Hyaluronic acid gel employing biphasic technology, and preparation method thereof

A technology of hyaluronic acid and sodium hyaluronate, applied in the field of biomedicine, can solve problems such as lack of uniformity and stability, lack of three-dimensional network structure and three-dimensional barrier, and lack of advanced and safe product production technology , to achieve the effect of guaranteeing product safety, improving product safety and improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

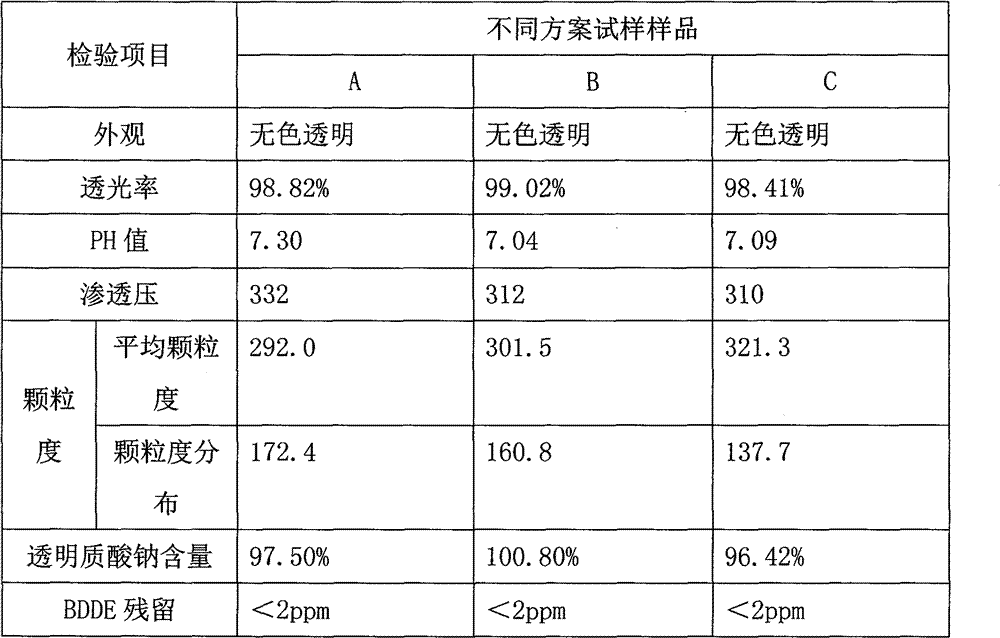

[0027] Example 1 Preparation of water-containing cross-linked sodium hyaluronate particles

[0028] Step 1), cross-linking reaction in an alkaline solution of about 1%, add a cross-linking agent to prepare a concentration of about 0.01g / ml, add high-purity sodium hyaluronate raw material (average molecular weight 1.5 million Daltons) to prepare a concentration of 0.15 About g / ml, stir at room temperature until it dissolves evenly, and heat at a constant temperature of 45°C to prepare sodium hyaluronate gel;

[0029] Step 2), cut the molding into blocks (1.2cm 3 ) into the physiological isotonic phosphate buffer solution for swelling and dialysis, the temperature of the dialysis swelling is controlled at 26 ° C, and the swelling and dialysis is more than 16 hours to obtain a cross-linked sodium hypronate hydrogel, which contains a hydrogel. The appearance of the glue requires no bubbles, no opaque and insoluble particle enrichment, and crystal clear;

[0030] The physiologica...

Embodiment 2

[0032] Example 2 Preparation of sodium hyaluronate aqueous phase solution

[0033] Step 1) Add high-purity sodium hyaluronate raw materials (average molecular weight is about 500,000 Daltons) to the physiological isotonic phosphate buffer solution, and the concentration of sodium hyaluronate aqueous phase solution is about 15mg / ml, shake and dissolve evenly, and obtain transparent Sodium hyaluronate aqueous phase solution;

[0034] Step 2) Filtrate through an 8um filter material to obtain a sodium hyaluronate aqueous phase solution, ensuring that its osmotic pressure is controlled at 270-330mOsmol / L, and its pH=6.5-7.5.

Embodiment 3

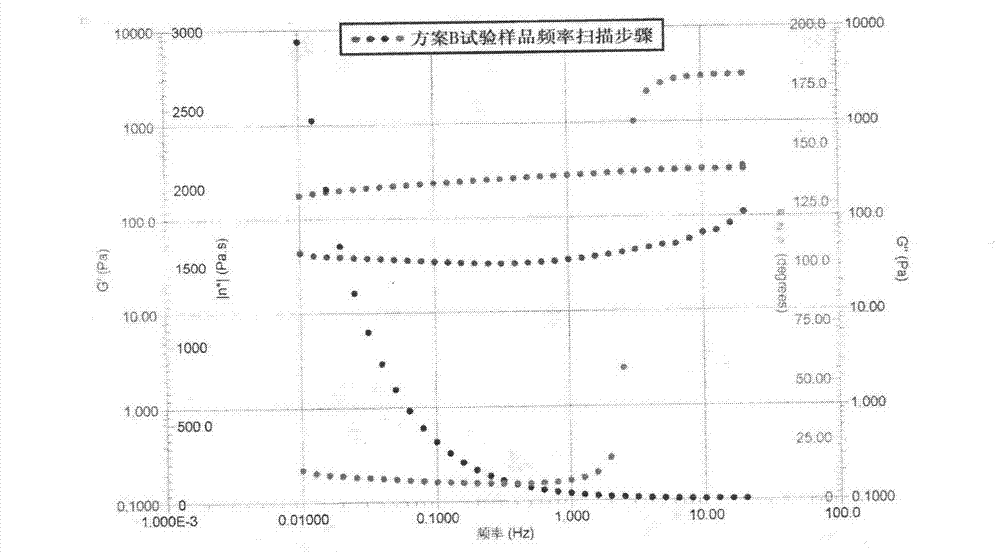

[0035] Example 3 Two-phase technology using hyaluronic acid gel preparation

[0036] Step 1) Mix the obtained solid particle cross-linked sodium hyaluronate with the sodium hyaluronate gel aqueous phase solution according to the glue-to-liquid ratio of 10:1, and use a two-dimensional oscillating mixer to mix to achieve a two-phase equilibrium to obtain sodium hyaluronate gel. Gel biphasic suspension gel;

[0037] The parameters of the mixer are controlled at about 180 rpm, the temperature is controlled at about 40°C, and the mixing time is controlled at about 48 hours.

[0038] Step 2) vacuum filling the sodium hyaluronate gel into a pre-filled syringe, where the vacuum degree is -0.08Mpa for filling;

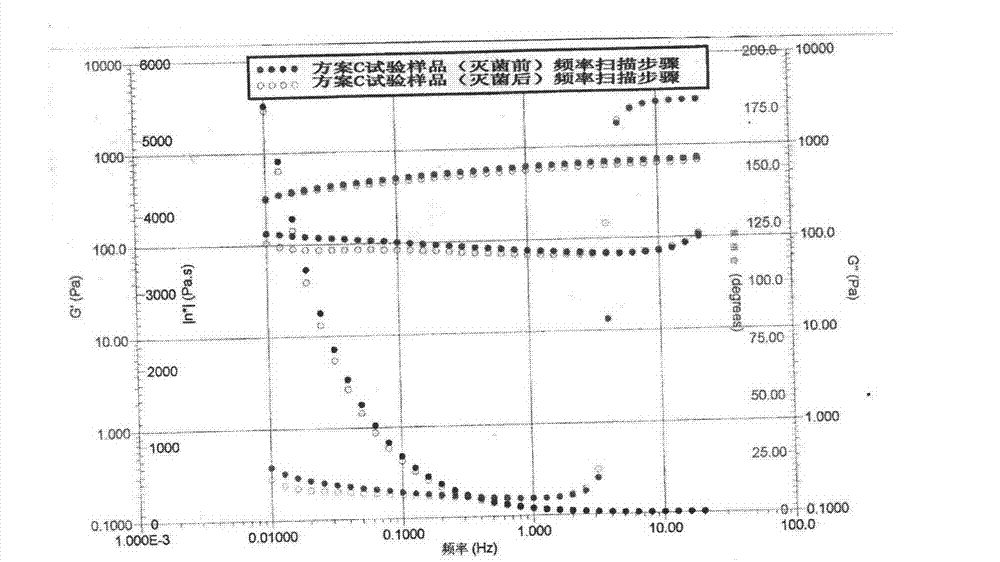

[0039] Step 3) 121°C, F 0 The obtained pre-filled injection gel was sterilized under the condition of =12, and packaged to obtain the sodium hyaluronate gel.

[0040] Prepare hyaluronic acid gel batches of 500ml, 1000ml and 3000ml respectively according to the above steps, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com