Manufacturing process for bracelet

A manufacturing process, bracelet technology, applied in the field of bracelet manufacturing technology, can solve the problems of complex processing technology, low degree of exquisiteness, low processing efficiency, etc., achieve obvious distortion effect, simple production process, and improve processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical solution of the present invention more clearly expressed, the present invention will be further described below in conjunction with the accompanying drawings.

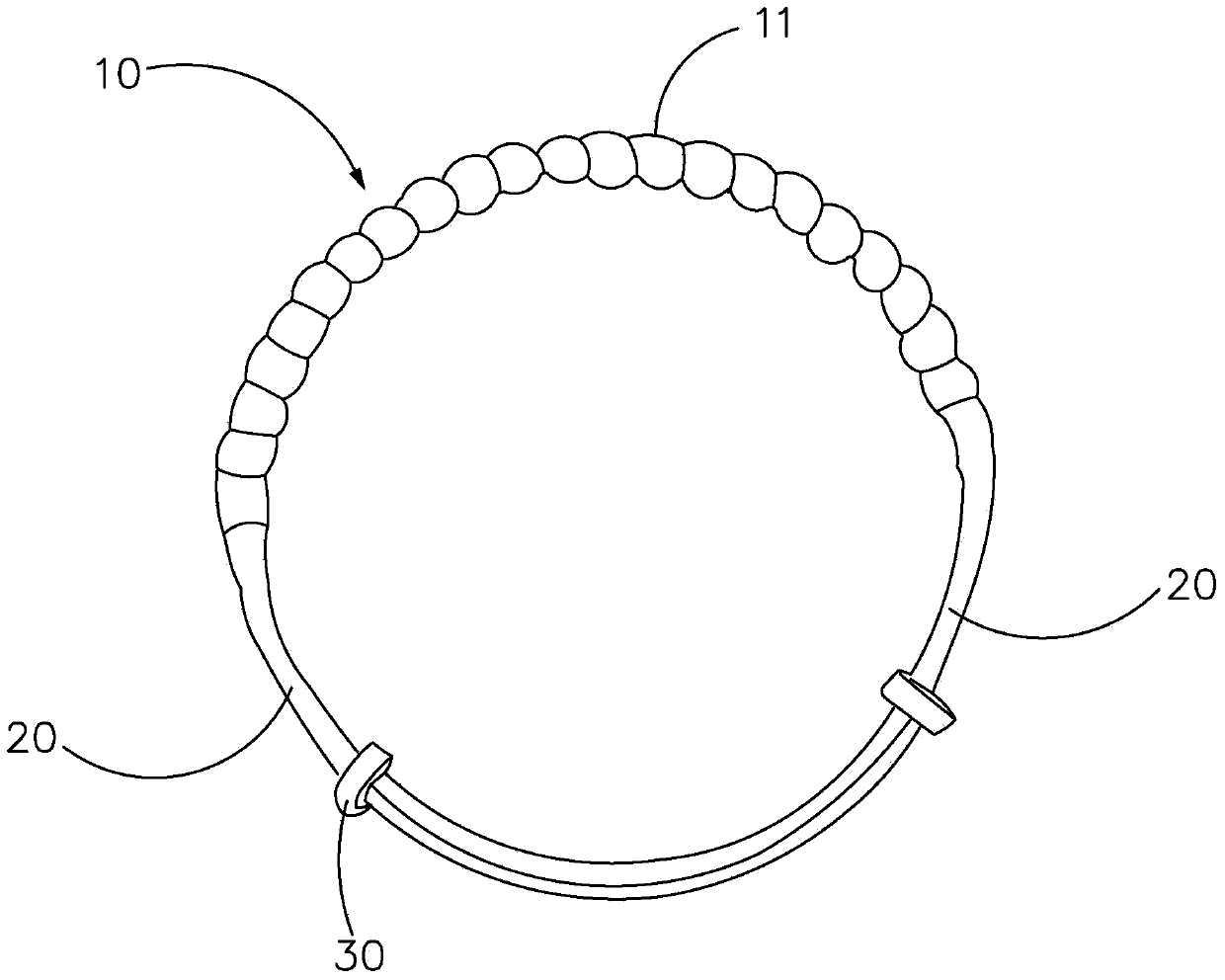

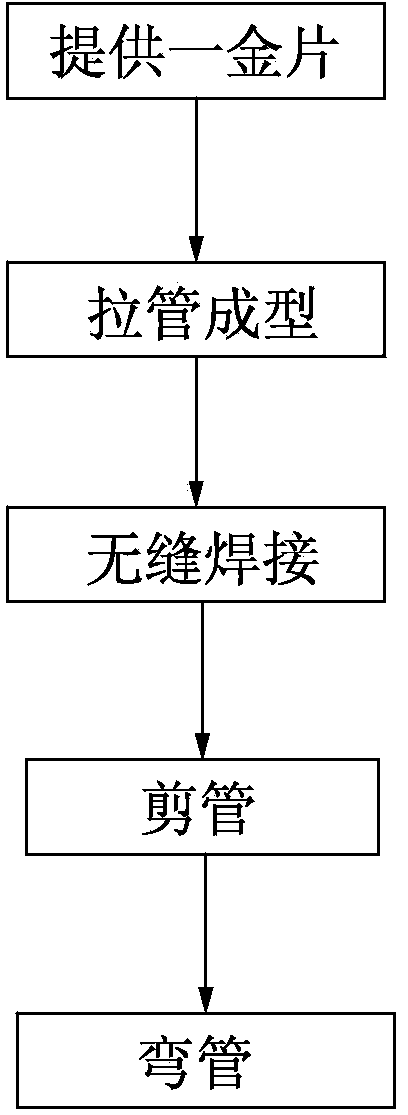

[0015] Please refer to Figure 1 to Figure 3 , the present invention provides a bracelet manufacturing process for manufacturing a bracelet, the bracelet includes a twisted part 10, two bent parts 20 connected to the two ends of the twisted part 10 and a lettering buckle 30 connected to the two bent parts 20, said The two bending parts 20 are arranged crosswise. The twisted part 10 and the two bending parts 20 form a ring structure. The bending part 20 is a hollow structure. Hollow tubular structure.

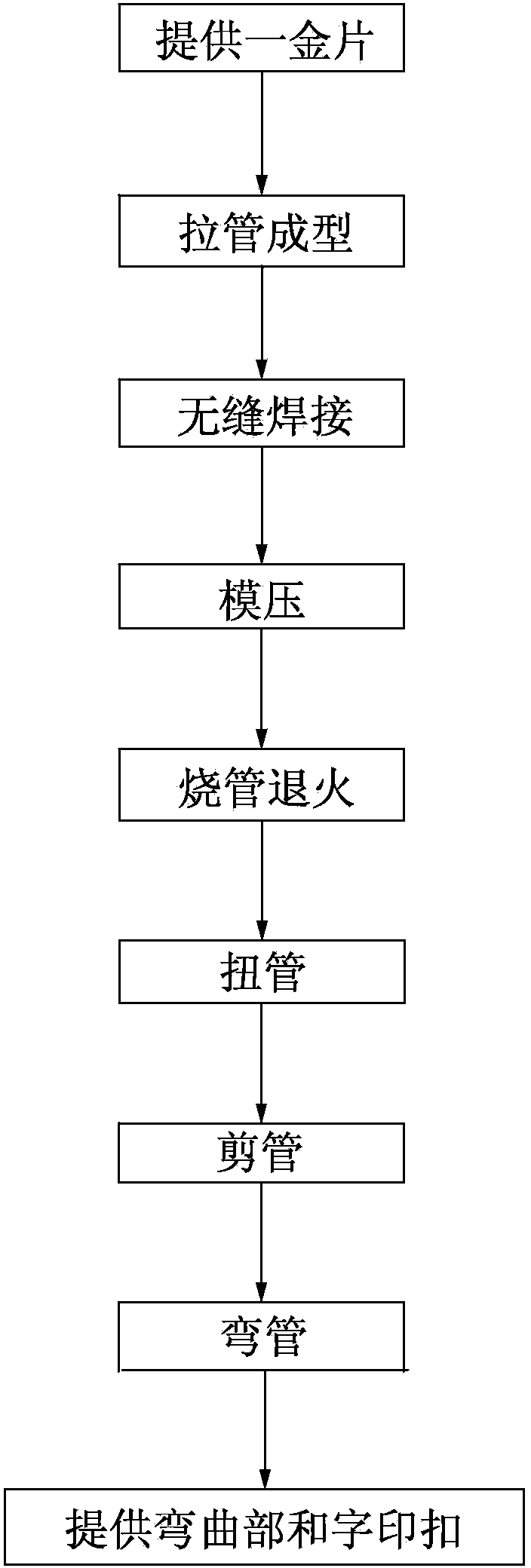

[0016] The torsion portion 10 is processed by the following process:

[0017] Step (1), providing a gold sheet, usually, the gold sheet is a strip-shaped square structure;

[0018] Step (2), drawing the tube to form, bending the gold sheet into a tube body with gaps after passing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com