Making method of easily-cooked red beans

A red bean and red bean granule technology, which is applied in food preparation, application, food science, etc., can solve the problems of poor taste and difficult cooking of red beans, and achieve good rehydration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

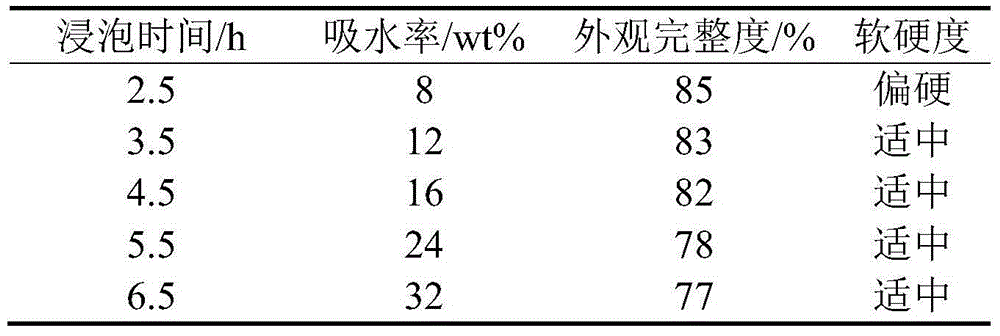

[0061] Embodiment 1: the influence of the soaking time of step (1) on the quality of easy-to-cook red bean

[0062] In this example, the effects of different soaking times on the integrity of the appearance of the easy-to-cook red bean product and the acceptance of the mouthfeel after cooking with rice were studied.

[0063] Prepare the easy-cooking red beans through the following process:

[0064] (1) Soaking step: remove impurities, broken red beans and diseased red beans in the commercially available red beans, wash with water for 3 times, and obtain red beans as raw materials. The raw material is divided into 5 parts according to each part of 500g. Under the condition of 25°C, add 3000g of water (that is, the mass ratio of red beans to water is 1:6), soak for 2.5h, 3.5h, 4.5h, 5.5h, 6.5h, get soaked red beans, decant excess water after soaking, set aside;

[0065] (2) Cooking and pre-cooking step: adding each red bean sample soaked in step (1) into a cooking pot, cooking...

Embodiment 2

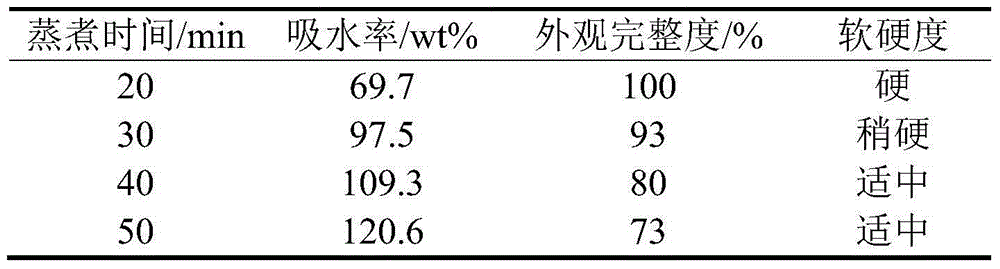

[0071] Embodiment 2: the influence of the steaming time of step (2) on the quality of easy-to-cook red beans

[0072] The soaking time in the control step (1) is 3.5h, and the cooking time of each sample in the step (2) is respectively 20min, 30min, 40min, 50min, and other steps and parameters are all the same as in Example 1. The appearance integrity of the easy-cooking red beans obtained at different cooking times and the acceptance of the taste after cooking with rice were compared, and the results are shown in Table 2. Make sure that the red bean rice is moderately soft and hard when the cooking time exceeds 40 minutes. However, too long cooking time will result in a lower integrity of the appearance of dried red beans, therefore, it is more preferable to control the cooking time within 30min-50min. Specifically, when the cooking time is less than 30 minutes, the taste of red beans cooked with rice after drying is hard, and when the cooking time is longer than 50 minutes,...

Embodiment 3

[0075] Embodiment 3: the impact of the slow drying time of step (3) on the quality of red bean easily cooked

[0076] Control the soaking time in step (1) to be 3.5h. In step (3), under normal pressure, use saturated water vapor to dry the precooked red beans obtained in step (2) for 30min, 60min, 90min, and 120min respectively at 50°C. , other steps and parameters are the same as in Example 1. The appearance integrity of the easy-cooking red beans obtained at different slow drying times and the acceptance of the taste after cooking with rice were compared, and the results are shown in Table 3. It is confirmed that after 90 minutes of slow drying, the red bean rice is moderately soft and hard, and the appearance of red beans is better. Therefore, the slow drying time is preferably controlled at 90-120 minutes. Too long slow drying time will increase energy consumption. After reaching 90 minutes, continue Prolonging the drying time had no significant effect on maintaining the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com