Patents

Literature

68results about How to "Improve water absorption rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyacrylic acid-type water absorbent resin and method for producing same

ActiveUS20130101851A1Improve water absorptionRaise the ratioSynthetic resin layered productsCellulosic plastic layered productsPolymer scienceALLYL SUCROSE

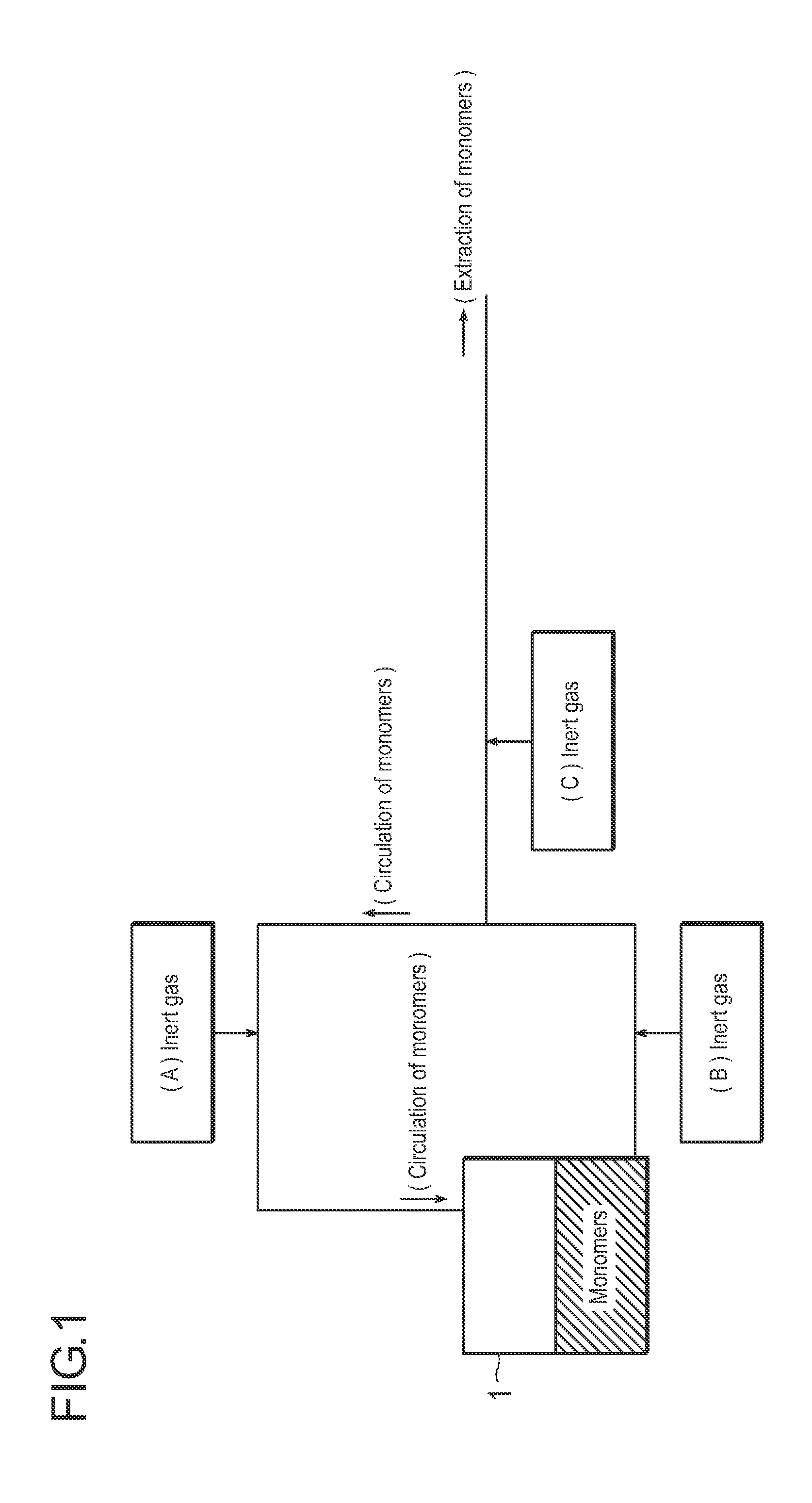

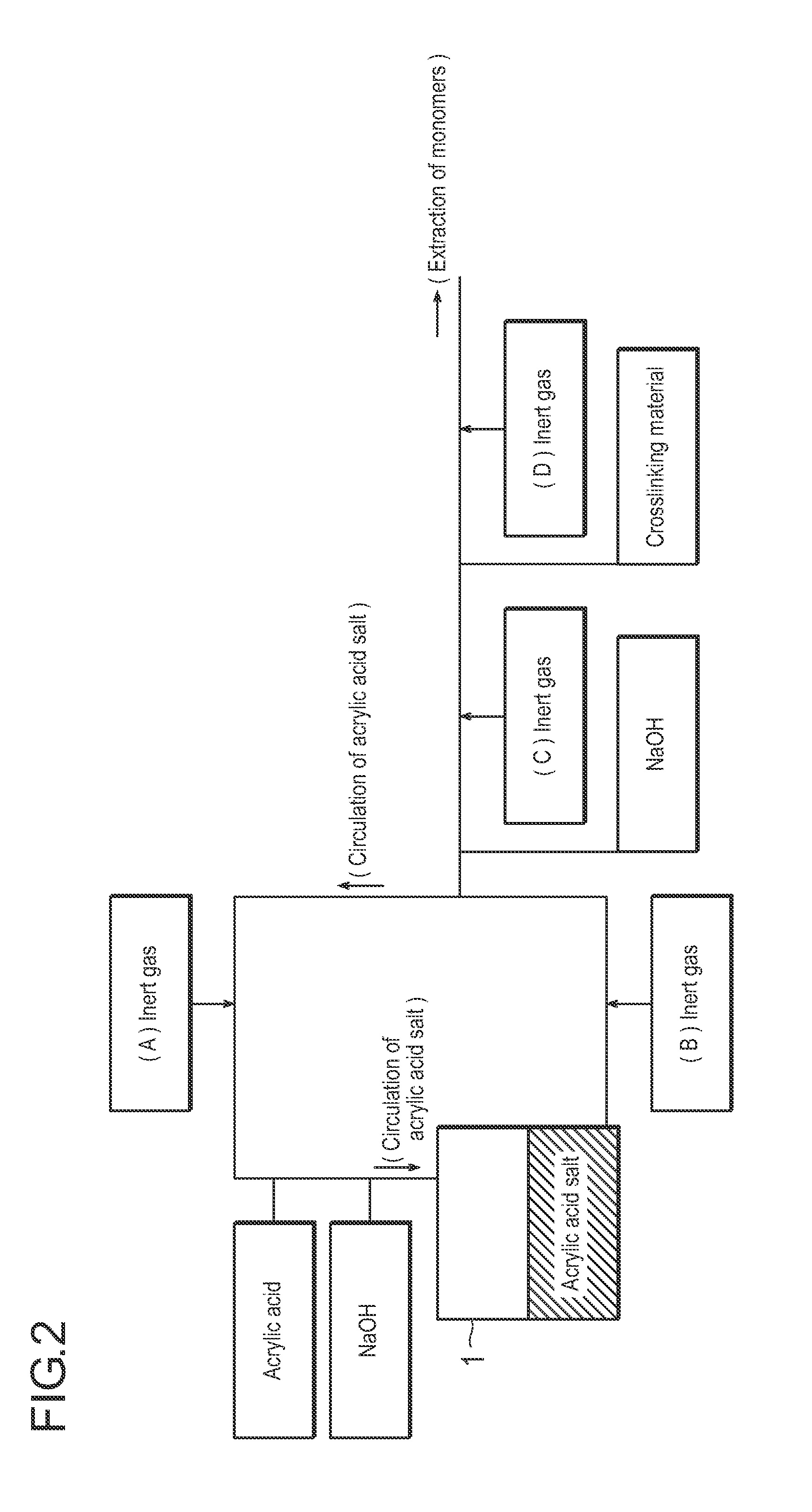

Provided is a method for producing a water absorbent resin, which promotes the formation of interconnected voids (continuous gas bubbles) in a foamed polymer (foam-like water absorbent resin) by a more convenient method, and produces with high efficiency a water absorbent resin which exhibits a high water absorption rate even when stepped into a sheet form or a powder form in hygiene articles and the like. Disclosed is a a method for producing a polyacrylic acid-type water absorbent resin, comprising (A) a step of obtaining an aqueous solution of acrylic acid-type monomers containing gas bubbles dispersed therein; (B) a step of polymerizing the aqueous monomer solution and thereby obtaining a foamed polymer; and (C) a step of heating and drying the foamed polymer,wherein gas bubbles are incorporated such that the volumetric expansion factor defined by the following formula (1);[Formula 1]Volumetric expansion factor=(Volume of aqueous monomer solution after gas bubble dispersion) / (volume of aqueous monomer solution before gas bubble dispersion) Formula (1); exceeds 1.1 times, and the aqueous monomer solution having a monomer concentration defined by the following formula (2);[Formula 2]Monomer concentration [wt %]=(Weight of a monomer) / {(weight of a monomer)+(weight of solvent)}×100 Formula (2); of 40% by weight or greater is boiling polymerized at a temperature of 100° C. or higher.

Owner:NIPPON SHOKUBAI CO LTD

Method for producing high absorptive resin

A process for preparing high-hydroscopicitiy resin includes prepolymerization between monomers to be polymerized, trigger, system and cross-linking agent, and polymerizing to obtain gel-state solid product. Its advantages are high hydroscopicity (500-2000 g / g for deionized water), high water absorbing speed (less than 10 S) and high gel strength after the water is absorbed by it.

Owner:KEYUAN PRODIVE POWER PROMOTION CENT OF PETROCHEM IND SHANDONG

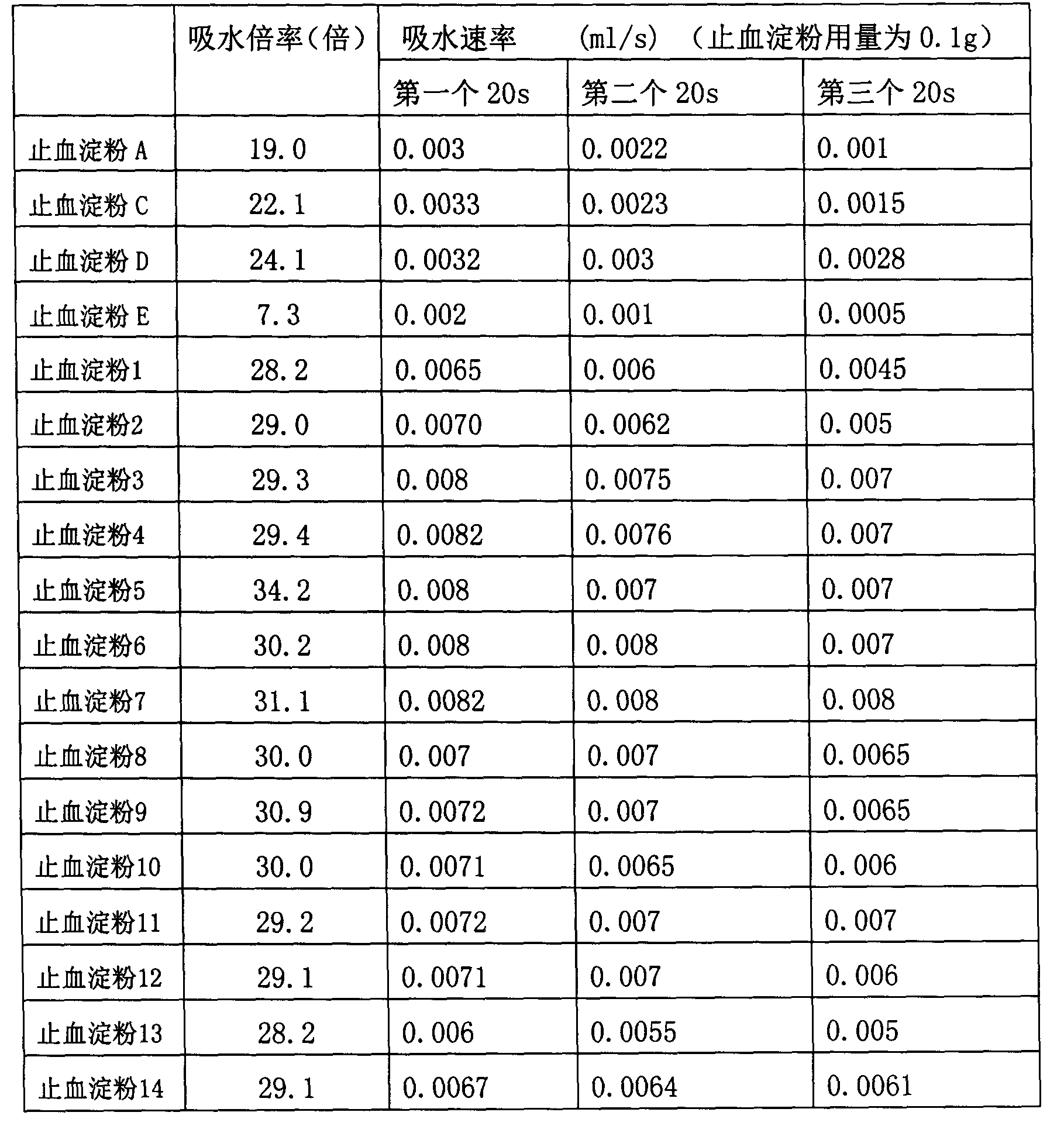

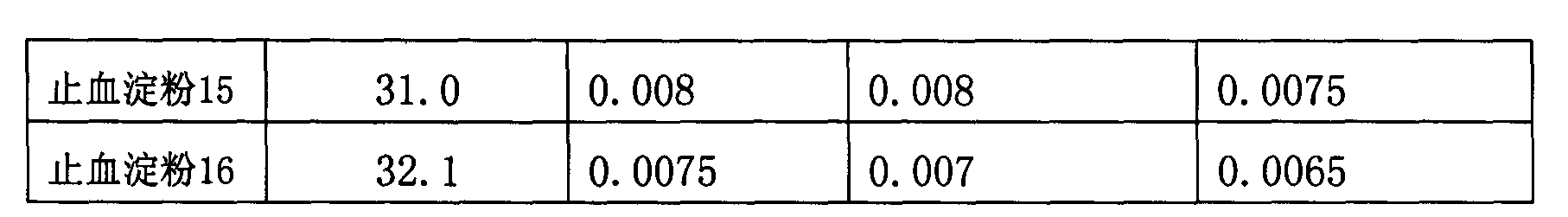

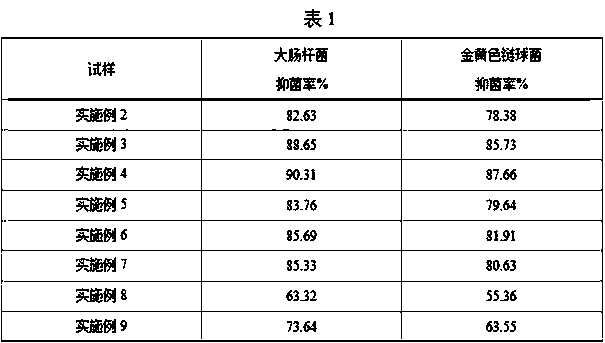

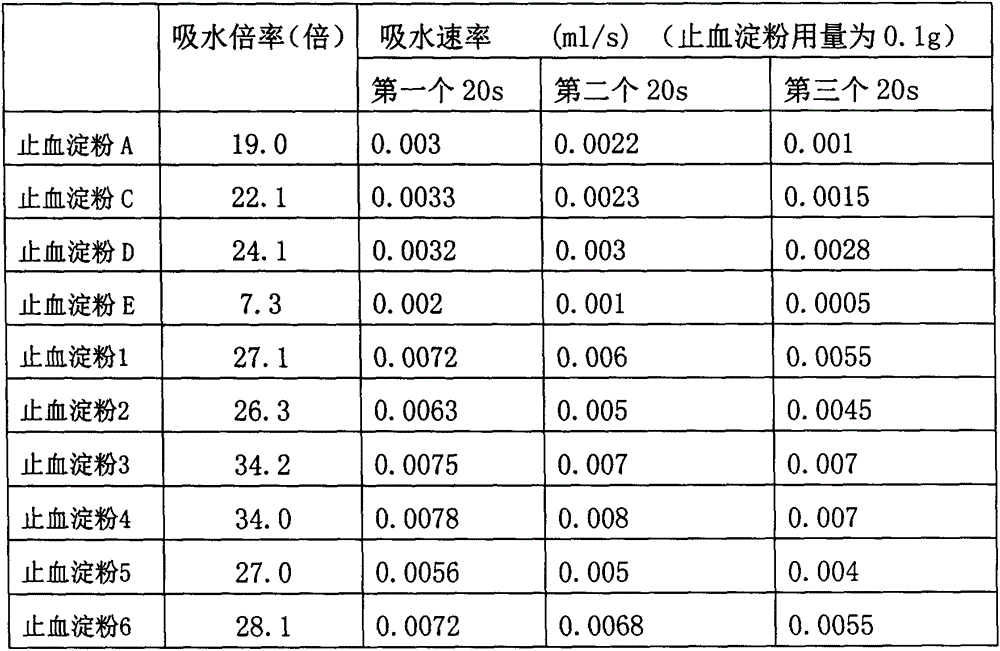

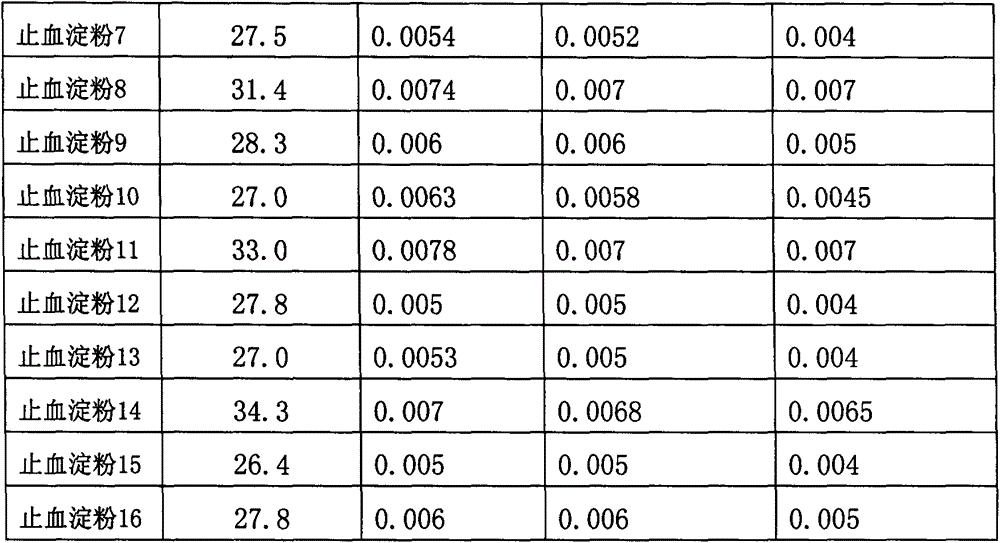

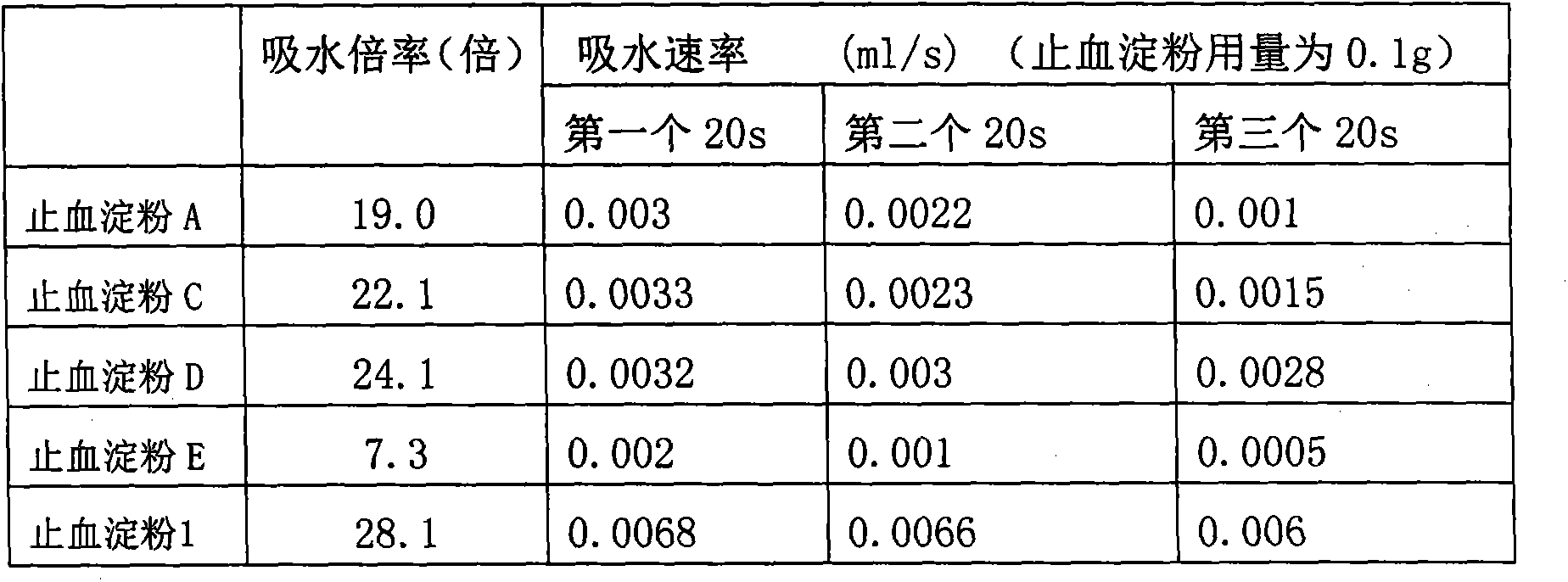

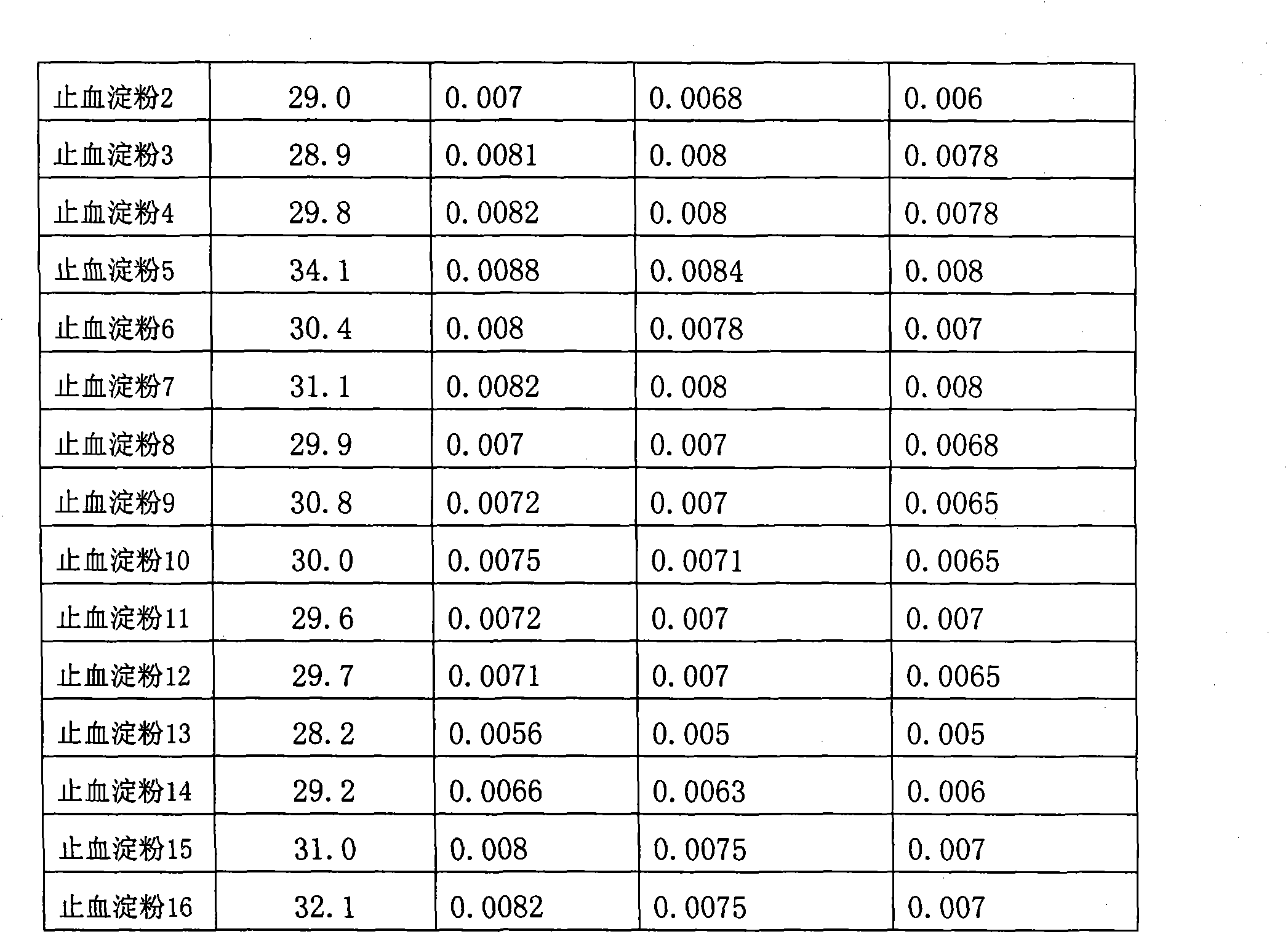

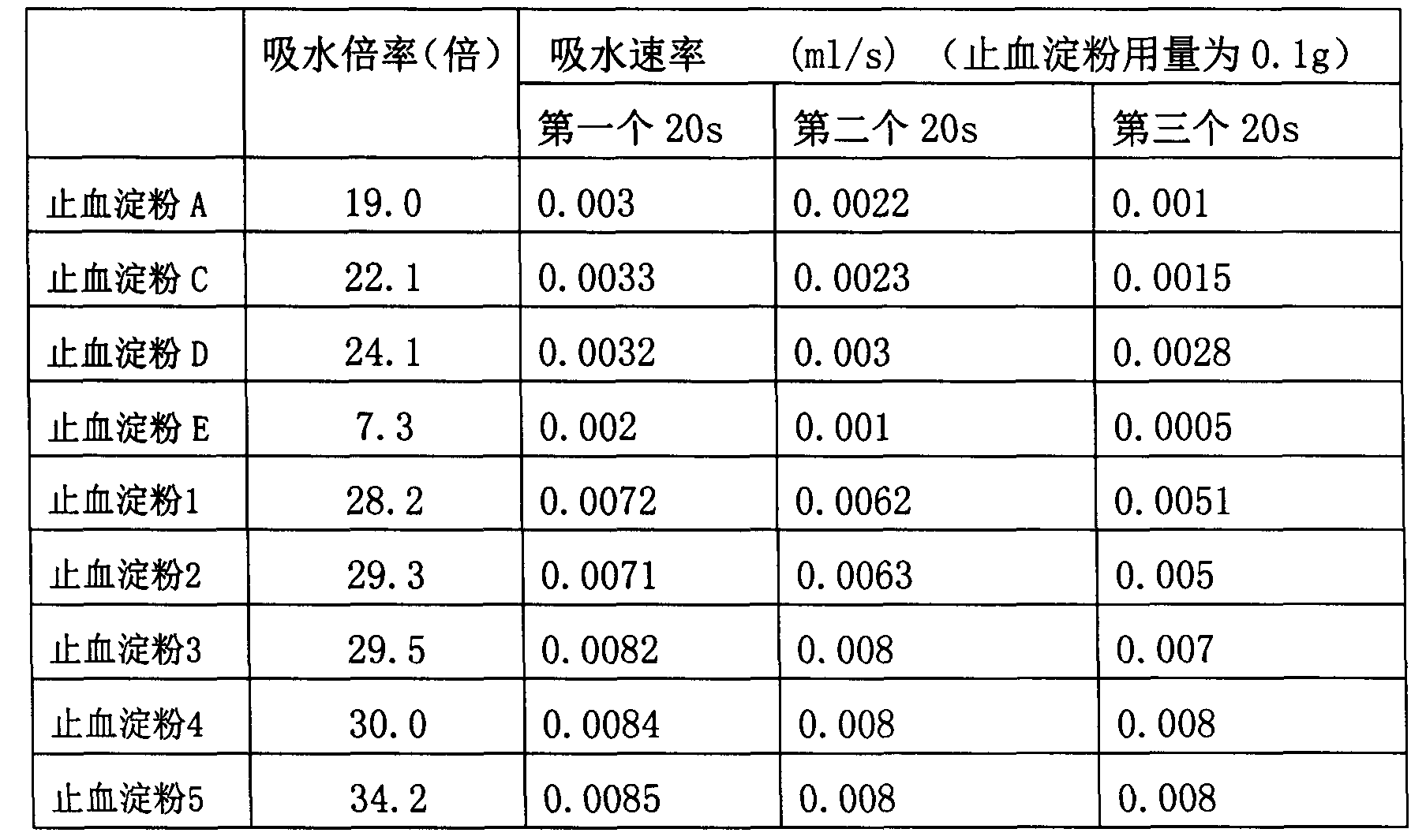

Hemostasis starch and preparation method thereof

ActiveCN103265641AImprove water absorptionImprove water absorption rateSurgeryAbsorbent padsBiocompatibility TestingWound surface

The present invention relates to hemostasis starch and applications thereof, wherein modified starch in the existing technology is subjected to denaturation again, and then is subjected to a ray irradiation treatment to finally prepare the hemostasis starch. The hemostasis starch has characteristics of excellent water absorption effect, safety, stability and biocompatibility, and can be directly used for a wound surface having blood.

Owner:江苏德威兰医疗器械股份有限公司 +1

Medical hydrocolloid pressure-sensitive adhesive and preparation method thereof

InactiveCN104371614AGood initial adhesionFast water absorptionNon-macromolecular adhesive additivesStarch derivtive adhesivesAntioxidantIsoprene

The invention provides a medical hydrocolloid pressure-sensitive adhesive and a preparation method thereof. The pressure-sensitive adhesive is prepared from styrene-isoprene-styrene block copolymer, ester gum, acetate starch, copal, sodium alginate, sodium carboxymethyl cellulose, phthalate, polyisobutylene, an antioxidant, an auxiliary antioxidant, ammonium persulfate, diethylene glycol vinyl ether, polytrimethyldihydroquinoline and naphthenic oil. The preparation method comprises the following steps: adding the styrene-isoprene-styrene block copolymer, acetate starch, copal, antioxidant and auxiliary antioxidant into a rheometer, and compounding; adding the ester gum, phthalate, polyisobutylene, ammonium persulfate, diethylene glycol vinyl ether and naphthenic oil into the rubber mixture, and compounding; and finally, adding the rest of components into the hot-melt pressure-sensitive adhesive, and compounding to obtain the hydrocolloid pressure-sensitive adhesive. The pressure-sensitive adhesive can be easily peeled from the skin surface, and has the advantages of high water absorptivity and high controllability on water-absorbing capacity when in use.

Owner:北京精诚通医药科技有限公司

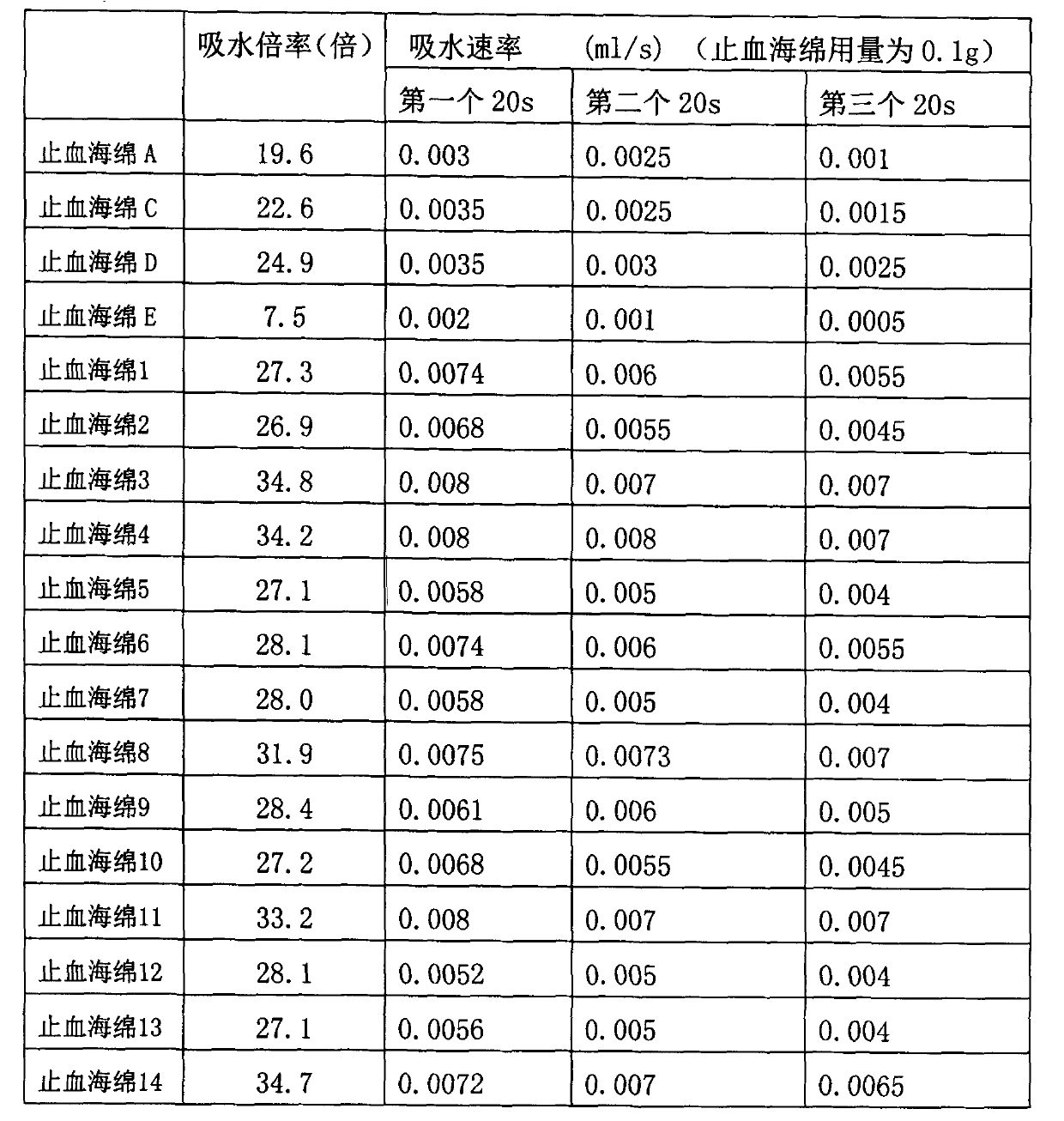

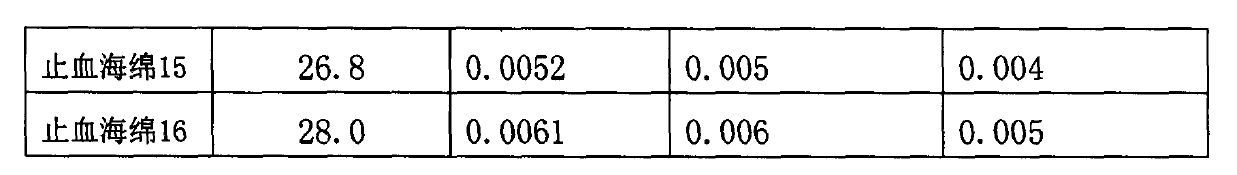

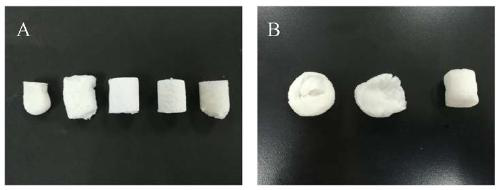

Hemostatic sponge and preparation method thereof

ActiveCN103275344AImprove water absorptionImprove water absorption rateSurgeryAbsorbent padsWound surfaceAbsorption effect

The invention relates to hemostatic sponge and applications of the hemostatic sponge. The hemostatic sponge is prepared from the modified starch in the prior art, which is re-modified and subjected to ultrasonic treatment. The hemostatic sponge is excellent in water absorption effect, safe and stable, and is biocompatible and can be directly applied to bloody wound surfaces.

Owner:江苏德威兰医疗器械股份有限公司 +1

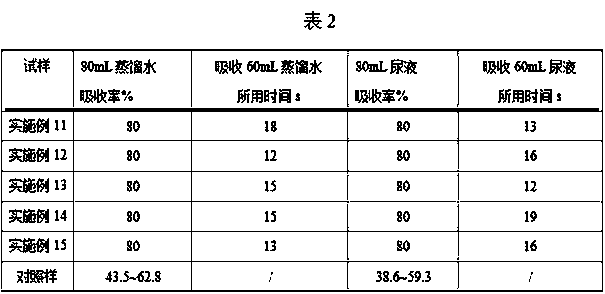

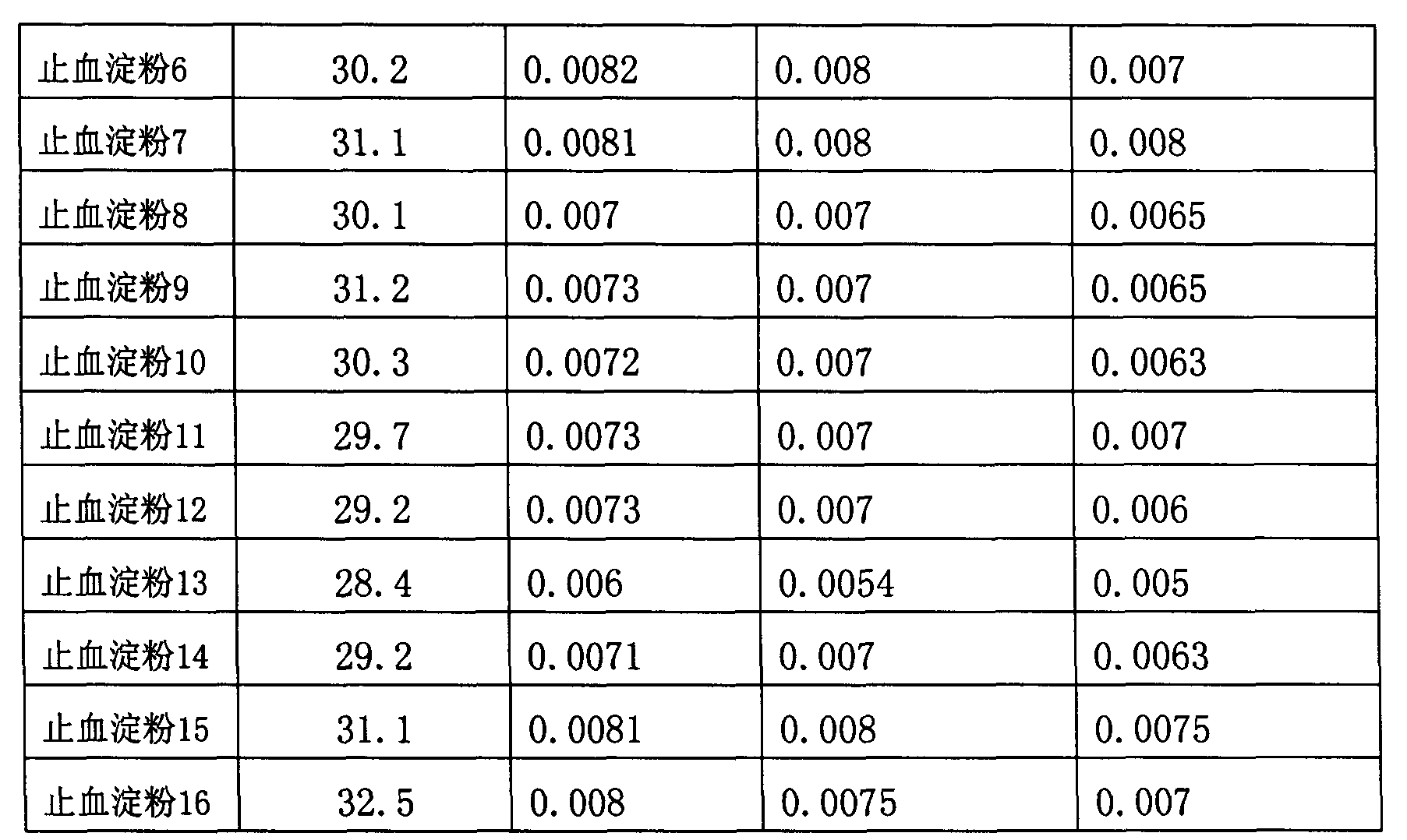

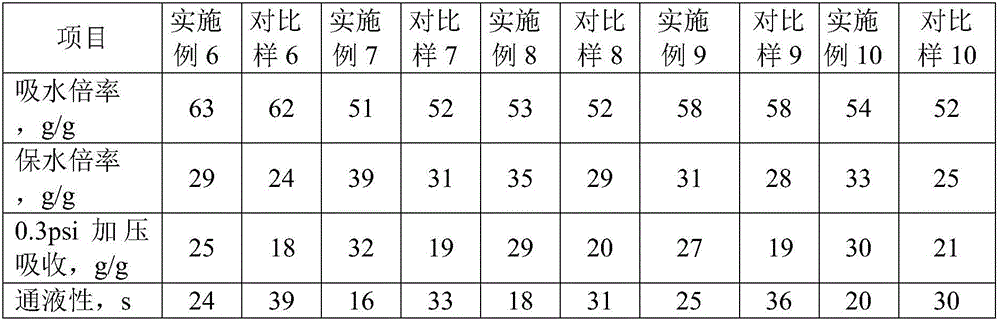

Mutli-layer protective type diaper and method for making diaper

ActiveCN108143542APreserves antimicrobial propertiesAvoid brittlenessAbsorbent padsBandagesSurface layerDeodorant

The invention discloses a multi-layer protective type diaper. The diaper comprises an antibacterial and deodorant fabric layer, a sweat-absorbent and moisture transfer fabric layer, a water-absorptiontype non-woven fabric layer and a surface layer from inside to ouTSide in sequence. The invention further discloses a method for making the multi-layer protective type diaper. The diaper has the advantages of being good in antibacterial effect, high in deodorant capacity and capable of absorbing moisture and releasing sweat.

Owner:DADDY BABY

Polysaccharide styptic powder, preparation method thereof and application

ActiveCN104721874AImprove water absorptionImprove water absorption rateAbsorbent padsBandagesBiocompatibility TestingGlycerol

The invention relates to polysaccharide styptic powder, a preparation method thereof and an application. The preparation method comprises the following steps of using plant native starch and etherified starch as raw materials; treating the plant native starch and the etherified starch by using a microwave oven and glycerol; performing emulsion dispersion on the plant native starch and the etherified starch by using span 80, tween 80 and vegetable oil under the conditions that the pH (potential of hydrogen) is 9-10 and the temperature is 45-70 DEG C; performing crosslinking on the plant native starch and the etherified starch by using sodium trimetaphosphate; performing extraction and skimming on the plant native starch and the etherified starch by using ethyl acetate; washing the plant native starch and the etherified starch by using absolute ethyl alcohol; and drying the plant native starch and the etherified starch by using an oven and performing sterilization so as to obtain the polysaccharide styptic powder. The polysaccharide styptic powder has high biocompatibility, can be directly used for stopping general bleeding, deep bleeding and bleeding of parts at which a surgical tool cannot reach, and is easy and convenient to use. The starch serves as the raw materials of the styptic powder and is non-toxic and non-irritant, the sources of the starch are extensive, the cost is low, a technology is simple and feasible, and the polysaccharide styptic powder has a wide clinical application prospect.

Owner:CHONGQING LIANBAI BOCHAO MEDICAL EQUIP

Hemostasis starch and preparation method thereof

ActiveCN103333261AImprove water absorptionImprove water absorption rateSurgeryAbsorbent padsBiocompatibility TestingWound surface

The present invention relates to hemostasis starch and applications thereof, wherein modified starch in the existing technology is subjected to denaturation again, and then is subjected to an ultrasonic treatment to finally prepare the hemostasis starch. The hemostasis starch has characteristics of excellent water absorption effect, safety, stability and biocompatibility, and can be directly used for a wound surface having blood.

Owner:江苏德威兰医疗器械股份有限公司 +1

Bleeding stopping starch and preparation method thereof

InactiveCN103224568AImprove water absorptionImprove water absorption rateSurgeryAbsorbent padsBiocompatibility TestingAbsorption effect

The invention relates to a bleeding stopping starch and an application thereof. The bleeding stopping starch is prepared through redenaturation of denaturated starch in the prior art, and microwave processing. The bleeding stopping starch has the advantages of excellent water absorption effect, safety and stability, has biocompatibility, and can be directly applied to bleeding wounds.

Owner:BEIJING JIADE SUNSHINE TECH

Calcium carbonate/bagasse cellulose-based super absorbent resin and preparation method thereof

ActiveCN112500530APromote sustainable developmentGood modification effectBulk chemical productionRaw material divisionCelluloseMeth-

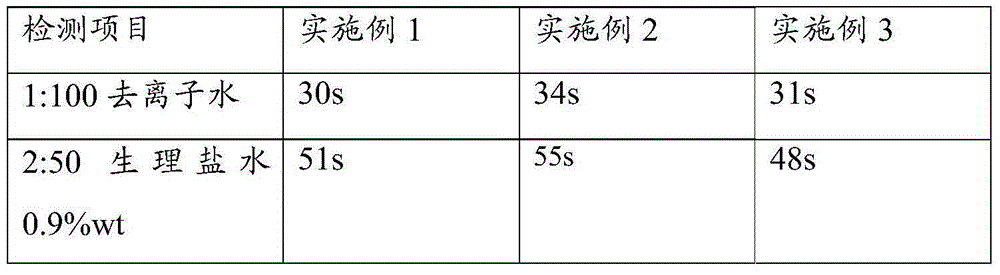

The invention discloses calcium carbonate / bagasse cellulose-based super absorbent resin and a preparation method thereof, and belongs to the technical field of super absorbent resin preparation. Bagasse and modified porous calcium carbonate are used as raw materials, ammonium persulfate is used as an initiator, N,N'-methylene bisacrylamide is used as a cross-linking agent, acrylic acid and acrylamide are used as grafting monomers, and the calcium carbonate / bagasse cellulose-based composite super absorbent material is prepared by adopting an aqueous solution polymerization grafting method. Under the optimal condition, the water absorption rate of the water-absorbent resin reaches 900 g / g or above, and the salt absorption rate (0.9 wt.% NaCl) reaches 135 g / g or above and is higher than thatof a water-absorbent material which is industrially applied at present. The water absorption rate of the material can reach 300 g / g or above within 1 min after water absorption is started, and the salt absorption rate (0.9 wt.% NaCl) reaches 45 g / g or above. Due to rapid water absorption, strong water absorption capacity and salt-tolerant effect, the water-retaining agent has a wide application prospect in the fields of hygienic products for children and adults, agricultural water-retaining materials and the like.

Owner:GUANGXI UNIV

Method for adopting inverse suspension polymerization to prepare humic acid super absorbent resin

The invention discloses a method for adopting an inverse suspension polymerization to prepare humic acid super absorbent resin. The preparing method specifically comprises the first step of taking decomposed coal, and conducting grinding, sieving and drying treatment in sequence on the obtained decomposed coal to obtain decomposed coal powder; the second step of extracting humic acid in the decomposed coal powder through an oxido-degradation with a nitric acid method after obtaining the decomposed coal powder from the first step; the third step of using acrylic monomer and the humic acid from the second step as the raw material, using N,N'-Methylenebisacrylamide solution as a cross-linking agent, using potassium persulfate solution as an initiator, using span-60 as a dispersing agent and using a sodium hydroxide solution as a neutralizer, and preparing humic acid super absorbent resin through the inverse suspension polymerization in cyclohexane. According to the method for adopting the inverse suspension polymerization to prepare humic acid super absorbent resin, inverse suspension polymerization is adopted to prepare the humic acid super absorbent resin, decomposed coal humid acid is used as a raw material, the humic acid super absorbent resin is prepared on the basis of inverse suspension polymerization, and performance of water-absorbent resin is thus effectively improved.

Owner:XI'AN POLYTECHNIC UNIVERSITY

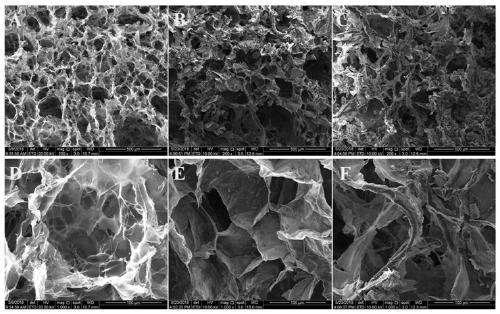

Preparation method of drug-loading hemostatic sponge as well as drug-loading hemostatic sponge prepared from same

ActiveCN109111591AHigh porosityImprove fluffinessSurgical adhesivesPharmaceutical delivery mechanismCelluloseMedicine

The invention discloses a preparation method of drug-loading hemostatic sponge. The preparation method comprises the following steps: (1) preparing lignocelluloses sponge; and (2) loading the lignocelluloses sponge with chitosan and a hemostatic drug in a spraying or immersion manner, and freeze drying to obtain the drug-loading hemostatic sponge. A preparation method of the lignocelluloses spongecomprises the following steps: (1) freezing an alkali urea solution, forming icy slurry, adding lignocelluloses into the icy slurry, and obtaining a lignocelluloses solution; (2) adding a surfactantinto the lignocelluloses solution, stirring, and forming a foam body; (3) freezing the foam body into foam icy slurry, adding a pore forming agent into the foam icy slurry, injection molding, freezing, aging, and obtaining gel; and (4) soaking to remove the surfactant and the pore forming agent in the gel, freeze shaping, freeze drying, and obtaining the lignocelluloses sponge. By adopting the drug-loading hemostatic sponge prepared by the invention, by virtue of the synergistic effect of the chitosan and hemostatic drug, the blood on the surface of a wound can be rapidly absorbed, the blood coagulation of the wound can be effectively promoted, and the bleeding can be rapidly stopped.

Owner:ZHENGZHOU UNIV

Nonwoven fabric for air wetting purification and preparation method thereof

ActiveCN102102296AHigh strengthAvoid breakingFibre treatmentDeodrantsNonwoven fabricUltimate tensile strength

The invention relates to a nonwoven fabric for air wetting purification, wherein the nonwoven fabric for air wetting purification has a liquid-absorption height of 100-200mm and a wetting tensile strength of 3.0-8.0KN / m; preferably, the liquid-absorption height is 120-180mm and the wetting tensile strength is 5.0-8.0KN / m; and optimally, the liquid-absorption height is 130-160mm and the wetting tensile strength is 5.5-8.0KN / m. A method for preparing the nonwoven fabric for air wetting purification comprises the following steps: mixing water-absorption resin with antibacterial agent as a working solution; coating the working solution onto the nonwoven fabric by using a soaking or coating method; and drying and baking the nonwoven fabric, so as to acquire the nonwoven fabric.

Owner:东纶科技实业有限公司

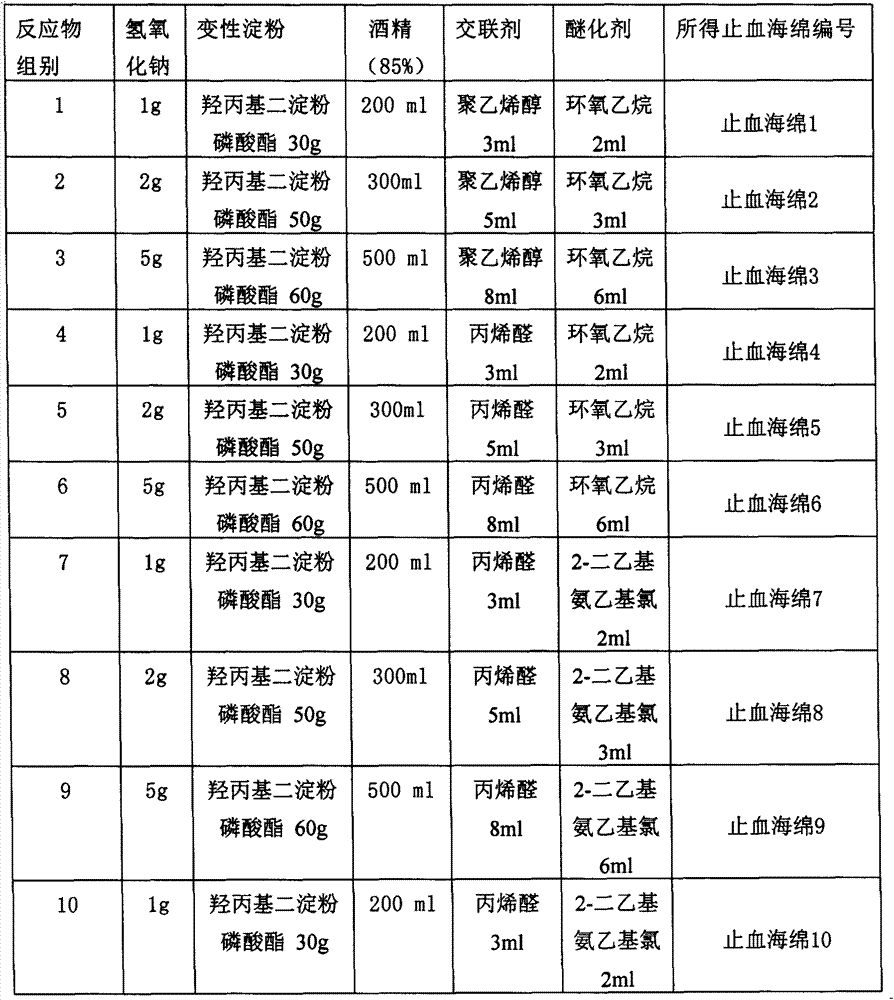

Hemostasis sponge and preparation method thereof

ActiveCN103319744AImprove water absorptionImprove water absorption rateSurgeryAbsorbent padsChemistryAbsorption effect

The invention belongs to the field of hemostasis sponges, and relates to a hemostasis sponge and applications thereof. In order to solve the problem of poor water absorption of the hemostasis sponge in the prior art, the technical scheme of the present invention is that various modified starches in the existing technology are adopted, and sodium hydroxide, the modified starch and alcohol are mixed, and are subjected to cross-linking, etherification and other steps to prepare the high water absorption hemostasis sponge. The hemostasis sponge has characteristics of excellent water absorption effect, safety, stability and biocompatibility, and can be directly used for wound surface having blood.

Owner:江苏德威兰医疗器械股份有限公司 +1

Instant coarse food grain cereal product and making method thereof

InactiveCN108244498AGuaranteed appearanceImprove water absorption rateFood thermal treatmentSeed preservation by heatingPolygonum fagopyrumSesamum

The invention relates to an instant coarse food grain cereal product and a making method thereof. The instant coarse food grain cereal product is made from the following coarse food grains in parts byweight of 5-10 parts of black beans, 5-10 parts of small red beans, 7-12 parts of lentils, 0-10 parts of black rice, 4-10 parts of red polished round-grained rice, 2-10 parts of oat, 4-12 parts of buckwheat, 5-15 parts of panicum miliaceum, 9-13 parts of polished glutinous rice, 10-20 parts of corn grits, 0-5 parts of white sesame seeds, and 0-5 parts of black sesame seeds. The method for makingthe instant coarse food grain cereal product is simple, the made instant coarse food grain cereal product has the characteristics of being free from rinsing and soaking and capable of being cooked with rice together before being eaten at the same time, besides, reserves original appearance and nutrient components of the coarse food grains, is free from harmful substances, and has good grain fragrance and mouth feel.

Owner:COFCO GROUP +1

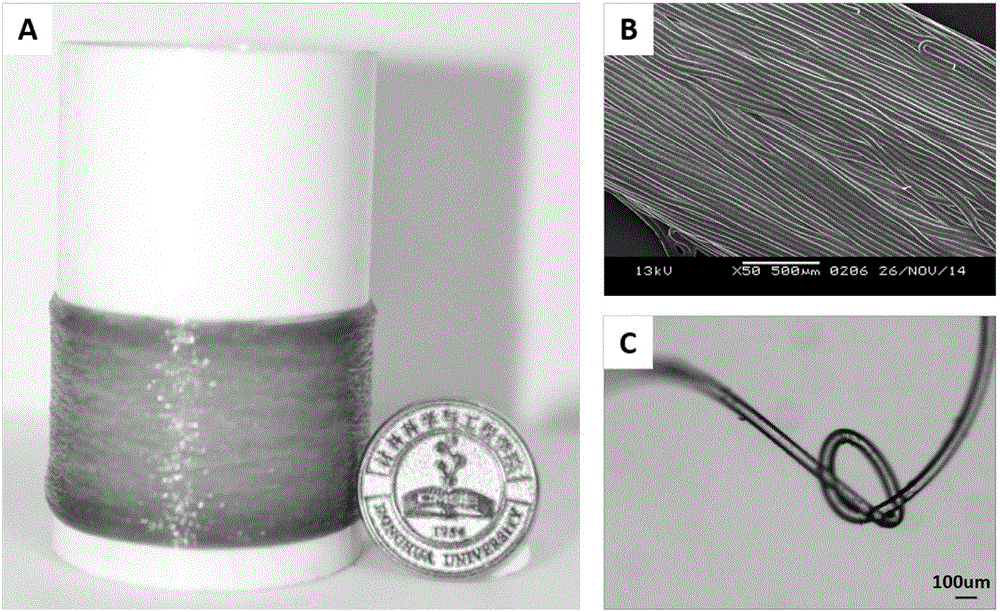

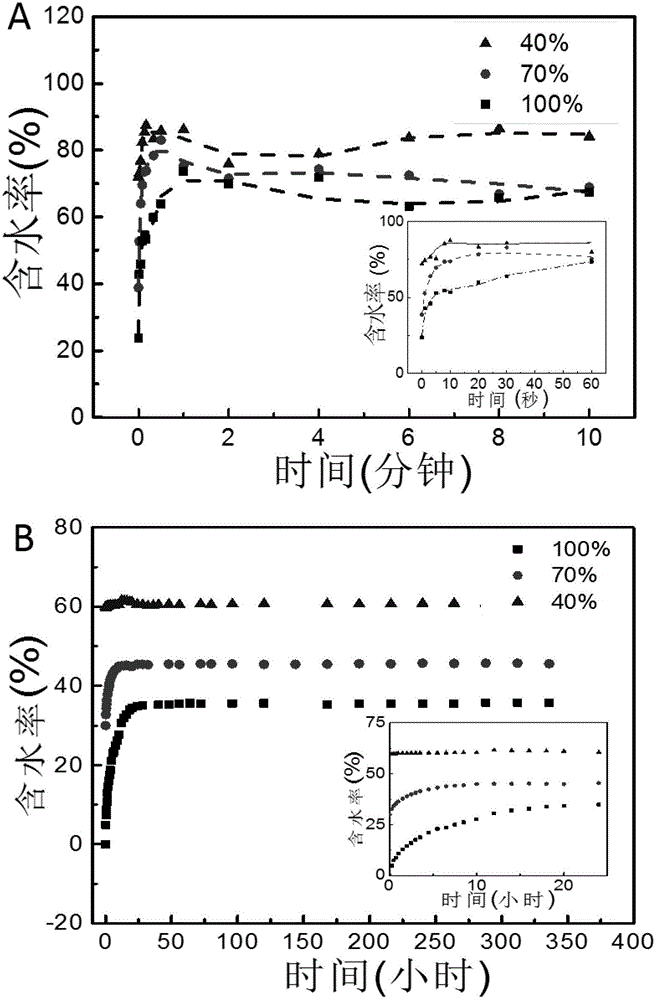

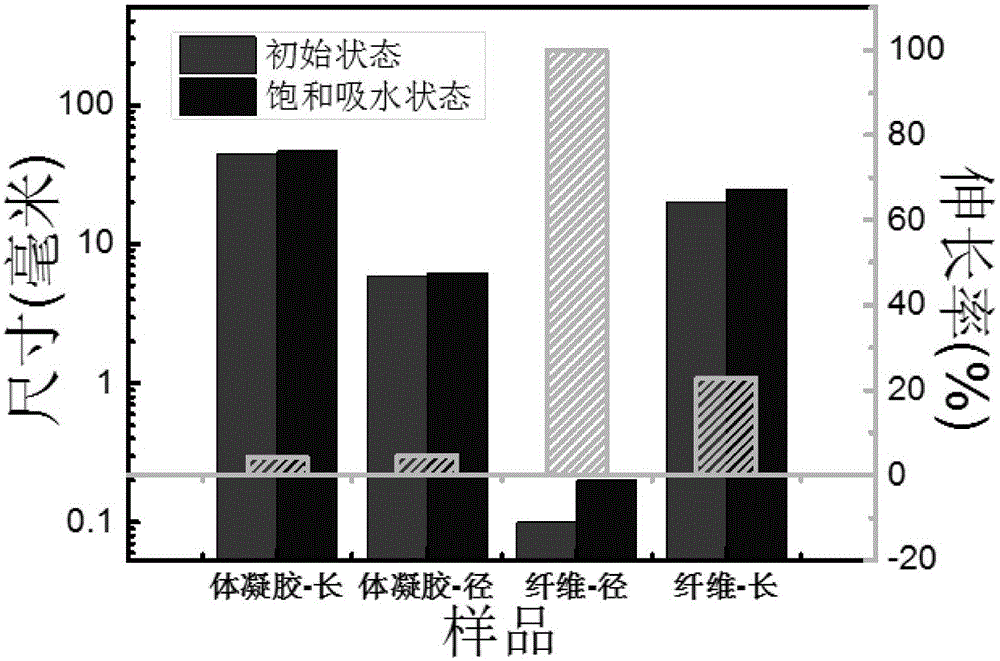

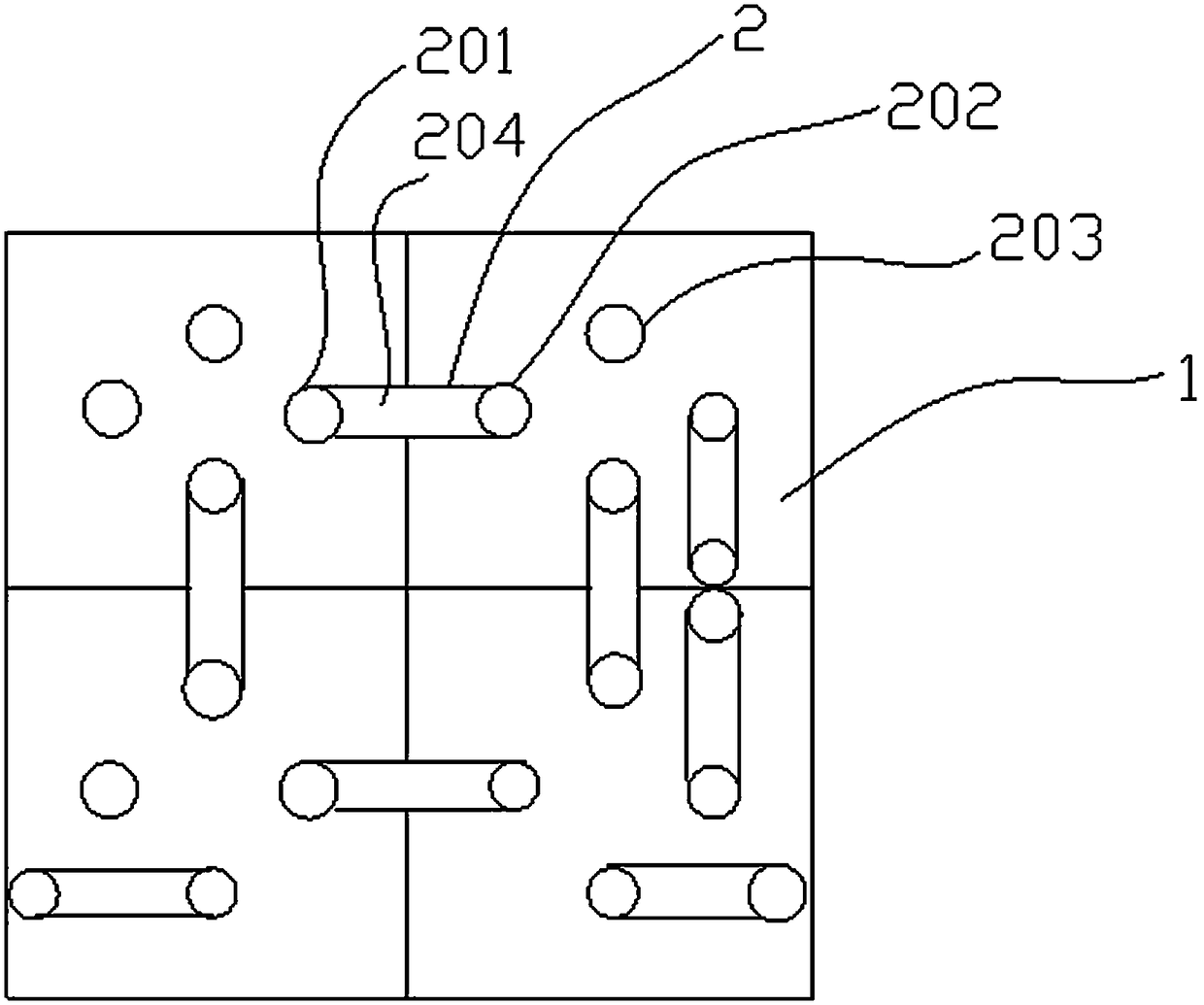

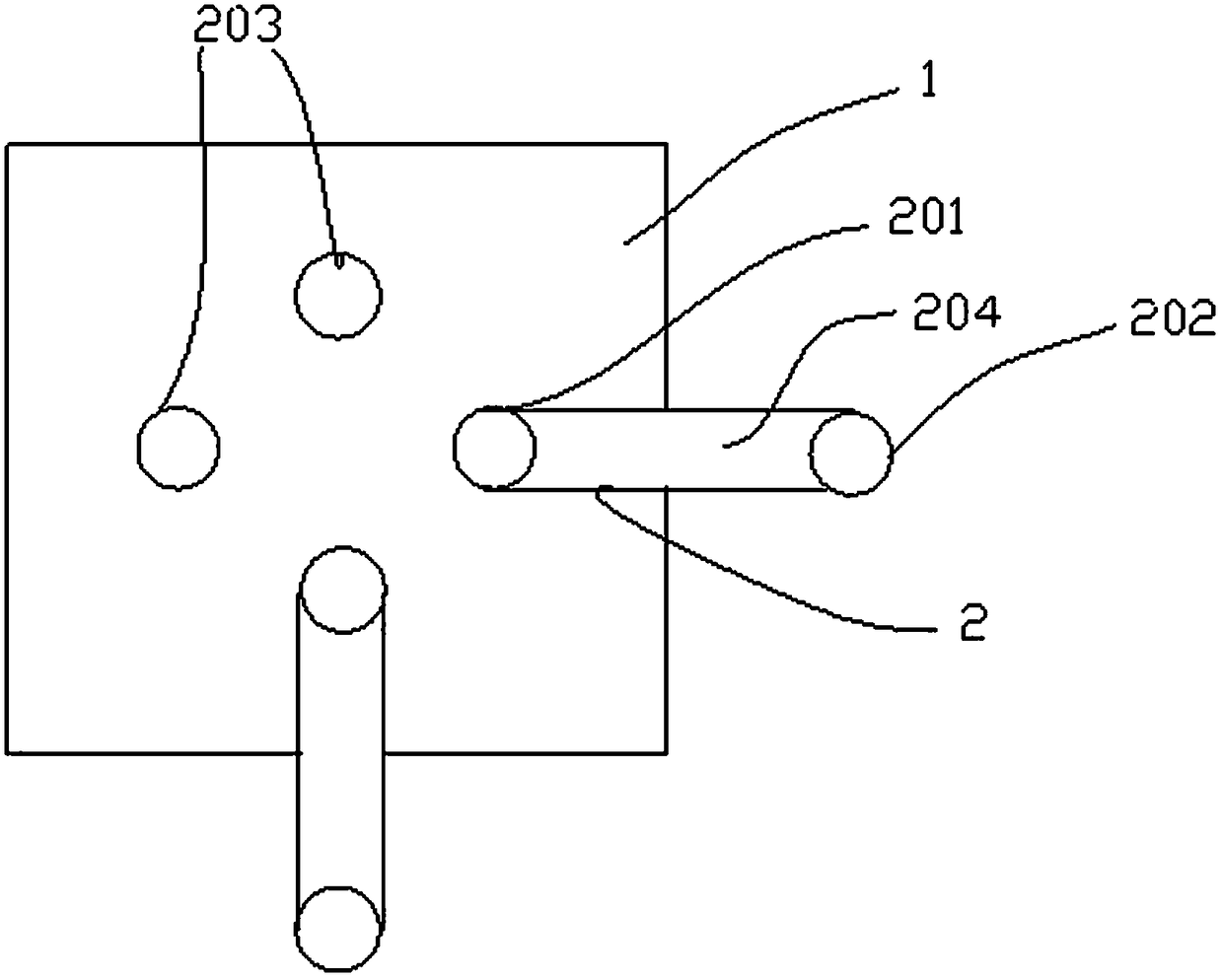

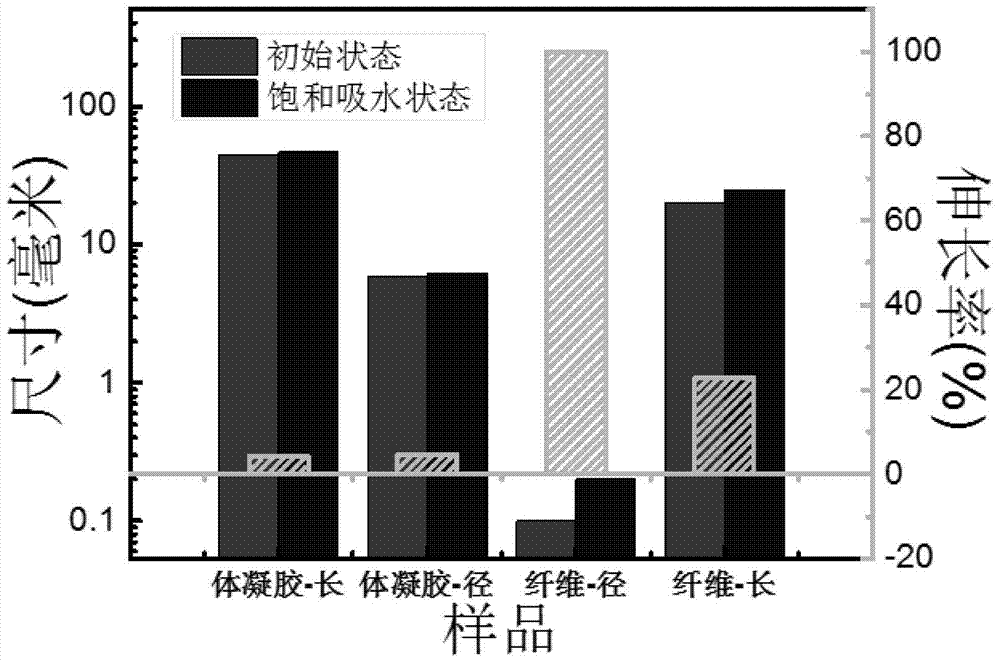

Preparation method of PEGMA/PEGDA hydrogel fiber having ultrafast-anisotropically water-absorption performance

ActiveCN105133065AStable structureImprove water absorptionArtificial filament physical treatmentWet spinning methodsWater bathsFiber

The invention relates to a preparation method of PEGMA / PEGDA hydrogel fibers having an ultrafast-anisotropically water-absorption performance. The preparation method comprises following steps: 1) preparing PEGMA through a polymerization reaction at room temperature; 2) preparing a polymer water solution from the PEGMA and the PEGDA, adding a photo-initiator, performing ultrasound dispersion, stirring the mixture until the photo-initiator is dissolved completely to obtain a PEDMA / PEGDA spinning solution; 3) at room temperature, feeding the spinning solution into a water bath through a spinning spray head by a metering pump, setting an ultraviolet point light source to enable a free radical polymerization reaction of the PEDGA in the spinning solution for preparing primary PEGMA / PEGDA hydrogel fibers; and 4) drafting the primary PEGMA / PEGDA hydrogel fibers to obtain the PEGMA / PEGDA hydrogel fibers. The PEGMA / PEGDA hydrogel fibers are stable in structure and good in water absorption performance. The preparation method has very important significance on development, application and post-processing of hydrogel materials.

Owner:DONGHUA UNIV

Hemostasis starch and preparation method thereof

ActiveCN103265640AImprove water absorptionImprove water absorption rateSurgeryAbsorbent padsBiocompatibility TestingWound surface

The present invention relates to hemostasis starch and applications thereof, wherein modified starch in the existing technology is subjected to denaturation again, and then is subjected to a heat stirring treatment to finally prepare the hemostasis starch. The hemostasis starch has characteristics of excellent water absorption effect, safety, stability and biocompatibility, and can be directly used for wound surface having blood.

Owner:江苏德威兰医疗器械股份有限公司 +1

Preparation method of spandex/nylon-6 two-component medical spunlaced non-woven wiping cloth

InactiveCN108867047AImprove antibacterial propertiesRaise application valueBiochemical fibre treatmentLiquid repellent fibresPhosphoric acidNonwoven fabric

The invention discloses a preparation method of spandex / nylon-6 two-component medical spunlaced non-woven wiping cloth, and relates to the technical field of preparation of non-woven fabrics. The preparation method comprises the following steps: ultrasonically washing a spandex / nylon-6 two-component spunlaced non-woven cloth substrate with acetone and distilled water, then immersing in a sodium hydroxide solution, taking out, drying in the air, immersing in formaldehyde added with phosphoric acid, and carrying out a reaction to obtain a pretreated non-woven cloth substrate; soaking the pretreated non-woven cloth substrate into an ethyl acetate solution of 2-mercaptopropyltriethoxysilane, carrying out a reaction, taking out, drying, and adding the product into ethanol containing N, N-methylenediacrylamide, butyl methacrylate and titanium dioxide nanoparticles, soaking, taking out, then soaking in a photoinitiator solution, taking out, irradiating with ultraviolet rays, washing, and drying. The spandex / nylon-6 two-component medical spunlaced non-woven wiping cloth prepared by the method has very good hydrophilia, lipophilicity and antibacterial properties, so that the application value of the medical spunlaced non-woven wiping cloth is improved.

Owner:望江汇通纺织有限公司

Preparation method of graphene anti-bacterial composition and anti-bacterial SPA (super absorbent resin)

ActiveCN107522996AImprove hydrophilicityIncrease osmotic pressureChemical compositionAdditive ingredient

The invention relates to a preparation method of a graphene anti-bacterial composition. The composition comprises the following ingredients in parts by weight: 5-45 parts of tea saponin, 10-50 parts of graphene oxide and 0.01-2 parts of a dispersing agent and is prepared by the following steps: step 1, dissolving an appropriate amount of tea saponin into deionized water, so as to form tea saponin solution with the mass concentration of 5%-20%; step 2, adding the dispersing agent into the deionized water, uniformly stirring the mixture, adding the graphene oxide into the deionized water until the concentration of the graphene oxide is 0.2-20 mg / mL, and performing ultrasonic dispersion for 30-240 min, so as to form graphene suspension liquid; step 3, adding the graphene suspension liquid obtained in step 2 into the tea saponin solution obtained in step 1, and performing ultrasonic dispersion for 30-120 min, so as to form tea saponin intercalated graphene suspension liquid; step 4, freezing and drying the tea saponin intercalated graphene suspension liquid obtained in step 3, so as to obtain powdery tea saponin intercalated graphene.

Owner:浙江卫星新材料科技有限公司

Multifunctional antibacterial mattress containing graphene

InactiveCN108185721AGuarantee life and healthEffective in inhibiting bacteriaStuffed mattressesSynthetic resin layered productsHigh densityGraphene

The invention provides a multifunctional antibacterial mattress containing graphene. The mattress comprises a plurality of antibacterial mattress bodies with the same size, wherein each antibacterialmattress body comprises a water locking layer, an antibacterial layer, a water absorbing layer and a waterproof layer; the water locking layer is synthesized from graphene fiber and nonwoven fabric with a spunlace process; the antibacterial layer is one or more of carbon sponge, latex sponge, high-density sponge and graphene fiber. Due to the antibacterial performance of the graphene material, theprepared antibacterial mattress has a remarkable inhibition effect on bacteria, besides, the antibacterial mattress bodies can be dismounted, spliced and replaced with one another, bed mattresses with different sizes can be formed, and a sofa cushion, a camping mat and the like can be formed.

Owner:林荣铨

Novel fire extinguishing material and preparation method thereof

InactiveCN108635721AImprove rigidityImprove water absorption rateFire extinguisherCross-linkGel preparation

The invention provides a novel fire extinguishing material and a preparation method thereof. According to the novel fire extinguishing material and the preparation method thereof, acrylic acid and acrylamide are used as water-absorbing monomers to be subjected to cross-linking reaction under the action of a cross-linking agent and an initiator so as to generate gel, chitosan is added in the gel preparation process, so that the rigidity of the gel is improved, the water absorption rate of the gel is increased, and the gel is not liable to be dried and cracked at a high temperature; and a surface active agent is further compounded to form a stable and efficient foaming agent, abundant and compact foams are formed through high-speed stirring at the later stage of the cross-linking reaction soas to achieve the fire extinguishing effect, in addition, the formation of gel pores is facilitated by the aid of a stabilizer and a pore-forming agent of sodium carbonate at the later stage of the gel forming process, so that the swelling rate can be greatly increased, meanwhile, ammonium polyphosphate is modified, so that the hydrophobicity and the grafting performance can be improved, and grafting is carried out on the gel by utilizing the cross-linking reaction, so that the fire extinguishing performance can be further improved. The fire extinguishing material has the advantages of beinghigh in fire extinguishing performance, high in speed, good in effect, capable of improving the fire extinguishing efficiency, capable of preventing recrudescence of a fire, low in application cost and suitable for large-scale popularization.

Owner:安徽龙安消防工程有限责任公司

Method for producing high absorptive resin

InactiveCN1208352CHigh linear molecular weightHigh molecular weightAbsorption capacityAbsorption rate

Owner:KEYUAN PRODIVE POWER PROMOTION CENT OF PETROCHEM IND SHANDONG

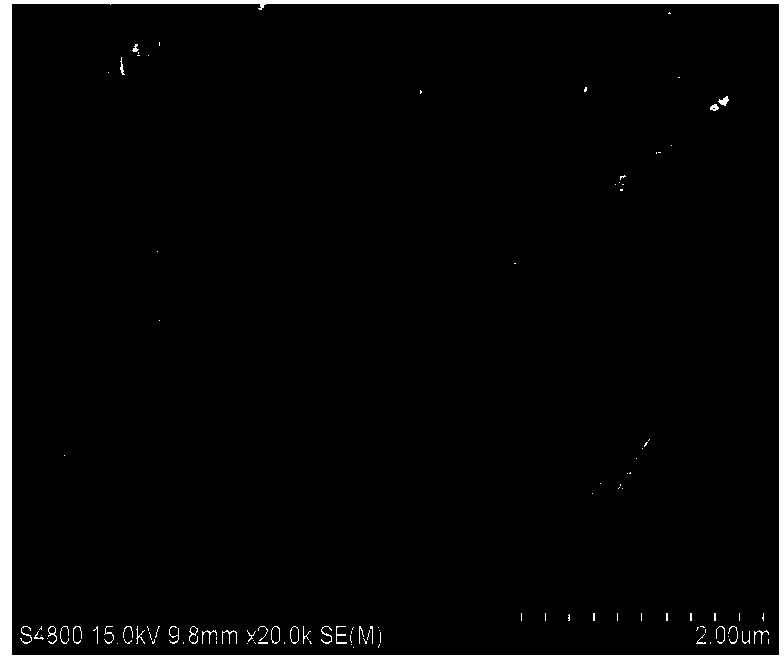

Method for synthesizing manganese dioxide nanowire composite super absorbent resin

InactiveCN103360543AImprove salt toleranceImprove water absorption rateManganese oxides/hydroxidesPotassium persulfateSaline water

The invention discloses a method for synthesizing a manganese dioxide nanowire composite super absorbent resin. The method mainly comprises the following steps of: preparing a manganese dioxide nanowire through a hydrothermal method; taking three resins such as acrylic acid, acrylamide and 2-acrylamide-2-methyl propanesulfonic acid, the prepared manganese dioxide nanowire, a crosslinking agent N,N'-methylene bisacrylamide and an initiator potassium persulfate as raw materials to synthesize a composite resin; adding the acrylic acid into an ice bath, adding the acrylamide and 2-acrylamide-2-methyl propanesulfonic acid for uniformly stirring, sequentially adding the manganese dioxide nanowire, the crosslinking agent and the initiator, reacting at the temperature of 60-70 DEG C for 4 hours in a staged temperature rise mode, and drying the obtained product in a constant-temperature drying box at the temperature of 80 DEG C. According to the composite resin, the salt tolerance, water absorption rate, gel strength, heat stability, water-retaining property and the like of the resin can be effectively improved, the saline water absorption rate of the composite resin is improved by 25 percent compared with that of the acrylic acid and acrylamide type super absorbent resin, and the lead ion adsorbing capacity is 6.139mg / g.

Owner:YANSHAN UNIV

A preparation method of pegma/pegda hydrogel fiber with ultrafast anisotropic water absorption

ActiveCN105133065BDisruption of regularityPromote swellingArtificial filament physical treatmentMonocomponent synthetic polymer artificial filamentWater bathsFiber

The present invention relates to a preparation method of PEGMA / PEGDA hydrogel fiber with ultra-fast anisotropic water absorption, comprising: preparing PEGMA through polymerization reaction at room temperature; preparing polymer aqueous solution with PEGMA and PEGDA, adding a photoinitiator, Ultrasonic dispersion, stirring, until the photoinitiator is completely dissolved, to obtain PEGMA / PEGDA spinning solution; at room temperature, pass the obtained spinning solution into the water bath through the spinning nozzle through the metering pump, and set the ultraviolet light source to trigger the spinning solution Free radical polymerization reaction of PEGDA in medium to obtain PEGMA / PEGDA nascent hydrogel fibers; stretching the obtained nascent hydrogel fibers to obtain. The hydrogel fiber prepared by the method of the invention has stable structure and good water absorption performance, and has very important significance for the development, application and post-processing of hydrogel materials.

Owner:DONGHUA UNIV

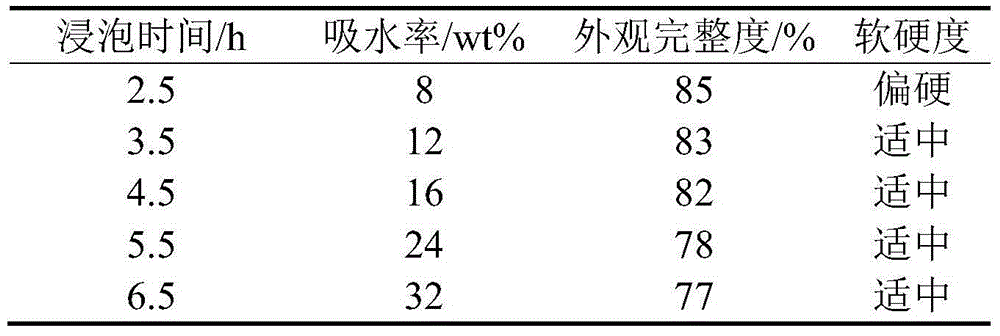

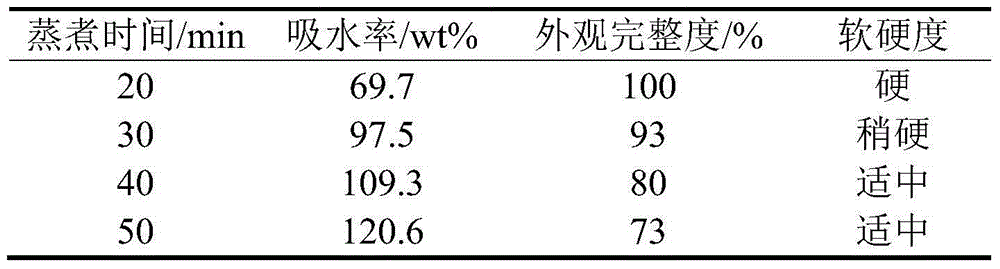

Making method of easily-cooked red beans

The invention relates to a making method of easily-cooked red beans.The method comprises the following steps of 1, a soaking step, wherein the red beans which serve as the raw material are soaked with water, and the soaked red beans are obtained; 2, a step of steaming the red beans for pre-cooking, wherein the soaked red beans obtained in the first step are steamed for pre-cooking, and the precooked red beans are obtained; 3, a drying step, wherein the precooked red beans obtained in the second step are slowly dried by means of vapor, rapid drying is conducted subsequently by means of microwave, and dried easily-cooked red beans are obtained; 4, a cooling step, wherein the dried easily-cooked red beans obtained in the third step are cooled at the temperature ranging from 10 DEG C to 30 DEG C, and an easily-cooked red bean product is obtained.The easily-cooked red bean product obtained through the method has the advantages of being easy to cook, capable of keeping the appearance of the red beans complete and not broken basically, easy to rewater and the like, and meanwhile the red beans have better mouthfeel and nutrition.

Owner:COFCO GROUP +1

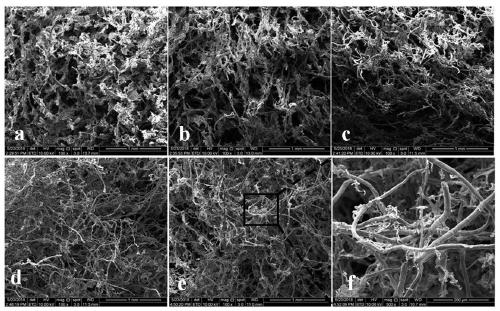

Preparation method for hydroxyethyl cellulose hemostatic gauze

InactiveCN105887331AHigh water absorption rateFast water absorptionUltrasonic/sonic fibre treatmentAbsorbent padsElectrospinningHydroxyethyl cellulose

The invention belongs to the field of biomedical materials, and particularly relates to a preparation method for hydroxyethyl cellulose hemostatic gauze. The hydroxyethyl cellulose hemostatic gauze is prepared by taking hydroxyethyl cellulose as a raw material and combining an ultrasonic processing technique with an electrospinning technique; a series of drying and sterilizing are performed, so that the hydroxyethyl cellulose hemostatic gauze is prepared. Hydroxy propyl cellulose belongs to neutral etherification products, overcomes a defect that the polar group is easy to generate a stimulation reaction to an organic body, and has the characteristics of high water swelling performance and quick hemostatic performance. The hydroxyethyl cellulose hemostatic gauze is nontoxic without stimulation, the process is simple and feasible, and the clinic application prospect is wide.

Owner:CHONGQING LIANBAI BOCHAO MEDICAL EQUIP

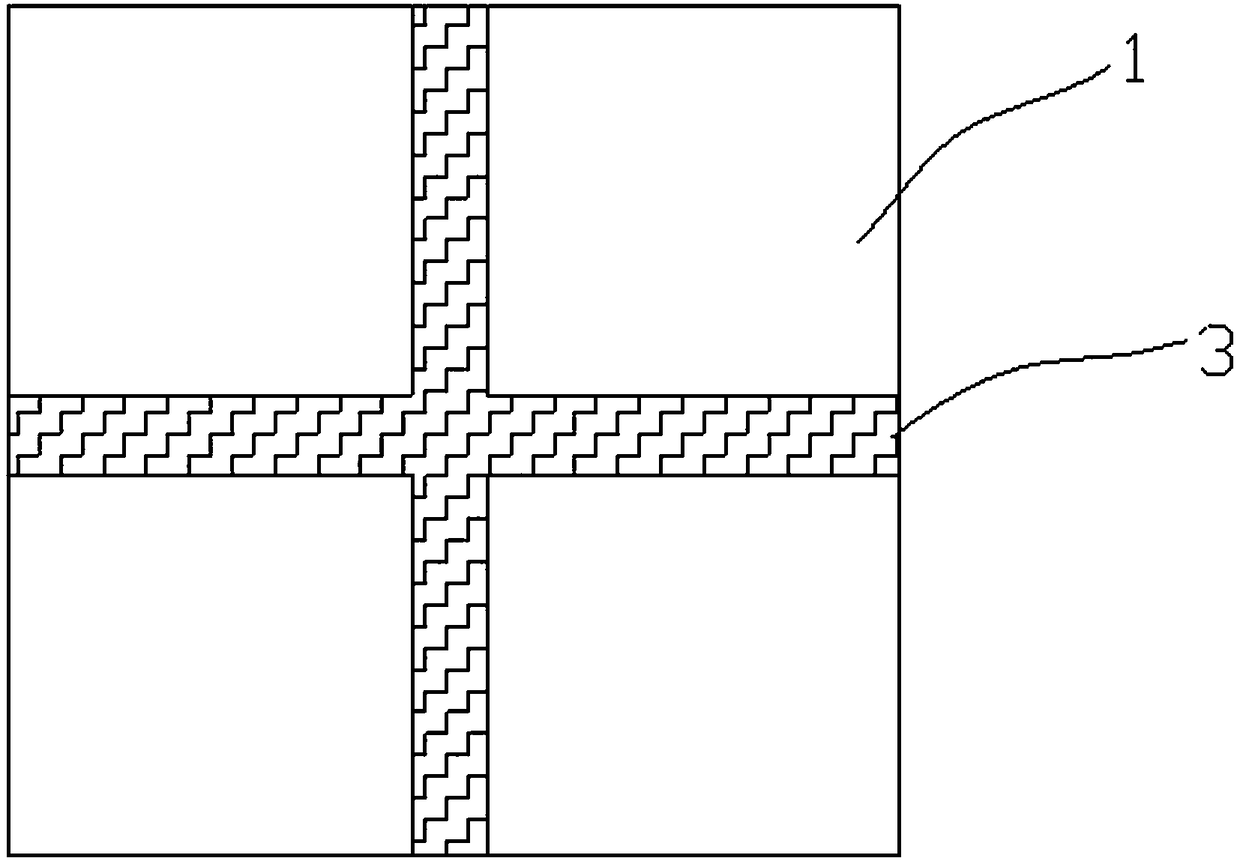

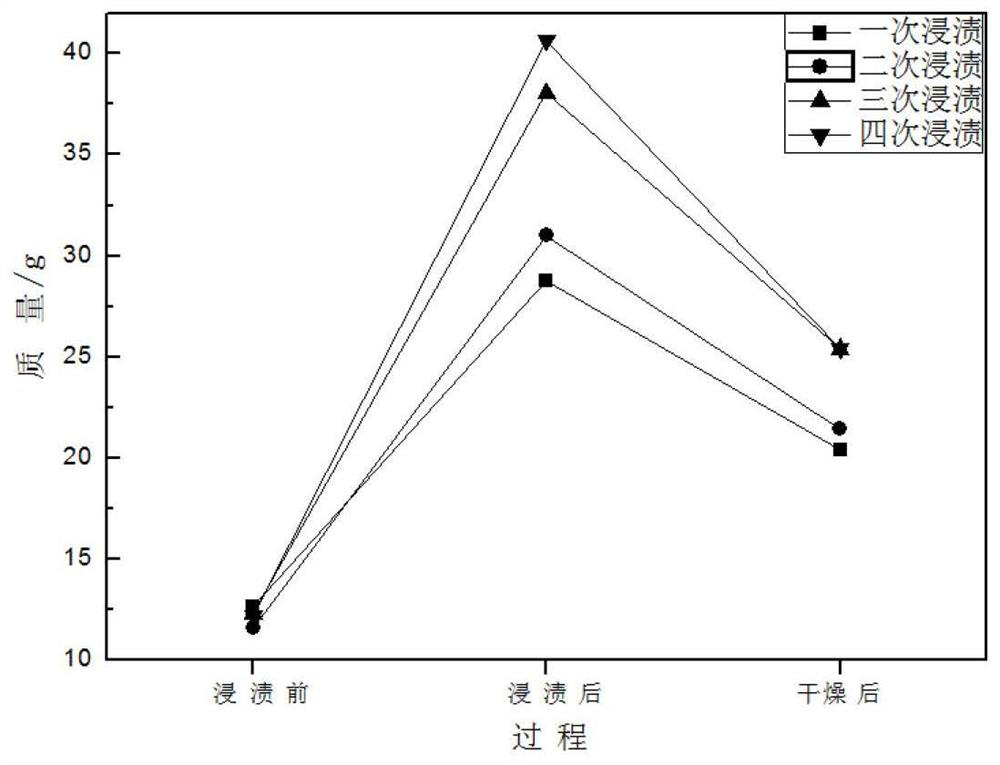

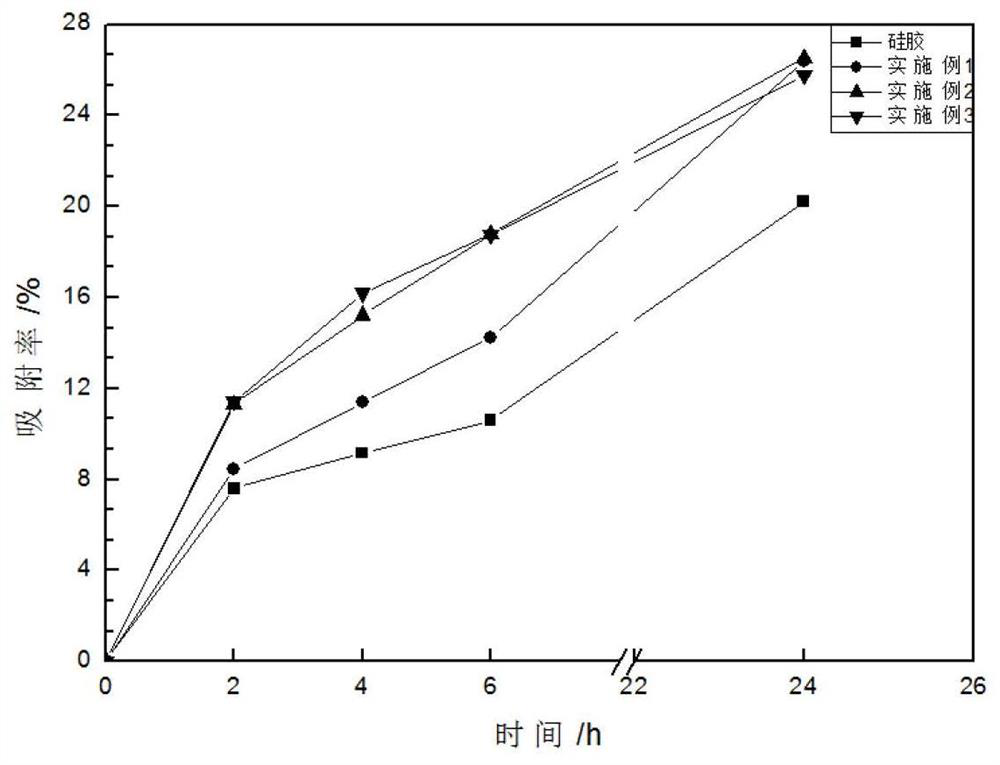

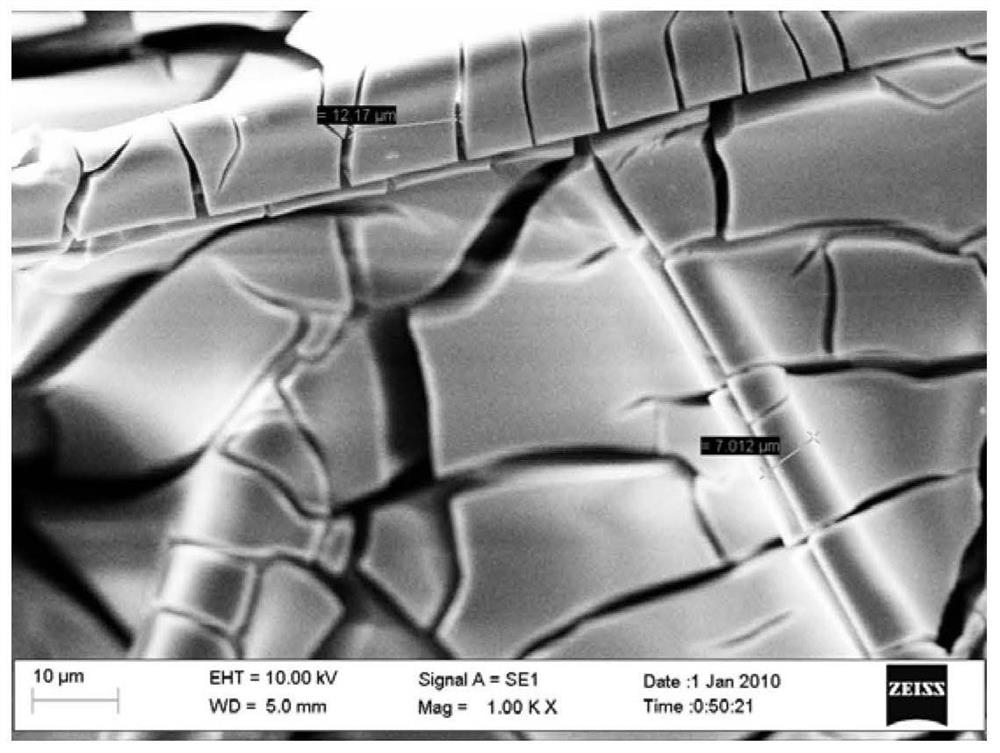

Preparation method of high-load modified silica gel dehumidification rotary core

PendingCN112705158AIncrease loadImprove water absorption rateOther chemical processesDispersed particle separationPhysical chemistrySilica gel

The invention discloses a preparation method of a high-load modified silica gel dehumidification rotary core, and belongs to the field of dehumidification material preparation. The method comprises the following steps of: (1) drying and purging a sample block of the dehumidification rotary core, then soaking the sample block in water glass, and then purging the sample block with hot air; (2) repeatedly and uniformly spraying the residual water glass in the step (1) onto the sample block obtained in the step (1), and then purging the sample block with hot air; (3) soaking the sample block obtained in the step (2) in a zinc salt solution in a water bath, and adjusting the pH value to an initial pH value by using acid in the reaction process; and (4) washing the sample block obtained in the step (3) with water until the sample block is neutral, and roasting and drying the sample block. According to the method, the modified silica gel dehumidification rotary core which is large in effective load capacity, good in adsorption performance and high in mechanical strength is obtained through twice dipping and metal doping process control.

Owner:QINGDAO HSJ ENVIRONMENTAL PROTECTION TECH CO LTD

Delustering high-strength low-elongation viscose fiber and preparation method and application thereof

InactiveCN104831394AGuaranteed multiple responsesHigh strengthMonocomponent cellulose artificial filamentBleaching apparatusBreaking strengthSocial benefits

The invention discloses a delustering high-strength low-elongation viscose fiber and a preparation method and application thereof. The delustering high-strength low-elongation viscose fiber is obtained by subjecting pulp materials to dipping, grinding, squeezing smashing, rubbing, depolymerizing, yellowing, dissolving, filtering, deaerating, ripening, spinning drawing and post-processing sequentially. The delustering high-strength low-elongation viscose fiber meets the technical indexes that the dry breaking strength is not smaller than 3.20cN / dtex, the wet breaking strength is not smaller than 1.70cN / dtex, the strength for generating 5% of elongation in wet condition is not smaller than 0.55cN / dtex, the dry breaking elongation is 13.0%-16.0%, the wet breaking elongation is 16.0%-21.0%, radial water swelling capacity is 22%-26%, and the content of a delustering agent is 0.8%-5%. The delustering high-strength low-elongation viscose fiber is a novel viscose fiber, is lower than a modal fiber in production cost, has great economic benefit and social benefit, and is mainly applied to the production fields of underwear and top-grade woven fabric.

Owner:YIBIN GRACE GROUP CO LTD +2

Preparation method of water superabsorbent polyacrylic resin

InactiveCN106496381AIncrease surface areaImprove water absorption and absorption speedChemistryHealth work

The invention discloses a preparation method of a water superabsorbent polyacrylic resin. An acrylic acid, an acrylate or an acrylic acid derivative as a polymerizable monomer undergoes an aqueous solution polymerization reaction under the action of a surfactant and an initiator to produce the superabsorbent polyacrylic resin. Through combination of aqueous solution polymerization and the surfactant, the water superabsorbent polyacrylic resin is obtained. The water superabsorbent polyacrylic resin can effectively improve the lubricity of the gel after polymerization, can be easily chopped and pelleted, does not easily adhere to a device and is conducive to industrial large-scale production. The preparation method effectively increases the specific surface area of the product and improves water absorbency and a water absorption speed of the product. The water superabsorbent polyacrylic resin can be applied to a water or blood adsorption product, and is particularly used in medical and health work-related products such as adult or baby diapers, or sanitary napkins for women, sanitary napkins and sanitary pads.

Owner:ZHONGSHAN HENGGUANGYUAN ABSORBENT MATERIAL CO LTD

Preparation method of environment-friendly grafted modified high-absorbent material

The invention discloses a preparation method of environment-friendly grafted modified high-absorbent material, comprising the following steps: (1), neutralizing with acrylic acid; (2), preparing grafted monomer mixed liquid; (3), preparing gelatinized starch solution; (4), graft-reacting; (5), extracting a product. The production method of this material is simple, is easy to implement, is imparted by replacing part of acrylic acid with itaconic acid and sodium lignin sulfonate, environmental friendliness and also enables reduced product cost; in addition, by using organic montmorillonite and taking advantage of own intercalation specificity and nano-scale size, water absorption rate and quantity of the absorbent material are effectively increased; the obtained material has excellent comprehensive performance and promising market prospect.

Owner:诚和环境科技(苏州)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com