Patents

Literature

138results about How to "Minimize maintenance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

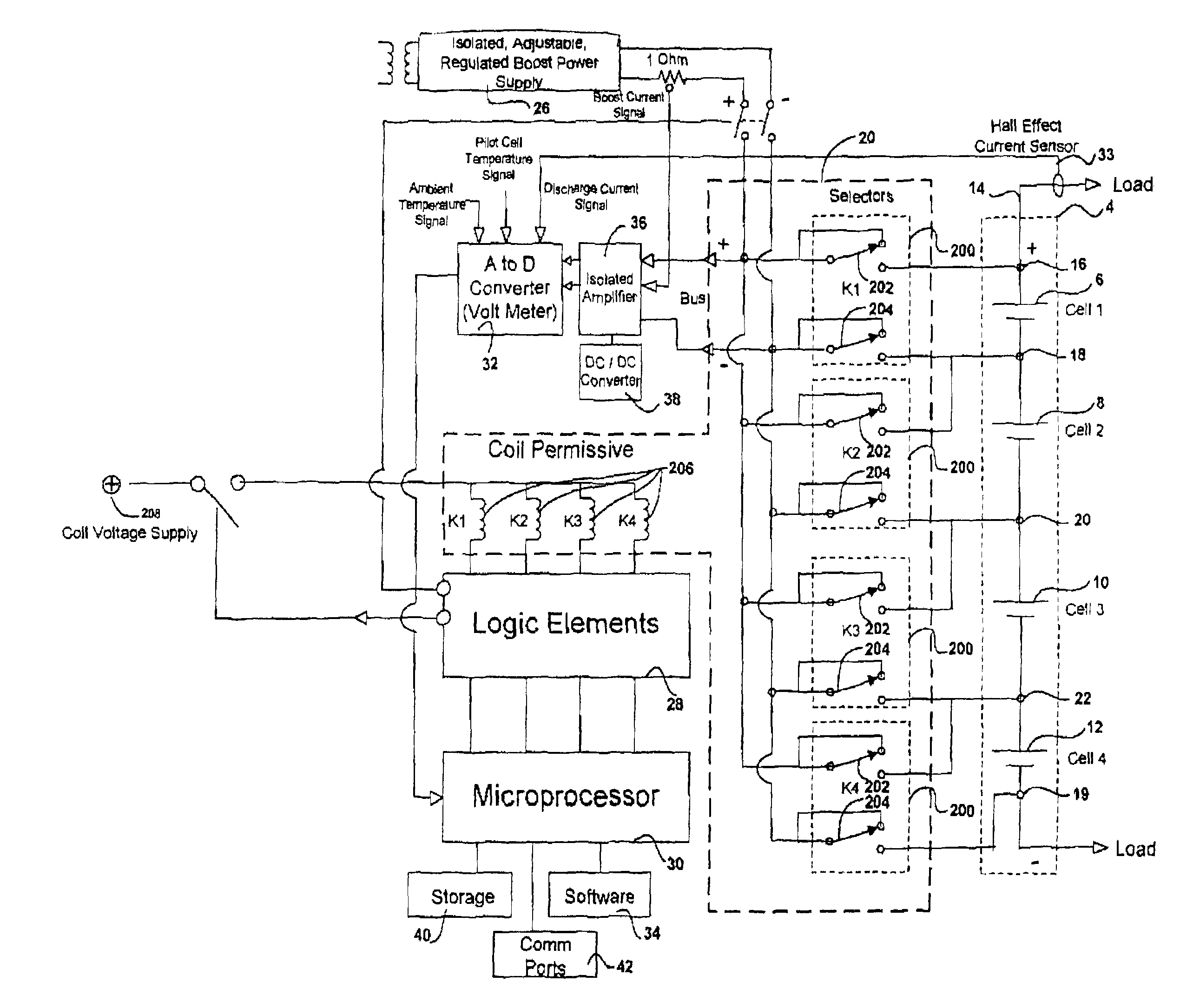

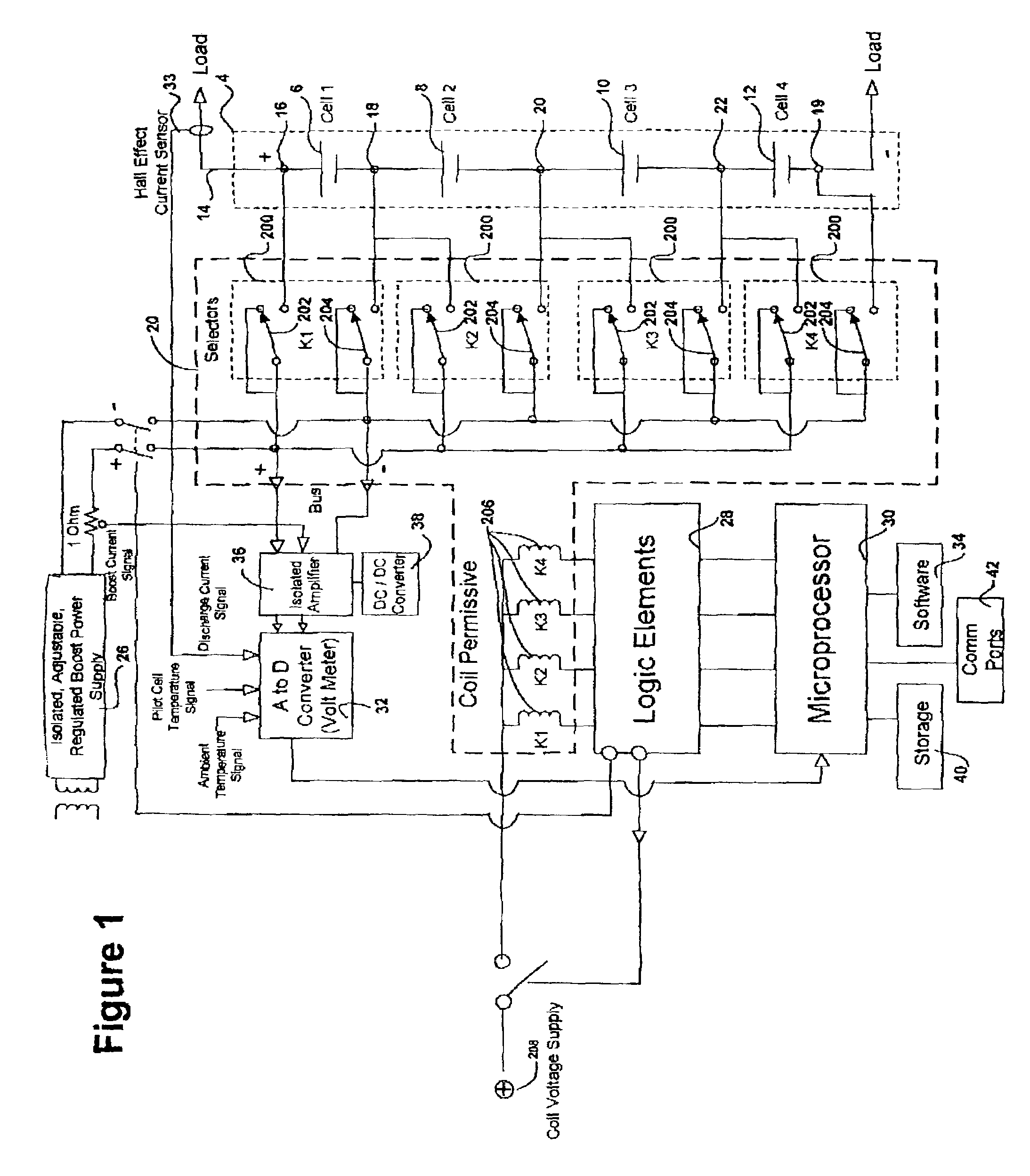

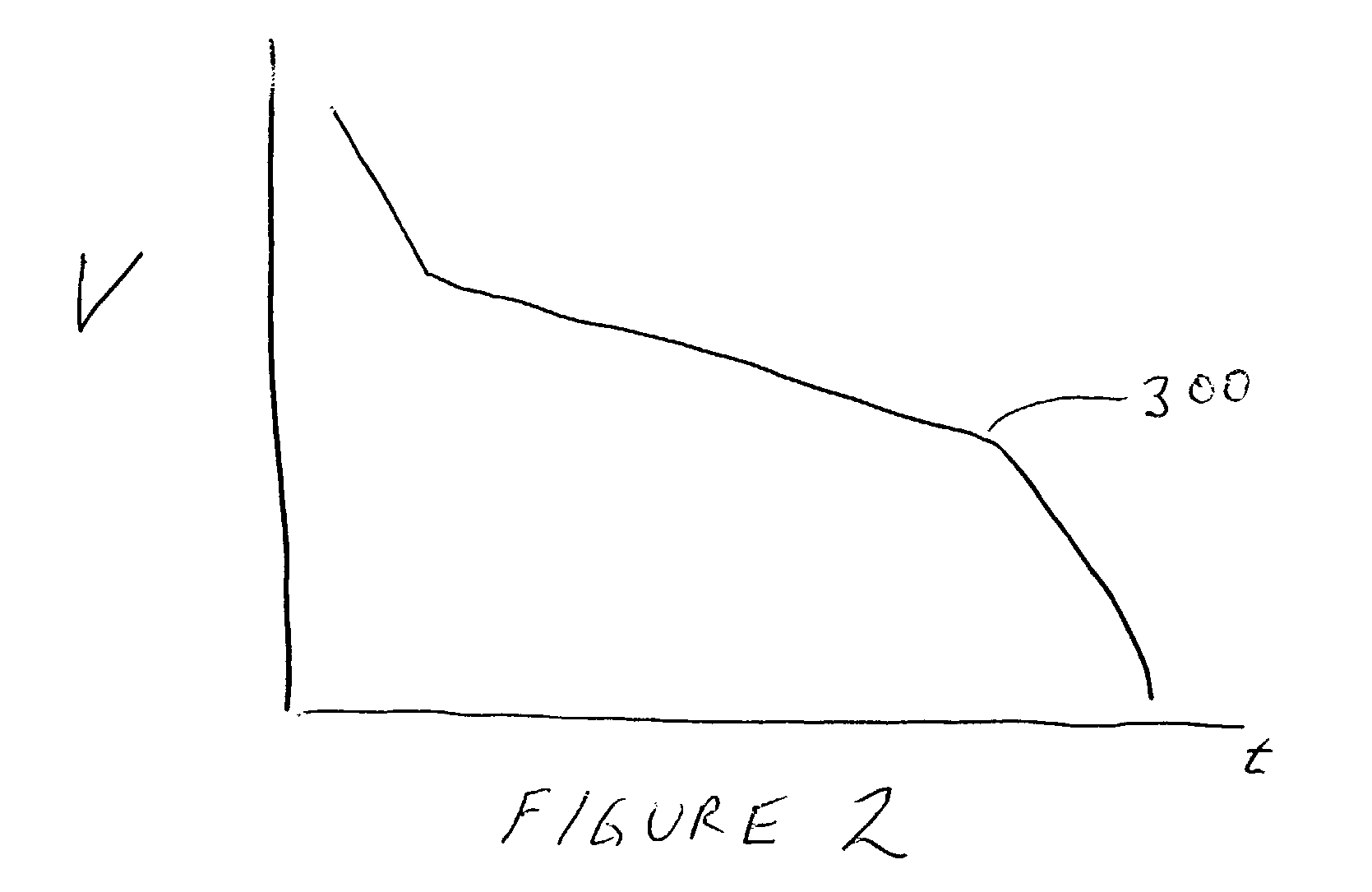

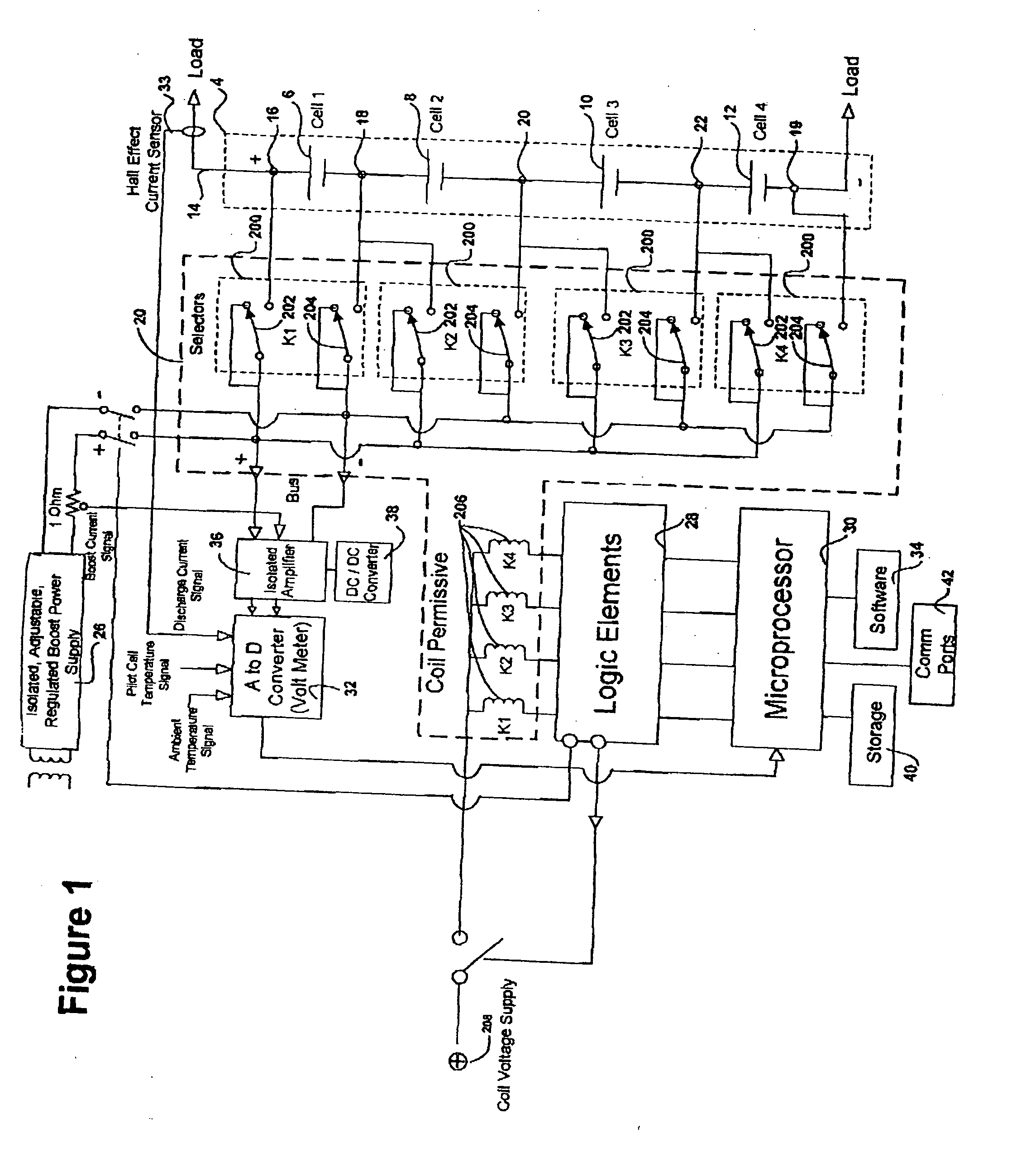

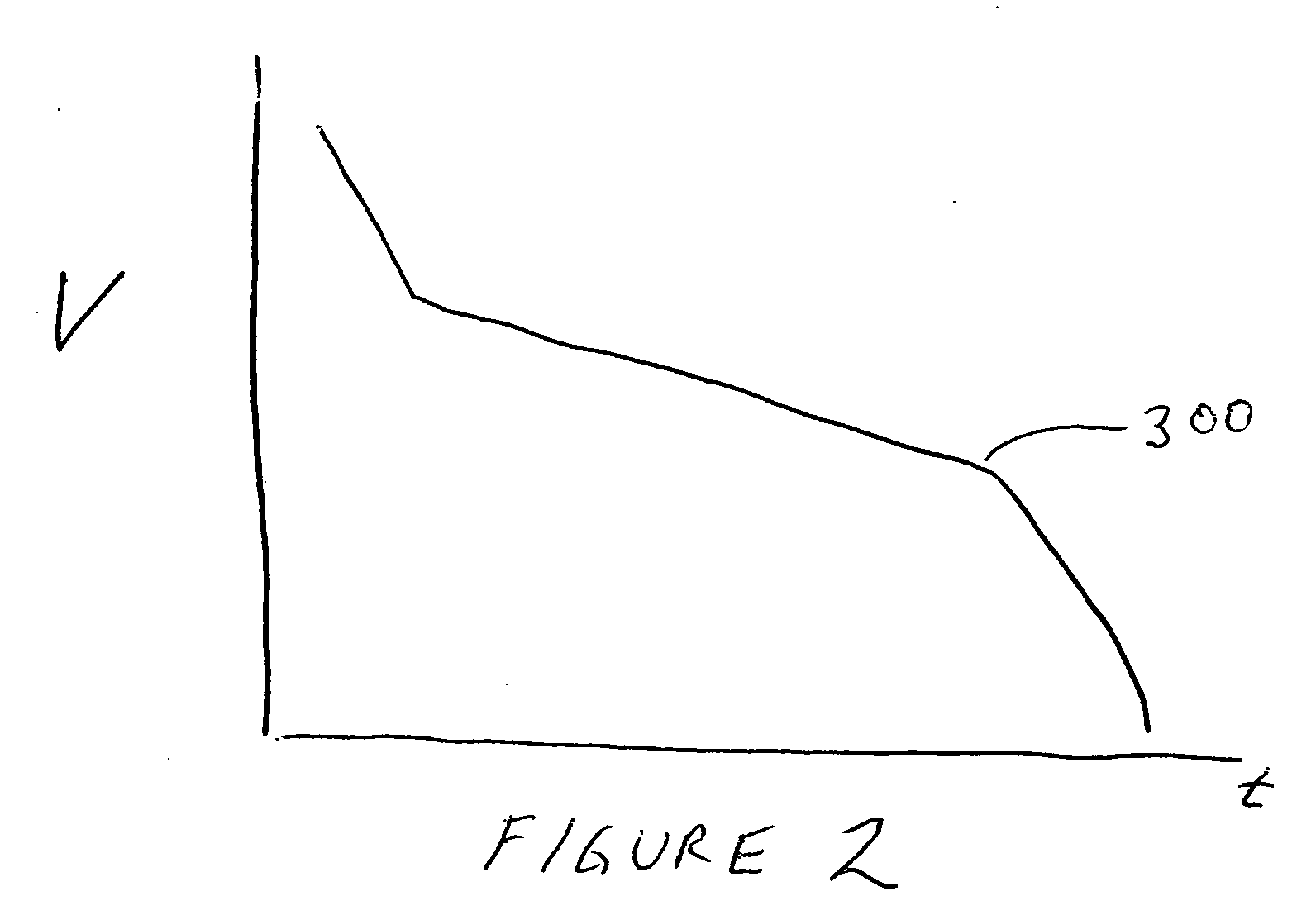

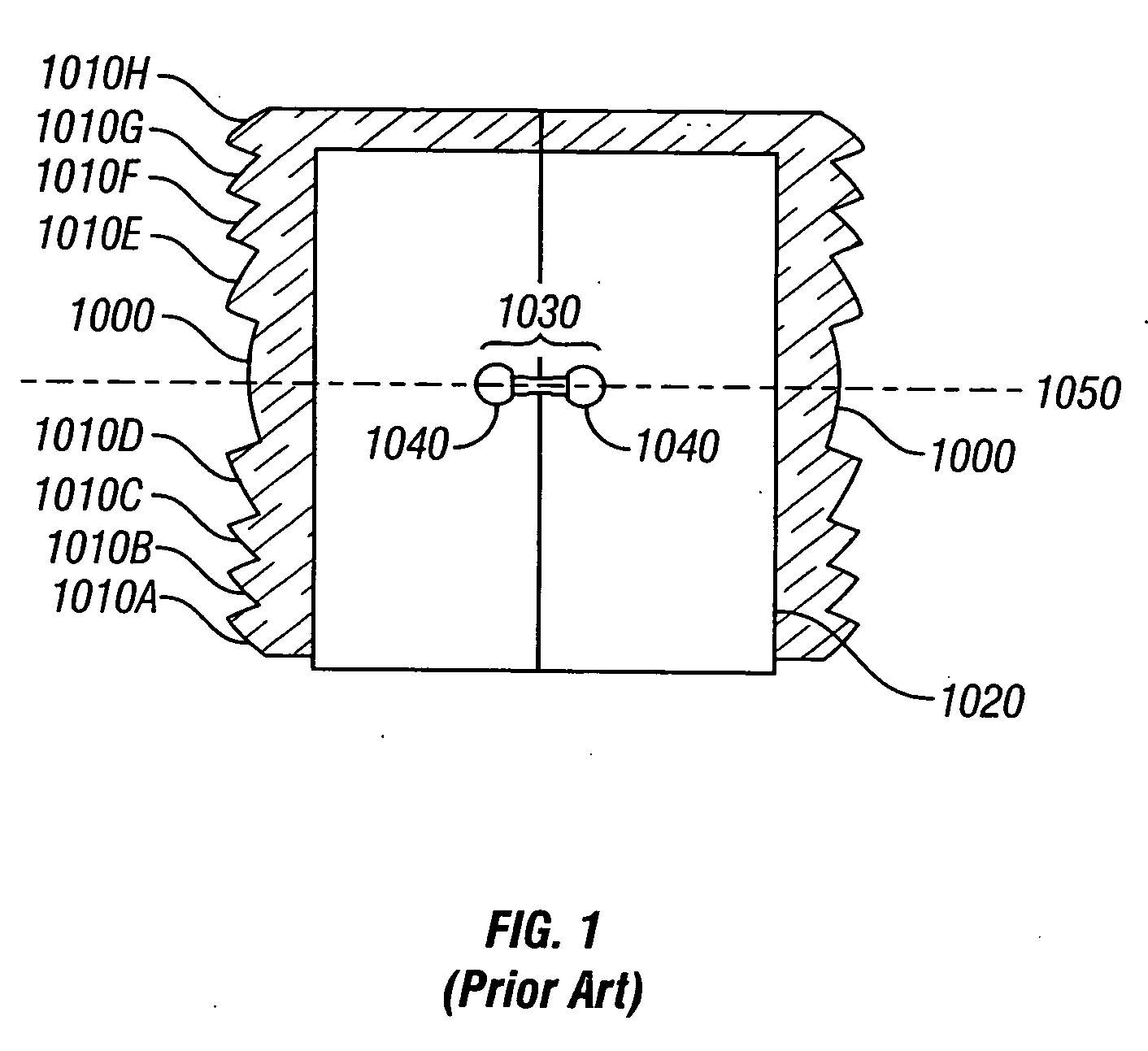

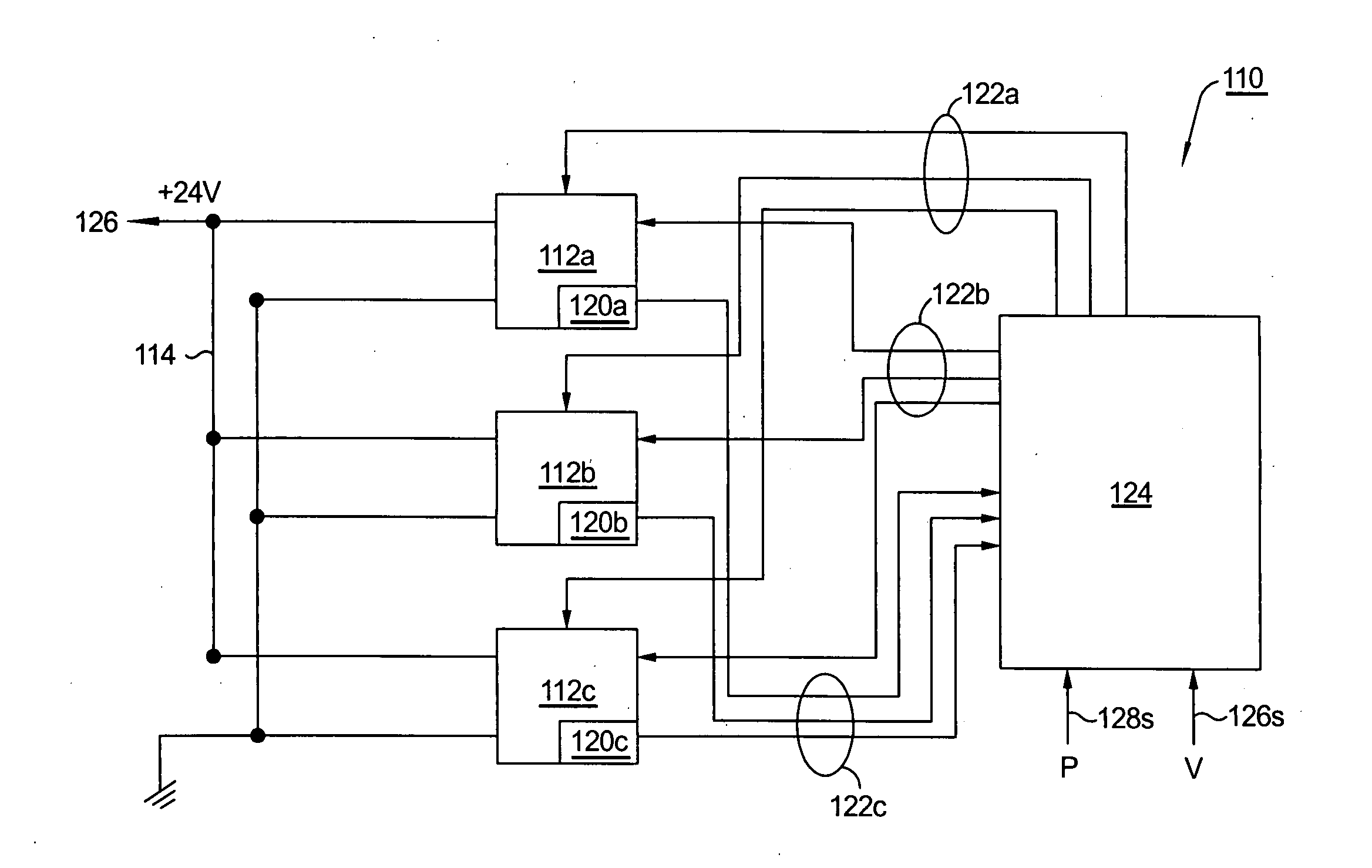

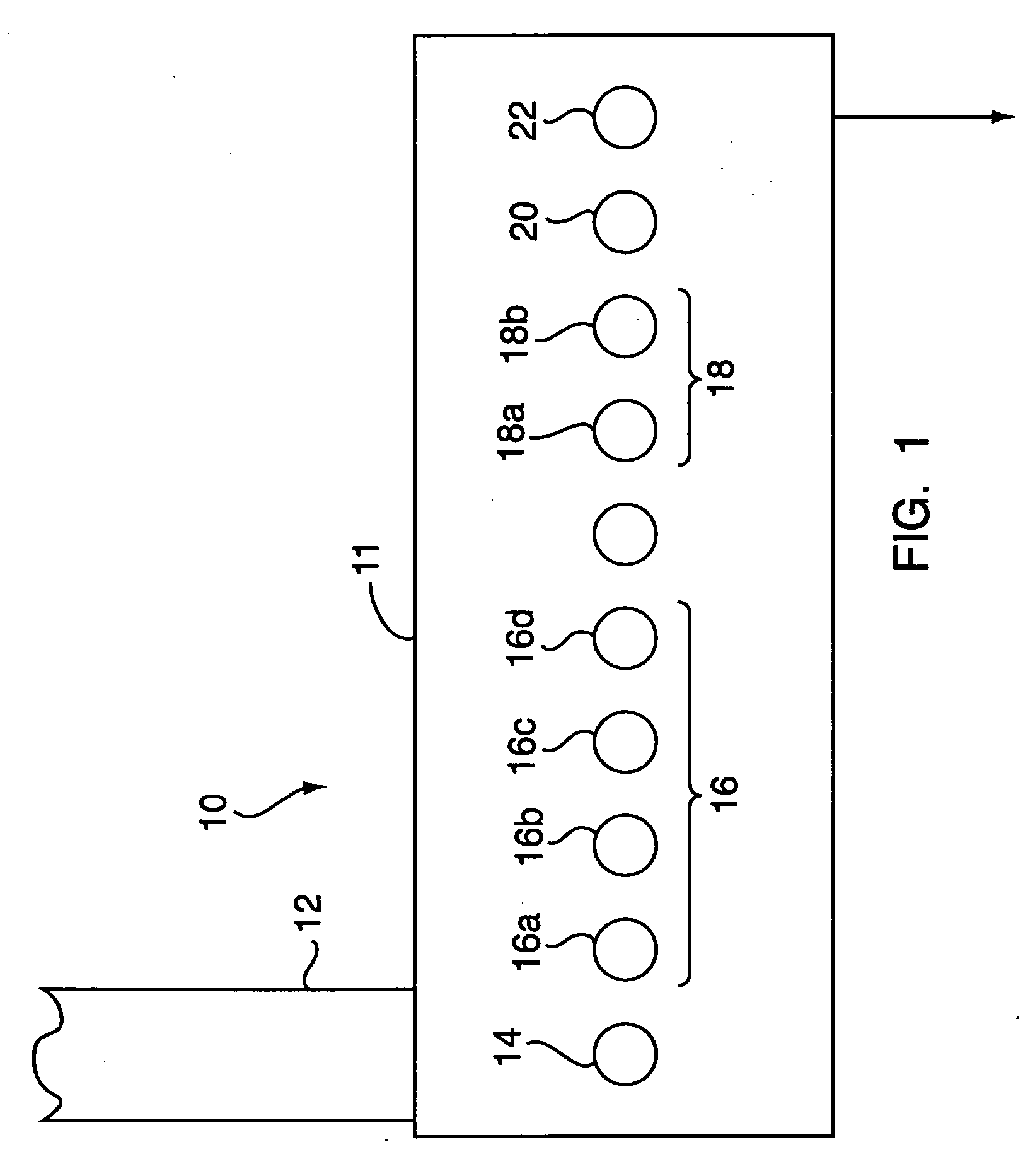

Battery management system and method

InactiveUS6983212B2Stable temperatureExtend battery lifeCircuit monitoring/indicationCharge equalisation circuitElectrical batteryVoltmeter

A battery management system is disclosed for control of individual cells in a battery string. The battery management system includes a charger, a voltmeter, a selection circuit and a microprocessor. Under control of the microprocessor, the selection circuit connects each cell of the battery string to the charger and voltmeter. Information relating to battery performance is recorded and analyzed. The analysis depends upon the conditions under which the battery is operating. By monitoring the battery performance under different conditions, problems with individual cells can be determined and corrected.

Owner:SCHNEIDER ELECTRIC IT CORP

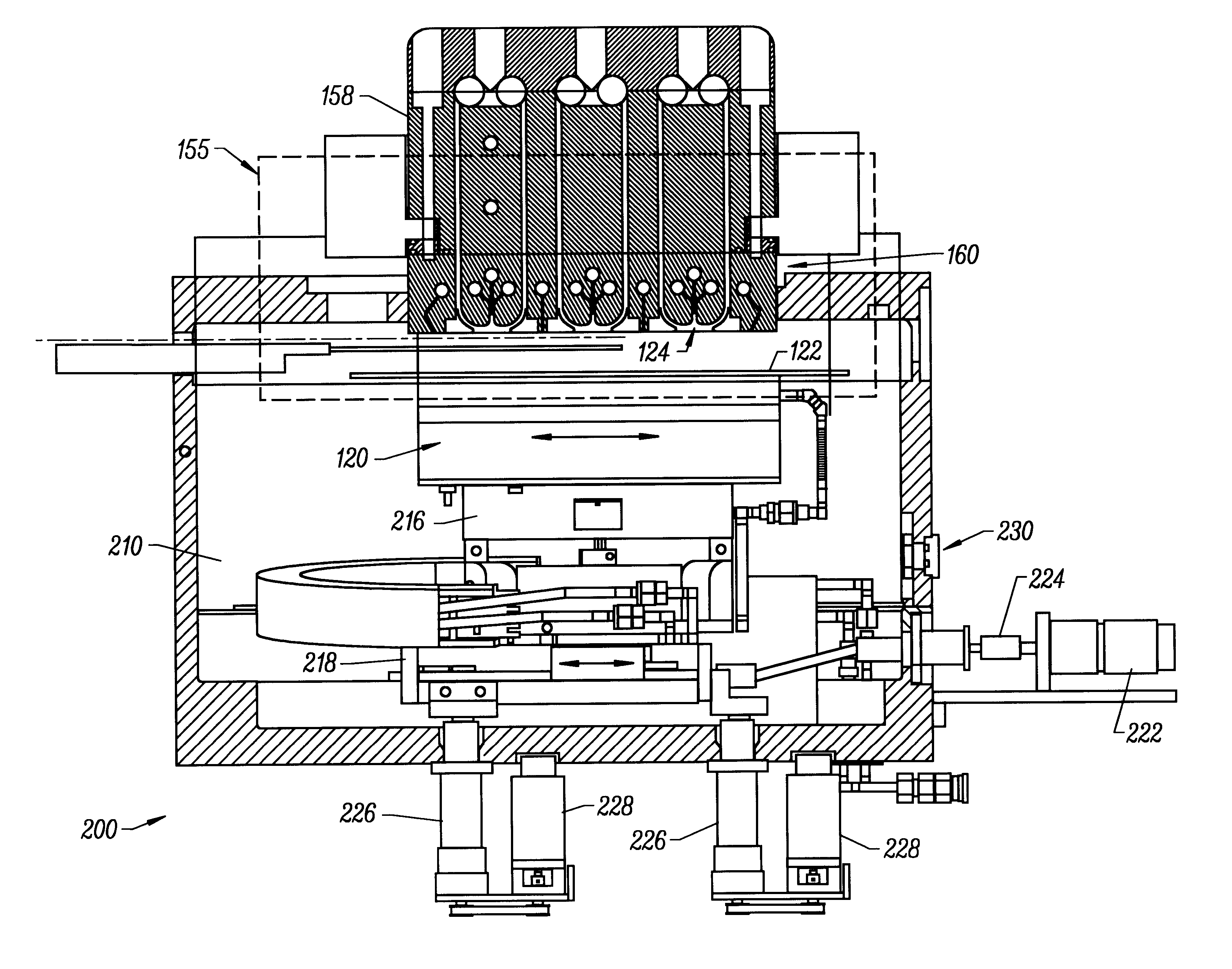

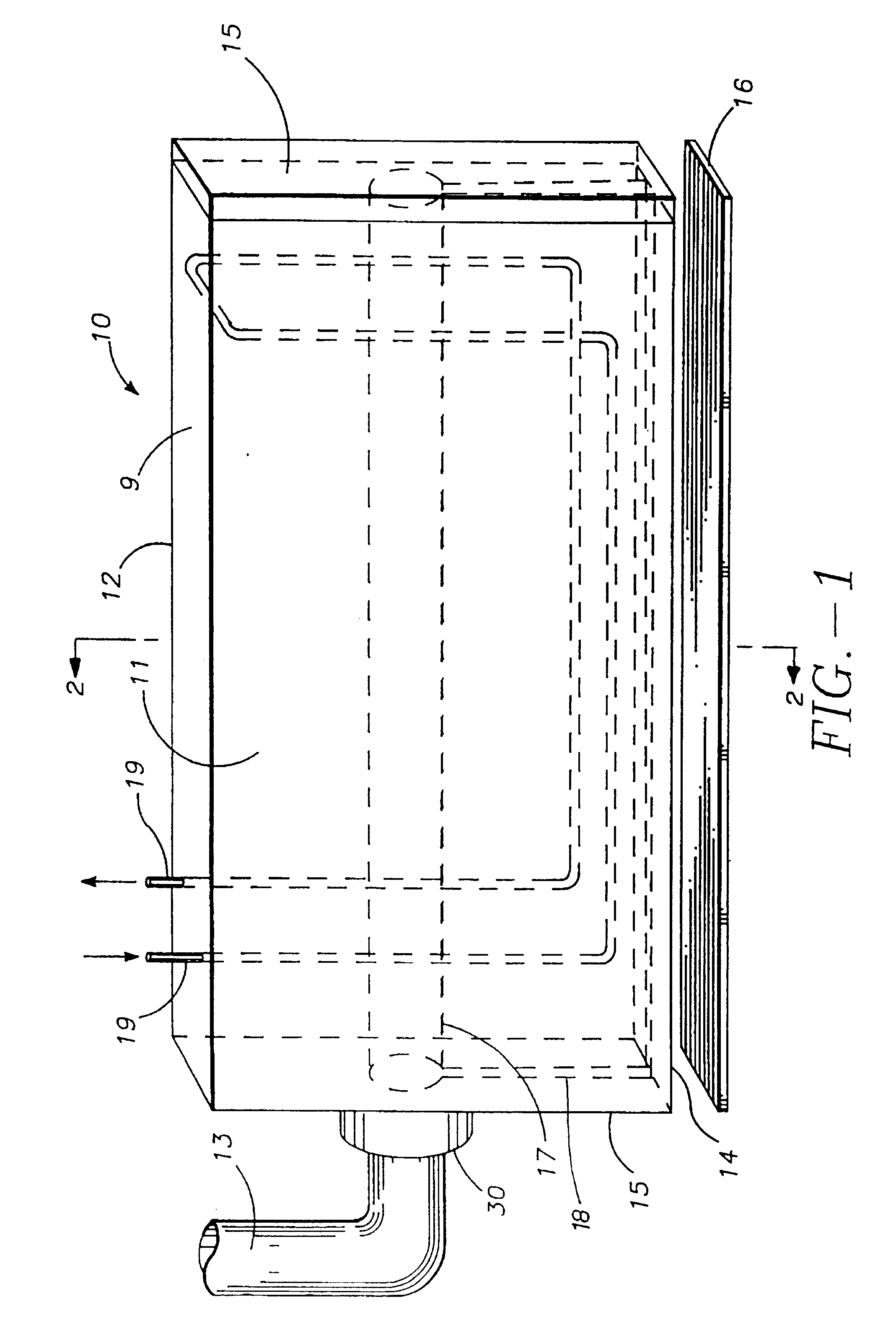

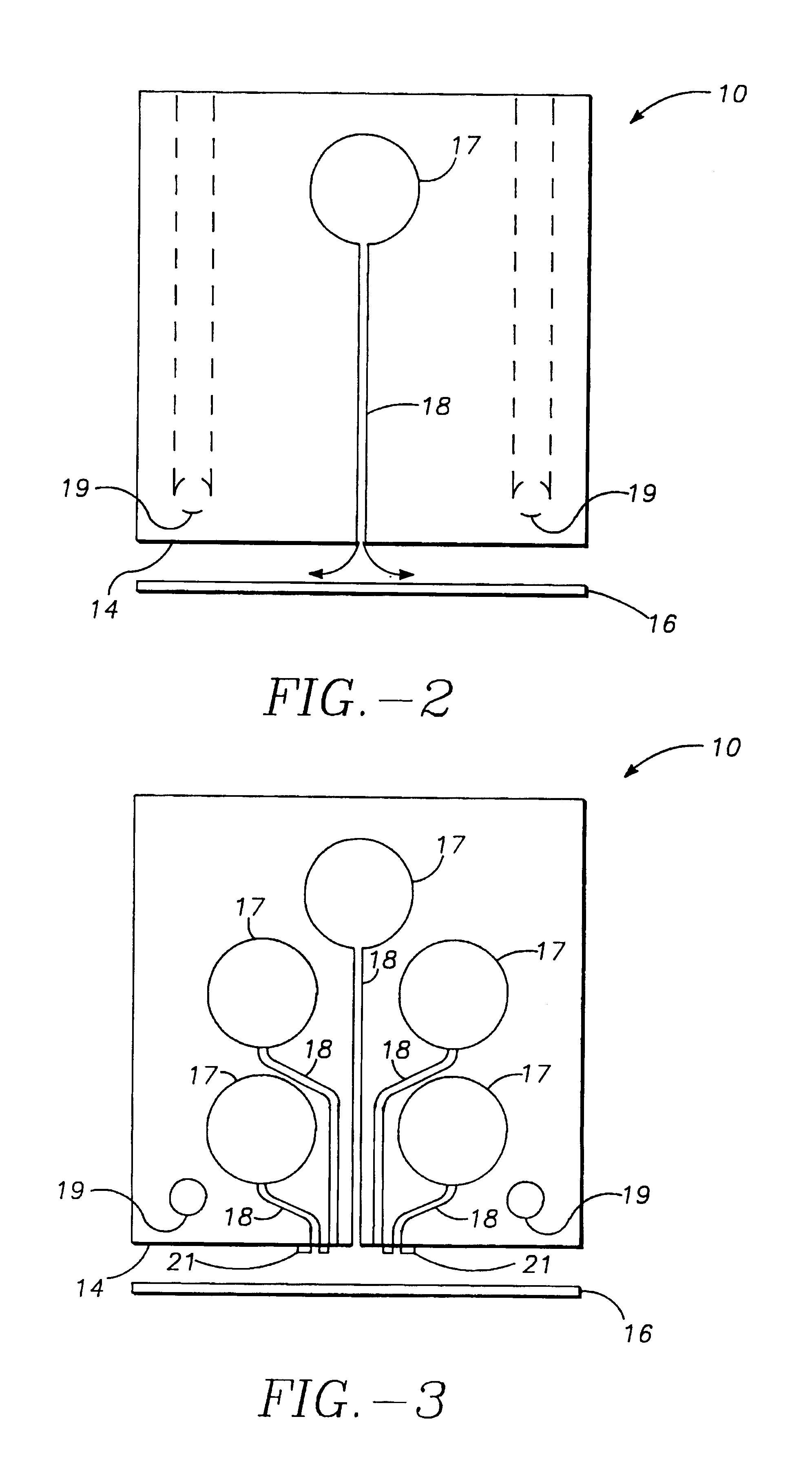

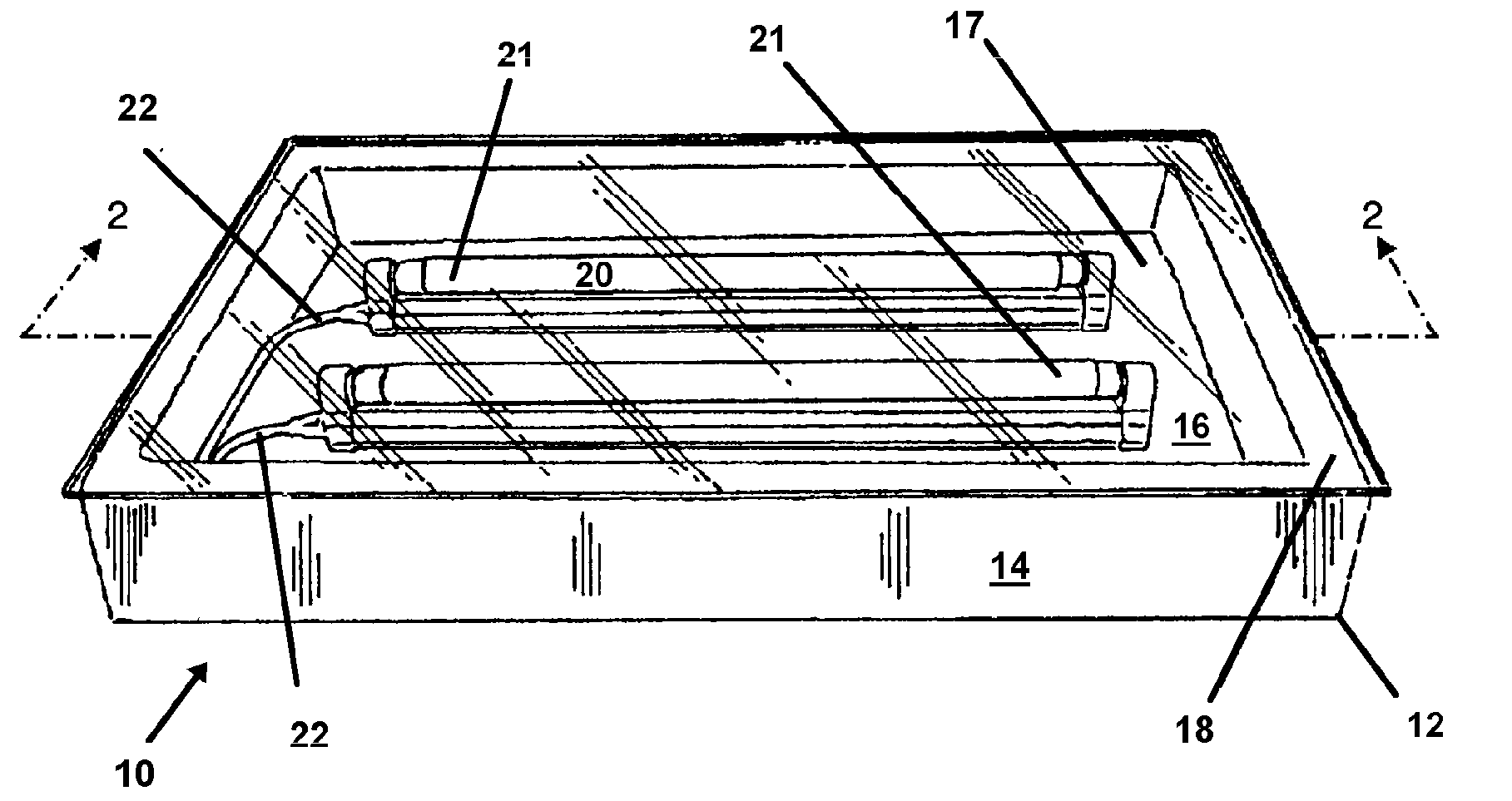

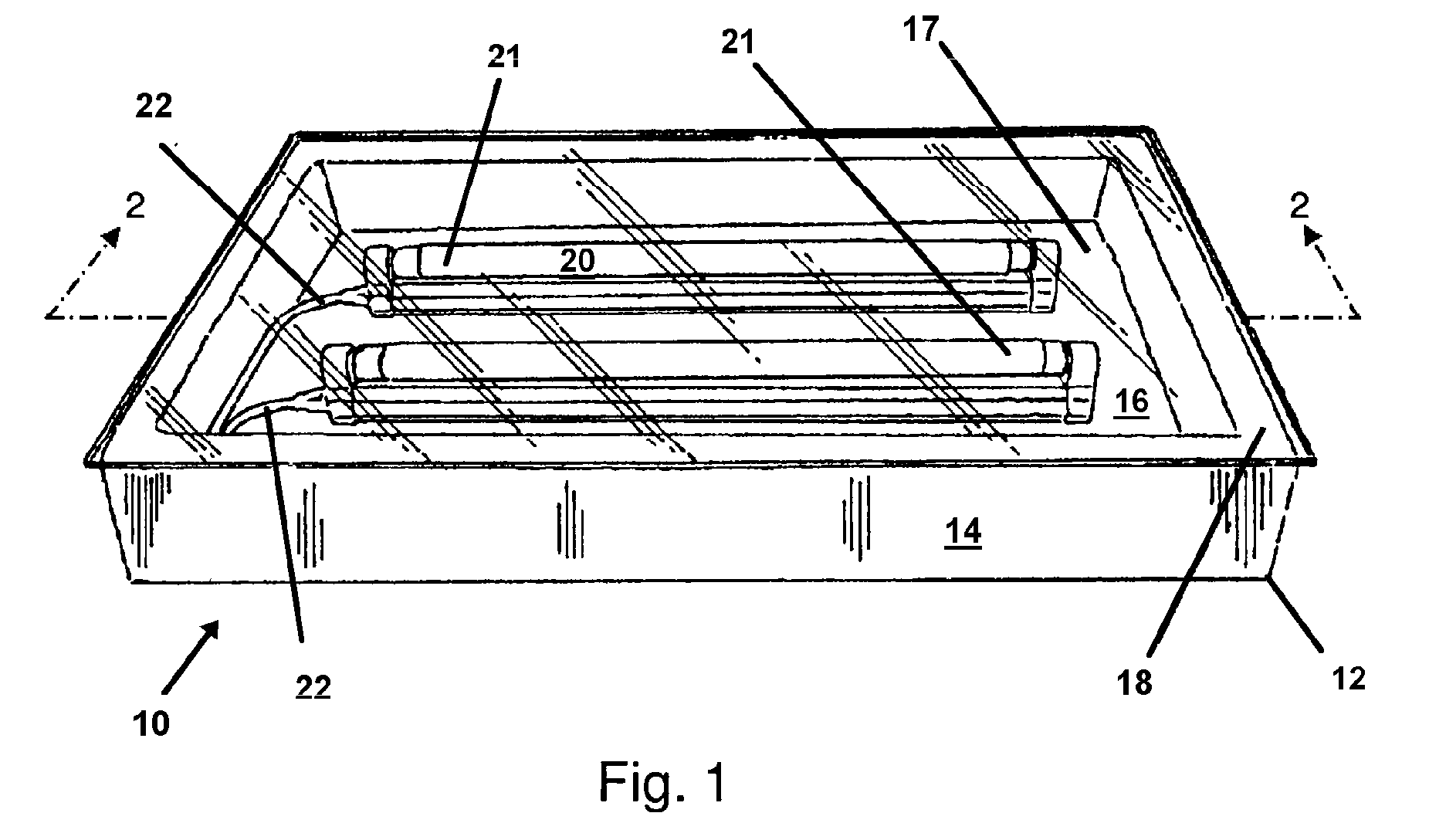

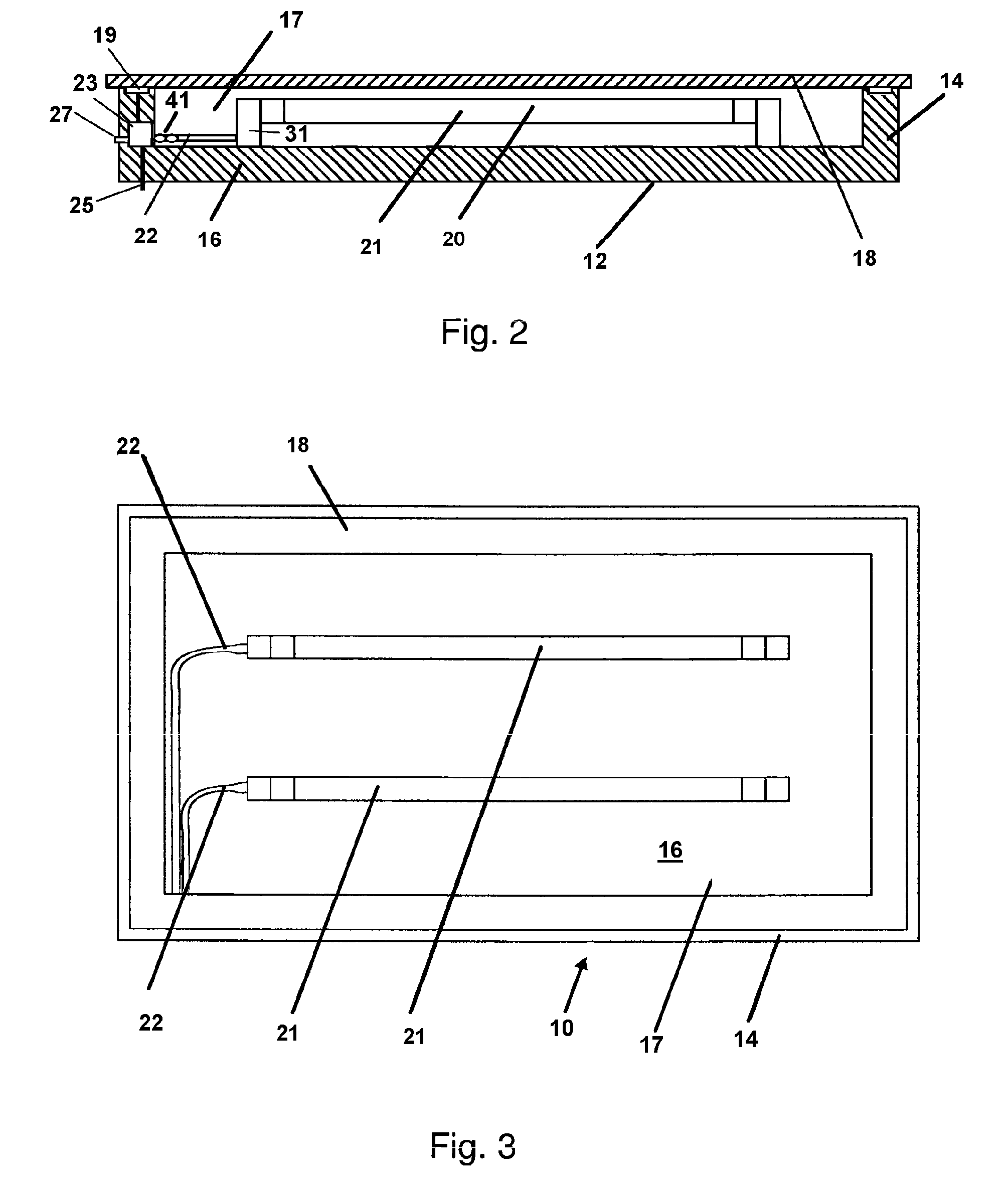

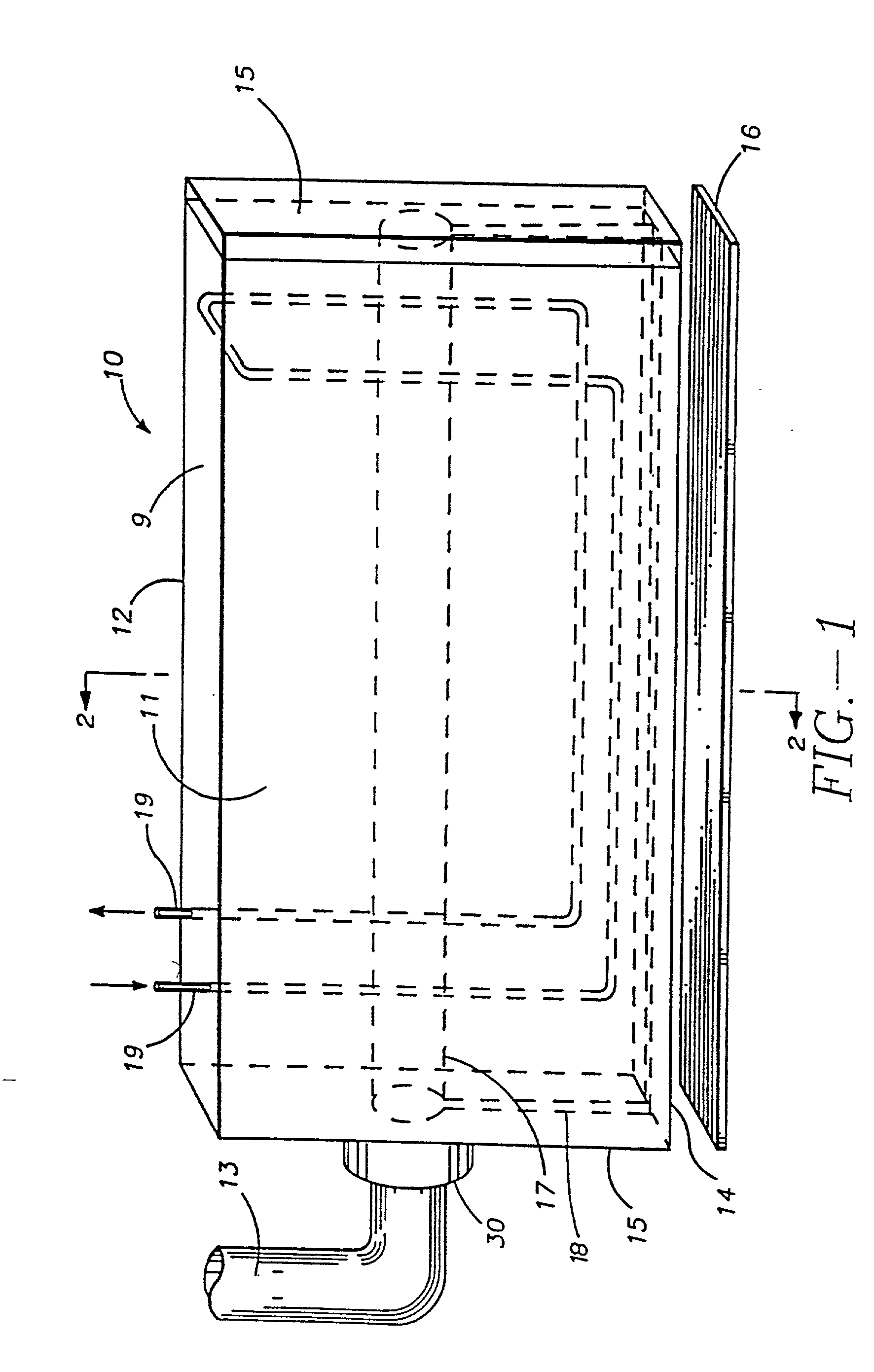

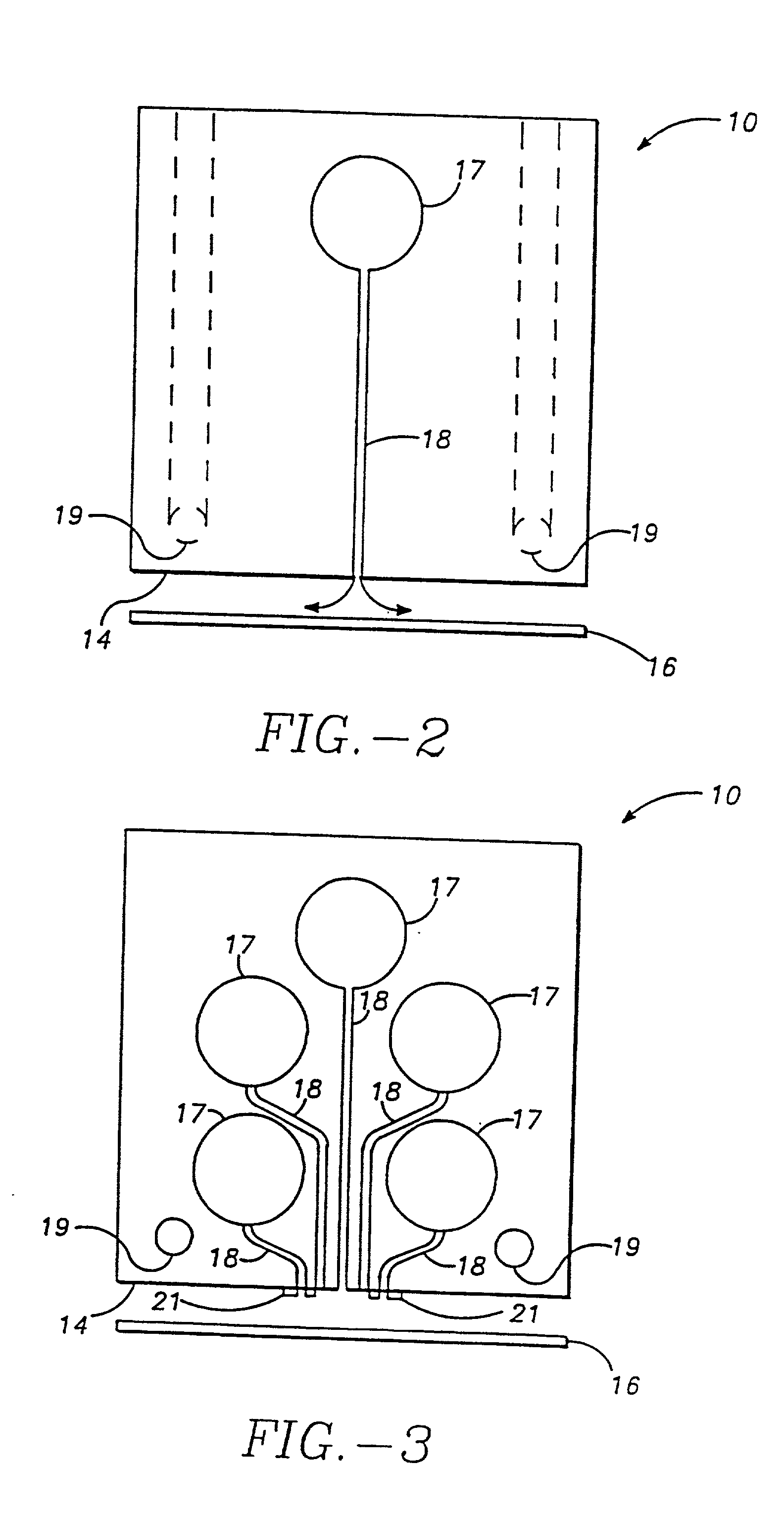

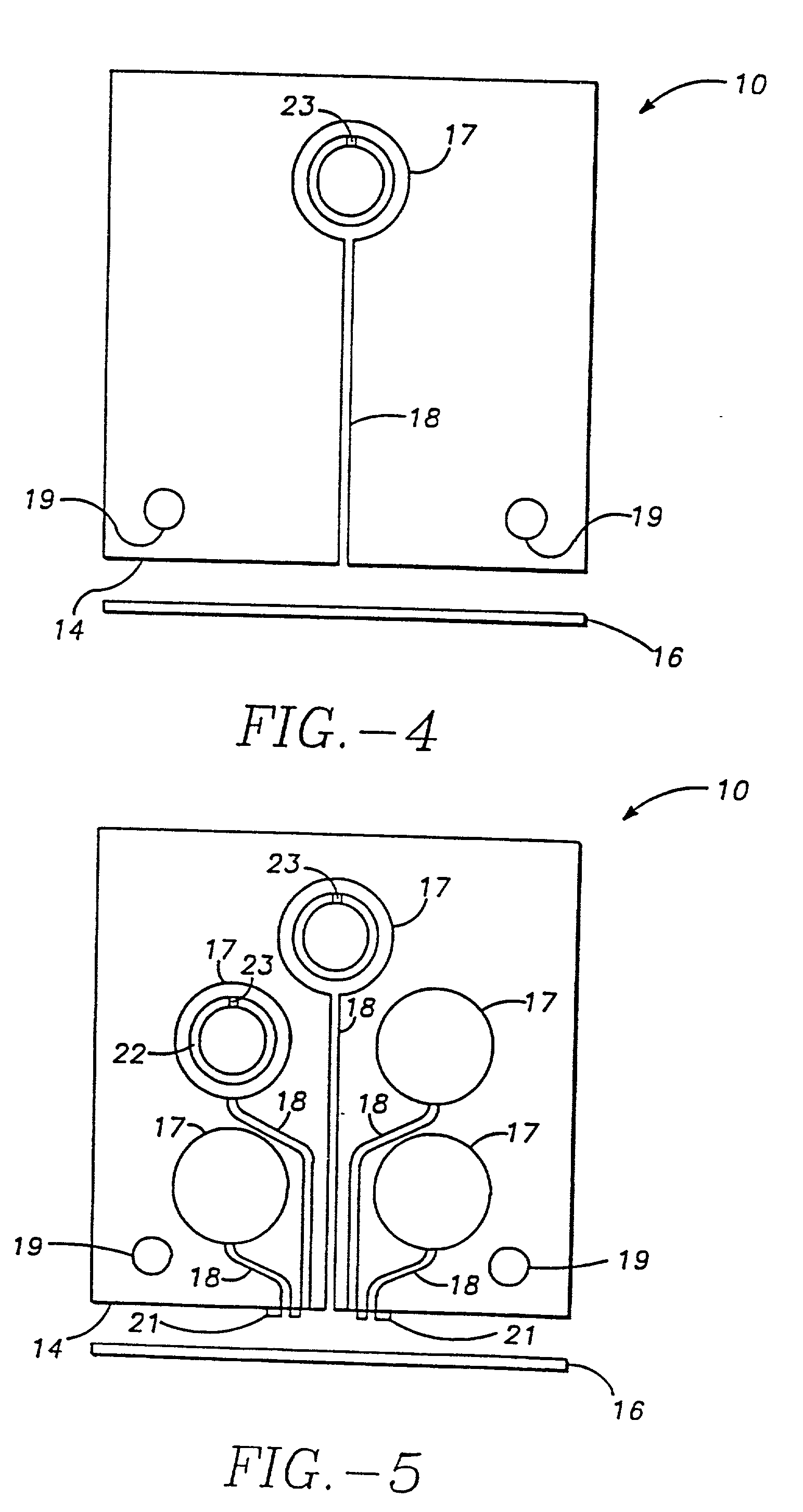

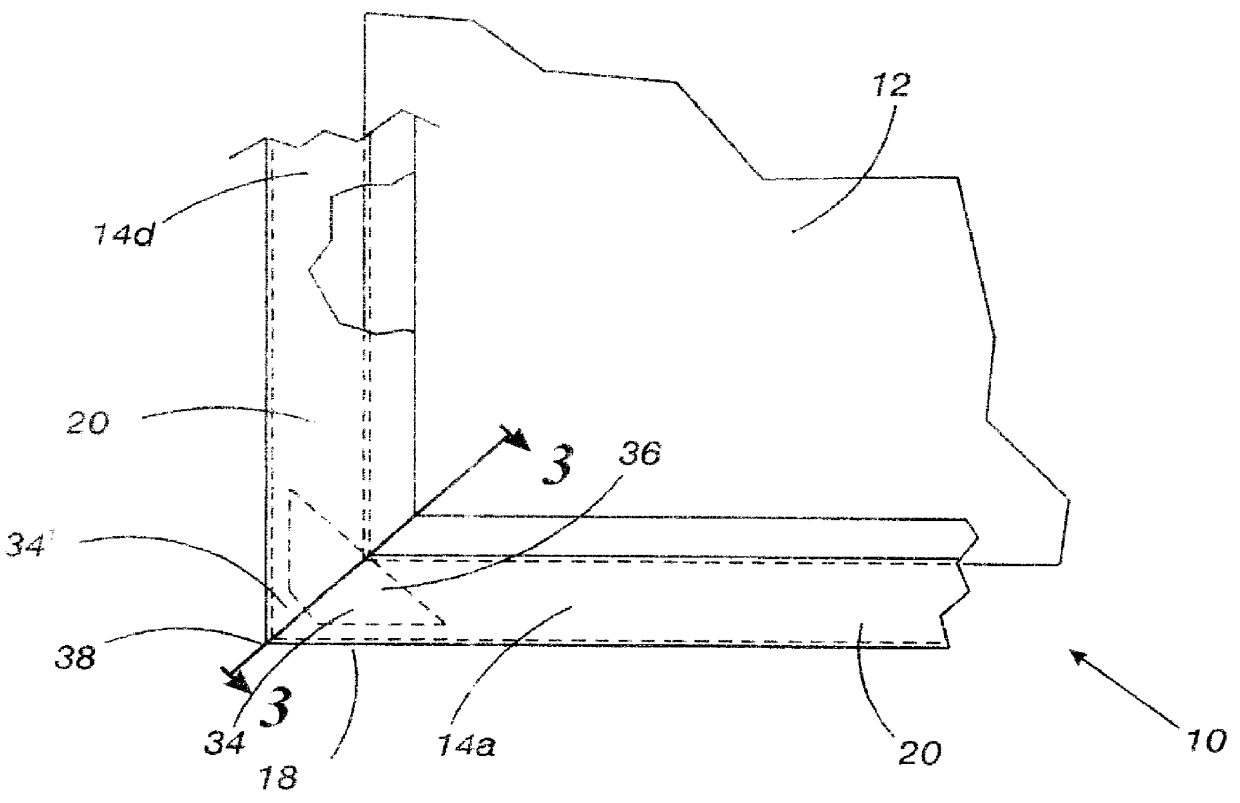

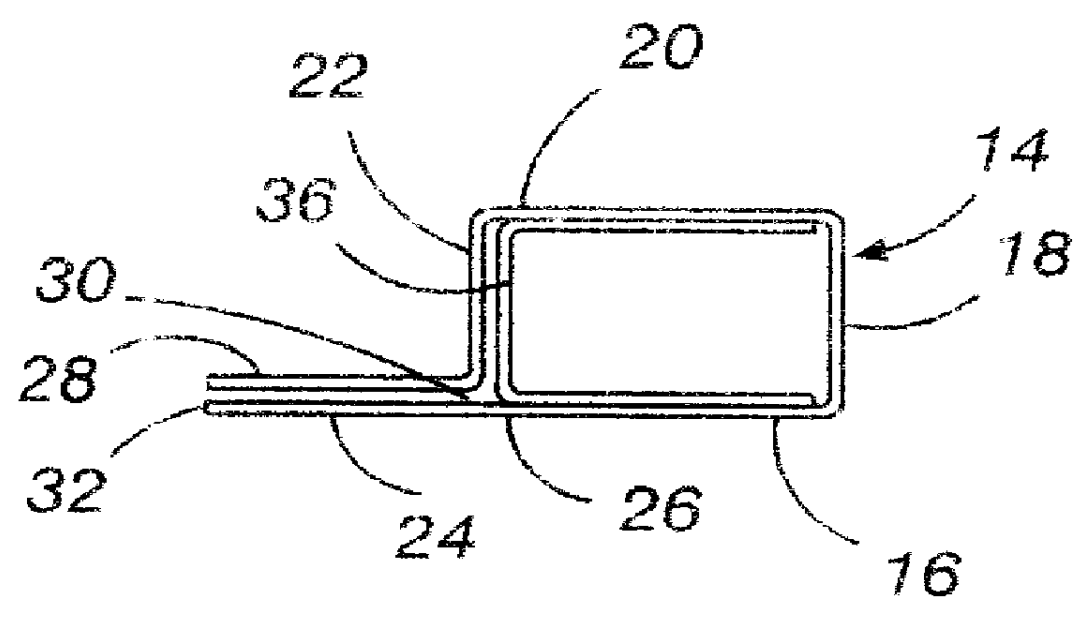

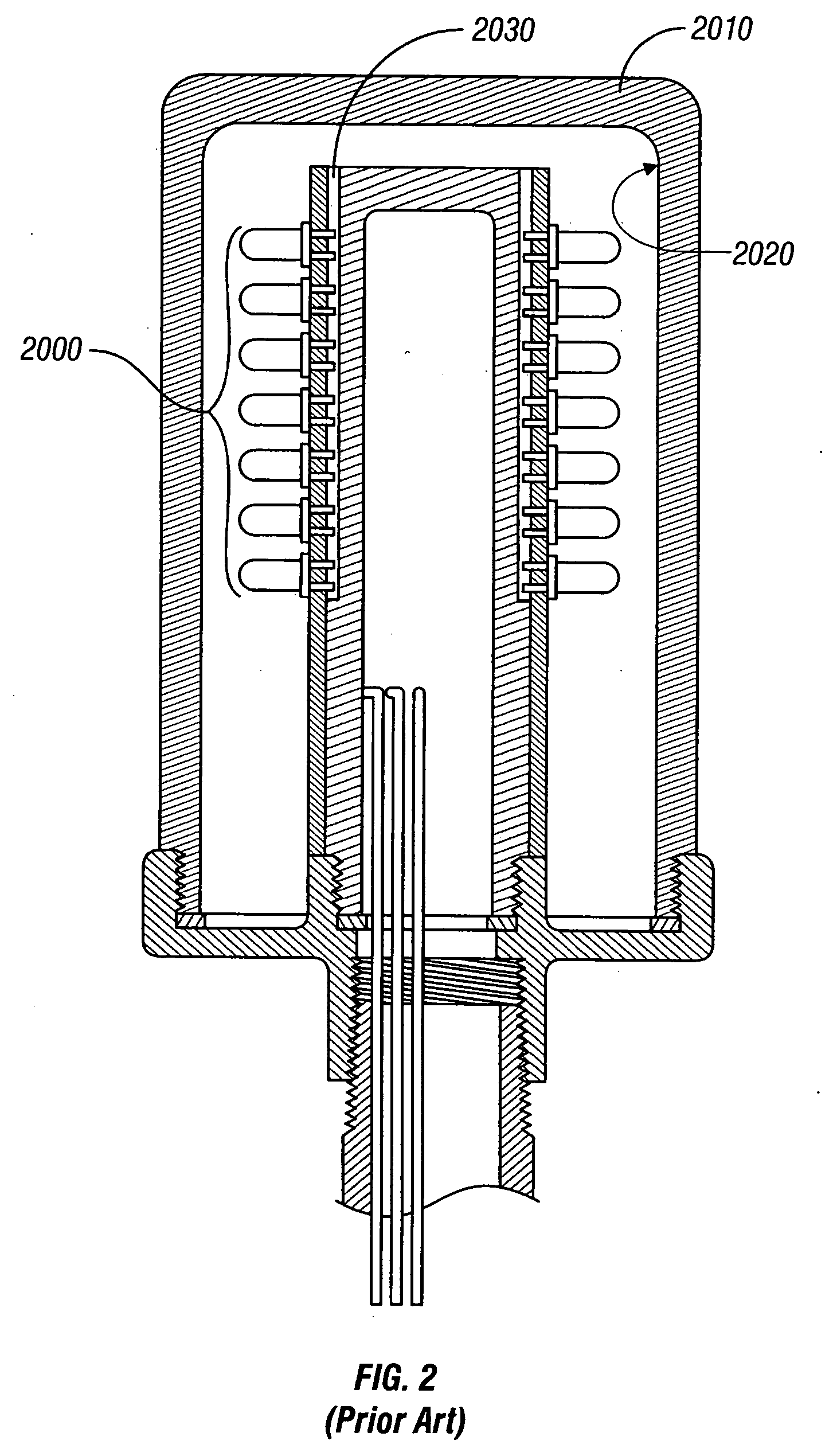

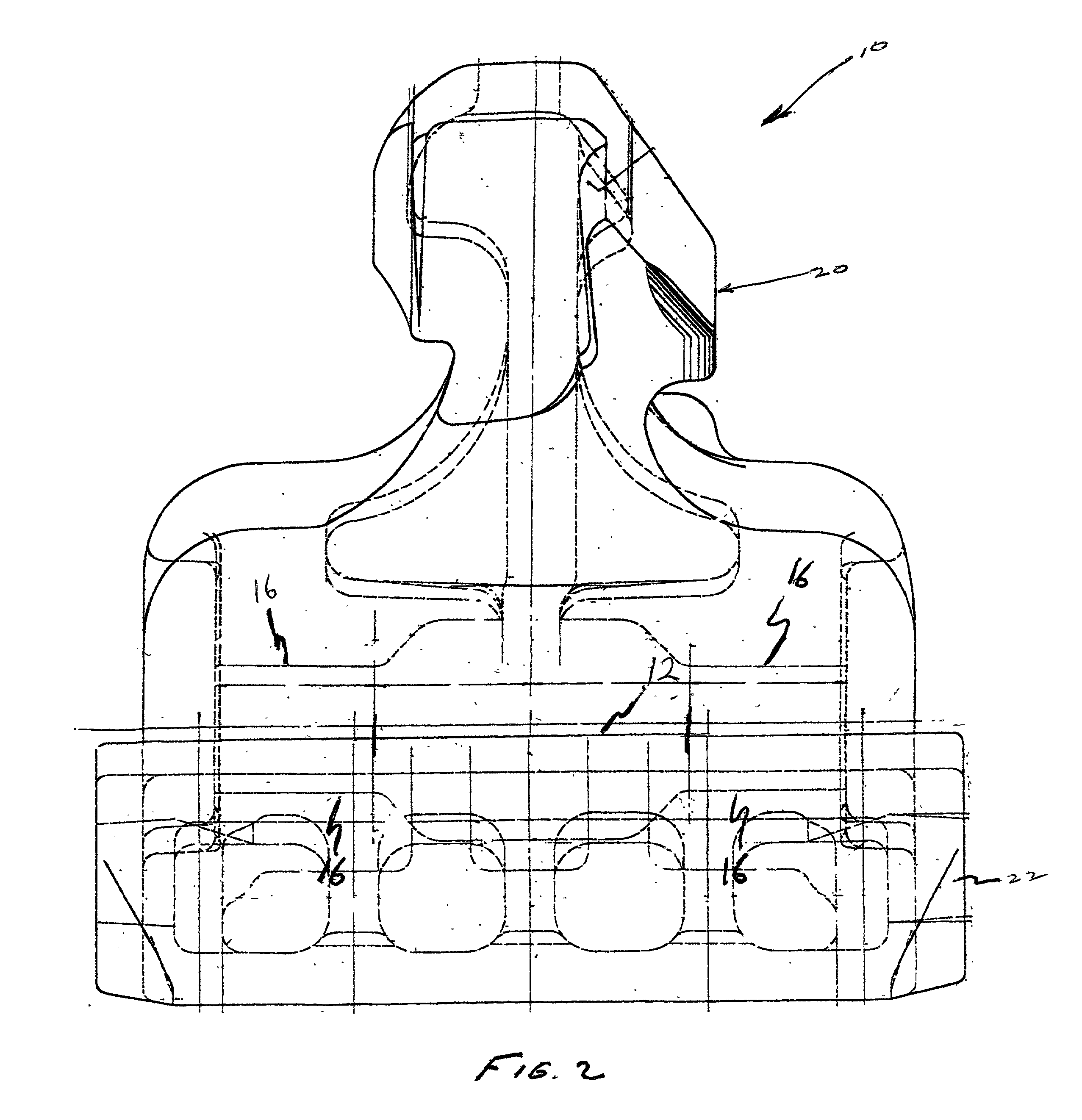

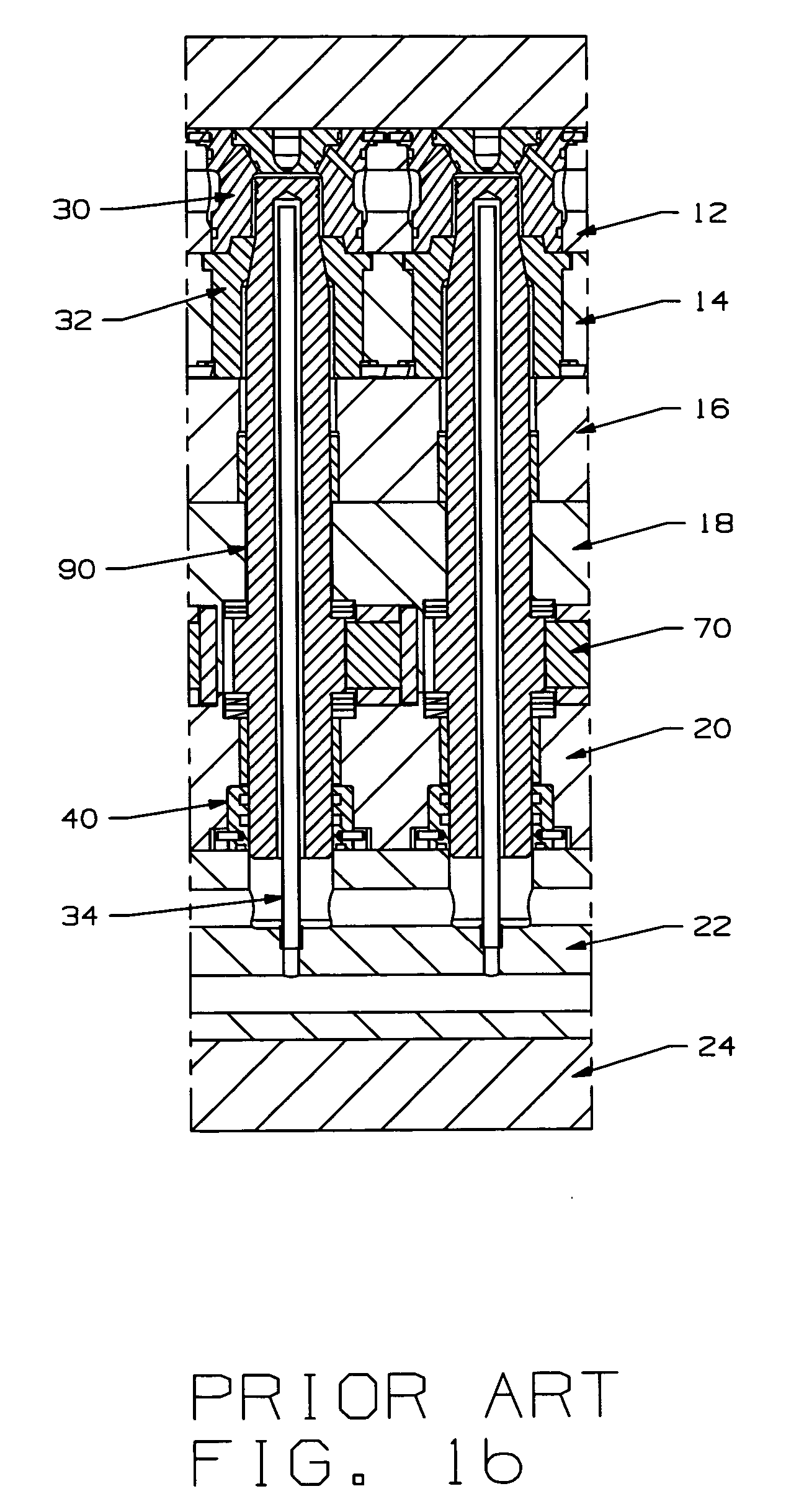

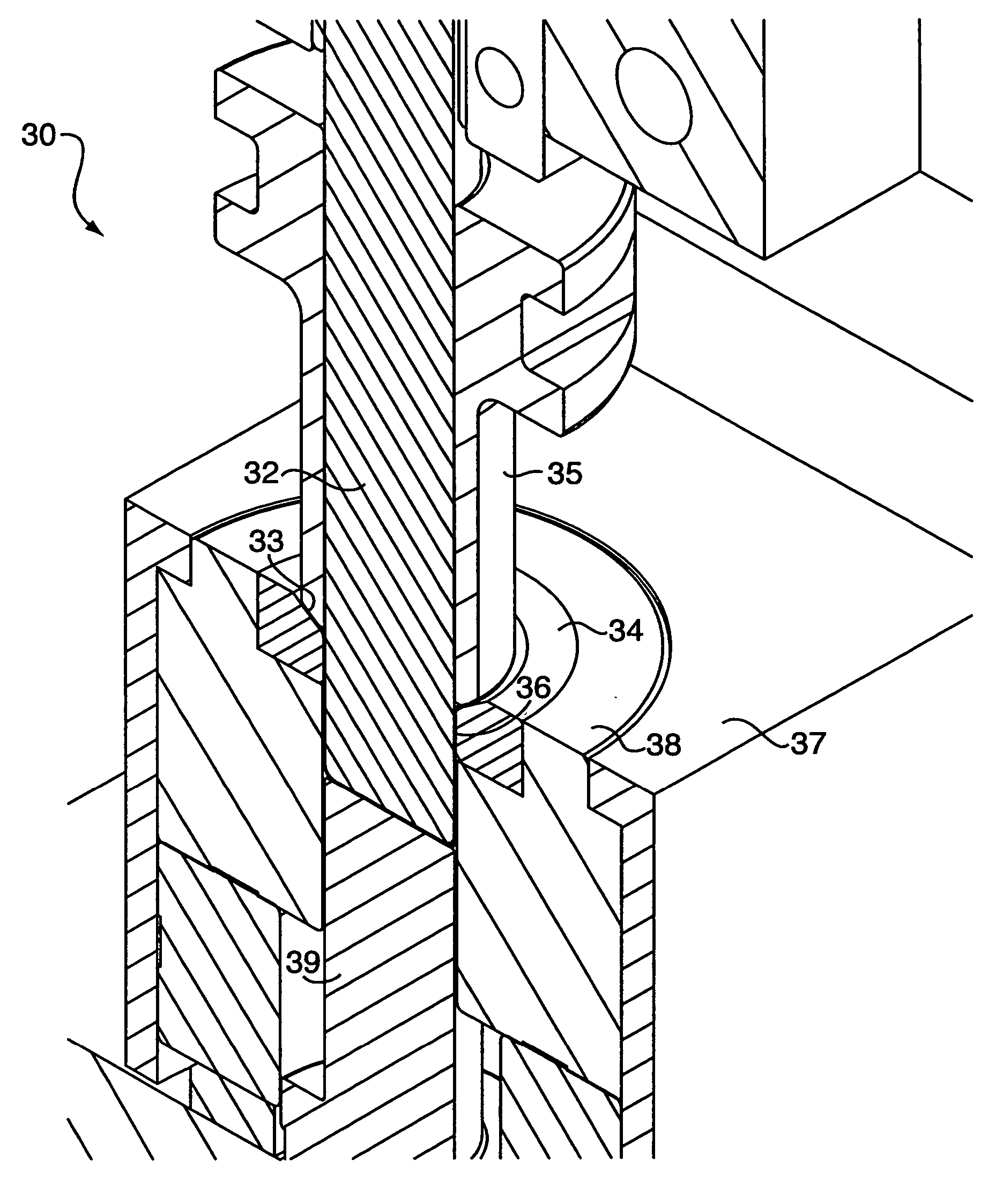

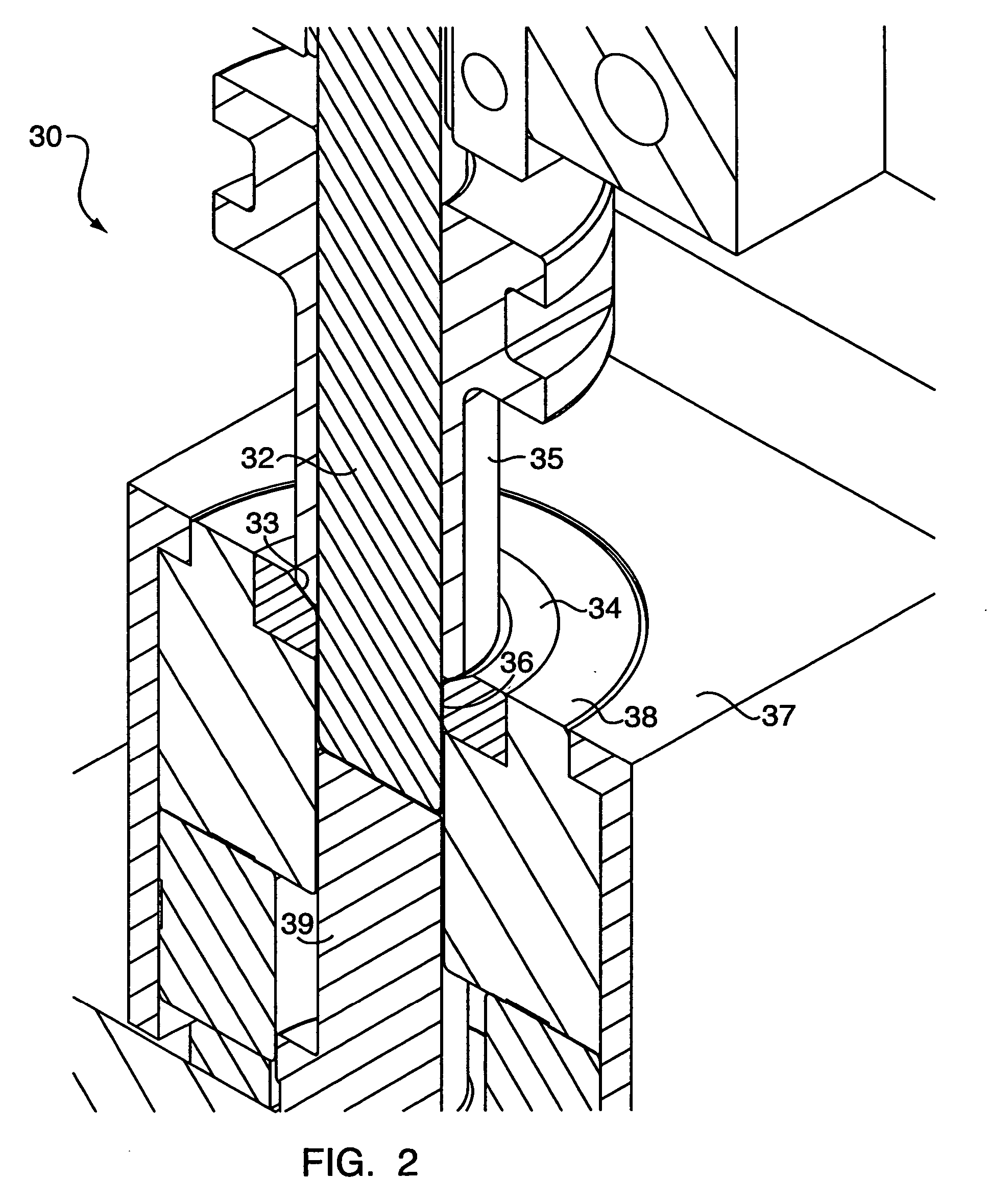

Single body injector and deposition chamber

InactiveUS6200389B1Eliminating complicated machined partMinimizing maintenanceSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringInjector

A deposition chamber for delivering gases to a substrate or wafer for processing of said substrate or wafer is provided. The injector is provided comprising an elongated member with end surfaces and at least one gas delivery surface extending along the length of the member and which includes a number of first elongated passages formed therein for received a gas. Also formed within the member are a number of thin distribution channels which extend between the first elongated passages and the gas delivery surface. In another embodiment, the injector further includes at least one second elongated passage formed therein for receiving an etchant species. Metering tubes may be inserted into each elongated passage and are spaced from the walls of said passages and extend between the ends. The deposition chamber includes at least one injector as described above; a plurality of vent blocks having end surfaces and at least one elongated external surface extending along the length of each of the vent blocks; and a support positioned beneath the injector and vent blocks, creating a deposition region there between. The vent blocks are positioned adjacent one on each side of the injector, and spaced from the injector to define exhaust channels there between for removing the gas.

Owner:SEMICON EQUIP GROUP

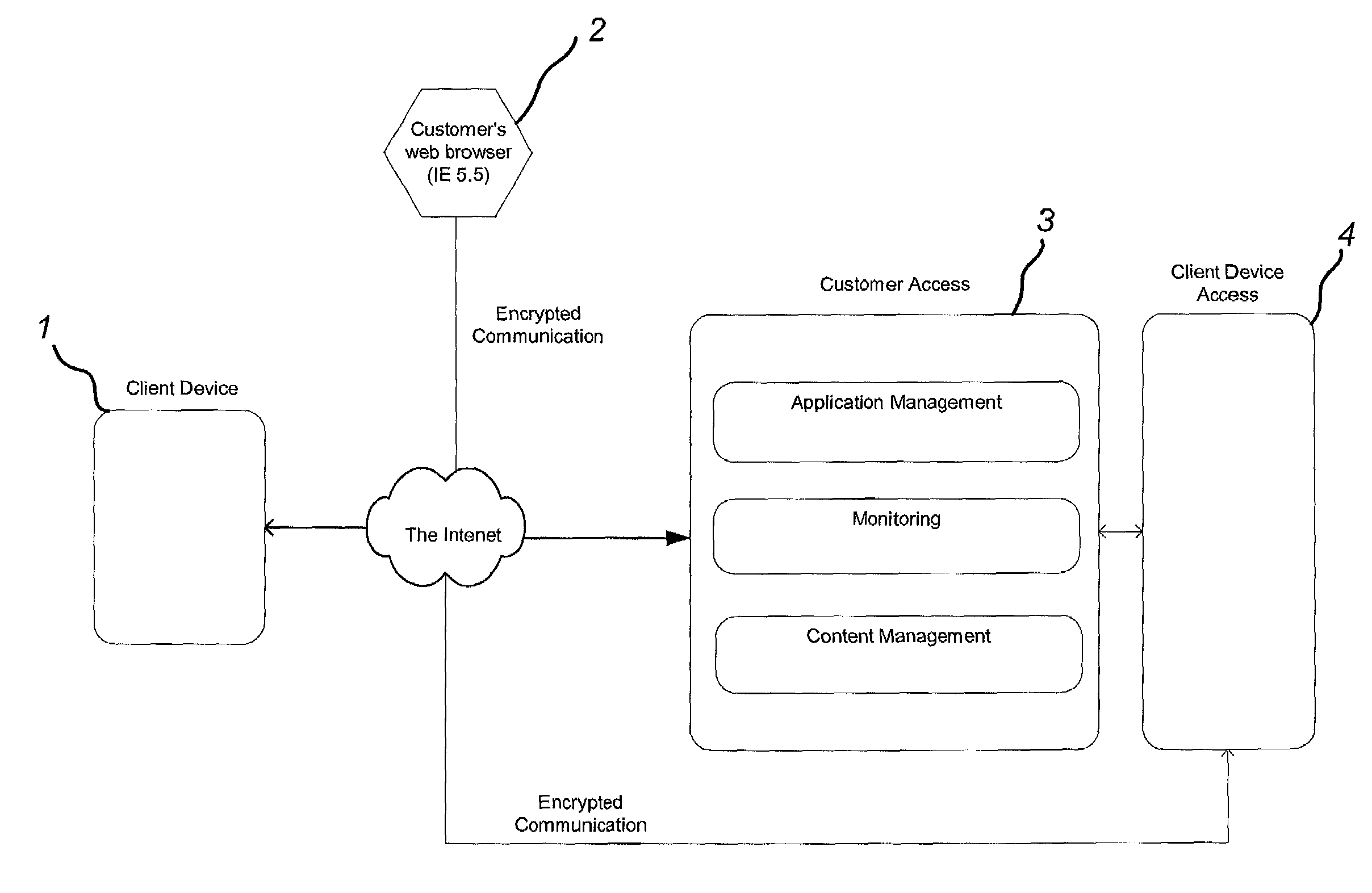

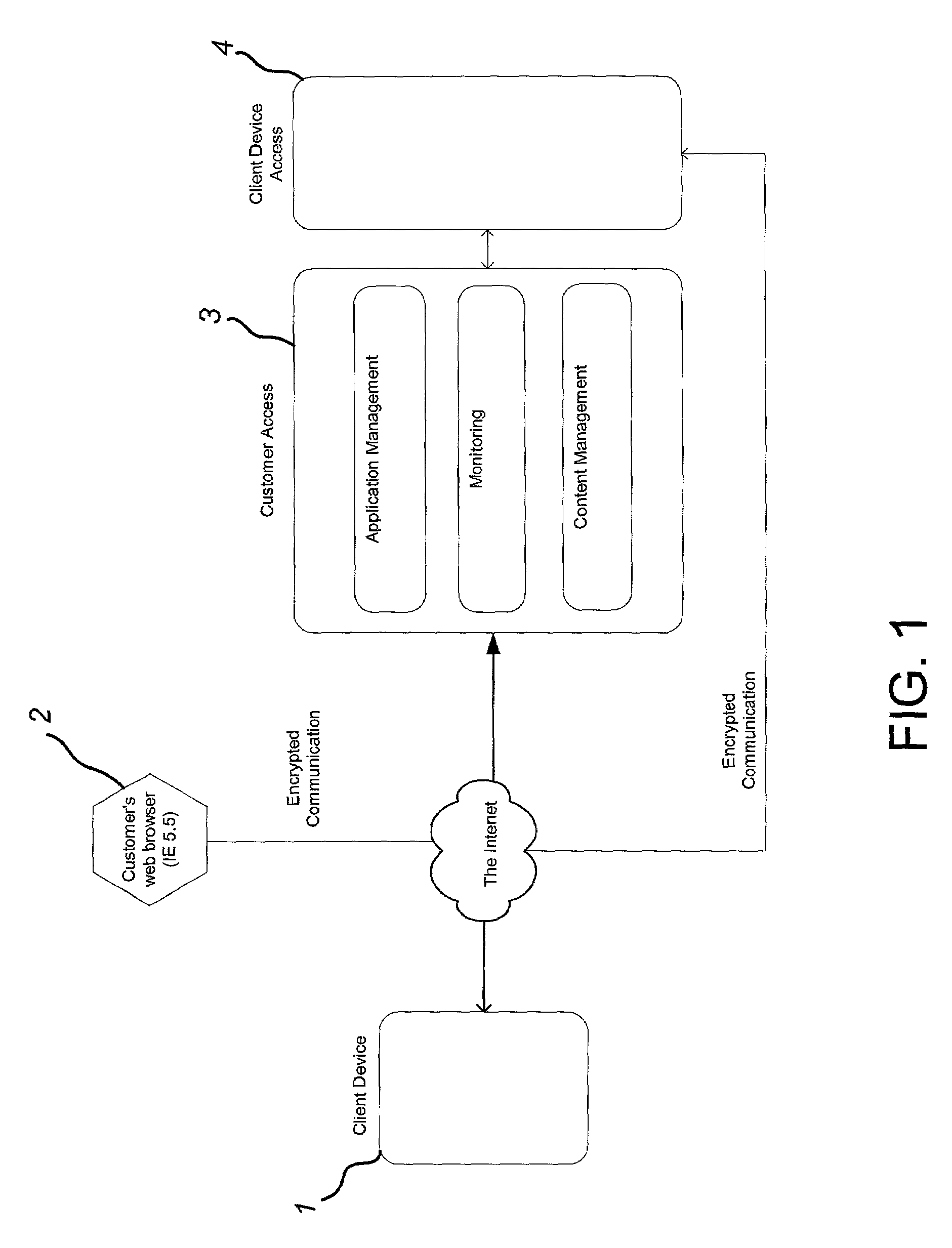

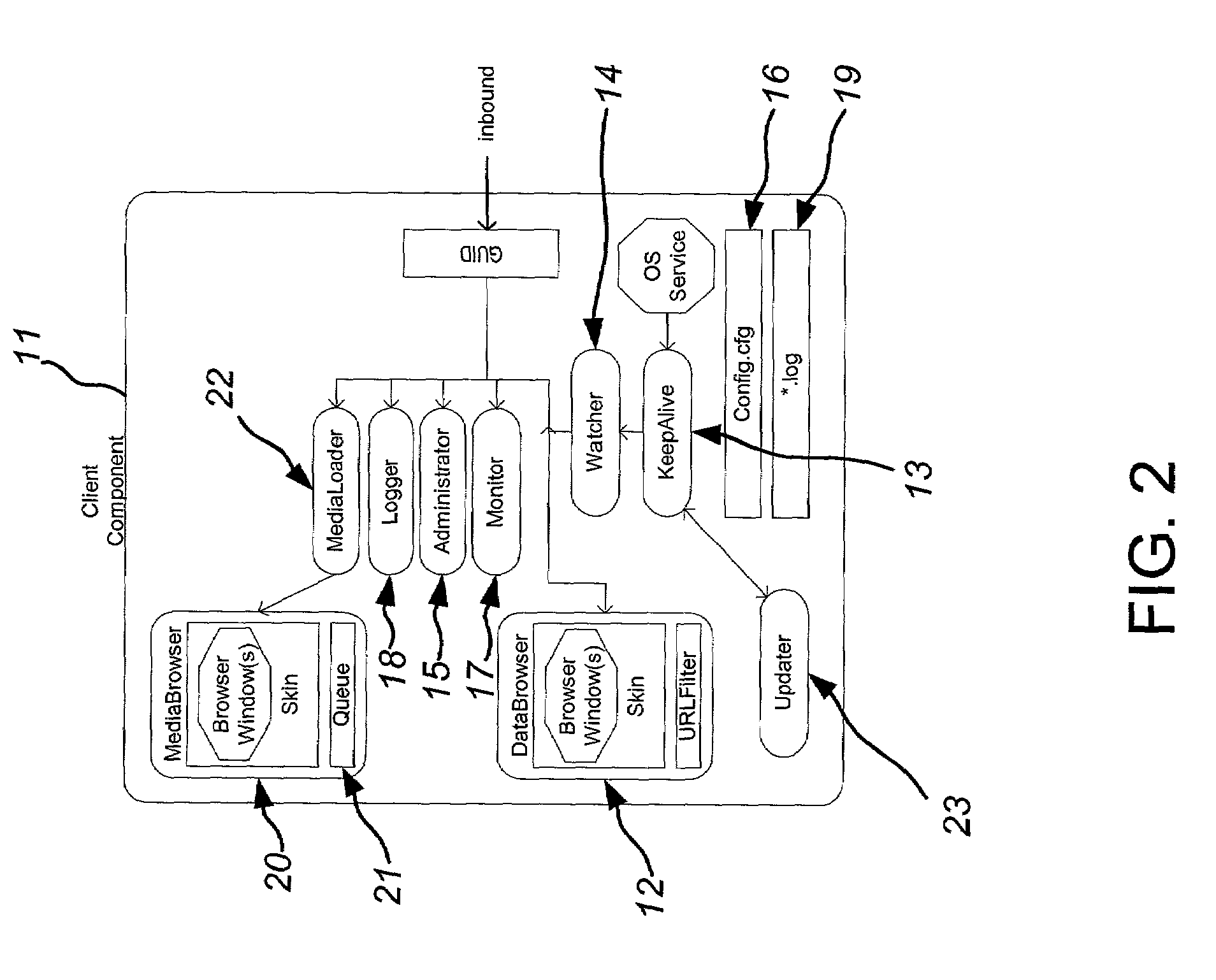

System and method for providing fault-tolerant remote controlled computing devices

InactiveUS7308487B1Minimize maintenanceMaximum reliabilityFinanceMultiple digital computer combinationsComputer hardwareOperational system

A system and method for providing a fault-tolerant remote controlled computing device. A multi-tasking operating system and at least one primary process are executed on the computing device. A first monitor process determines whether any primary process is in a fault state. In response to any primary process being in a fault state, the first monitor process resolves the fault state of each such primary process. In certain embodiments, a local copy of a common configuration file and multimedia content are stored on the computing device. The computing device polls a server at pre-determined time intervals via a public Internet connection for updates to one or more processes, the local copy of the common configuration file, and the multimedia content. In response to updates being available from the server, the computing device downloads one or more updates via a fault-tolerant network connection and plays the multimedia content based on instructions contained within the local copy of the central configuration file. In one configuration, a user-defined notification system is provided which allows users to define threshold values. Once the threshold values are satisfied, one or more users may be notified.

Owner:CDN INNOVATIONS LLC

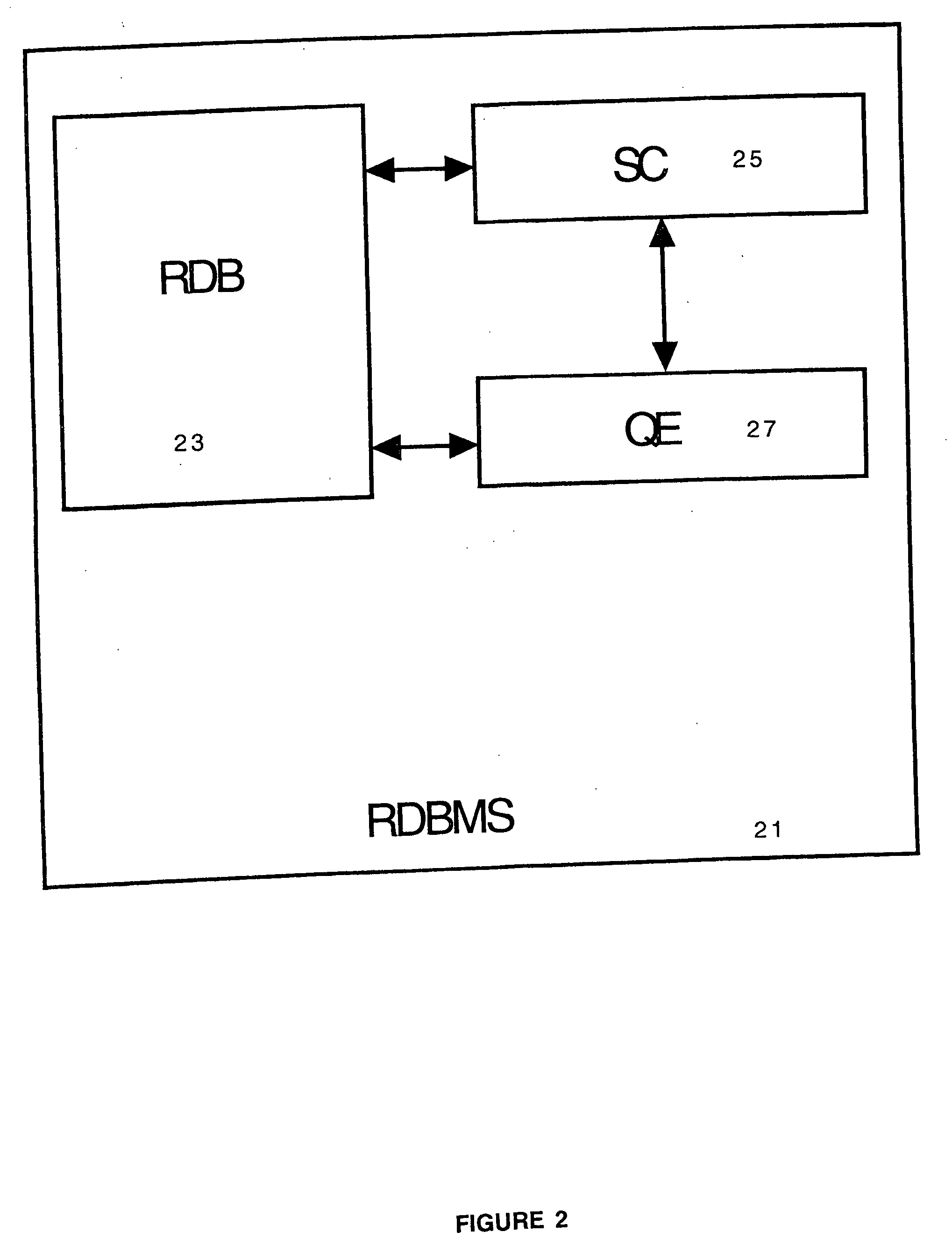

Computer-implemented method for managing through symbolic abstraction of a membership expression multiple logical representations and storage structures

InactiveUS20080010241A1Maximum flexibilityImprove performanceRelational databasesSpecial data processing applicationsLogical representationData independence

This is a computer-implemented method for managing and enhancing data independence among multiple logical representations and storage structures of data by accessing and updating physical storage through a relational representation. The present invention supports both data independence and storage flexibility by using membership abstraction as the equalizing access for any logical representation and actual storage, while the prior art is restricted to user-supplied denotations and catalog entries.

Owner:MCGOVERAN DAVID O

Apparatus and Method for Sanitizing Feet and the External Surfaces of Footwear

InactiveUS20100193709A1Low costLow penetration abilityRadiation pyrometryLight therapyHuman bodyEngineering

A disinfecting device for objects such as shoes or human body parts such as feet. The device employs light radiating from a cavity below a transparent platform, to contact and disinfect surfaces on objects placed on a top surface of the platform. The spectral range of the light is adapted to disinfect the surface with Ultra Violet light being a preferred spectral range. An upper housing may be provided above the platform to protect the user's eyes from UV radiation which is substantially indiscernible to the human eye and as a housing for a reflective means to reflect disinfecting light communicating through the transparent platform, back toward the top surfaces of the object on the platform. A signal component for user safety such as a visible light emitter, an audible alarm, or vibration of the platform may be employed to provide the user a means to ascertain emanating UV light during operation of the device.

Owner:DALTON LINDA M

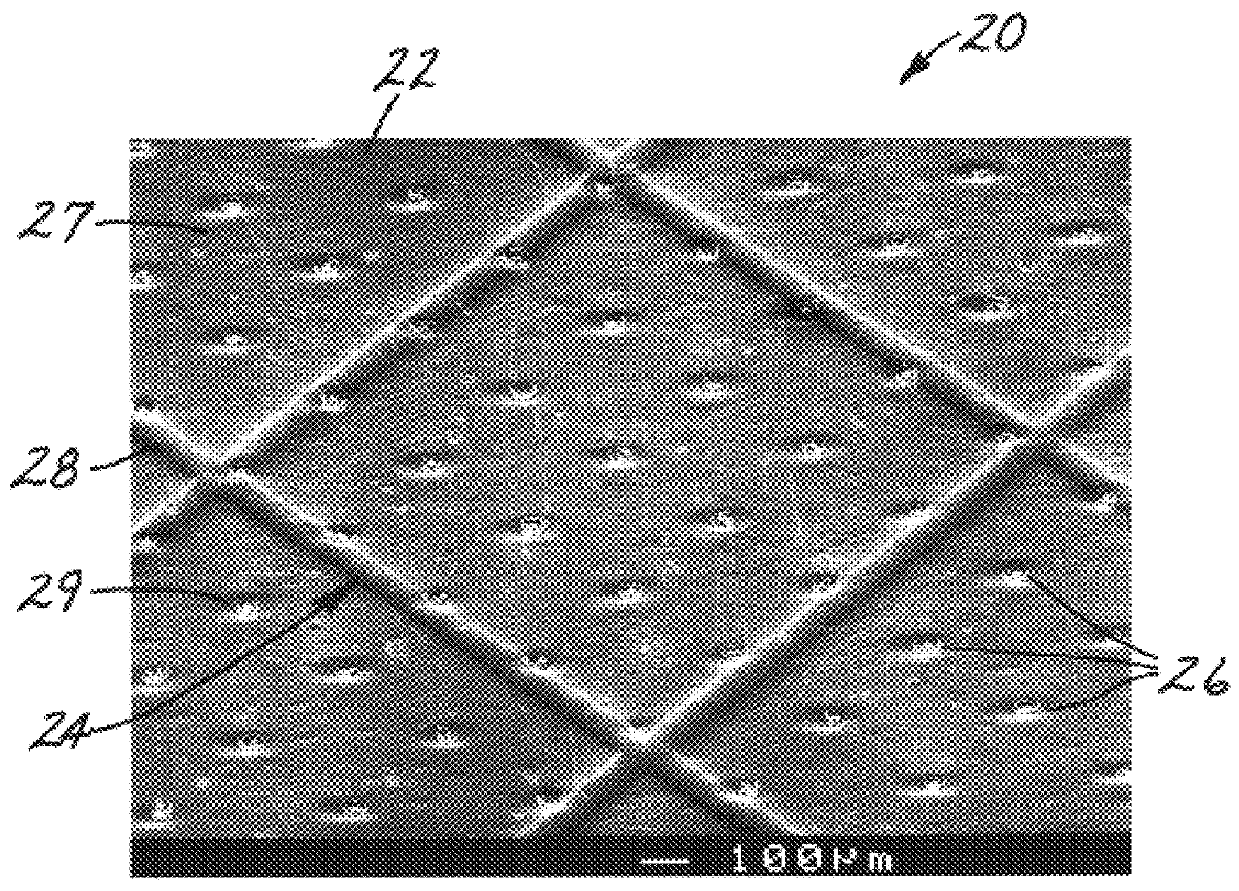

Cling films having a microreplicated topography and methods of making and using same

InactiveUS6203885B1Easy to disassembleChange surface propertiesAdditive manufacturing apparatusLayered productsTopographyElectrical and Electronics engineering

Films having a microreplicated topography are prepared from contacting a microembossed pattern to a layer of film. When an adhesion interface is established between the layer of film and a supporting substrate, the topography of the film surface controls the performance of the adhesion interface. Articles having microreplicated film surfaces are also disclosed that have an advantage of providing microchannels for fluid egress for an effective period of time. Multiple microembossed patterns produce microreplicated film surfaces having both microchannels for fluid egress and pegs for improved film properties.

Owner:3M INNOVATIVE PROPERTIES CO

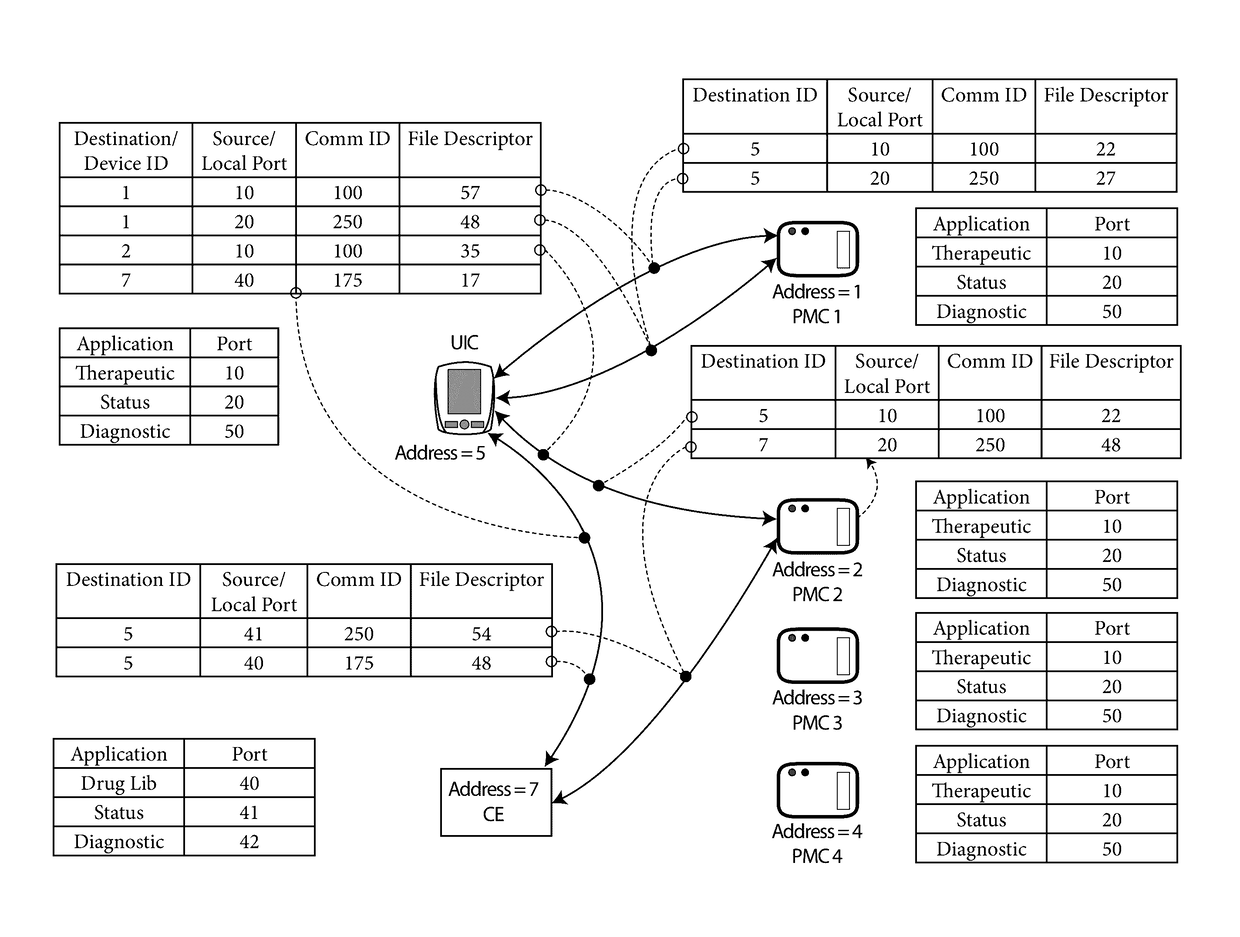

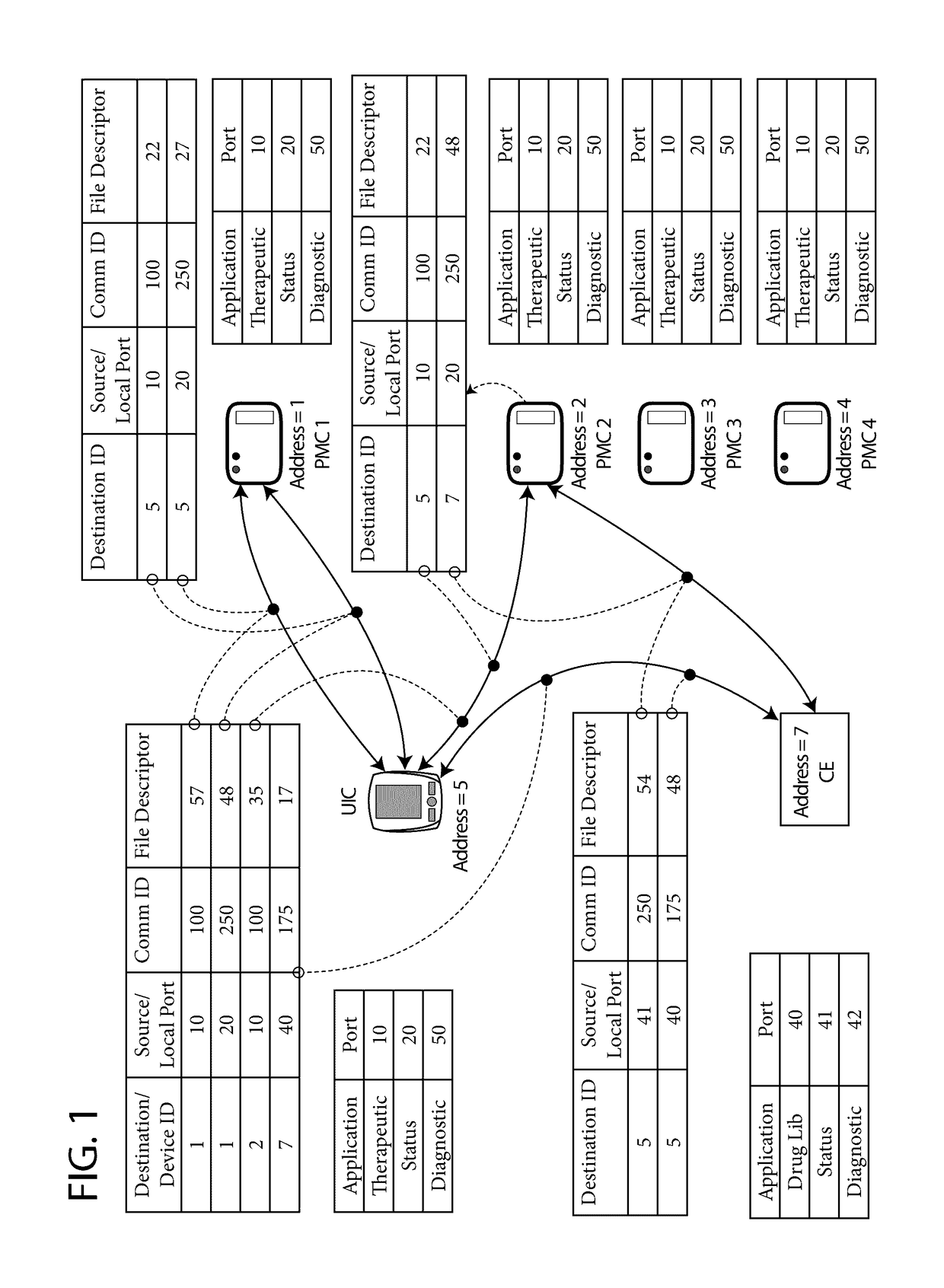

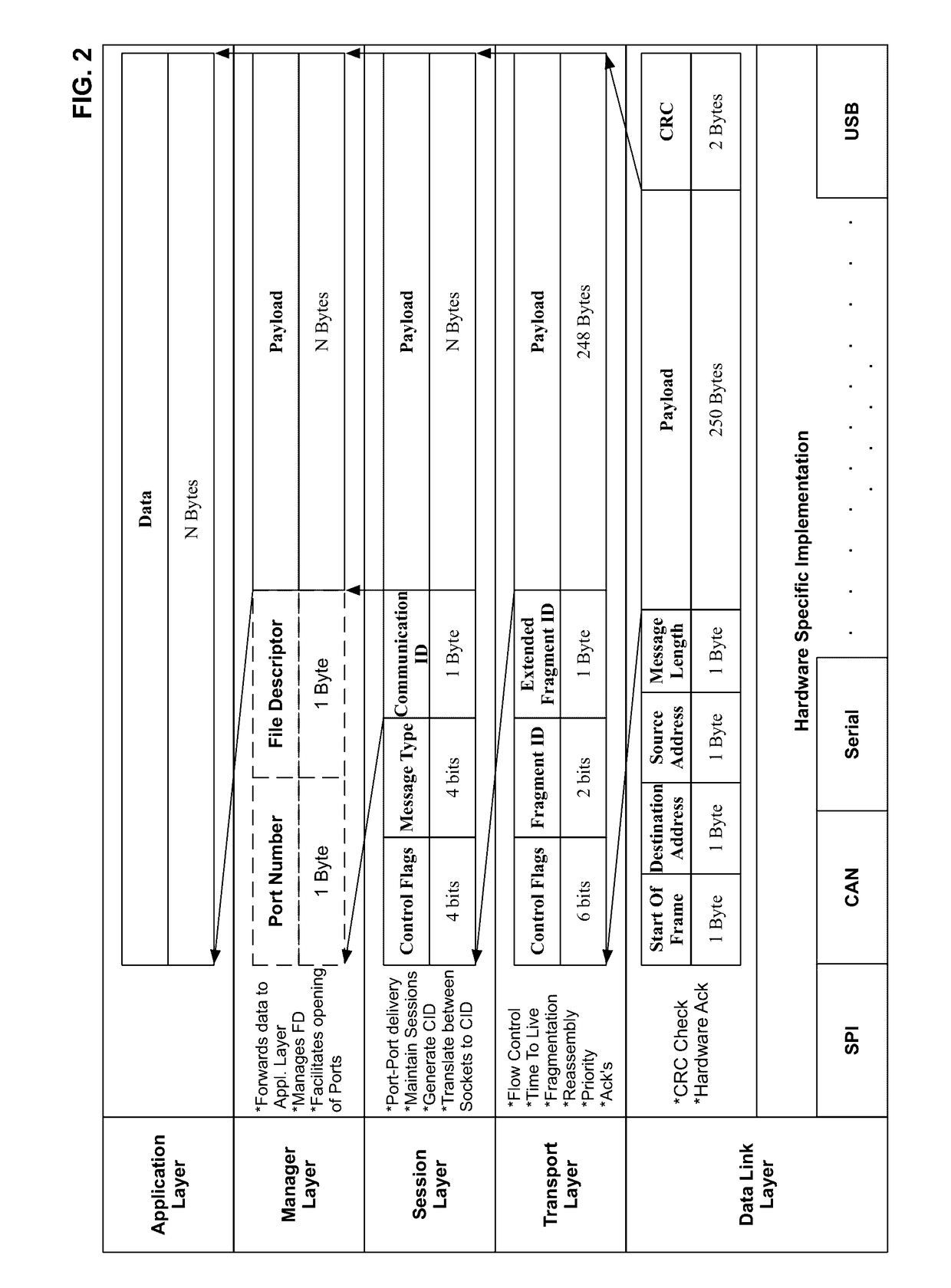

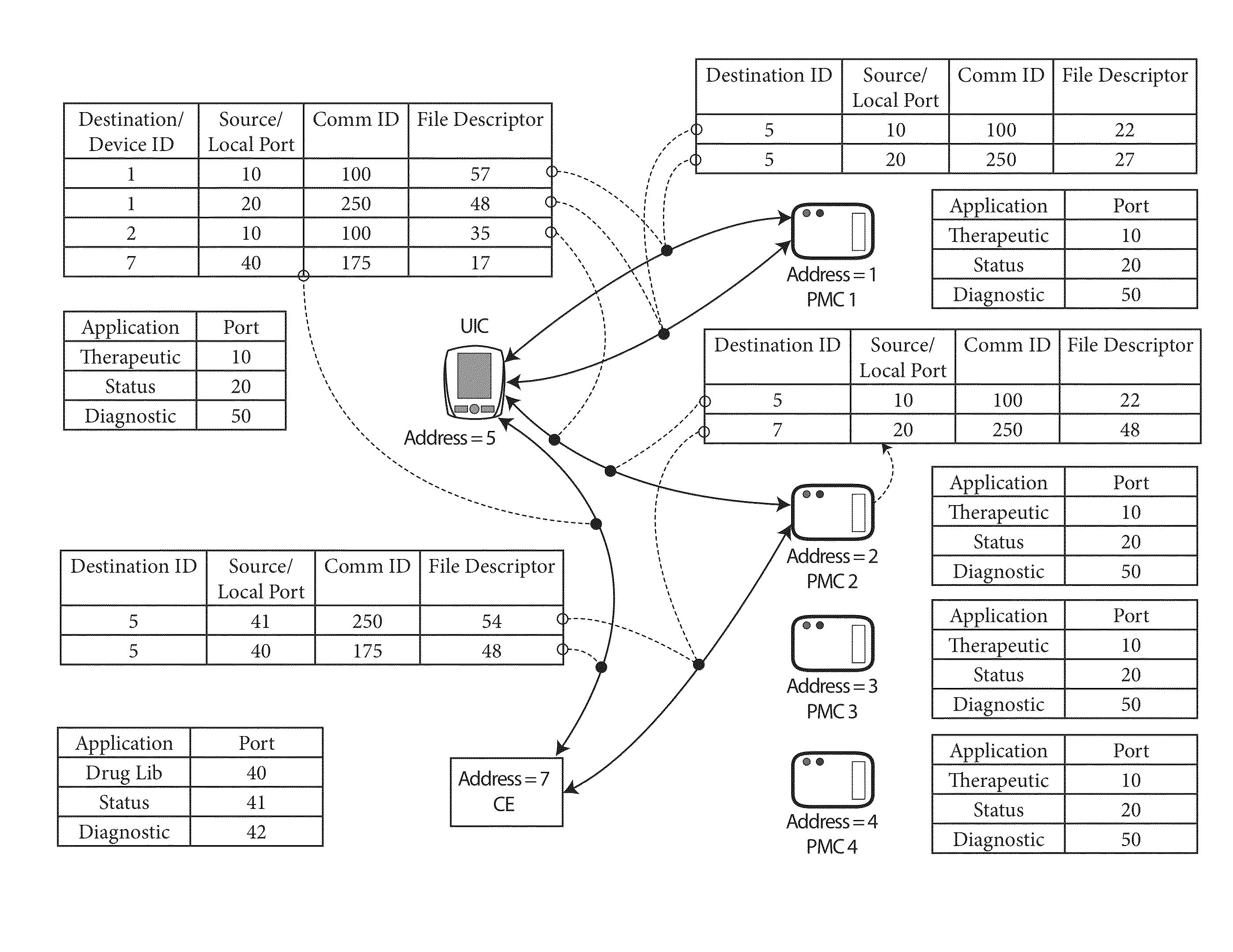

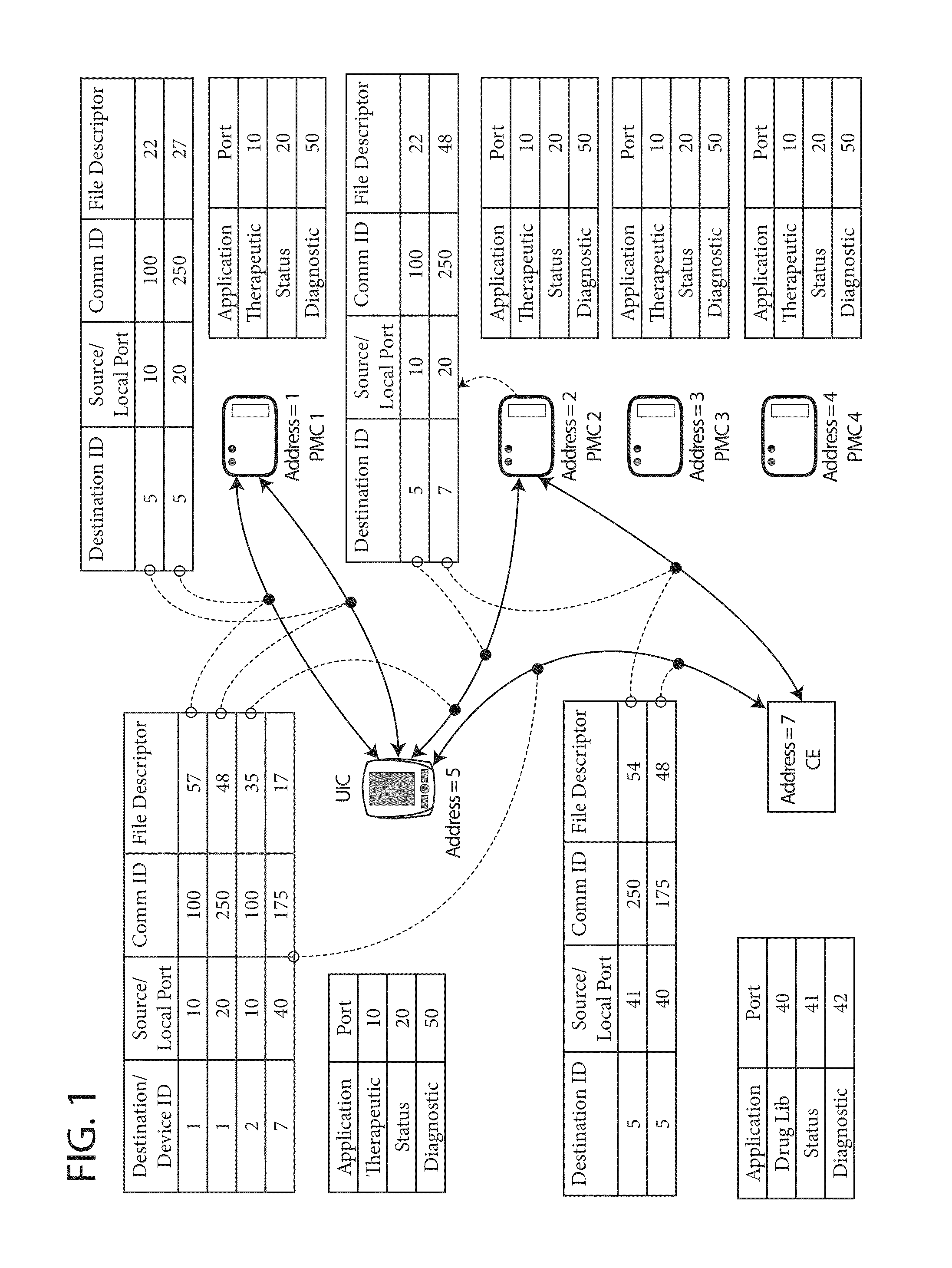

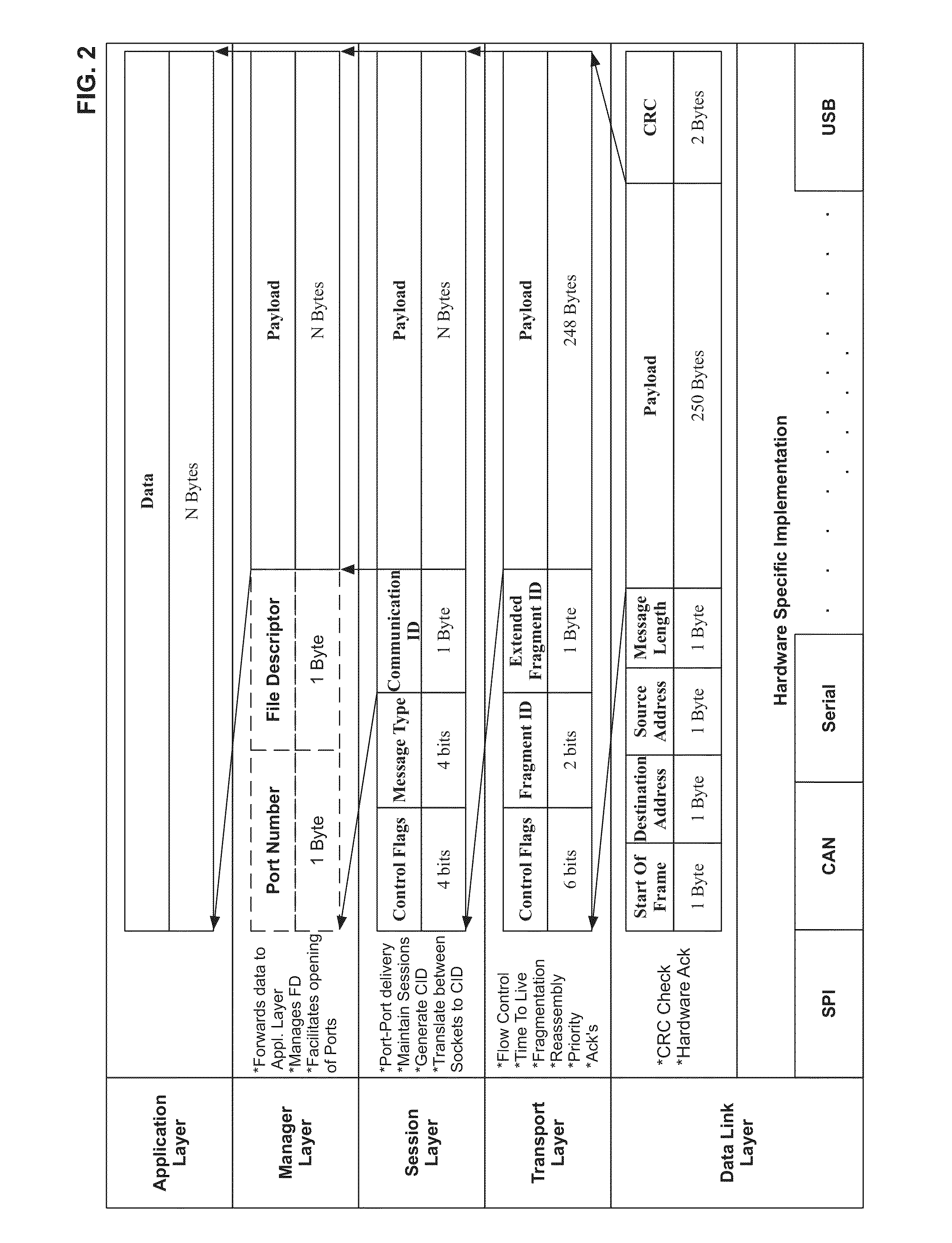

Medical device communication method

ActiveUS9641432B2Minimize maintenanceMinimization requirementsDrug and medicationsTelemedicineData exchangeBroadcasting

Owner:ICU MEDICAL INC

Medical device communication method

ActiveUS20140254598A1Minimize maintenanceMinimization requirementsDrug and medicationsData switching by path configurationData exchangeBroadcasting

A medical device communication method that may be implemented within a variety of medical devices including but not limited to infusion pumps. The method may be implemented with a protocol stack for at least intra-device communication. Embodiments provide connection-oriented, connectionless-oriented, broadcast and multicast data exchange with priority handling of data, fragmentation, and reassembly of data, unique static and dynamic address assignment and hot swap capability for connected peripherals or subsystems.

Owner:ICU MEDICAL INC

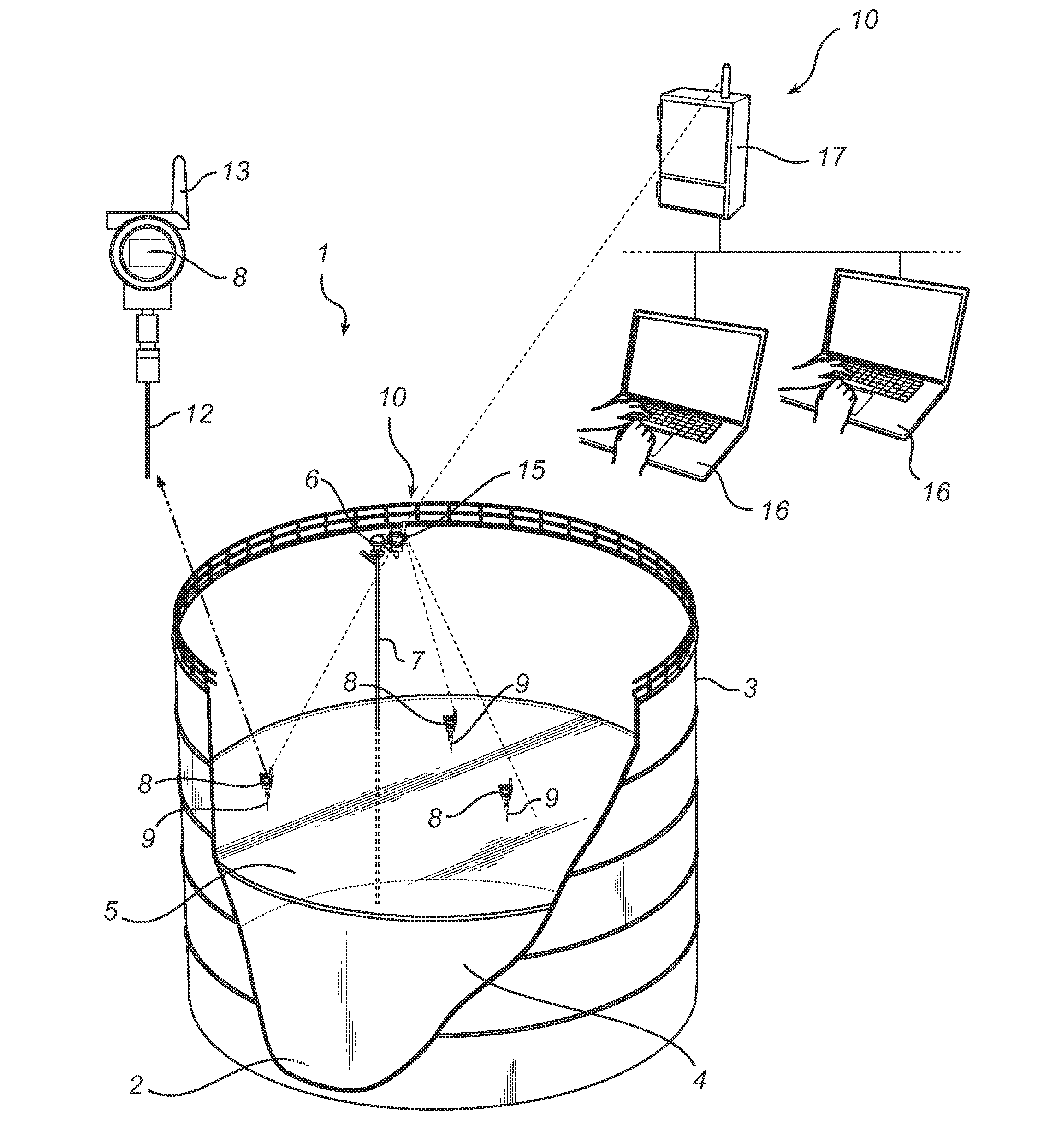

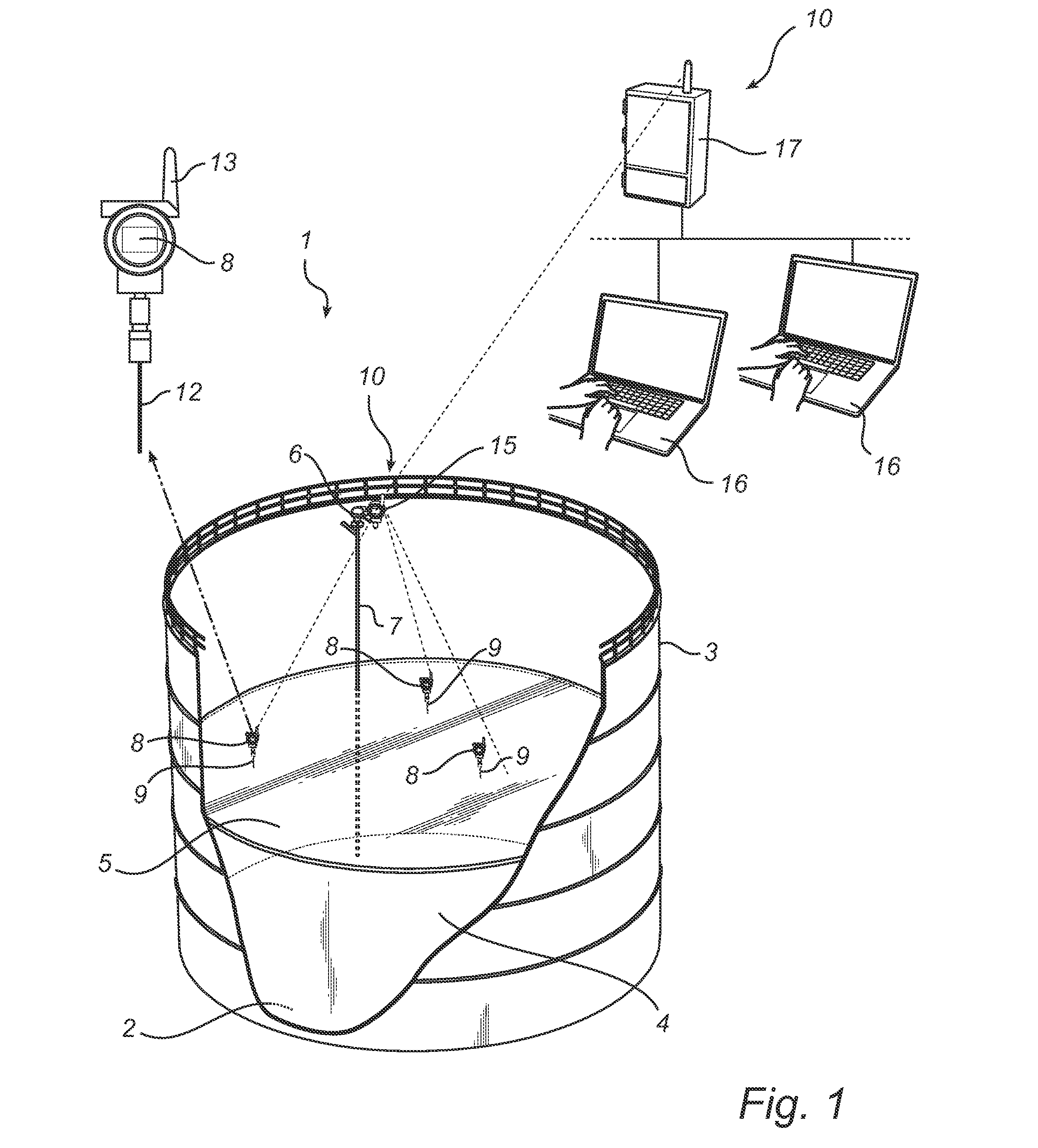

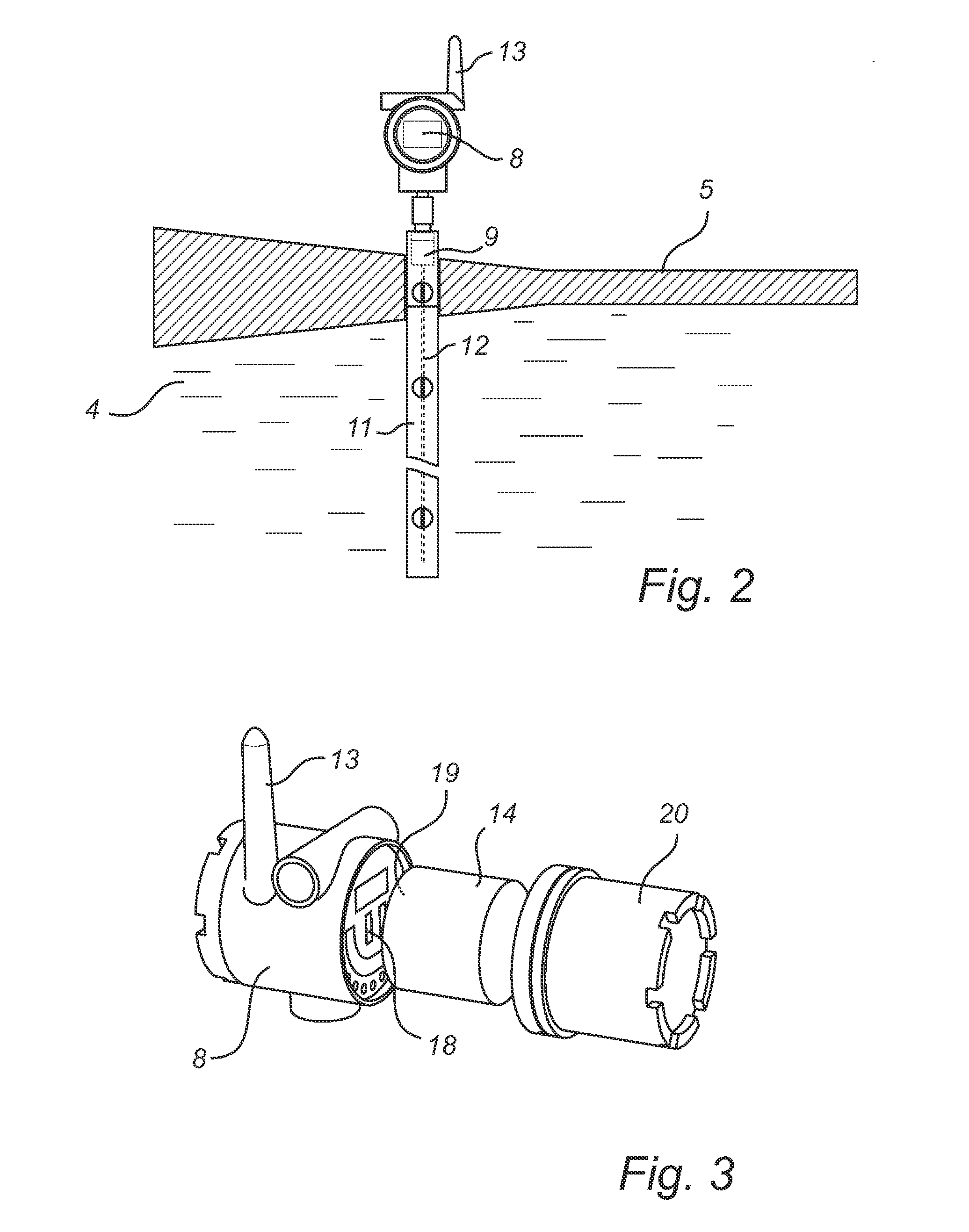

Monitoring of floating roof tank

ActiveUS20130120155A1Life maximizationMinimize maintenanceElectric signal transmission systemsSub-station arrangementsIntrinsic safetyTelecommunications

System for monitoring a floating roof of a tank containing a liquid, wherein the system determines a local status of the floating roof in spaced apart sensing element locations. In a hazardous or potentially hazardous environment, there is an on-roof subsystem including a sensing element in each sensing element location, intrinsically safe measuring circuitry coupled a sensing elements and arranged for determining said local status, intrinsically safe radio communication on-roof circuitry coupled for communicating externally of the on-roof subsystem the local, an intrinsically safe power supply circuitry connected to an intrinsically safe and interchangeable energy storage unit for powering the on-roof subsystem. The system further includes monitoring circuitry for receiving the indication of local status and for determining an overall monitored status of said floating and further radio communication circuitry. The on-roof subsystem is wireless in its power supply and communication.

Owner:ROSEMOUNT TANK RADAR

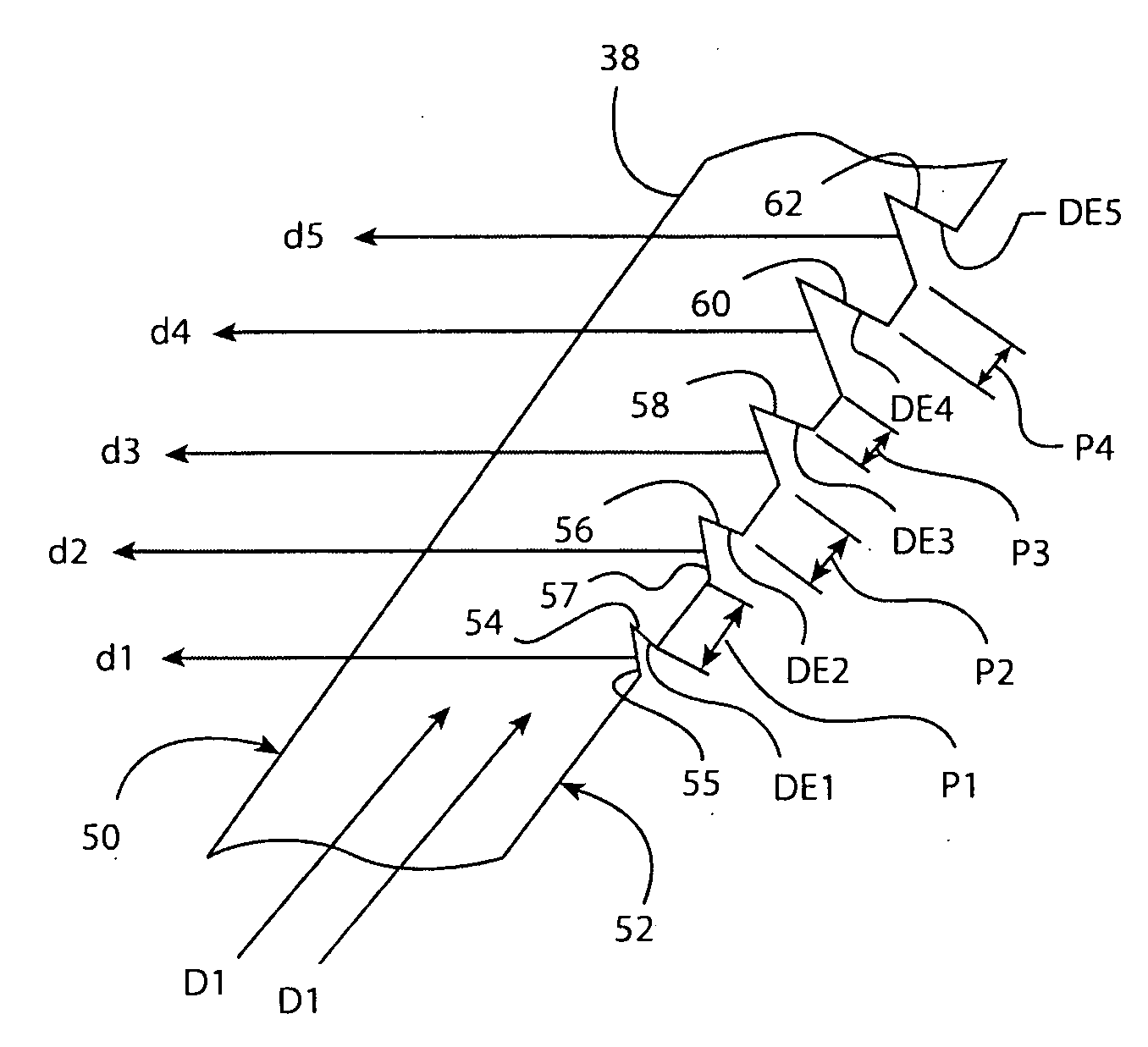

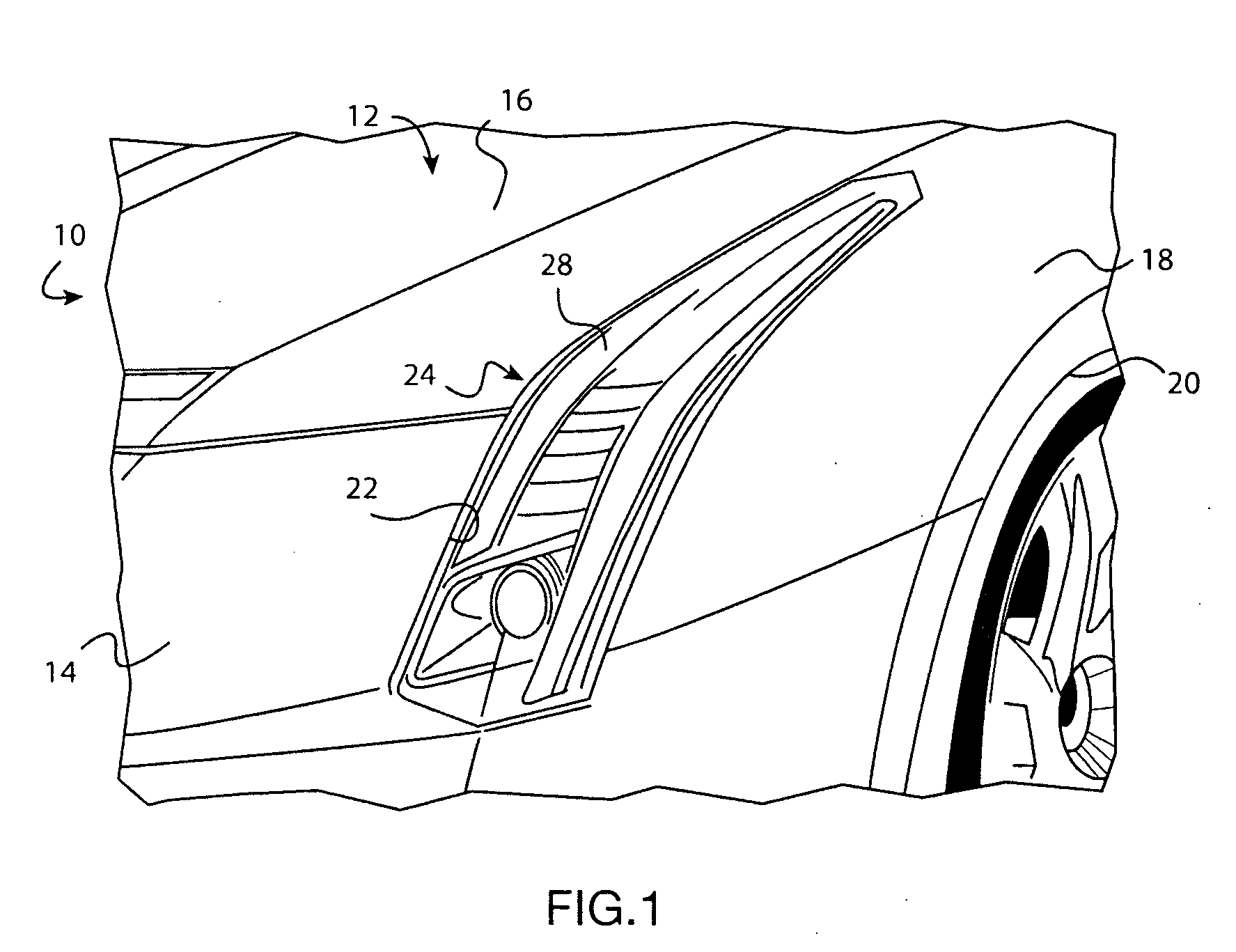

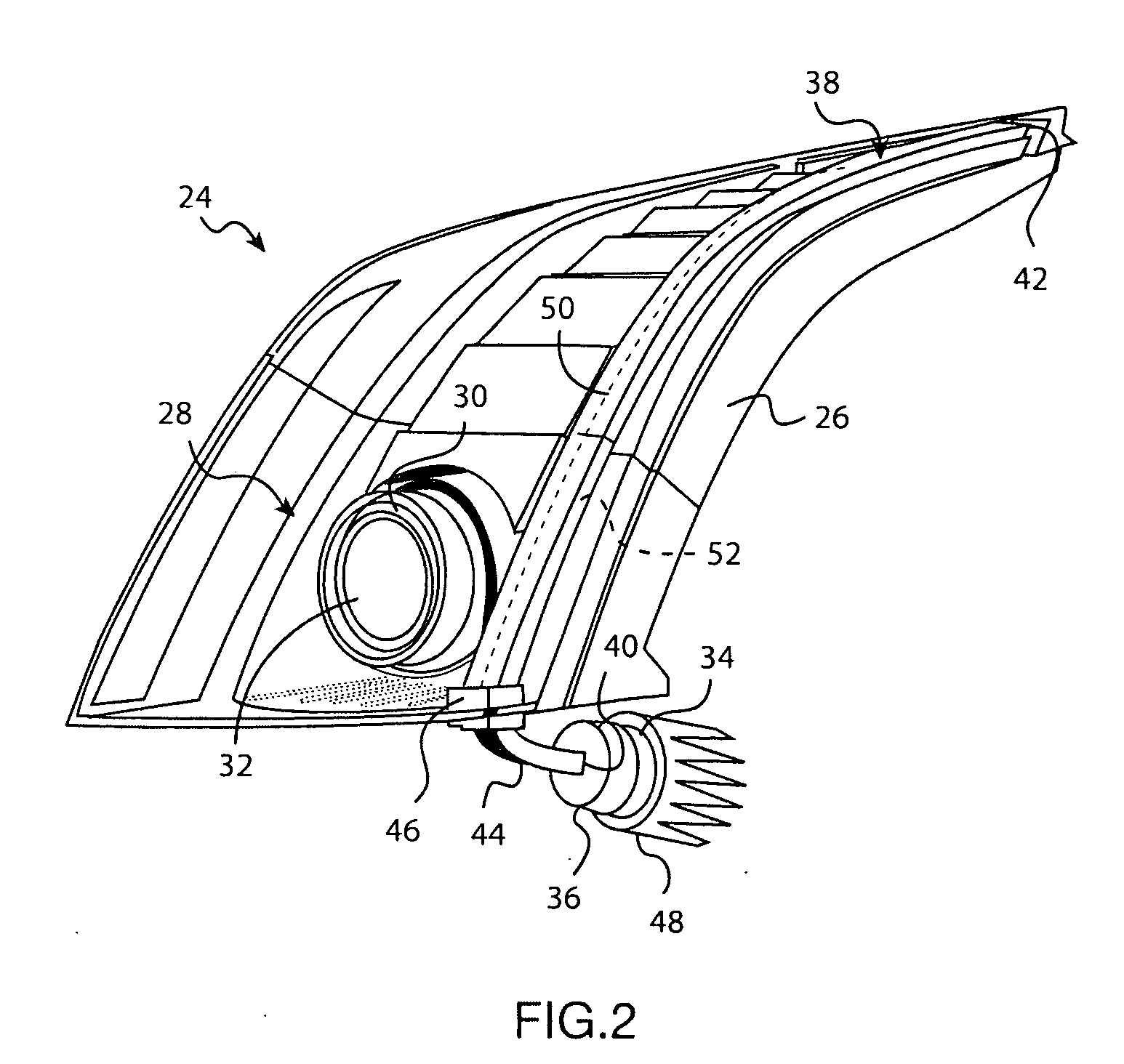

Light guide for vehicle lamp assembly

InactiveUS20100202153A1Reduce brightnessMore dispersedPoint-like light sourceLighting support devicesLight guideEngineering

A light guide and various vehicular lamp assemblies using the same are presented herein. In one embodiment, the lamp assembly includes a light source, such as an LED module. A light coupler is operable to receive light from the light source, and distribute the light in a first direction. The light guide includes an elongated, curvilinear body with first and second longitudinal end faces, and opposing light-emitting and light-guiding surfaces extending between the two end faces on a respective side of the body. The first end face communicates with the light coupler to receive light therefrom. The light guide body transmits light generated by the light source along the longitudinal expanse thereof. The light-guiding surface includes an array of longitudinally-spaced optical grooves configured to refract light generated by the light source in a second direction. The depth of preselected optical grooves is varied along the length of the light guide.

Owner:GM GLOBAL TECH OPERATIONS LLC

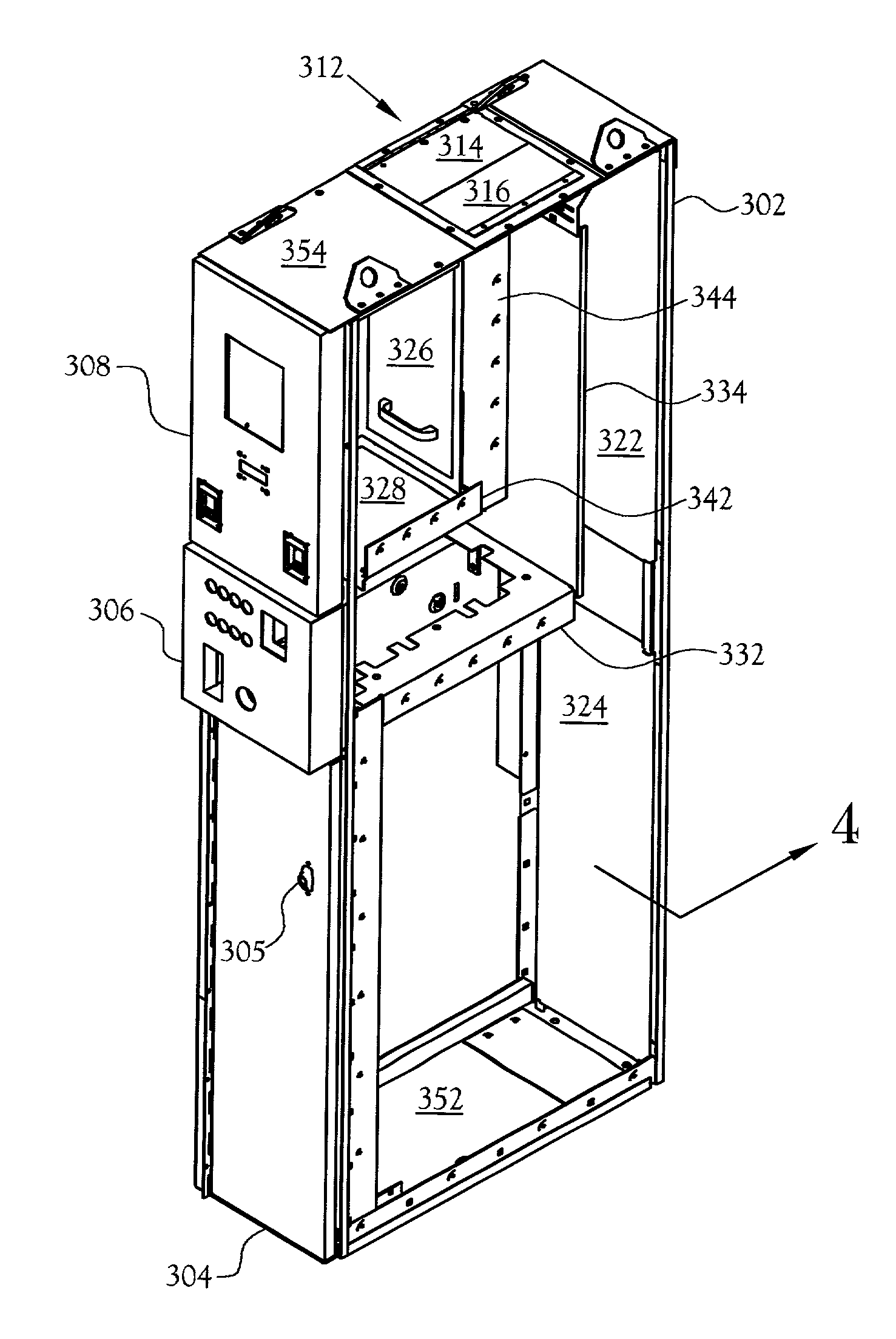

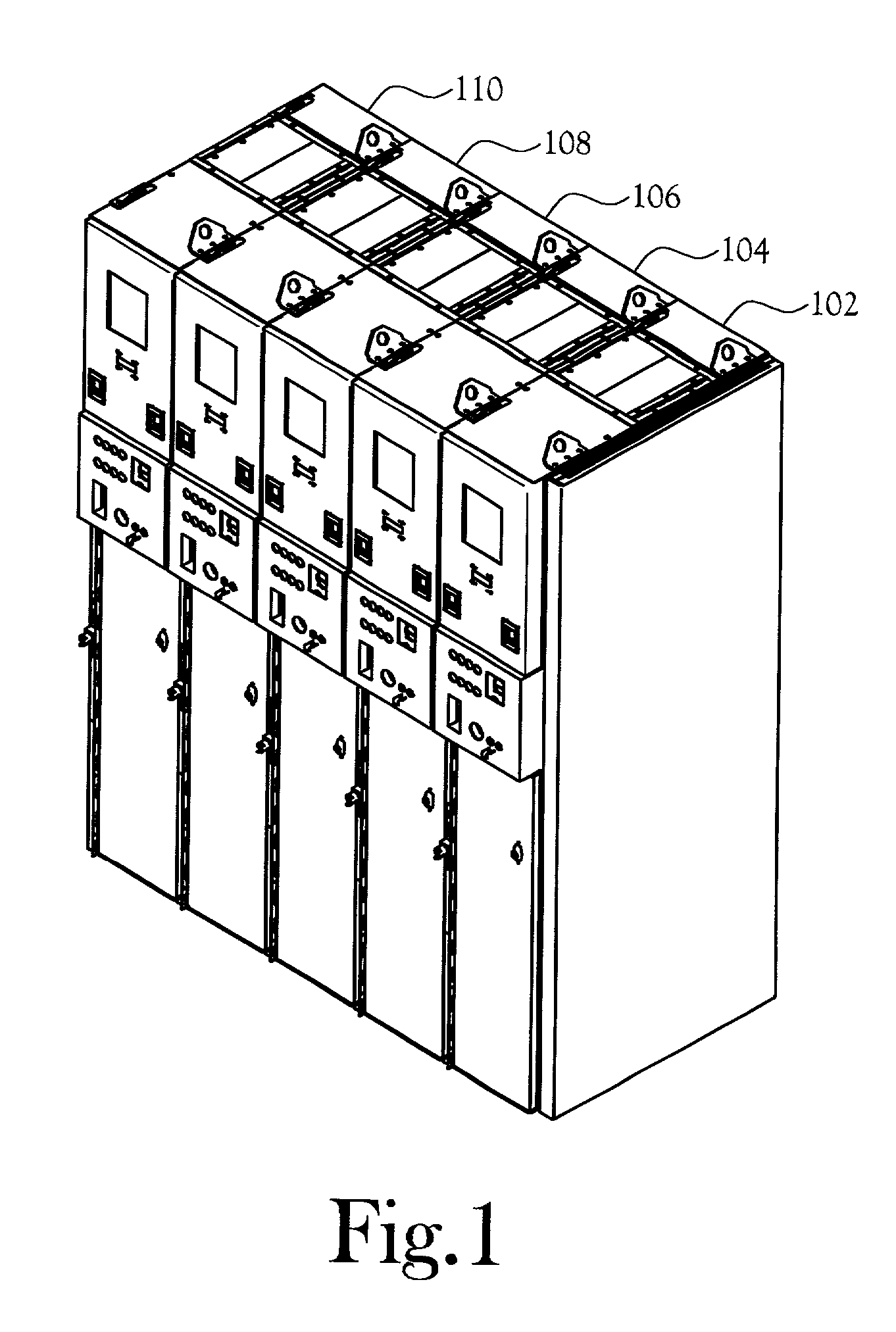

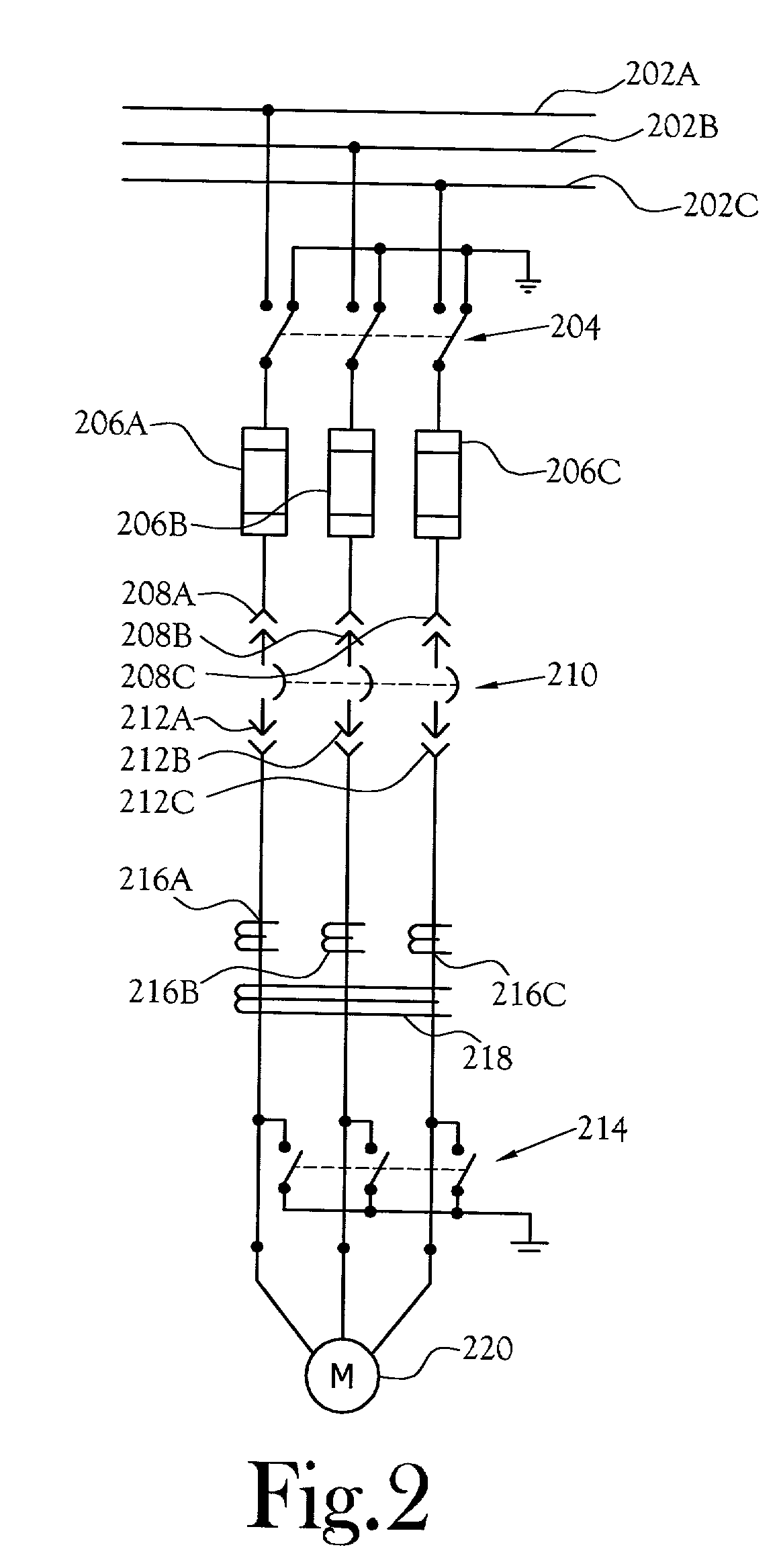

Medium voltage motor control center arc resistant enclosure

InactiveUS7140702B2Minimize componentMinimize fabrication stepShow cabinetsSwitchgear arrangementsElectrical connectionEngineering

A medium voltage controller for electrical equipment, such as motors, transformers, reactors, and capacitors, having an arc resistant cabinet, swaged internal electrical connections, a one-piece self-aligning withdrawable finger cluster, a pull-out instrument compartment, a load discharge device, cast fuse holders, disconnect switch, a switch illuminator, low power current transformers, and an optical temperature measuring system. The arc resistant cabinet relies on the pressure generated by an arc fault to provide the sealing action to contain the fault forces. The cabinet's rear panels are inside the cabinet and the panel lips mate to edges of the cabinet opening. The front doors each have a series of latching tabs along one side and a hinge along the opposing side. A dimple-in-a-dimple joint provides shear strength for panel joints. At the top of the cabinet is an exhaust vent.

Owner:SQUARE D CO

Battery management system and method

InactiveUS20060012341A1Eliminate needMinimizes water lossCharge equalisation circuitCircuit monitoring/indicationVoltmeterManagement system

A battery management system is disclosed for control of individual cells in a battery string. The battery management system includes a charger, a voltmeter, a selection circuit and a microprocessor. Under control of the microprocessor, the selection circuit connects each cell of the battery string to the charger and voltmeter. Information relating to battery performance is recorded and analyzed. The analysis depends upon the conditions under which the battery is operating. By monitoring the battery performance under different conditions, problems with individual cells can be determined and corrected.

Owner:AMERICA POWER CONVERSION CORP

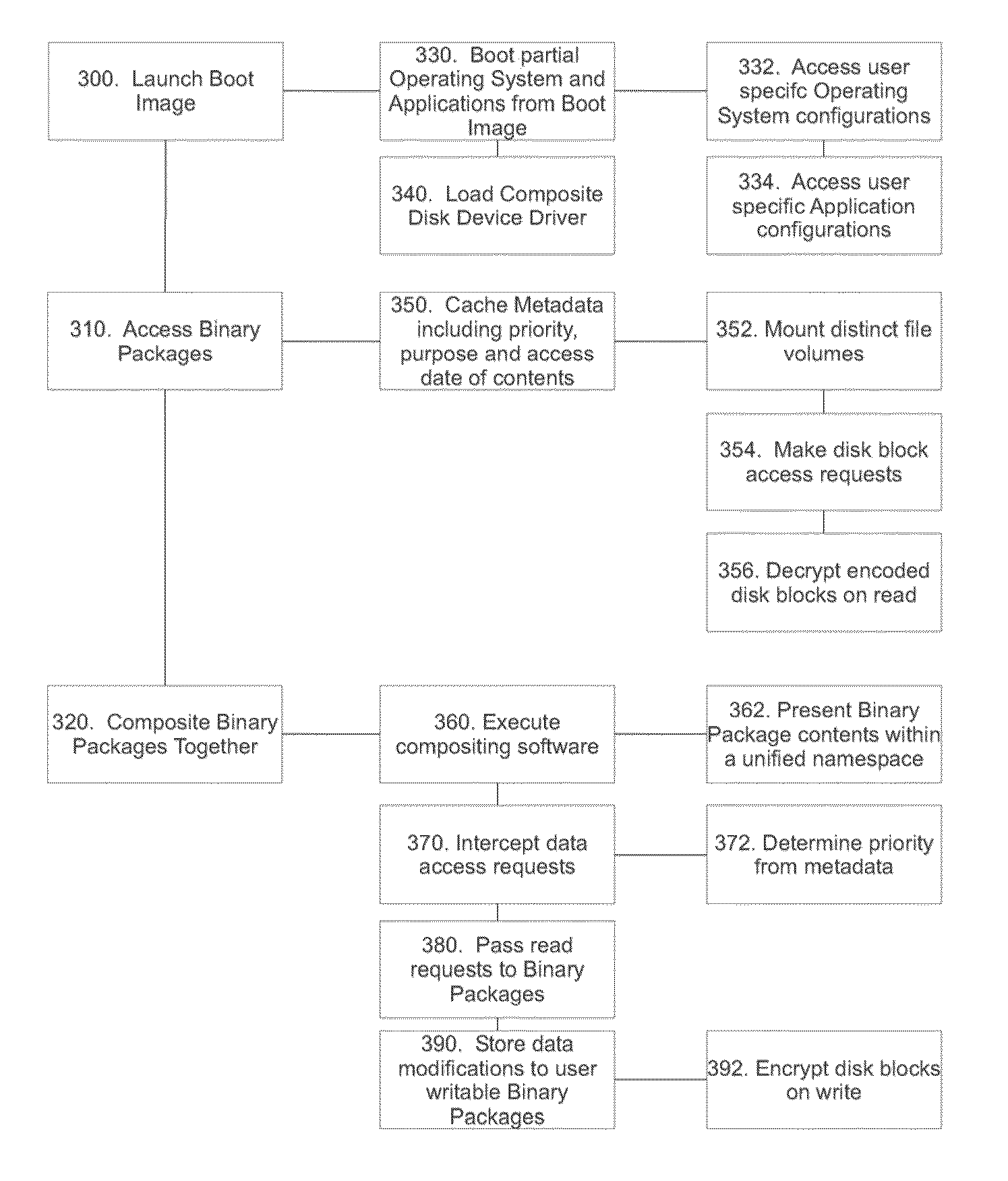

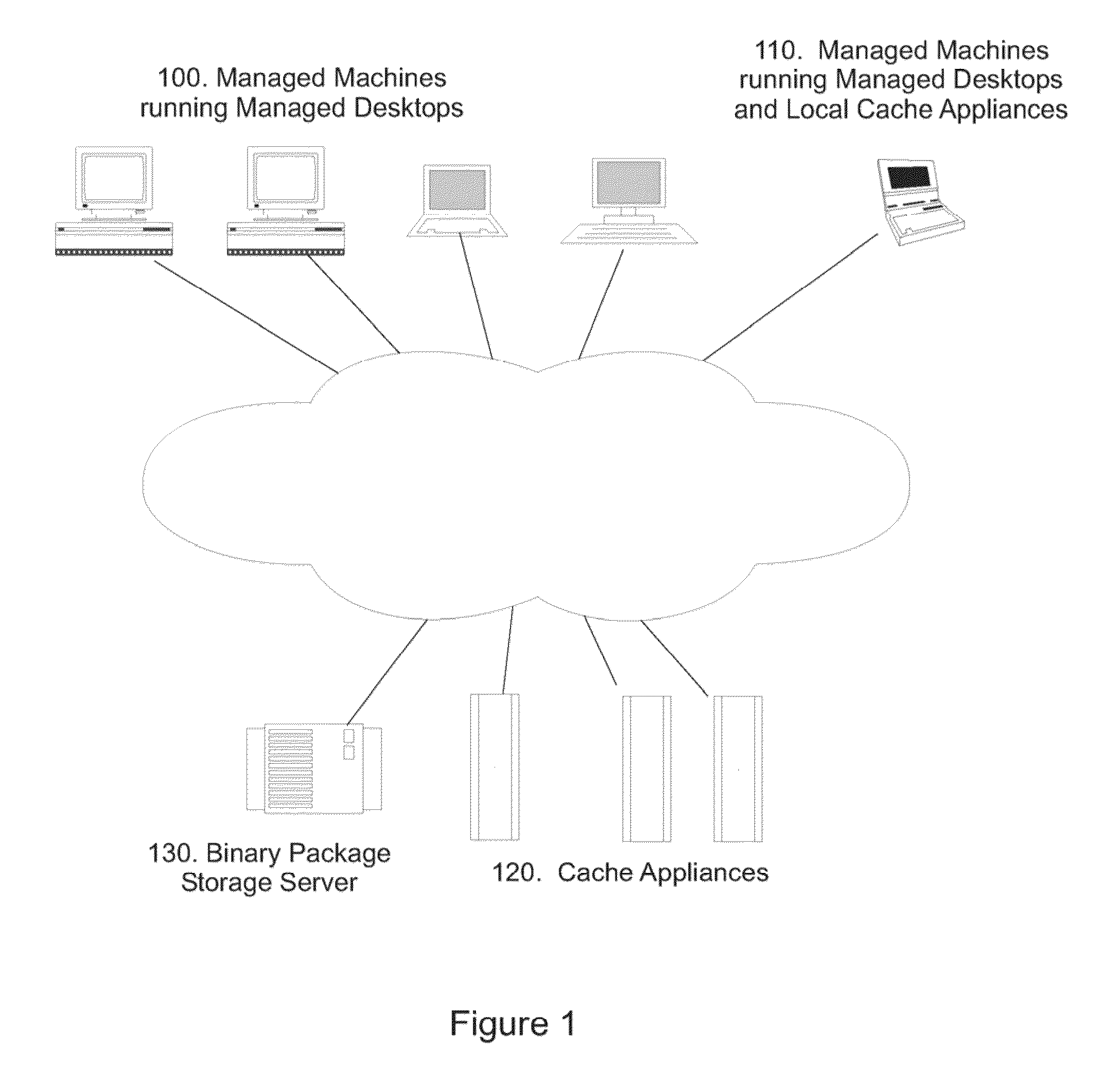

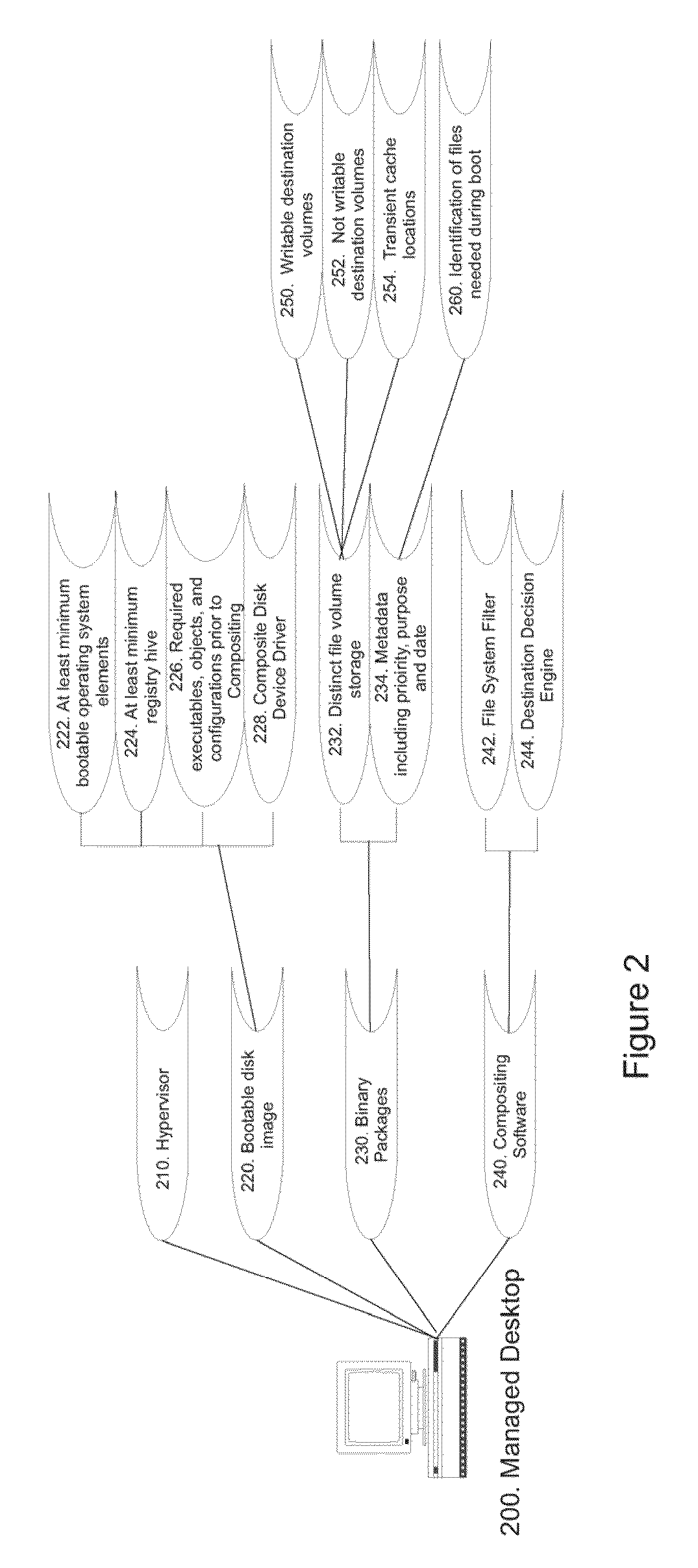

Managed desktop system

ActiveUS8386757B1Minimize maintenanceSpace minimizationInput/output for user-computer interactionMultiple digital computer combinationsOperational systemApplication software

A method and system of operating an actual or virtual desktop or server and managing such desktops and servers involves a cache appliance serving desktop, operating system, and application objects to a managed machine. The objects are composited together to present a normal file structure to the user, with all user configuration and data stored in the desktop object. Management requirements are minimized to maintain operating system and application objects, while users maintain distinct and customizable desktops.

Owner:CITRIX SYST INC

Single body injector and deposition chamber

InactiveUS20010004881A1Complicated machined partLow costSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringInjector

An injector and deposition chamber for delivering gases to a substrate or wafer for processing of said substrate or wafer is provided. The injector is provided comprising an elongated member with end surfaces and at least one gas delivery surface extending along the length of the member and which includes a number of first elongated passages formed therein for received a gas. The gas delivery surface contains rounded side regions and a center recessed region. Also formed within the member are a number of thin distribution channels which extend between the first elongated passages and the center recessed region of the gas delivery surface. In another embodiment, the injector further includes at least one second elongated passage formed therein for receiving an etchant species. The etchant species is conveyed via at least one thin distribution channel which extends between the second elongated passage and one of the rounded side regions of the gas delivery surface. Metering tubes may be inserted into each elongated passage and are spaced from the walls of said passages and extend between the ends. The deposition chamber includes at least one injector as described above; a plurality of vent blocks having end surfaces and at least one elongated external surface extending along the length of each of the vent blocks; and a support positioned beneath the injector and vent blocks, creating a deposition region therebetween. The vent blocks are positioned adjacent one on each side of the injector, and spaced from the injector to define exhaust channels therebetween for removing the gas.

Owner:ASML US LLC

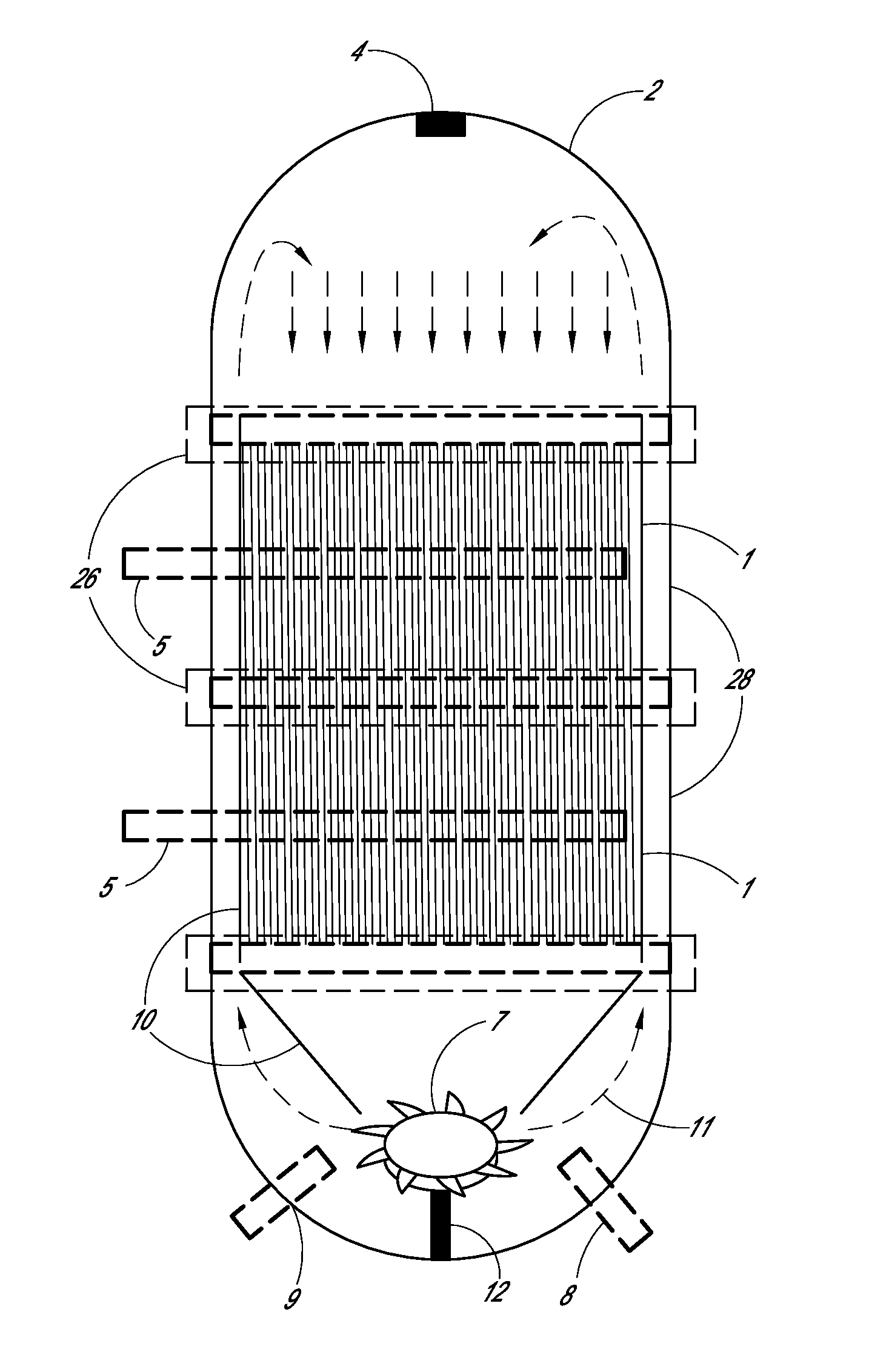

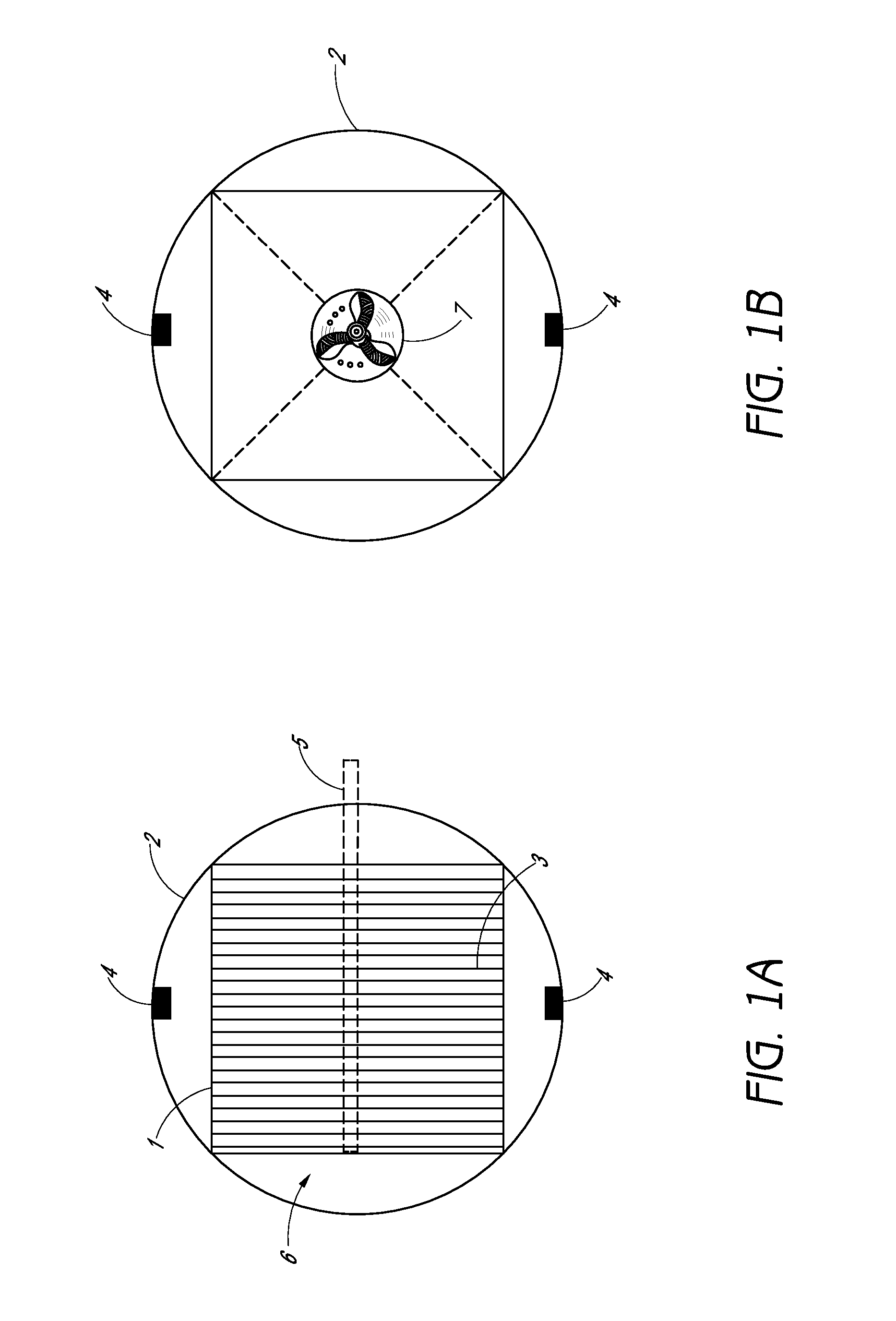

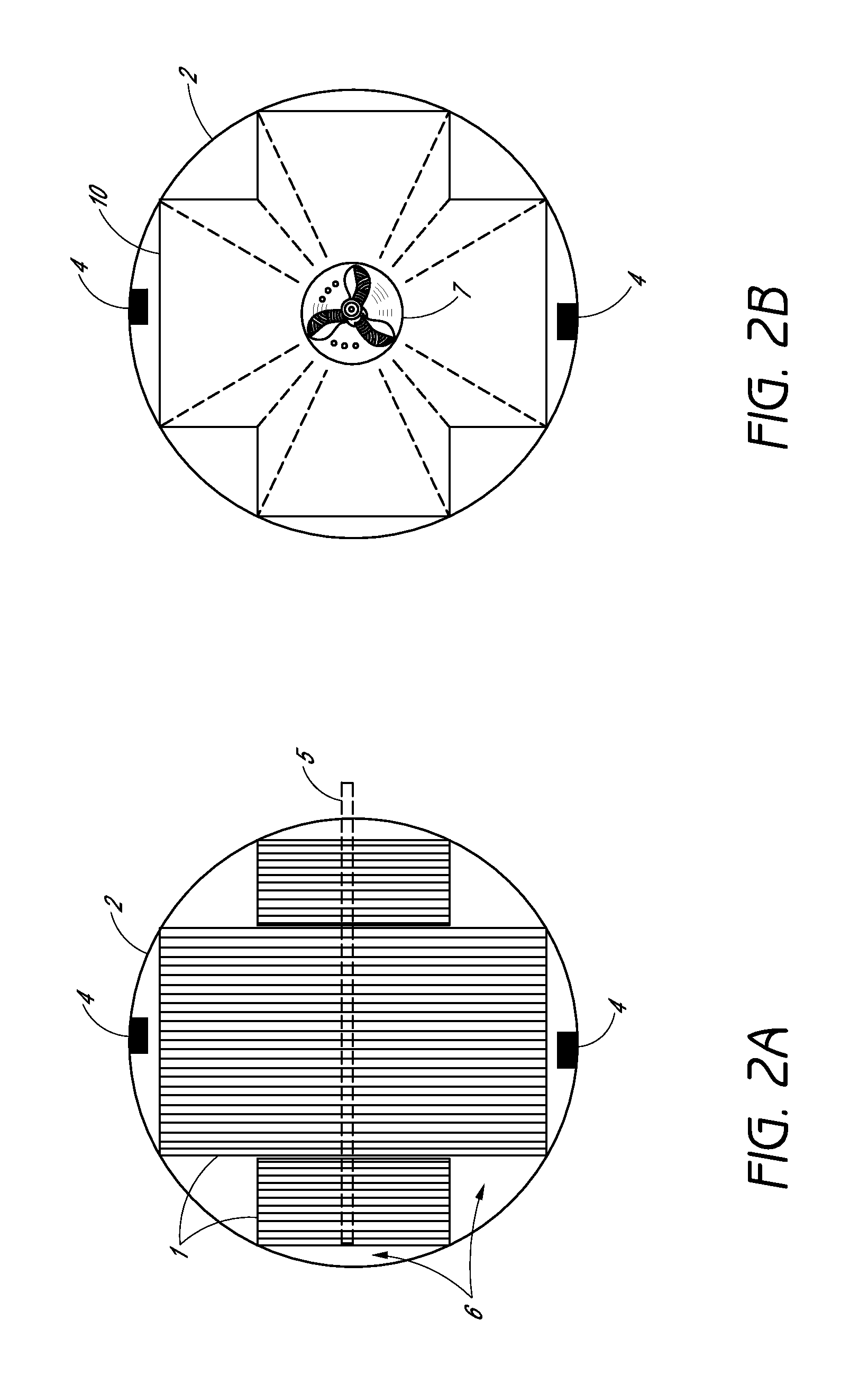

Water treatment systems and methods

InactiveUS8685252B2Reduce cost and complexityReduce and prevent settlementMembranesSpecific water treatment objectivesActivated carbonImpeller

Water treatment systems and methods are provided to minimize membrane fouling and the required maintenance that results therefrom. A water treatment system includes a pressure vessel with a plurality of spaced-apart membranes disposed therein, and an impeller or other means for circulating feed water through the interior of the vessel and past the membranes. Antifouling particles (such as diatomaceous earth or activated carbon) and / or pellets can be added to the feed water inhibit membrane fouling and extend the useful life of the membranes.

Owner:DXV WATER TECH

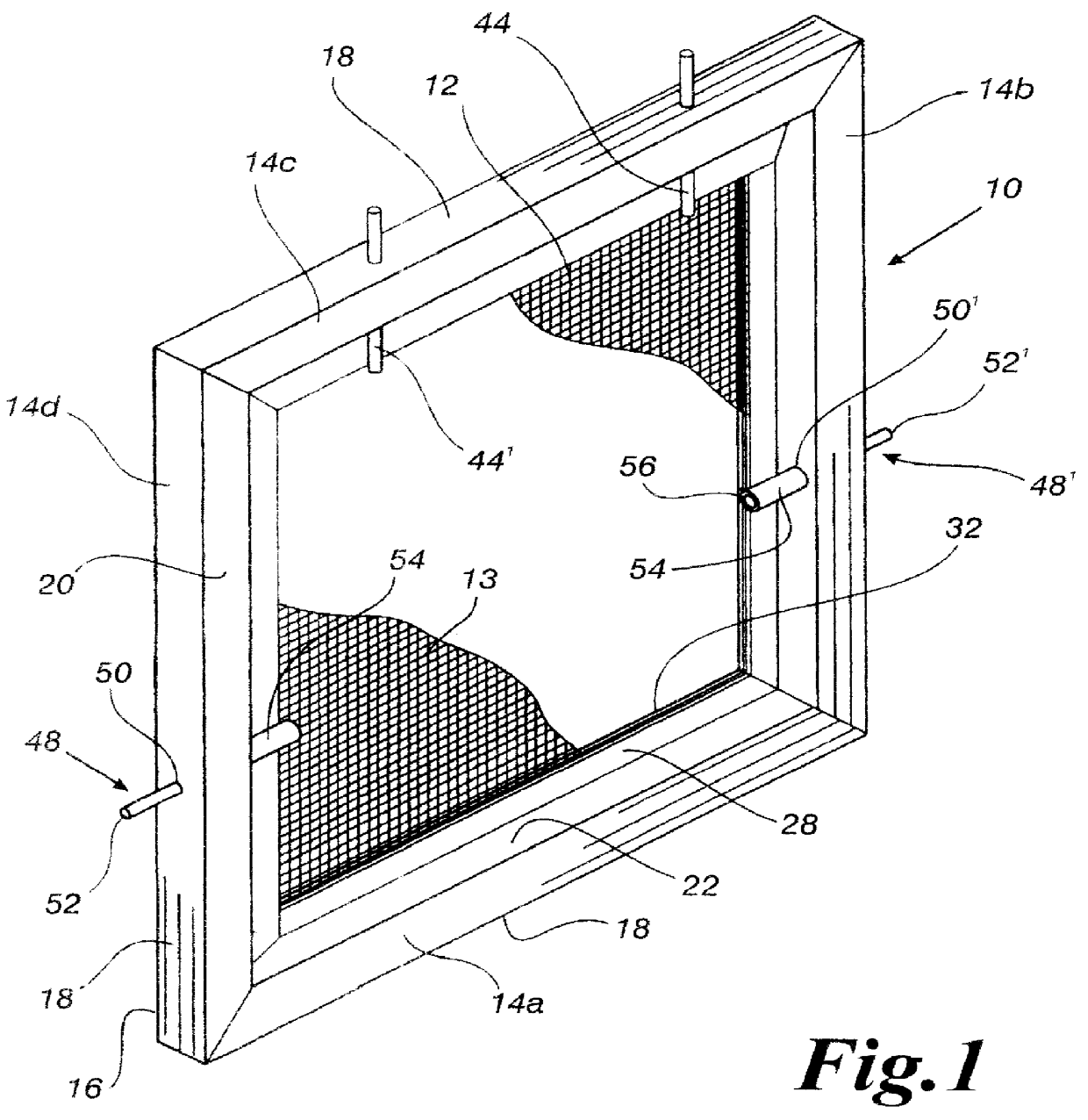

Screen frame and screen door

The present invention is a screen frame and screen positionable in most window frames and door frames. The invented screen frame is comprised of four screen frame segments joined together at corners to form a generally rectangular or multi-sided screen frame. Corner joint inserts are inserted in each corner of the four screen frame segments and the inserts are spot welded to adjoining screen frame segments to provide a sturdy and rigid screen frame. The screen frame segments are preferably stainless steel extrusions having two parallel flanges extending from a generally square shaped hollow body. An alternative construction of the screen frame is a continuous extruded segment that is notched at certain locations for bending and forming into a continuous screen frame having one junction requiring spot welding. A metal, preferably stainless steel screen is secured in the screen frame by spot welding the screen between the screen frame flanges of the screen frame segment. Stainless steel support pins are used to secure the screen frame enclosing the screen in a window frame casing. The screen frame and screen provides a long-lasting, corrosive resistant, and rigid frame and screen for positioning in window or door frames which withstand damage from intruders, projectiles, and environmental stresses.

Owner:STORY JR PAUL J

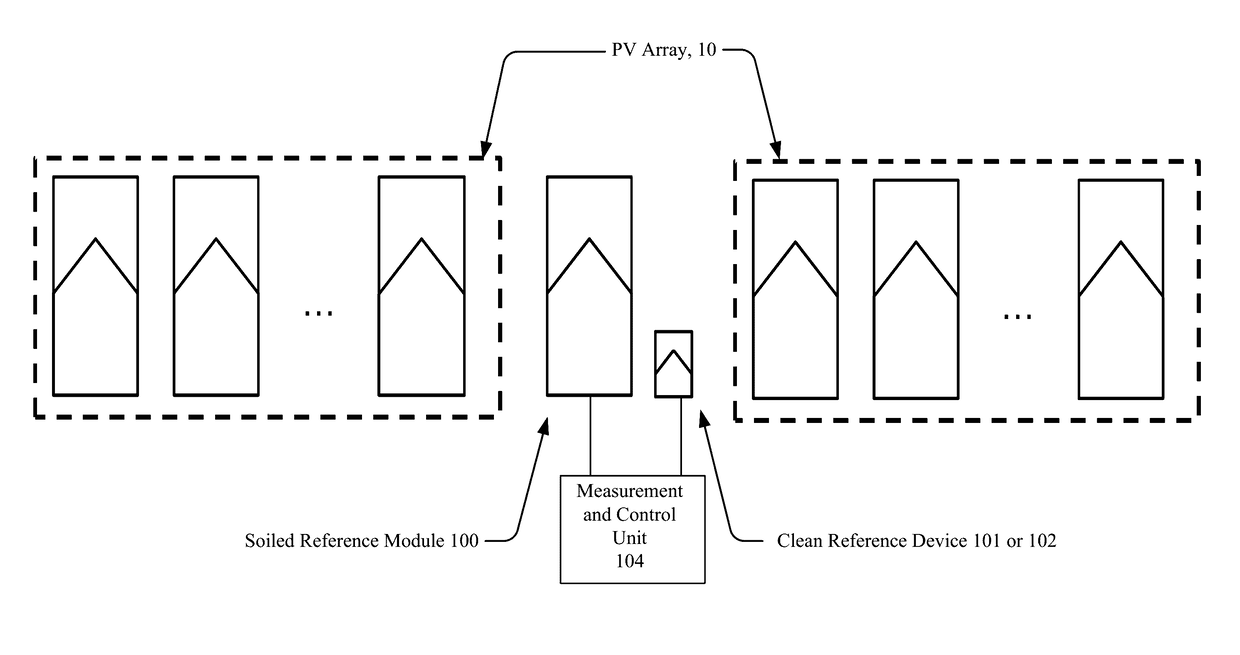

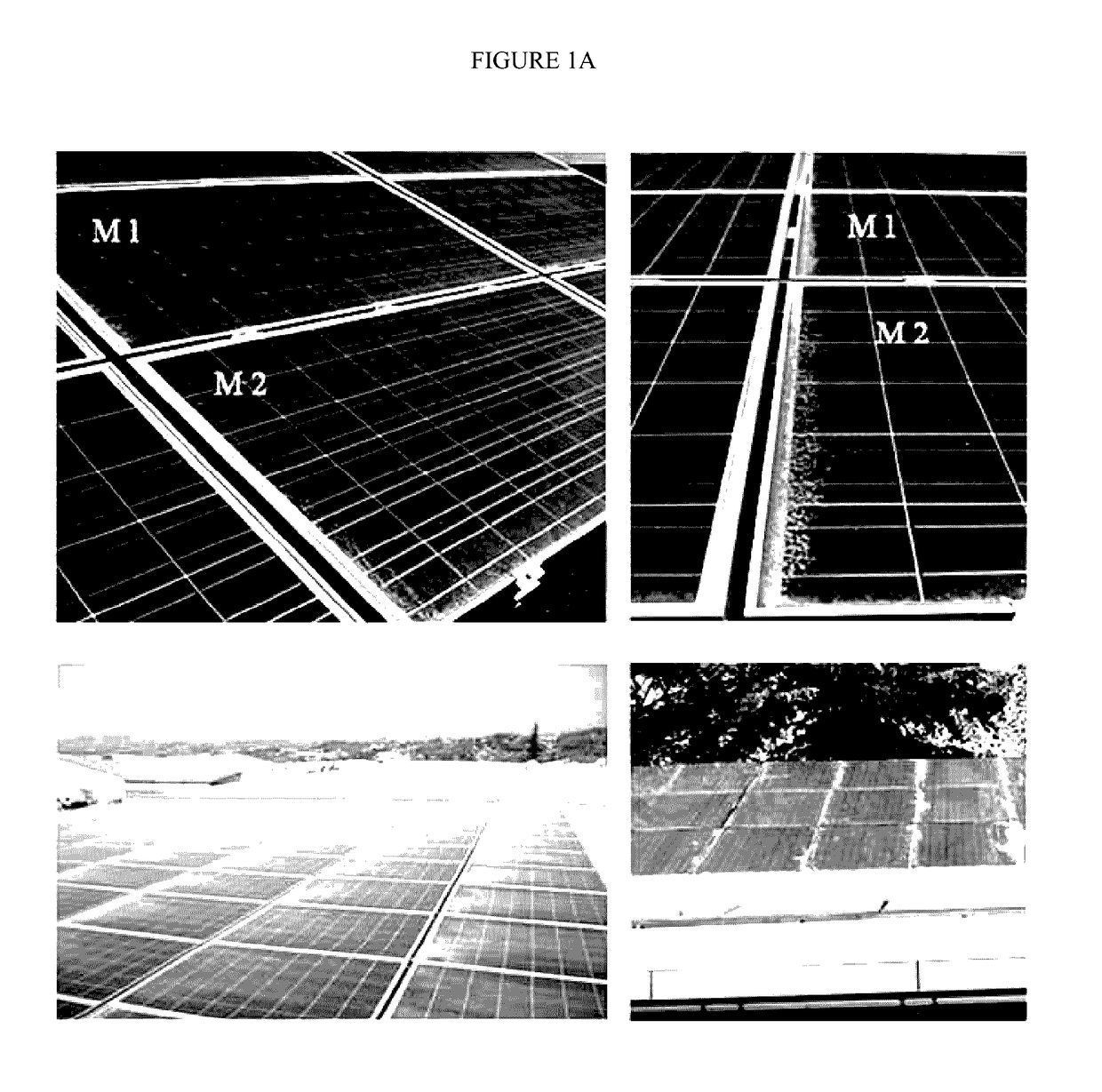

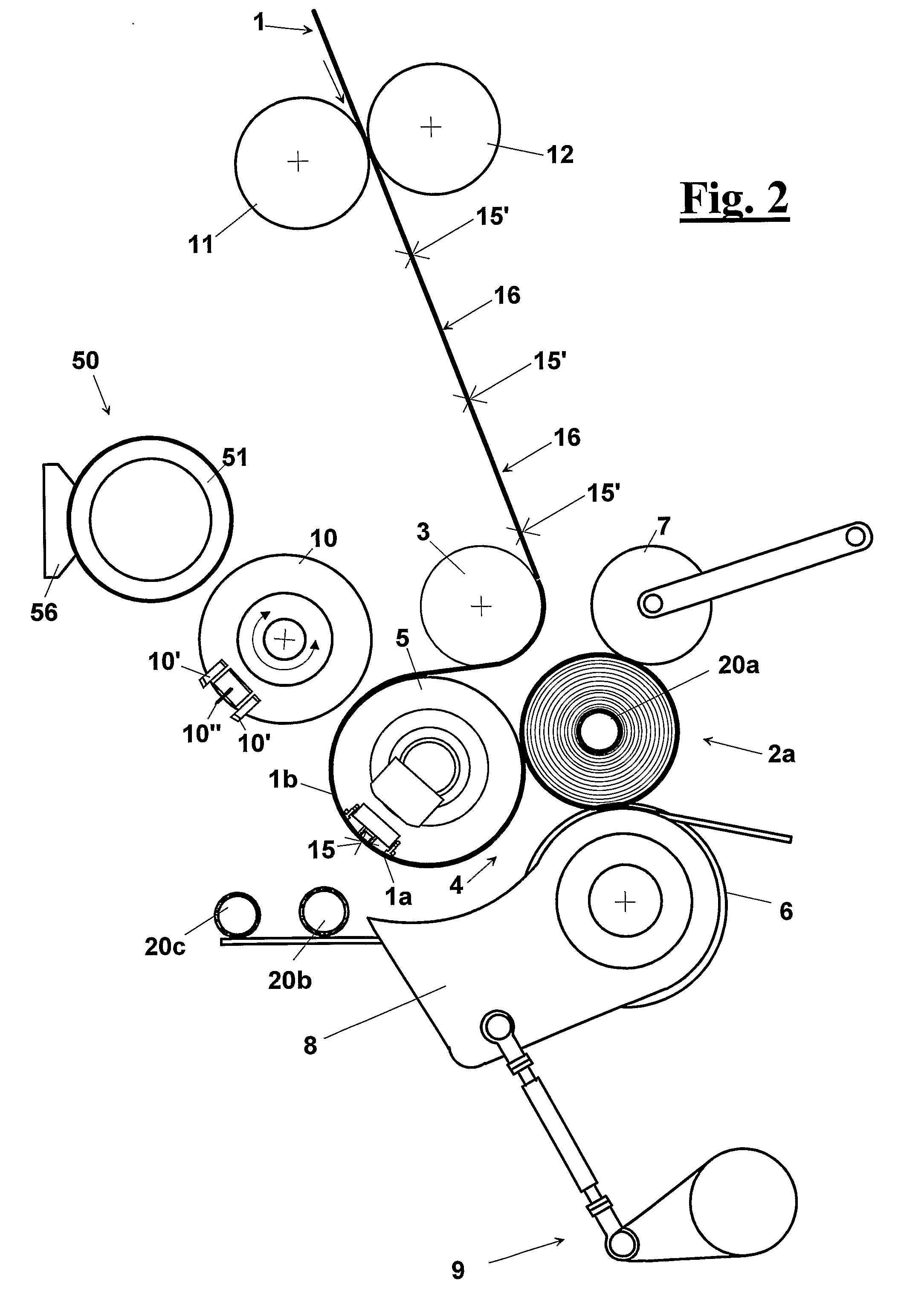

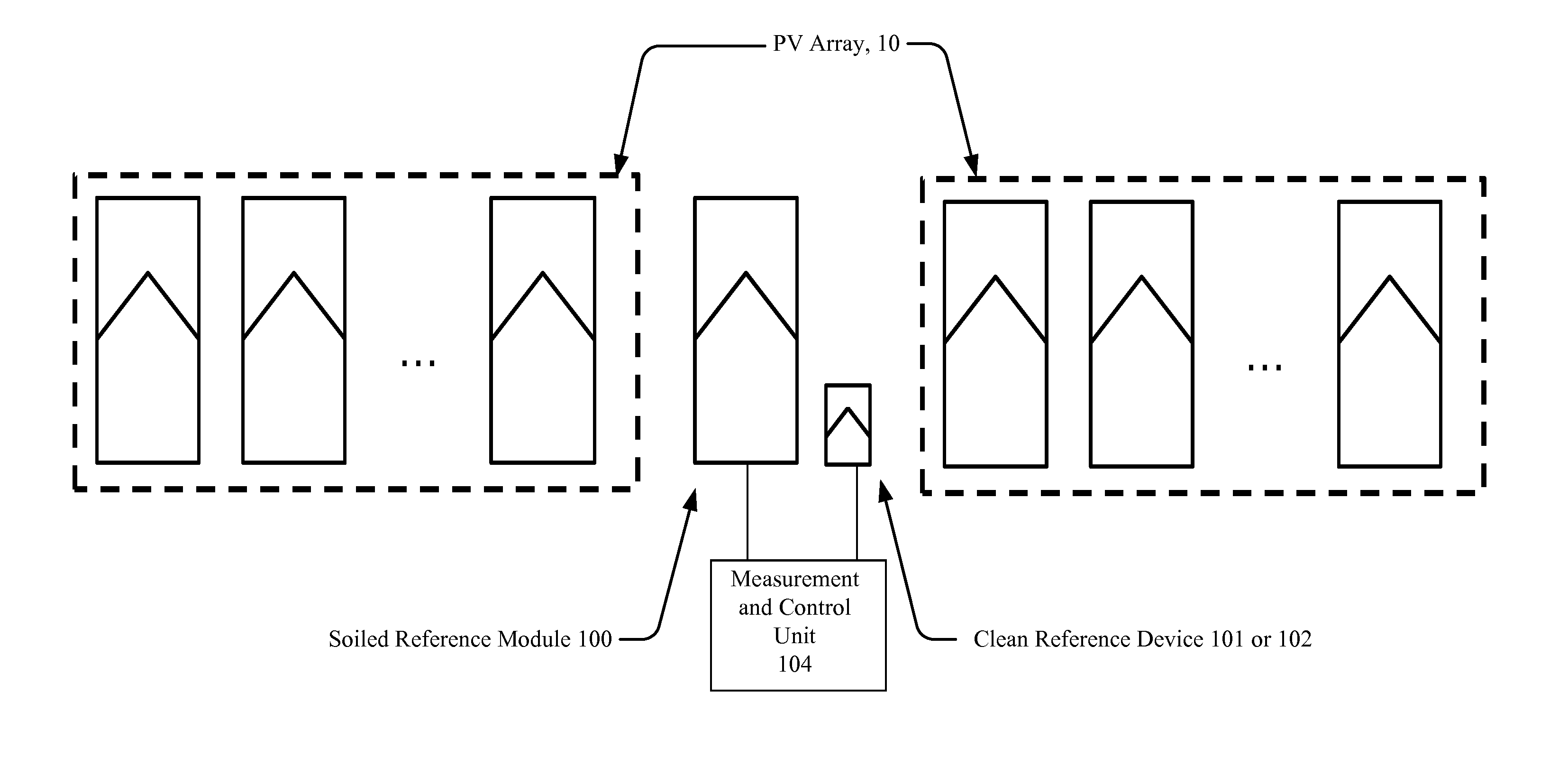

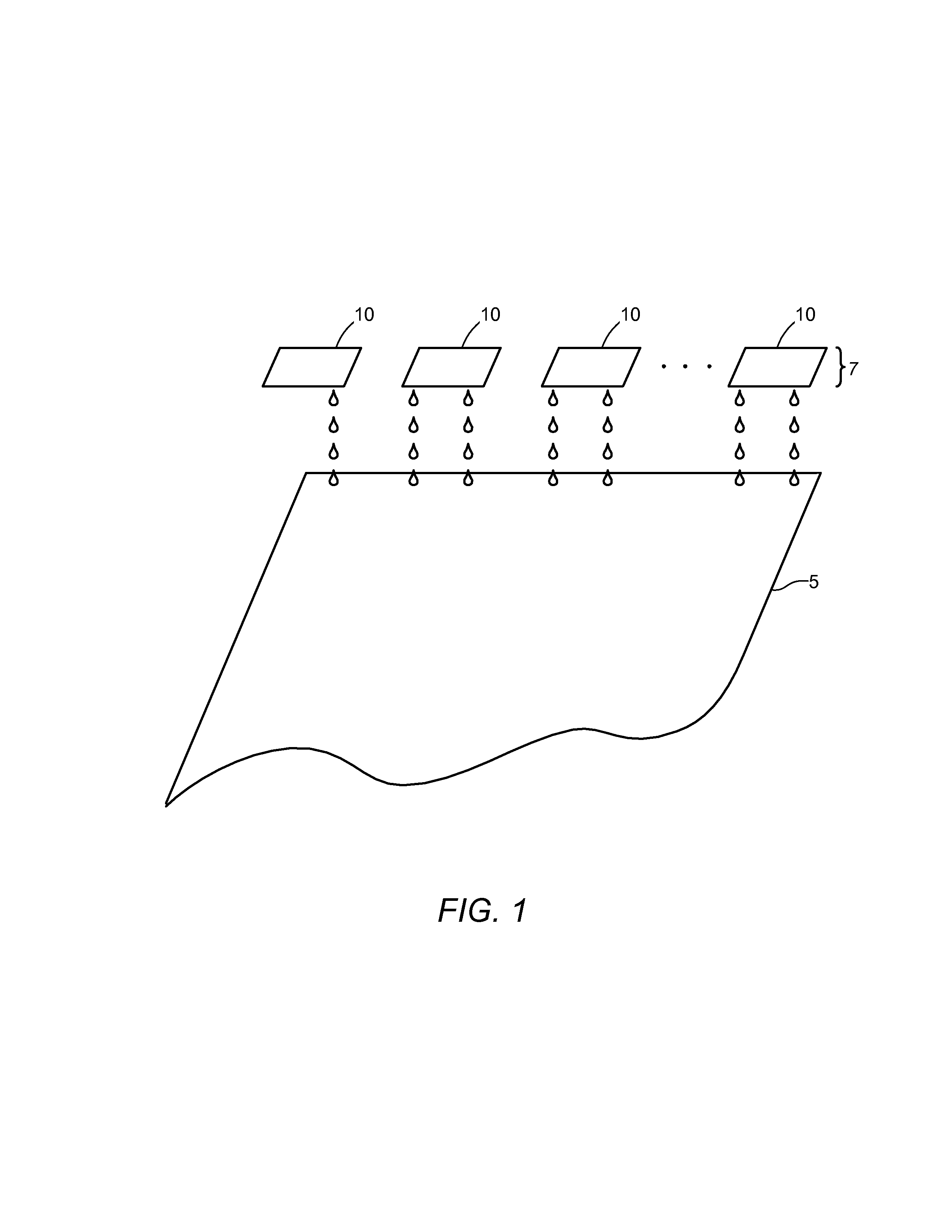

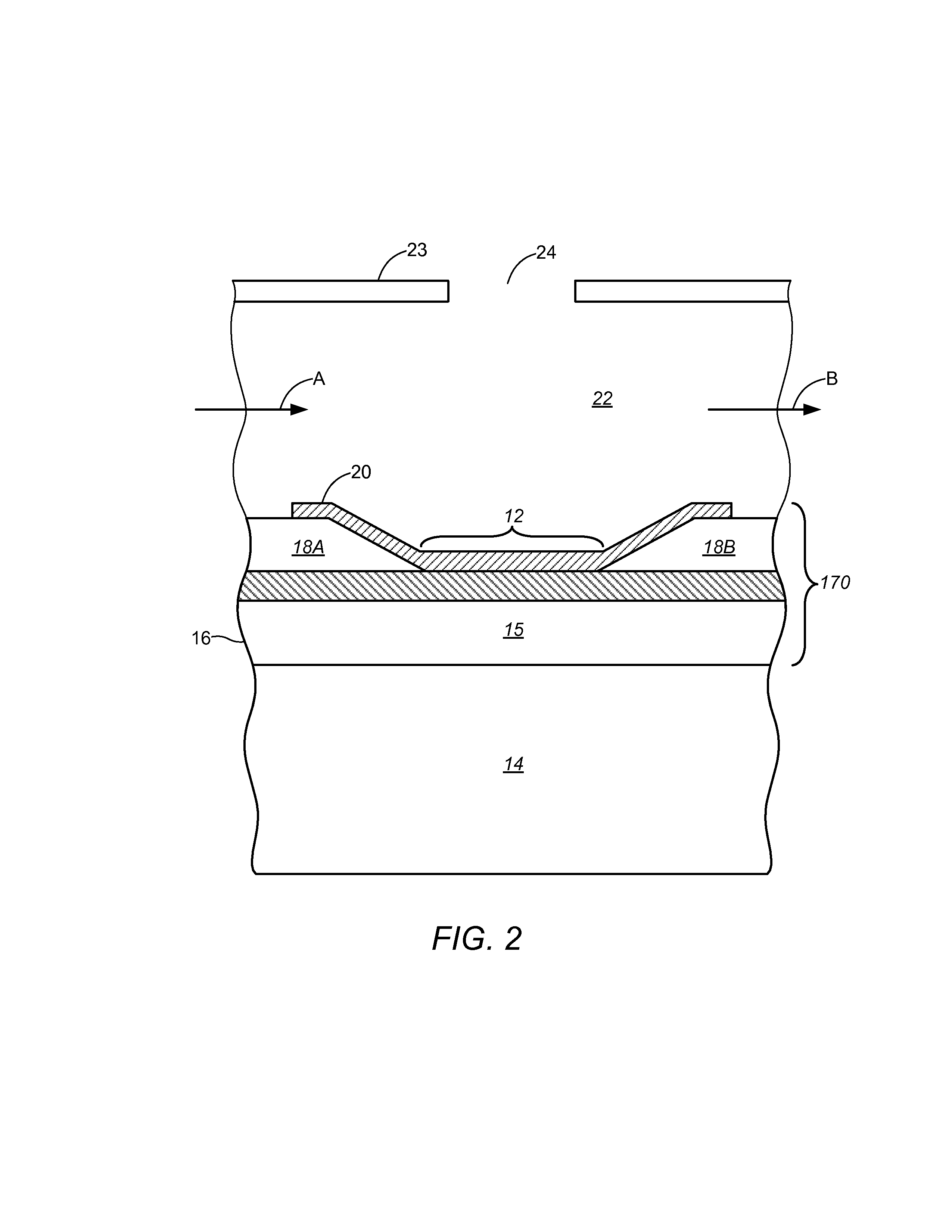

Soiling measurement system for photovoltaic arrays

ActiveUS20170104451A1Minimize maintenanceMore accuratePhotovoltaic monitoringPhotovoltaic energy generationEnergy lossControl unit

A system for measuring the power or energy loss in a photovoltaic array due to soiling, which is the accumulation of dust, dirt, and / or other contaminants on the surfaces of photovoltaic modules, comprising: a pair of photovoltaic reference devices placed within or near the photovoltaic array and co-planar to the modules comprising the array, wherein one reference device is a module similar to those of the array and is allowed to accumulate soiling at the natural rate, and wherein the second reference device is a module or a cell and is periodically cleaned; and a measurement and control unit which measures and compares the electrical outputs of the soiled reference device and the clean reference device in order to determine the fraction of power lost by the soiled reference module due to soiling.

Owner:ATONOMETRICS

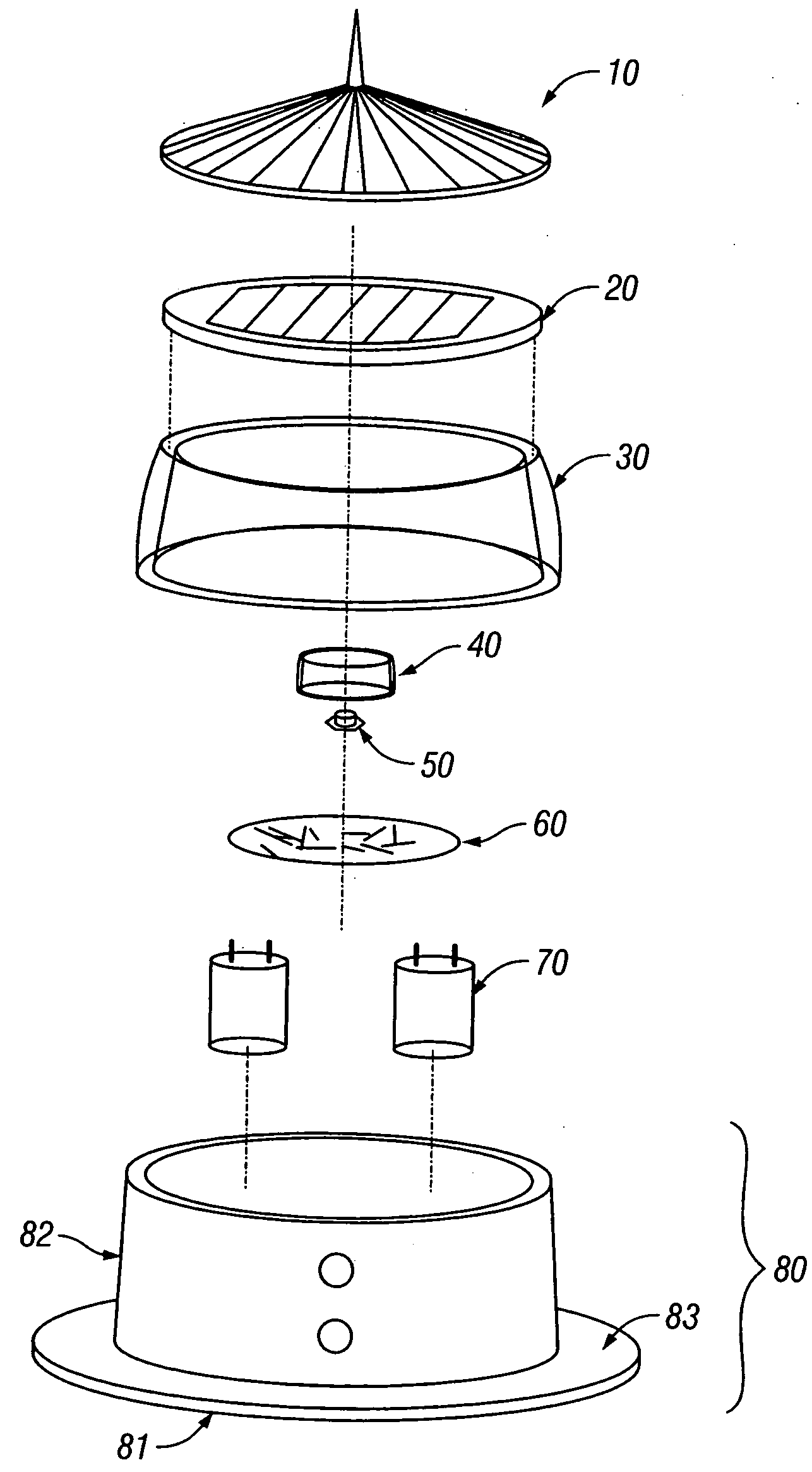

Side-emitting led marine signaling device

InactiveUS20050146875A1Minimize maintenanceMinimize power consumptionLighting applicationsPoint-like light sourceLight beamEngineering

The present invention is directed to a signaling device that incorporates a side-emitting light emitting diode (LED), a first optic, which partially deviates and focuses the radiated light, and a second optic, which centers the beam on the horizon and determines the final vertical divergence. The means for powering the device is either a self-contained photovoltaic system or an external battery supply. The means for controlling the device is electronic circuitry.

Owner:TIDELAND SIGNAL

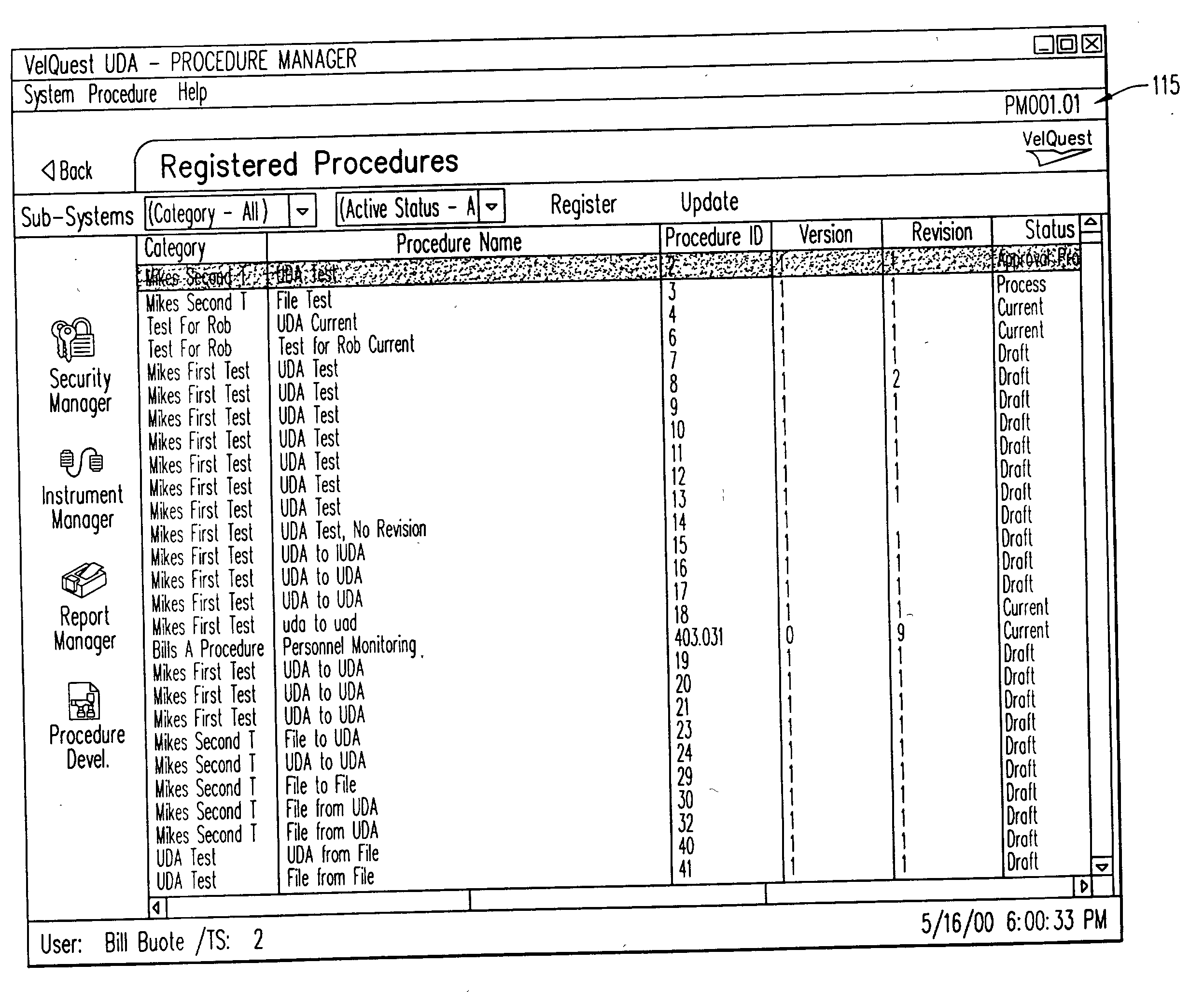

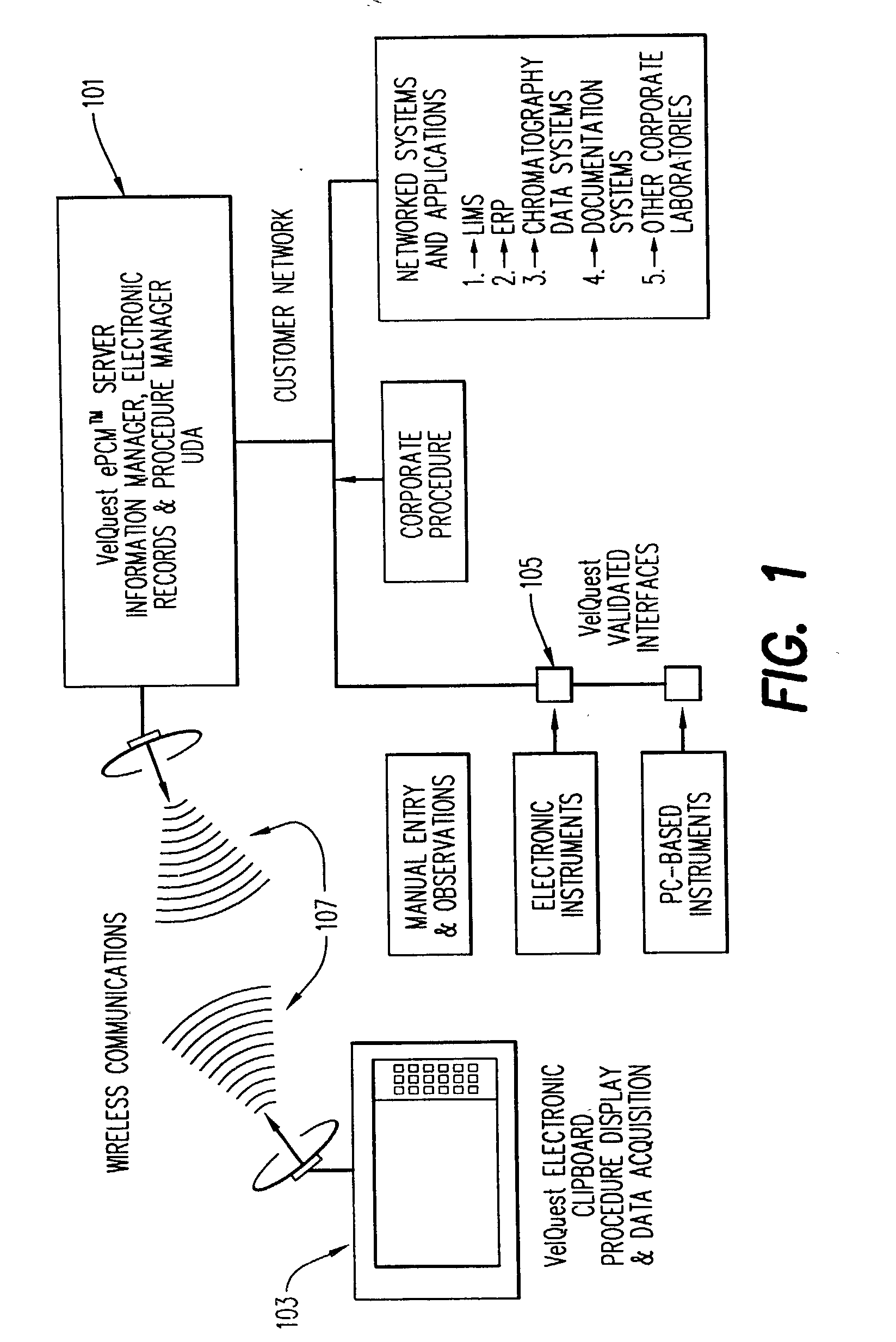

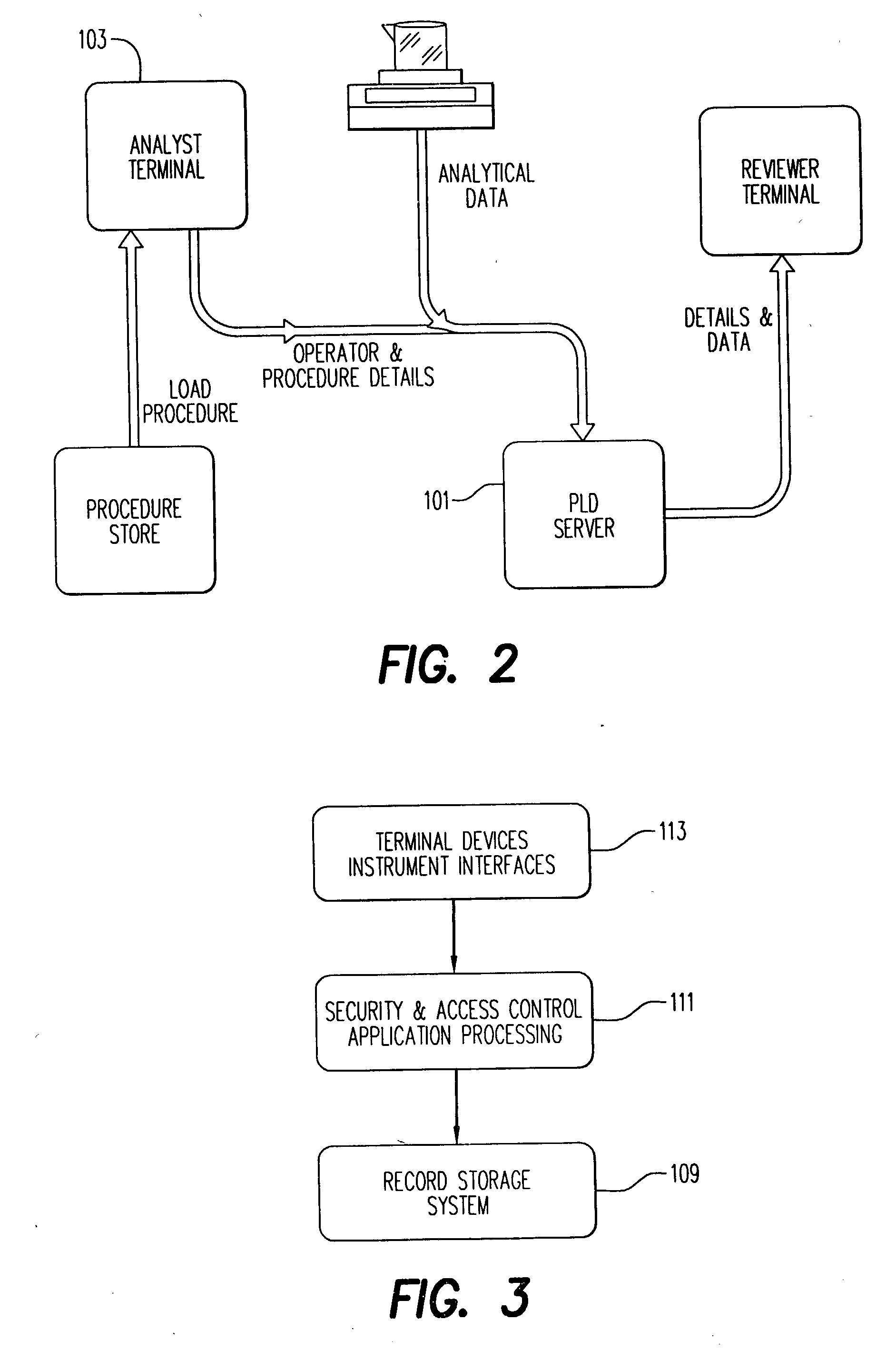

Process-linked data management system

InactiveUS20020193966A1Minimize maintenanceReduce maintenanceDatabase queryingDigital computer detailsData acquisitionData management

A system for managing and reporting laboratory data wherein the data is obtained at remote data-taking stations, transferred instantaneously by wireless communication to a main data-storing / manipulating station for recording therein without being recorded at the remote data-taking stations, and reported only from the data-storing / manipulating.

Owner:DASSAULT SYST AMERICAS CORP

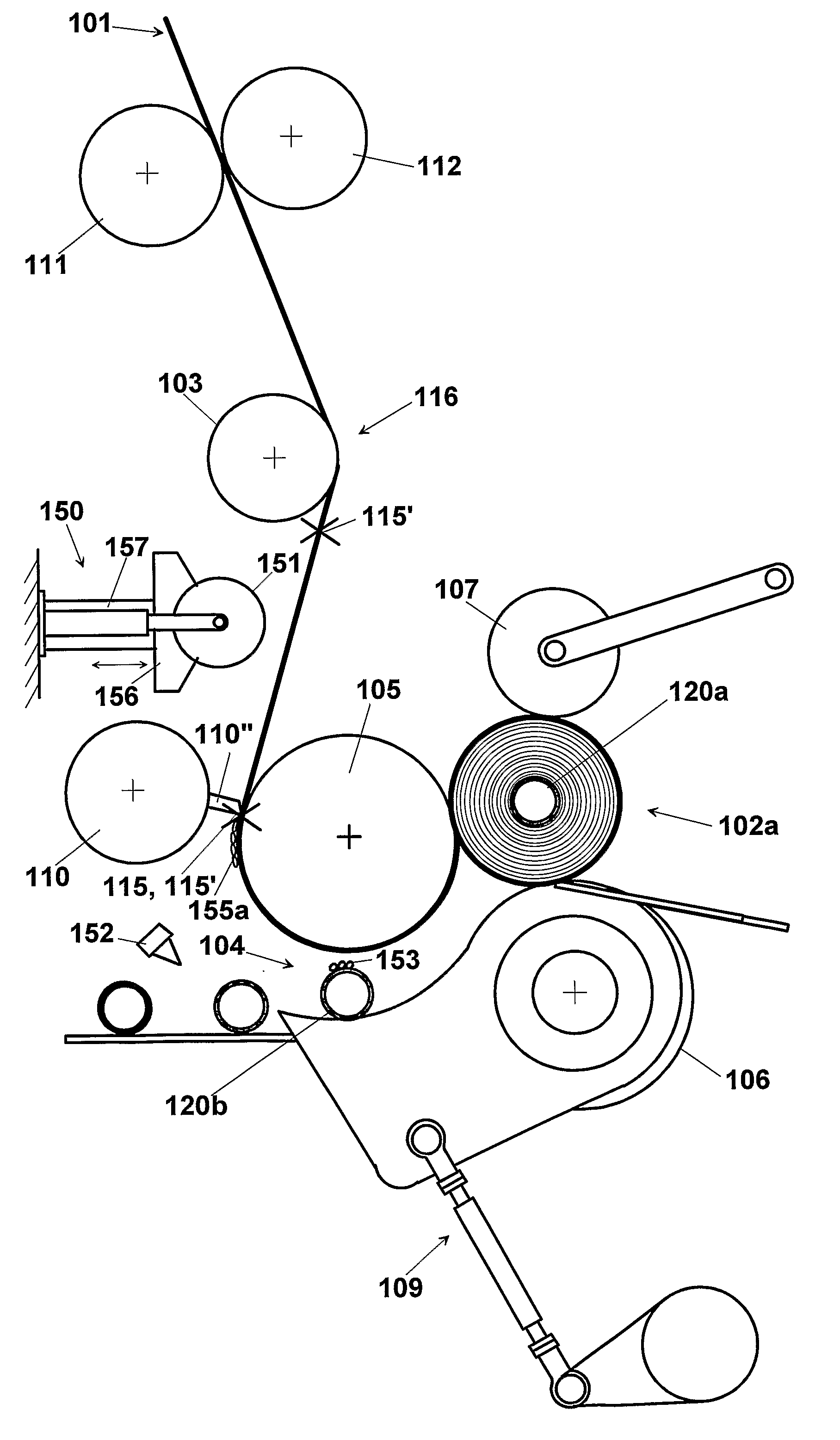

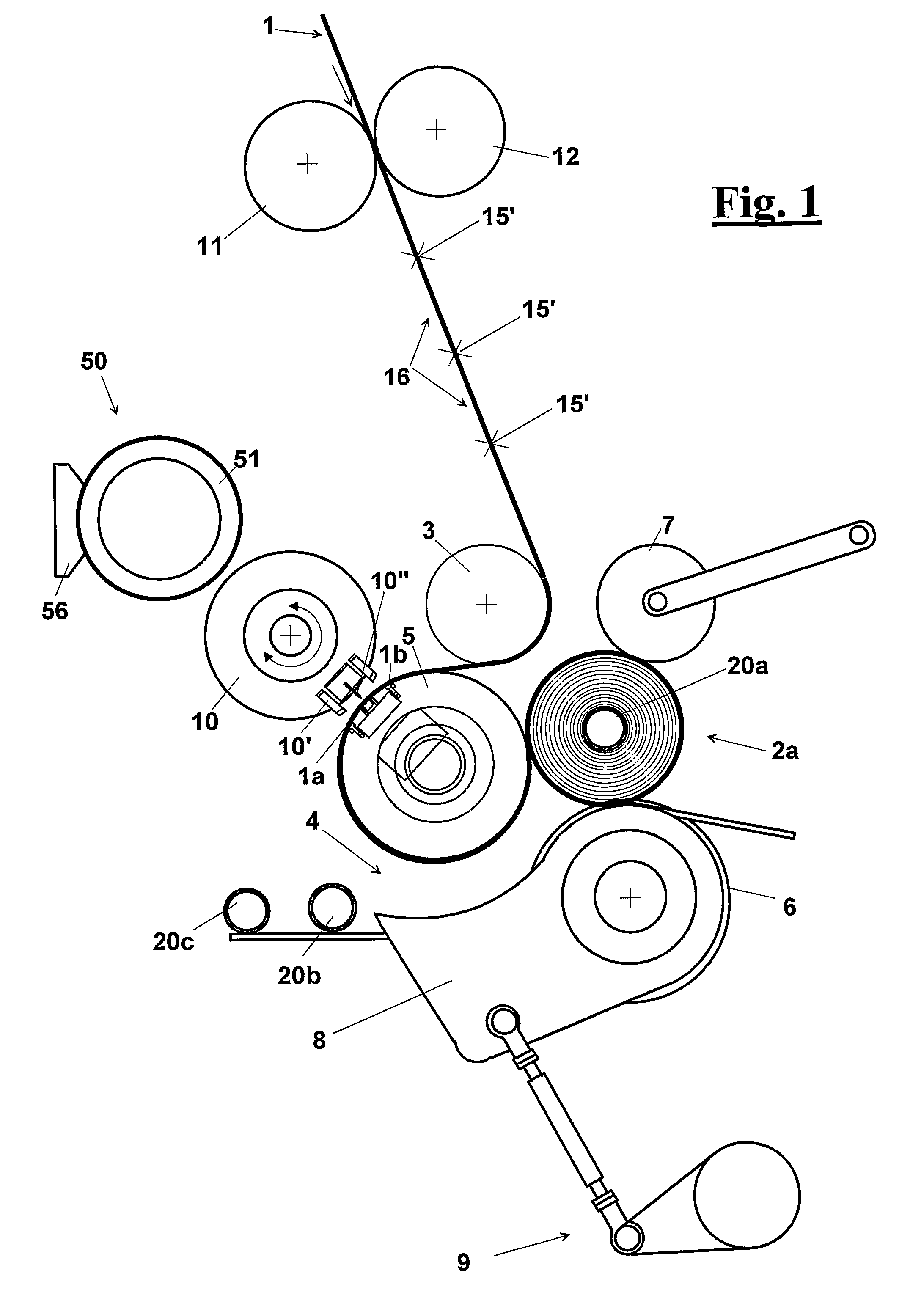

Rewinding method and rewinding machine that carries out this method

InactiveUS20100237179A1Effective distributionQuality improvementArticle deliveryWebs handlingEngineeringMechanical engineering

Rewinding method and rewinding machine of a paper web (1) for making a log (2a) comprising a feed roller (3) for feeding the web (1) and a winding cradle (4) in which a log (2a) is formed winding the paper web (1) about a core (20). The latter is supplied into the cradle (4) by introduction means by a loading unit that draws the cores (20) from a chute guide. Upstream from the feed roller (3) a perforation roller (11) is provided that acts in combination with a counter-roller (12) to make a plurality of transversal tear lines (15′) on the paper web (1) forming a plurality of panels (16) connected to each other united by the tear line. Upstream from the means for introducing the core (20), furthermore, a gluing means is provided (50) for application of a measured amount of glue (55) on a determined portion of the paper web (1), in particular upstream from (Ia), down-stream of (Ib), or bridging the tear line or clean cut (15). Such lines are made by cutting means, which make either a tear line or clean cut (10″), in coincidence or direct vicinity with the gluing means for applying the glue (50, 10′). The gluing means (50) can, for example, provide a pad (10′) that receives the glue by a gluing roller (51).

Owner:MTC MACCINE TRASFORMAZIONE CARTA SRL

Soiling measurement system for photovoltaic arrays

ActiveUS20150280644A1Minimize maintenanceProcess economyPhotovoltaic monitoringElectrical testingPollutantEnergy loss

A system for measuring the power or energy loss in a photovoltaic array due to soiling, which is the accumulation of dust, dirt, and / or other contaminants on the surfaces of photovoltaic modules, comprising: a pair of photovoltaic reference devices placed within or near the photovoltaic array and co-planar to the modules comprising the array, wherein one reference device is a module similar to those of the array and is allowed to accumulate soiling at the natural rate, and wherein the second reference device is a module or a cell and is periodically cleaned; and a measurement and control unit which measures and compares the electrical outputs of the soiled reference device and the clean reference device in order to determine the fraction of power lost by the soiled reference module due to soiling.

Owner:ATONOMETRICS

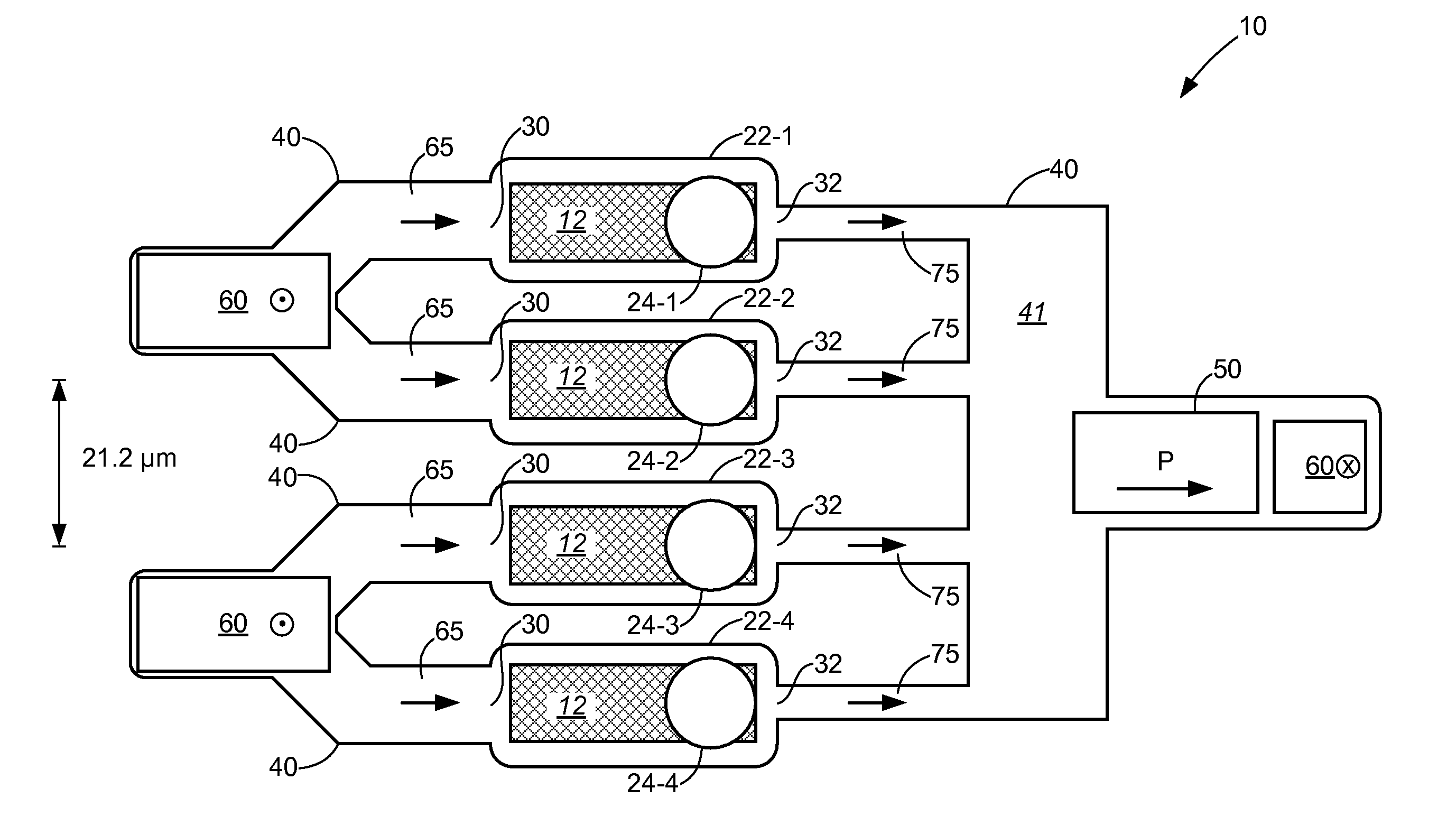

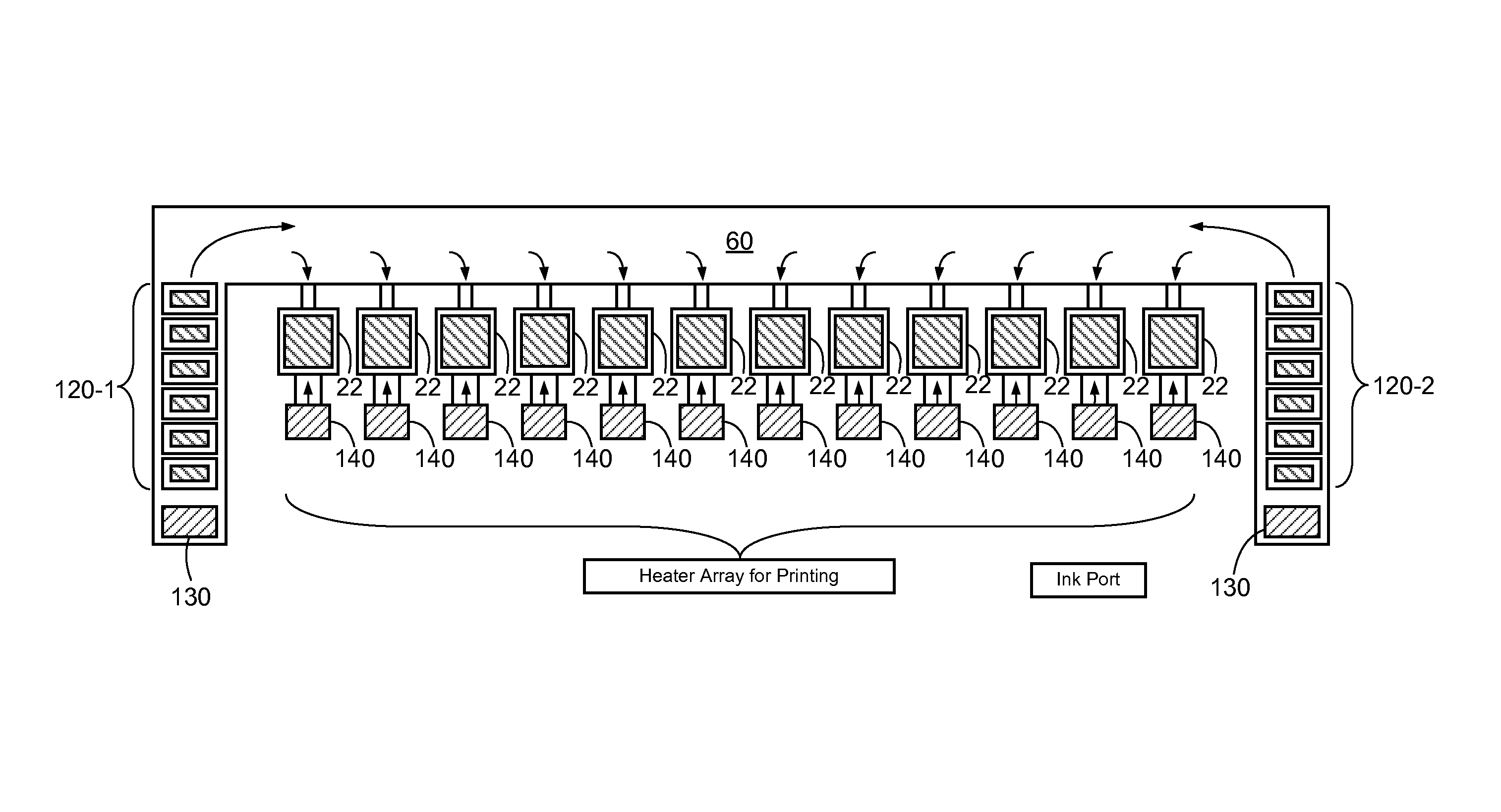

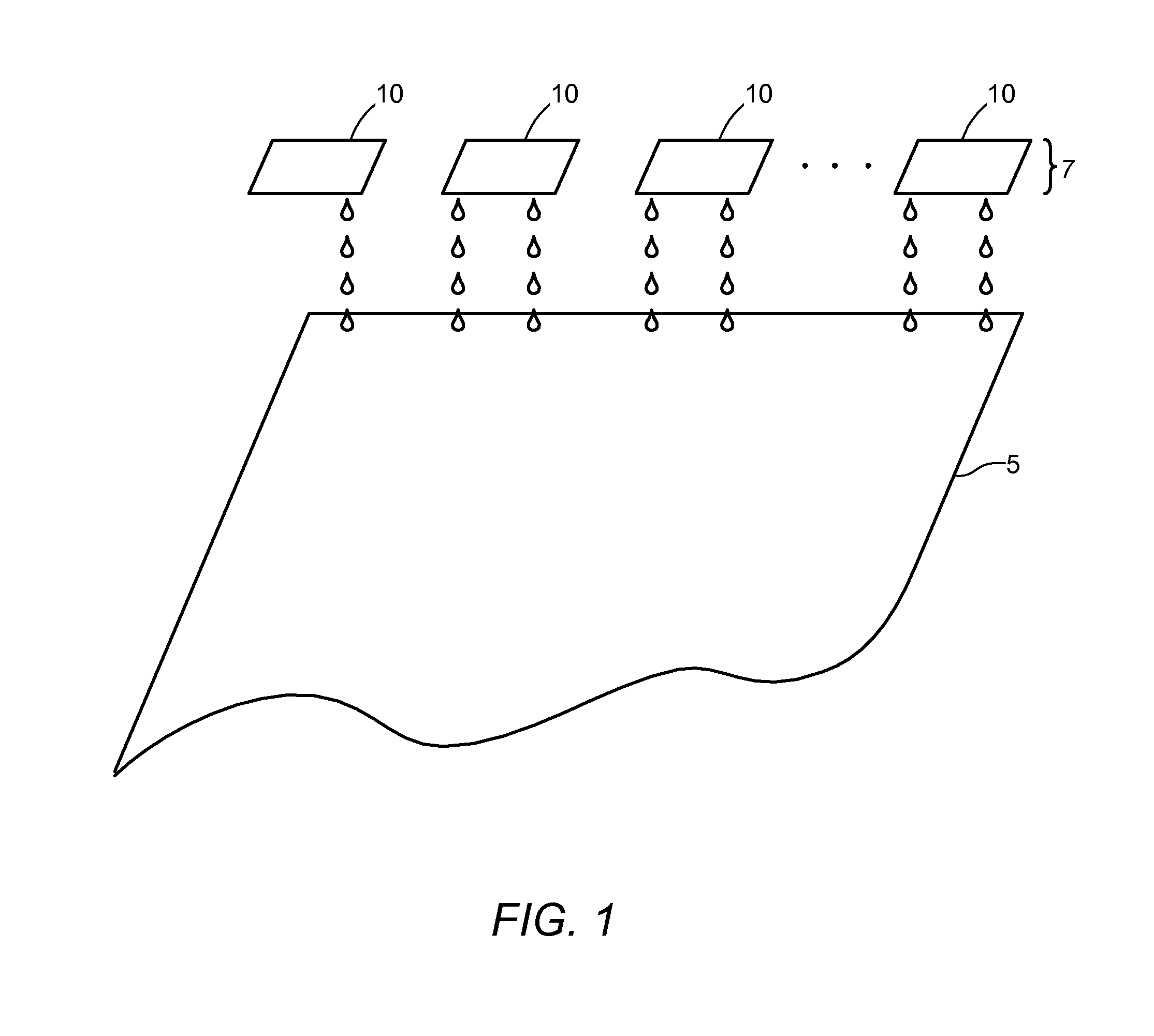

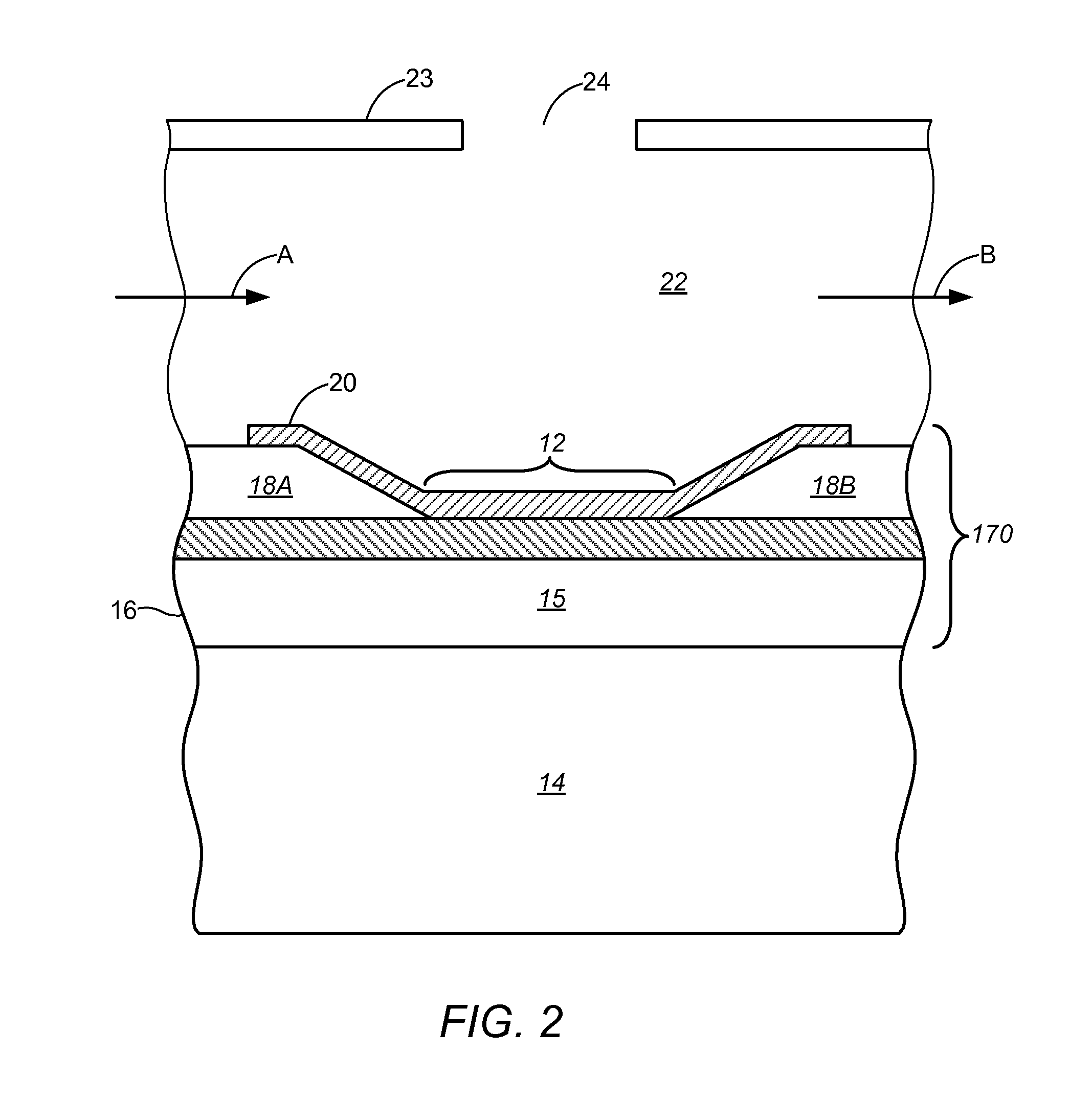

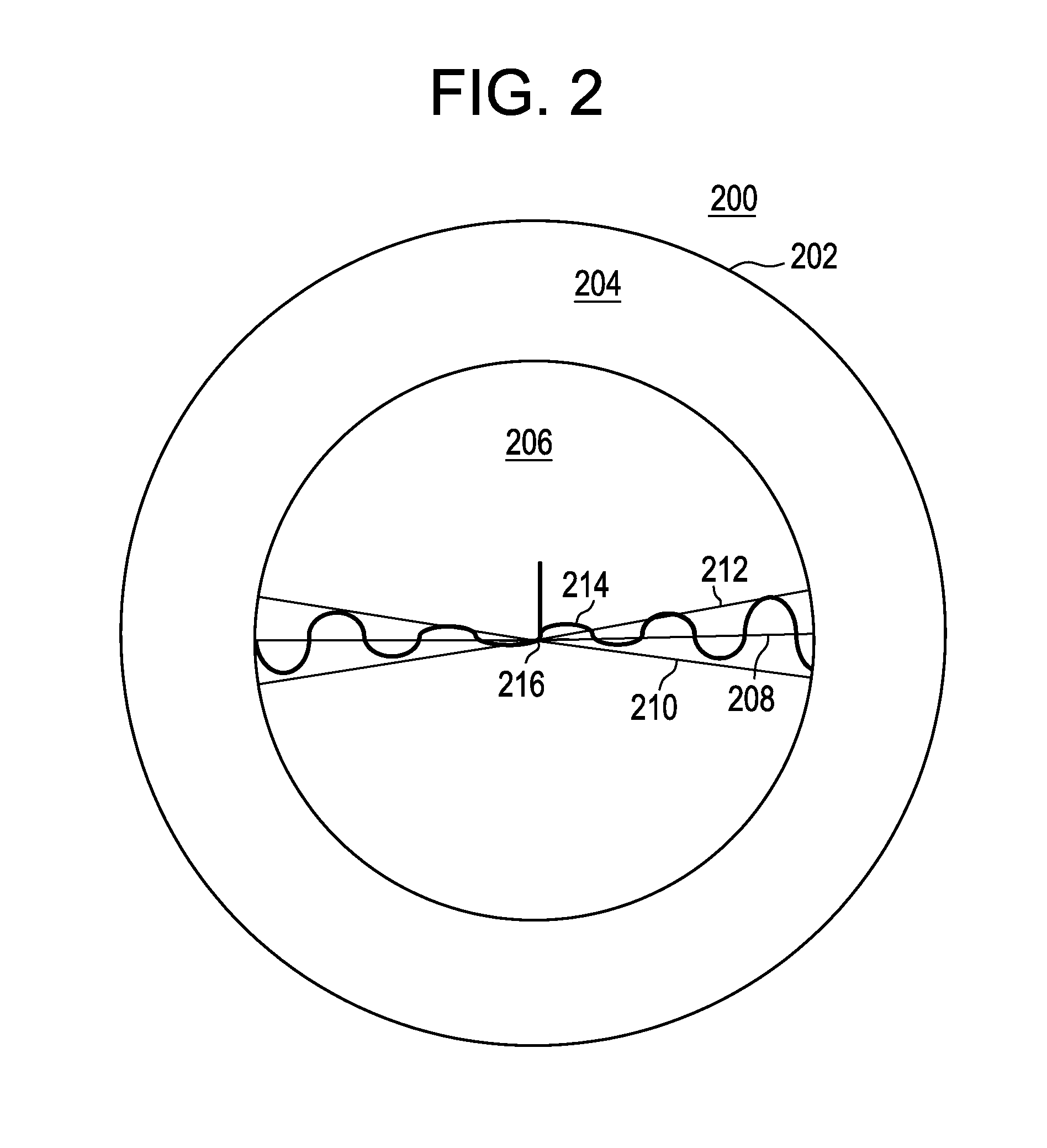

On-chip fluid recirculation pump for micro-fluid applications

ActiveUS20130182022A1Minimizing operational maintenanceAvoids wasteful fluid spittingInking apparatusOther printing apparatusProduction rateEvaporation

A micro-fluid ejection head has fluid ejection elements formed as thin film layers on a substrate. Fluid flow features on the substrate channel fluid from a fluid source to ejection chambers surrounding the ejection elements. A pump on the substrate circulates the fluid from the source to the ejection chambers and back again to the source. The flow refreshes the fluid in the chambers to minimize deleterious effects of evaporation. A controller coordinates the flow rate of the pump and other variables to optimize system productivity. Other embodiments contemplate pump locations, pump types, pump enumeration, and fluidic features, such as pathways, diffusers, chokes and dimensions, to name a few.

Owner:SHANGHAI AUREFLUIDICS TECH CO LTD

On-chip fluid recirculation pump for micro-fluid applications

ActiveUS8814293B2Minimize maintenanceAvoid wastingInking apparatusOther printing apparatusProduction rateEvaporation

A micro-fluid ejection head has fluid ejection elements formed as thin film layers on a substrate. Fluid flow features on the substrate channel fluid from a fluid source to ejection chambers surrounding the ejection elements. A pump on the substrate circulates the fluid from the source to the ejection chambers and back again to the source. The flow refreshes the fluid in the chambers to minimize deleterious effects of evaporation. A controller coordinates the flow rate of the pump and other variables to optimize system productivity. Other embodiments contemplate pump locations, pump types, pump enumeration, and fluidic features, such as pathways, diffusers, chokes and dimensions, to name a few.

Owner:SHANGHAI AUREFLUIDICS TECH CO LTD

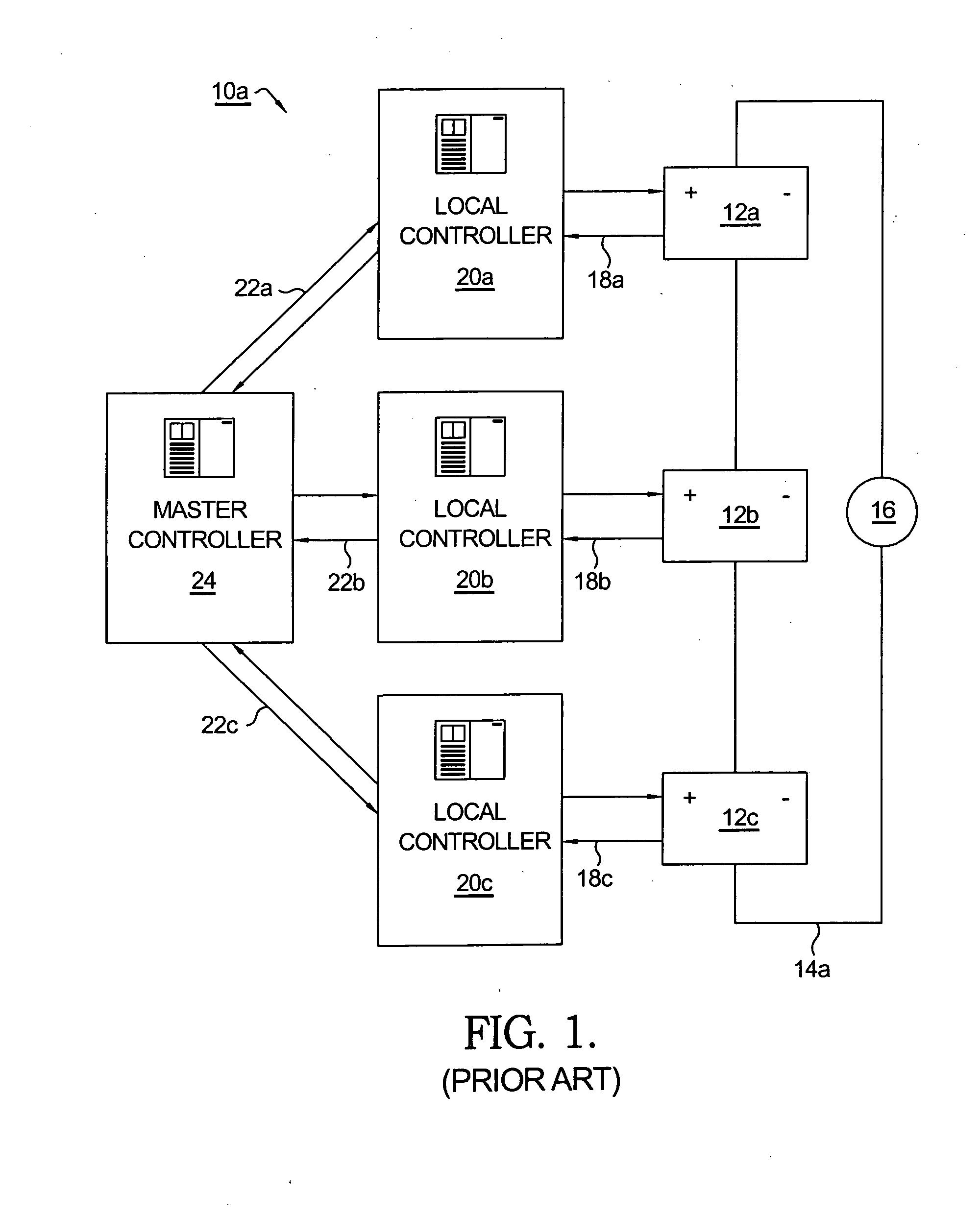

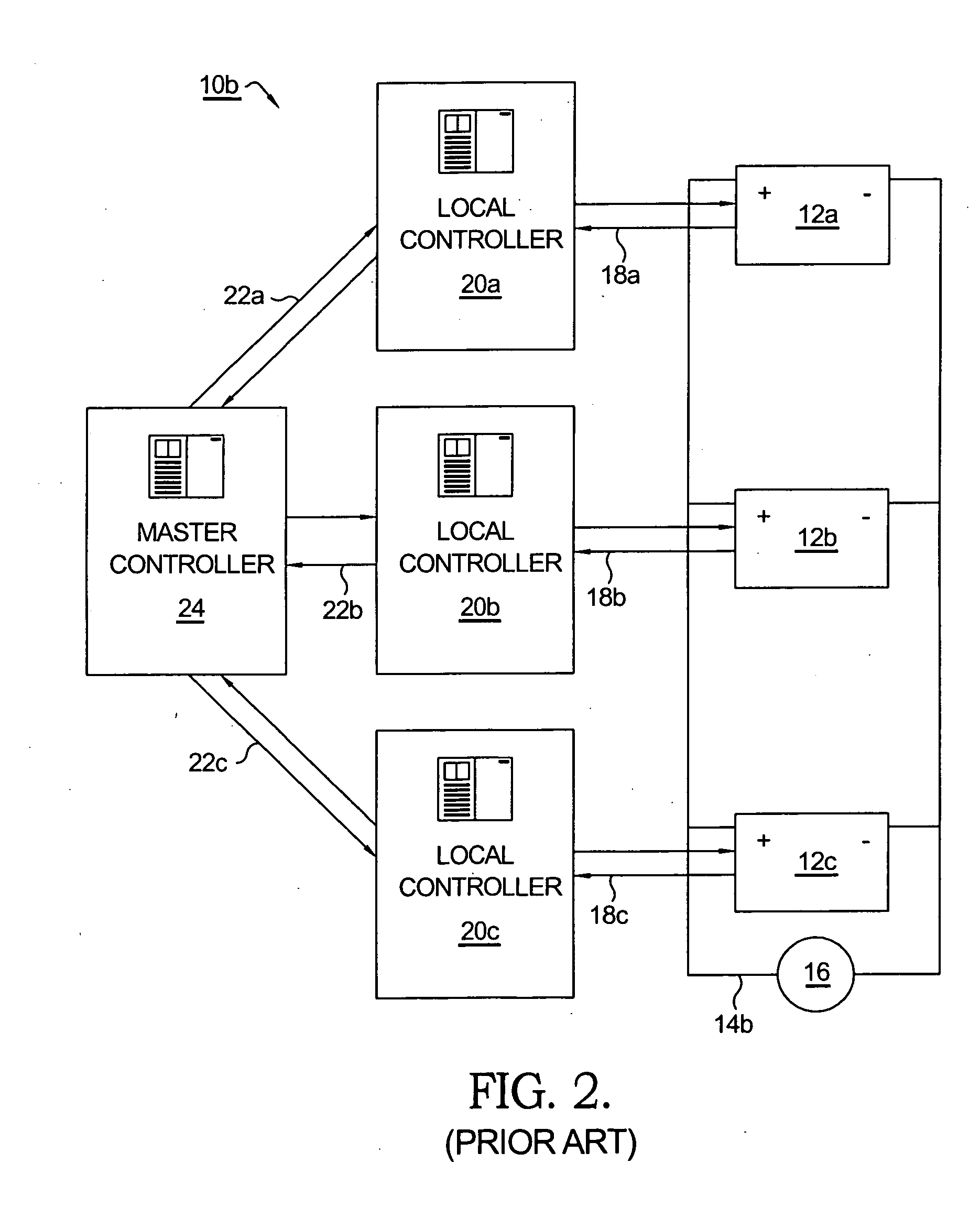

Method and apparatus for controlling a fuel cell system having a variable number of parallel-connected modules

InactiveUS20090305087A1Maximize system lifeMinimizing maintenanceFuel cell auxillariesFuel cellsMaster controller

A fuel cell APU system comprising a plurality of fuel cell modules connected in parallel. Each module includes a local controller connected to a master controller that coordinates the modules to achieve a desired power output at any given time. Each module is operated within an output range to maximize efficiency of the system. When load demand on a first module exceeds the desired output range of the module, an additional module is brought online in parallel with the first. As the load increases further, additional modules are brought online in cascade fashion to permit all modules to be operated efficiently. If a module is disabled, it is automatically switched out of service and replaced by a standby module. The master controller keeps track of the total operating time of each module and varies the sequence in which different modules are brought into service to balance deterioration among the modules.

Owner:DELPHI TECH INC

Railway car coupler knuckle having improved bearing surface

InactiveUS20030127412A1Increase the bearing surfaceFine surfaceRailway coupling accessoriesEngineeringBearing surface

A coupler knuckle casting having an enhanced bearing surface area and which is utilized in a railway freight car coupler. The coupler knuckle casting includes a tail section, and a hub section. The hub section has a pivot pinhole formed therein. Such pivot pinhole has generally straight cylindrical sidewalls. A front face section is connected to the hub section. Such front face section includes a nose section and a pulling face portion formed inwardly from such nose section. At such least a portion of such front face portion and such nose section includes an enhanced bearing surface area which includes a substantially flat portion disposed substantially in a vertical direction and which is substantially arcuate in a horizontal direction. The substantially flat portion extends for a predetermined distance in the vertical direction and for a predetermined length along the horizontal direction. There is the a transition section joining the tail section to the hub section. Such transition section includes a top metal section and a bottom metal section extending toward each other.

Owner:MCCONWAY & TORLEY LLC

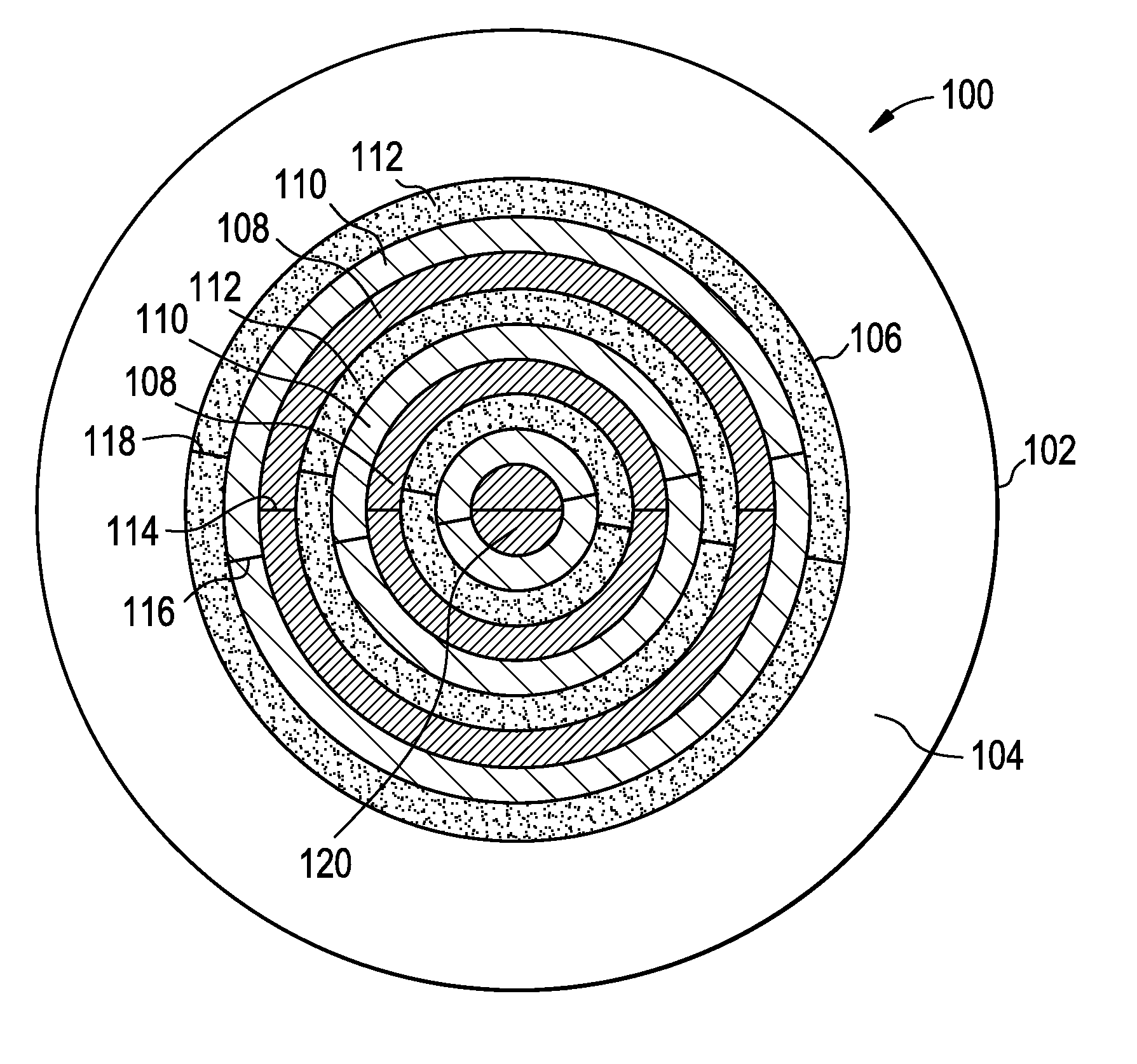

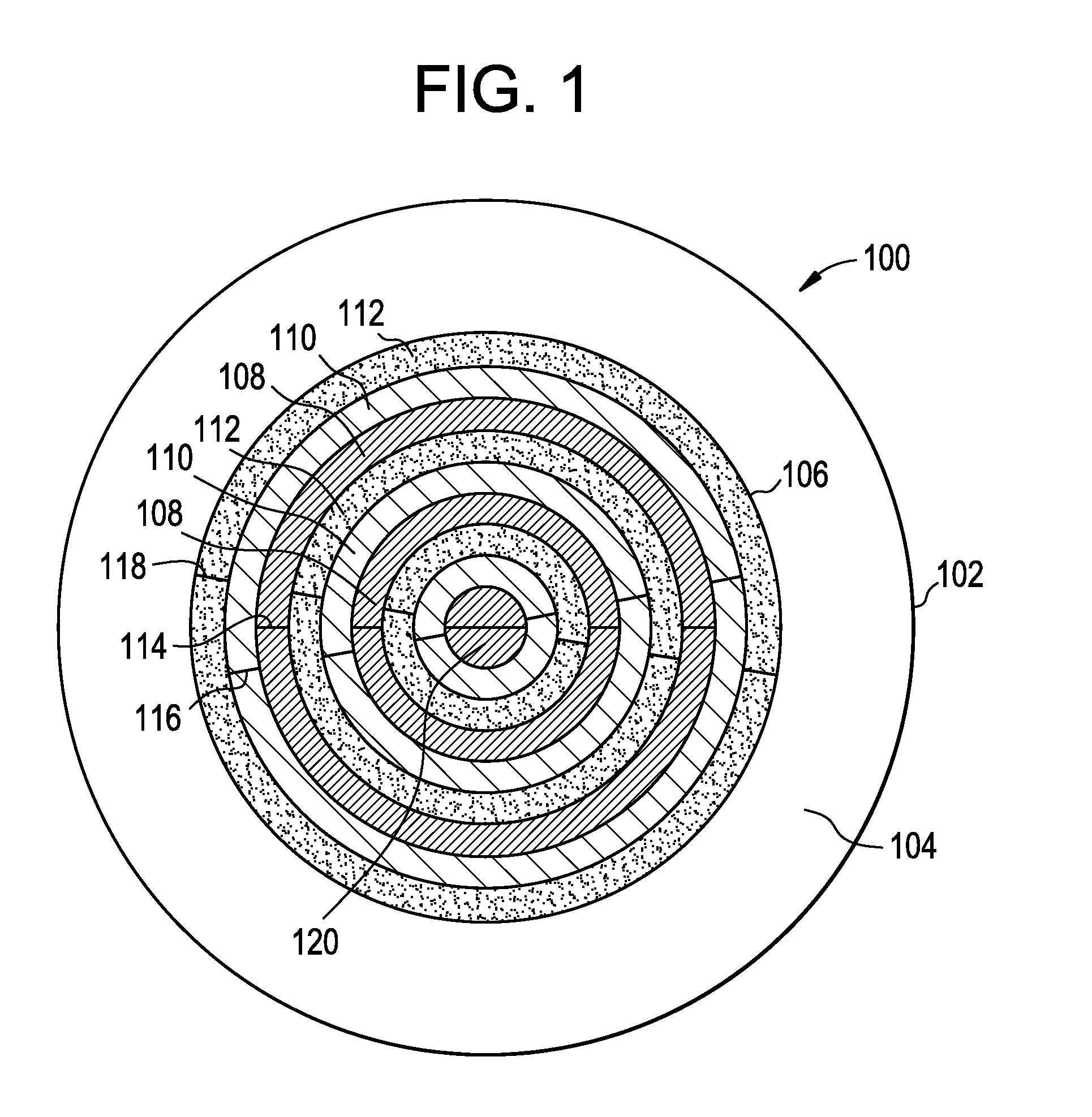

Multi-axis lens design for astigmatism

ActiveUS20130222761A1Minimize maintenanceReduce sensitivitySpectales/gogglesEye diagnosticsPhysicsAstigmatism

A toric contact lens utilizes concentric annual rings, a continually varying lens design as a function of distance from the lens center or any other function to create a range of cylinder axis zones on a single lens.

Owner:JOHNSON & JOHNSON VISION CARE INC

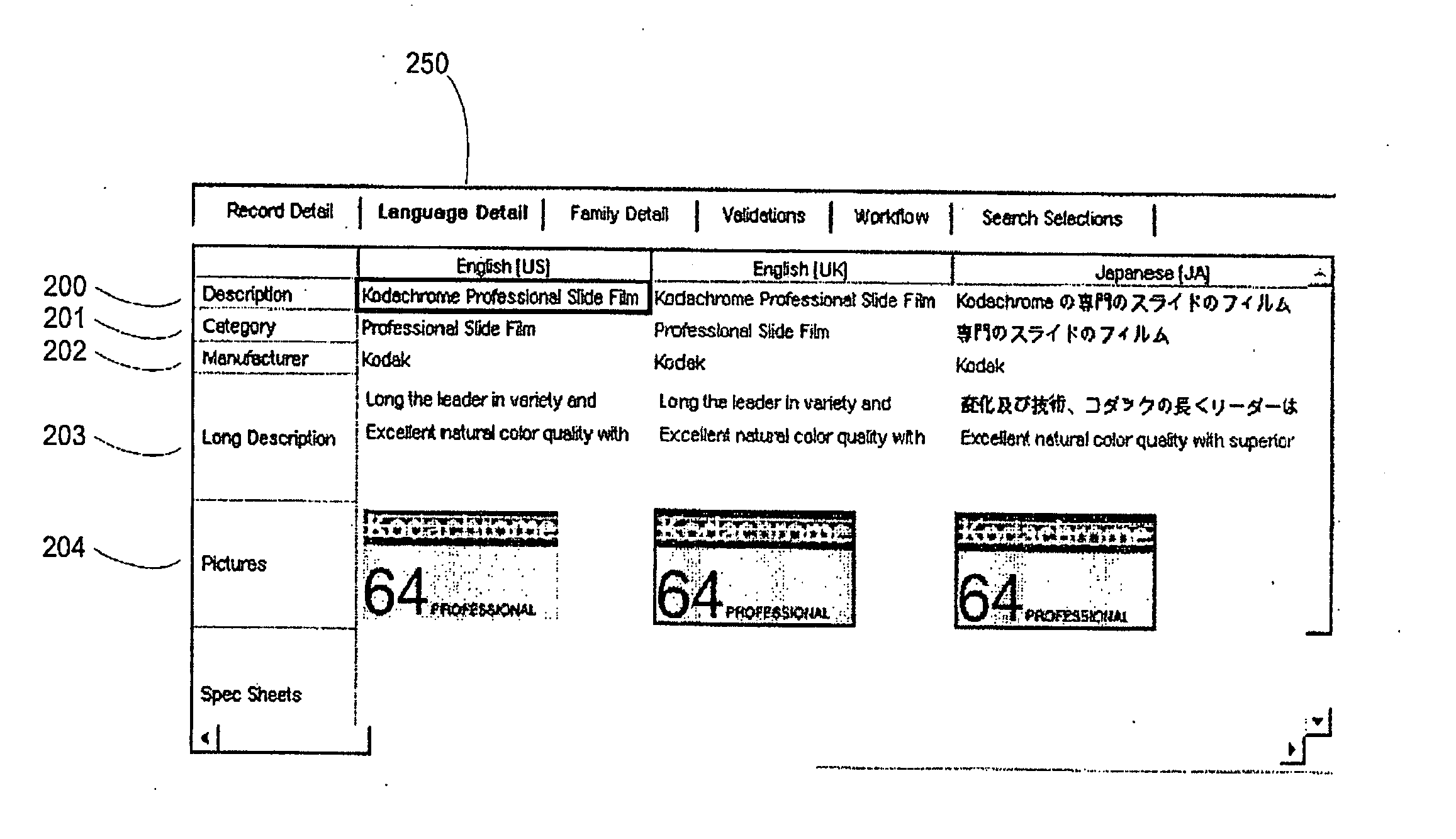

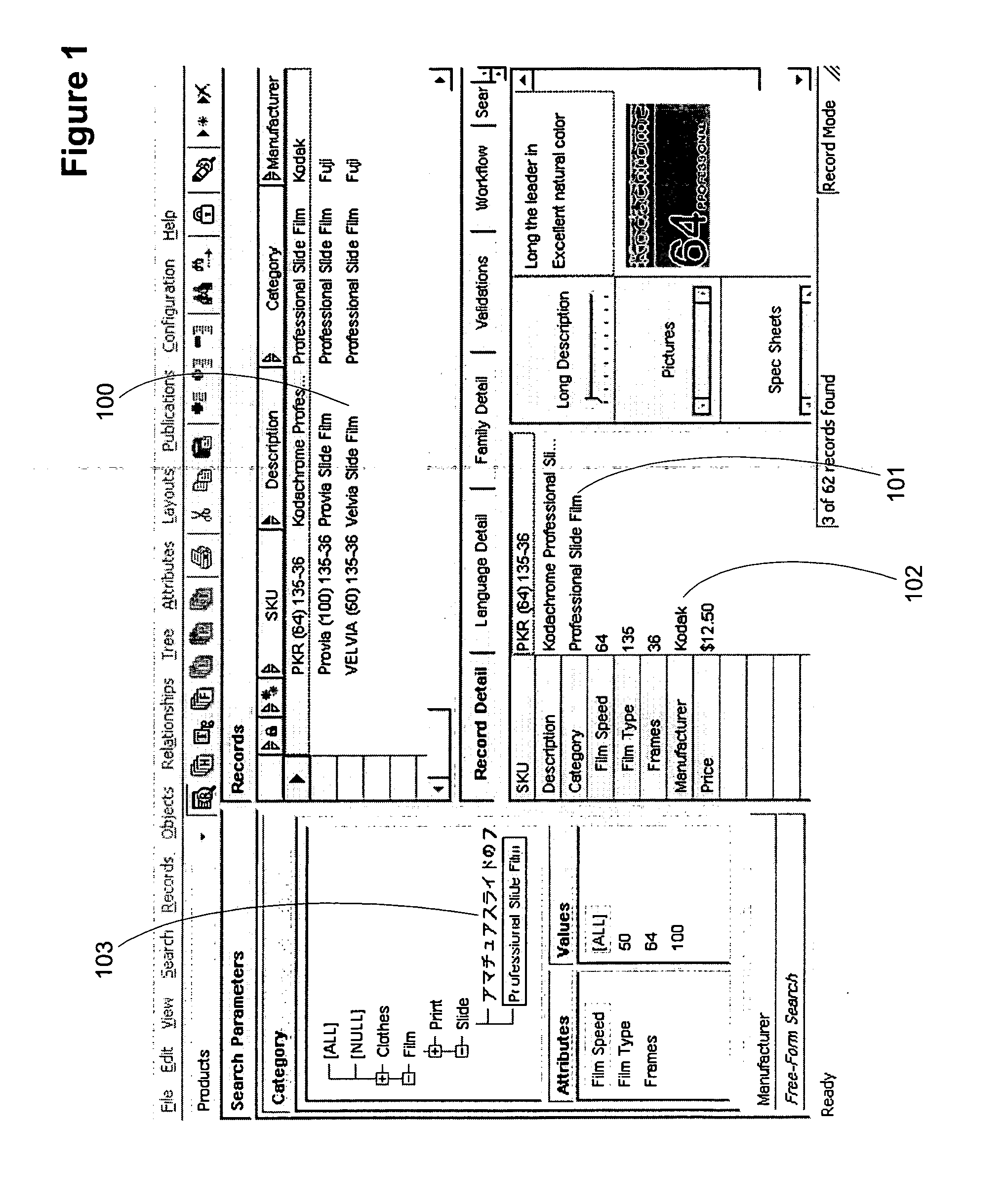

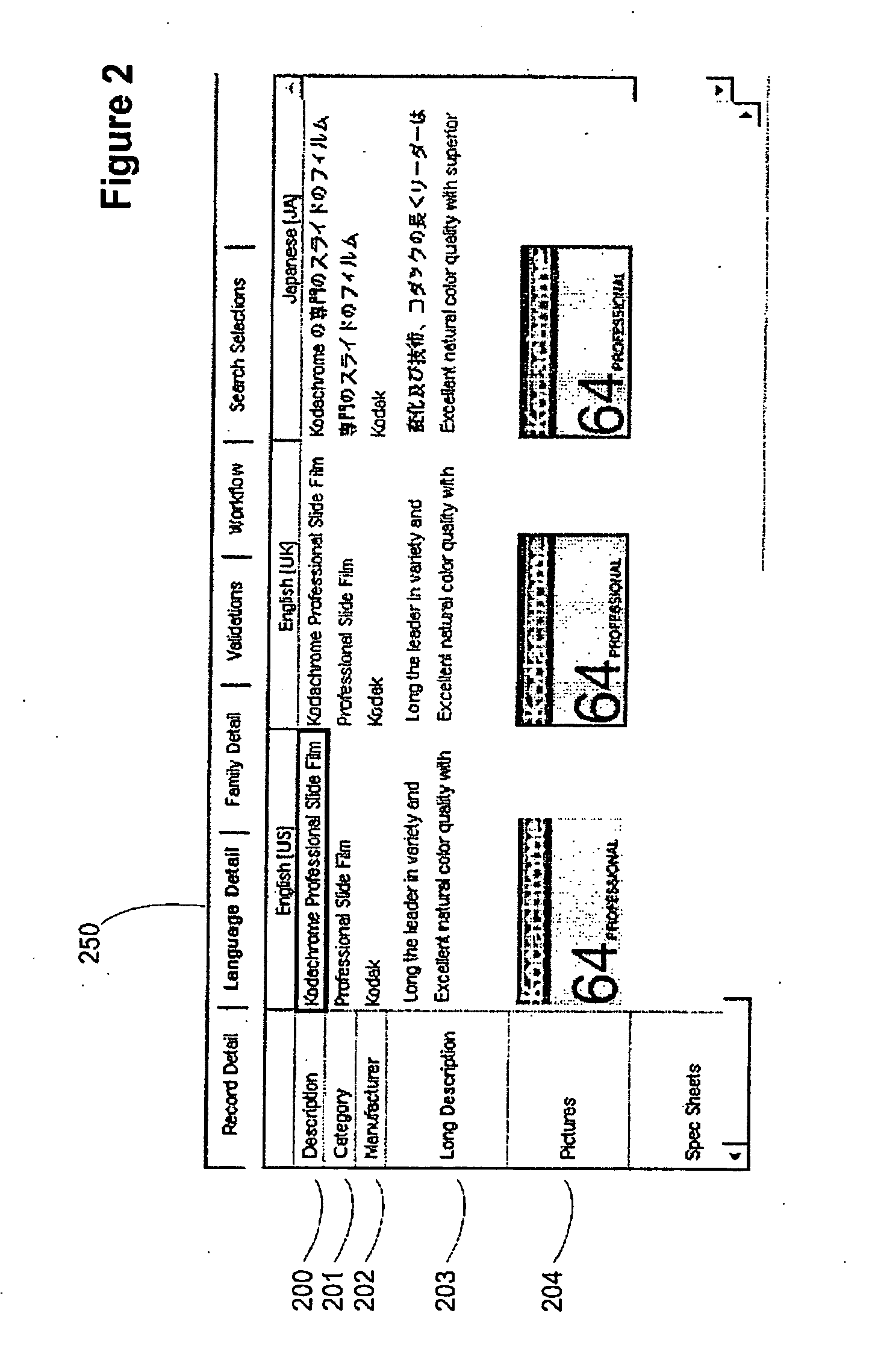

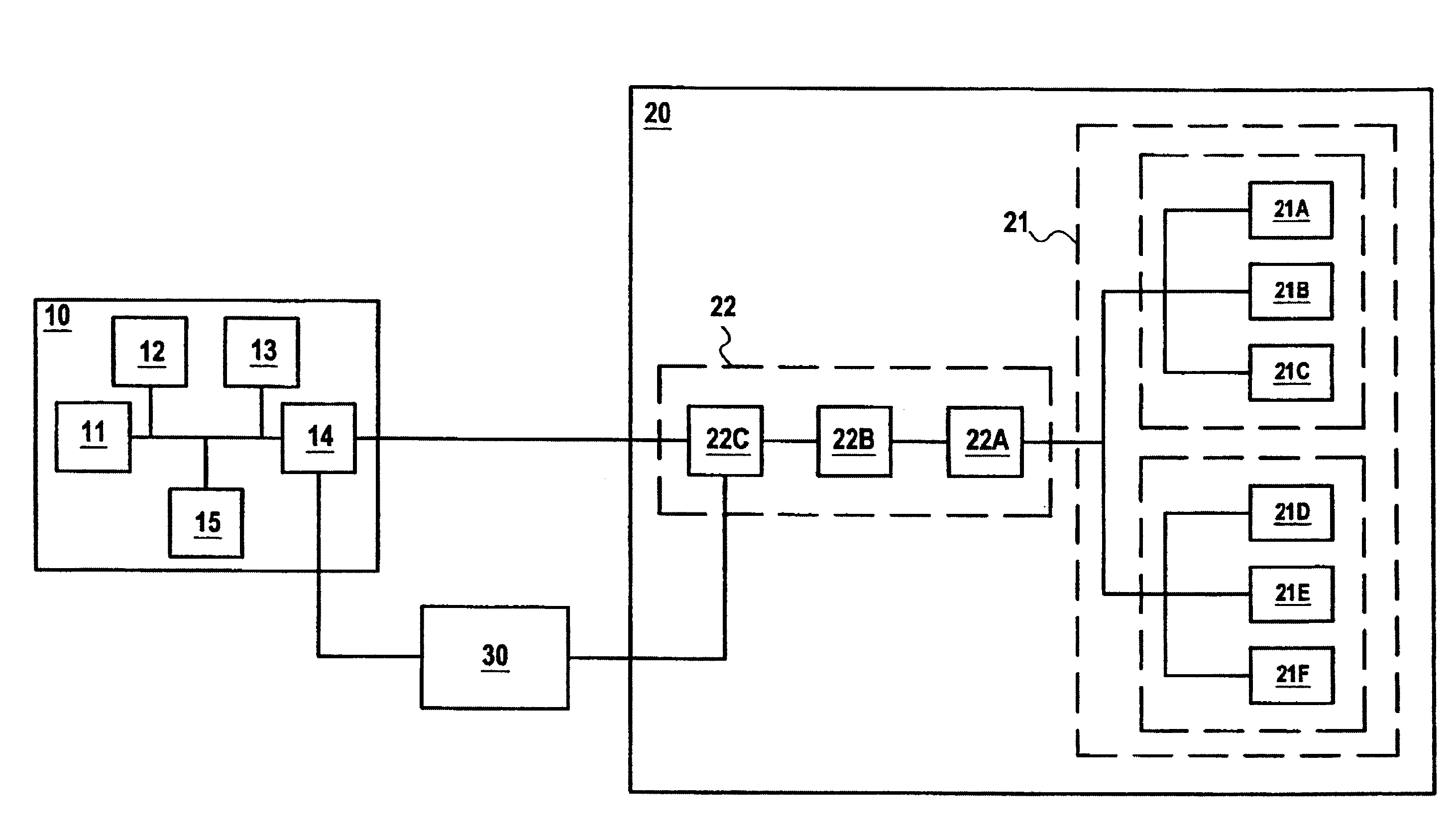

Interface for indicating the presence of inherited values in a document

ActiveUS20060271868A1Quick supportQuick identificationNatural language data processingProgram controlPaper documentDocument preparation

An interface for indicating the presence of inherited values in a document. The interface enables a user to rapidly determine if an audience specific document conforms to the expectations or requirements of an intended audience. The interface distinguishes between current, primary and secondary audience layer values through the use of color or any other mechanism that allows a user to quickly identify data that is missing and needs to be populated, changed or remain unchanged if the inherited data is suitable for the given audience. Using the interface, users can determine at a glance what information is inherited and what level of inheritance that information is from. Before generating an audience specific document targeted at a particular media type, an audience hierarchy may be created and utilized for entry and edit of data for a desired audience.

Owner:SAP AG

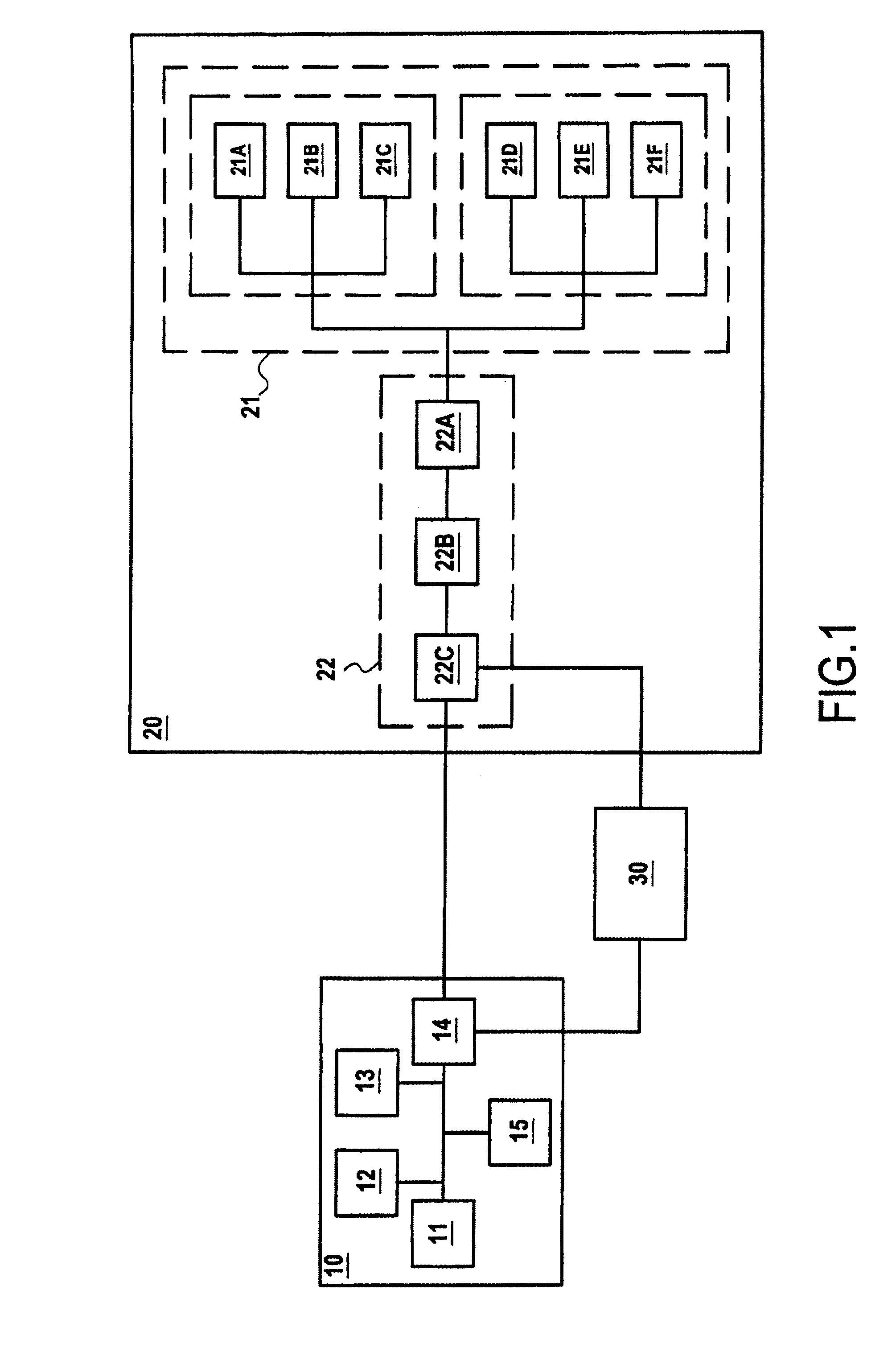

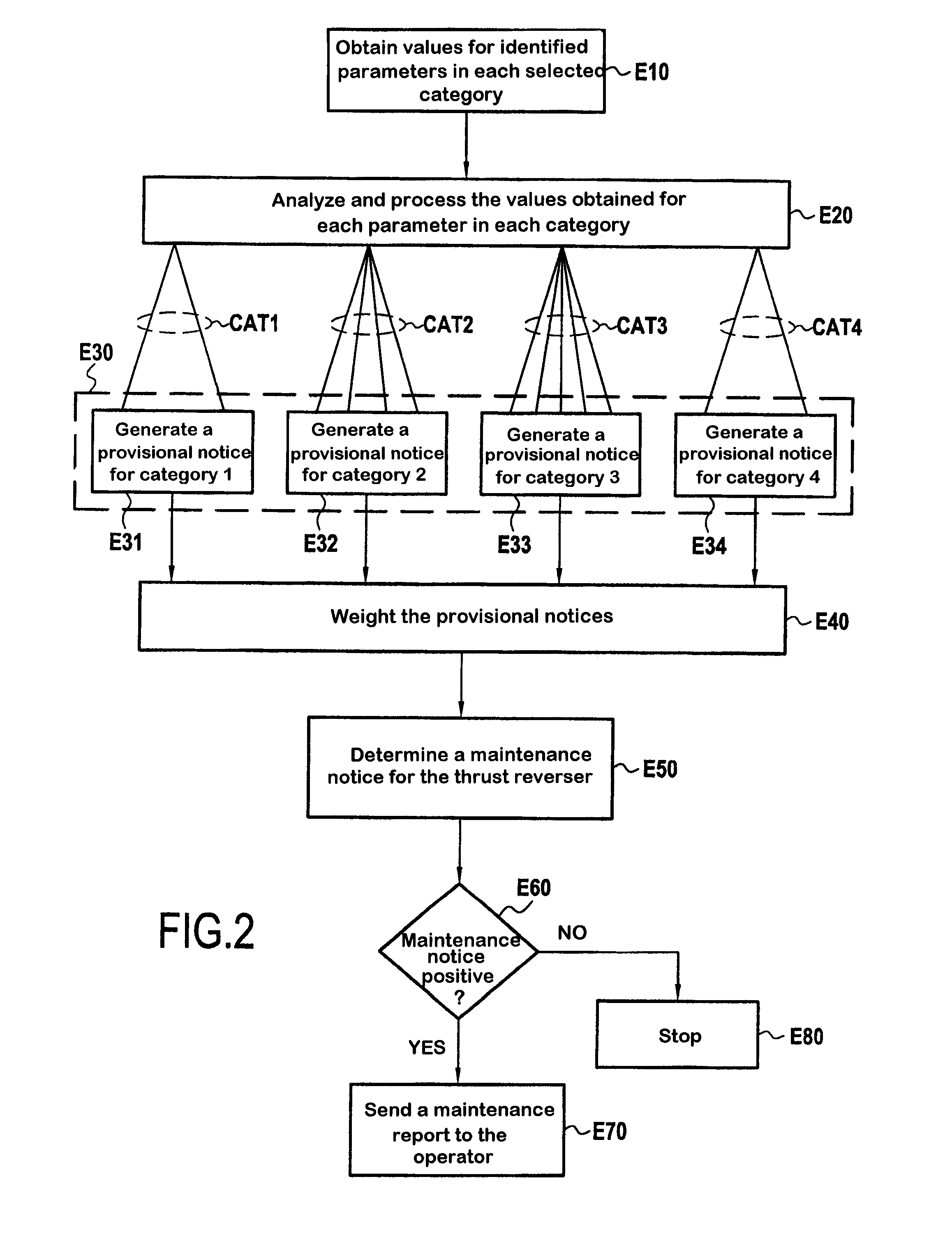

Method of monitoring a thrust reverser

ActiveUS20100242434A1Effective monitoringMinimizing maintenance false alertVehicle testingRegistering/indicating working of vehiclesPhase correlationActuator

The method of the invention for monitoring a thrust reverser of a turbojet having an actuator controlled by an electric motor consists in determining a maintenance notice from a weighted combination of provisional notices, each provisional notice relating to a category of parameters associated with at least one phase of an operating cycle of the reverser, the category being selected from a category of parameters representative of a duration of said phase, of an energy seen by the motor during said phase, of a torque seen by the motor at a predefined instant of said phase, and of a duration during which the setpoint speed of rotation and the measured speed of rotation of the motor differ during said phase, each provisional notice being generated by analyzing values obtained during at least one cycle for at least one parameter of said category relative to a degradation threshold.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

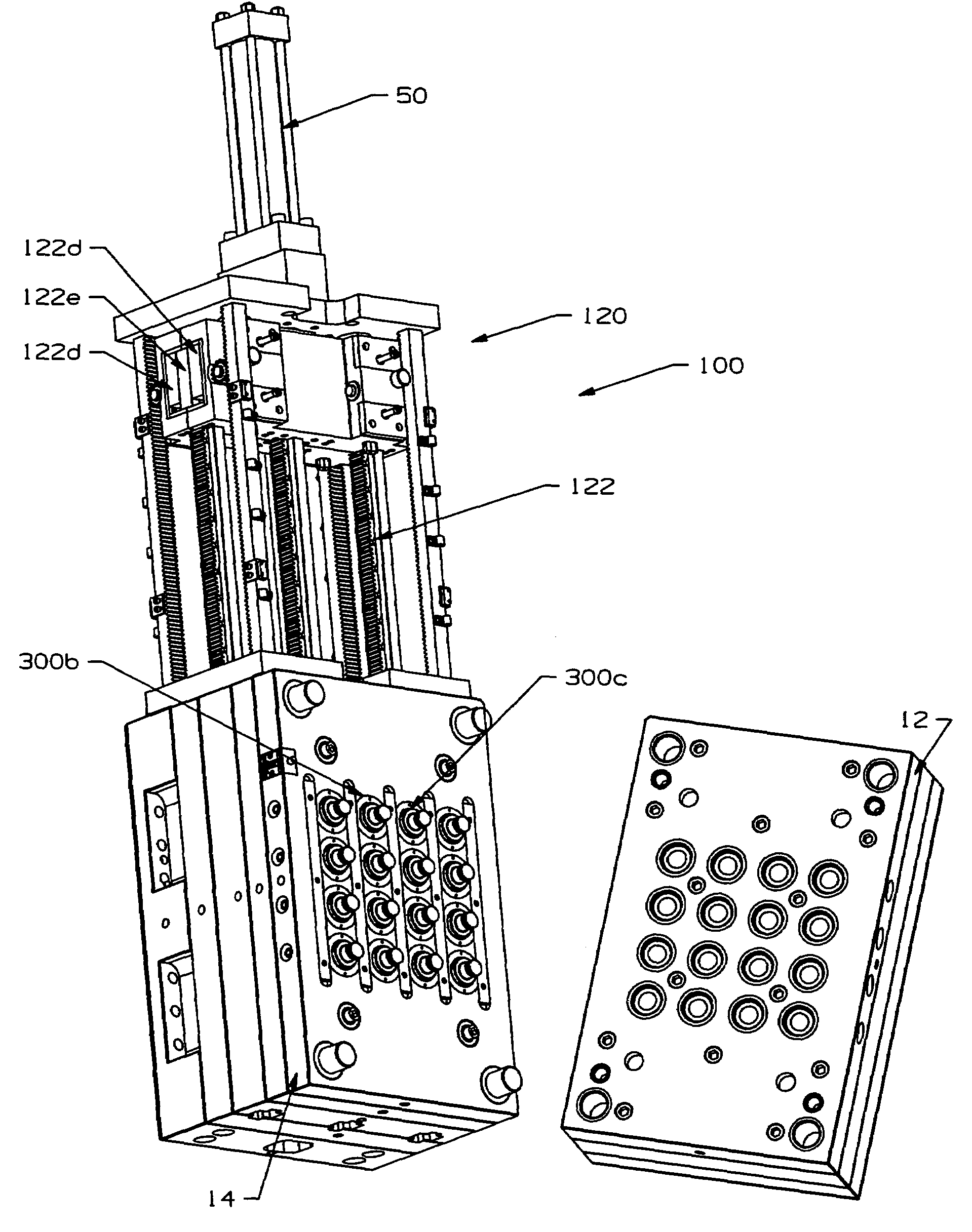

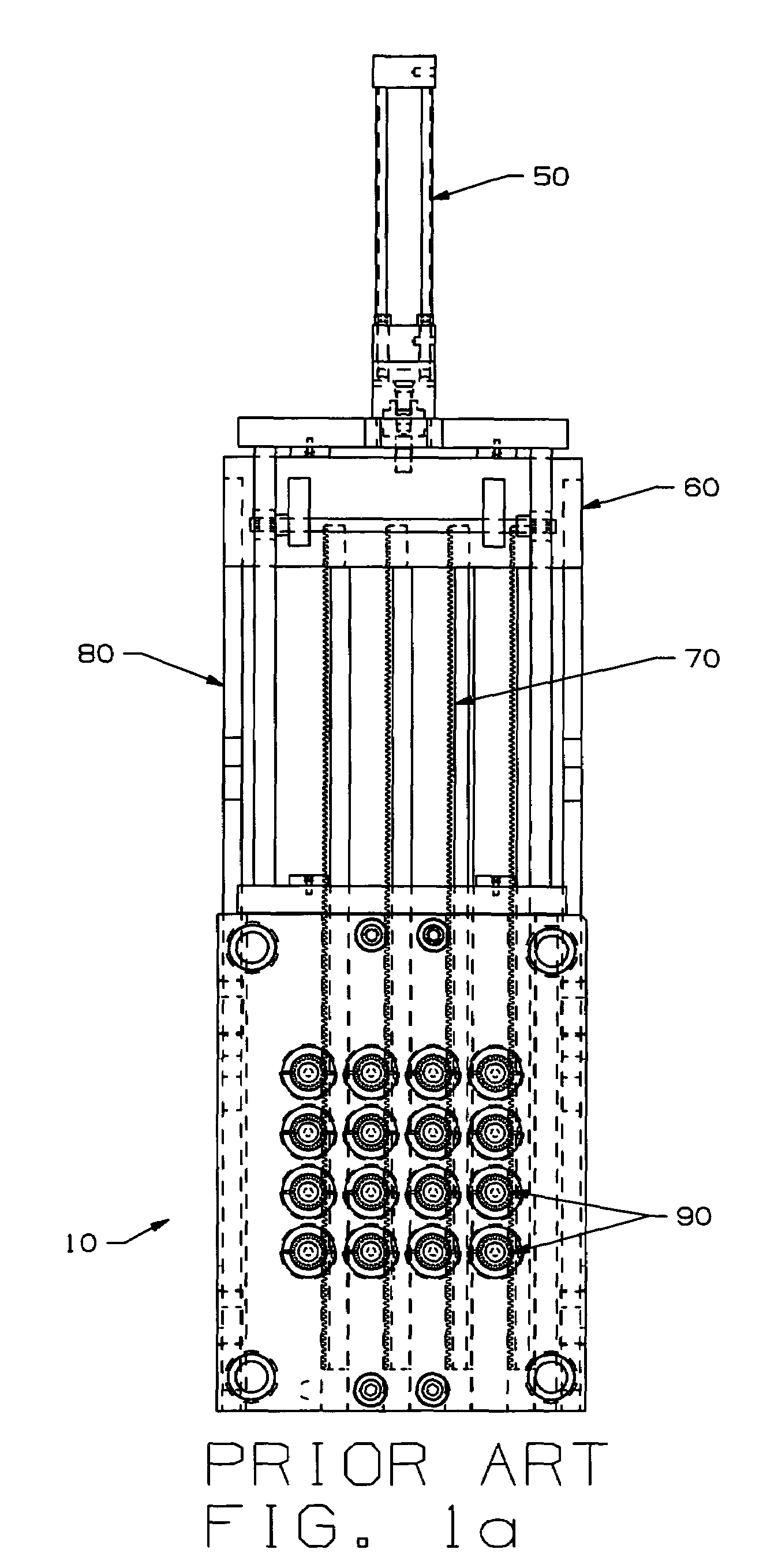

Apparatus for making threaded articles in a plastic injection molding process

A Bi-directional rack assembly that rotates one column of threaded cores and unscrews threaded closures while moving in the forward direction. The Bi-directional rack then mechanically changes position to engage an adjacent column of rotating threaded cores and at the end of a second molding cycle rotates the threaded cores and unscrew threaded closures while moving in the reverse (reset) direction. A set of timed-advance devices are engaged by a smaller pinion gear and idler gear assemblies to the Bi-directional rack and as the Timed-Advance devices are activated, they allow pneumatic pistons to advance the stripper plate in time with the threaded closures as they are being unscrewed from the threaded cores. A second “rapid advance” pneumatic piston eliminates the need for an external rapid rise camming feature. A rotating core comprising a stock, rotating core, a stock water-seal insert and a custom core top.

Owner:CREATIVE MOLD SOLUTIONS

System and process for forming battery cans

InactiveUS20060159989A1Moderate roughnessMinimize internal resistanceSmall-sized cells cases/jacketsDry cellsElectricityEngineering

A process for producing a battery can in a transfer press comprises drawing a metal cup in a first station to form an elongated cylinder, ironing the elongated cylinder in a second station, and redrawing the elongated cylinder in a third station. In either or both the drawing and ironing steps, the cup or the elongated cylinder may be processed in more than one station. The process includes a final redraw station for redrawing the cylinder so as to roughen the inner surface of the battery can to improve its electrical properties.

Owner:H & T BATTERY COMPONENTS USA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com