Motorcycle and front fairing assembly thereof

A front shroud, motorcycle technology, applied to bicycle accessories, optical signals, weather guards, etc., can solve the problems of reduced work efficiency, difficult assembly, messy layout, etc., to simplify the installation and disassembly process and ensure firmness and stability, convenient and simple layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

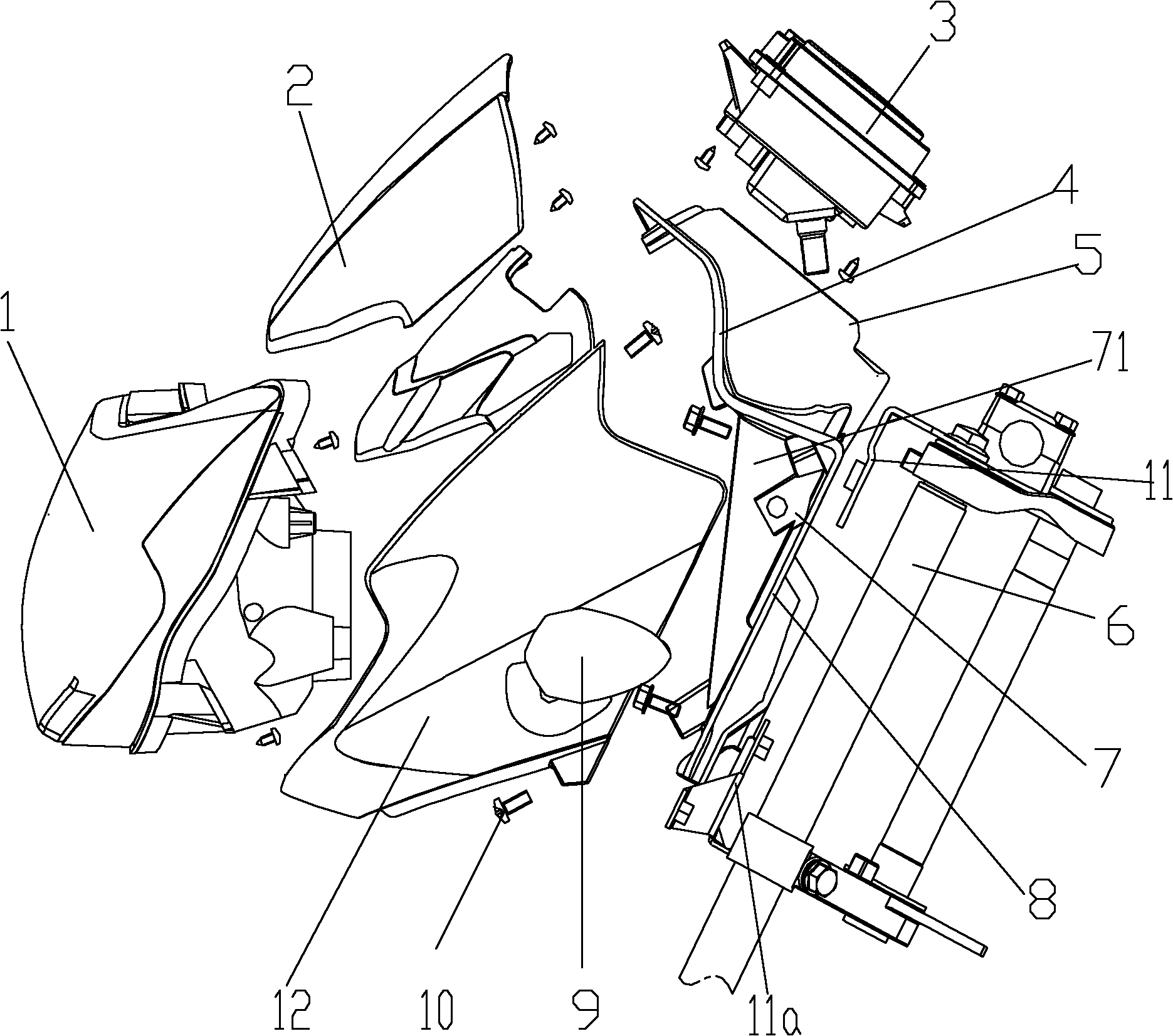

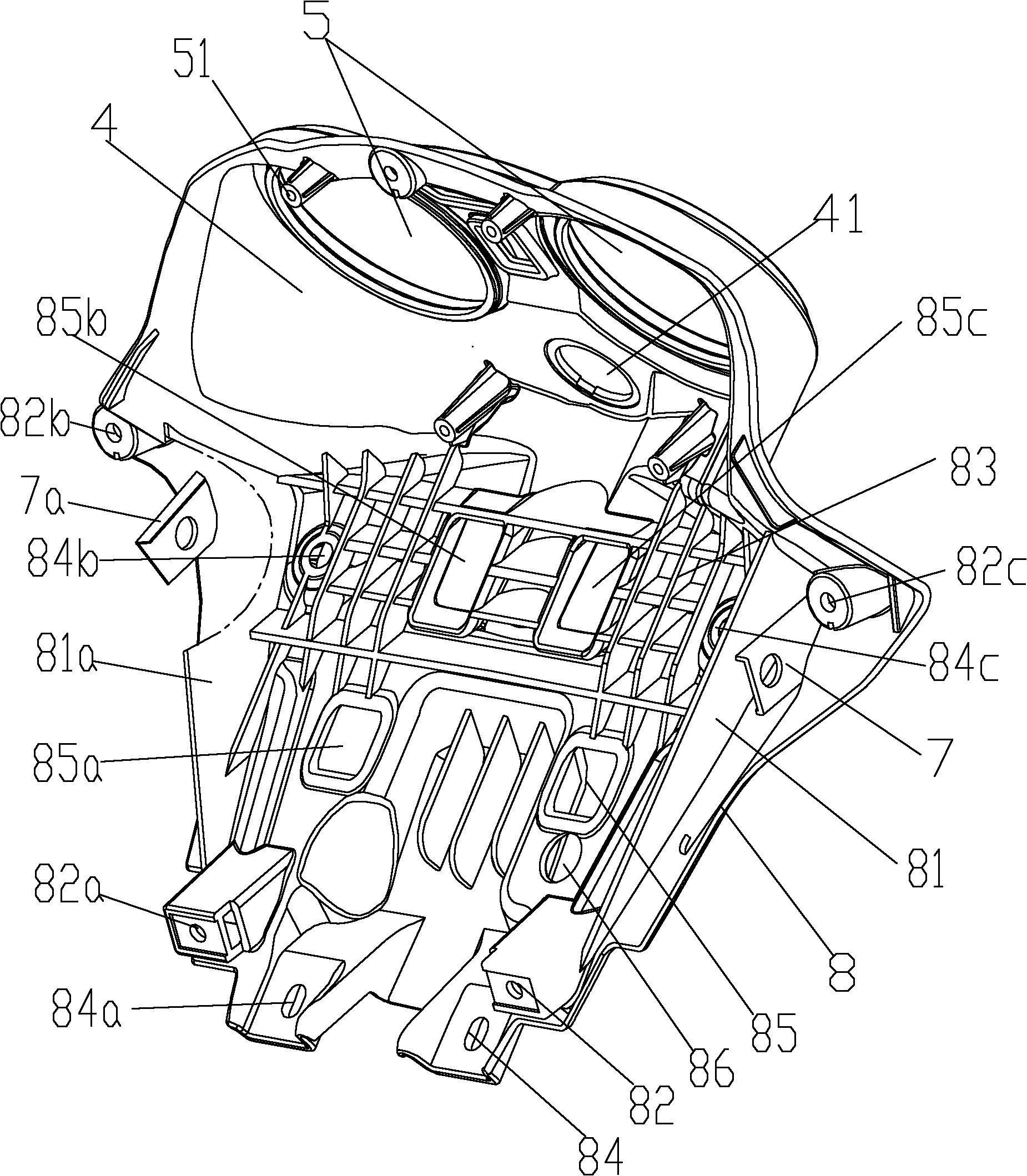

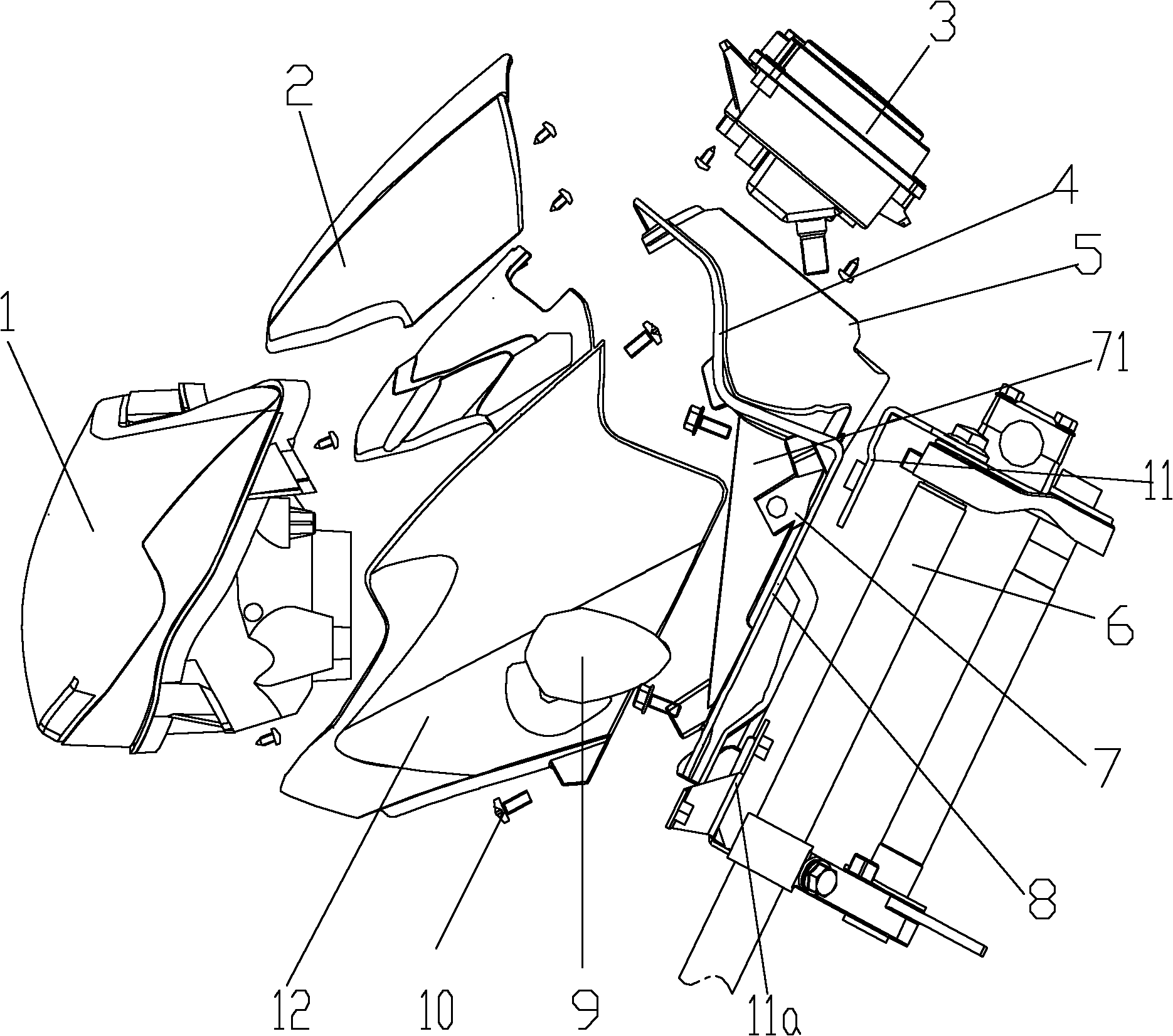

[0021] figure 1 For the installation structure explosion diagram of the present invention, figure 2 It is a schematic diagram of the backboard structure, as shown in the figure: the front wind deflector assembly of the motorcycle of the present embodiment includes a cover body 12, a headlight assembly 1, a turn signal 9, an instrument assembly 3 and a backboard, and the The backboard includes a backboard body 8 for covering the motorcycle front fork 6 and detachably connected with the front fork 6, and a bending part 4 formed by bending the upper end of the backboard body 8 forward. The cover body 12 is located at The front part of the backboard body 8 is detachably fixedly connected with the backboard body 8 and the bending part 4 respectively, the headlight assembly is detachably fixedly connected to the front end of the cover body 12, and the turn signal lamp 9 is detachably Fixedly connected to the left and right sides of the cover body 12, the instrument assembly 3 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com