Patents

Literature

42results about How to "Moderate roughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

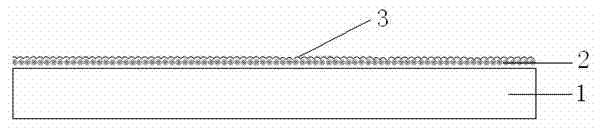

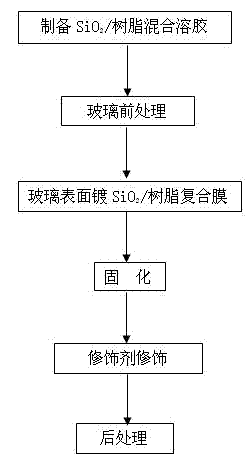

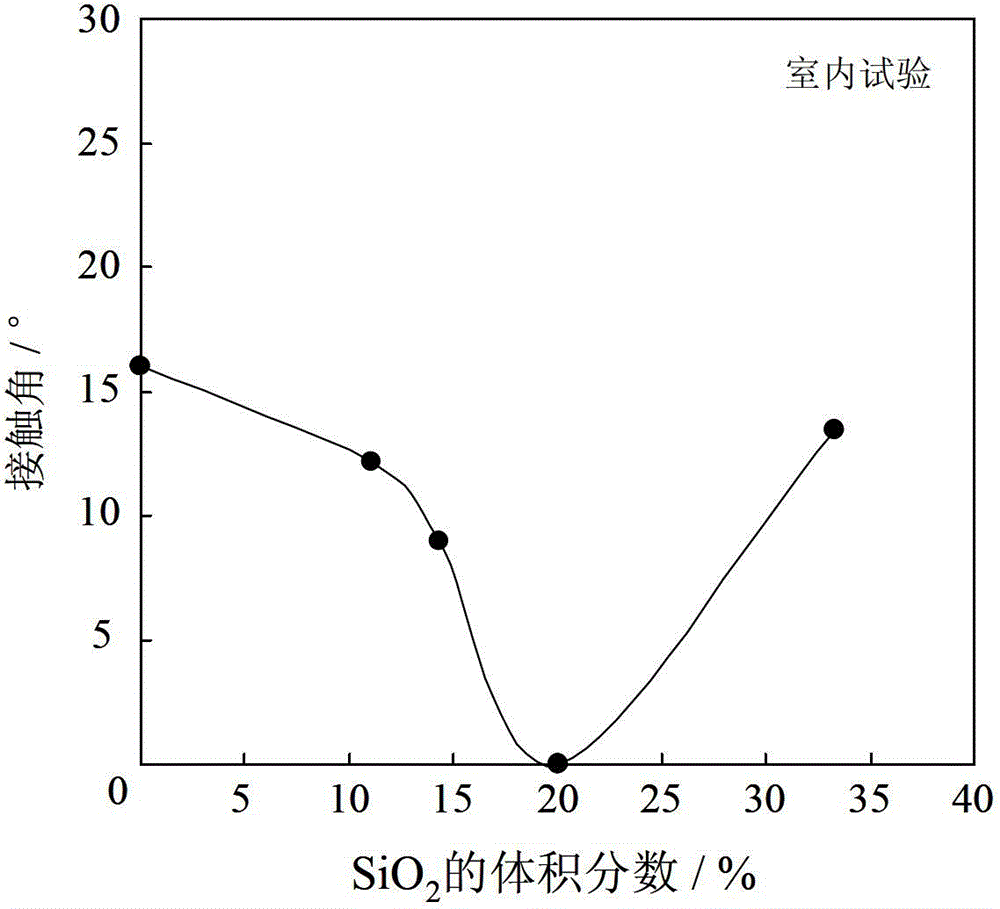

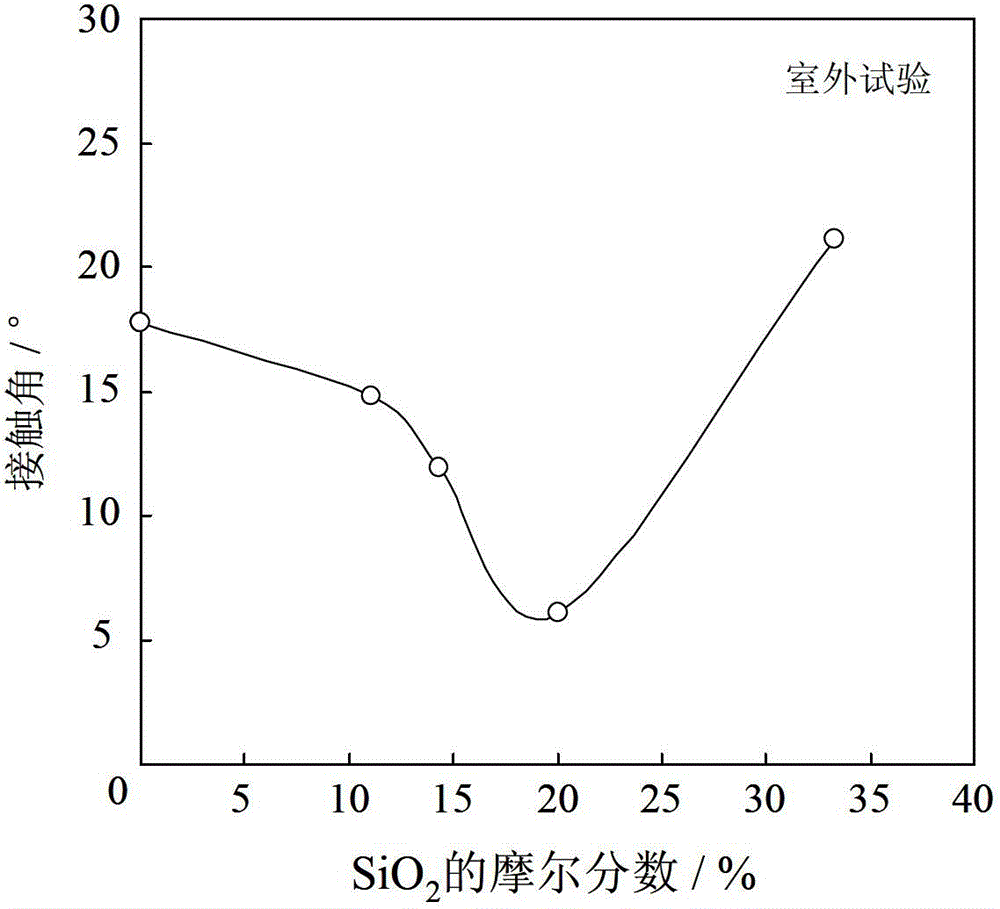

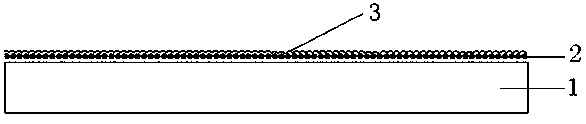

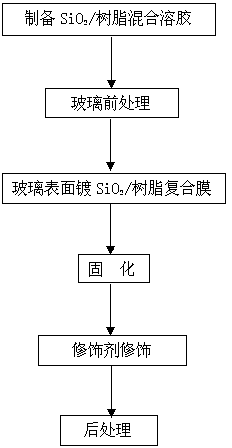

Preparation method of wear-resistant hydrophobic glass

The invention provides a preparation method of wear-resistant hydrophobic glass which is excellent in wear resistance, high in light permeability and low in preparation cost. The method includes steps of A, preparation of SiO2 / resin mixed sol; B, preprocessing of glass; C, coating of a SiO2 / resin composite membrane on the surface of glass; D, solidification; E, modification via modifier; and F, postprocessing. The preparation method has the advantages that firstly, particle size of SiO2 is controlled in a range of from 90 to 110nm by controlling PH value of prepared sol solution, so that high light transmission can be guaranteed while proper roughness can be provided for a hydrophobic membrane layer; secondly, by means of the technique that resin and SiO2 gel are mixed and directly coated, SiO2 particles are wrapped by resin, and structural strength among the SiO2 particles and between the SiO2 particles and a glass substrate can be improved greatly; and thirdly, using the once filming technique for the SiO2 / resin mixed gel is simpler in process and lower in cost than using the traditional technique for separately coating SiO2 gel and resin.

Owner:CHERY AUTOMOBILE CO LTD

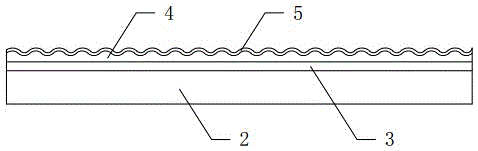

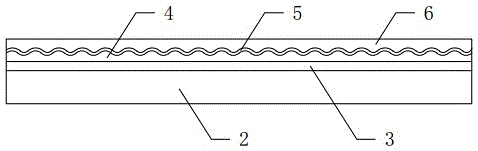

Method for preparing mineral-fiber-filled high-strength environment-friendly rich mineral paper

InactiveCN104119600AModerate roughnessHigh hardnessSynthetic resin layered productsFiberLinear low-density polyethylene

The invention relates to a mineral-fiber-filled high-strength environment-friendly rich mineral paper. The rich mineral paper is prepared by combining high-density polyethylene, linear low-density polyethylene resin, inorganic powder, non-metallic mineral fiber, a foaming agent, an antioxidant, a light stabilizer and additives as raw materials. The rich mineral paper comprises the following components in parts by weight: 10-15 parts of high-density polyethylene, 10-15 parts of linear low-density polyethylene resin, 65-75 parts of inorganic powder, 5 parts of non-metallic mineral fiber, 0.1-0.2 part of a foaming agent, 0.1-0.2 part of an antioxidant, 0.1-0.2 part of a light stabilizer and 0-2 parts of additives, wherein the total sum of the amount of the materials as the reference starting materials is 100 parts by weight. The preparation method comprises the steps of blending, mixing, granulating and molding. By virtue of the method disclosed by the invention, the dimensional stability, heat resistance, chemical resistance, flame resistance, electrical insulation and other properties of the rich mineral paper are improved. Due to the adoption of a three-layer co-extrusion process, the specific surface area is large, the specific weight is reduced, and the hardness, paper feeling, printing effect and ink absorption property are improved.

Owner:宋旭

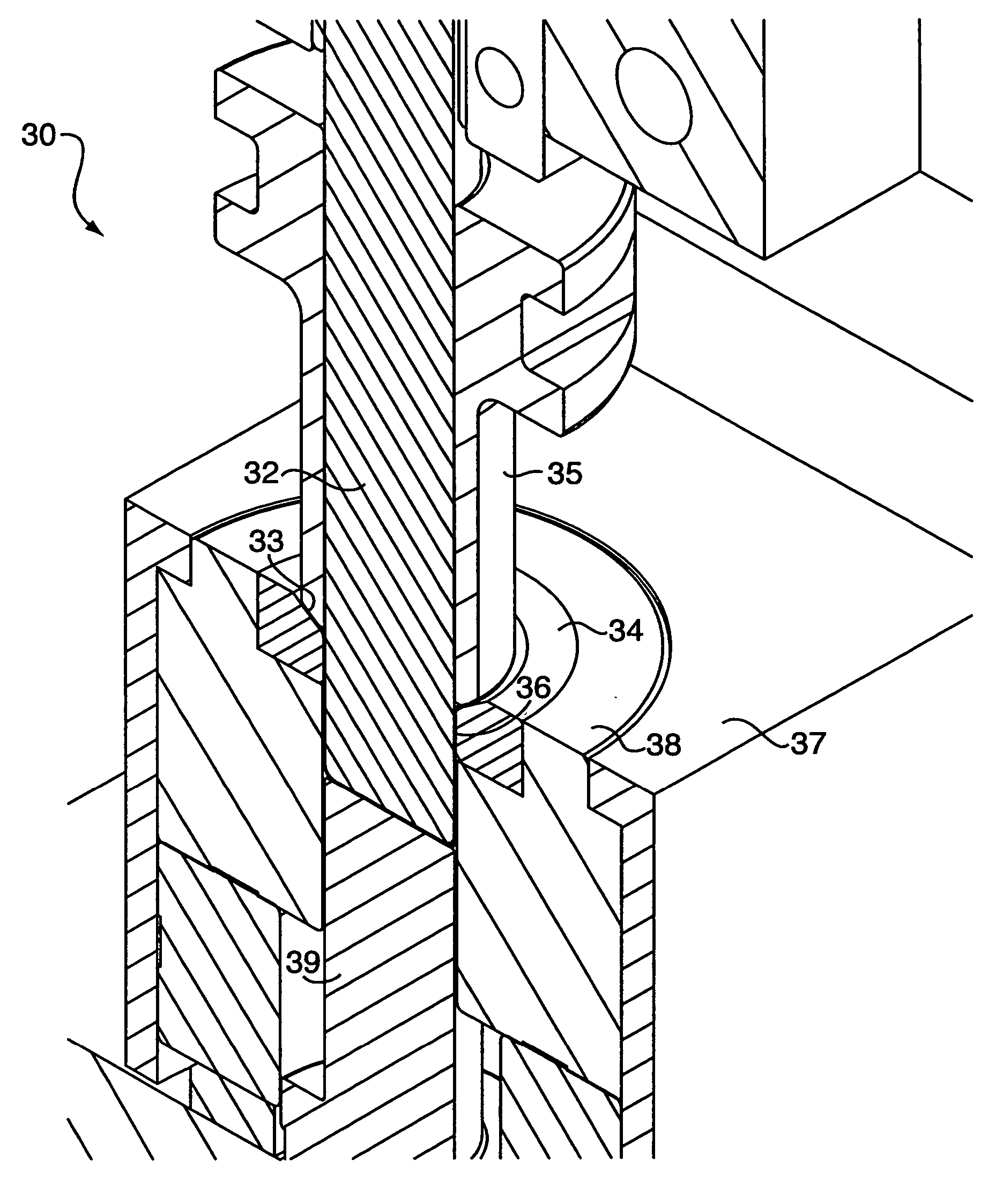

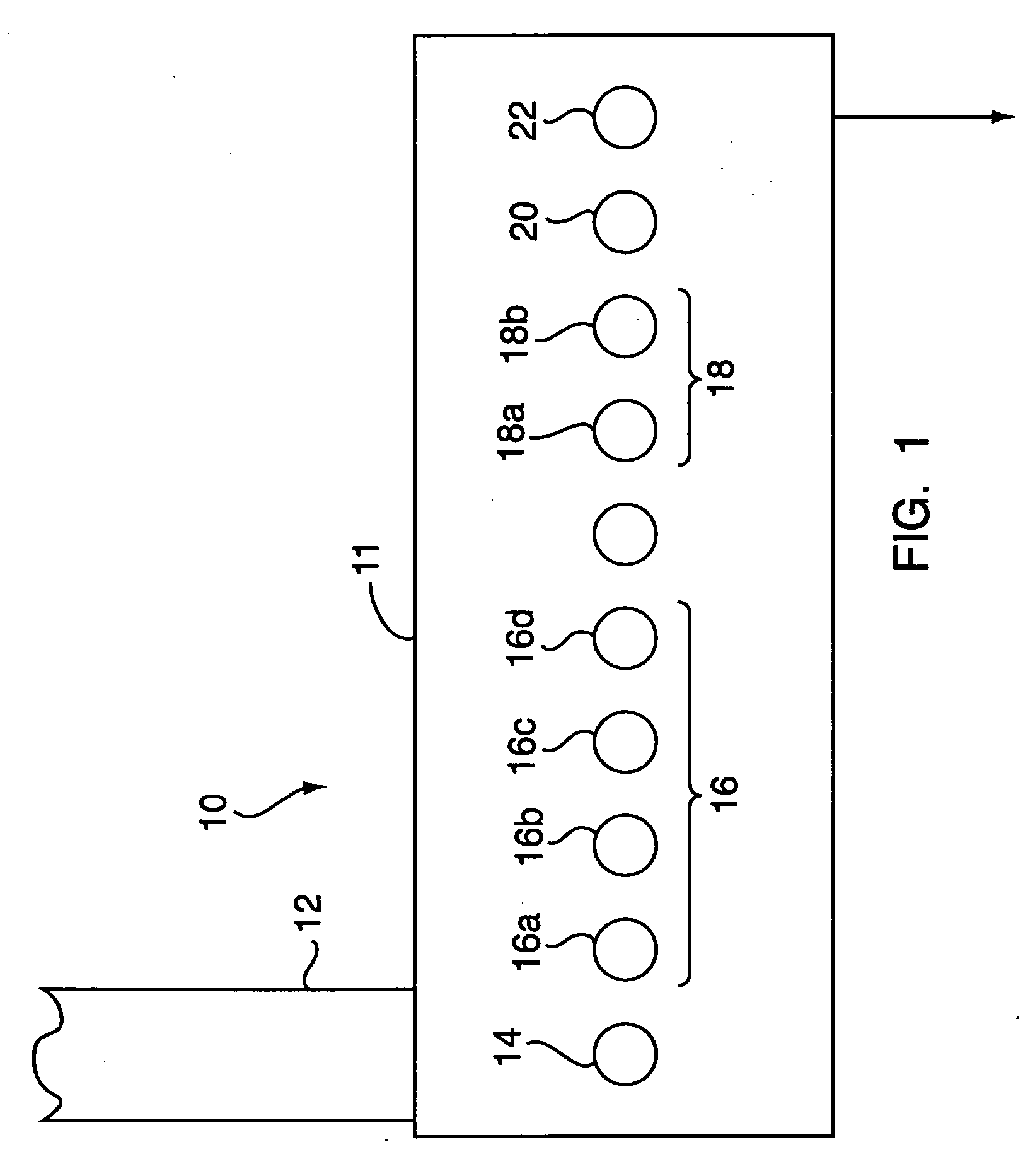

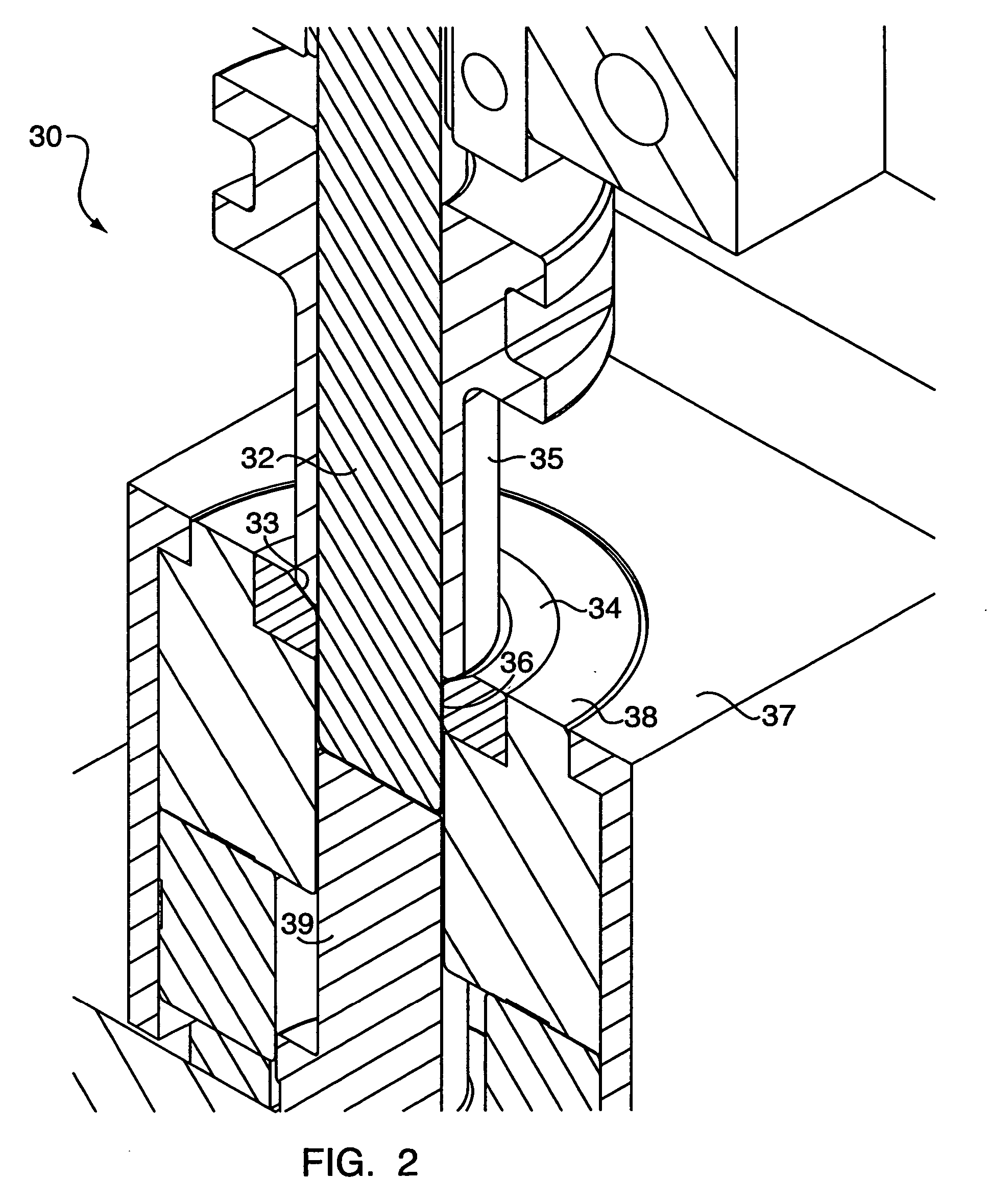

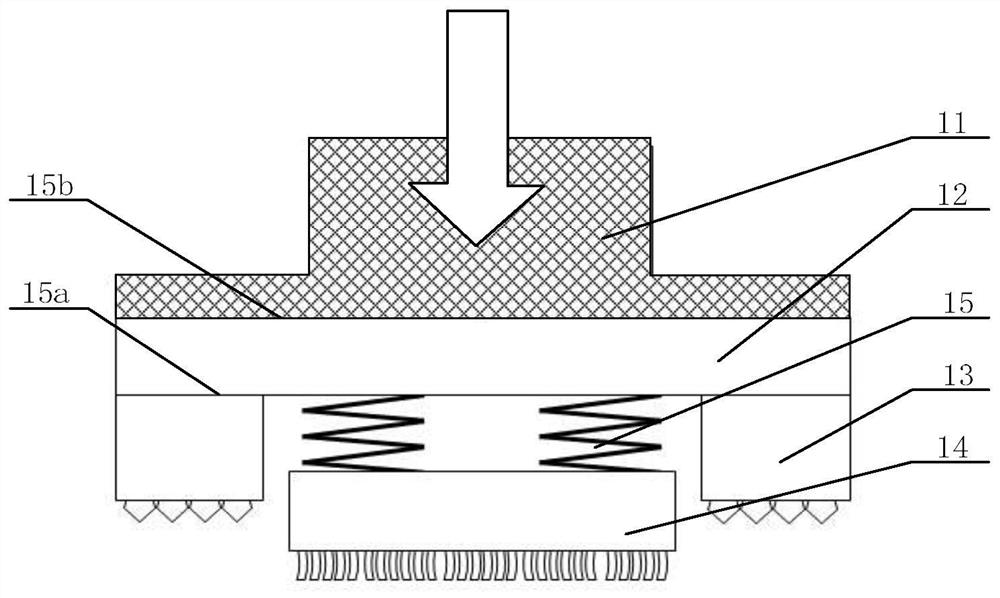

System and process for forming battery cans

InactiveUS20060159989A1Moderate roughnessMinimize internal resistanceSmall-sized cells cases/jacketsDry cellsElectricityEngineering

A process for producing a battery can in a transfer press comprises drawing a metal cup in a first station to form an elongated cylinder, ironing the elongated cylinder in a second station, and redrawing the elongated cylinder in a third station. In either or both the drawing and ironing steps, the cup or the elongated cylinder may be processed in more than one station. The process includes a final redraw station for redrawing the cylinder so as to roughen the inner surface of the battery can to improve its electrical properties.

Owner:H & T BATTERY COMPONENTS USA

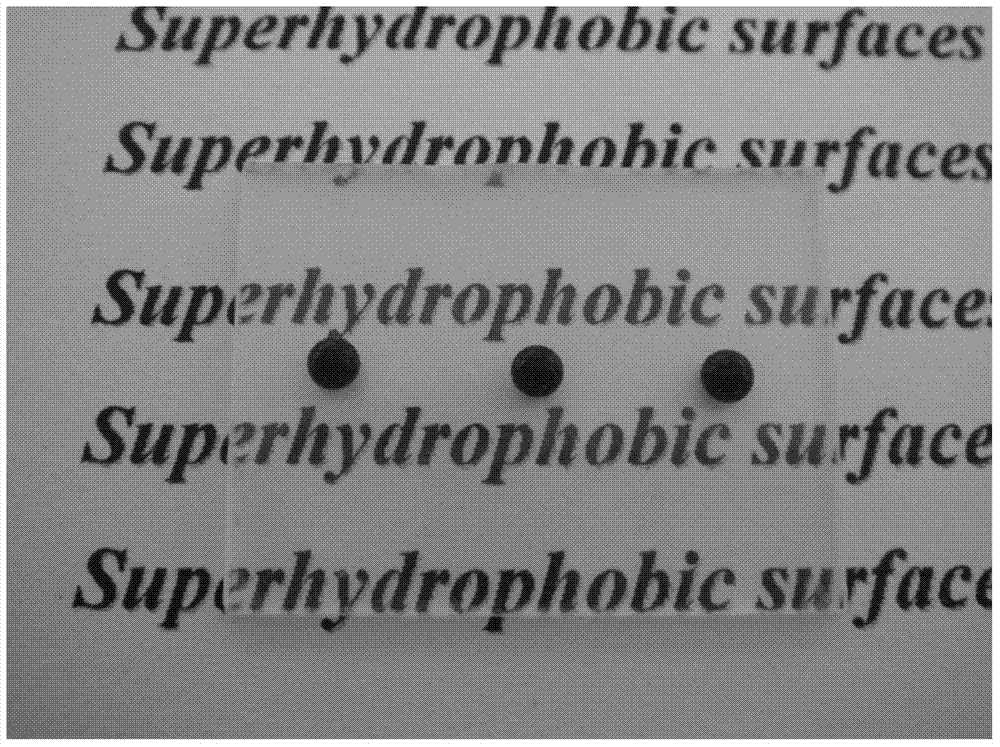

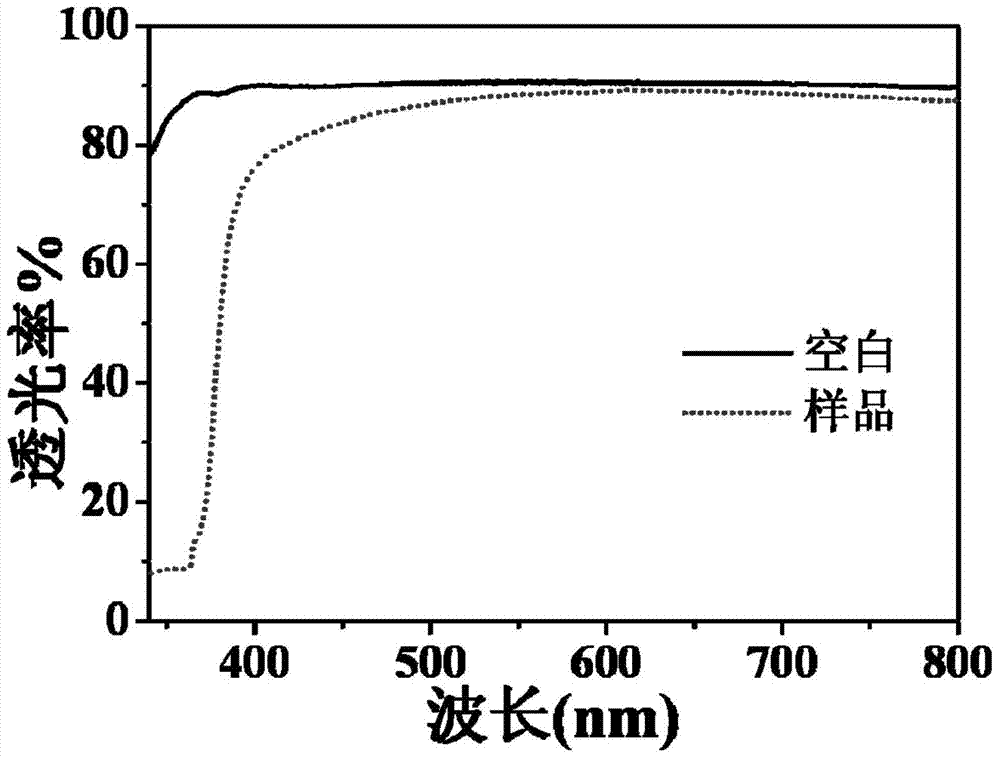

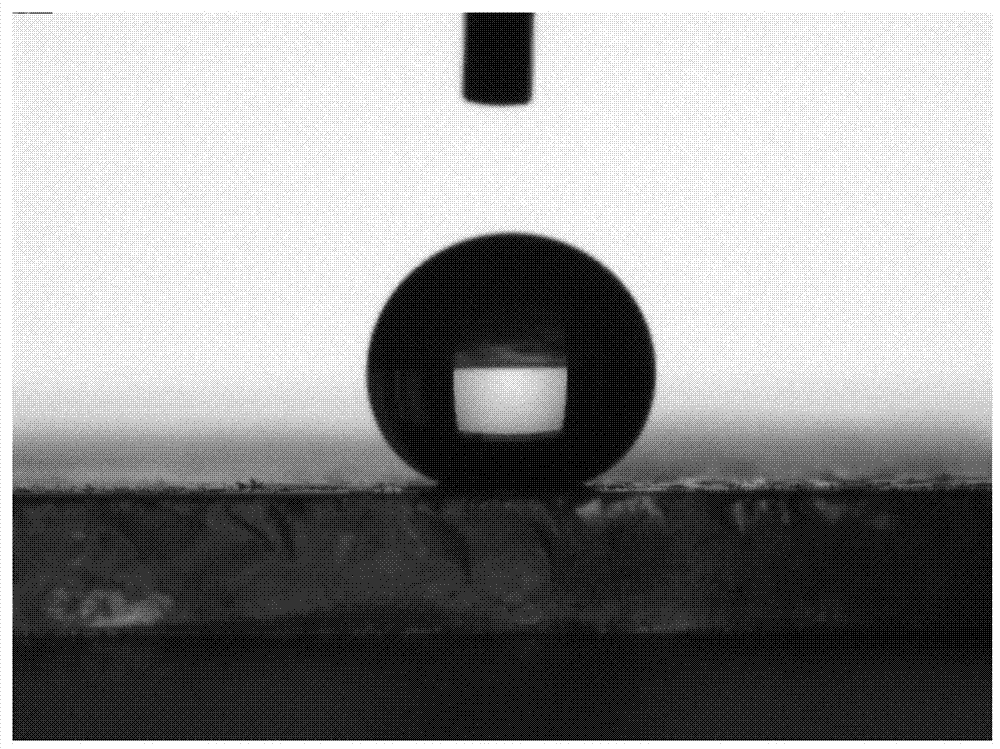

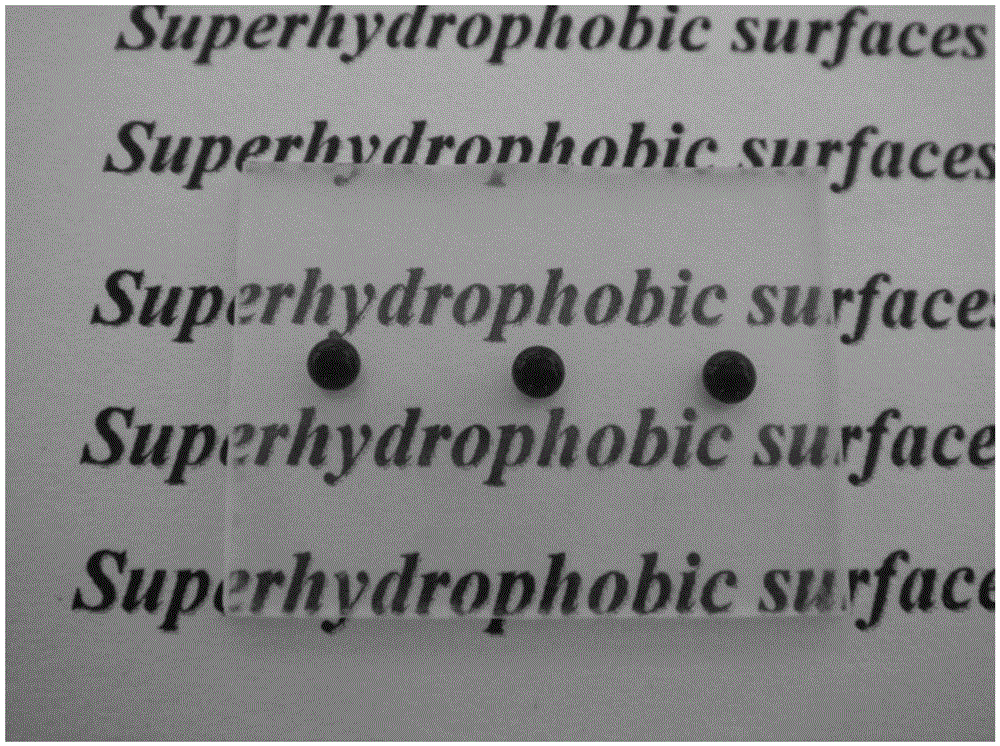

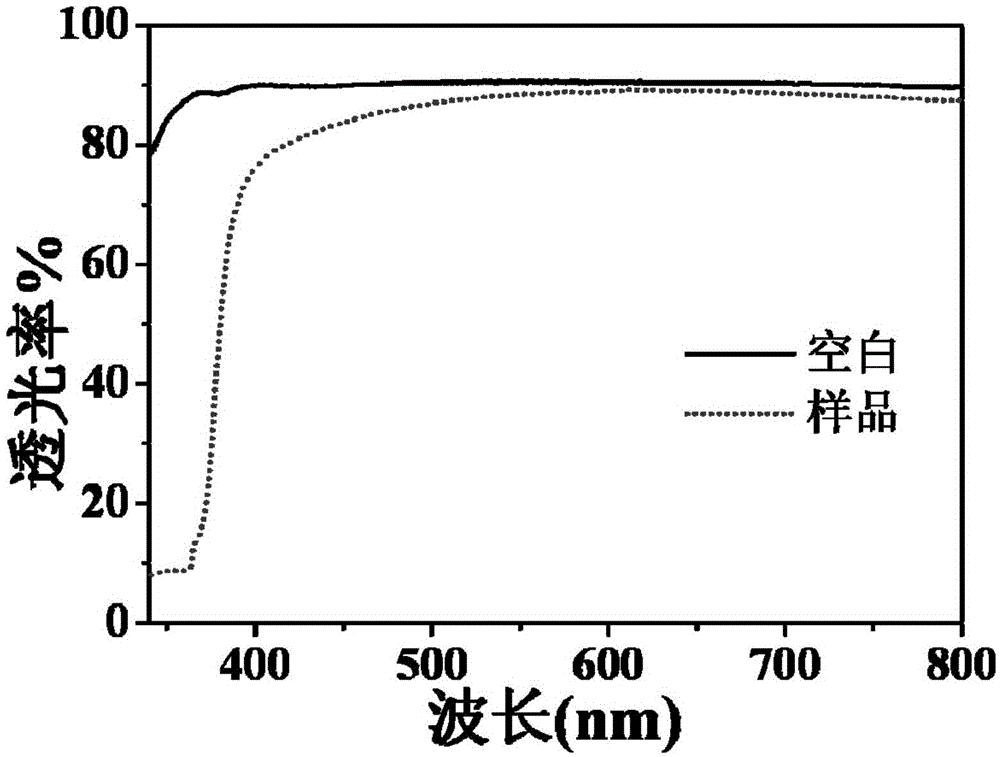

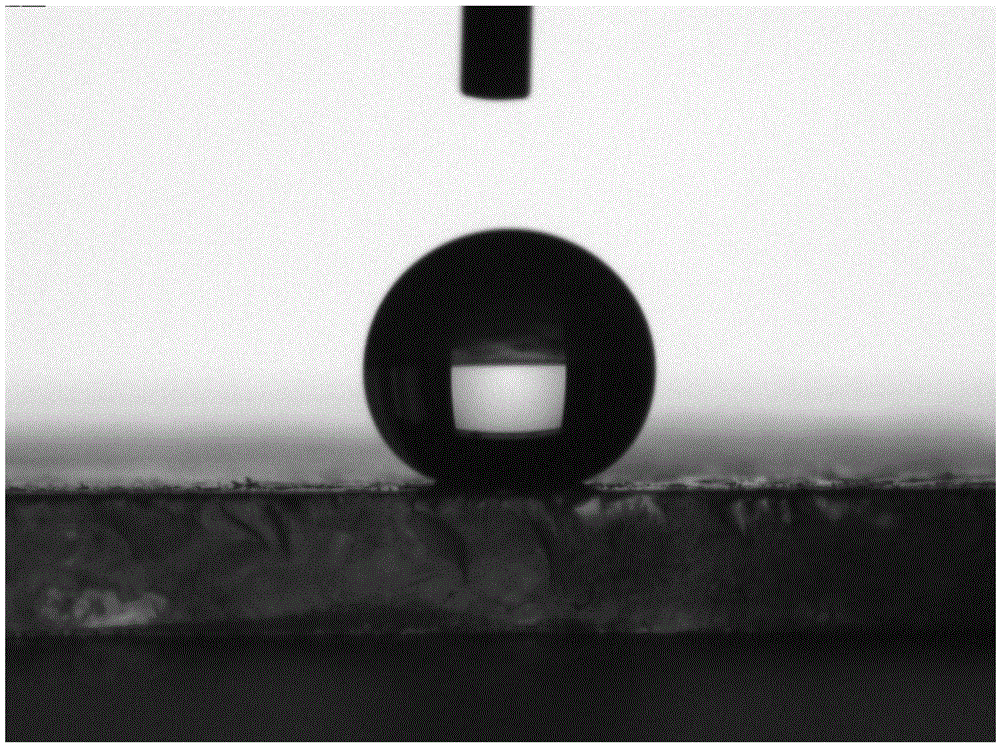

Preparation method of transparent super-hydrophobic zinc oxide coating

The invention relates to a preparation method of a transparent super-hydrophobic zinc oxide coating on a glass substrate. The preparation method comprises the following steps of a, substrate pretreatment; b, zinc oxide solution preparation; c, zinc oxide coating preparation; and d, zinc oxide coating surface modification. Compared with the prior art, the preparation method has the beneficial effects of simple equipment process, low cost and mild reaction condition and is beneficial to large-scale industrial production. The transparent super-hydrophobic zinc oxide coating prepared by using the method has excellent hydrophobicity and transparency; the contact angle is larger than 160 degrees, the rolling angle is smaller than 8 degrees, and water drops can freely roll on the coating, so that the transparent super-hydrophobic zinc oxide coating has relatively good self-cleaning performance; and the light transmittance is approach to 90% which is close to that of blank glass, so that the transparent super-hydrophobic zinc oxide coating has favorable visible light transmittance. A surface modifier used in the preparation method is an alkyl silane coupling agent instead of a fluorinated compound, so that the cost is low, the environment pollution is relatively low, and the modified coating is relatively stable.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

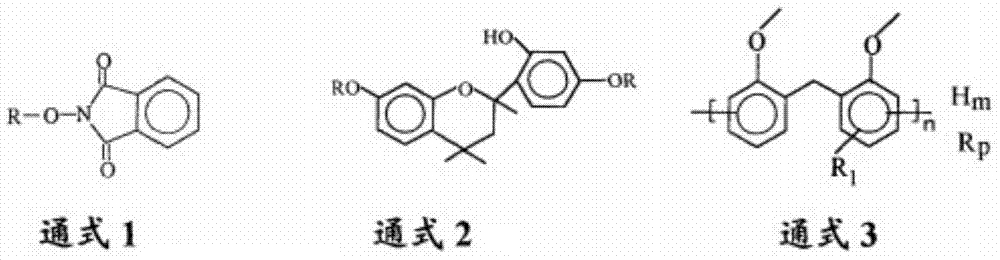

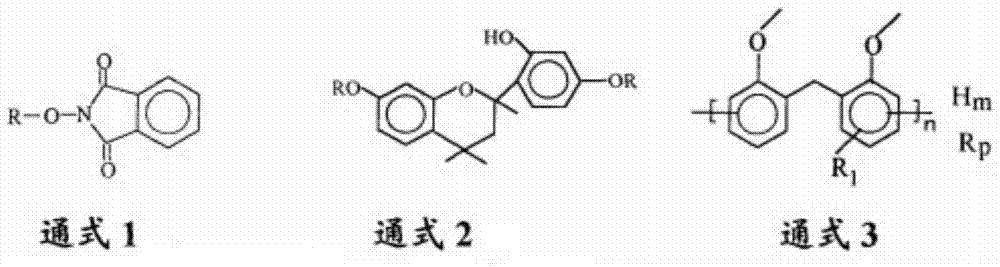

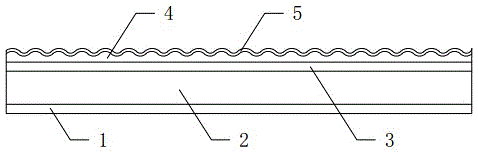

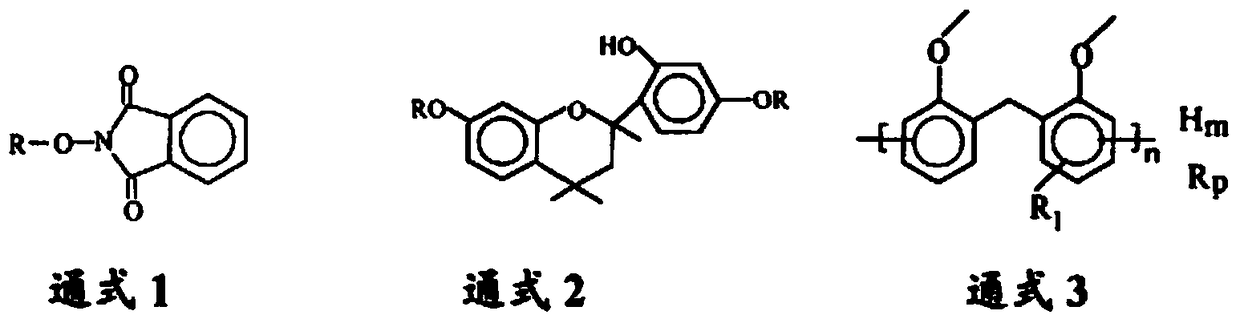

Photosensitive grain-free printing plate and manufacturing method and application thereof

InactiveCN103587273AImprove wear resistanceImprove adhesionPrinting pre-treatmentPhotosensitive materials for photomechanical apparatusWater useMicron scale

The invention discloses a photosensitive grain-free printing plate and a manufacturing method of the photosensitive grain-free printing plate. The photosensitive grain-free printing plate is composed of a printing plate substrate, a hydrophilic layer and a photosensitive layer, wherein the printing plate substrate is sequentially coated by the hydrophilic layer and the photosensitive layer. According to the photosensitive grain-free printing plate and the manufacturing method of the photosensitive grain-free printing plate, the surface of the printing plate substrate is coated with nanoscale and / or micron-scale particles or composition containing nanoscale and / or micron-scale particles to obtain the hydrophilic coating, and the obtained hydrophilic layer has proper roughness, so that the surface of the printing plate substrate has hydrophilia and water retentivity. Due to the existence of the nanoscale and / or micron-scale hydrophile particles in the hydrophilic layer, not only is the ink absorption requirement met, but also the abrasion performance of the surface of the printing plate substrate is improved, and meanwhile, the adhesive force between the hydrophilic layer and the printing plate substrate as well as the photosensitive layer is good. According to the photosensitive grain-free printing plate and the manufacturing method of the photosensitive grain-free printing plate, not only is the performance of an existing photosensitive printing plate improved, but also it is avoided that the environment is polluted by waste acid and waste lye generated when an aluminum printing plate is electrolyzed and oxidized by the existing photosensitive printing plate, meanwhile, water using amount is saved by 70%, and electricity using amount is saved by 50% or so.

Owner:BEIJING ZHONGKE NANO THINK PRINT TECH

Method for producing organic solderability preservative on surface of circuit board

InactiveCN104918417AModerate roughnessUniform colorNon-metallic protective coating applicationOrganic filmEtching

The invention belongs to the circuit board production technical field and relates to a method for producing an organic solderability preservative on the surface of a circuit board. According to the method of the invention, sand blasting and board grinding procedures are omitted in a pretreatment process, and technological parameters of pickling and micro-etching are adjusted, and therefore, the problem of the smash of fine sands onto a board surface and the problem of high roughness and unevenness of a copper surface when a grinding brush is adopted to perform board grinding can be solved, and the roughness of the copper surface of the circuit board can be moderate and uniform, and the thickness of a formed organic film can be basically consistent with the thickness of etched copper; the circuit board is arranged in an antioxidant cylinder before the production of the organic film, a cylinder dragging plate is adopted to perform cylinder dragging processing at first, so that impurities in an antioxidant solution can be removed, and production parameters can be stabilized, and the concentration of Cu<2+> in the solution is controlled below 15ppm, and therefore, the organic film can be effectively prevented from blackening or color difference of the organic film can be effectively prevented, and yield can be improved; technological methods and parameters in various links are modified, and optimal parameter combinations can be explored, and therefore, the color of the organic film formed on the copper surface can be uniform.

Owner:JIANGMEN SUNTAK CIRCUIT TECH

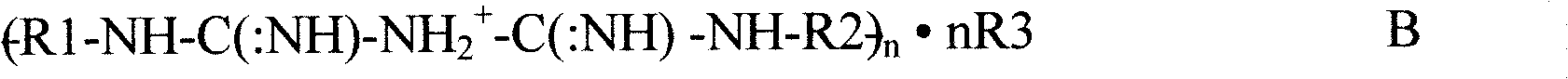

Acid etching solution used for copper or copper alloy surface and surface treatment method

InactiveCN101230461ASimple processing methodPlay the role of cleaning and degreasingAcid etchingOxidation resistant

The invention relates to an acidic microetching solution used for the surface of copper or copper alloys, is characterized in that the solution contains poly-guanidine. The invention still relates to a method of treating the surface of copper or copper alloys and includes the following steps: firstly, the acidic microetching solution of the invention is used for contacting the surface of copper or copper alloys; and secondly, the surface is covered by an organic coating. Compared with the prior art, the invention has the advantages that the following requirements can be met at the same time, i.e. firstly, the copper surface is provided with a desirable roughness, which can provide enough adhesive power for the combination of the copper surface and the organic coating (a dry film for example); secondly, the treated copper surface is light-colored, friction-resistant and oxidation-resistant; thirdly, the copper surface does not need cleaning in advance, and the microetching and degreasing can be accomplished at the same time; and fourthly, the microetching amount can be as small as possible to meet the lamination requirement of the selective dry film.

Owner:SHANTOU ULTRASONIC PRINTED BOARD NO 2 FACTORY

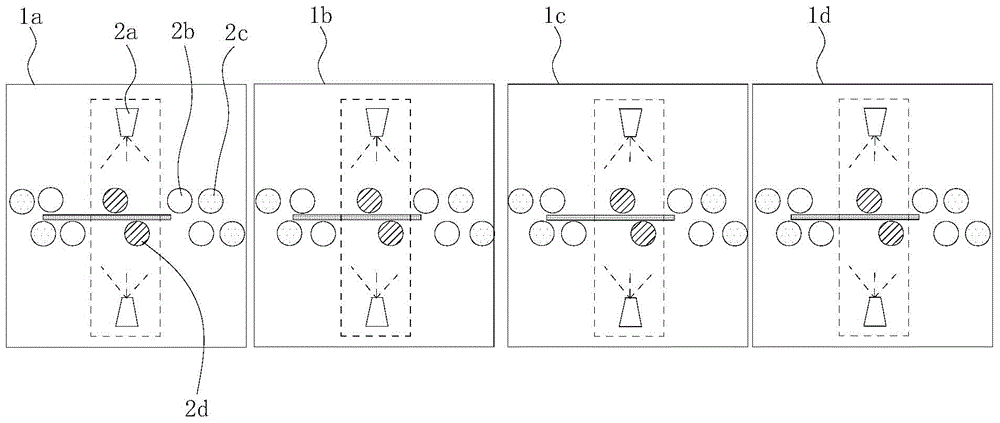

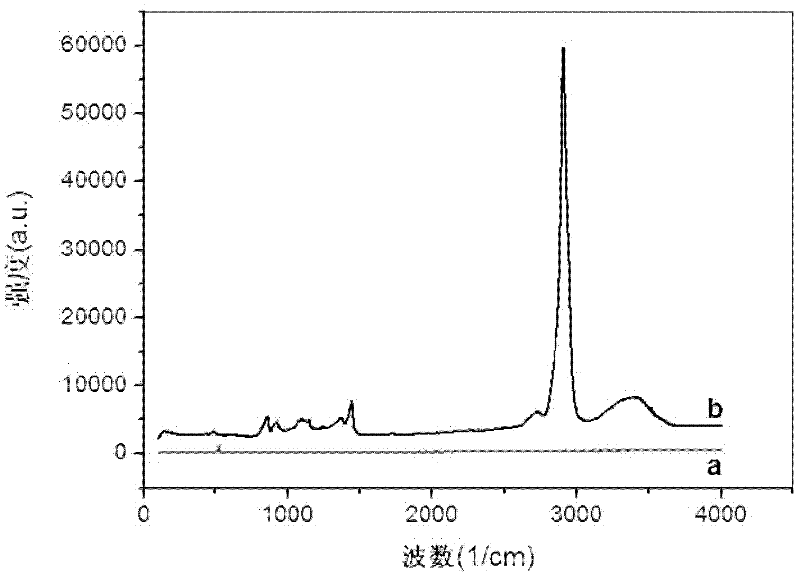

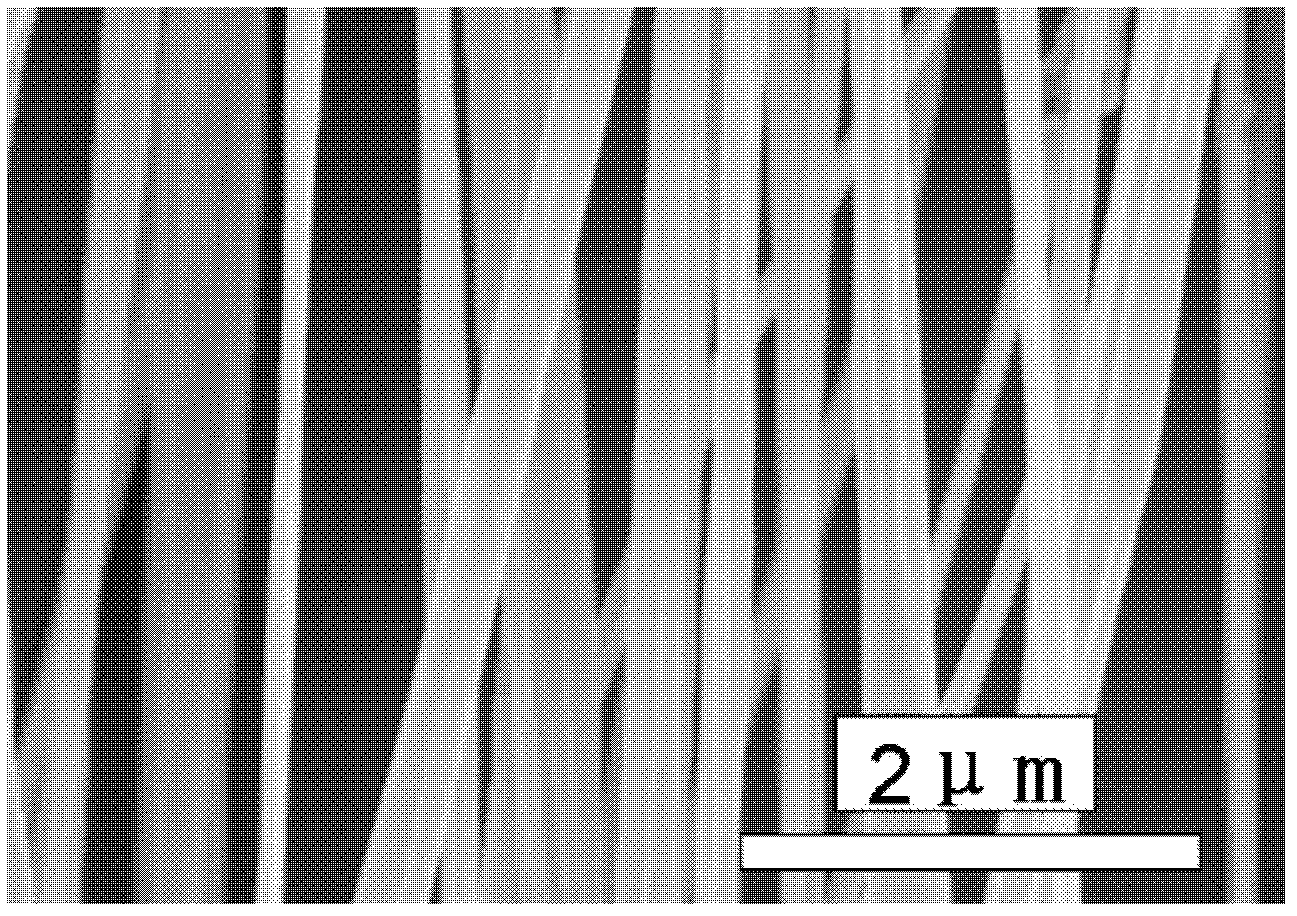

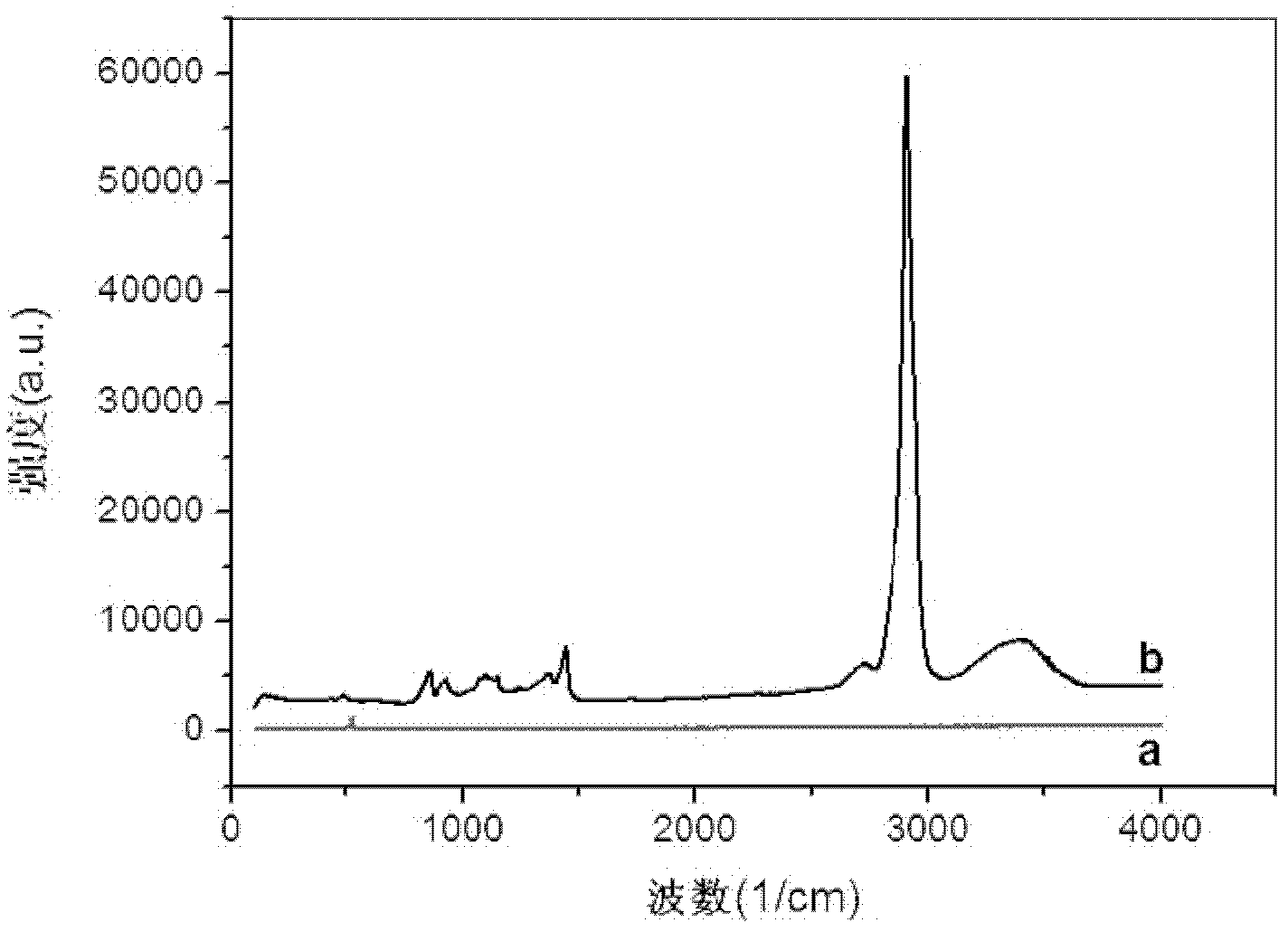

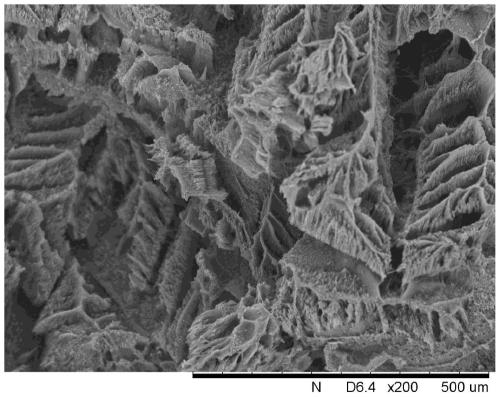

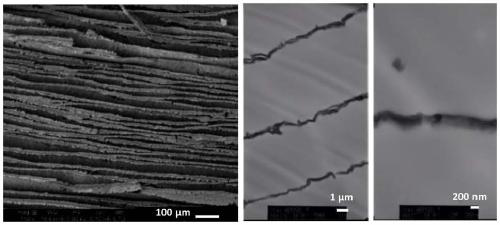

Method for preparing transparent Raman effect film

InactiveCN102642362ADifficult to disperseSolve the uniform dispersionLamination ancillary operationsSynthetic resin layered productsFiberAcetic acid

A method for preparing a transparent Raman effect film relates to preparation of optical fiber films and aims to solve the problems of complicated equipment and difficulty in controlling a production process of an existing method for preparing SERS (surface enhanced Raman scattering) base materials. The method includes the steps: firstly, preparing cellulose acetate solution with acetone, acetic acid and cellulose acetate; secondly, uniformly mixing Ag NPs suspending liquid and the cellulose acetate solution to obtain spinning liquid; thirdly, spinning the spinning liquid into a nano-fiber nonwoven felt by means of electrostatic spinning process; and fourthly, tiling the cut nano-fiber nonwoven felt in a slot of a composite film forming tool, pouring polyvinyl alcohol water solution into the slot, leading the polyvinyl alcohol water solution to be lower than the upper edge of the slot of the composite film forming tool, and maintaining pressure and drying to obtain the transparent Raman effect film. The method is mainly used for preparing the transparent Raman effect film.

Owner:NORTHEAST FORESTRY UNIVERSITY

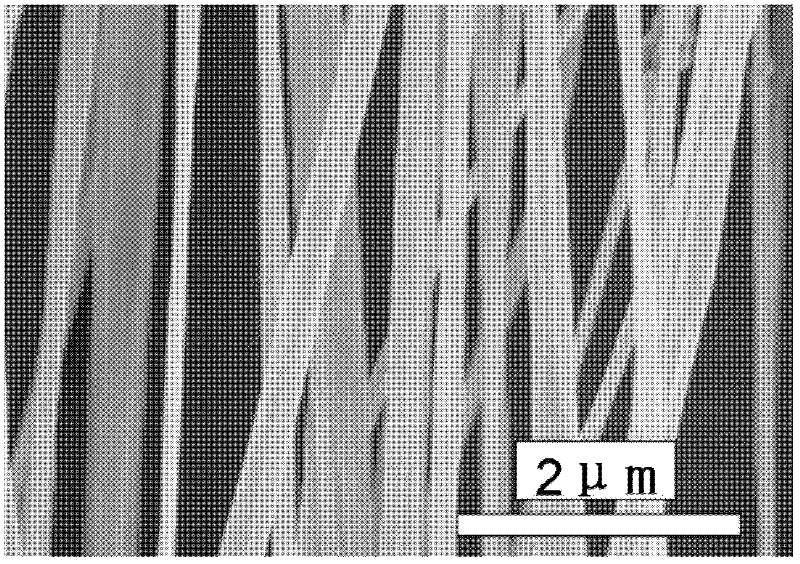

Self-roughened porous meshed super-hydrophobic polyester fabric and preparation method thereof

InactiveCN104790206AGood low surface energy propertiesImprove wear resistanceFibre typesPolyesterFiber

The invention provides self-roughened porous meshed super-hydrophobic polyester fabric and a preparation method thereof. Firstly, the fabric is soaked with an ethyl alcohol, then soaked with a polydimethylsiloxane / polyvinyl chloride tetrahydrofuran mixture solution and dried for 2h at the temperature of 40 DEG C, and then the super-hydrophobic polyester fabric full of roughened porous meshed structure on the surface of fiber can be obtained. A static contact angle between the surface of the polyester fabric prepared with the method and a water drop is larger than 150 degrees, and the fabric has good super-hydrophobic performance, wear resistance, solvent resistance and stability.

Owner:SHAANXI UNIV OF SCI & TECH

Thermo-sensitive non-grain plate, manufacturing method for thermo-sensitive non-grain plate and application of thermo-sensitive non-grain plate

InactiveCN103587272AModerate roughnessImprove wear resistancePlate printingCoatingsHydrophilic coatingNano size

The invention discloses a thermo-sensitive non-grain plate and a manufacturing method for the thermo-sensitive non-grain plate. The thermo-sensitive non-grain plate is formed by a support body, a hydrophilic layer and a thermo-sensitive layer, wherein the support body is coated with the hydrophilic layer and the thermo-sensitive layer in sequence. The surface of the support body is coated with nano-sized particles and / or micron-sized particles or combinations containing the nano-sized particles and / or the micron-sized particles, so that a hydrophilic coating is obtained and has proper roughness, and in this way the surface of a plate substrate has hydrophilicity and a water-retaining property. Due to the nano-sized and / or the micron-sized hydrophilic particles in the hydrophilic layer, not only is the requirement for ink absorption satisfied, but also the abrasion resistance of the surface of the plate substrate is improved, and meanwhile the bonding force between the hydrophilic layer and the support body and the bonding force between the hydrophilic layer and the thermo-sensitive layer are both good. According to the thermo-sensitive non-grain plate, the manufacturing method for the thermo-sensitive non-grain plate and the application of the thermo-sensitive non-grain plate, an improvement is made to an existing thermo-sensitive plate, so that the performance of the existing thermo-sensitive plate is improved; moreover, the environmental pollution caused by acid and alkali waste liquid produced in the process of electrolyzing and oxidizing an aluminum plate by the existing thermo-sensitive plate is avoided, meanwhile, water consumption is saved by 70%, and power consumption is saved by about 50%.

Owner:BEIJING ZHONGKE NANO THINK PRINT TECH

Butt welding method for lengthening steel wire

InactiveCN102873446AUnbreakableQuality assuranceResistance welding apparatusButt weldingWire segment

The invention discloses a butt welding method for lengthening a steel wire, which is characterized by comprising the following steps: adopting a butt welding technology to weld tyre wires which are 1.5 mm thick and 10-20 m long together to obtain a tyre wire which is about 200 m long; and then rolling the tyre wire to form a steel wire scroll. The section of a steel wire segment is a cross section and the steel wire section is not easy to break so that the product can be effectively recycled repeatedly. Therefore, the invention is approved by the industry. In the consumption process, the invention has the smoothness of a steel shot and the characteristic of zero breakage of the steel wire section. Not only can rust on the surface of the product be effectively cleaned, but also residual consumption of equipment can be prevented. Meanwhile, the coarseness on the surface of the product is suitable for reducing the consumption of paint. As for a steel wire base body, the less the heat is, the smaller the temperature rise of materials out of the welding point is. Annealing and color changing conditions are avoided, and the quality of the steel wire section is ensured.

Owner:TIANJIN XINCHAO AST STEEL & ABRASIVE FOUNDRY

Coarse micro-etching agent used in circuit board and preparation method of coarse micro-etching agent

The invention relates to the technical field of metal surface treatment chemicals, in particular to a coarse micro-etching agent used in a circuit board and a preparation method of the coarse micro-etching agent. The coarse micro-etching agent is composed of, by weight, 5%-10% of sulfuric acid, 0.01%-0.1% of copper sulfate pentahydrate, 0.05%-1% of piperidine or 4-Cloperastine or 4-Hydroxypiperidine or 4-aminopiperidine, 0.1%-1% of 2-aminobenzimidazole or 2-mercapto benzimidazole or benzimidazole-2-methanal or 2-alkylbenzimidazole or 2-phenylbenzimidazole or 2-(4-pyridine) benzimidazole or 2-(4-benzyl) benzimidazole, 0.1%-1% of benzenesulfonic acid or p-chlorobenzenesulfonic acid or sulfanilic acid or p-methyl benzene sulfonic acid, 0.05%-1% of tetrazole or 5-amino-1H-tetrazole hydrate or 5-methyl tetrazole or 5-phenyl-tetrazole and the balance being deionized water. The coarse micro-etching agent used in the circuit board is stable in component, long in service life, capable of effectively removing oxides on the surface of metal and enabling the surface of the metal to be in proper coarse degree after micro-etching and especially suitable for increasing the binding force of a dry film and the copper surface in the process of pressing the dry film; in addition, through control over the coarse degree, the dry film is firm during pressing, and the exposed dry film can be removed more easily.

Owner:东莞市富默克化工有限公司

Ceramic repairing method

InactiveCN111718209AImprove bindingTightly boundCeramic shaping apparatusSand blastingRepair material

The invention relates to the technical field of ceramic repairing, in particular to a ceramic repairing method. The method comprises the following steps: firstly polishing a defect part; then carryingout sand blasting on the ground part with a micro sand blasting machine; then treating the sand blasted part with a cotton swab dipped in hydrofluoric acid; completely flushing hydrofluoric acid at the part; blow-drying the part; filling the part with a repairing material and compacting; after the repairing material is dried, polishing the repaired part to make the repaired part smoothly transitwith the surrounding ceramic green body and accord with the curved surface profile of the original ceramic green body; glazing the repaired part, and firing the repaired ceramic green body. Accordingto the method disclosed by the invention, the binding force between the repairing material and the ceramic body is strong, so that the ceramic body is not easy to crack during firing; and the surfaceof the repairing material is polished after the repairing material is dried, so that the influence of shrinkage of the repairing material after drying on the surface flatness is avoided, and repairingtraces of a repaired part and an unrepaired part are not obvious.

Owner:ZHONGTAO SANITARY WARO MFG CO LTD OF TANGSHAN

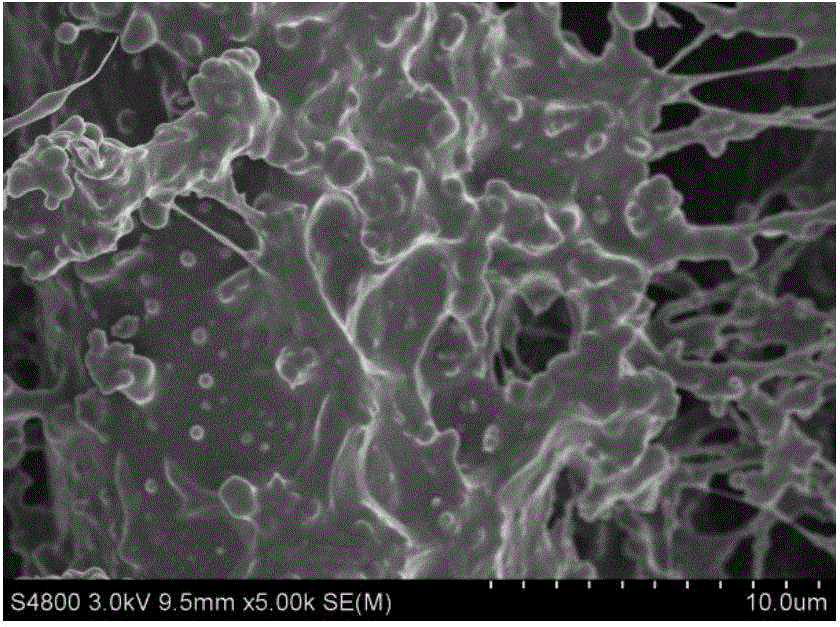

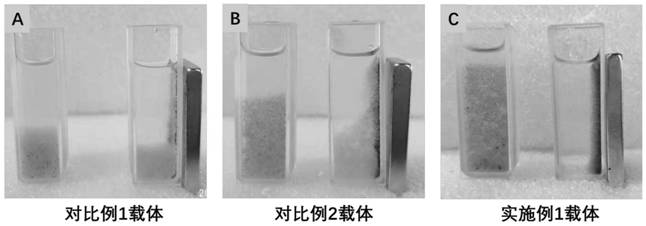

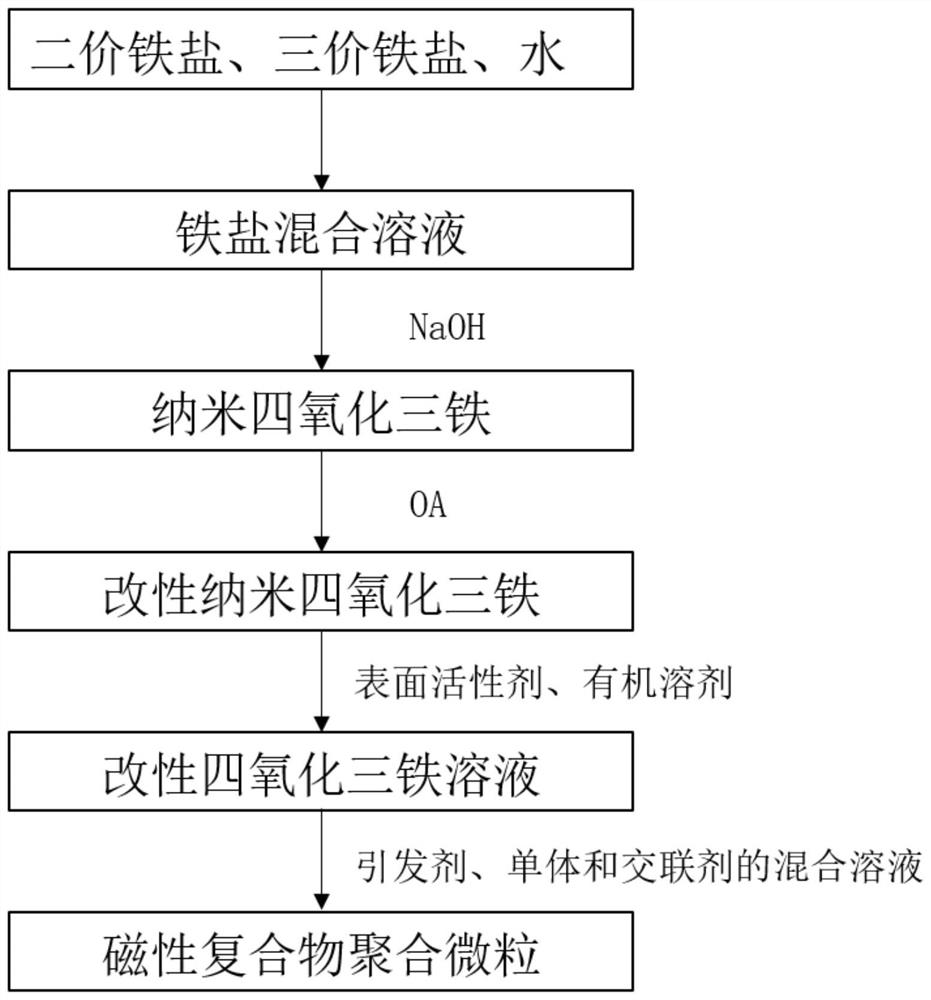

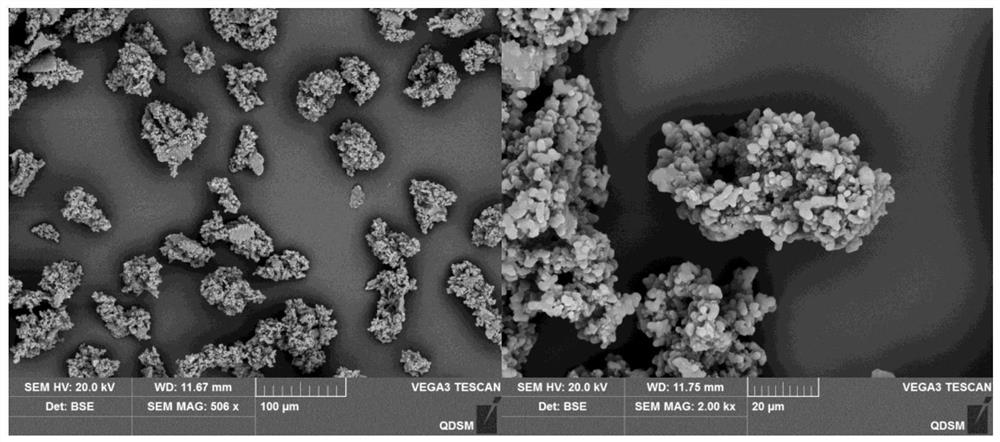

Magnetic polymer composite particle as well as preparation method and application thereof

PendingCN113908783AUniform particle size distributionGood superparamagneticMicroballoon preparationMicrocapsule preparationPolymer sciencePolymer chemistry

The invention discloses a magnetic polymer composite particle as well as a preparation method and application thereof, and relates to the technical field of composite materials. According to the technical scheme, the preparation method of the magnetic polymer composite particle is provided, and compared with the prior art, the method has the advantages that the method is environment-friendly, the production process is simple, and the magnetic polymer composite particles can be prepared by a one-pot method. The invention also provides a magnetic polymer composite particle. The particle size of the magnetic polymer composite particle is 50-250 [mu] m, and the magnetic polymer composite particle is formed by aggregating a plurality of small particles with the diameter of 1-10 [mu]m and has a macroporous structure. The invention also provides an application of the magnetic polymer composite particle. The magnetic polymer composite particle can be used as a carrier for microbial immobilization.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

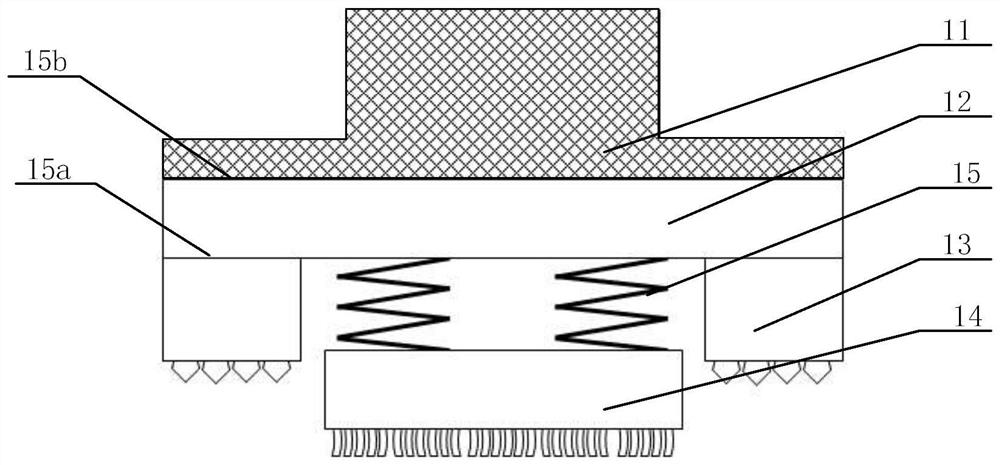

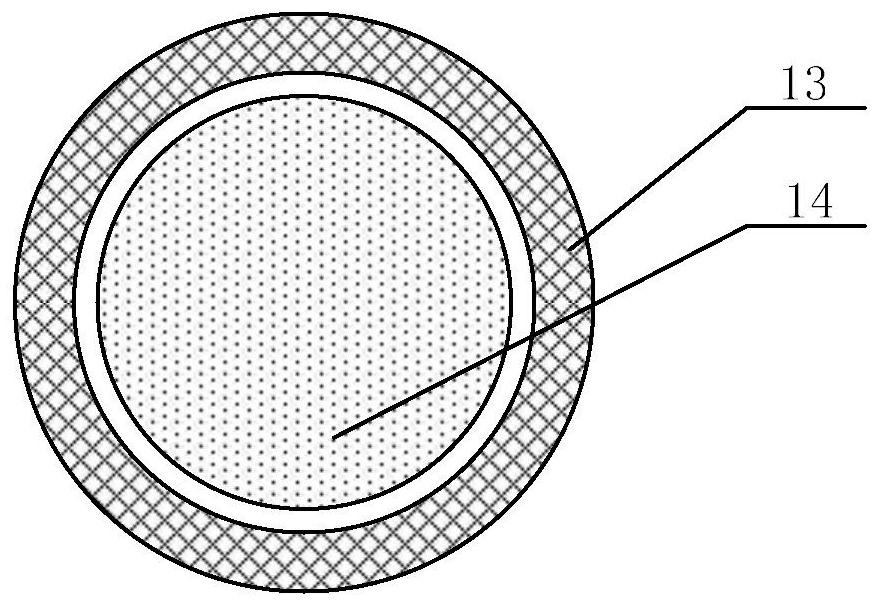

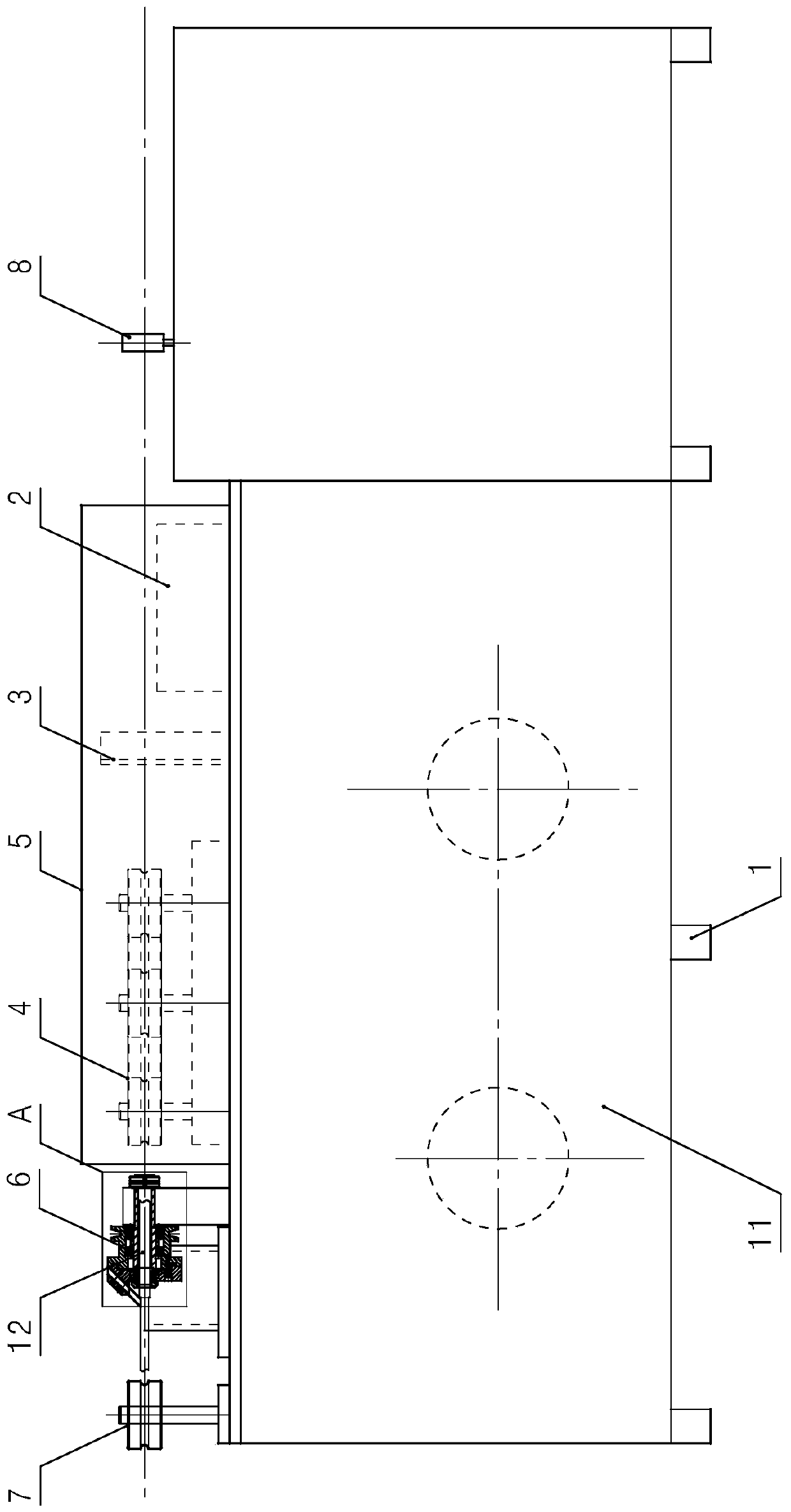

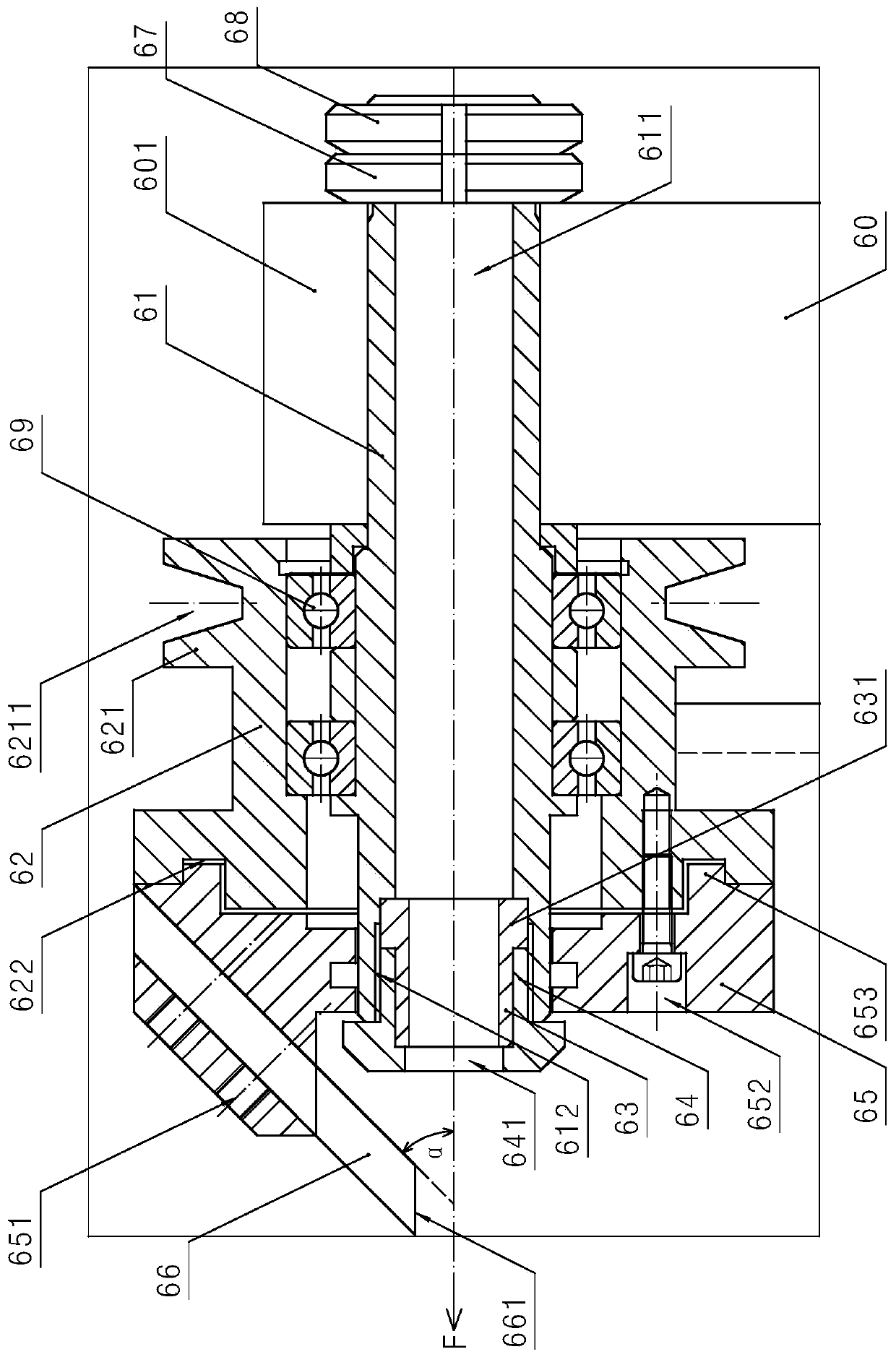

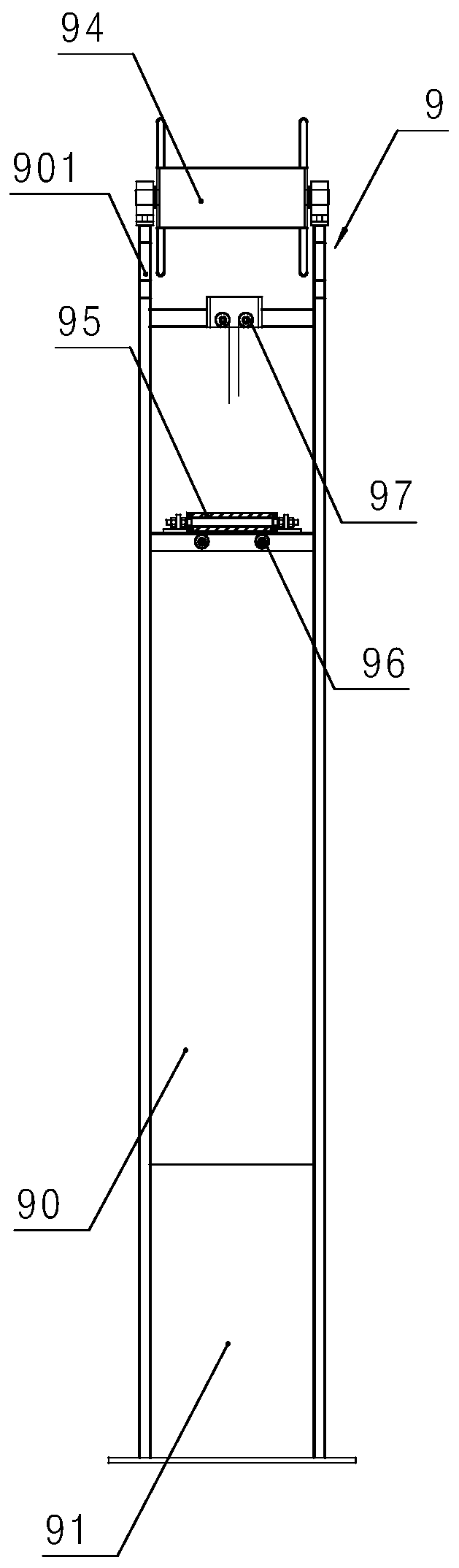

Polishing pad trimmer, polishing equipment and method

InactiveCN112077743ASimple structural designImprove polishing effectAbrasive surface conditioning devicesPolishingEngineering

The invention provides a polishing pad trimmer, polishing equipment and a method. The polishing pad trimmer comprises a driving device, a mounting base plate, a diamond trimming head, a brush, an elastic connecting piece and a controller, wherein the mounting base plate comprises a first surface, the diamond trimming head is arranged on the first surface of the mounting base plate, and the brush is arranged on the first surface of the mounting base plate through the elastic connecting piece; and the driving device is connected with the mounting base plate and the controller and is used for applying pressure to the mounting base plate under the control of the controller, and the expansion degree of the elastic connecting piece is changed along with the change of the pressure, so that the height of the brush relative to the diamond trimming head is changed, and different trimming purposes are achieved. By the adoption of the polishing pad trimmer, in the polishing operation process, thediamond trimming head or the brush can be flexibly switched as required, the polishing effect is improved, and the polishing efficiency is improved.

Owner:ZING SEMICON CORP

Method for preparing transparent Raman effect film

InactiveCN102642362BDifficult to disperseSolve the uniform dispersionLamination ancillary operationsSynthetic resin layered productsFiberAcetic acid

A method for preparing a transparent Raman effect film relates to preparation of optical fiber films and aims to solve the problems of complicated equipment and difficulty in controlling a production process of an existing method for preparing SERS (surface enhanced Raman scattering) base materials. The method includes the steps: firstly, preparing cellulose acetate solution with acetone, acetic acid and cellulose acetate; secondly, uniformly mixing Ag NPs suspending liquid and the cellulose acetate solution to obtain spinning liquid; thirdly, spinning the spinning liquid into a nano-fiber nonwoven felt by means of electrostatic spinning process; and fourthly, tiling the cut nano-fiber nonwoven felt in a slot of a composite film forming tool, pouring polyvinyl alcohol water solution into the slot, leading the polyvinyl alcohol water solution to be lower than the upper edge of the slot of the composite film forming tool, and maintaining pressure and drying to obtain the transparent Raman effect film. The method is mainly used for preparing the transparent Raman effect film.

Owner:NORTHEAST FORESTRY UNIVERSITY

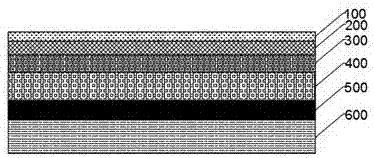

Waterborne mixed type plastic track

The invention discloses a waterborne mixed type plastic track. The waterborne mixed type plastic track comprises a plastic-surface surface layer, an asphalt concrete layer, a middle layer and a ground surface layer, the plastic-surface surface layer is formed by combining a polyurethane prepolymer, calcium carbonate and PU particles, an ultraviolet light absorber and ferric oxide are added, the asphalt concrete layer is composed of an AC-10 fine particle type asphalt concrete layer and an AC-20 coarse particle type asphalt concrete layer, the middle layer is a lime stone or cement stable gravel base layer, the ground surface layer comprises a gravel layer and a 37 lime earth layer, the plastic track is the plastic-surface surface layer, the AC-10 fine particle type asphalt concrete layer, the AC-20 coarse particle type asphalt concrete layer, the middle layer, the gravel layer and the 37 lime earth layer from the top to the bottom, and several plastic particles are evenly distributed on the plastic-surface surface layer. The waterborne mixed type plastic track is simple in material structure and good in abrasion resistance, and the track has high performance parameters in all aspects.

Owner:青岛科兴教育装备有限公司

A kind of preparation method of transparent superhydrophobic zinc oxide coating

The invention relates to a preparation method of a transparent super-hydrophobic zinc oxide coating on a glass substrate. The preparation method comprises the following steps of a, substrate pretreatment; b, zinc oxide solution preparation; c, zinc oxide coating preparation; and d, zinc oxide coating surface modification. Compared with the prior art, the preparation method has the beneficial effects of simple equipment process, low cost and mild reaction condition and is beneficial to large-scale industrial production. The transparent super-hydrophobic zinc oxide coating prepared by using the method has excellent hydrophobicity and transparency; the contact angle is larger than 160 degrees, the rolling angle is smaller than 8 degrees, and water drops can freely roll on the coating, so that the transparent super-hydrophobic zinc oxide coating has relatively good self-cleaning performance; and the light transmittance is approach to 90% which is close to that of blank glass, so that the transparent super-hydrophobic zinc oxide coating has favorable visible light transmittance. A surface modifier used in the preparation method is an alkyl silane coupling agent instead of a fluorinated compound, so that the cost is low, the environment pollution is relatively low, and the modified coating is relatively stable.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

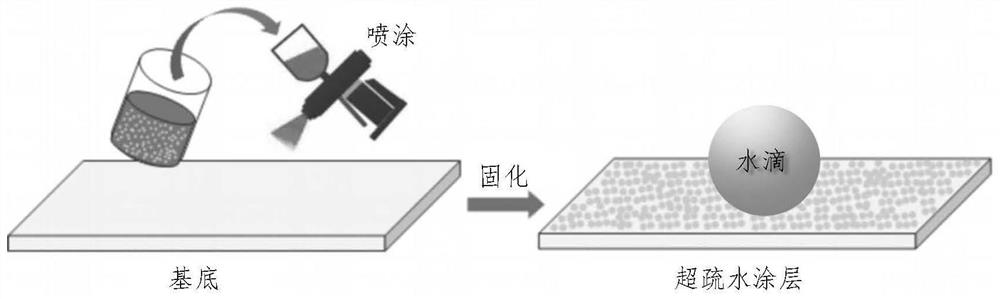

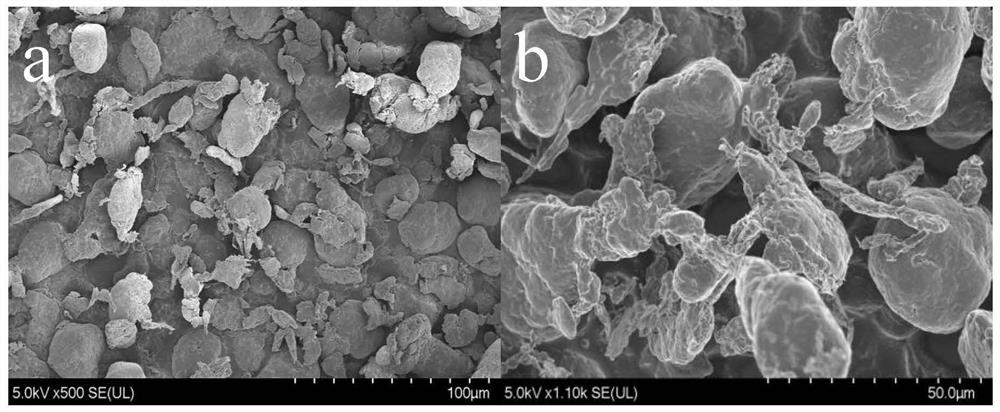

Preparation method and application of substrate-unlimited super-hydrophobic coating

The invention provides a method for rapidly preparing a super-hydrophobic coating with excellent tolerance on a large scale without limitation of a substrate. Comprising the following steps: uniformly mixing an adhesive in a solvent to obtain a solution A; based on the total mass of the adhesive and the solvent, the ratio of the mass percent of the adhesive to the mass percent of the solvent is (0.05-1): (0.95-0); the adhesive is a silicone adhesive taking organic silicon as a main component; adding micro-nano particles into the solution A, and uniformly mixing to prepare a super-hydrophobic composite coating solution; on the basis of the total mass of the micro-nano particles and the solution A, the ratio of the mass percent of the micro-nano particles to the mass percent of the solution A is (0.2-0.3): (0.7-0.8). The preparation method is easy to operate, does not need expensive instruments, is low in cost, is easy to repair, is not limited by a substrate, can complete the preparation of the super-hydrophobic coating only by adopting a simple spraying mode, and can realize large-scale rapid application in industry and life.

Owner:CENT CHINA BRANCH OF CHINA DATANG CORP SCI & TECH RES INST CO LTD

Emulsifying method of polyurethane micro-powder, polyurethane micro-powder emulsion, leather mending agent and application thereof

PendingCN111072996AImprove performanceImprove healing effectLeather surface finishingEmulsionActive agent

The invention discloses an emulsifying method of polyurethane micro-powder, a polyurethane micro-powder emulsion, a leather mending agent and application of the leather mending agent, and the emulsifying method comprises the following steps: mixing nonionic surfactants with different HLB values to obtain a compound emulsifier; adding the polyurethane micro-powder into the composite emulsifier to obtain a polyurethane micro-powder suspension; dropwise adding deionized water into the polyurethane micro-powder suspension; dropwise adding a curing agent into the polyurethane micro-powder suspension, adjusting the pH value of the system to 7.5-9, and stirring to obtain the polyurethane micro-powder emulsion; according to the invention, the problem that in the prior art, polyurethane micro-powder is difficult to form a stable body in a water phase or a solvent phase is solved; the technical problem that the application of the polyurethane micro-powder emulsion in leather finishing is limitedin the prior art is solved, the polyurethane micro-powder emulsion is formed and applied to the leather mending agent, the performance of the leather mending agent is improved, and meanwhile, if theleather mending agent containing the polyurethane micro-powder is applied to the grain surface of crust leather, the mending effect can be remarkably improved.

Owner:XINGYE LEATHER TECH CO LTD

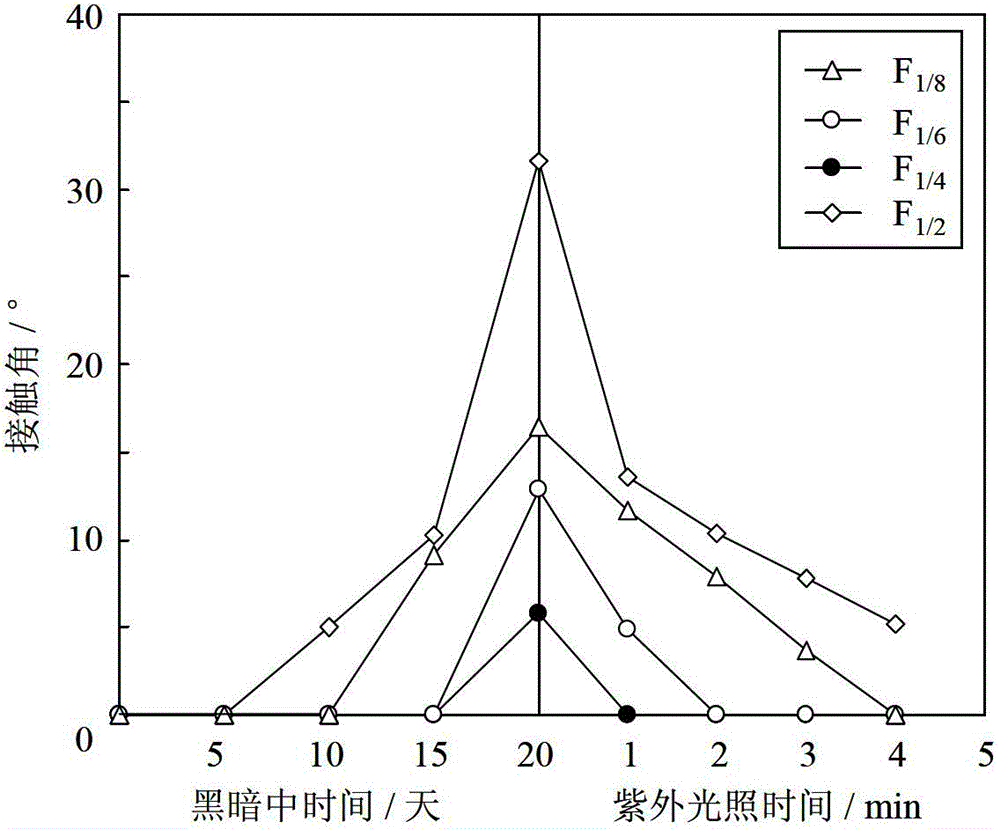

Method for preparing self-cleaning antifogging coating film

InactiveCN102718410BImprove photocatalytic activityImprove superhydrophilicityComposite filmThin membrane

Owner:佛山市南牧新材料有限公司

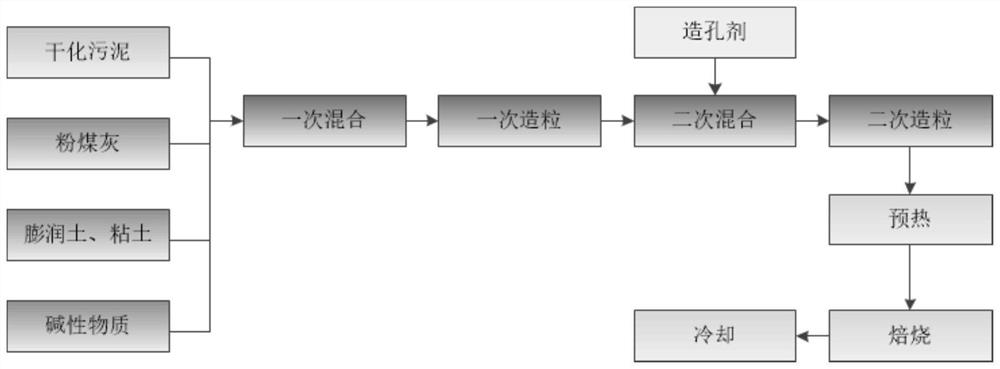

Deodorizing ceramsite and preparation method thereof

PendingCN114436627AGood deodorizing effectModerate roughnessGranulation in rotating dishes/pansSustainable biological treatmentMicroorganismSludge

The invention discloses deodorization ceramsite and a preparation method thereof, and belongs to the technical field of waste gas treatment. The ceramsite comprises the following components: 10-20% of dry sludge, 20-30% of fly ash, 30-50% of bentonite, 10-20% of clay, 5-10% of a pore-forming agent and 5-10% of an alkaline substance. The preparation method comprises the following steps: firstly, uniformly mixing all the raw materials except the pore-forming agent, granulating, then uniformly mixing the raw material nodules subjected to primary granulation with the pore-forming agent and other raw materials again, granulating, and finally drying, preheating, roasting and cooling. The prepared ceramsite is rich in outer pores, growth of microorganisms is guaranteed, filler blockage caused by excessive breeding of the microorganisms can be avoided, meanwhile, the strength and corrosion resistance of the ceramsite can meet the use requirements of a deodorization filter tank, the ceramsite has an acidity buffering function, the odor removal effect is effectively guaranteed, the preparation process is simple, and the ceramsite is suitable for industrial production. The energy consumption is low, and the purpose of recycling resources is achieved.

Owner:HUAQI ENVIRONMENT PROTECTION SCI & TECH

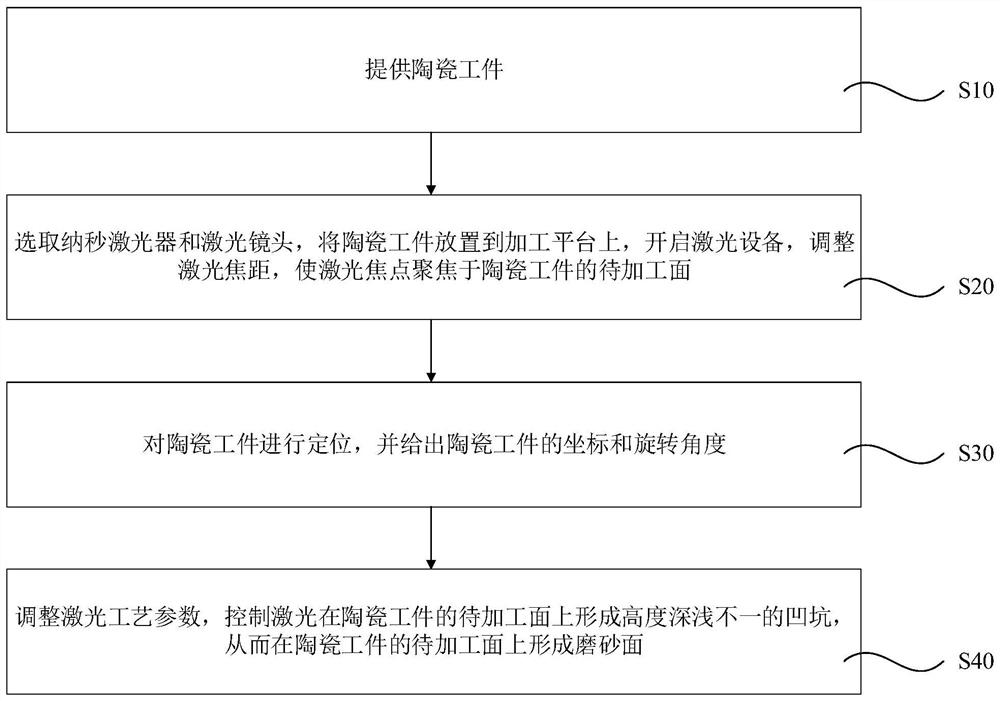

Laser polishing method for ceramic workpiece

InactiveCN113119285AGuaranteed Laser Path WidthAppropriate depthCeramic shaping apparatusNanosecond laserLaser processing

The invention relates to a laser polishing method for a ceramic workpiece. According to the laser polishing method for the ceramic workpiece, a nanosecond laser is selected to enable the pulse width of laser processing to be in a nanosecond level; the pulse width is in the nanosecond level, so that proper thermal diffusion can be ensured during laser processing, and the laser path width of the frosted surface obtained through processing is guaranteed; and the power of laser processing is controlled to range from 15 W to 26 W, so that the frosted surface obtained through processing can have the proper depth, the ratio of the average power to the pulse width of laser processing can be at the proper value, and the frosted surface obtained through processing has the proper roughness.

Owner:HANS LASER TECH IND GRP CO LTD

Preparation method of wear-resistant hydrophobic glass

The invention provides a preparation method of wear-resistant hydrophobic glass which is excellent in wear resistance, high in light permeability and low in preparation cost. The method includes steps of A, preparation of SiO2 / resin mixed sol; B, preprocessing of glass; C, coating of a SiO2 / resin composite membrane on the surface of glass; D, solidification; E, modification via modifier; and F, postprocessing. The preparation method has the advantages that firstly, particle size of SiO2 is controlled in a range of from 90 to 110nm by controlling PH value of prepared sol solution, so that high light transmission can be guaranteed while proper roughness can be provided for a hydrophobic membrane layer; secondly, by means of the technique that resin and SiO2 gel are mixed and directly coated, SiO2 particles are wrapped by resin, and structural strength among the SiO2 particles and between the SiO2 particles and a glass substrate can be improved greatly; and thirdly, using the once filming technique for the SiO2 / resin mixed gel is simpler in process and lower in cost than using the traditional technique for separately coating SiO2 gel and resin.

Owner:CHERY AUTOMOBILE CO LTD

Acid etching solution used for copper or copper alloy surface and surface treatment method

InactiveCN101230461BSimple processing methodPlay the role of cleaning and degreasingAcid etchingCopper oxide

The invention relates to an acidic microetching solution used for the surface of copper or copper alloys, is characterized in that the solution contains poly-guanidine. The invention still relates to a method of treating the surface of copper or copper alloys and includes the following steps: firstly, the acidic microetching solution of the invention is used for contacting the surface of copper or copper alloys; and secondly, the surface is covered by an organic coating. Compared with the prior art, the invention has the advantages that the following requirements can be met at the same time, i.e. firstly, the copper surface is provided with a desirable roughness, which can provide enough adhesive power for the combination of the copper surface and the organic coating (a dry film for example); secondly, the treated copper surface is light-colored, friction-resistant and oxidation-resistant; thirdly, the copper surface does not need cleaning in advance, and the microetching and degreasing can be accomplished at the same time; and fourthly, the microetching amount can be as small as possible to meet the lamination requirement of the selective dry film.

Owner:SHANTOU ULTRASONIC PRINTED BOARD NO 2 FACTORY

A copper-clad aluminum cladding process

ActiveCN109390105BSmooth routingGuaranteed to proceed normallySingle bars/rods/wires/strips conductorsMetal/alloy conductorsWire rodMetallurgy

The invention discloses a copper clad aluminum coating process capable of ensuring the roundness of a core rod, reducing cost and shortening process. The process comprises the steps that unwinding, drawing, lubricating, straightening, rotary cutting of the aluminum core rod, copper strip unwinding and coated face roughening are carried out; a roughened copper strip and the rotary-cut aluminum rodenter the coating process together; in the coating process, the copper strip is repeatedly curled and deformed to form a copper reel which is close to the aluminum core rod, so that the aluminum corerod is completely wrapped in the copper reel; the joint of the copper reel is welded to form a copper clad aluminum wire; and finally, the copper clad aluminum wire is wound up on a reel. The coatingprocess eliminates the need to clean the aluminum core rod, is more environmentally friendly, and has the advantages of shortened process flow, reduced manufacturing cost and improved product qualityand yield.

Owner:ZHANGJIAGANG CITY GUANGCHUAN ELECTRONICS

Baking varnish writing board and preparation method thereof

The invention discloses a stoving varnish writing board and a preparing method for the stoving varnish writing board, and relates to the technical field of teaching tools. The stoving varnish writing board comprises a substrate, the upper surface of the substrate is sequentially provided with a passivation layer and a stoving varnish layer, the upper surface of the stoving varnish layer is provided with an impervious layer, the stoving varnish layer is made of stoving varnish, and the stoving varnish is formed by mixing, grinding and filtering, by mass, 30-40% of acrylic resin, 0.5-1% of dispersing agents, 1.5-3% of coloring pigments, 8-15% of anti-settling agents, 20-32% of water, 10-15% of urea, melamine and formaldehyde resin, 1-2% of catalysts, 10-18% of wear-resistant filler, 2-5% of flatting agents and 5-10% of auxiliaries. The stoving varnish writing board has the advantages that hardness is high, glossiness is low, the surface of the stoving varnish writing board is uniform, coarseness is moderate and character strokes can be prevented from permeating the writing board, chalk and fountain pens can be used for writing, vision of teachers and students can be effectively protected, the service life of the writing board is prolonged, the preparation process is good and environment protection is achieved.

Owner:SHIJIAZHUANG KEDA STATIONERY

A kind of lightweight airgel material and preparation method thereof

ActiveCN108353797BImprove water absorptionImprove water absorption rateAnimal housingAerogel preparationPolymer scienceLitter

The present disclosure provides a lightweight aerogel material including a polymer and clay. The lightweight aerogel material in the present disclosure may be a lightweight and strong absorbent material prepared by mixing the clay, hydrophilic polymer, and other inorganic raw materials that may be added, adding water to the mixture as a medium, stirring the mixture at a high speed to become viscous, and lyophilizing the mixture. The lightweight aerogel material prepared in this manner may have a micron-sized and nano-sized pores, which contributes to the high water absorbency and water absorption rate. When the lightweight aerogel material is used as cat litter, the water absorbency and water absorption rate of the cat litter may be much higher than the similar products. Furthermore, the density of the lightweight aerogel material in the present disclosure is controllable, which may meet the needs for different applications including the cat litter. Moreover, the lightweight aerogel material may be crushed to obtain irregular structures with rough surfaces, or may be formed into various special shapes through mold freezing.

Owner:王宇昕

A kind of photosensitive non-grit mesh printing plate and its preparation method and application

InactiveCN103587273BImprove wear resistanceImprove adhesionPrinting pre-treatmentPhotosensitive materials for photomechanical apparatusHydrophilic coatingElectricity

A photosensitive grain-free printing plate, consisting of a plate base, a hydrophilic layer and a photosensitive layer, with the hydrophilic layer and the photosensitive layer being successively coated on the plate base. A hydrophilic coating is obtained by coating a composition of nano-scale and / or micron-scale particles or a composition containing nano-scale and / or micron-scale particles on the surface of the plate base. The hydrophilic coating thus obtained has an appropriate roughness, which imparts to the surface of the plate base hydrophilic and water-retaining properties. The presence of hydrophilic particles in nano scale and / or micron scale in the hydrophilic layer does not only ensure that the printing plate meets the requirements of ink absorption but also improves the abrasive resistance of the plate base surface, and furthermore maintains good cohesive forces between the hydrophilic layer and the printing base and between the hydrophilic layer and the photosensitive layer. In comparison with the existing photosensitive plates, the contamination caused by the waste acid and waste base liquids produced by electrolysis and oxidation of aluminium plates is avoided and the water and electricity consumption is reduced.

Owner:BEIJING ZHONGKE NANO THINK PRINT TECH

A heat-sensitive non-gritty printing plate and its preparation method and application

InactiveCN103587272BModerate roughnessImprove wear resistancePlate printingCoatingsMicron scaleElectrolysis

The invention discloses a heat-sensitive non-grain printing plate and a preparation method thereof. The heat-sensitive non-gritty printing plate is composed of a support body, a hydrophilic layer and a heat-sensitive layer, and the hydrophilic layer and the heat-sensitive layer are sequentially coated on the support body. In the present invention, nano-scale and / or micron-scale particles or a composition containing nano-scale and / or micron-scale particles are coated on the surface of the support to obtain a hydrophilic coating, and the prepared hydrophilic layer has a suitable roughness, so that The surface of the base is hydrophilic and water-retaining. The presence of nano-scale and / or micron-scale hydrophilic particles in the hydrophilic layer not only meets the requirements of ink absorption, but also improves the wear resistance of the surface of the plate substrate, and at the same time, the adhesion of the hydrophilic layer to the support and the heat-sensitive layer The knot strength is very good. The present invention not only improves the performance of the existing thermosensitive plate, but also avoids the environmental pollution caused by the waste acid and lye produced by the electrolysis and oxidation of the aluminum plate by the existing thermosensitive plate, and the water consumption Save 70% and save about 50% in electricity consumption.

Owner:BEIJING ZHONGKE NANO THINK PRINT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com