Preparation method of wear-resistant hydrophobic glass

A hydrophobic glass and glass technology, which is applied in the field of automotive glass manufacturing, can solve the problems of difficulty in having both superhydrophobic and light transmittance, high cost, poor wear resistance of superhydrophobic film layers, etc., and achieve low cost, high bonding strength, The effect of excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

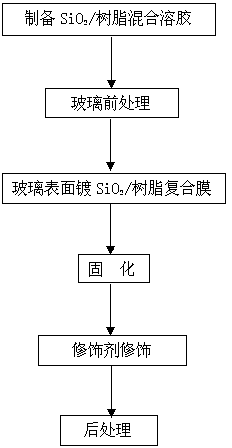

[0025] Such as figure 2 As shown, the preparation method of the wear-resistant hydrophobic glass of the present embodiment specifically includes the following steps:

[0026] A: Preparation of SiO 2 / Resin mixed sol: Measure 50ml of absolute ethanol, 4ml of ammonia water, and 4ml of tetraethyl orthosilicate for mixing, and stir at 60°C for 90 minutes at a speed of 100 rpm to obtain SiO 2 Sol; then add Dow 350 curing agent to Dow epoxy resin 301 with a ratio of 28wt%, after stirring evenly, add SiO according to the mass ratio of 0.5% 2 In the sol, continue to stir at 300 rpm for 30 minutes to obtain a uniform SiO 2 / resin mixed sol; the concentration of above-mentioned ammoniacal liquor is 30%;

[0027] B: Glass pre-treatment: Polish the glass with 80-mesh cerium oxide polishing powder, rinse with deionized water and dry with hot air to remove the dirt on the glass surface, and then use 98% sulfuric acid and 33% hydrogen peroxide solution Mix according to the volume ratio ...

Embodiment 2

[0034] Such as figure 2 As shown, the preparation method of the wear-resistant hydrophobic glass of the present embodiment specifically includes the following steps:

[0035] A: Preparation of SiO 2 / Resin mixed sol: Measure 50ml of methanol, 1.5ml of ammonia water, and 1.5ml of tetraethyl orthosilicate to mix, stir at 60°C for 90 minutes at a speed of 100 rpm to obtain SiO 2 sol; then add Dow 350 curing agent to the polyacrylic acid resin in the proportion of 28wt%, after stirring evenly, add SiO according to the mass ratio of 1% 2 In the sol, continue to stir at 300 rpm for 30 minutes to obtain a uniform SiO 2 / resin mixed sol; the concentration of above-mentioned ammoniacal liquor is 30%;

[0036] B: Glass pre-treatment: Polish the glass with 100-mesh cerium oxide polishing powder, rinse with deionized water and dry with hot air to remove the dirt on the glass surface, and then use 98% sulfuric acid and 33% hydrogen peroxide solution Mix according to the volume ratio o...

Embodiment 3

[0043] Such as figure 2 As shown, the preparation method of the wear-resistant hydrophobic glass of the present embodiment specifically includes the following steps:

[0044] A: Preparation of SiO 2 / Resin mixed sol: Measure 50ml of acetone, 3.5ml of ammonia water, and 3.5ml of orthobutyl silicate for mixing, and stir at 60°C for 90 minutes at a speed of 100 rpm to obtain SiO 2 Sol; then add Dow 350 curing agent to the unsaturated polyester resin in the proportion of 28wt%, after stirring evenly, add SiO2 according to the mass ratio of 1%. 2 In the sol, continue to stir at 300 rpm for 30 minutes to obtain a uniform SiO 2 / resin mixed sol; the concentration of above-mentioned ammoniacal liquor is 30%;

[0045] B: Glass pre-treatment: Polish the glass with 80-100 mesh cerium oxide polishing powder, rinse with deionized water and dry with hot air to remove the dirt on the glass surface, and then use sulfuric acid with a concentration of 98% and sulfuric acid with a concentrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com