Instant coarse food grain cereal product and making method thereof

A technology for grains and coarse grains, which is applied in food science, food heat treatment, heating and preservation of seeds, etc. It can solve the problems of poor taste and difficult cooking of coarse grains, and achieve the effects of increasing water absorption rate, low production cost, and shortening cooking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

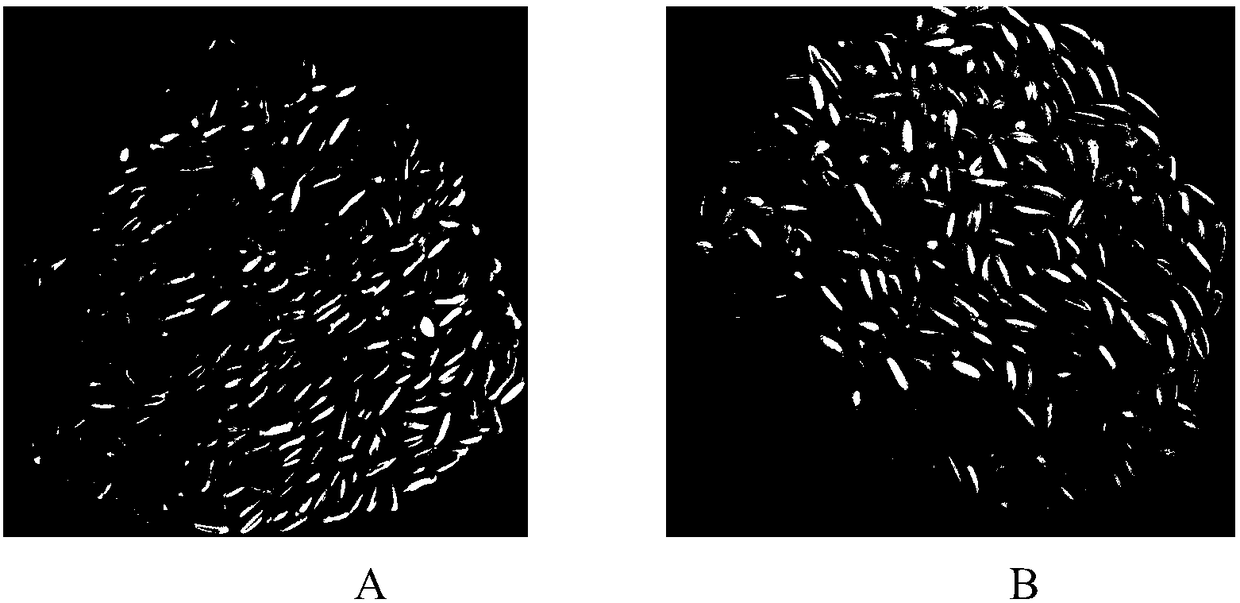

Method used

Image

Examples

preparation example Construction

[0024] The water mentioned in the method for preparing the instant coarse grain cereal product of the present invention is any water that can be used in the food manufacturing industry, such as but not limited to domestic tap water, deionized water, distilled water and the like.

[0025] In a preferred embodiment of the present invention, the coarse grains used as raw materials are preferably coarse grains from which impurities, broken grains, and diseased grains have been removed. In a further preferred embodiment, the coarse grains as raw materials are calculated in parts by weight: 5-10 parts of black beans, 5-10 parts of red beans, 7-12 parts of lentils, 0-10 parts of black rice, red japonica rice 4-10 parts, 2-10 parts of oats, 4-12 parts of buckwheat, 5-15 parts of large yellow rice, 9-13 parts of glutinous rice, 10-20 parts of corn grits, 0-5 parts of white sesame and 0-5 parts of black sesame .

[0026] The amount of water used for rinsing the coarse grains in the met...

Embodiment

[0083] Unless otherwise specified, the materials and devices in the examples of the present invention are specifically described as follows: the microwave baking equipment was purchased from Jinan Huanuo Microwave Equipment Co., Ltd.; the hydraulic cleaning machine was purchased from Jinan Yuchu Food Co., Ltd. The cleaning machine whose model is YXM-500B; the coarse grains used are the corresponding commercially available common coarse grains.

[0084] Hereinafter, the preparation of the quick-cooking coarse-grain cereal product as a rice companion and various quick-cooking coarse-grain cereals as its raw materials will be described through exemplary embodiments and preparation examples, and it is not intended to limit the scope of the present invention. protected range.

preparation example 1

[0085] Preparation Example 1: Preparation of Quick-cooking Black Beans

[0086] The method for preparing quick-cooking black beans comprises the steps:

[0087] (1) At ambient temperature, after removing impurities, broken grains, and diseased grains from the black beans, rinse them with water for 5 minutes using a hydraulic cleaning machine, wherein the weight ratio of the black beans to water is 1:3, and drain the excess moisture to obtain rinsed black beans;

[0088] (2) Put the rinsed black beans obtained in step (1) into water for soaking, the weight of black beans and water is 1:2, the soaking temperature is controlled at 20-30°C, and the soaking time is 0.5h to obtain soaked black beans ;

[0089] (3) Utilize the material distribution hopper to evenly spread the soaked black beans obtained in step (2) on the conveyor belt, the thickness of the layer is 1.0cm, and the control conveyor speed is 1m / min. After being composed of 4 microwave heating boxes (each heating The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com