Railway car coupler knuckle having improved bearing surface

a technology for railway freight cars and couplers, which is applied in the direction of railway couplings, railway components, railway coupling accessories, etc., can solve the problems of increasing the cost of producing a satisfactory coupler, affecting the quality of the coupler, so as to achieve the effect of improving the bearing surfa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

, particularly, when such detailed description is taken in conjunction with the attached drawing figures and with the appended claims.

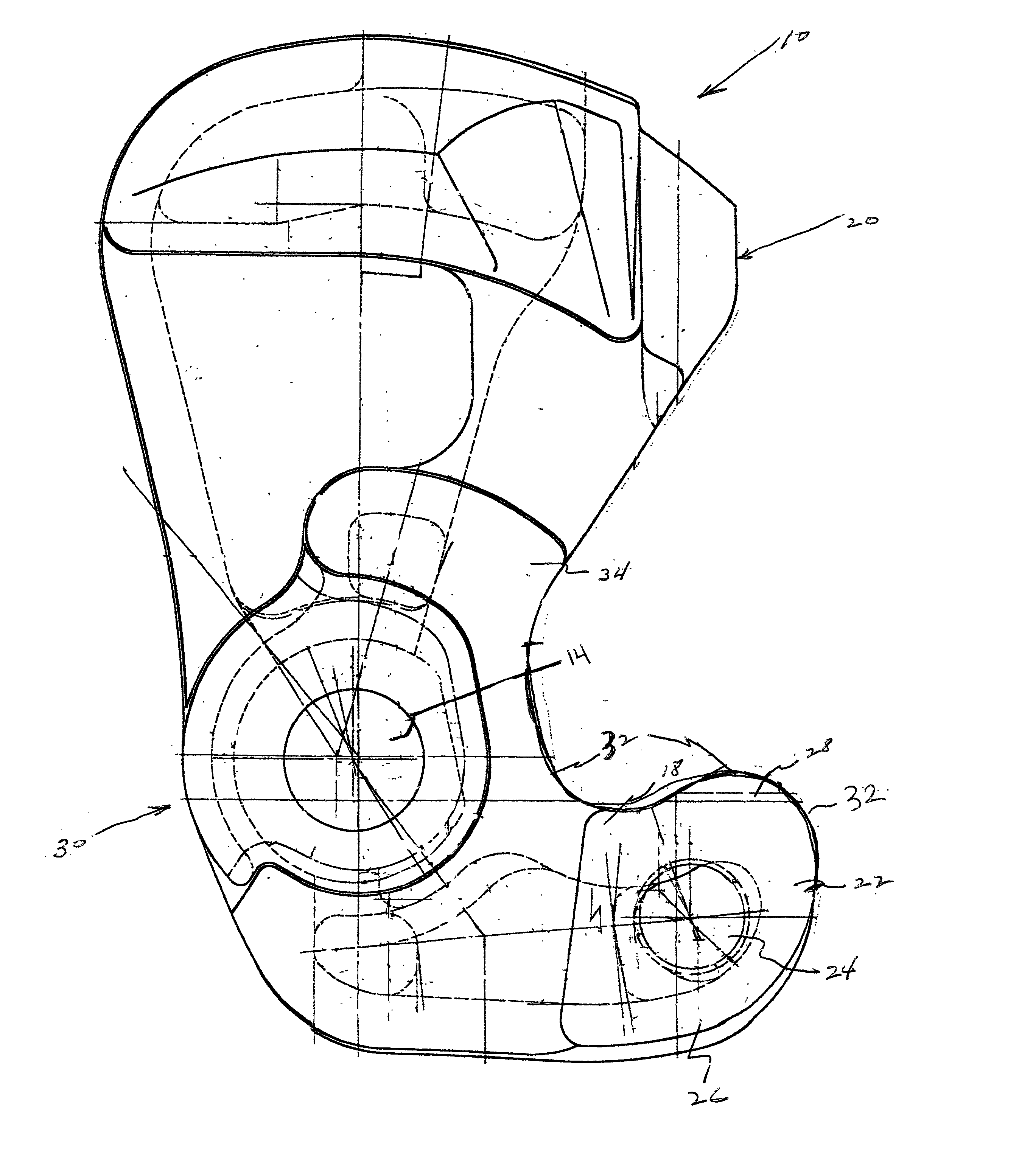

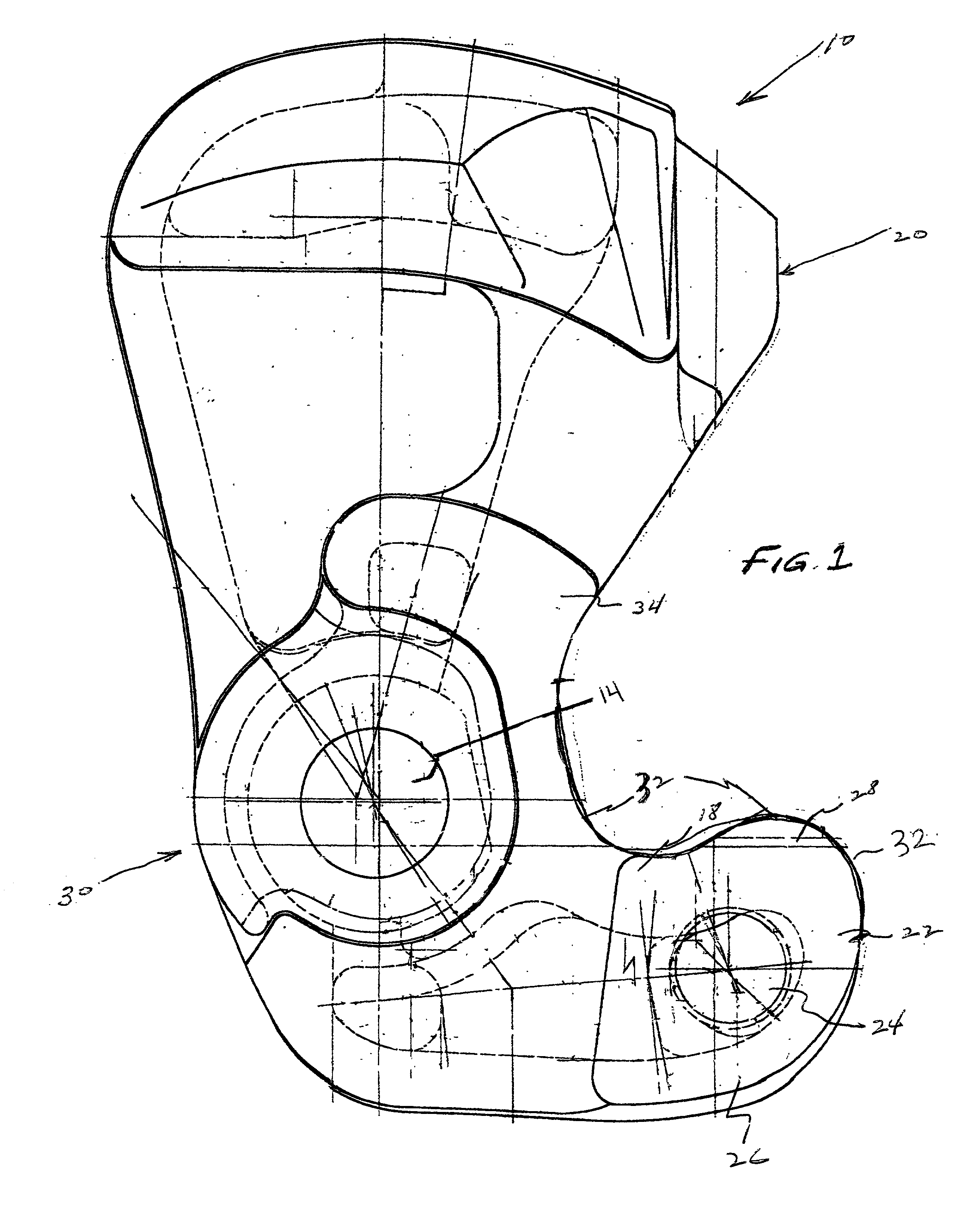

[0019] FIG. 1 is a top elevation view of a railway car coupler knuckle which has been modified in accordance with present invention; and

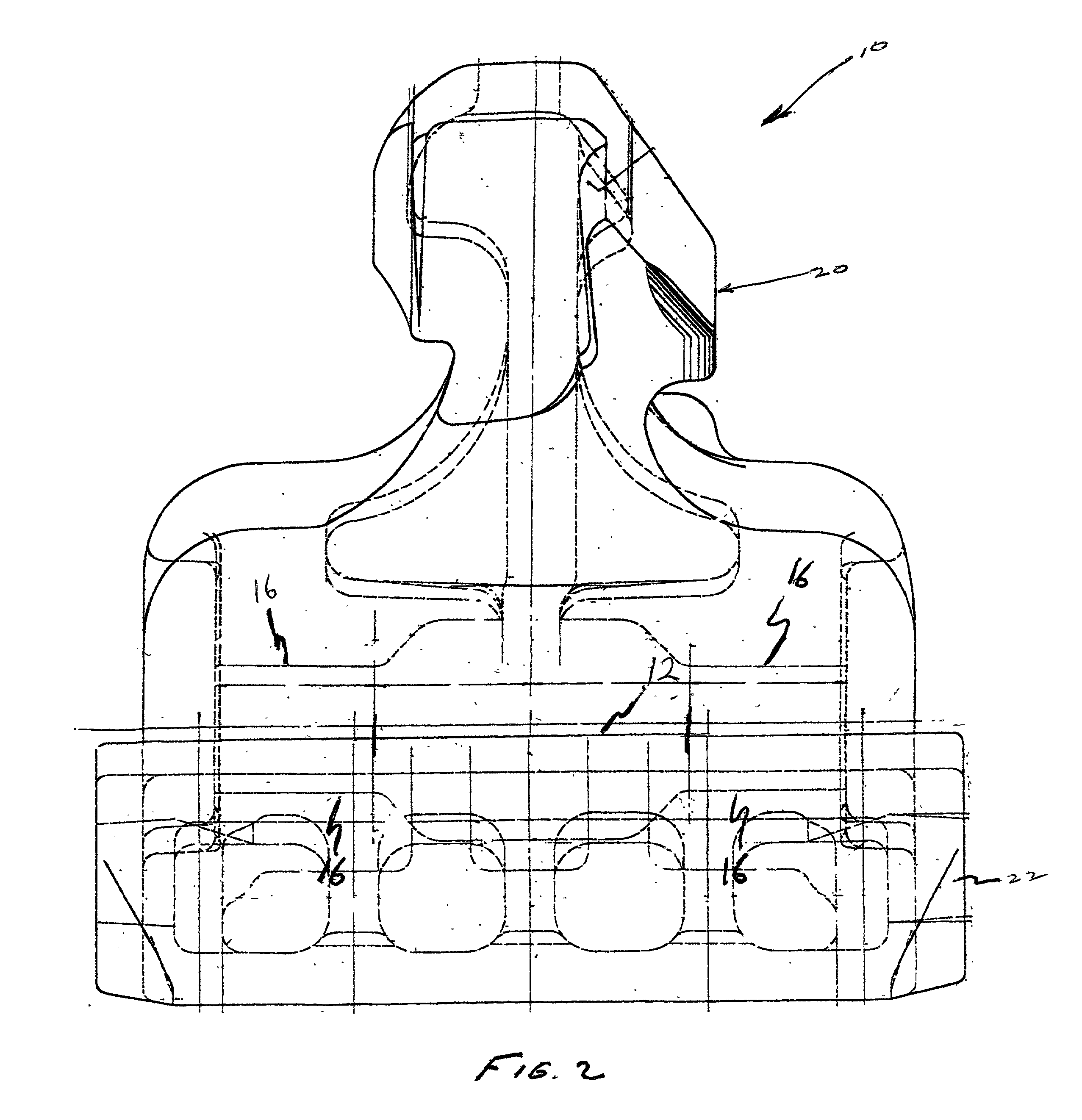

[0020] FIG. 2 is a side view of the railway car coupler knuckle illustrated in FIG. 1.

BRIEF DESCRIPTION OF A PRESENTLY PREFERRED AND VARIOUS ALTERNATIVE EMBODIMENTS OF THE INVENTION

[0021] Prior to proceeding to the much more detailed description of the present invention is should be noted that identical elements, having identical functions, have been identified with identical reference numerals throughout the several views which have been illustrated in the drawing figures for the sake of clarity and understanding of the invention.

[0022] Now reference is made, more particularly, to FIGS. 1 and 2 of the drawings. Illustrated therein and is a presently preferred embodiment of a railway freight car (not shown) coupler kn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com