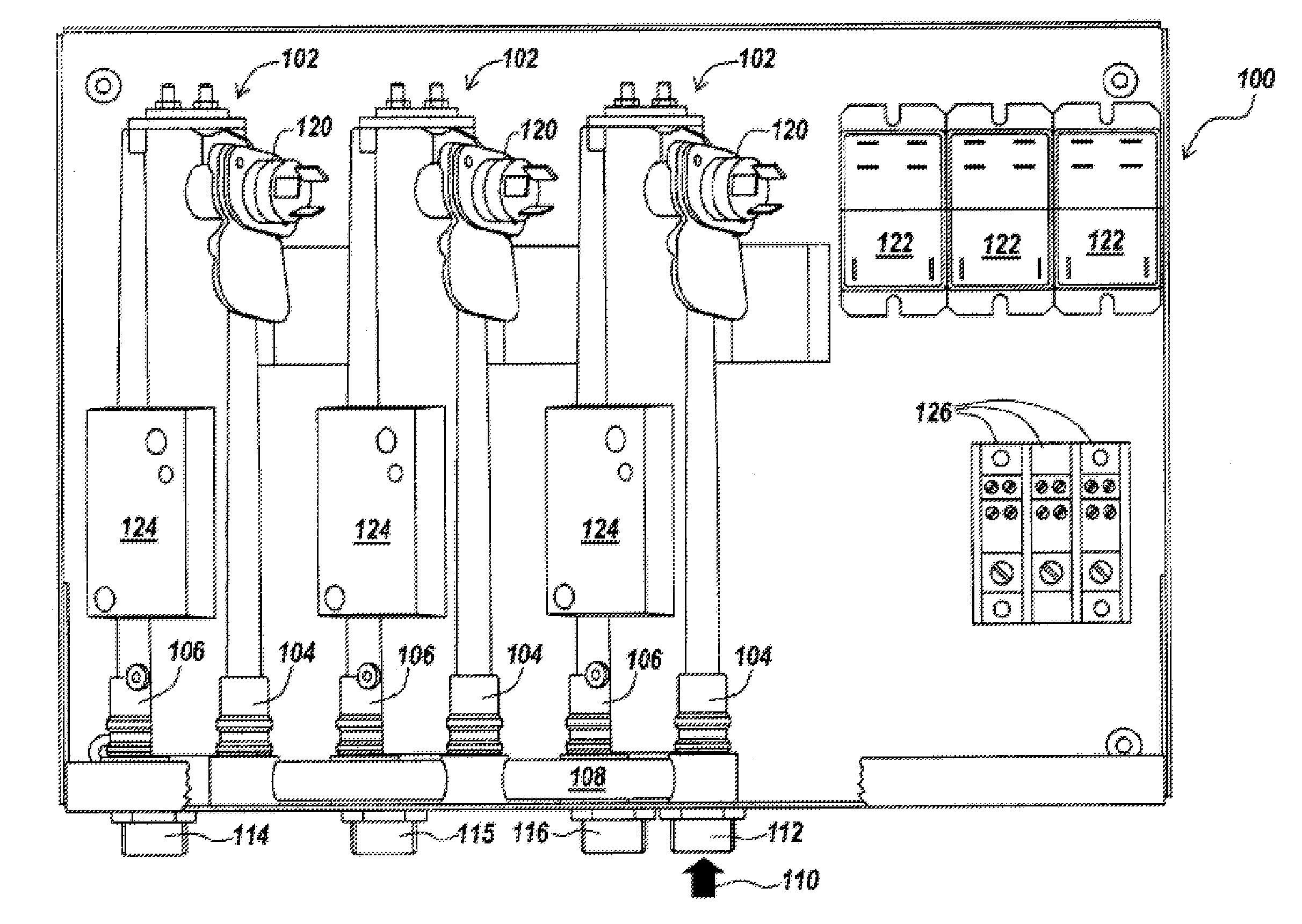

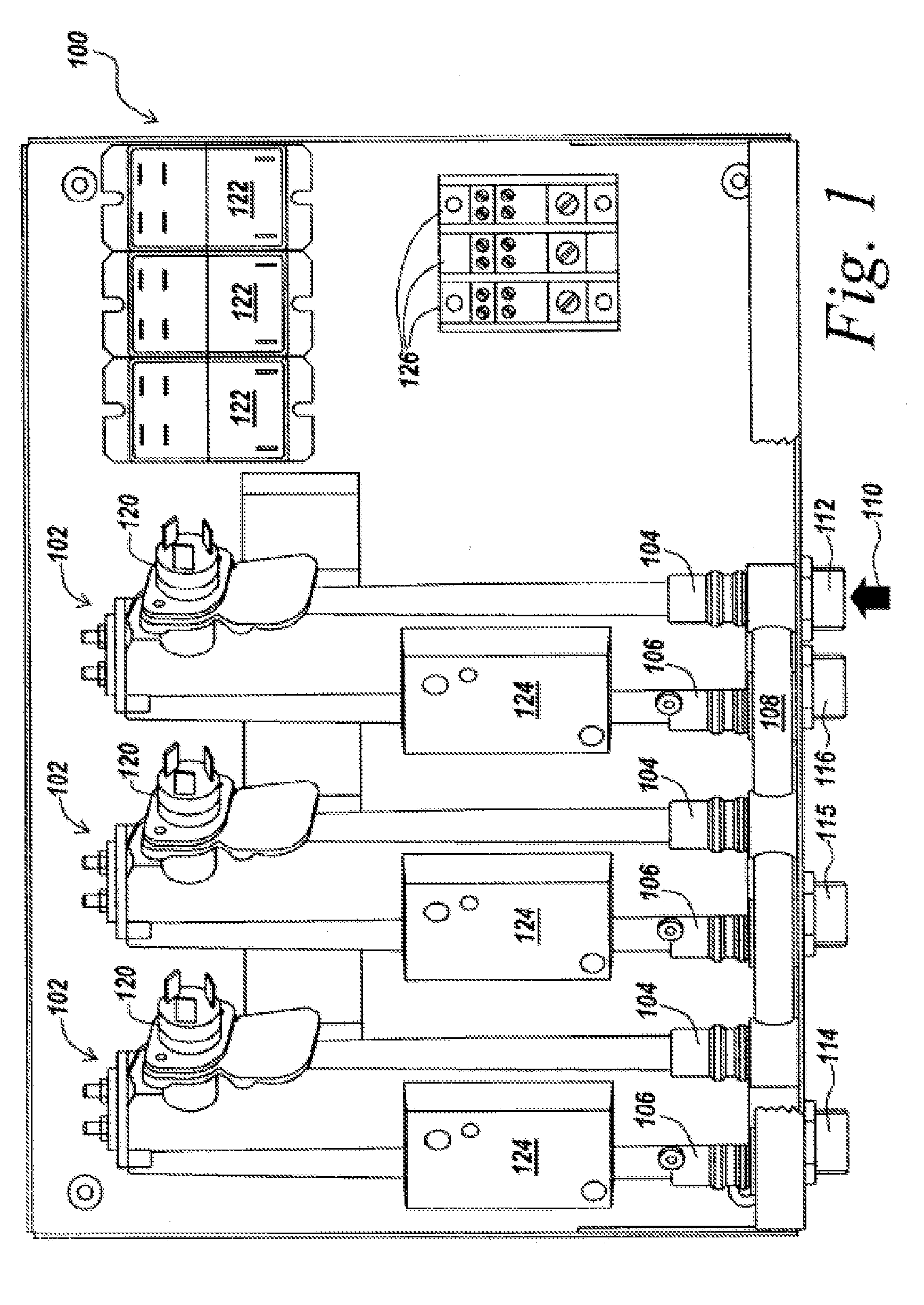

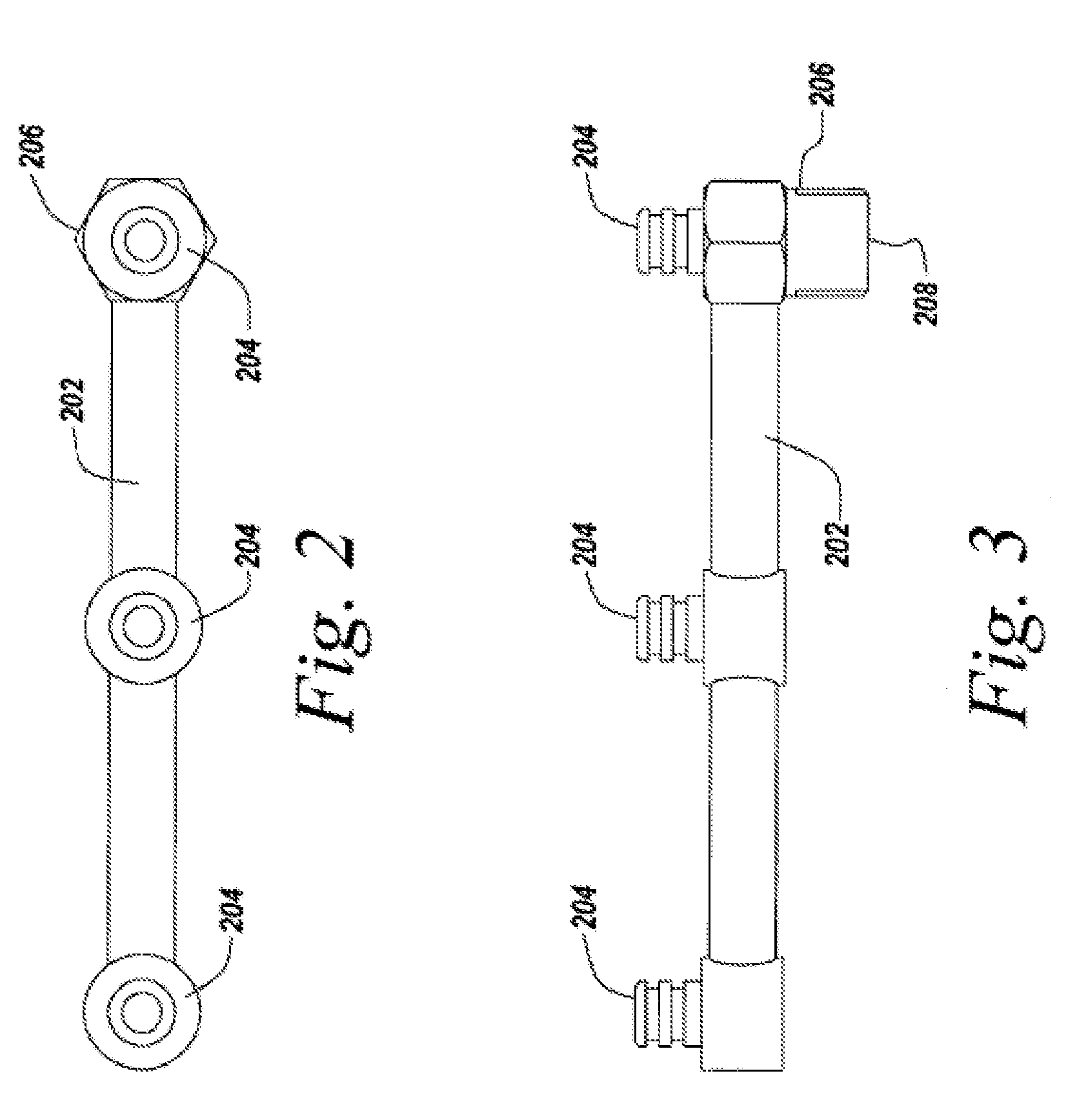

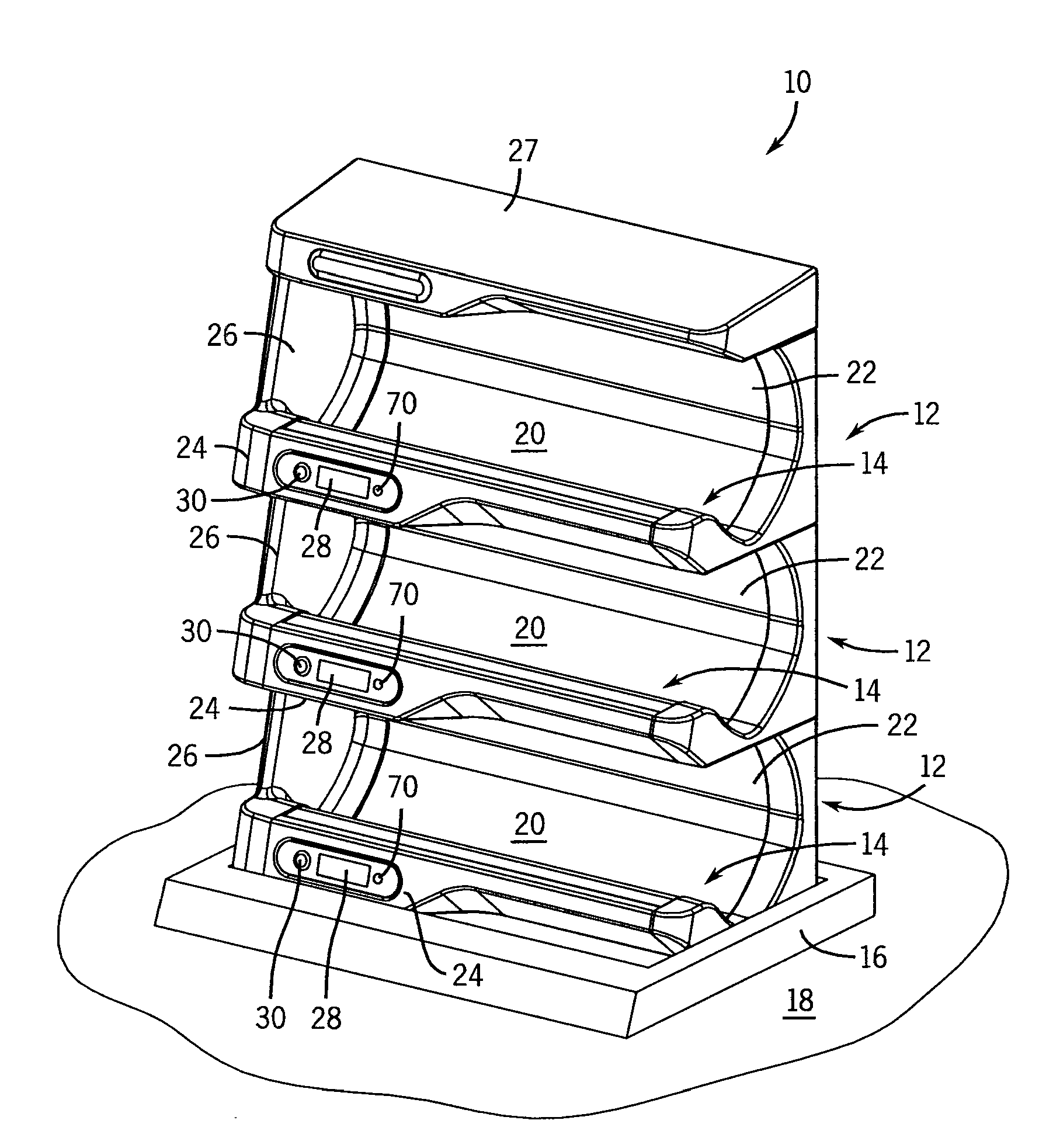

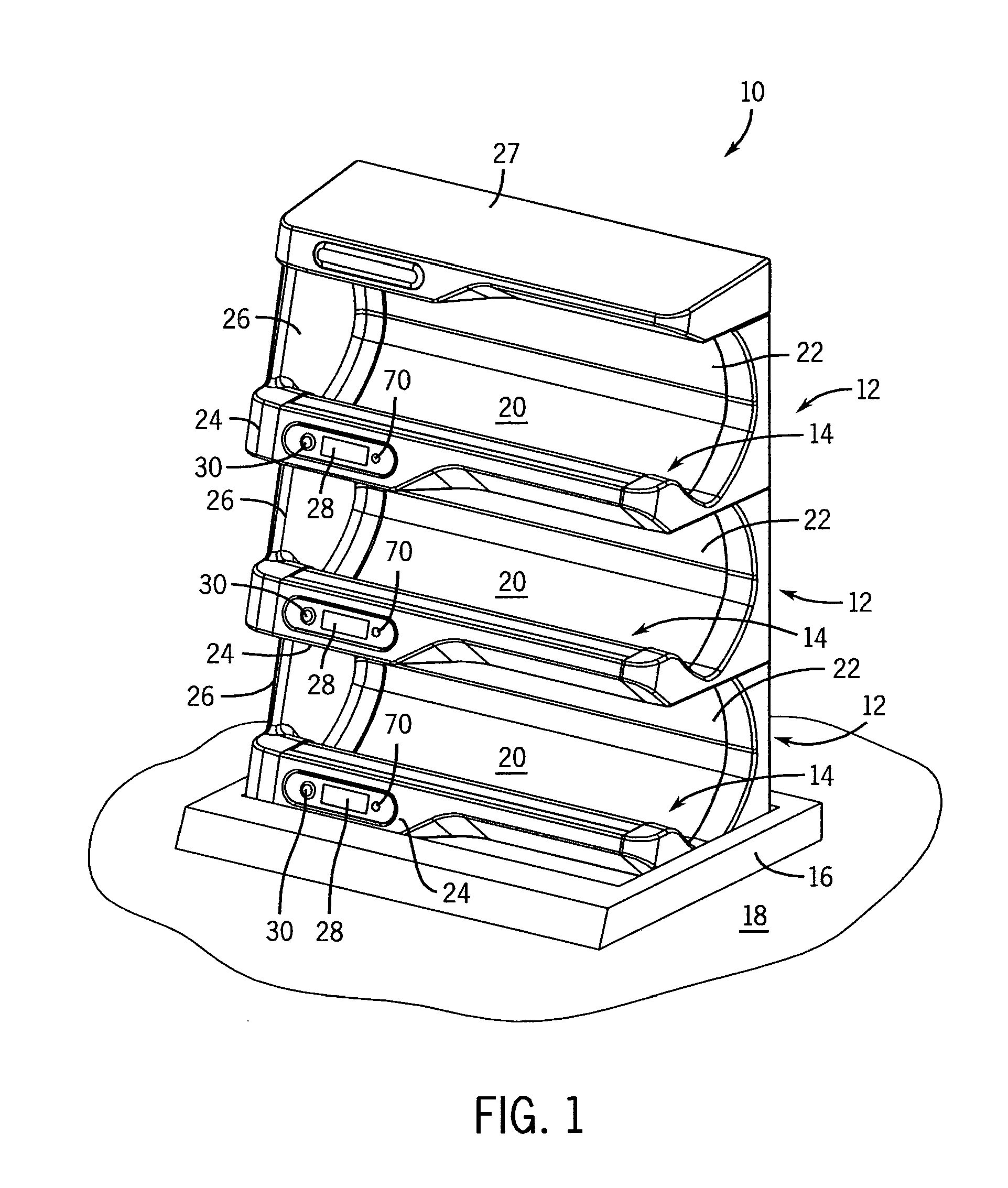

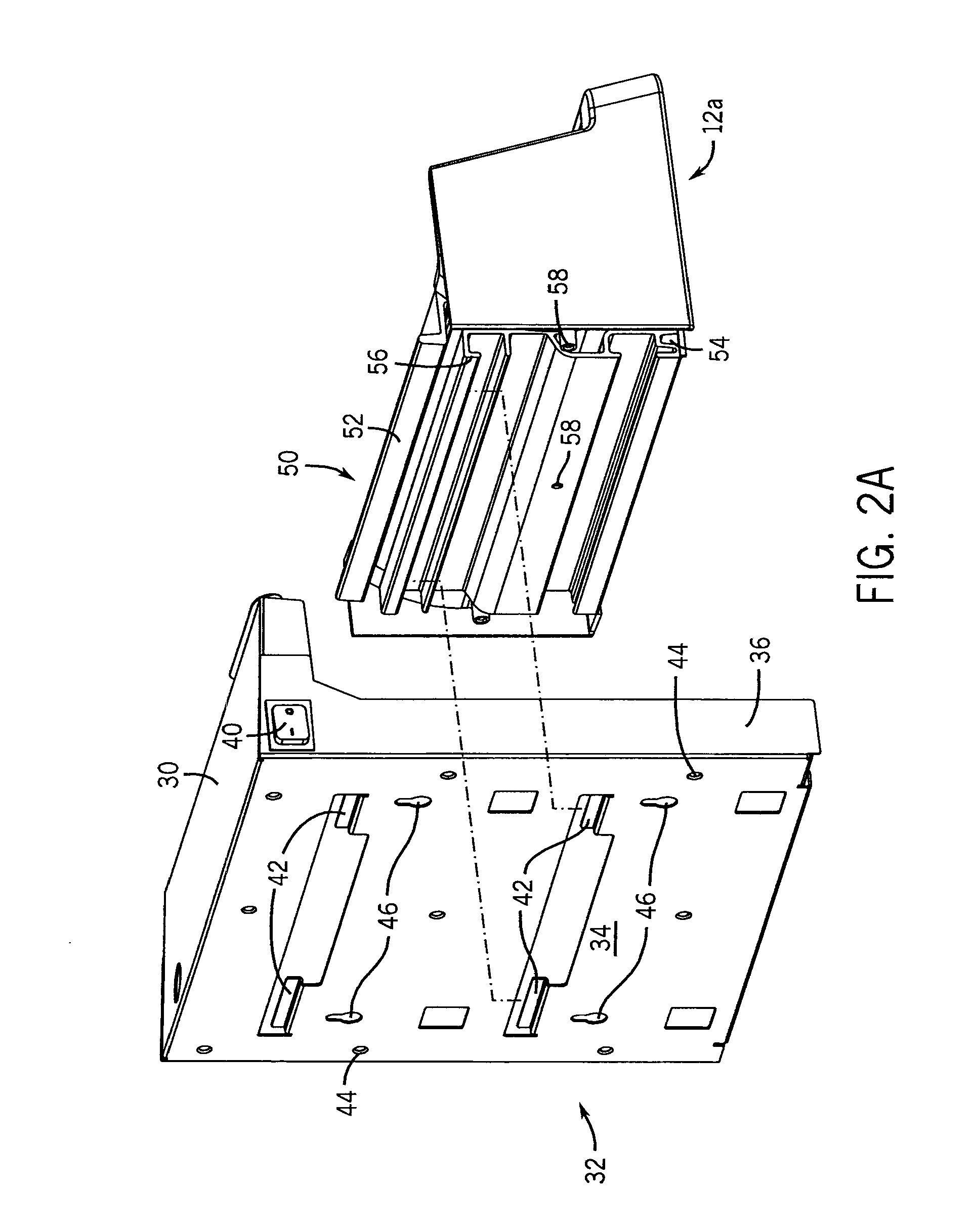

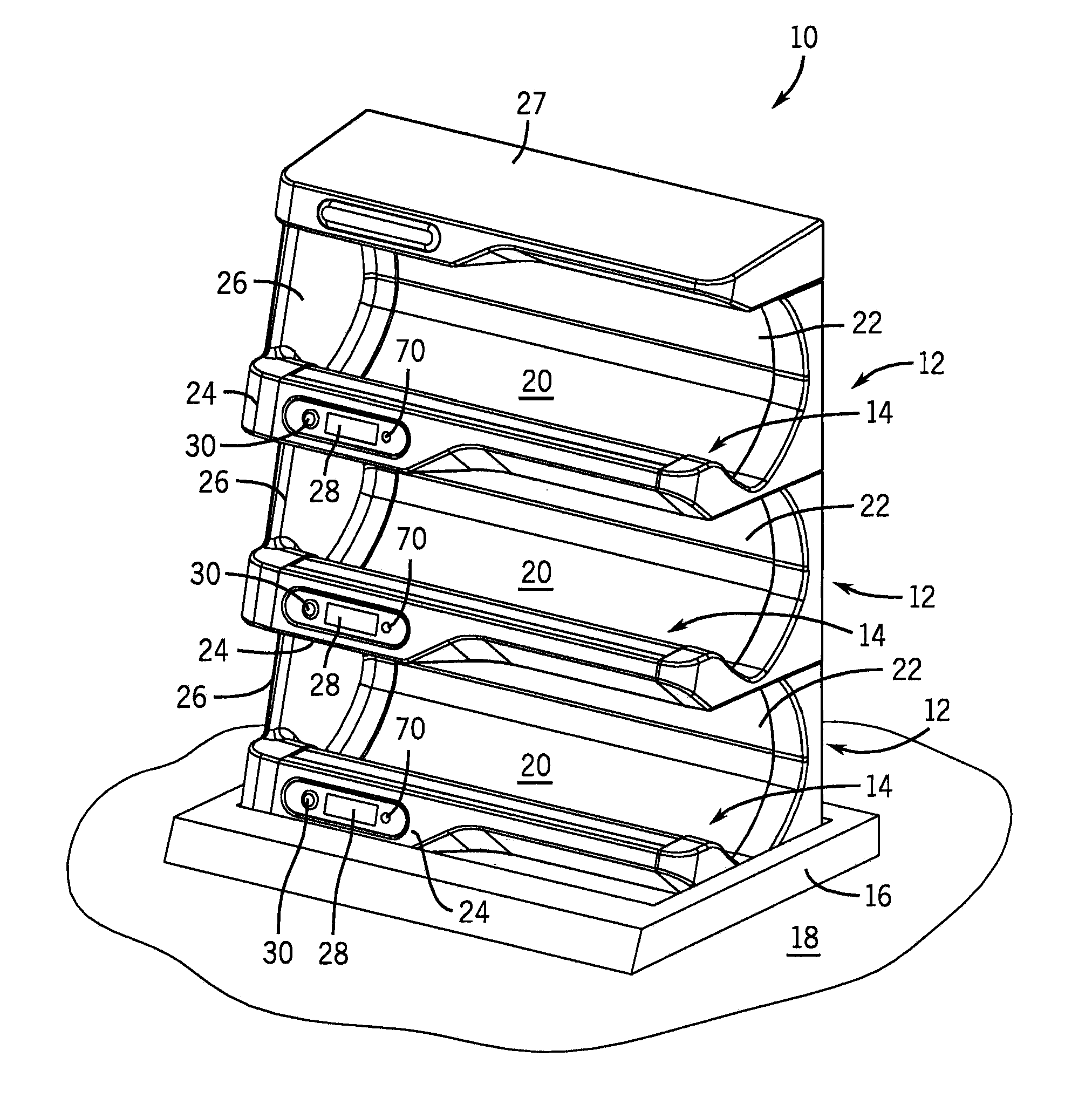

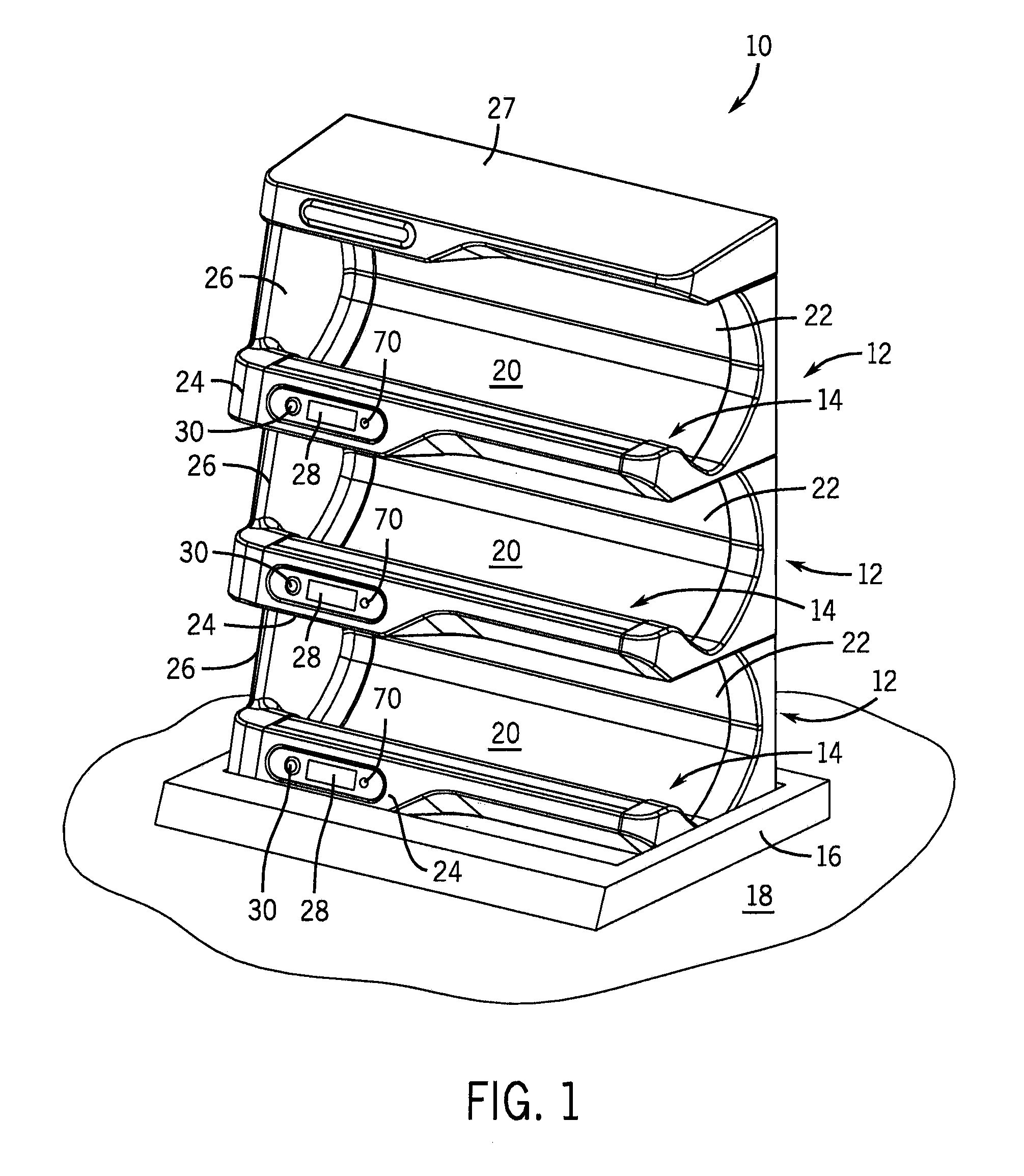

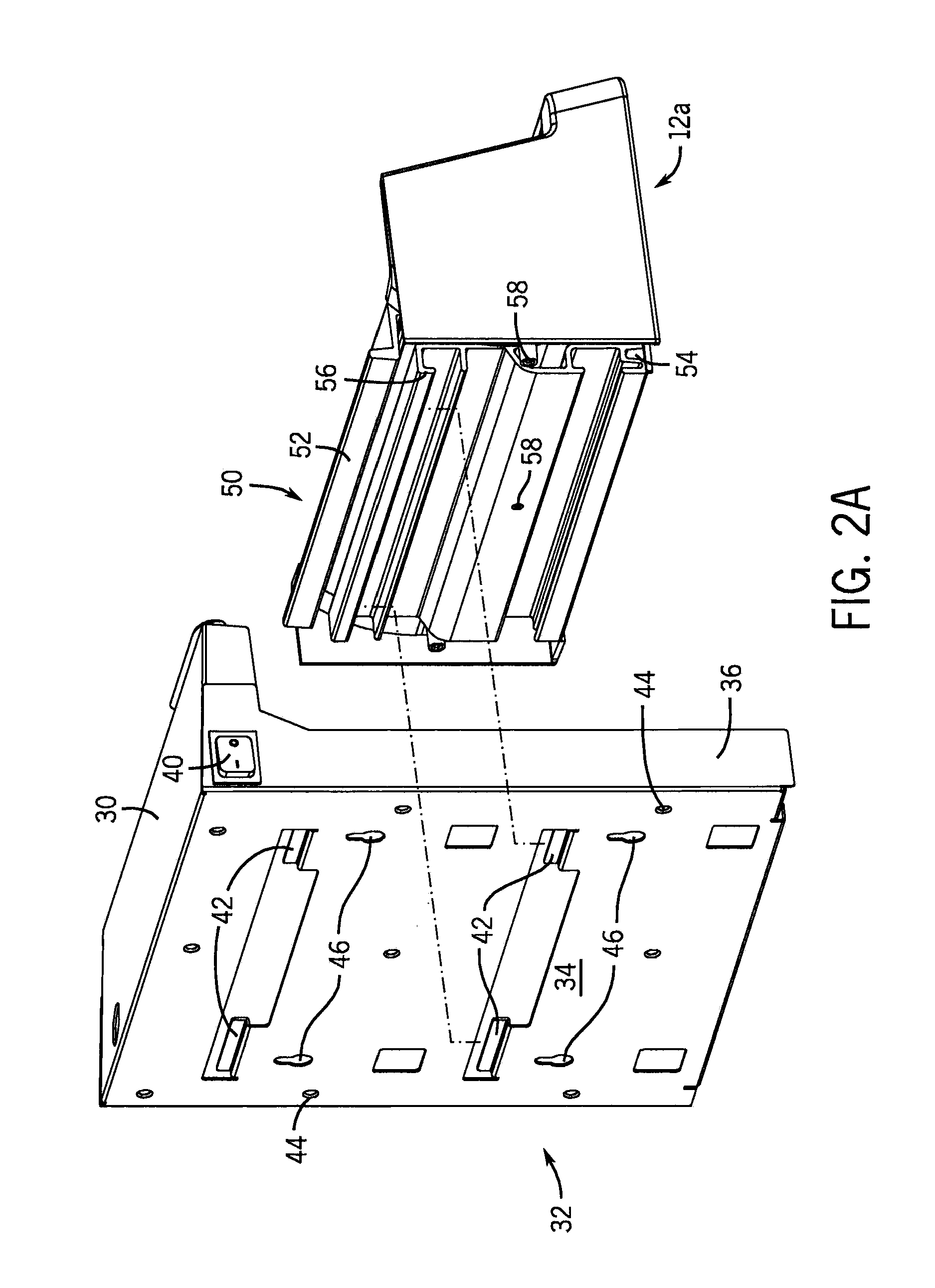

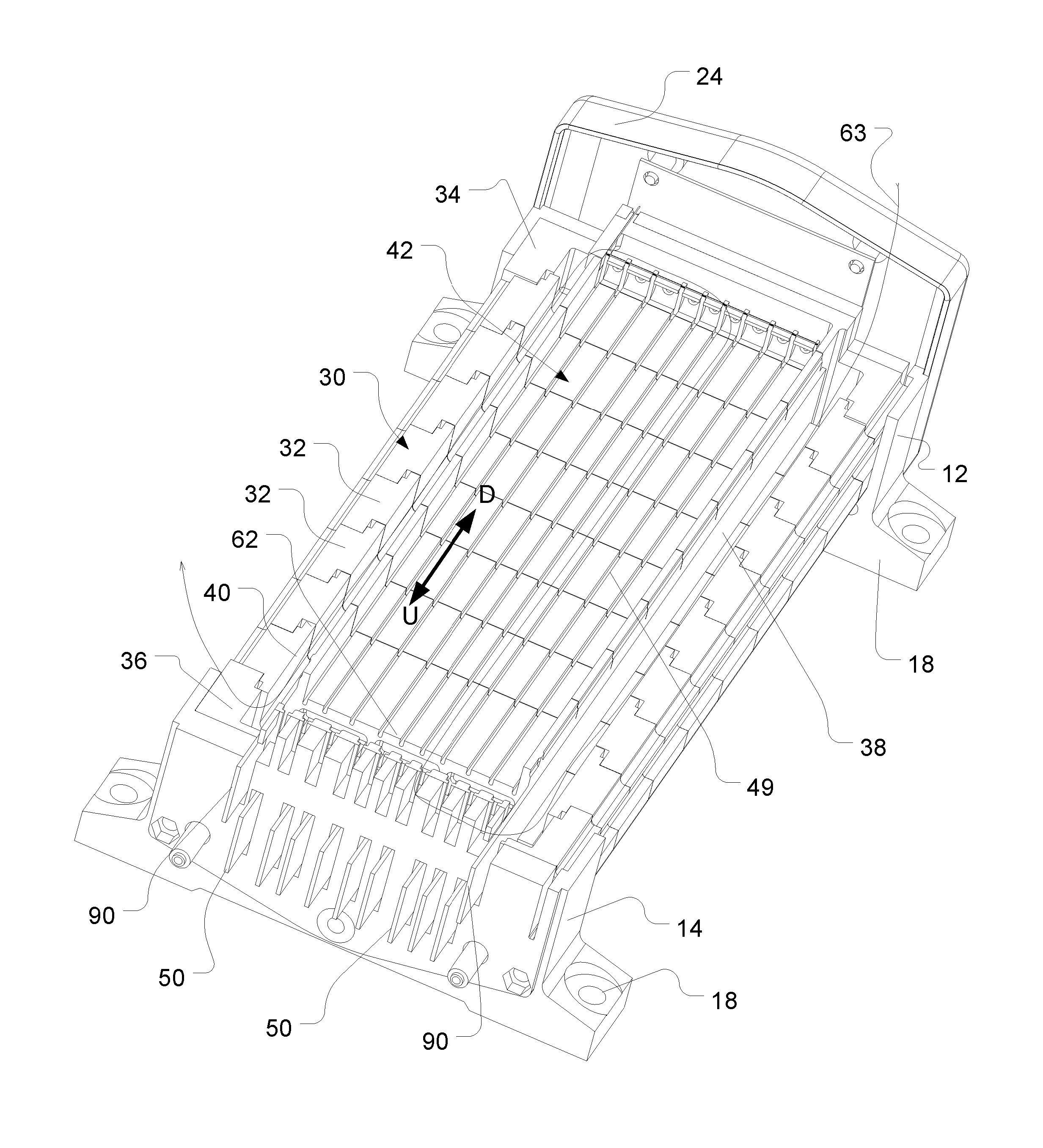

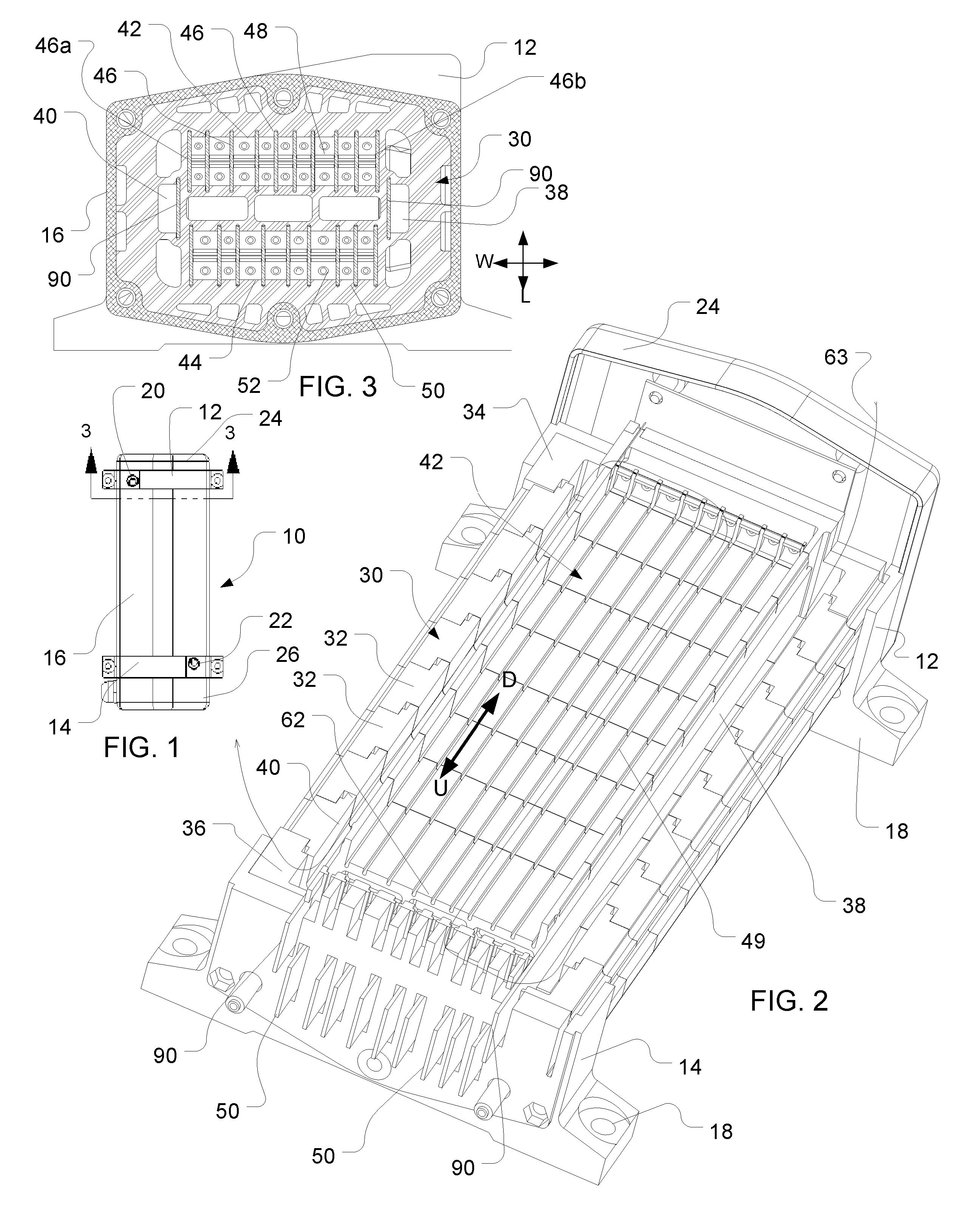

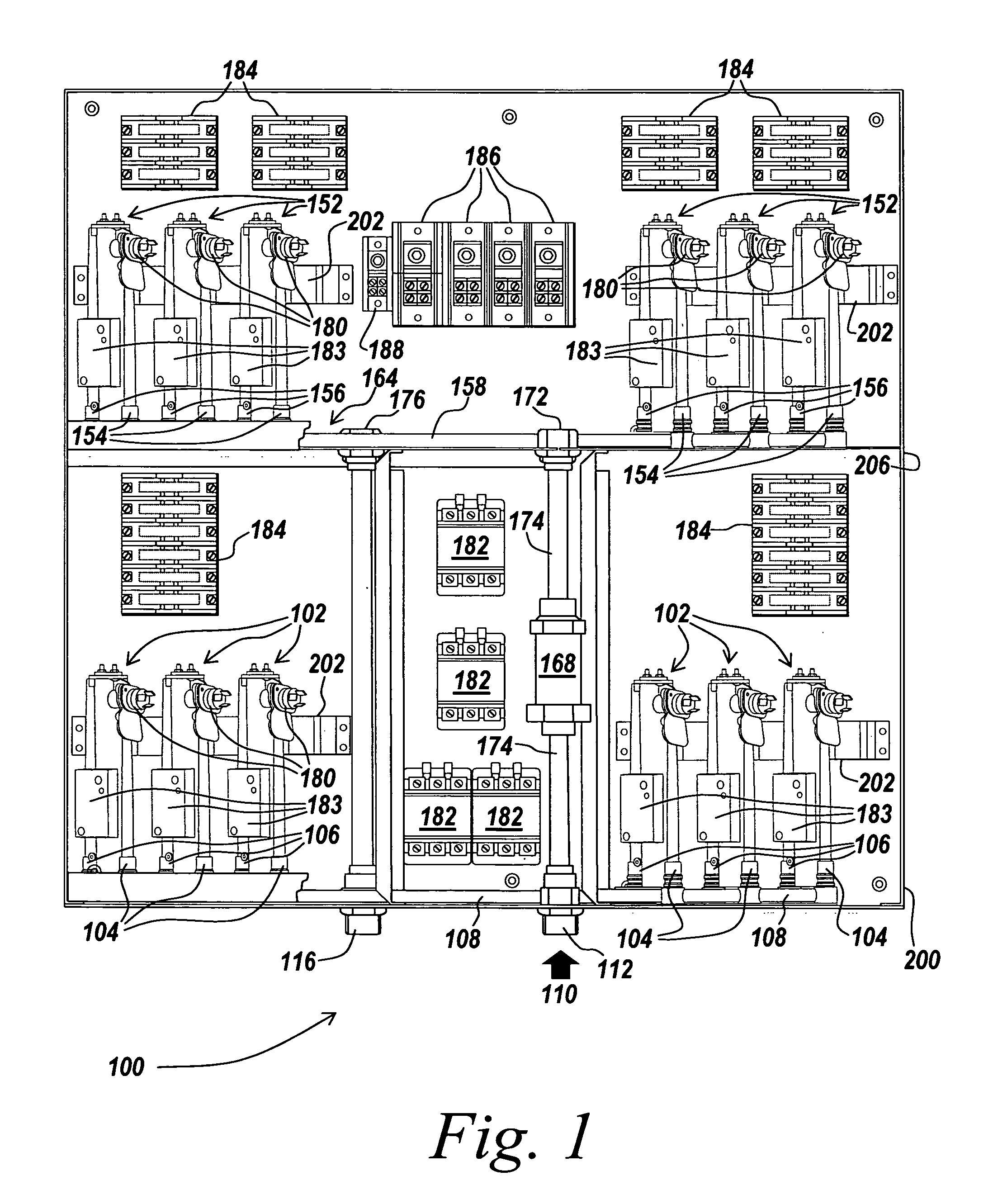

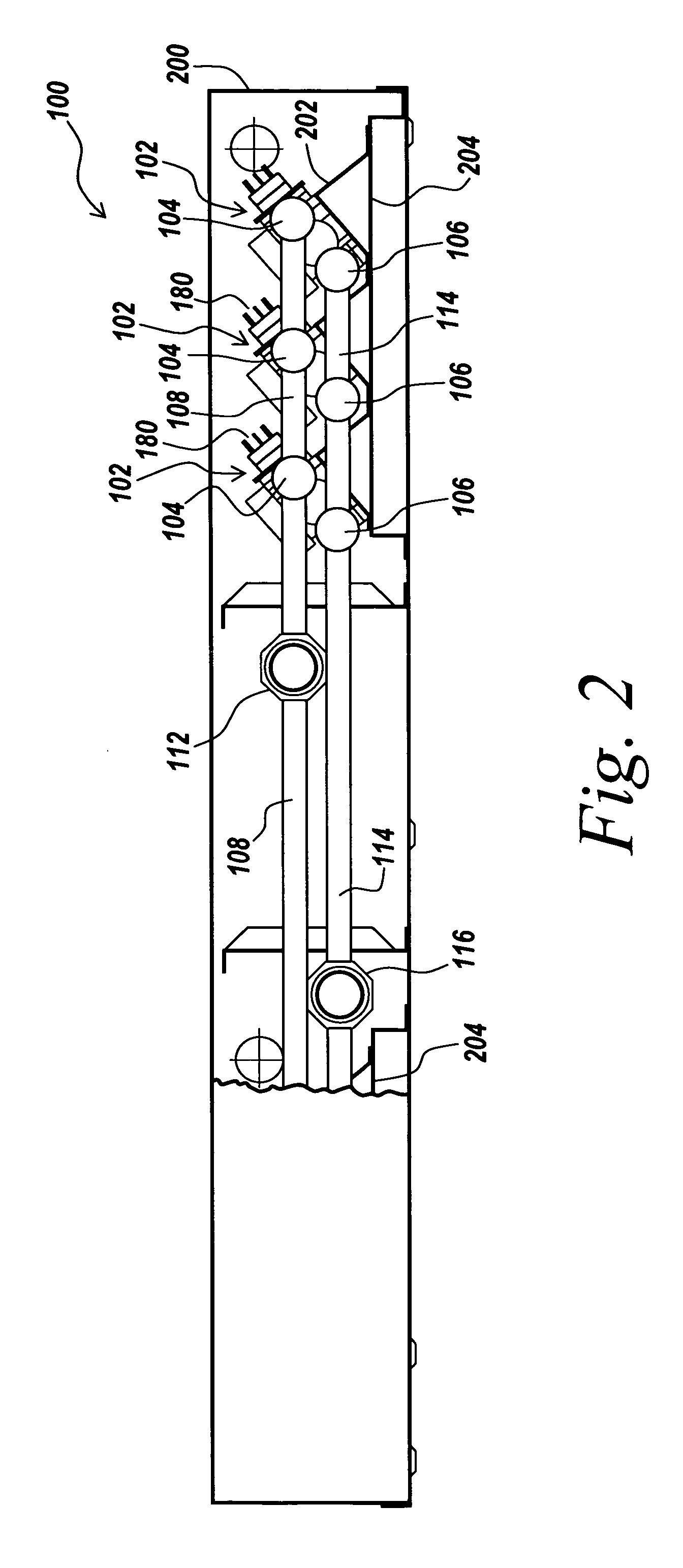

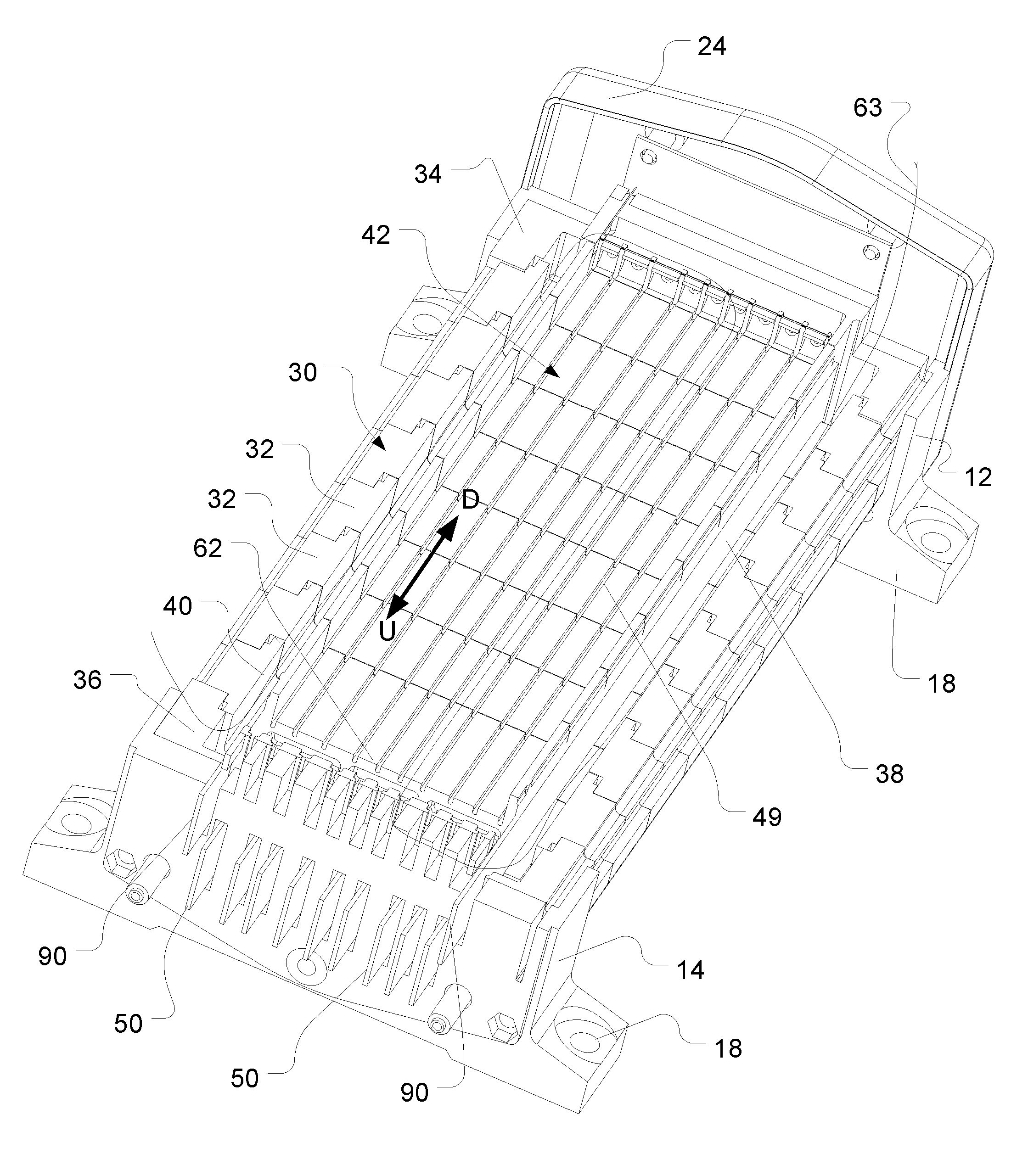

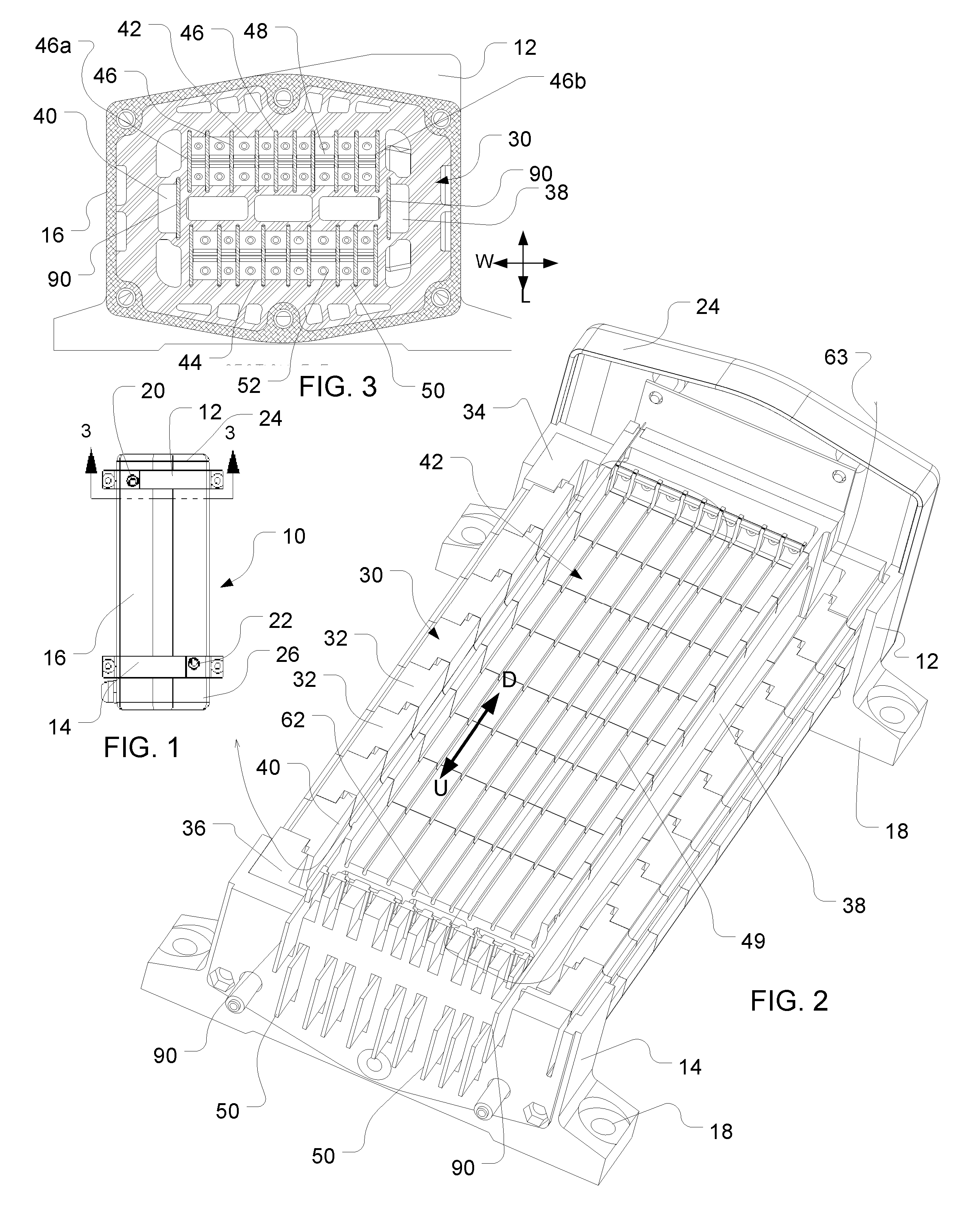

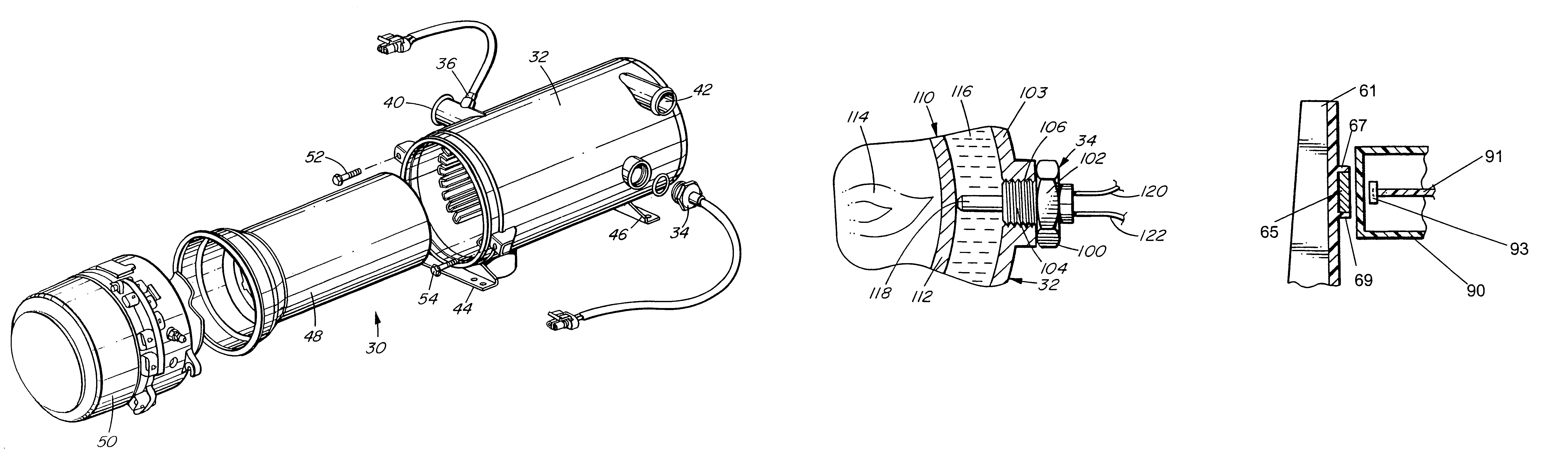

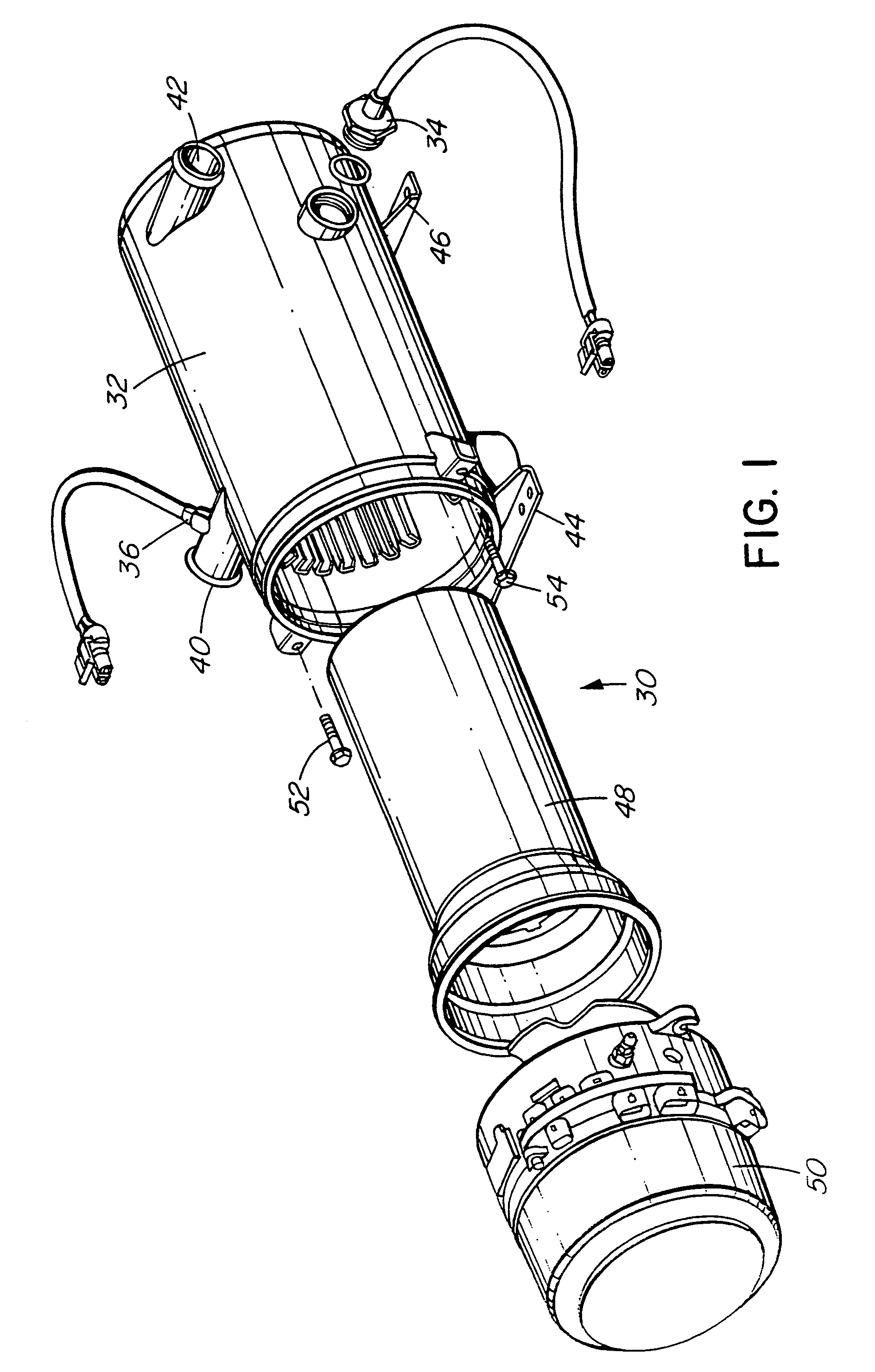

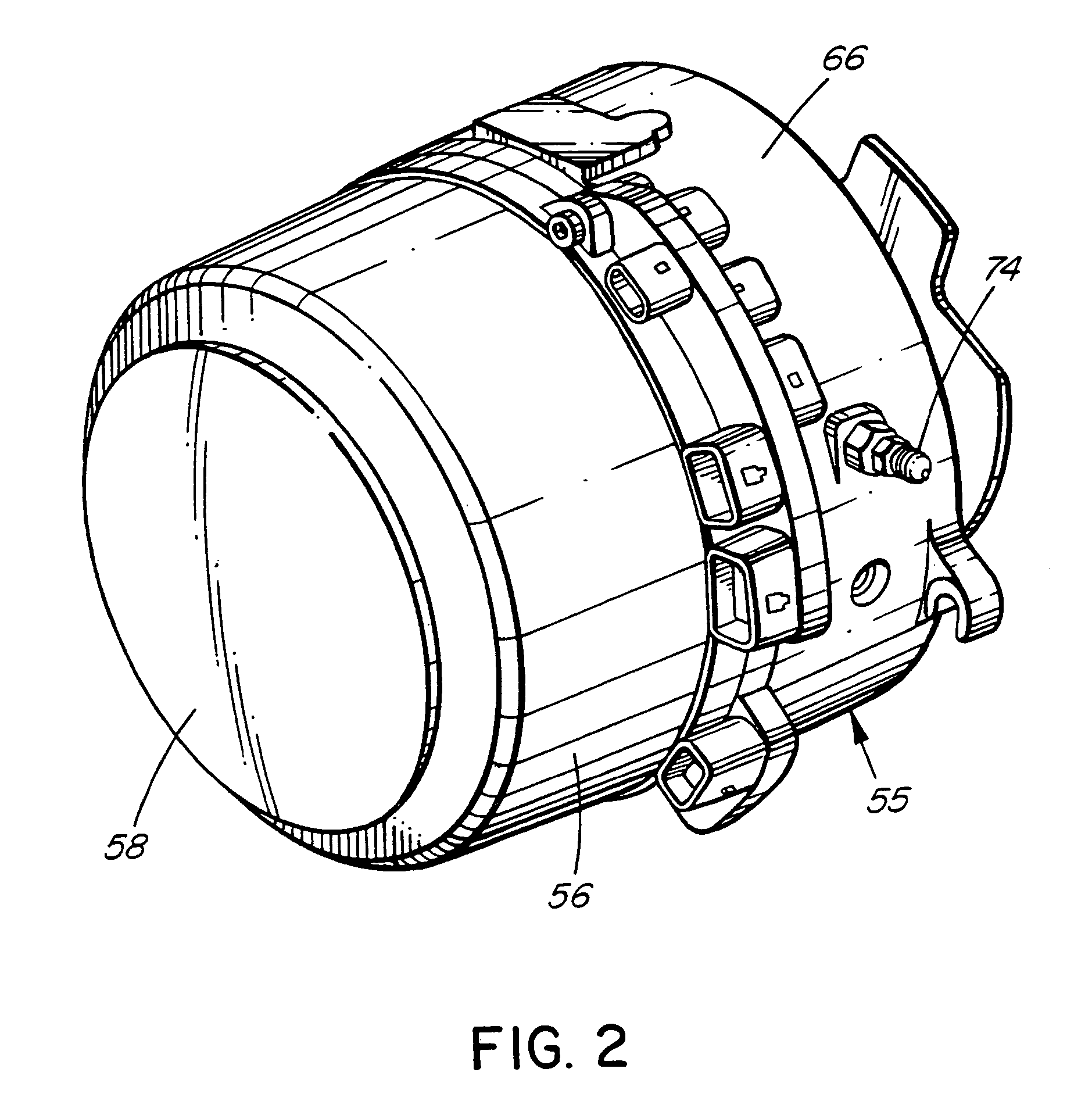

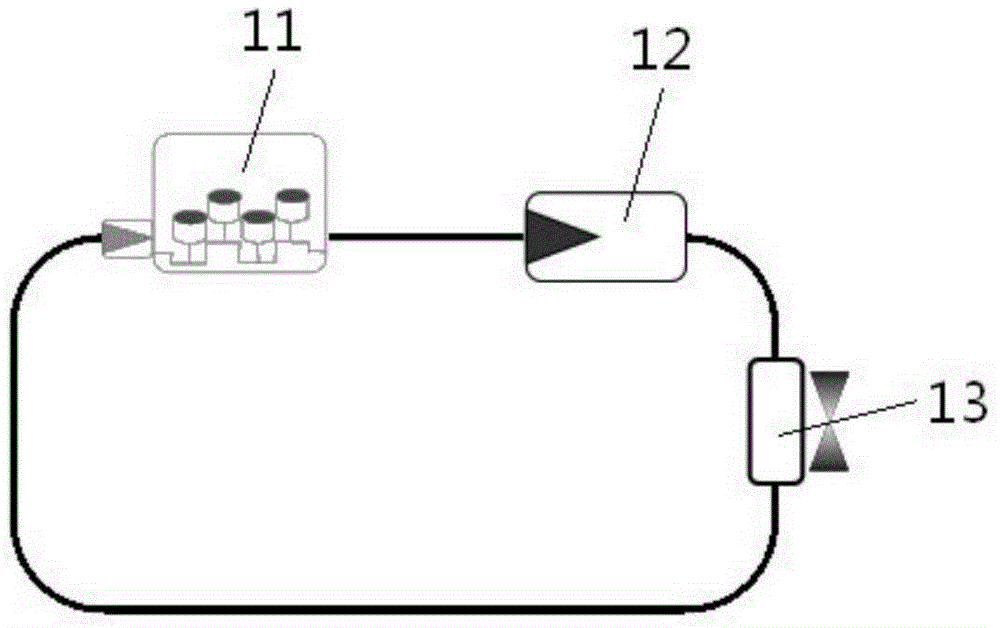

Modular fluid warmer

ActiveUS20100059498A1Heated quickly and efficientlyEasy to operateDomestic stoves or rangesElectrical heating fuelModularityEngineering

The present invention provides a modular fluid warmer and a method of stacking a plurality of modular fluid warmers. As each of the modular fluid warmers is independently operated, the modular fluid warmers are energy efficient. Further, each modular fluid warmer may be equipped with sensors and a controller that reduces the required amount of user interaction with the modular fluid warmer.

Owner:ENTHERMICS MEDICAL SYST

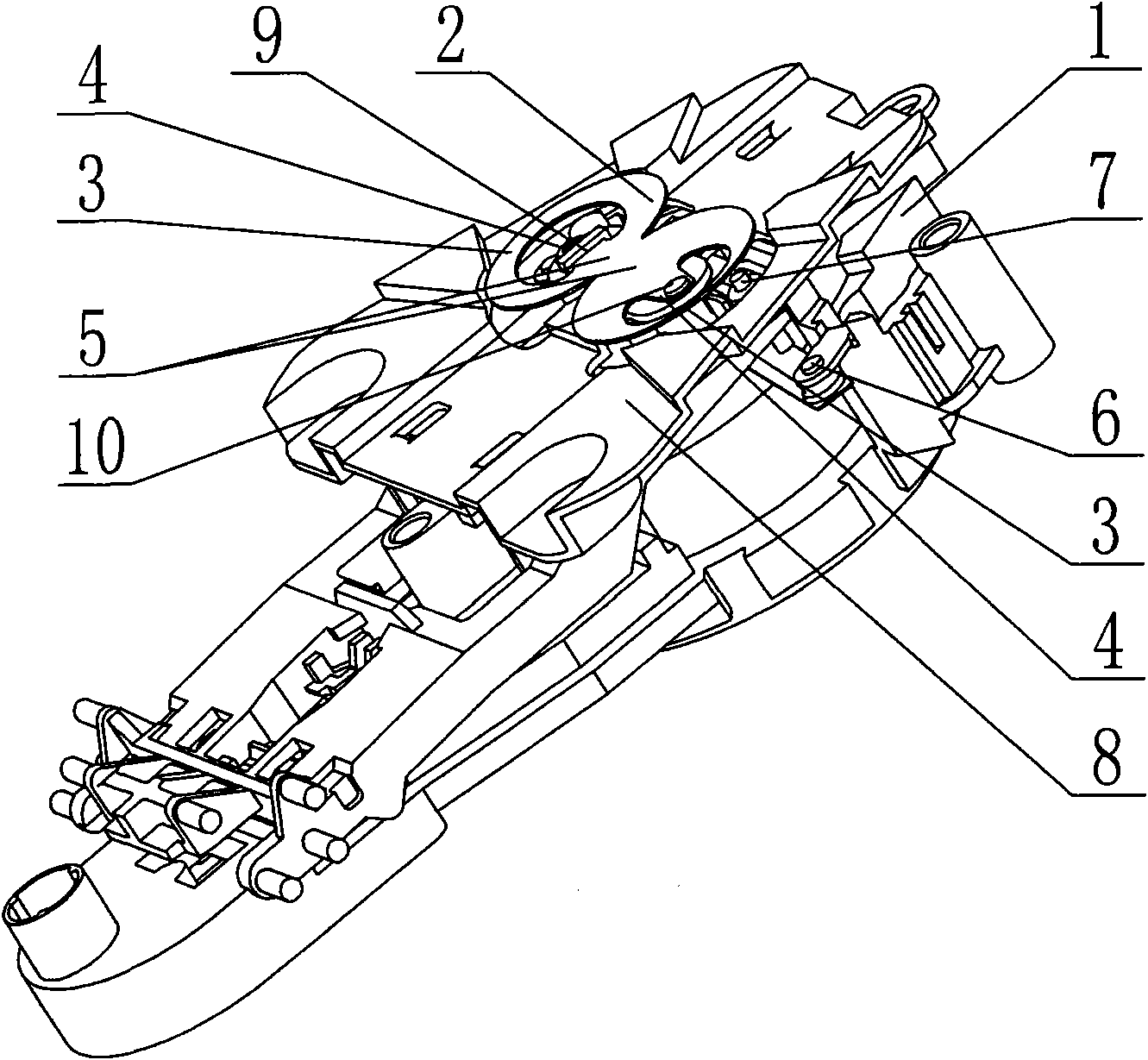

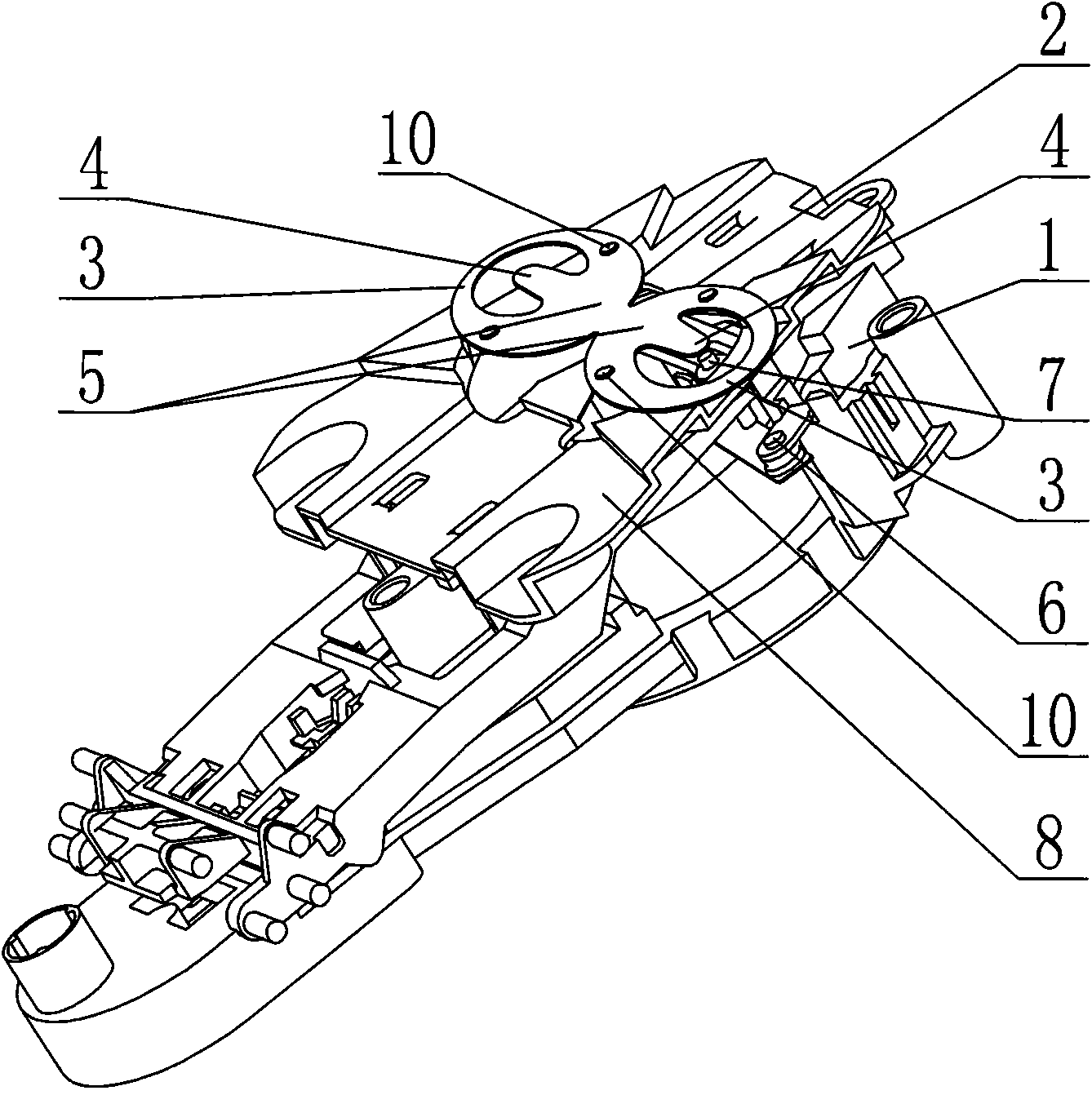

Fluid warmer with switch assembly

ActiveUS20100276411A1Quickly and accurately measureAccurate readingHot plates heating arrangementsIntravenous devicesTime segmentThermocouple

A fluid warmer is disclosed. The fluid warmer includes a support surface, a heating element configured to selectively heat the support surface, and a switch assembly extending through the support surface. The switch assembly includes a switch, a movable switch plate, and a thermocouple. The switch has at least two states, one of which indicates the presence of an item on the support surface. The movable switch plate operably links to the switch to move the switch between the states and further includes a contact surface that contacts an item placed on the support surface. One or more thermocouples are embedded in the movable switch plate below the contact surface. The movable switch plate comprises a material having a thermal conductivity that permits the thermocouple(s) embedded in the switch plate to measure a temperature of an item placed on the support surface within a predetermined period of time.

Owner:ENTHERMICS MEDICAL SYST

Liquid heater with temperature control

ActiveUS8861943B2Inhibition of attachmentImprove actionOhmic-resistance heatingWater heatersElectrical resistance and conductanceTemperature control

Owner:OHMIQ INC

Electric tankless water heater

ActiveUS20060027673A1Increase temperatureAir-treating devicesVehicle heating/cooling devicesLiquid temperatureEngineering

In various aspects, the present invention provides an electric tankless liquid heater system capable of delivering liquid, such as, for example, water, with an acceptable increase in output liquid temperature upon a sudden and substantial decrease in liquid demand. In various aspects, the electric tankless liquid heater comprises an inlet manifold and a plurality of liquid heaters the inlets of which are connected in a parallel flow relationship by the inlet manifold, and the outlets of which are each connected to a separate outlet conduit, and which is configured to provide water to a plurality of automatic water fixtures with a less than about 2° F. (about 1.1° C.) increase in output water temperature upon about a one-and-a-half-fold or greater decrease in water demand that occurs in less than about 500 milliseconds as measured by the increase time of the inlet liquid pressure.

Owner:RHEEM MFG CO

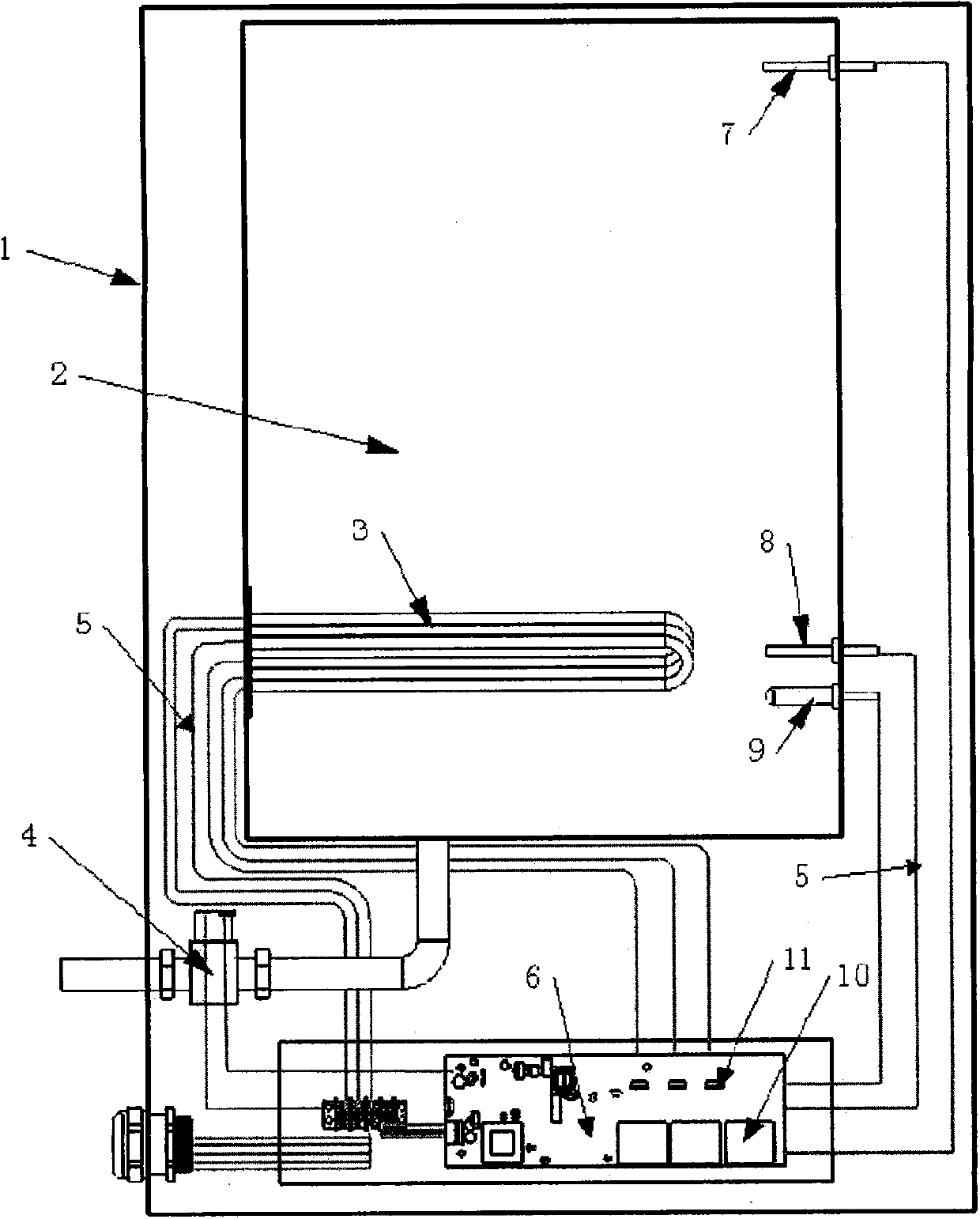

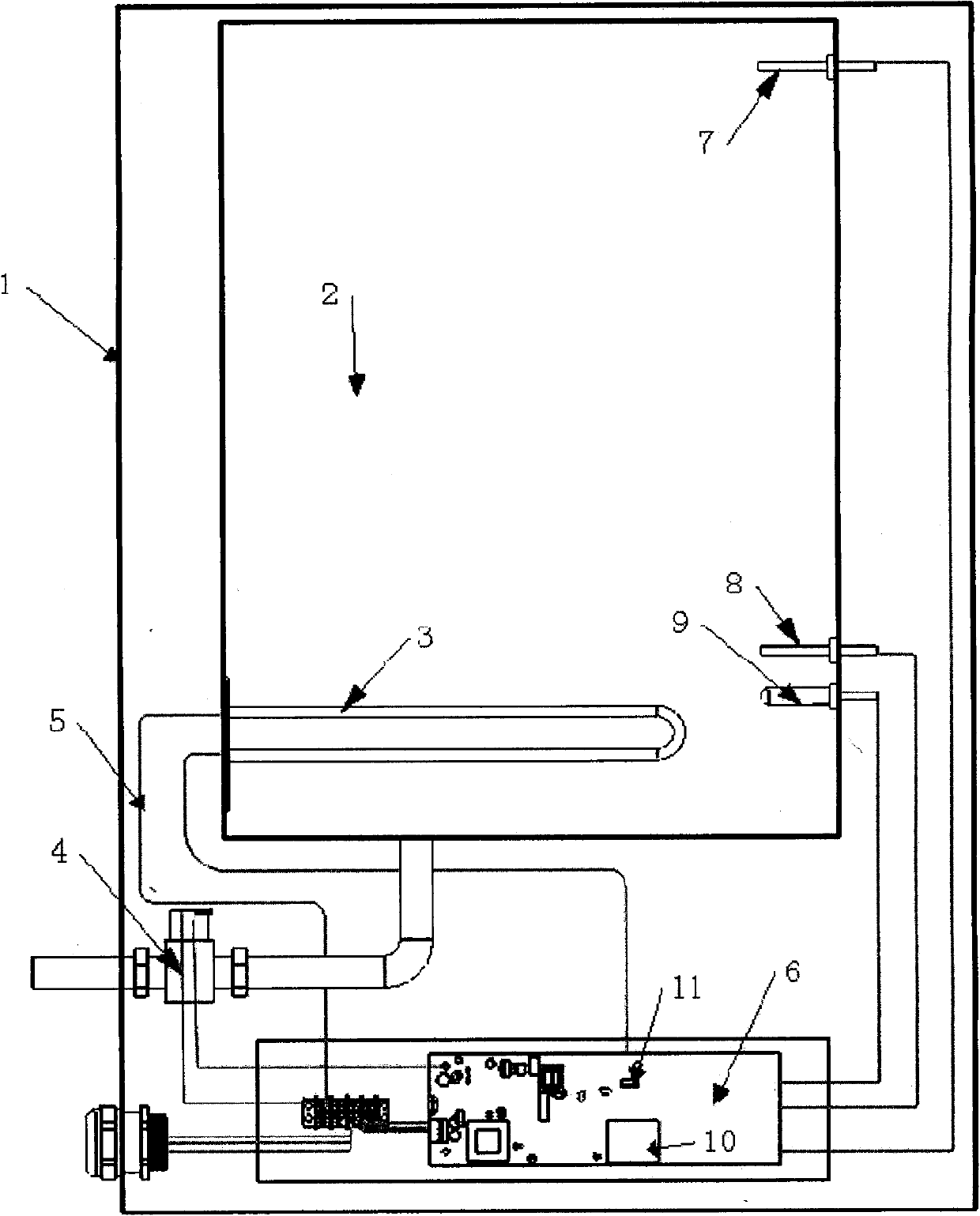

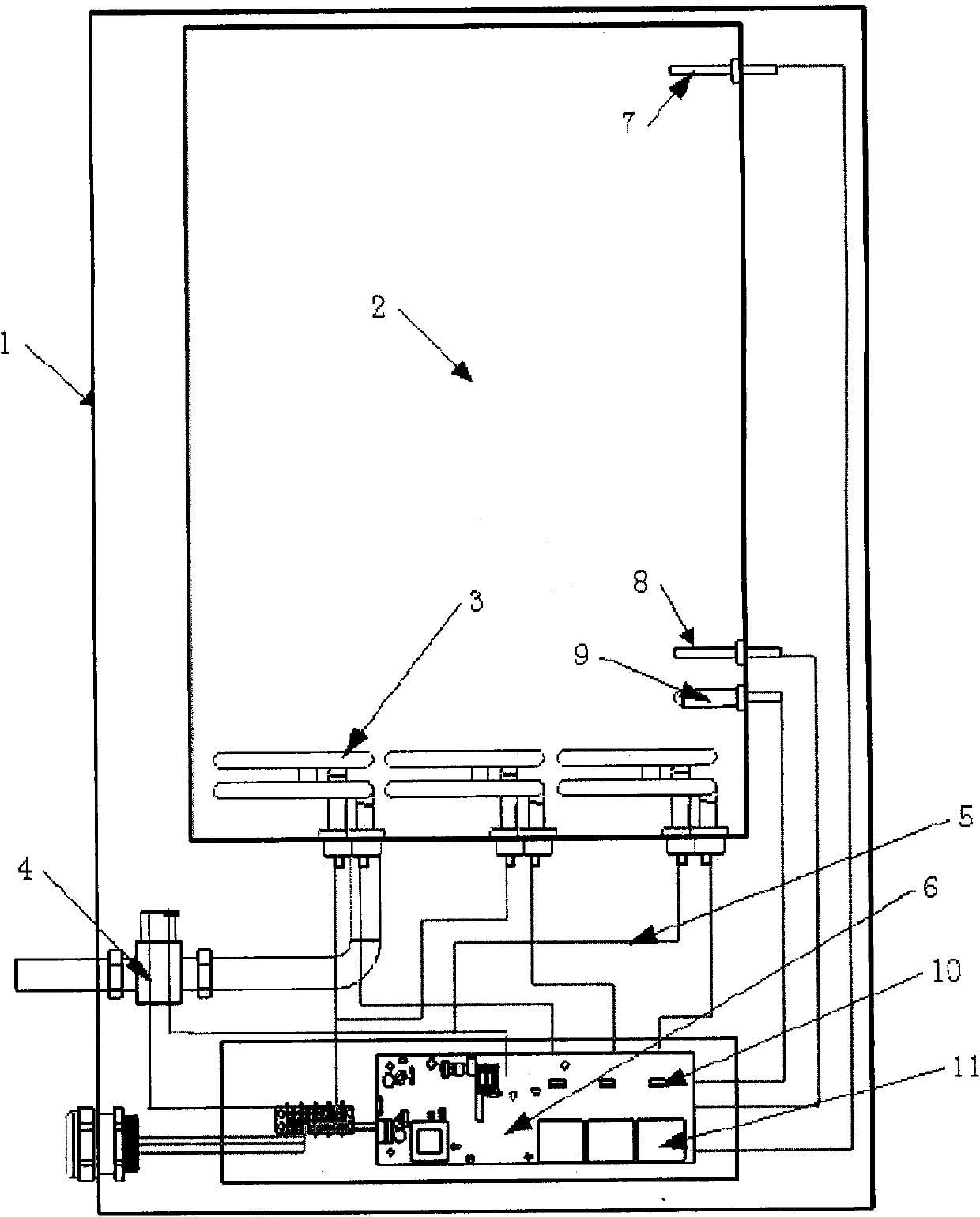

Liquid heating device with adjustable power

The invention discloses a liquid heating device with adjustable power and a power control circuit of the device. The liquid heating device and the power control circuit are applied to the fields of liquid heaters such as electric water boilers and electric water heaters. The power can be adjusted automatically and intelligently according to different heating stages of the device. A group of relays and a group of three-terminal bidirectional silicon-controlled switches are connected in parallel on a circuit board, and switching and alternative use of the three-terminal bidirectional silicon-controlled switches and the relays are intelligently controlled in the heating stages of the liquid heating device according to an embedded chip calculation result. Therefore, when the liquid heating device operates under full power, the relays with low cost are switched to control opening and closing of a heating device. When the liquid heating device operates under low power, the three-terminal bidirectional silicon-controlled switches with small current are switched to control opening and closing of a heating pipe. The device achieves a power adjustable function, has high reliability, is low in cost and reduces energy consumption by means of calculation of software, an embedded intelligent chip and a control circuit, so that the liquid heating device avoids multiple boiling and effects of heavy metal produced in the multiple boiling on health.

Owner:QINGDAO GEMI COMML EQUIP

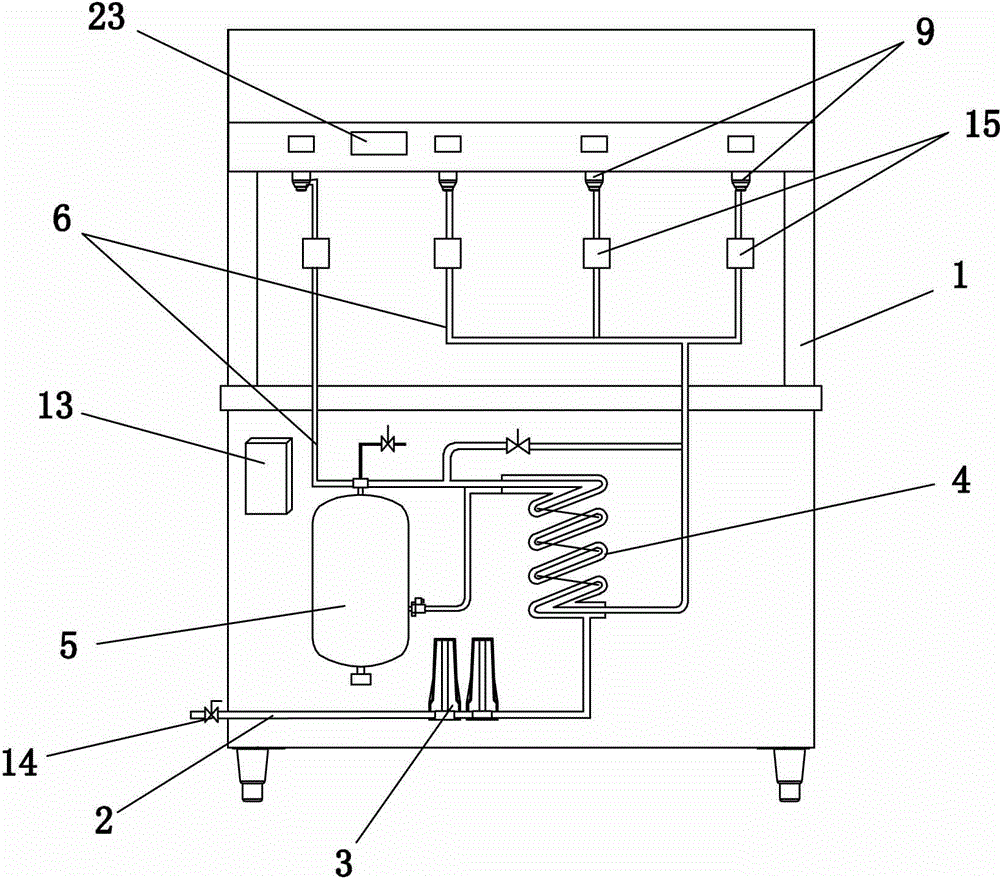

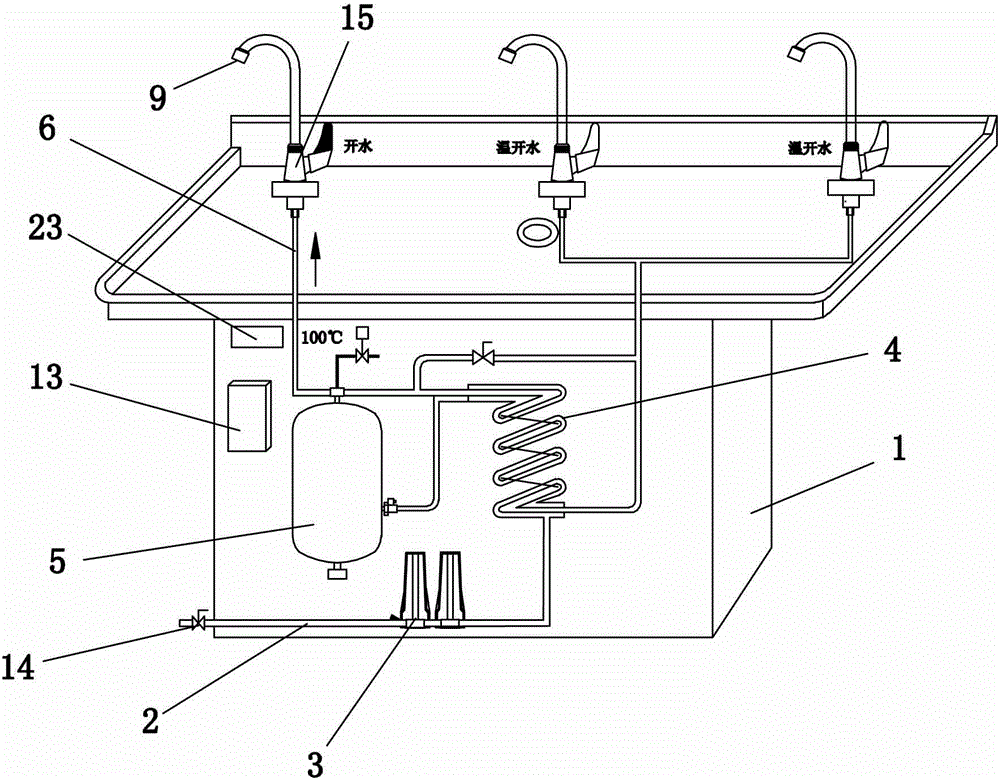

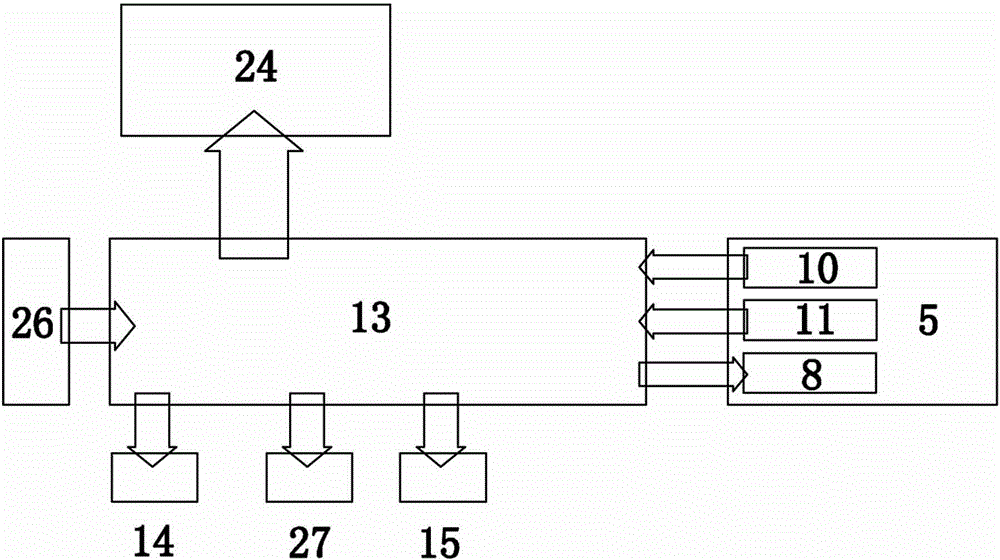

Smart sterile multifunctional automatic water dispenser

InactiveCN104799694ARealize the effect of intelligent sterilityReal-time monitoring of water levelBeverage vesselsElectricityWater quality

The invention discloses a smart sterile multifunctional automatic water dispenser. The smart sterile multifunctional automatic water dispenser comprises a box and a water inlet pipe, a filter, a heat exchanger, a liquid heater, a water outlet pipe and an electric control module which are arranged on the box. A heating module is arranged on the liquid heater, the filter is arranged on the water inlet pipe, the heat exchanger is arranged between the water inlet pipe and an inlet of the liquid heater, an outlet of the liquid heater is connected with the water outlet pipe, and a water outlet is formed in the water outlet pipe, wherein a disinfection drainage and water change module is arranged on the water outlet pipe and is electrically connected with a electric control device. The smart sterile multifunctional automatic water dispenser can completely drain sewage in a dispenser body by additionally arranging the disinfection drainage and water change module, can renew (refill) fresh, safe and hygienic water into the dispenser body, and thus achieves a smart sterile effect.

Owner:GUANGDONG BILI DRINKING WATER EQUIPMENT CO LTD

Electric tankless water heater

In various embodiments, the invention provides a system for heating a liquid, such as, for example, water, comprising a plurality of liquid heaters, the inlets and outlets of which are respectively connected in a parallel flow relationship by respective manifolds, and configured to provide liquid having a temperature of greater than about 90 degrees Fahrenheit at a flow rate of greater than about 10 gallons per minute. In various embodiments, the present invention provides an electric tankless liquid heater system capable of delivering hot liquids, and in particular water, at even higher flow rates and or temperatures, including, but not limited to, flow rates greater than about: (1) 12 gpm; (2) 18 gpm; (3) 20 gpm; and (5) 20 gpm; and / or temperatures of greater than about: (1) 100° F.; (2) 120° F.; (3) 140° F.; and (4) 180° F.

Owner:RHEEM MFG CO

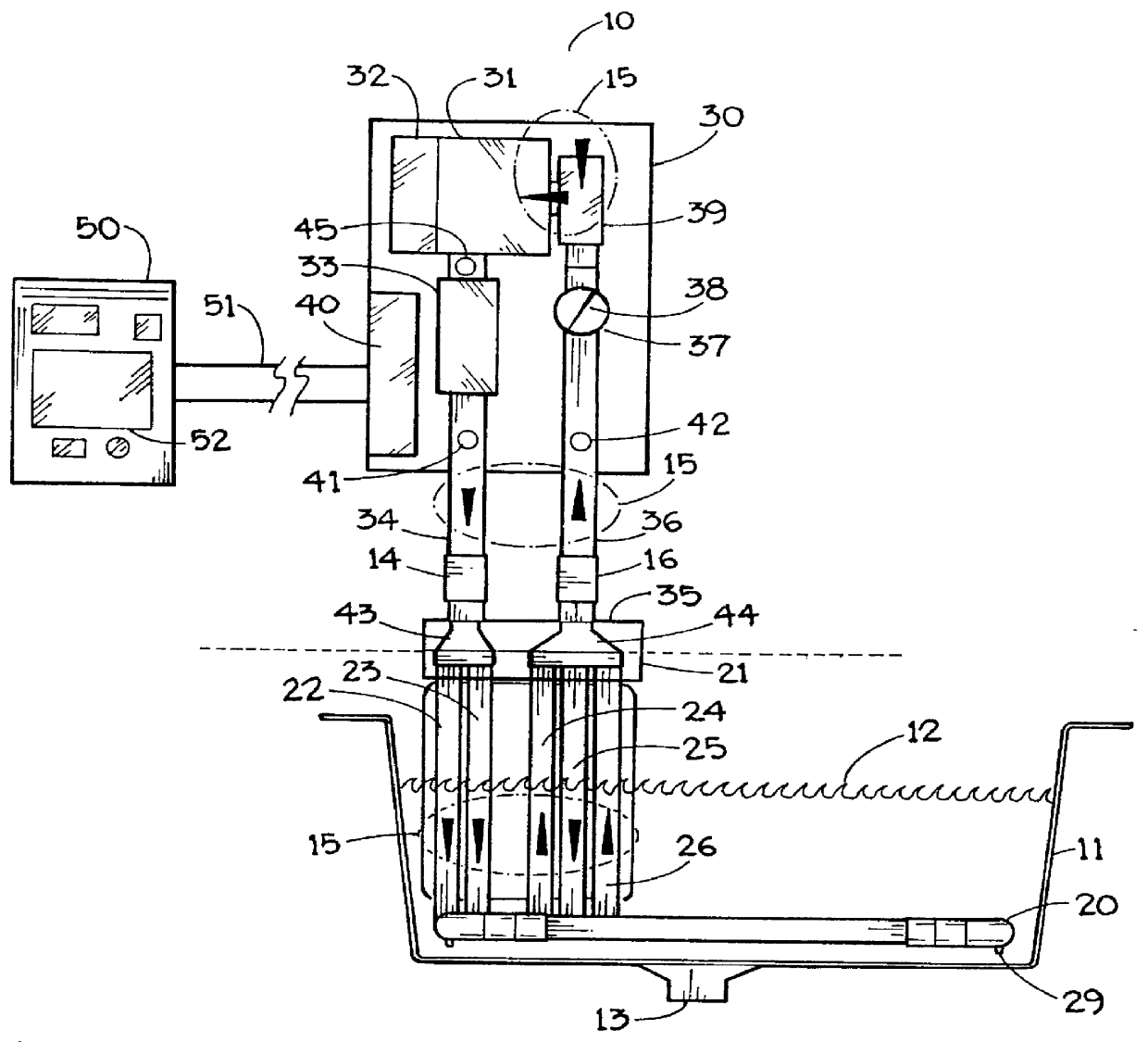

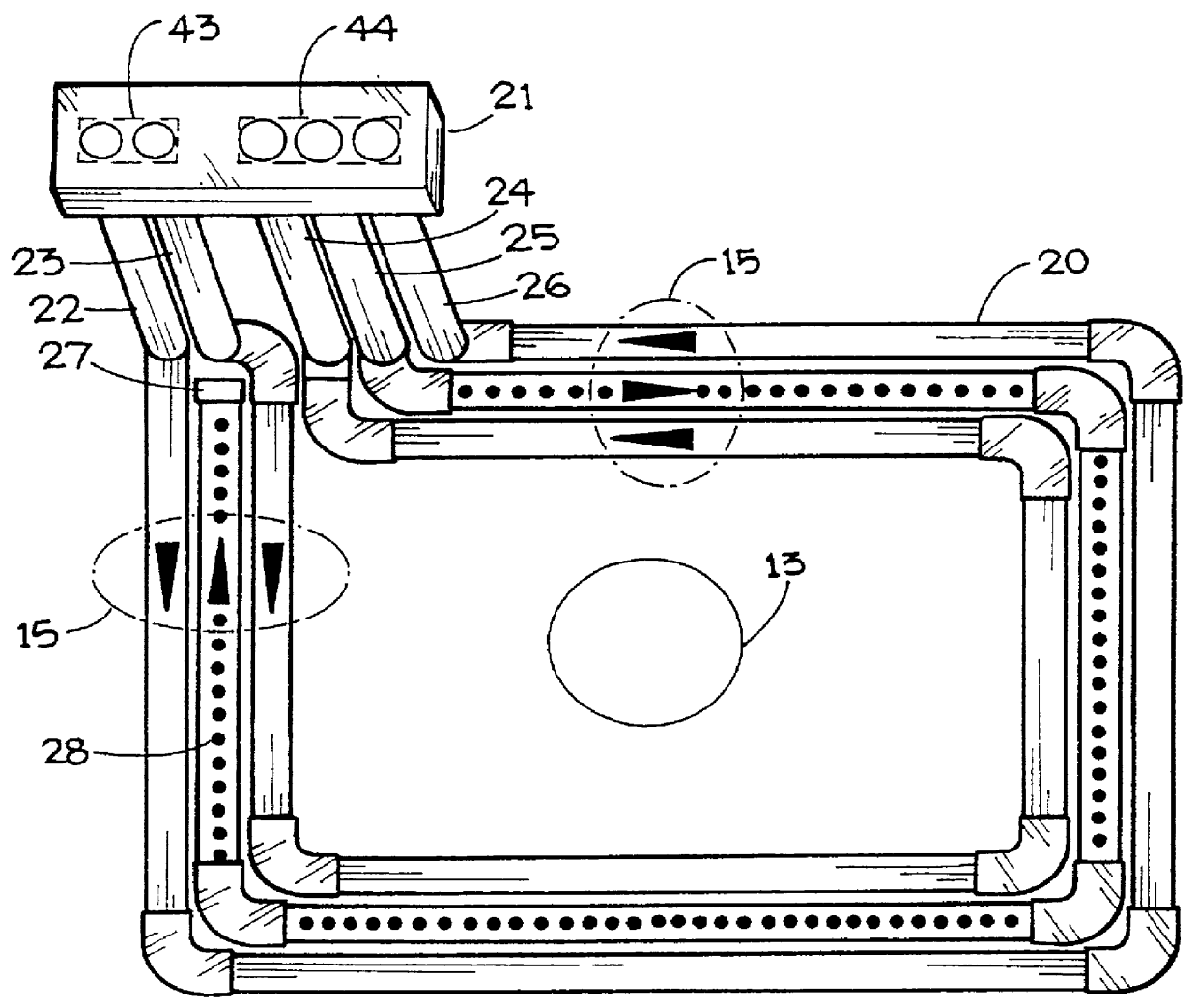

Apparatus and method for washing articles

InactiveUS6021788AResidue reductionEfficient scrubbingHollow article cleaningCleaning using gasesTemperature controlProduct gas

This invention includes apparatus that circulates and agitates a liquid cleansing solution in a sink by means of gas jet bubbles, in order to clean dirty articles therein. The basic device comprises a base structure, a pressurized gas supply, hollow jet nozzle means disposed in the sink, the jet nozzle means having a sealed end and a plurality of apertures thereon for gas ejection, so as to produce gas bubble jet streams which scrub and clean the articles by both article impact and agitation of the liquid cleansing solution. Preheating of the pressurized gas, coupled with a manifolded heat exchanger in the cleansing solution, provides the means for heating the cleansing solution. Temperature control means are then used to maintain the temperature of the cleansing solution against cooling. Alternately, the heat source may include a separate liquid heater. The warmed gas may also be used to dry the articles after washing.

Owner:KING KENYON M

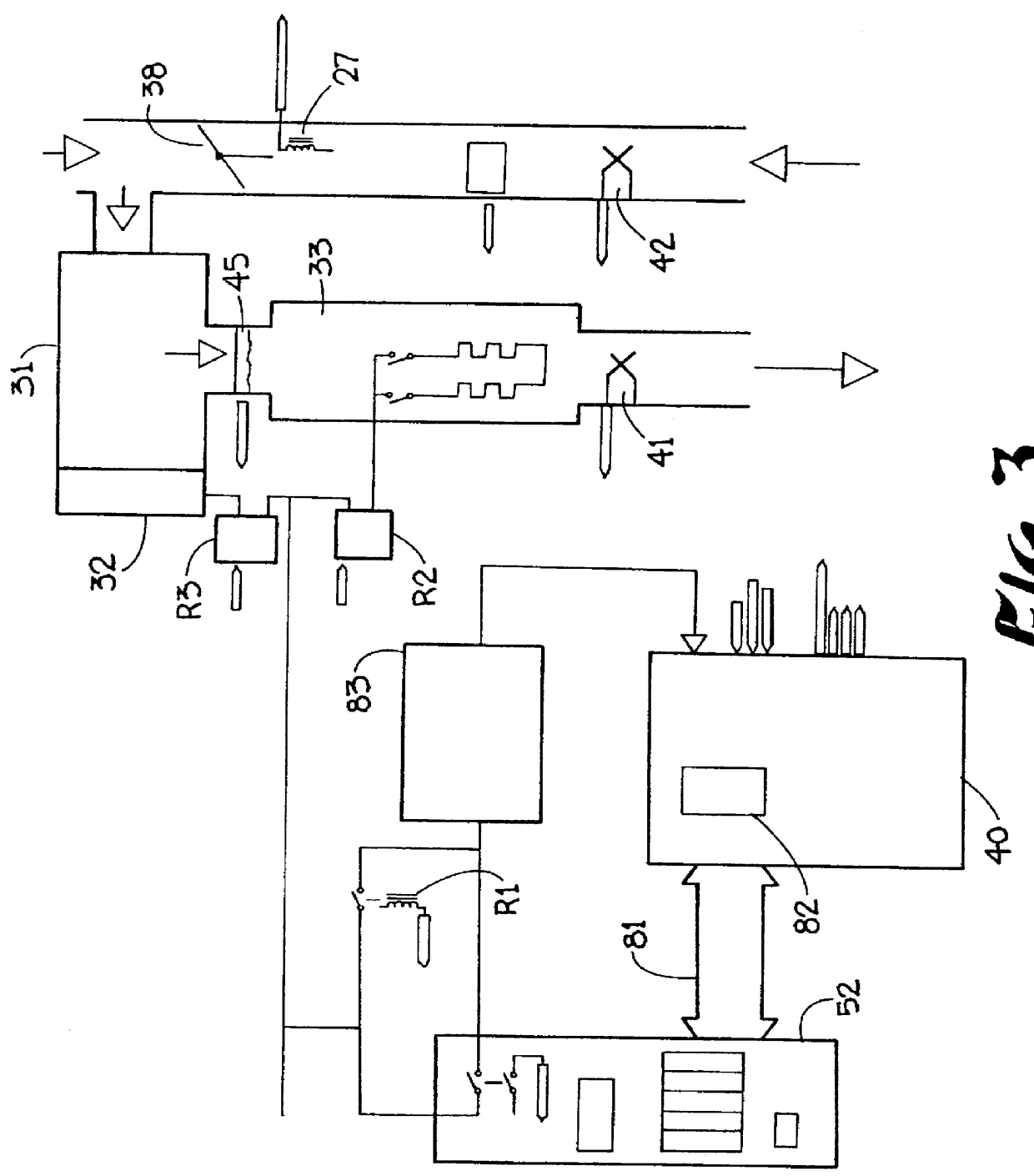

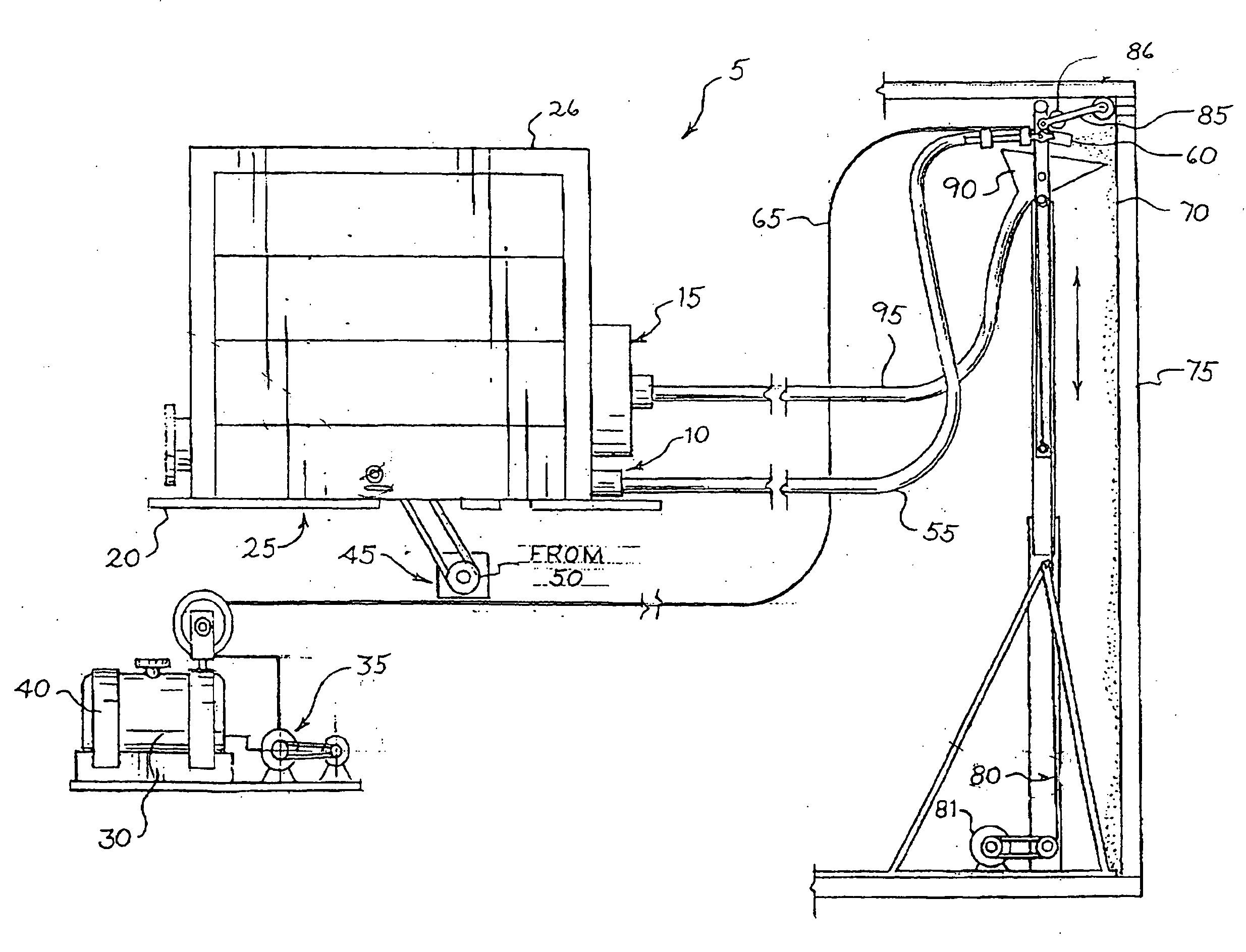

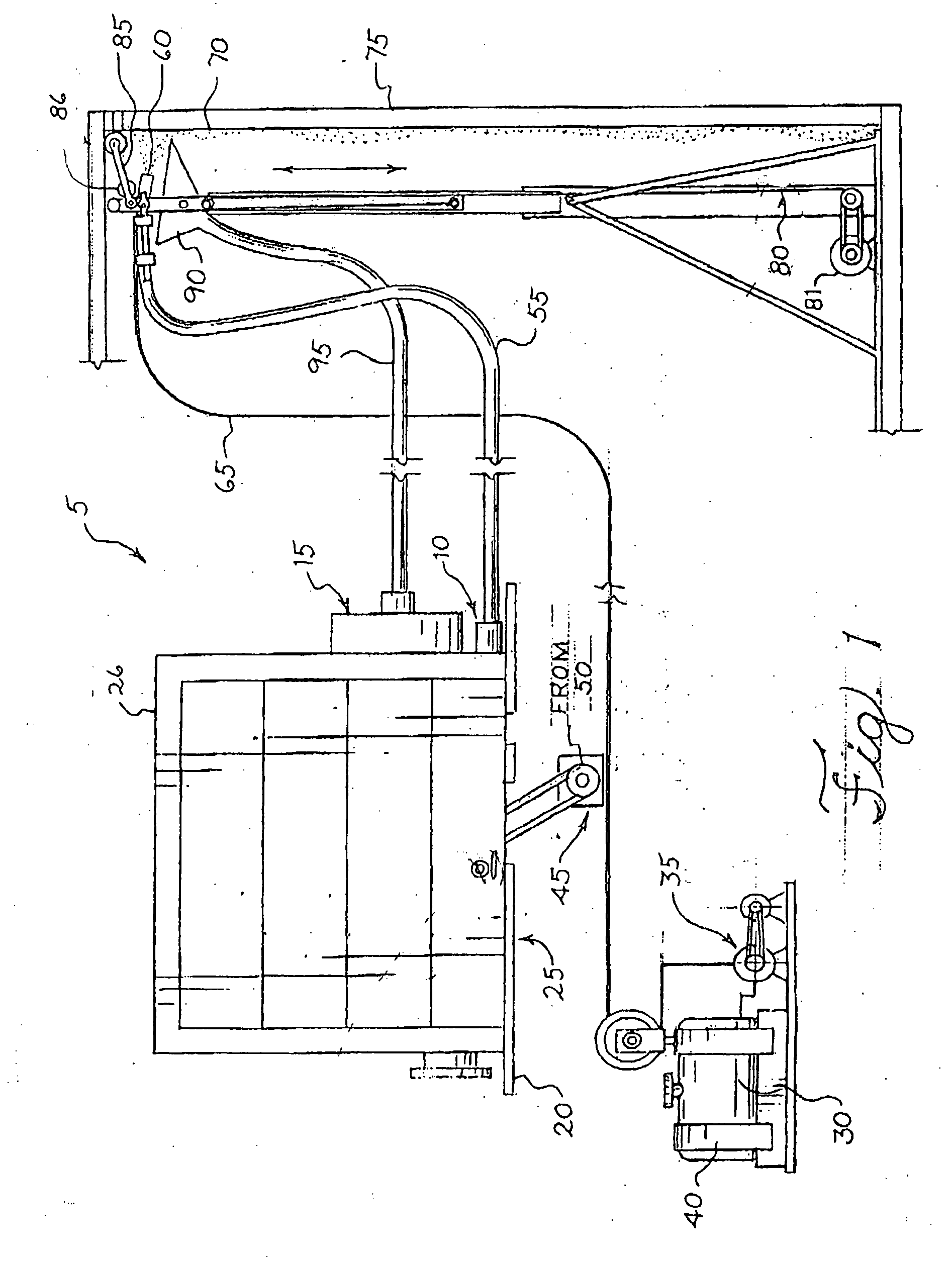

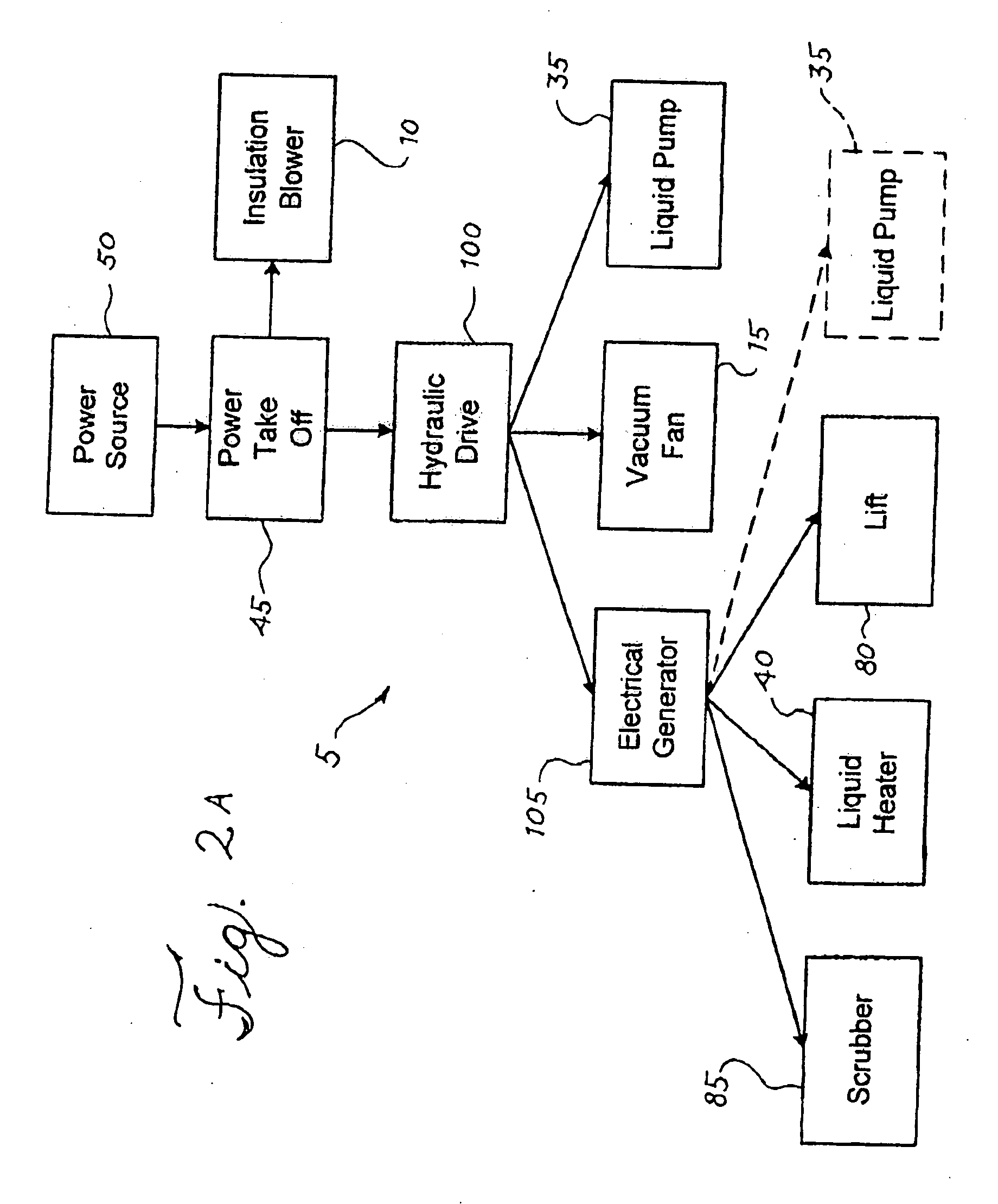

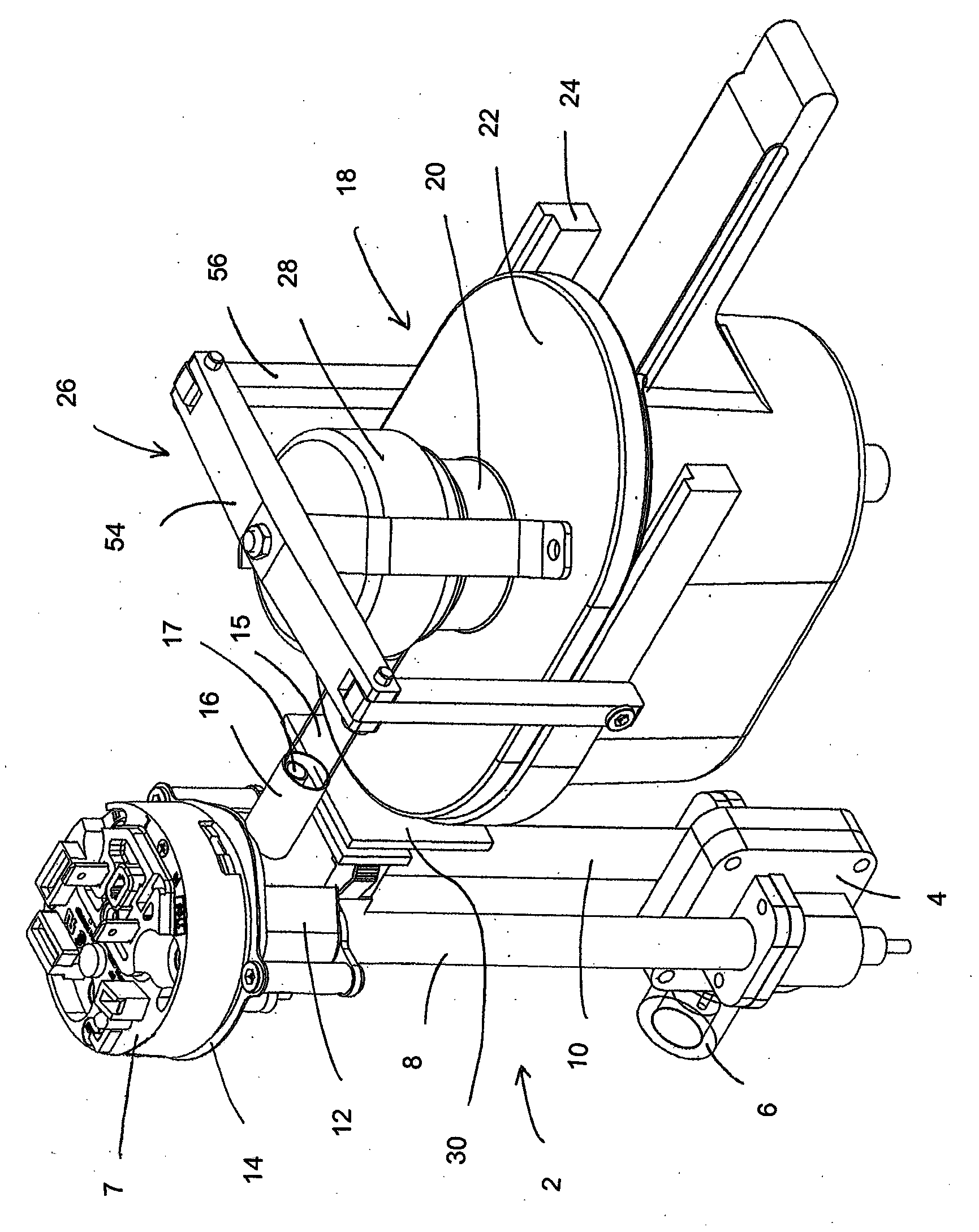

Sprayed insulation application system having variably locatable components

ActiveUS20070151201A1Liquid surface applicatorsMechanical apparatusHydraulic motorElectrical conduit

This invention relates generally to sprayed insulation application systems, and more particularly to systems that utilizes a sole power source to directly or indirectly drive the system's multiple components independent of the location of a power-take-off. In one embodiment of the invention, the system utilizing a sole power source comprises at least one power-take-off operably associated with the power source. An insulation blower and a hydraulic drive are operably associated with the at least one power-take-off. An electrical generator and a vacuum fan are operably associated with the hydraulic drive, with at least one control regulating the operable association of the generator and the vacuum fan with the hydraulic drive. In another embodiment of the invention, the hydraulic drive is operably associated with the power-take-off, with the generator, vacuum fan and insulation blower operably associated with the hydraulic drive. The electrical generator, driven by the generator hydraulic motor in fluid communication with the hydraulic drive, preferably provides electrical energy to the scrubber, and to the at least one liquid heater and / or the electrically powered lift, if utilized within the system, via electrical conduits. A pump may be optionally driven by the hydraulic drive or energized by the generator.

Owner:JOHNS MANVILLE CORP

Liquid heater with temperature control

ActiveUS20110236004A1Inhibition of attachmentImprove Sensing PerformanceCooking vesselsImmersion heating arrangementsElectrical resistance and conductanceTemperature control

Owner:OHMIQ INC

Liquid heating ware overheating protection controller assembly

ActiveCN101630607AReliable overheating protectionImprove assembly efficiencyHeating/cooling contact switchesThermal switch detailsEngineeringActuator

The invention provides a liquid heating ware overheating protection controller assembly, which comprises a controller body, wherein the upper surface of the controller body is provided with a monolithic connected double braking thermosensitive bimetal actuator; the monolithic connected double braking thermosensitive bimetal actuator is to form two brake units of relatively independent parallel connection bodies on a bimetal sheet; the edge lines of the two brake units are separated from each other; off-unit auxiliary connection parts are arranged between edge lines adjacent to the two brake units; the off-unit auxiliary connection parts are positioned outside the edge lines of the two brake units and effectively ensure that the two brake units form the monolithic connected double braking thermosensitive bimetal actuator; and the corresponding controller body is provided with two sets of switch contacts and each set of switch contacts are matched with the corresponding brake unit.

Owner:ZHEJIANG JIATAI ELECTRICAL APPLIANCE

Liquid heating apparatus

An infusion beverage making apparatus (100) comprises a liquid heater, an infuser (140) for receiving beverage solid and conveying means for conveying heated liquid from the liquid heater onto the beverage solids. The apparatus (100) is configured to operate in at least one phase in which heated liquid is passed from the liquid heater through the beverage solids and in another phase in which steam is passed through at least a portion of the conveying means. A quantity of water is heated to boiling by the liquid heater and a steam pressure allowed to develop as a result which is sufficient to force steam through at least a portion of the conveying means.

Owner:STRIX LTD

Temperature maintaining apparatus and temperature control apparatus and method therefor

InactiveUS7055760B2Improve comfortLong operationAir-treating devicesTemperature control using digital meansTemperature controlTime segment

A method and apparatus are provided for maintaining a temperature between a first value and a second value. The method and apparatus utilize a heat transfer device capable of cycling through a series of cycles, the device being capable of changing the temperature from the second value to the first value when operational. During each cycle the device transfers heat for a first period of time when the temperature reaches the second volume until the first value is reached and thereafter the device stops transferring heat. The first period of time is compared to a desired cycle-on period of time during each cycle and the second temperature value then is adjusted for a subsequent cycle of the device so the first period of time when the device transfers heat approaches the desired cycle-on period of time. There may also be provided temperature controls for a liquid heater having a jacket containing the liquid. The jacket has an inner heated wall and an outer wall spaced apart from the inner wall. The controls include a temperature sensor capable of fitting to the jacket so that the sensor contacts the inner wall and the liquid. A control module monitors temperature sensed by the temperature sensor. The control module causes the heater to stop heating when the temperature is heated by the heater to a first value and causes the heater to heat when the liquid cools to a second value lower than the first value. The control module senses overheating when temperature sensed by the sensor increases to a third value, higher than the first value, when the heater is not heating, and then causes the heater to shut down.

Owner:MARINE CANADA ACQUISITIONS INC

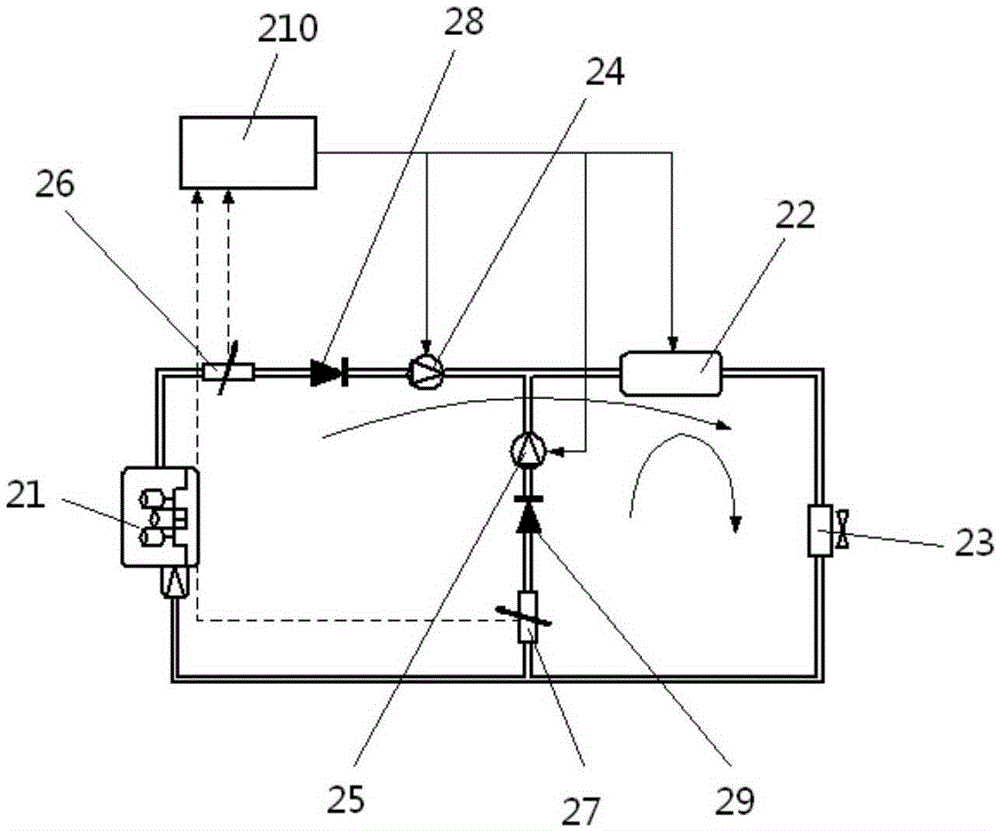

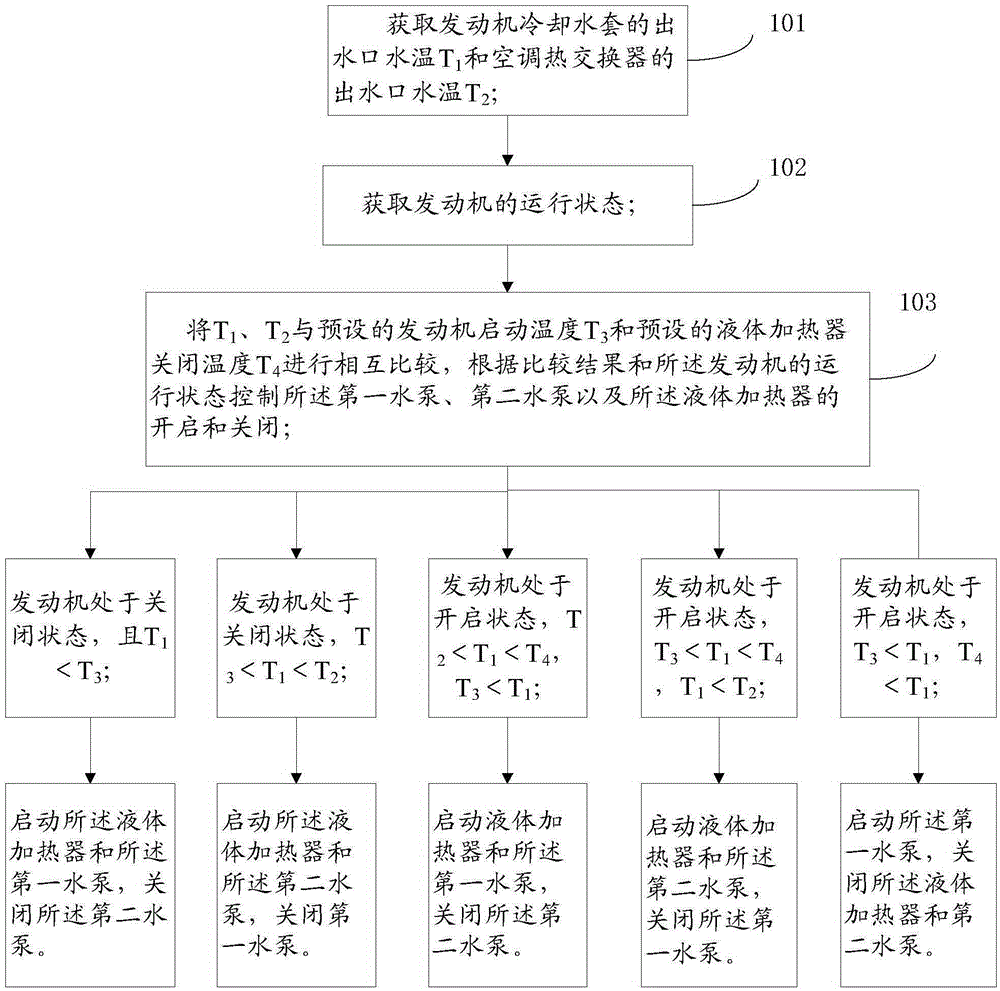

Automobile cooling water circulation control system and method and automobile

ActiveCN105275571AImprove utilization efficiencyLiquid coolingAir-treating devicesControl systemEngineering

The invention discloses an automobile cooling water circulation control system and method and an automobile. The circulation control system comprises an engine cooling water jacket, a first water pump, a liquid heater and an air-conditioning heat exchanger which are connected through pipelines in an end-to-end mode in sequence. The circulation control system further comprises a second water pump, a first one-way valve, a second one-way valve and a controller, wherein a water inlet of the second water pump is connected with a water outlet of the air-conditioning heat exchanger through a pipeline; a water outlet of the second water pump is connected with a water inlet of the liquid heater through a pipeline; the first one-way valve is arranged on a water inlet or outlet pipeline of the first water pump, and the conducting direction of the first one-way valve is the flowing direction from the engine cooling water jacket to the first water pump; the second one-way valve is arranged on a water inlet or outlet pipeline of the second water pump, and the conducting direction of the second one-way valve is the flowing direction from the second water pump to the liquid heater; the controller controls on and off of the first water pump, the second water pump and the liquid heater. By adopting the circulation control system, heat provided by the liquid heater cannot be emitted by an engine, and therefore the energy utilization efficiency is improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Magnetically propelled engine with magnetic field reduction

Owner:KELLER MR CHRISTIAN HARVEY

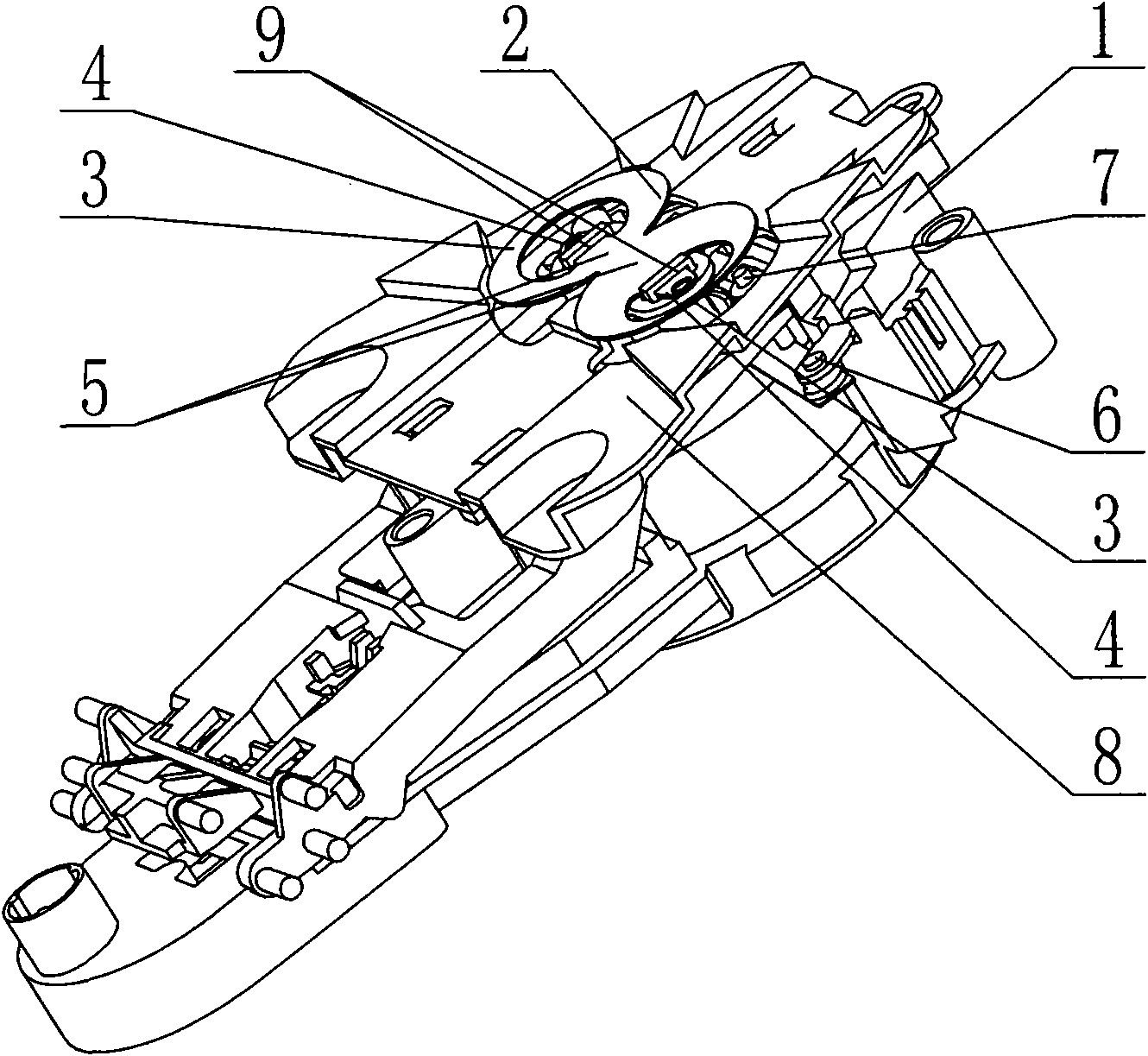

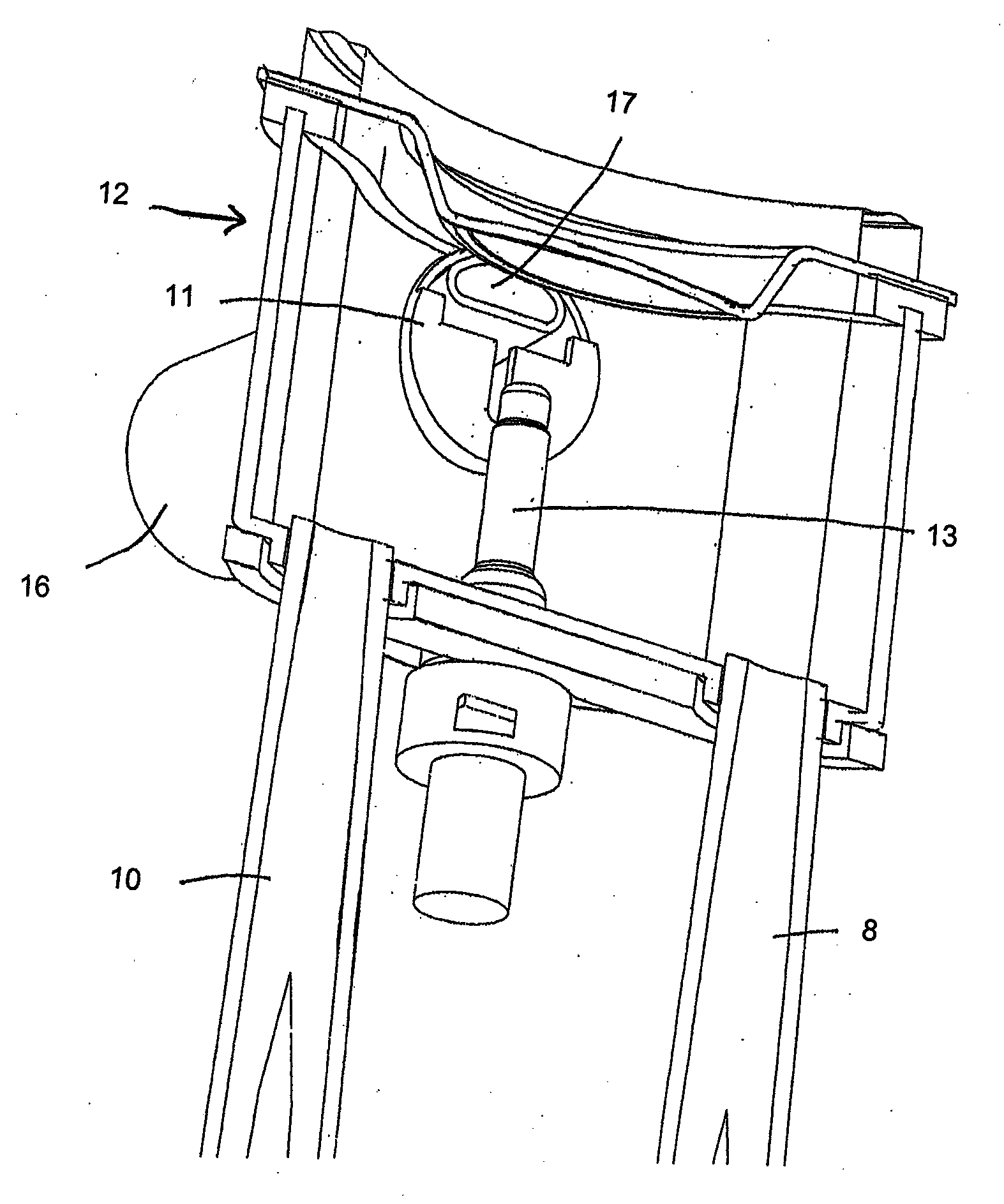

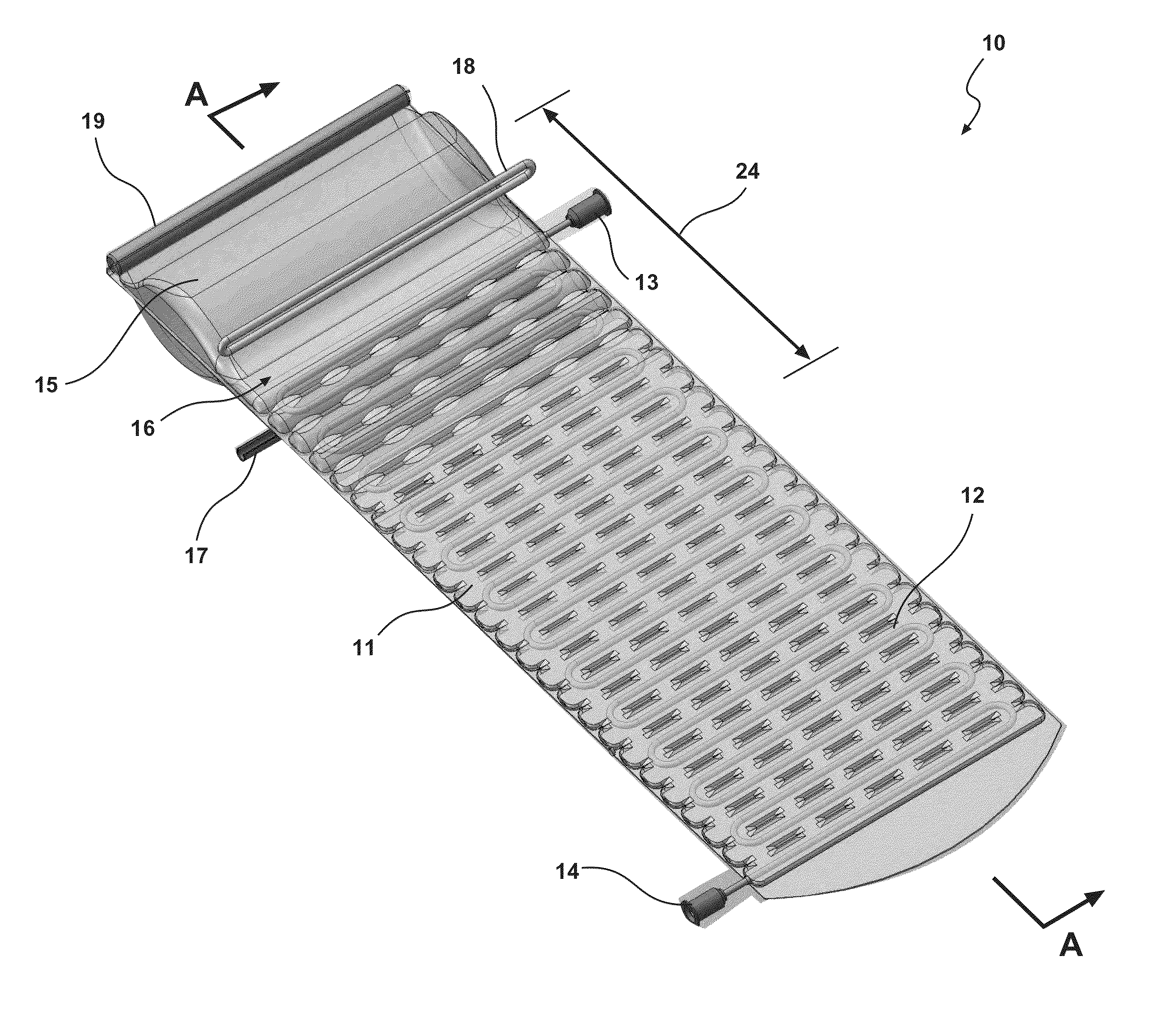

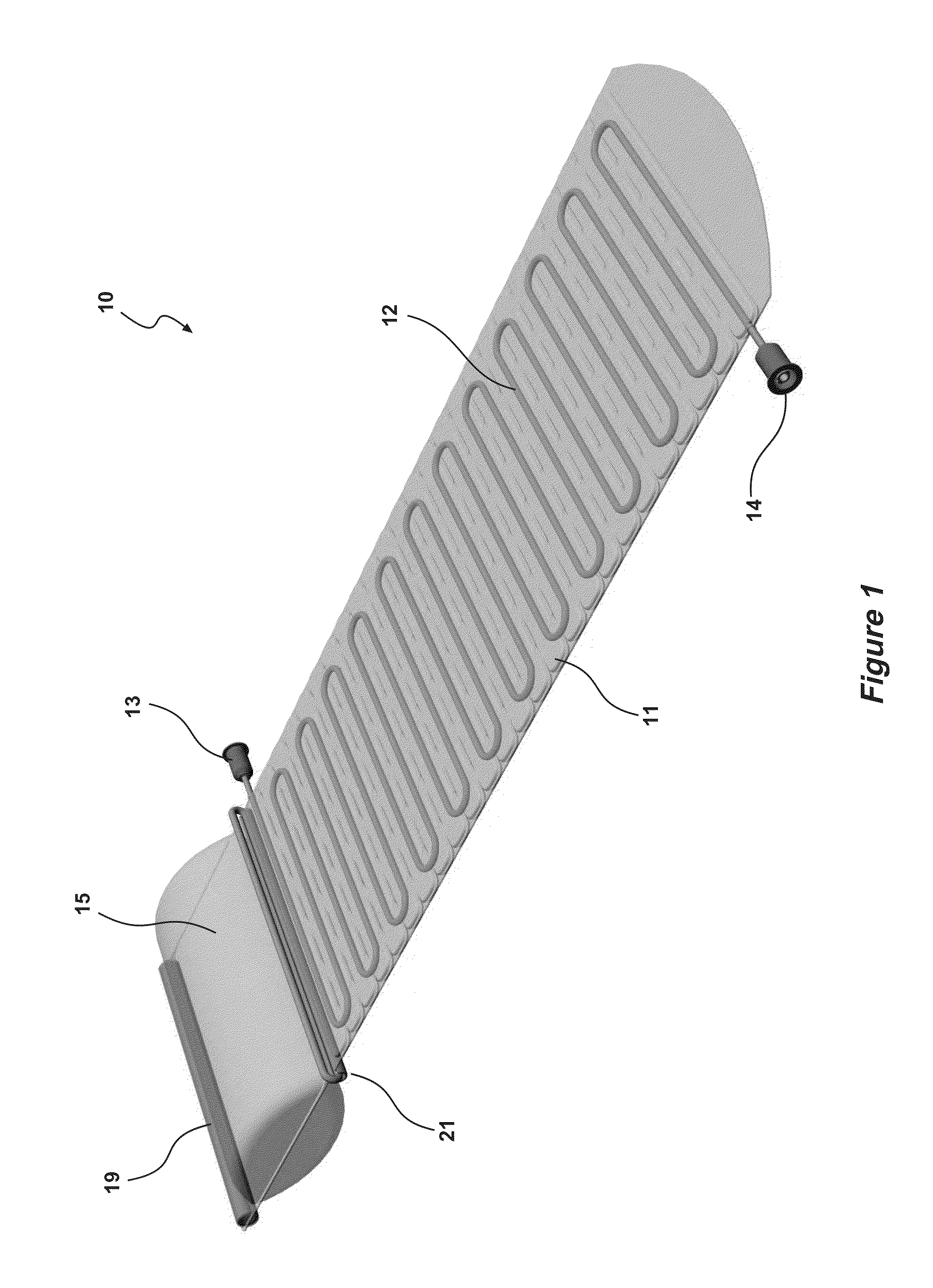

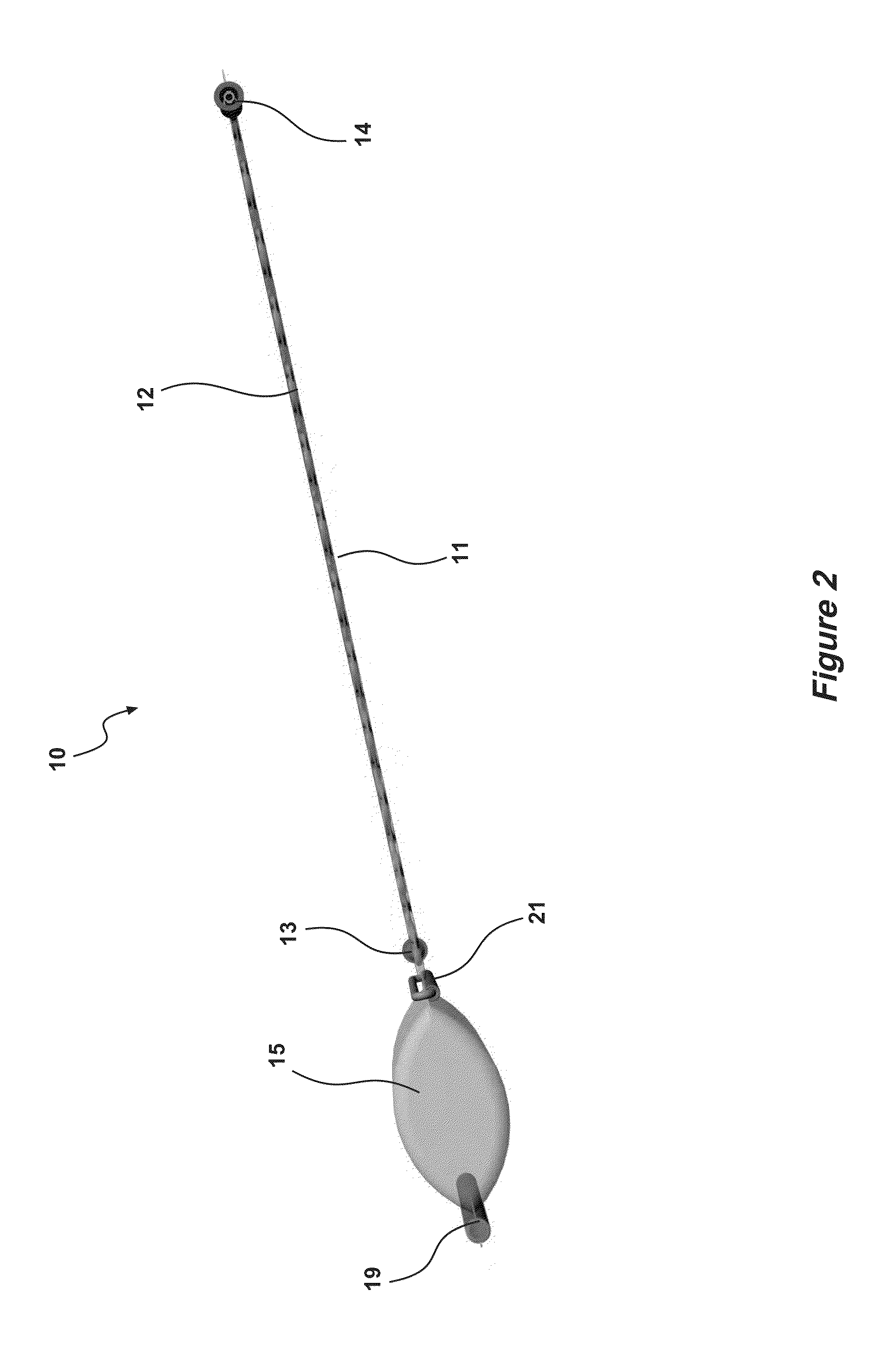

Portable fluid warmer

InactiveUS20130267930A1Move quicklyMaximize heat transferExothermal chemical reaction heat productionMedical devicesExothermic reactionFluid warmer

A device (10) for warming infusion or transfusion fluids by an exothermic reaction of a reactive liquid, including at least one reaction chamber (11) containing a trigger, and a passageway (12) extending through said reaction chamber (11) for movement of said infusion or transfusion fluids therethrough, wherein the reactive liquid is introduced into said reaction chamber (11), being at least partially evacuated of air, to thereby initiate said exothermic reaction.

Owner:FBE

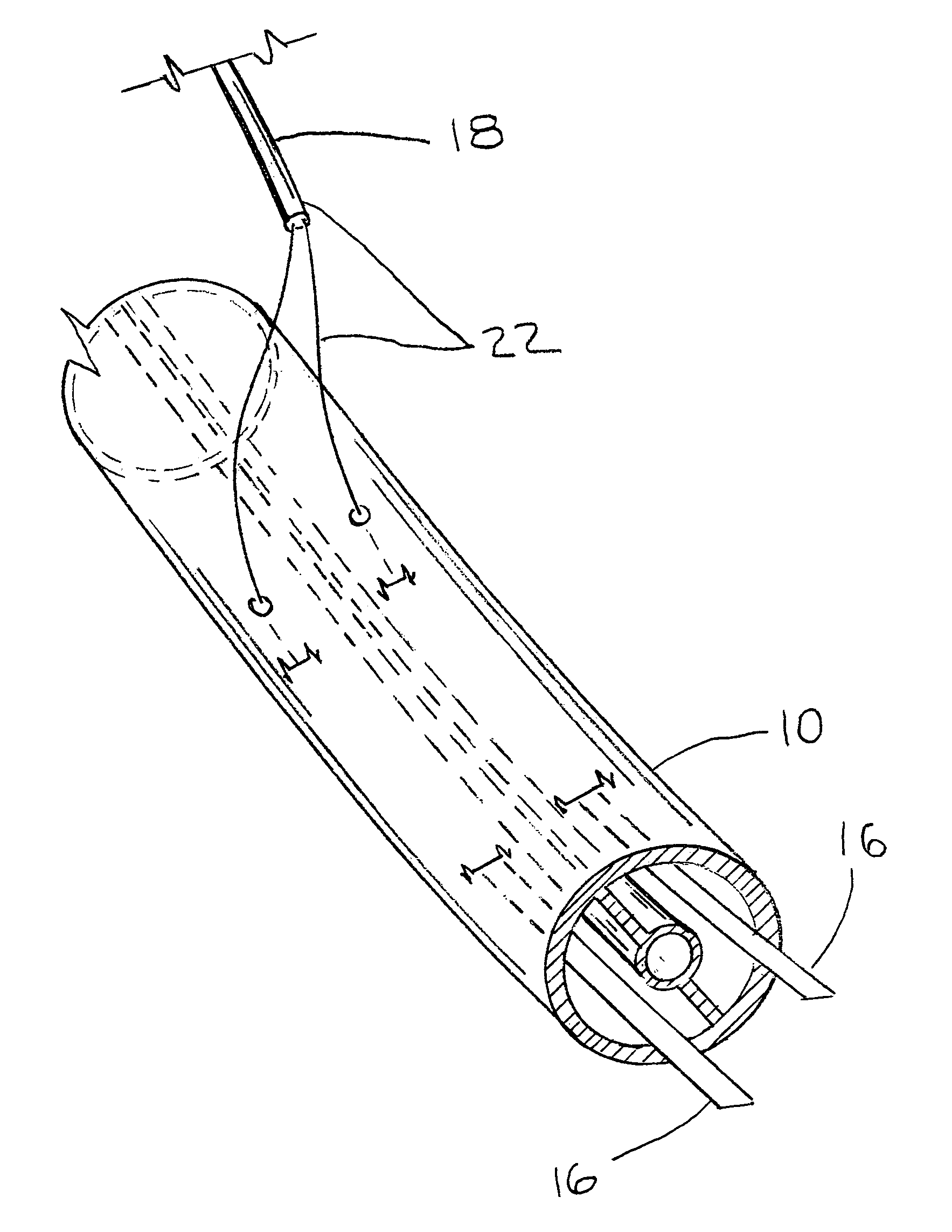

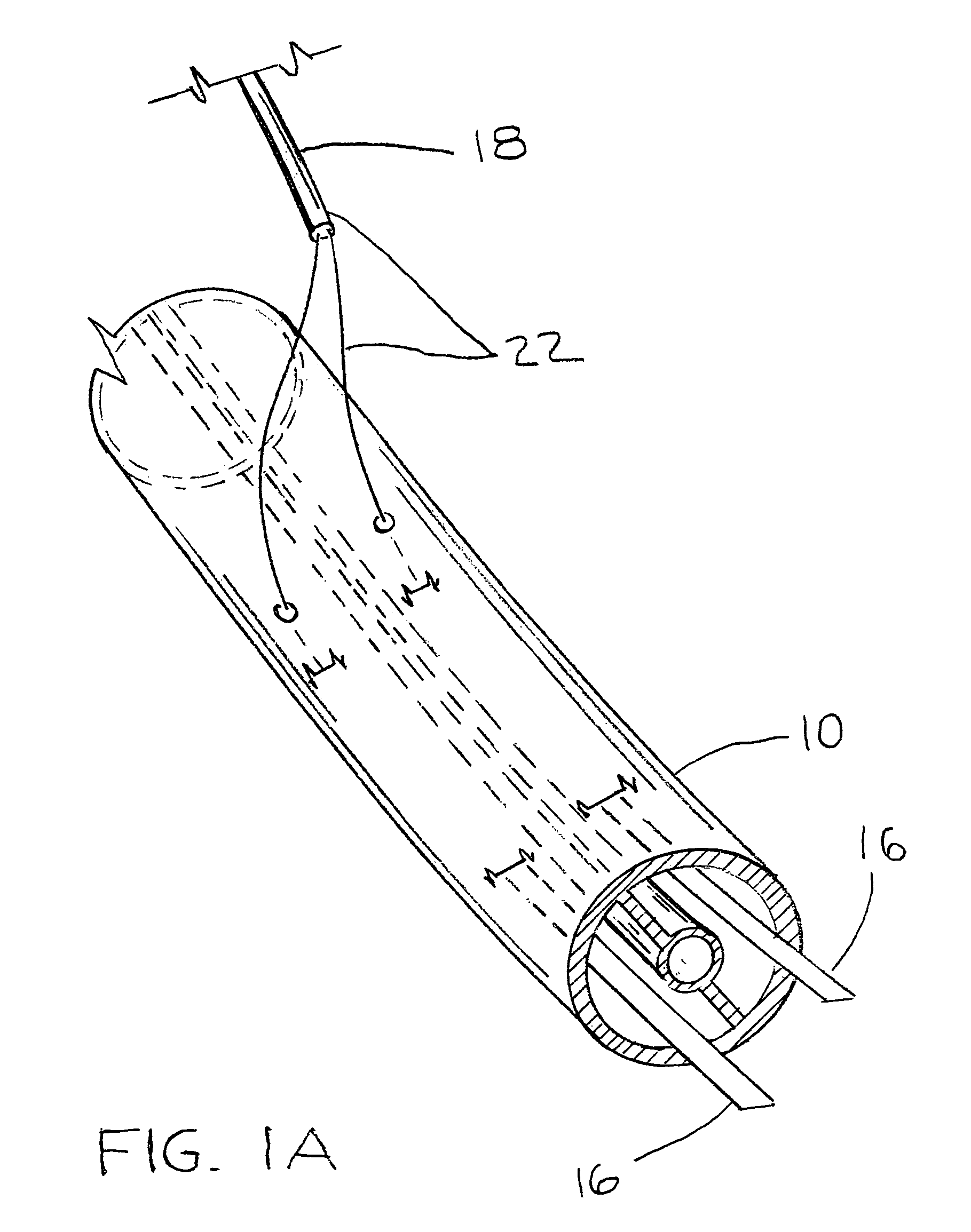

Disposable outlet patient flow line employing active warming and passive insulation to provide normothermic fluid at very low flow rates for in-line blood warmers

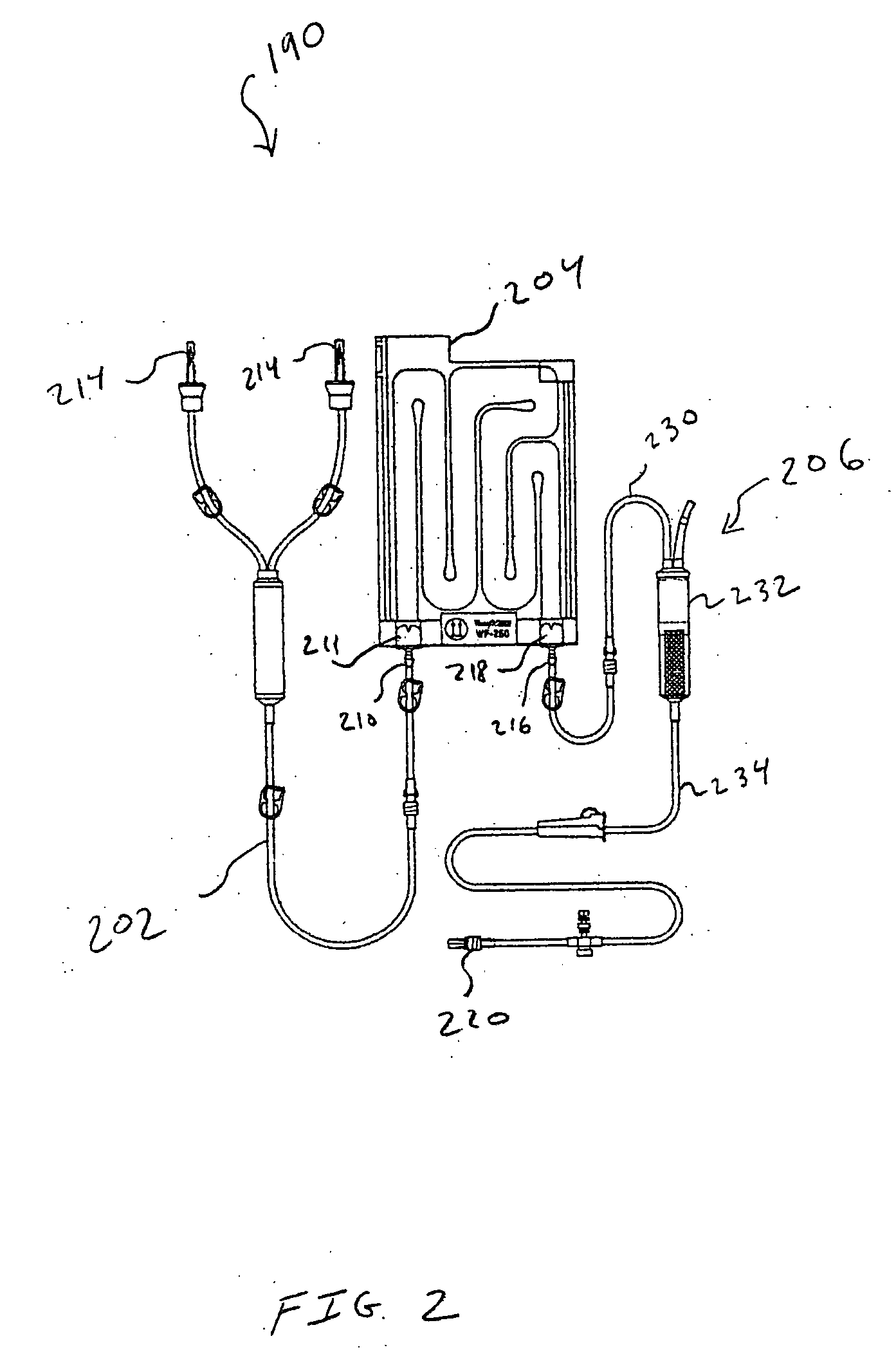

ActiveUS7357786B1Reduce flow rateLow costSurgical instruments for heatingTherapeutic coolingEngineeringAir space

A disposable outlet patient flow line for in-line blood / fluid warmer devices uses both passive insulation and active warming to deliver normothermic intravenous fluid to the patient connection site at very low flow rates. A co-extruded annular air space provides passive insulation which reduces heat loss to the cooler ambient air, but by itself this is inadequate for flow rates less than about 15 milliliters per minute. Temperature controlled heating elements located inside the annular air space replace heat lost to ambient air outside the flow line, maintaining the annular air space at about 42 degrees C., thus preventing heat loss from the central blood / fluid carrying lumen. Normothermic fluid is delivered to the patient at body temperature down to essentially zero flow-rate, using a low cost, convenient disposable outlet patient flow line.

Owner:BAKKE ALLAN P

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com