Patents

Literature

59results about How to "Change traits" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

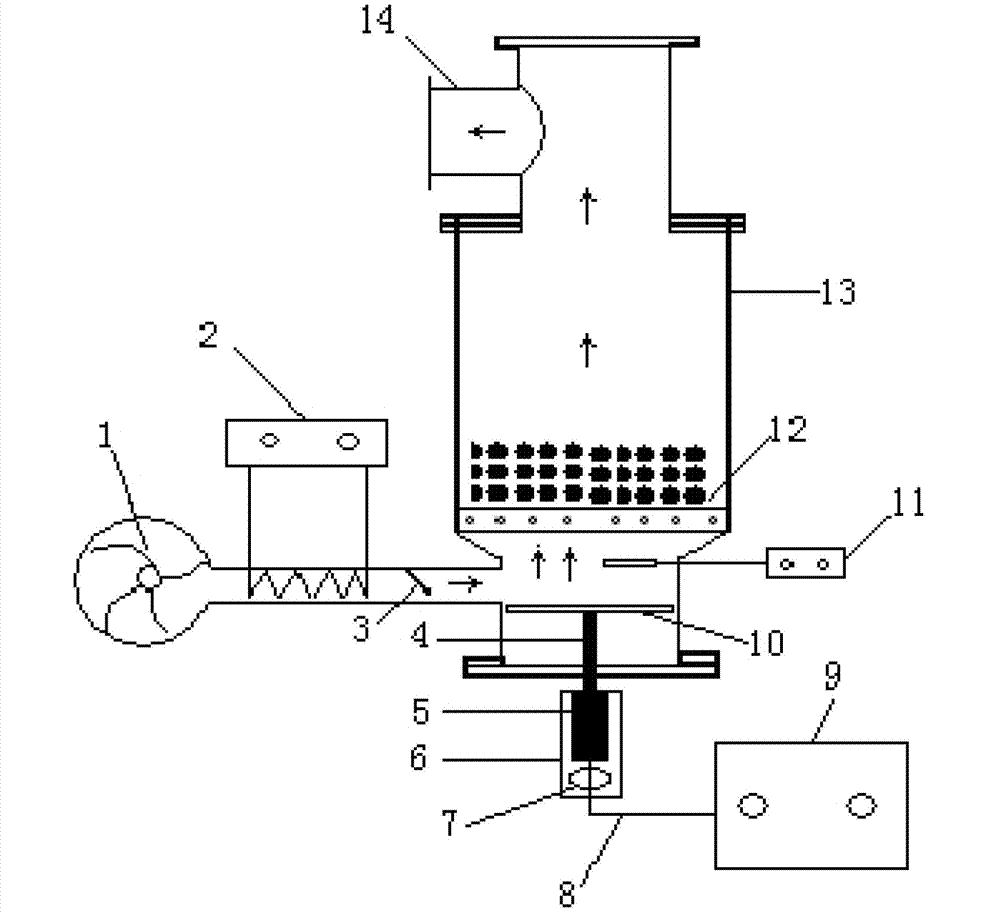

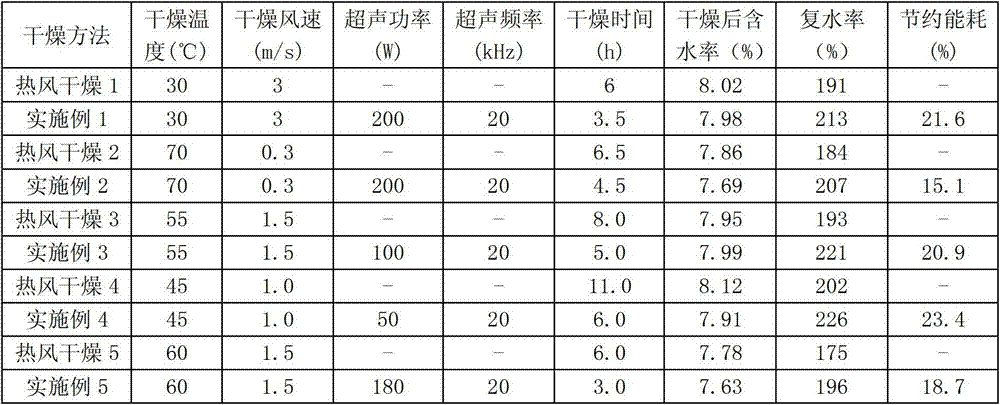

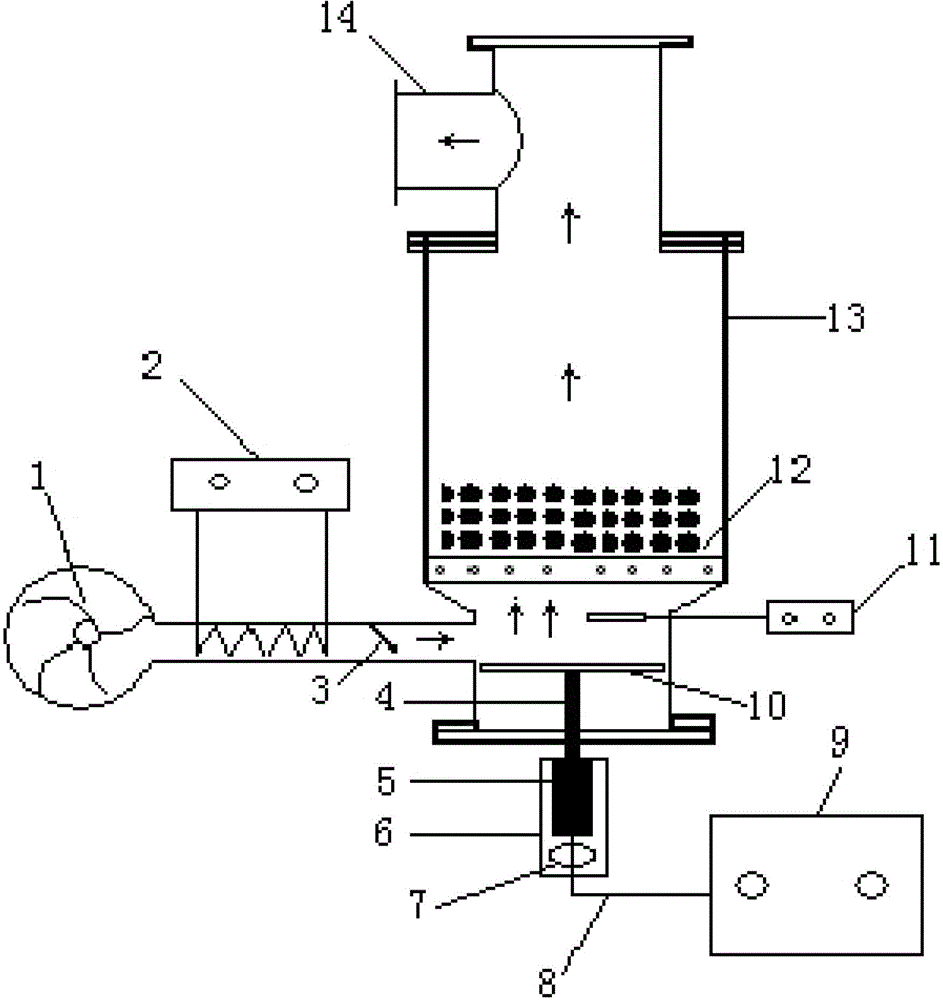

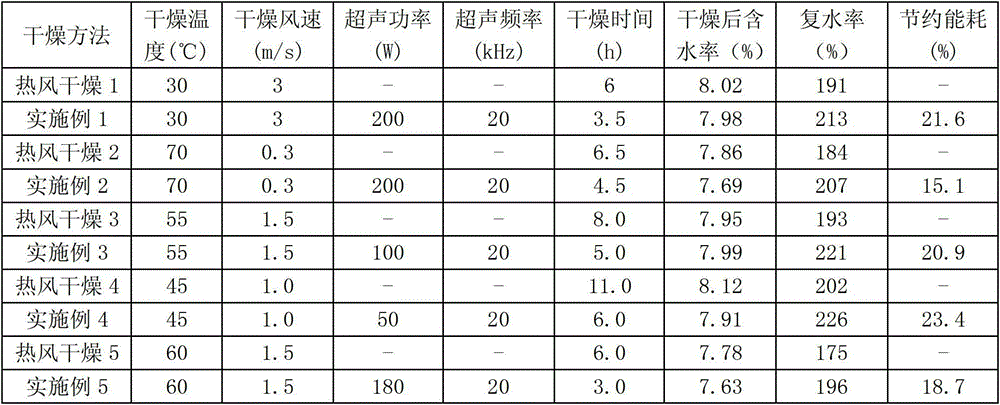

Ultrasonic and hot air combined carrot drying method and ultrasonic and hot air combined drying device

InactiveCN103109919AChange traitsIncrease the gapFood processingFruits/vegetable preservation by dehydrationProcess engineeringUltrasonic irradiation

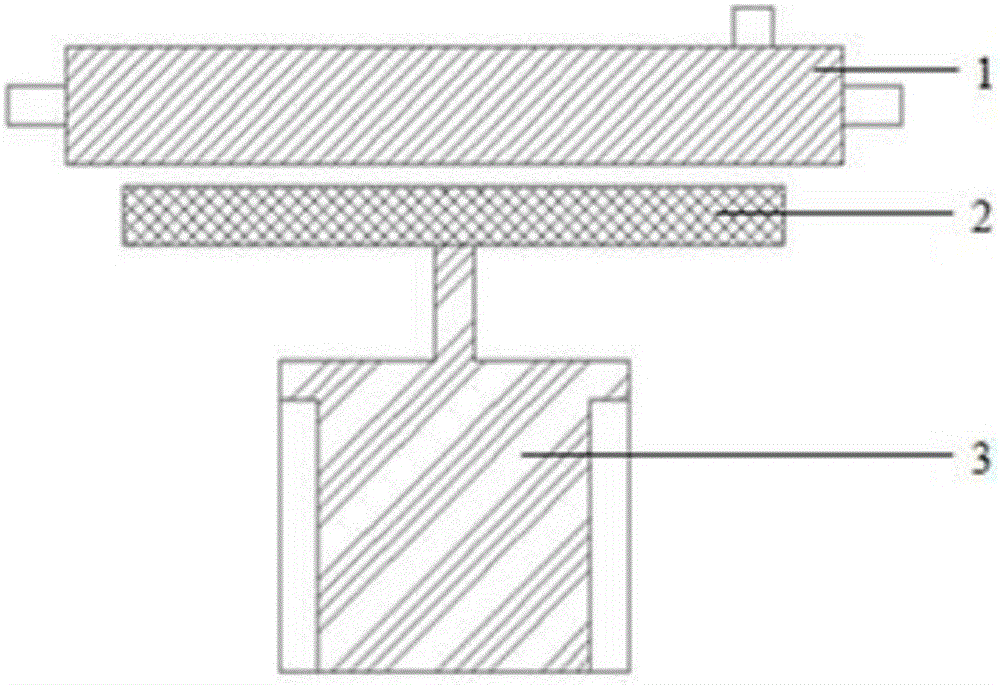

The invention discloses an ultrasonic and hot air combined carrot drying method and an ultrasonic and hot air combined drying device. The ultrasonic and hot air combined carrot drying method comprises the following steps of: (1) pretreatment of a carrot raw material, namely washing and slicing fresh carrots; and (2) ultrasonic and hot air combined drying, namely, putting carrot slices on a sieve, sequentially starting a heating and blowing device and an ultrasonic irradiation device, and carrying out ultrasonic and hot air combined drying on the carrot slices, wherein the drying temperature is 30-70 DEG C, the drying air speed is 0.3-3m / s, the ultrasonic power is 100-200W, the ultrasonic frequency is 20kHz, the distance between the ultrasonic irradiation device and the sieve is 5-15cm and the drying time is 3-6 hours. According to the ultrasonic and hot air combined carrot drying method, an ultrasonic technology is directly and effectively coupled to a hot air drying process, so that the heat transfer and mass transfer efficiencies in the drying process are improved, the drying time is shortened, the energy consumption is saved and the product quality is improved.

Owner:HENAN UNIV OF SCI & TECH

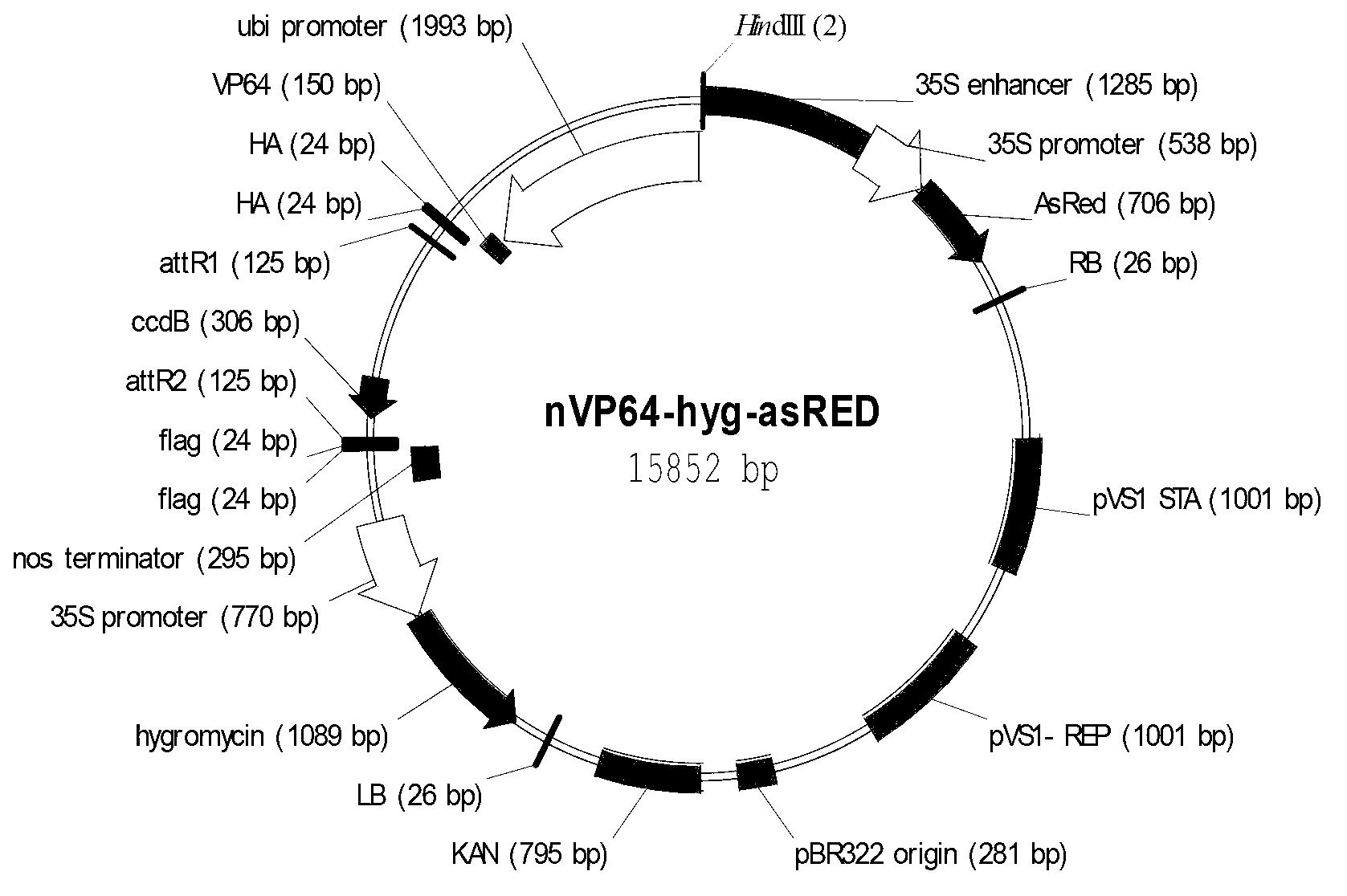

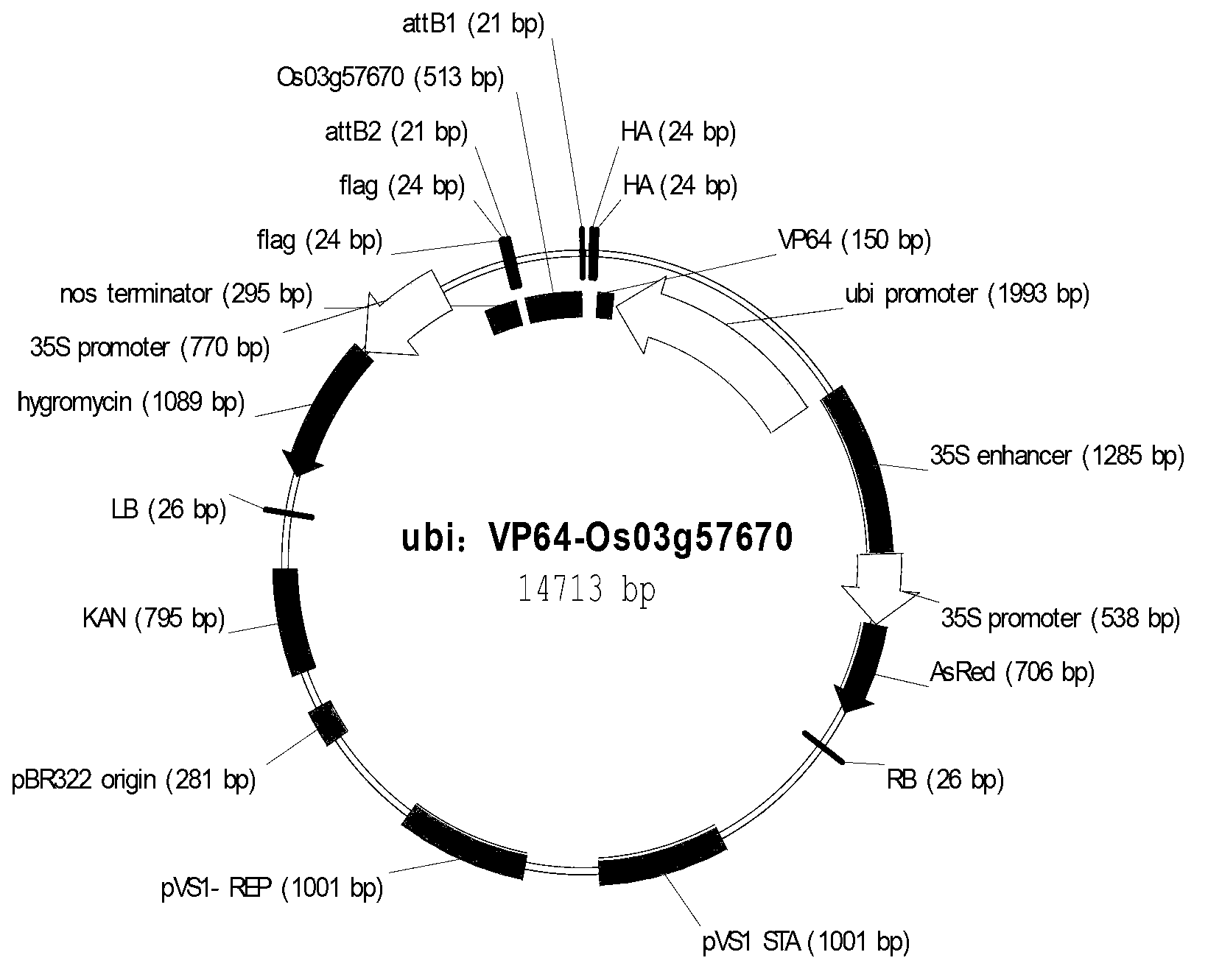

Application of synthetic transcription factor VP64-Os03g57670

ActiveCN103214581AChange traitsEnhanced coercion capabilitiesBacteriaHybrid peptidesGenetically modified riceSequence motif

The invention provides an application of a synthetic transcription factor VP64-Os03g57670. The synthetic transcription factor is constructed by fusing a transcription factor activated sequence motif VP64 (namely four transcription factor activated sequence motifs VP16) and paddy transcription factor Os03g57670 gene, and is converted to the paddy, so as to change the grain characteristic of paddy, so that the transgenic paddy seed is remarkably shorter, wider, and lighter in thousand seed weight, and paddy blade is crimped, therefore, the paddy has a better market application prospect.

Owner:CROPEDIT BIOTECHNOLOGY INC

Method for reusing saline-alkali waste cultivated land to grow plants

InactiveCN102523779AReduce the impactNormal emergenceHorticultureSoil-working methodsTerrainWater discharge

The invention discloses a method for reusing saline-alkali waste cultivated land to grow plants, comprising the following steps of: (1) digging grooves and holes, ensuring length according to terrain, setting slight gradient at the bottom of the grooves, and arranging a water outlet at a lower place; (2) building a water discharge groove at the end of the water outlet; (3) digging a water return pool at the head of the land, reflowing redundant water in the grooves and holes, and storing the water in the water return pool; (4) isolating the saline-alkali waste cultivated land from the matrix by an agricultural greenhouses film at the bottom and the periphery of the grooves and holes, or paving furnace clinker at the bottom of the grooves and holes, and isolating the periphery of the grooves and holes by the agricultural greenhouses film; (5) the proper matrix has mixture of pearlstone, vermiculite and silver sand, mixture of furnace clinker, danty and coal ash, mixture of exotic soil and straw fermented substrate and exotic soil of the mixture, respectively filling the matrix into the different grooves and holes; (6) applying compound fertilizer and diamine with fixed quantity before the plants are grown, and topdressing urea and diamine with fixed quantity at twice at the fruiting period of the plants; (7) irrigating by means of trickle irrigation by a drip tape; (8) ridging, film paving and growing when the plants are grown; and (9) leading the grooves and holes to have a certain gap, and replacing the surfaces of the grooves and holes with the straw fermented substrate, so that the influence of the saline alkali to the matrix is reduced.

Owner:BAIYIN AGRI SCI RES INST

Maintenance method of converter lining

InactiveCN106367556AHigh carbon contentChange traitsManufacturing convertersProcess efficiency improvementSlagOxygen content

The invention provides a maintenance method of a converter lining. According to the maintenance method of the converter lining, slag repair is conducted on a damaged lining through iron blocks with the carbon content being 3.5%-4.5%, and carbon in the iron blocks and slag perform a deoxidation reaction, so that the oxygen content of the slag is reduced; additionally, the iron blocks have the heat absorption function, so that the low-oxidizability high-refractoriness slag is made to rapidly adhere to the peripheries of the iron blocks; a generated splashed slag layer and a combination face of a foundational lining perform a metallurgical reaction, and the connection between the splashed slag layer and the combination face of the foundational lining is metallurgical bonding connection, so that the bonding force is larger, combination is tighter, an obvious layered phenomenon is avoided, and the fettling effect is improved; iron block fettling is conducted 1-2 times per shift, the deslagging face of a converter is basically not fettled with a fettling material any more so that the consumption of the fettling material can be reduced by 50% or above, the converter shutdown time of per shift is shortened by about 40 min, and the production stability is greatly improved; and after slag splashing of the iron blocks, the splashed slag layer can be kept for five batches or above, and the maintenance effect is even better than that of fettling adopting the fettling materials.

Owner:SHANDONG IRON & STEEL CO LTD

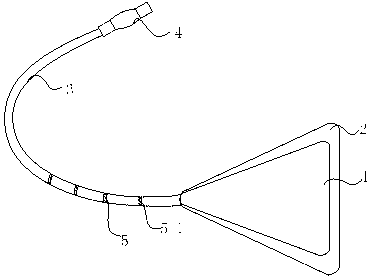

Inductive uterine slow release system

The invention discloses an inductive uterine slow release system. The incidence of uterine adhesion after an induced abortion operation is high, the re-adhesion is serious after a uterine adhesion operation, and no good solution is available at present. The system comprises a uterus-shaped elastic balloon stent, a slow release drug film, a catheter and a one-way inflation valve, wherein the uterus-shaped elastic balloon stent is a hollow isosceles triangle structural body; waists of the isosceles triangle are 3.5cm; the bottom edge of the isosceles triangle is 3cm; one end of the catheter is connected and communicated with the vertex angle end of the uterus-shaped elastic balloon stent; the other end of the catheter is connected with the one-way inflation valve; a plurality of annular scales are arranged on the outer side face of one end, close to the uterus-shaped elastic balloon stent, of the catheter; and the one-way inflation valve comprises an inflation valve and a pressure sensor. The uterus-shaped elastic balloon stent is coated with the slow release drug film, and the slow release drug film is made of fibrin glue and contains a slow release drug. The system is simple in structure and easy to operate, does not injure a uterine cavity easily, and can effectively avoid the uterine adhesion.

Owner:杭州安体科技有限公司

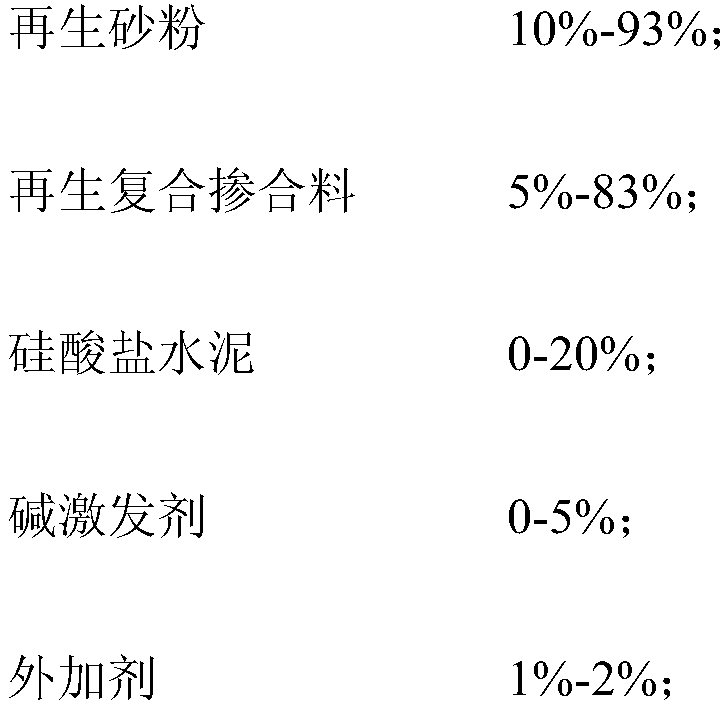

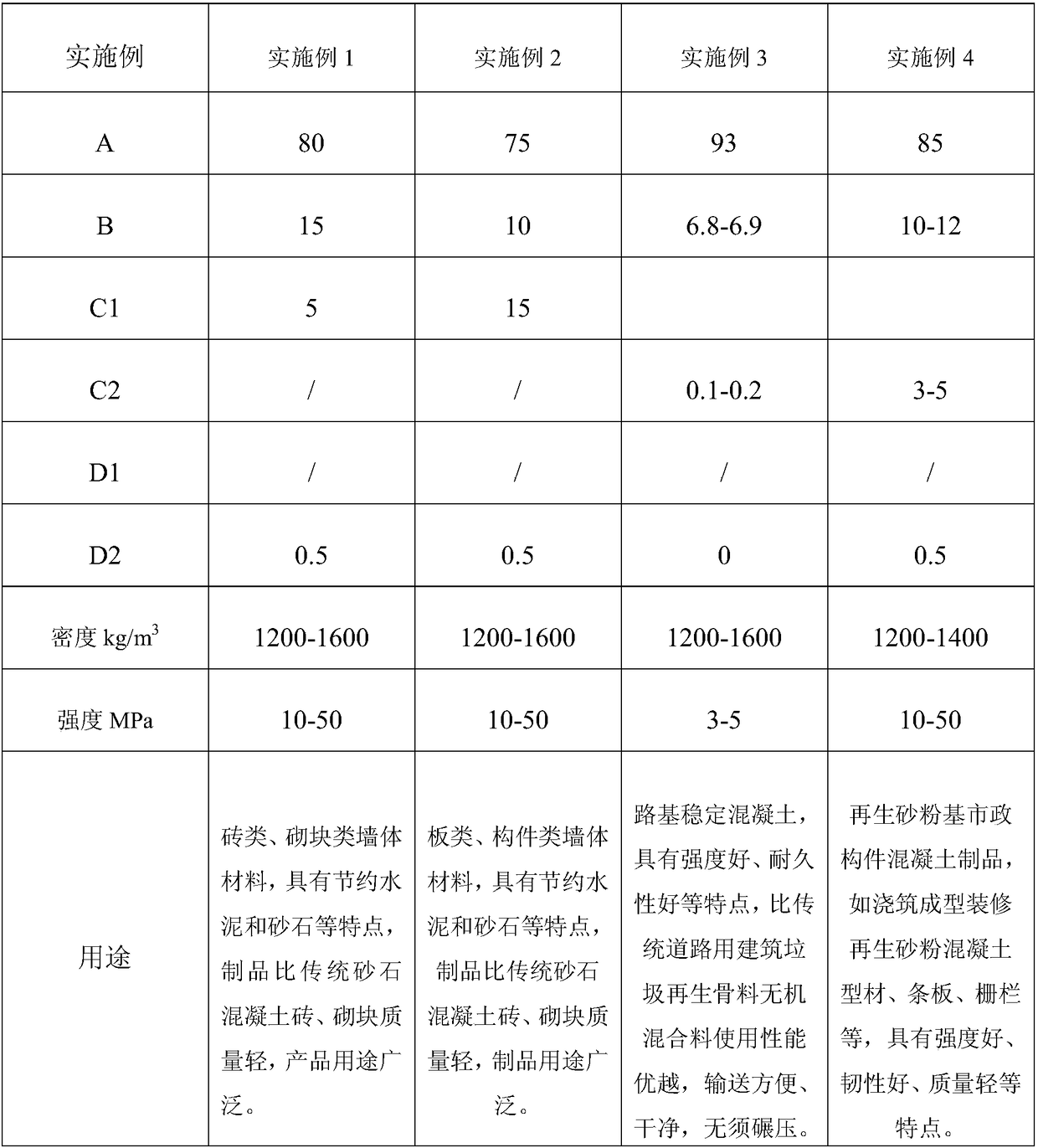

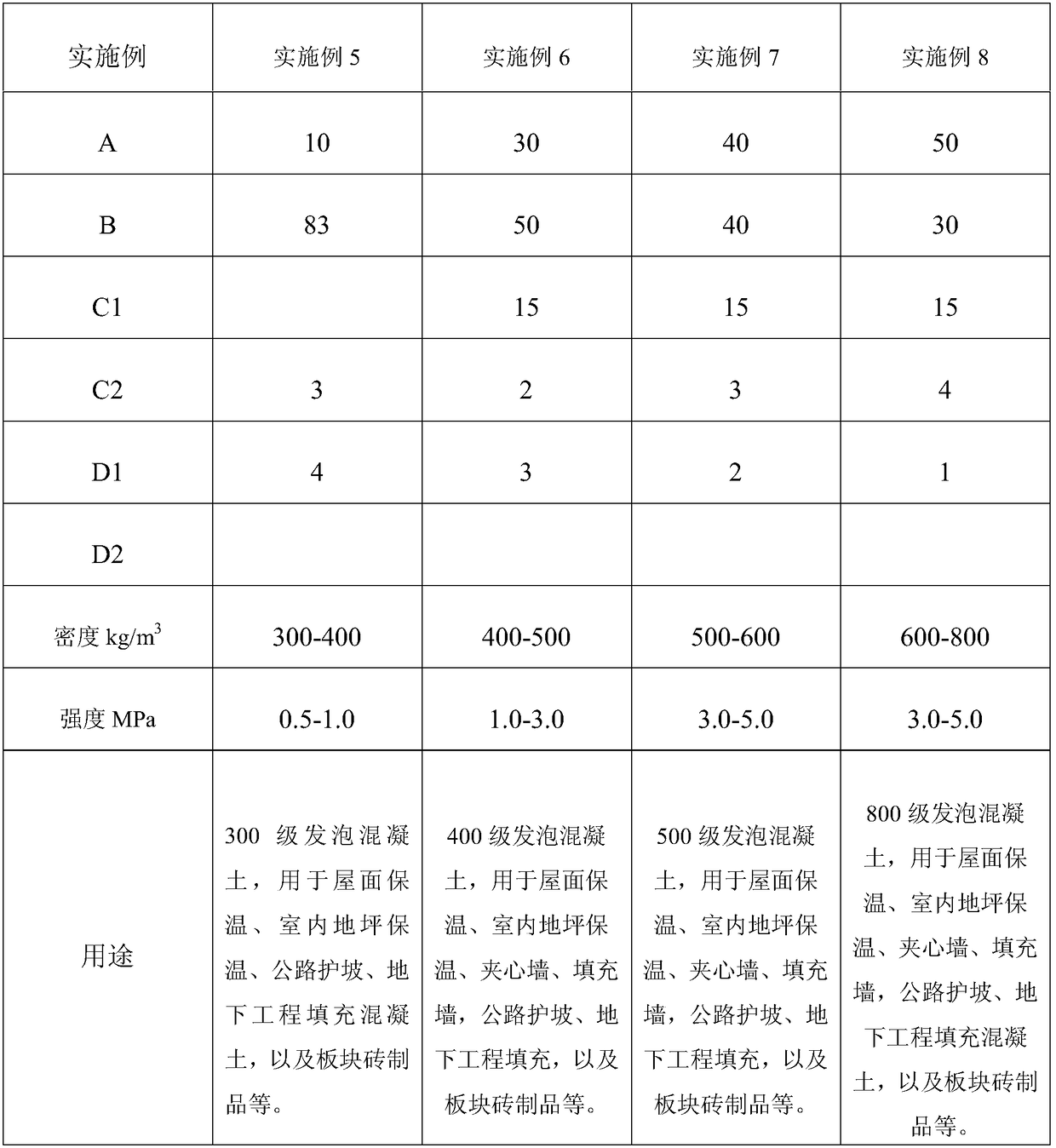

Regenerated sand powder green concrete, and preparation method thereof

The invention provides a regenerated sand powder green concrete. The regenerated sand powder green concrete comprises, by mass, 10 to 93% of regenerated sand powder, 5 to 83% of a regenerated composite admixture, 0 to 20% of Portland cement, 0 to 5% of an alkali-activator, and 1 to 2% of an additive; a coarse aggregate free lightweight concrete with a density smaller than 1900kg / m<3> is prepared from regenerated sand powder and regenerated composite admixture at a double component doping amount of 70% or larger. The invention also discloses a preparation method of the regenerated sand powder green concrete. According to the preparation method, waste concrete cement stone flour and brick-concrete regenerated sand powder are subjected to mixing grinding so as to obtain the regenerated composite admixture which is a multi-component composite gelling material and possesses composite gelling and superimposed effect. The regenerated sand powder green concrete possesses the filling effect andmicro-aggregate effect of regenerated sand powder, and the gelling performance of the regenerated composite admixture, the double component doping amount is higher than 70%, so that regenerated material large amount doping is realized, and it is beneficial for promotion of building waste resource utilization and green development of concrete industry.

Owner:SHANGHAI GUOTONG ENVIRONMENTAL PROTECTION EQUIP

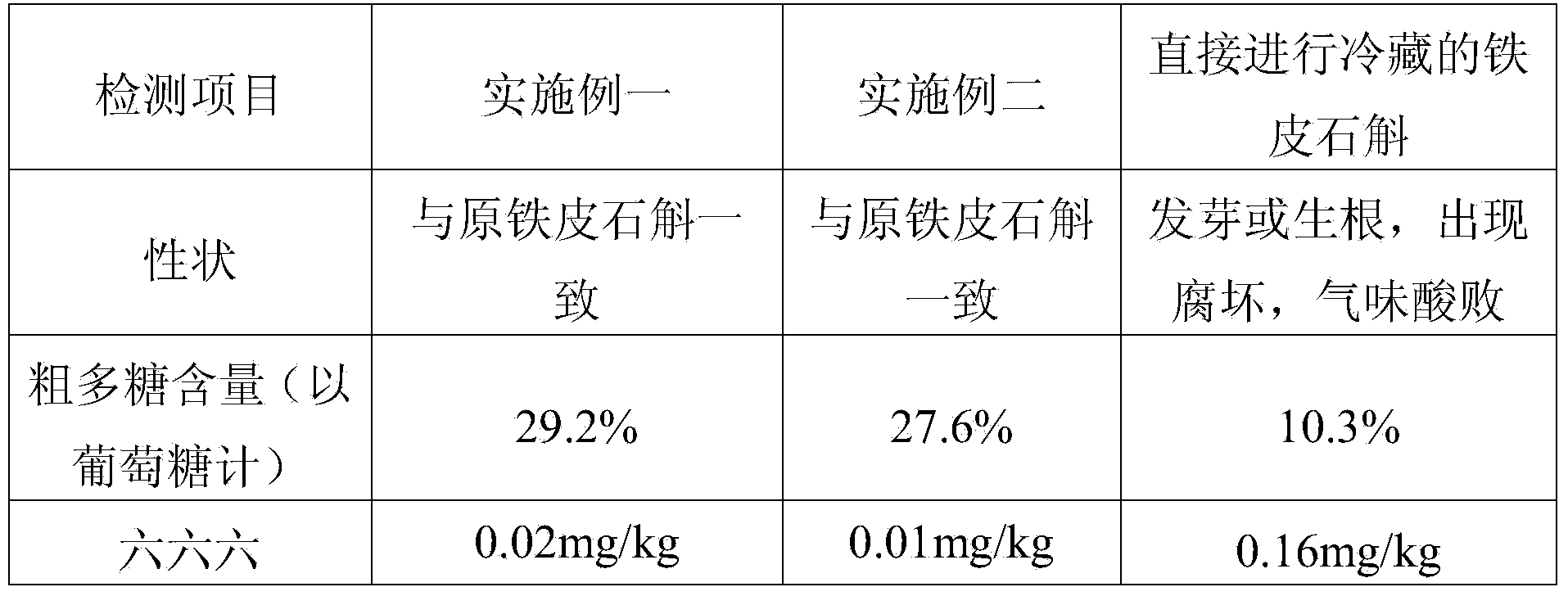

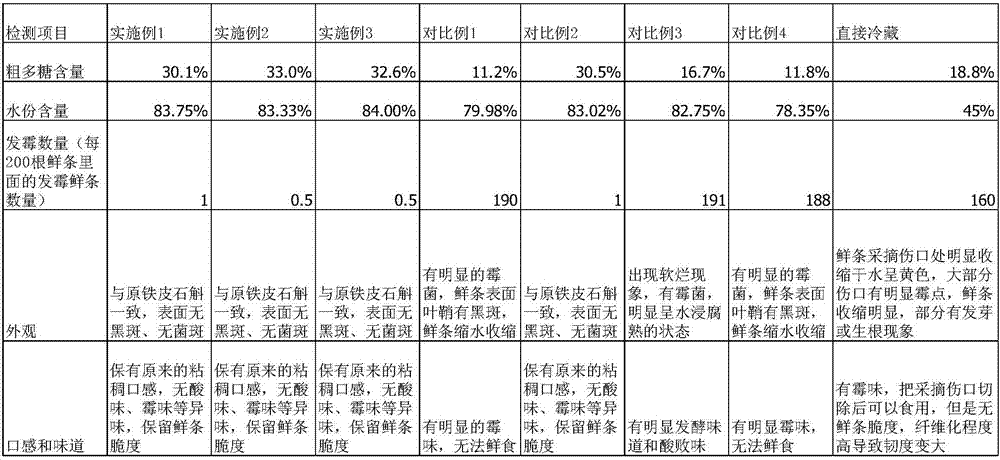

Method for fresh-keeping of dendrobe

InactiveCN103404586AChange traitsCause damageFruits/vegetable preservation by freezing/coolingPre treatmentDewatering

The invention relates to a method for fresh-keeping of dendrobe, belonging to the technical field of fresh-keeping. The method takes fresh dendrobe as a raw material, and sequentially comprises the steps of preprocessing, soaking in a fresh-keeping solution, centrifugal dewatering, low-temperature vacuum processing and packaging to obtain the finished dendrobe product. The method has the beneficial effects of being capable of keeping the special characteristics and the nutrient content of dendrobe for a long time, and solving the problem that fresh dendrobe cannot be supplied in a balanced mode.

Owner:周元鼎

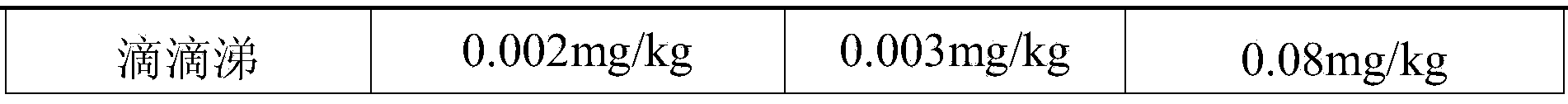

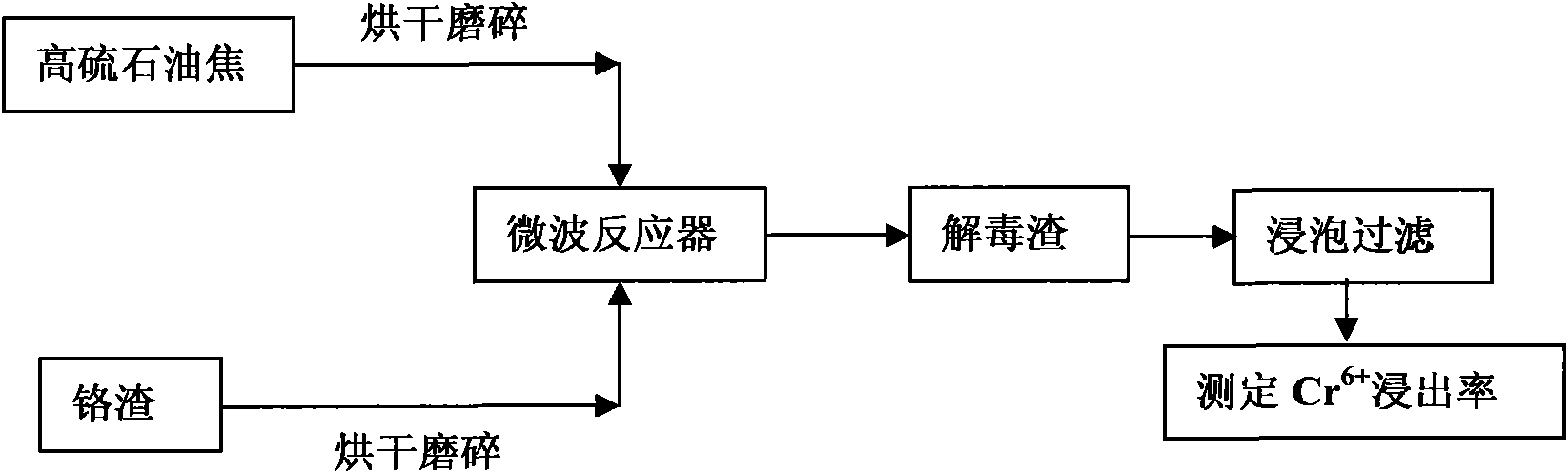

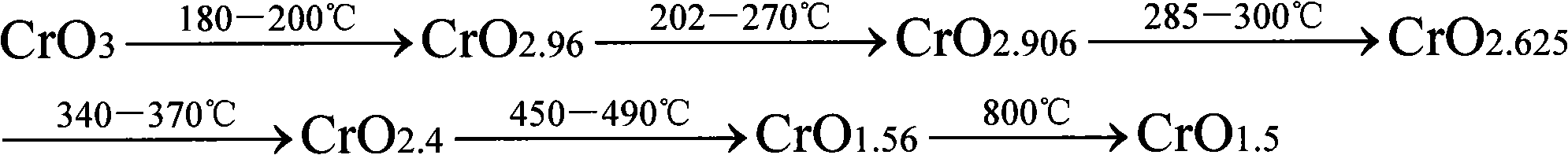

Method for detoxicating chromium residue by utilizing high sulfur petroleum coke through microwave

InactiveCN101569783AHeating fastHeating evenlySolid waste disposalElectronic waste recyclingPetroleum cokeHigh heat

The invention discloses a method for detoxicating chromium residue by utilizing high sulfur petroleum coke through microwave, which mainly uses C in the high sulfur petroleum coke to have redox reaction together with the chromium residue; Cr compound in the chromium residue is deacidized into Cr compound in medium under the high temperature condition; as the Cr with higher toxicity is deacidized into the Cr with lower toxicity, the aim of decontaminating the chromium residue can be achieved, effect for decontaminating the Cr reaches more than 99%, and the detoxicated residue can be taken as mineralizing agent for the cement production, coloring agent in glass and ceramic industry as well as aggregate in highway construction. The method comprises the steps: a ceramic crucible of a reactor is added with the chromium residue and the high sulfur petroleum coke according to the proportion; the mixture is evenly mixed; then, the crucible is placed into a microwave oven and is surrounded with silicate cotton heat insulating material for heat preservation; a shielded armored thermocouple is adopted for measuring the temperature in the microwave field; when the temperature raises to 700-1000 DEG C, heat preservation is carried out for 20-35min, the microwave oven is closed for 8min, and then a door of the microwave oven is opened; after being cooled, the material is dipped into distilled water for 24h and then filtered; finally, the filtrate has the constant volume of 250ml.

Owner:KUNMING UNIV OF SCI & TECH

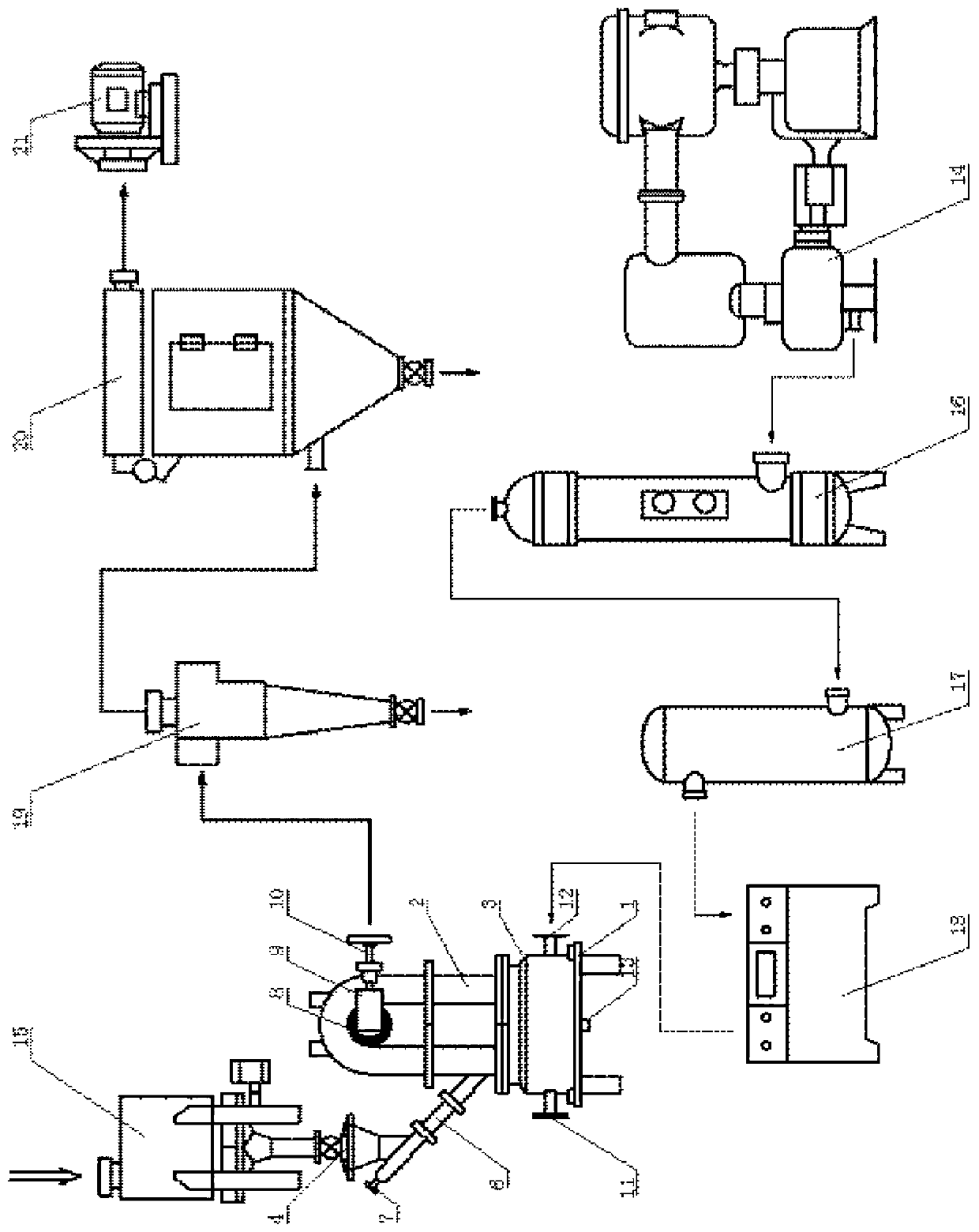

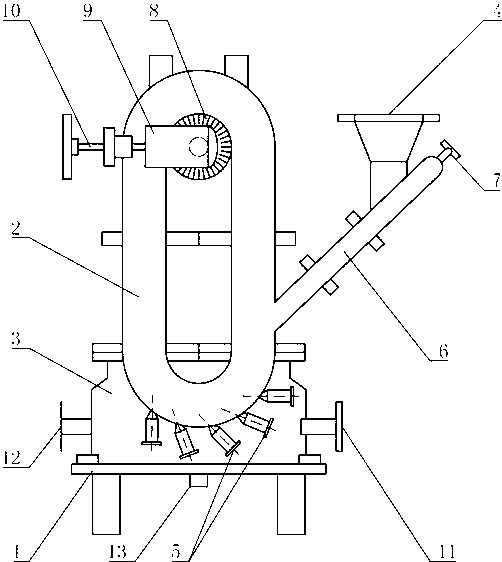

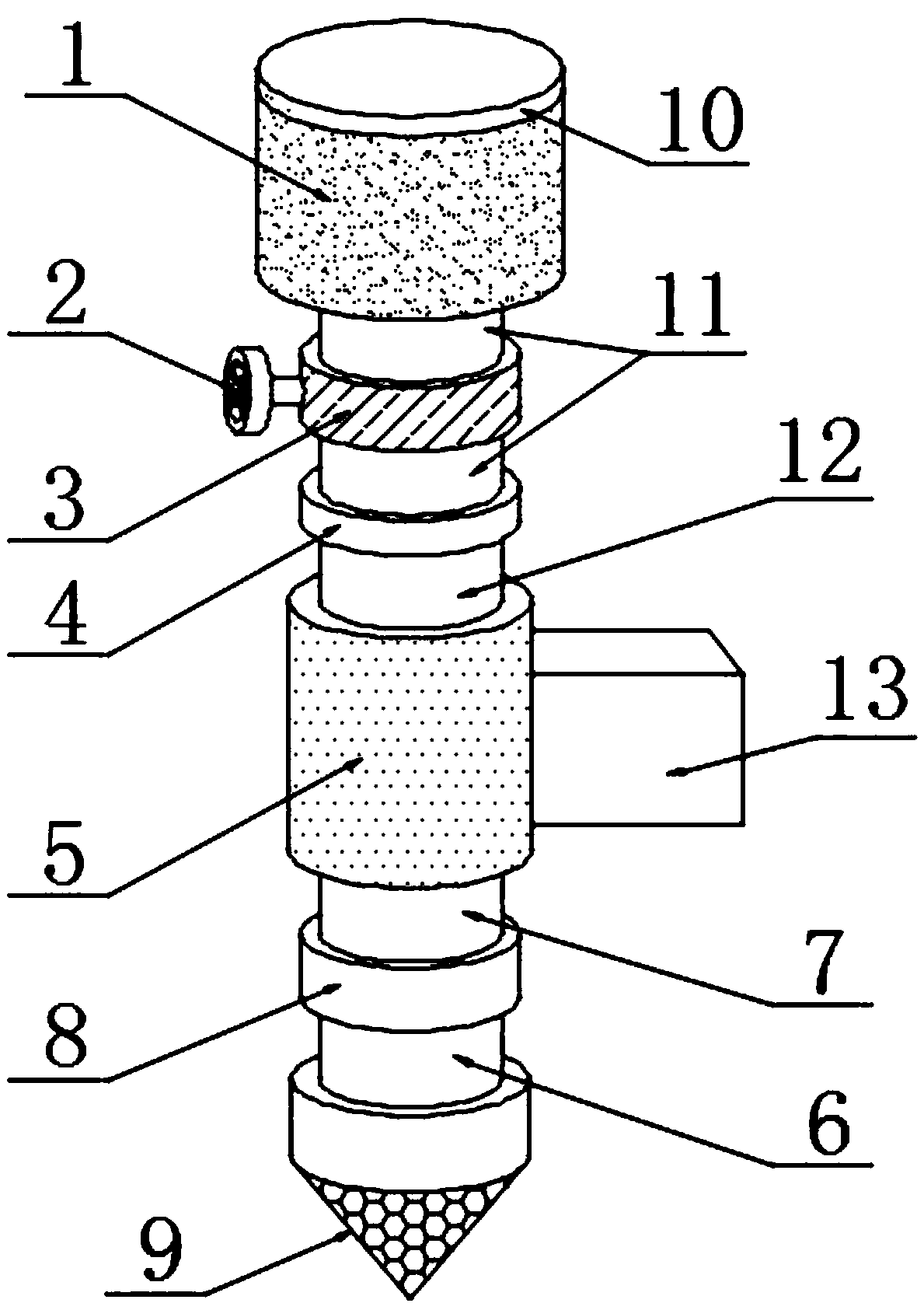

Circulating type jet mill and milling system thereof

InactiveCN102836766AIncrease concentrationIncrease productionGrain treatmentsEngineeringAir compressor

The invention relates to a milling device and system, specifically relates to a circulating type jet mill with convenience in use, high classifying precision and good milling effect, and relates to a milling system matched with the circulating type jet mill. The circulating type jet mill provided by the invention comprises a frame (1), a milling chamber (2) and a compressing air reservoir (3), wherein the milling chamber (2) is arranged on the frame (1); the compressing air reservoir (3) is connected with the lower part of the milling chamber (2); the milling chamber (2) is of annular oval shape; a classifying device is arranged on the upper part of the milling chamber (2); a feeding port (4) and a plurality of milling nozzles (5) are arranged on the lower part of the milling chamber (2); air inlet ends of the milling nozzles (5) are communicated with the compressing air reservoir (3); and air outlet ends of the milling nozzles (5) are respectively in tangential connection with the circles on the lower part of the milling chamber (2). The milling system provided by the invention comprises any circulating type jet mill, a product separating device and an air compressor (14), wherein the product separating device is connected with the outlet end of the classifying device and the air compressor (14) is connected with the compressing air reservoir (3).

Owner:计伟

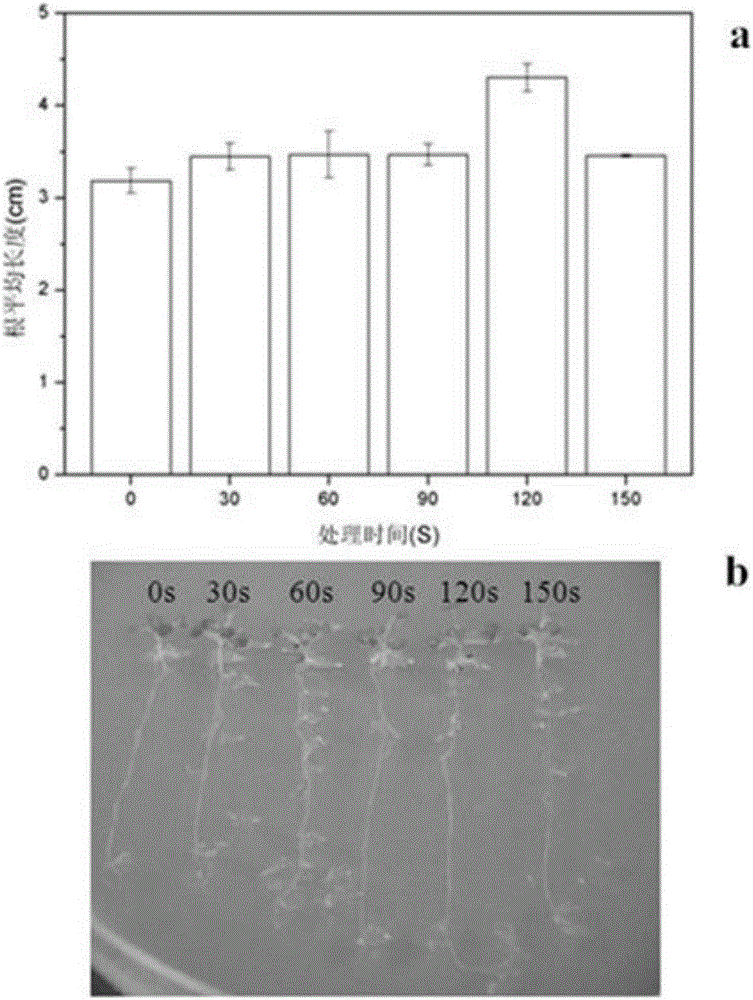

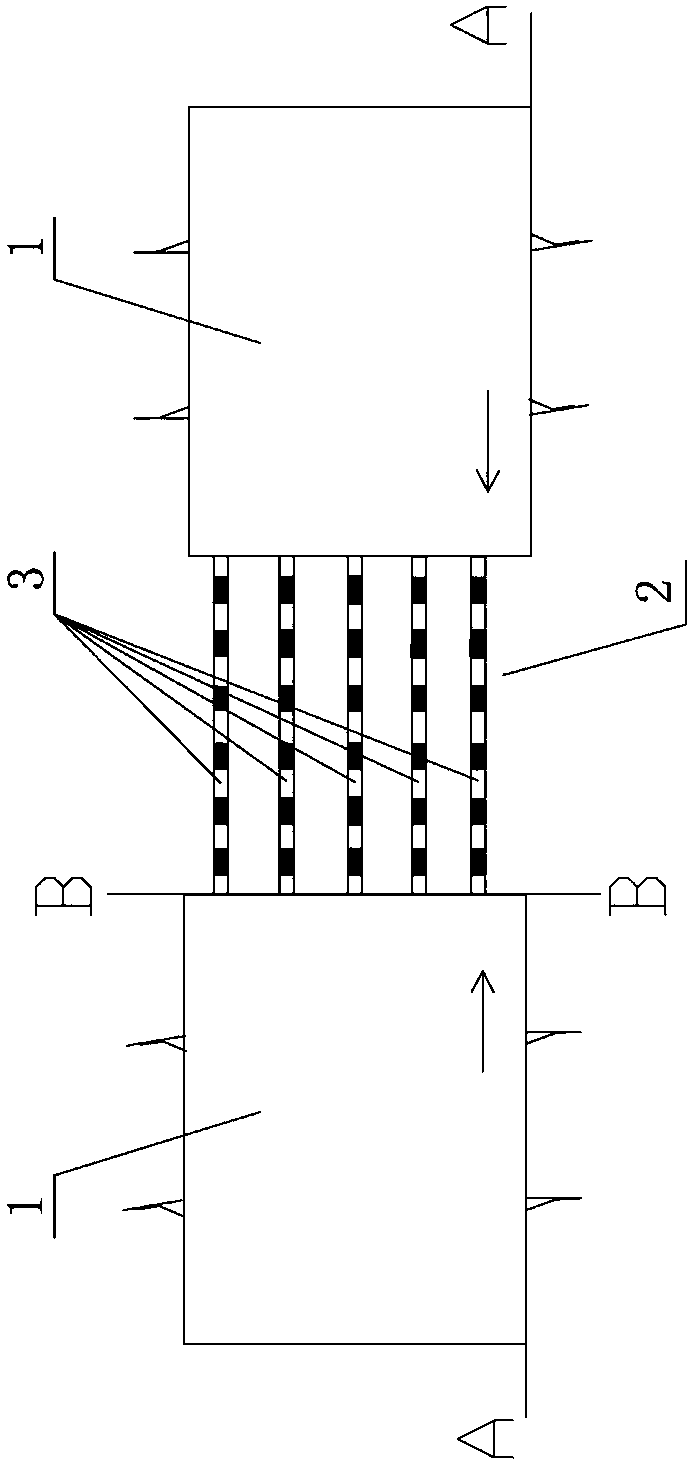

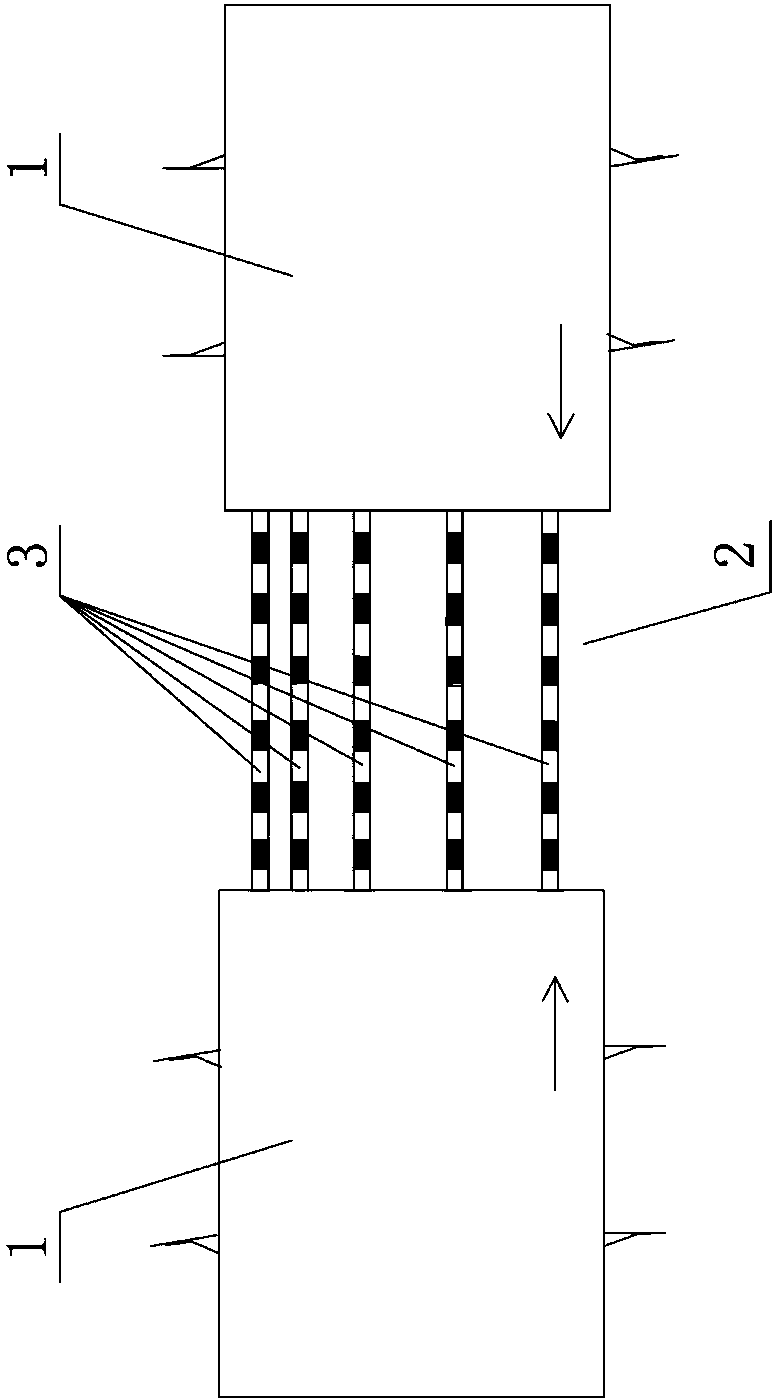

Method for processing plant material by use of plasma

InactiveCN107432134AChange traitsImprove securitySeed and root treatmentPlasma techniquePlanting seedPlant cell

The invention provides a method for processing a plant material by the use of plasma. The plasma is a normal-pressure room-temperature plasma and is generated after a naked metal electrode discharges under the conditions of normal pressure and room temperature. The plant material contains plant seeds, plant buds, plant seedlings, plant callus or plant cells. By using the normal-pressure room-temperature plasma to irradiate the above plant material, a plant with excellent traits can be obtained. The plasma used in the method is generated under the conditions of normal pressure and room temperature without harsh environments such as vacuum, high pressure, etc. Different from methods for changing gene structure of plants such as DNA recombination, cell fusion, etc., the method is physical modification, has good safety and is simple to operate.

Owner:LUOYANG TMAXTREE BIOTECH CO LTD

Rock pillar rockburst step-by-step relief water filling blasting method in deep-buried tunnel penetrating process

ActiveCN103075936AChange traitsEliminate or reduce the level of energy accumulationBlastingTO-18Slag

The invention relates to a rock pillar rockburst step-by-step relief water filling blasting method in a deep-buried tunnel penetrating process. The method aims at rockburst control and solves the construction safety and construction progress problems caused by strong rockblast. The method adopts the technical scheme that a, when the rock pillar thickness between the two tunnels is 30m, the digging is stopped; and a group of blast holes penetrating through the whole rock pillars are horizontally drilled in the digging surface of one tunnel; b, powder charging is respectively carried out in the depth ranges being 12 to 13m and 17 to 18m from the hole openings, and the two powder charging sections are simultaneously initiated; c, the powder charging is respectively carried out in the depth ranges being 7 to 8m and 22 to 23m from the hole openings, and the two powder charging sections are simultaneously initiated; and d, the powder charging is respectively carried out in the depth ranges being 2 to 3m and 27 to 28m from the hole openings, the total blasting intensity is controlled to be 0.07kg / T, the two powder charging sections are simultaneously initiated, and the slag tapping is carried out after the blasting completion until the tunnel penetration is completed. The method is applicable to underground engineering of hydraulic and hydro-power engineering, traffics, coal mines and the like.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

Ibuprofen slow-release suspension and preparation method thereof

InactiveCN101810571AMask the spicinessImprove complianceOrganic active ingredientsAntipyreticCurative effectSuspending Agents

The invention relates to an ibuprofen slow-release suspension and a preparation method thereof, relating to medicines, in particular to the technical field of the pharmacy of chemical medicines. The preparation method of the ibuprofen slow-release suspension comprises the following steps of: firstly mixing a flavoring agent, an antiseptic and pure water, and heating to be prepared into simple syrup; preparing ibuprofen and glutin into an ibuprofen microcapsule; then mixing the simple syrup, the ibuprofen microcapsule and a suspending agent, adding edible pigments and the flavoring agent, and uniformly stirring. The invention has the advantages of simple process, easy production and operation, good curative effect of the medicines and convenient carrying and preservation.

Owner:祝瑞章

Plant tissue culture support

InactiveCN105993961AGrow vigorouslyHigh transplant survival ratePlant tissue cultureHorticulture methodsCulture mediumsPollution

The invention belongs to the technical field of biology, and particularly relates to a plant tissue culture support. The support comprises dry sphagnum and de-ionized water, wherein the volume ratio of the dry sphagnum to the de-ionized water is (0.5-1):1. Compared with the prior art, the plant tissue culture support has the beneficial effects that the plant tissue culture support is easy to operate and low in tissue culture cost; energy resources are saved; the working time is shortened, the labor intensity is reduced, the inoculation efficiency is improved, and the pollution probability is reduced; an explant grows robustly, and is high in transplantation survival rate; good fixing effects are achieved; the air permeability is high; a culture medium is long in service cycle; a tissue culture environment can more meet physiological requirements of a plant.

Owner:DALIAN UNIV

Method for innocent treatment of surplus sludge after biochemical treatment of organic chemical waste water

InactiveCN102942295ARealize resource utilizationReduce pollutionSludge treatment by de-watering/drying/thickeningCement productionSludgeSlag

The invention relates to a method for the innocent treatment of surplus sludge after the biochemical treatment of organic chemical waste water, which comprises the following steps: settling the surplus sludge, slaking, dehydrating and calcining. The method is characterized in that the settled sludge having a water content of 97-99% is slaked; in the slaking step, the sludge and carbide slag slurry are thoroughly stirred with compressed air in a slaking tank and are slaked with strong alkali, the volume of the sludge is 0.02-0.08% of the volume of the carbide slag slurry, the pH value of the carbide slag slurry is 12-14, and the solid content is 5-8%; after the slaking step is finished, filter press dehydration is performed to obtain a filter cake having a water content of 30-35%; and in the calcining step, the filter cake is used as one of components for producing cement clinker and is calcined in a kiln. The treatment method realizes the reutilization of sludge.

Owner:ANHUI WANWEI UPDATED HIGH TECH MATERIAL CO LTD

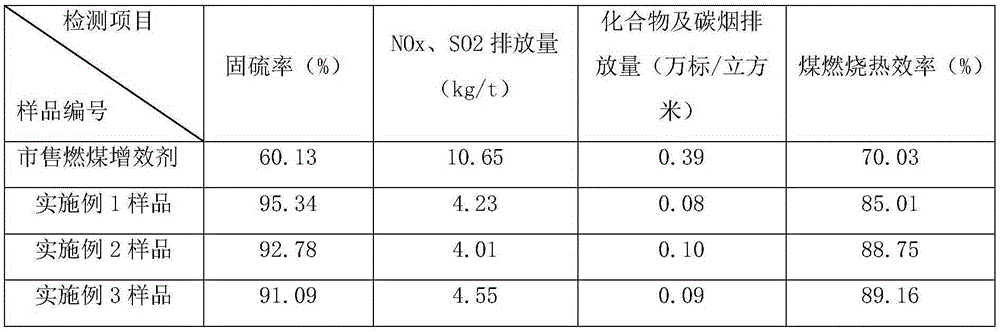

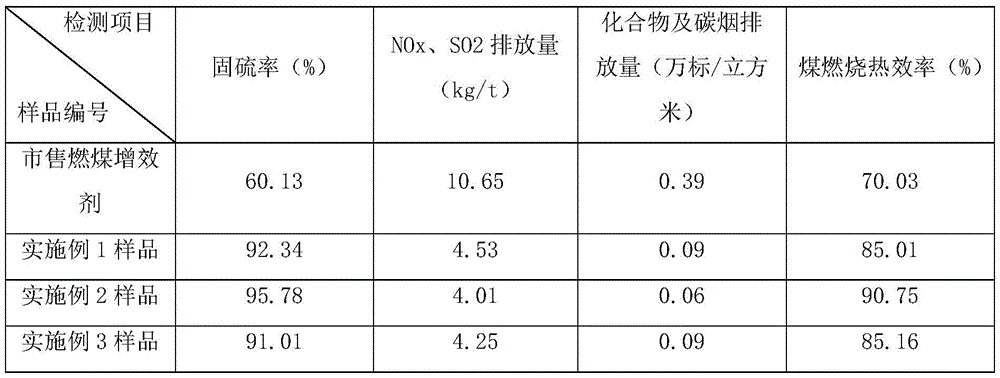

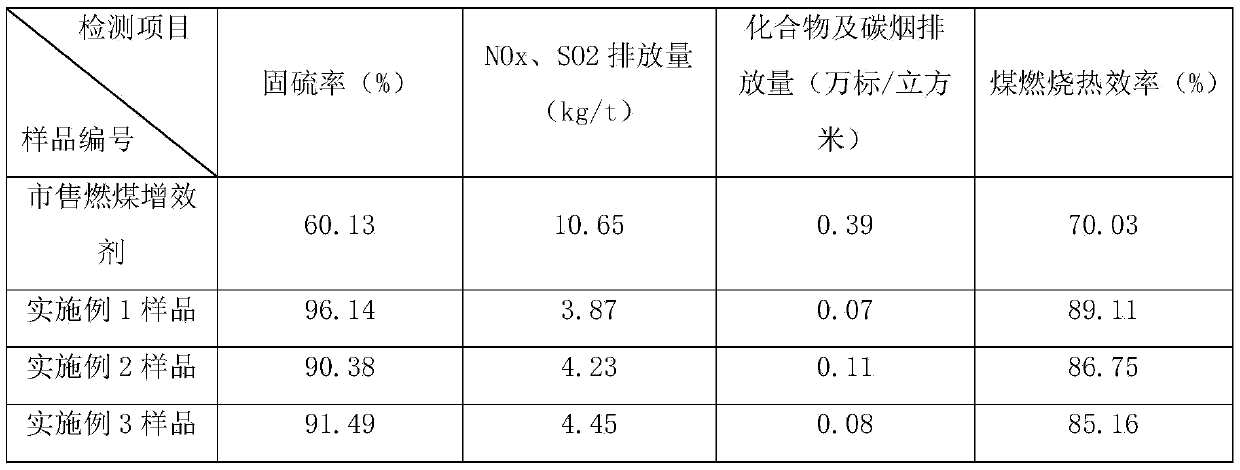

Energy-saving and emission-reduction synergist for coal

The invention discloses an energy-saving and emission-reduction synergist for coal. The synergist comprises the following materials by weight: 6-8 parts of yttrium oxide, 8-10 parts of manganese dioxide, 10-15 parts of ferrum dioxide, 10-15 parts of ferrous oxide, 3-5 parts of sodium carbonate, 3-5 parts of potassium nitrate, 2-6 parts of lignosulfonate, 4-10 parts of ammonium bicarbonate, 5-10 parts of potassium carbonate, 6-10 parts of urea, 3-5 parts of active carbons, 2-8 parts of diatomite, and 2-3 parts of activated alumina. The energy-saving and emission-reduction synergist for coal has a good desulfurization effect and a stable desulfurization product, and largely reduces pollutant emission.

Owner:GUANGXI KUONENGBA ENERGY TECH DEV CO LTD

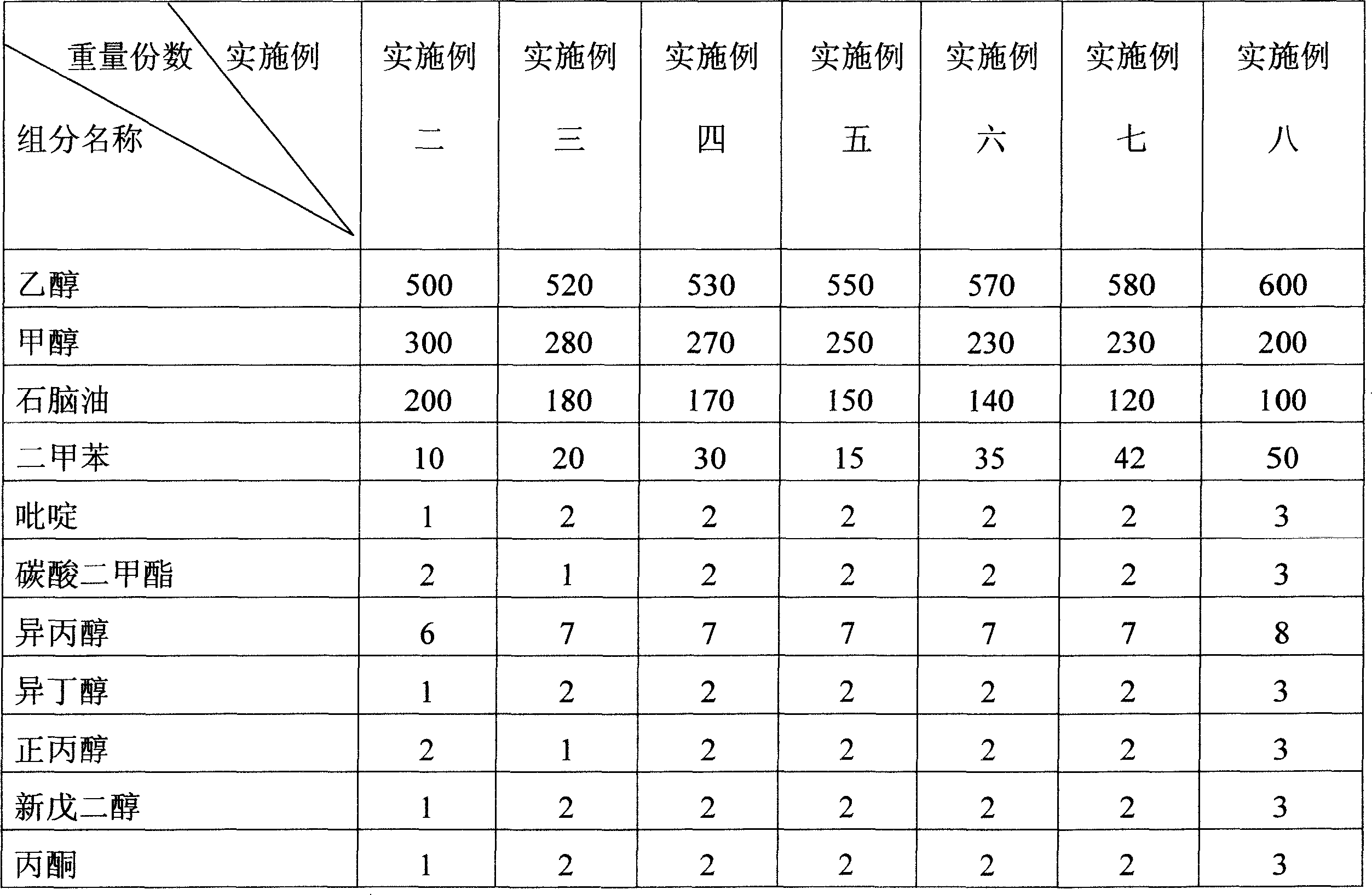

Biological liquid fuel and preparation method thereof

The invention discloses a biological combusting liquid and making method, which comprises the following parts: alcohol, isopropanol, carbinol, isobutanol, benzine naphtha, normal propyl alcohol, neopentyl glycol, pyridine, acetone and dimethyl carbonate, wherein the dimethylbenzene is the composition of p-xylene or ortho-xylene. The making method comprises the following steps: blending each component under normal temperature and pressure; adding alcohol modifying additive in the alcohol; adding additive, carbinol and benzine naphtha in each component adding course; stirring 2-4 min for each adding course; stirring 3-5min after finishing adding course.

Owner:杜茂华 +2

An yttrium oxide containing environmental-friendly coal-saving synergist

InactiveCN105462647AReduce volumeIncrease overall volumeSolid fuelsAmmonium Hydrogen CarbonateYttrium

An yttrium oxide containing environmental-friendly coal-saving synergist is disclosed. The synergist comprises following raw materials by weight: 10-15 parts of yttrium oxide, 2-5 parts of manganese dioxide, 10-15 parts of iron(II) peroxide, 5-10 parts of ferrous oxide, 1-3 parts of sodium carbonate, 1-5 parts of potassium nitrate, 2-5 parts of lignin sulfonate, 5-10 parts of ammonium hydrogen carbonate, 5-10 parts of urea, 1-5 parts of activated carbon, 1-5 parts of diatomite and 2-5 parts of activated aluminium oxide. The synergist has good sulfur fixing effects, a sulfur fixing product is stable and pollutant emission is greatly reduced.

Owner:GUANGXI KUONENGBA ENERGY TECH DEV CO LTD

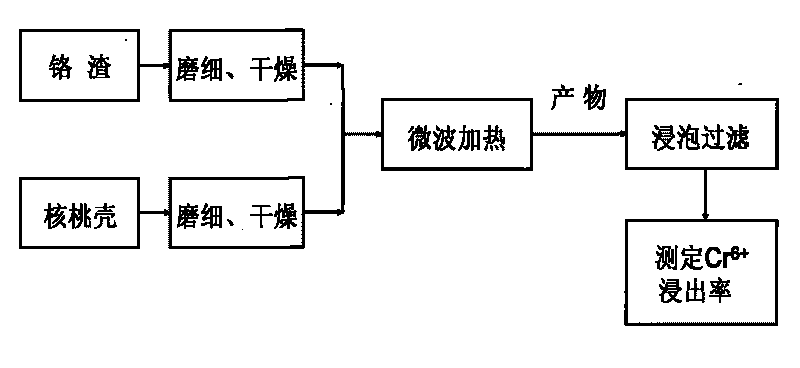

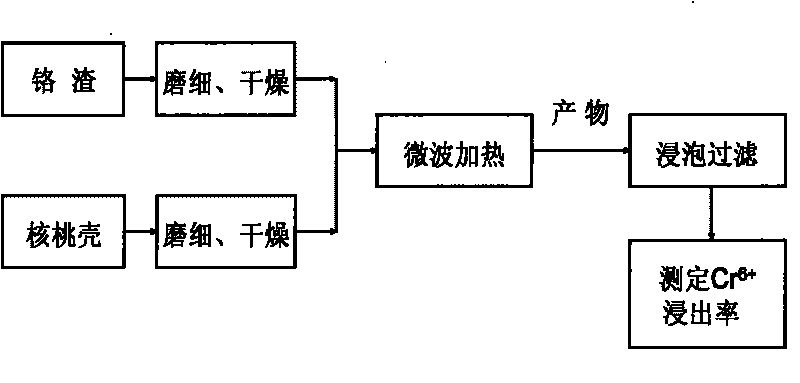

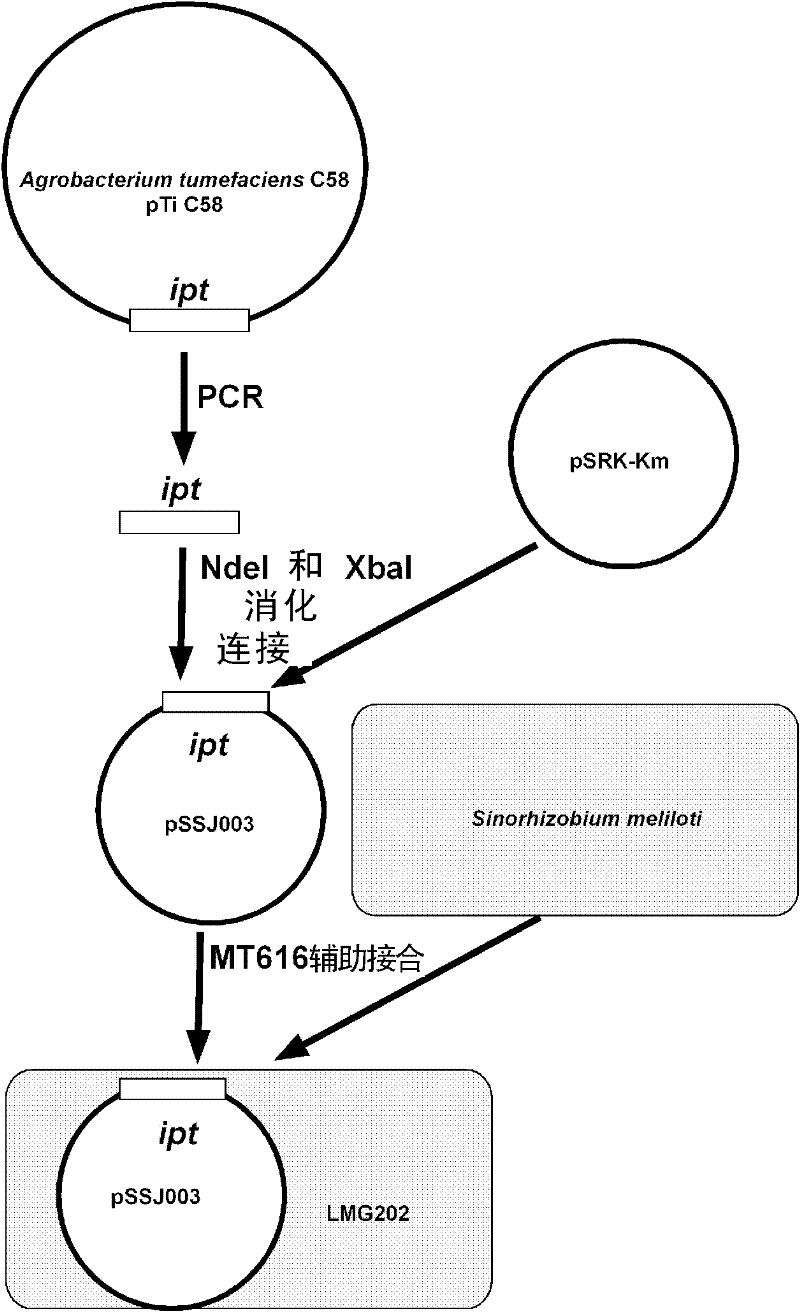

Method for detoxifying chromium slags

The method discloses a method for detoxifying chromium slags. The method comprises the following steps of: drying and grinding the chromium slags and walnut shells; placing the dried and ground chromium slags and walnut shells into a ceramic crucible in a certain ratio and mixing the chromium slags and the walnut shells uniformly; then placing the crucible into a microwave oven, wherein the crucible is enclosed by slag wool heat insulating material for heat preservation; adopting an armored thermocouple with a shield to measure the temperature in a microwave field; performing heat preservation for 10 to 20 minutes when the temperature rises to 700 to 1,000 DEG C, and then turning off the microwave oven; opening the oven port in 5 to 10 minutes; immersing the material into distilled water for 24h after the material is cooled; filtering the material and setting the volume of the filtrate to be 250 ml; measuring the concentration of Cr6+ in the filtrate by adopting a diphenylcarbazide spectrophotometric method; and converting the Cr6+ concentration into the mass percent of the mass of extractive hexavalent chrome accounting for the mass of a sample chromium slag to finally calculate the detoxification ratio. The method for detoxifying the chromium slags deoxidizes the chromium slags by using C in the walnut shells, so both the walnut shells and the chromium slags are fully used, resources are saved, and the waste is changed into a useful material. The method has the characteristic of improving the chemical yield to lower the production cost, and has simple steps and convenient operations to further reduce the production cost.

Owner:KUNMING UNIV OF SCI & TECH

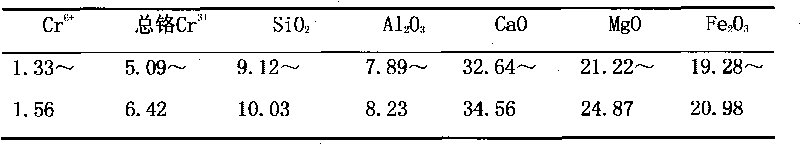

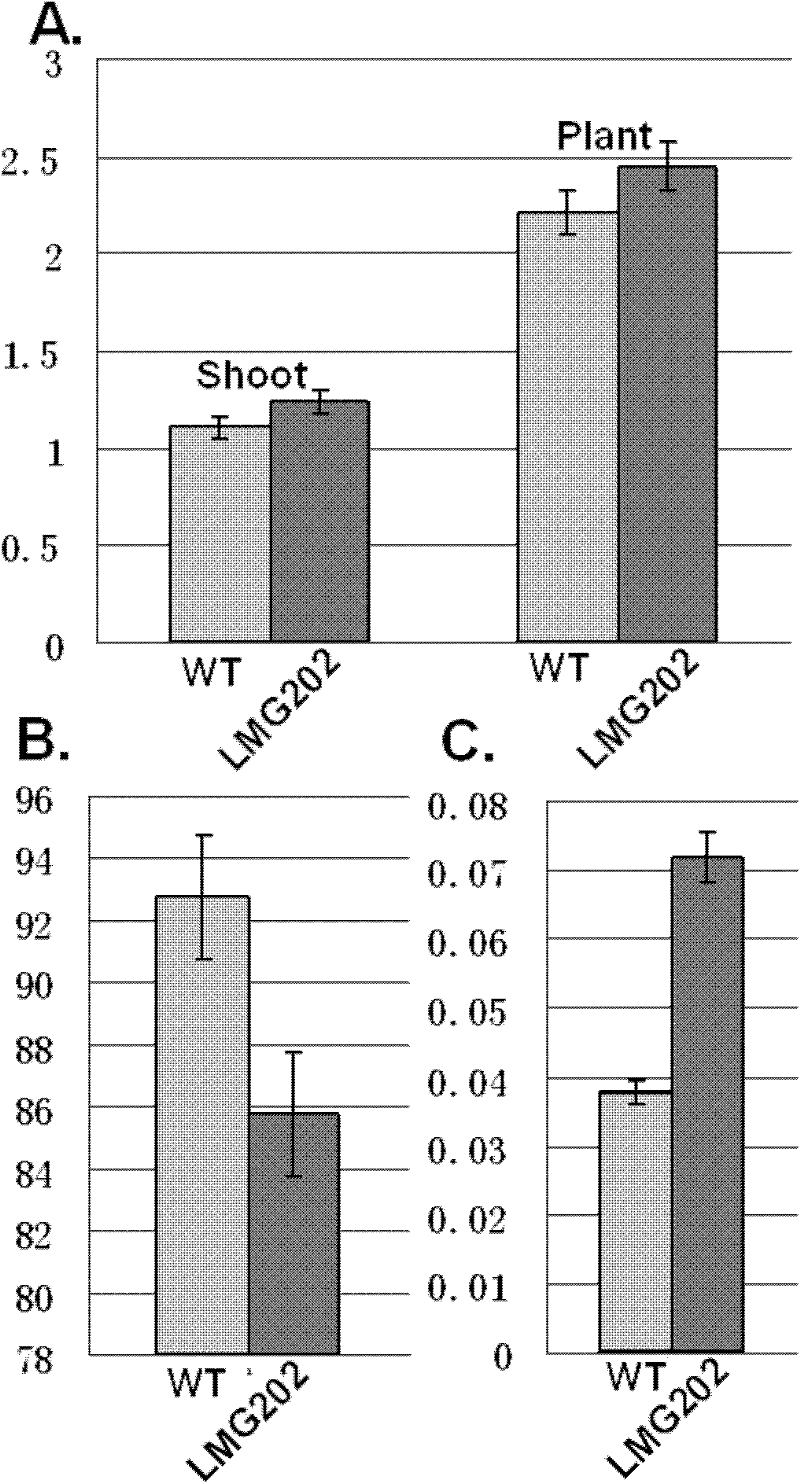

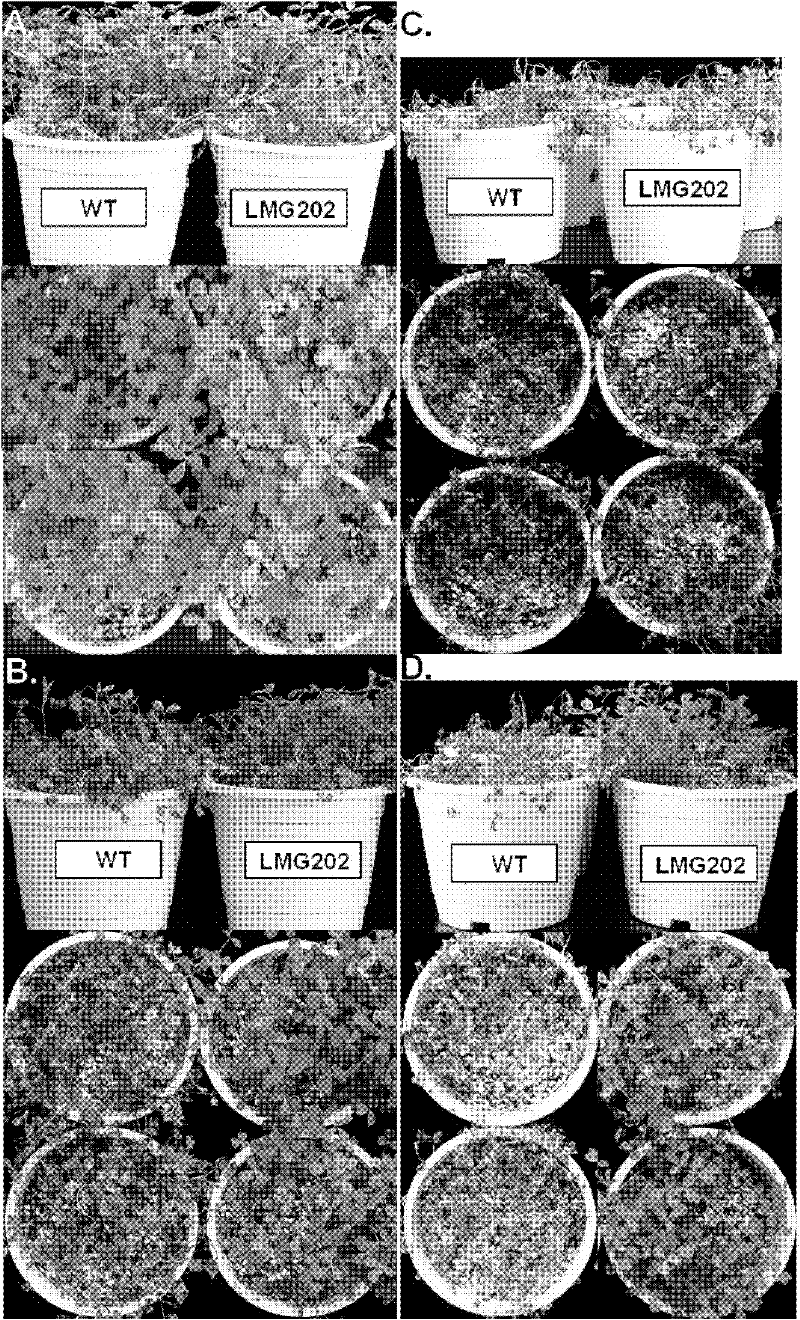

Method for changing characteristics of plants

The invention relates to a method for changing characteristics of plants. According to the invention, a special property is adopted, that plants which permit root nodules can realize a symbiosis relation with rhizobium; exogenous genes are expressed in the rhizobium colonized in plant root nodule cells; through existing transporting systems in the plants, gene expression products or components are transferred to other tissue organs of the plants. With the method provided by the present invention, characteristics or phenotypes of the plants are changed.

Owner:SHANGHAI INST OF BIOLOGICAL SCI CHINESE ACAD OF SCI

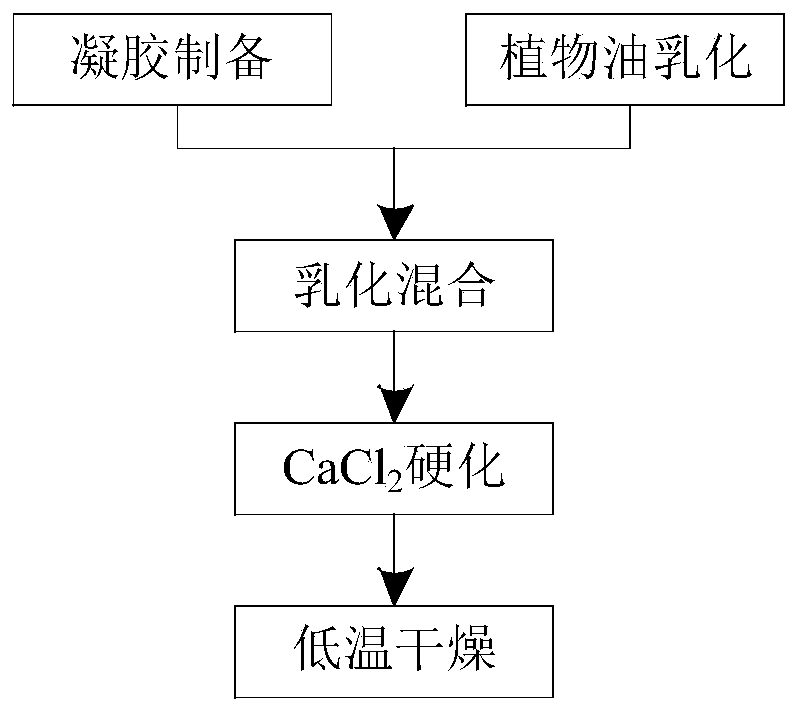

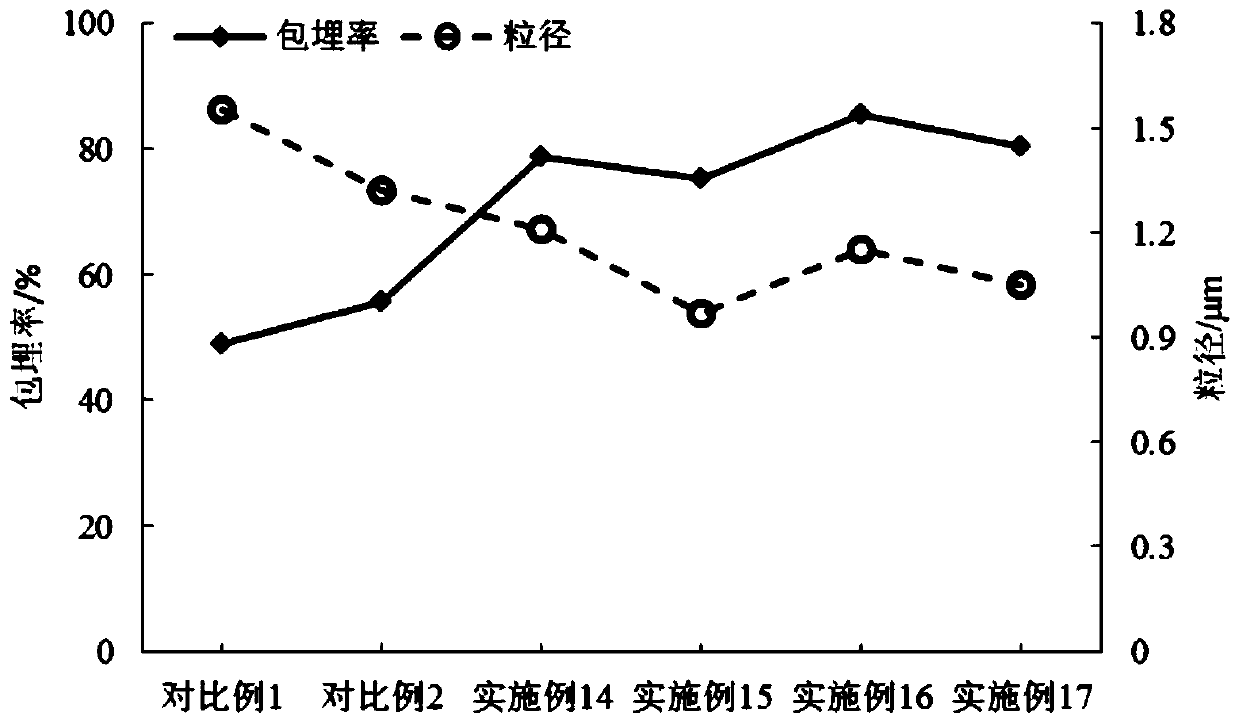

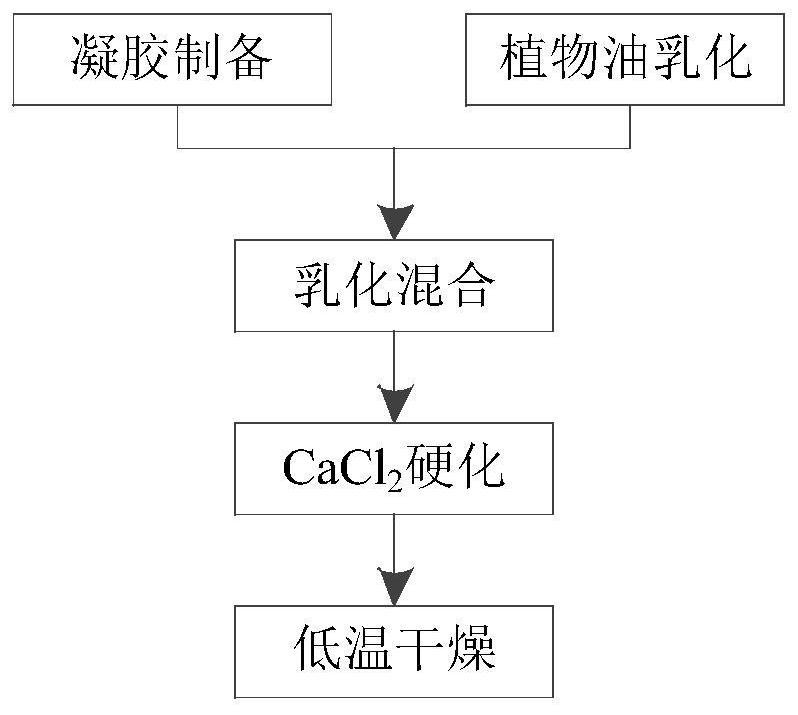

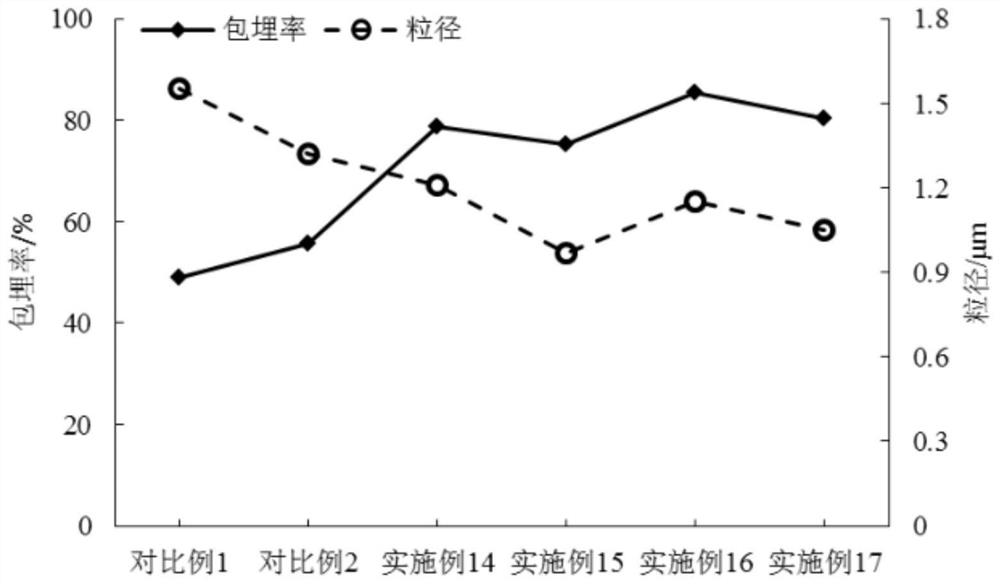

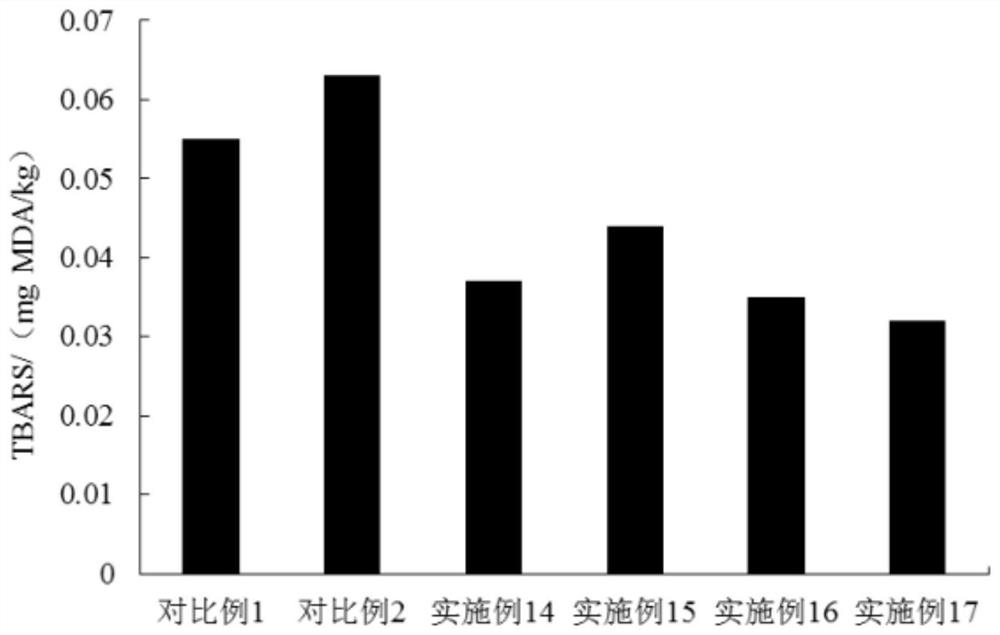

Vegetable oil microcapsule powder applied to cereal electuary and preparation method thereof

The invention discloses vegetable oil microcapsule powder applied to cereal electuary. The vegetable oil microcapsule powder is prepared from sucrose fatty acid ester, citric acid, psyllium husk powder, maltodextrin and tween-80, tocopherol, vegetable oil and a calcium chloride solution. According to the vegetable oil microcapsule powder applied to the cereal electuary and the preparation method thereof, in the mode, the vegetable oil and psyllium husk gel are emulsified into a uniform 'oil / water' gel system through the oil-water emulsification principle, then psyllium husk gel particles are prepared through the principle that the psyllium husk gel and calcium ions are crosslinked and hardened, and finally the particles are dried at low temperature to obtain the vegetable oil microcapsulepowder. On the basis of keeping the original nutritive value of the vegetable oil, the properties of the vegetable oil are changed, the liquid vegetable oil is prepared into the vegetable oil powder through a microcapsule technology, the stability and the application range of the vegetable oil are greatly increased, and the vegetable oil microcapsule powder is especially suitable for the cereal electuary.

Owner:镇江市智农食品有限公司

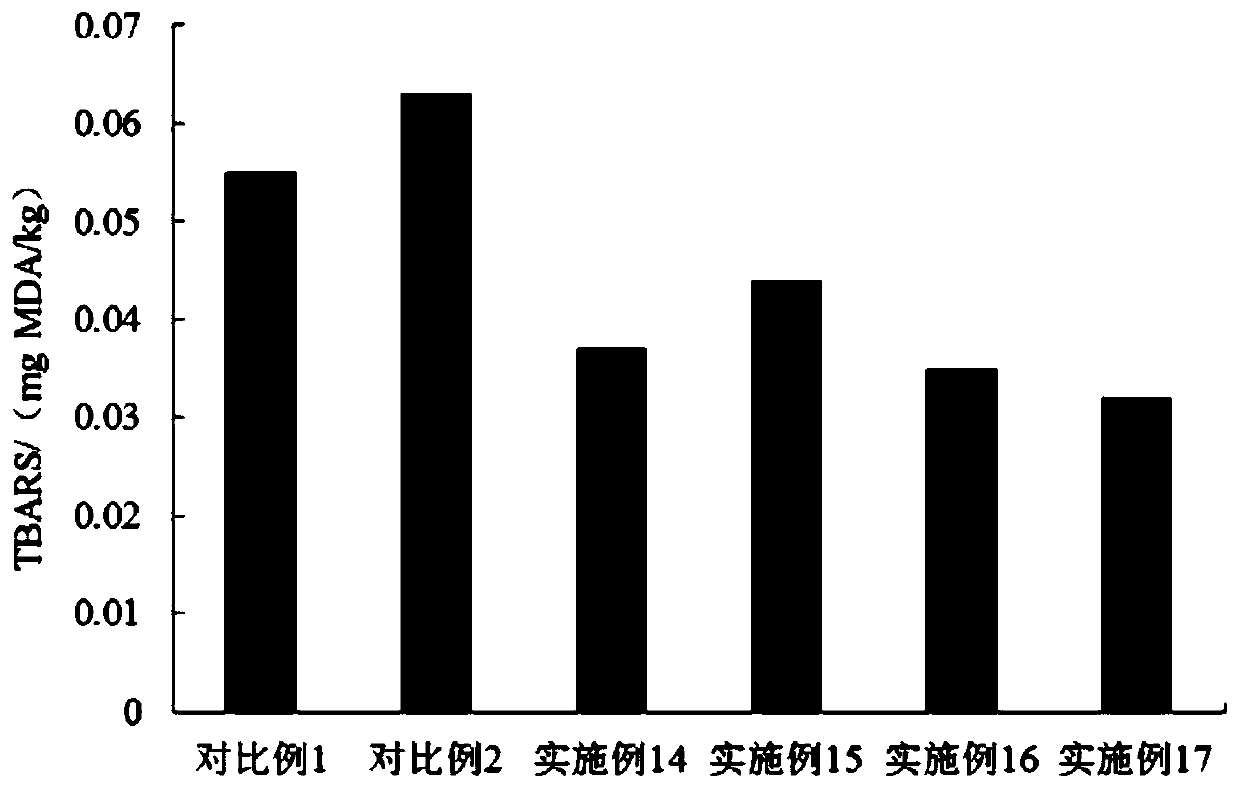

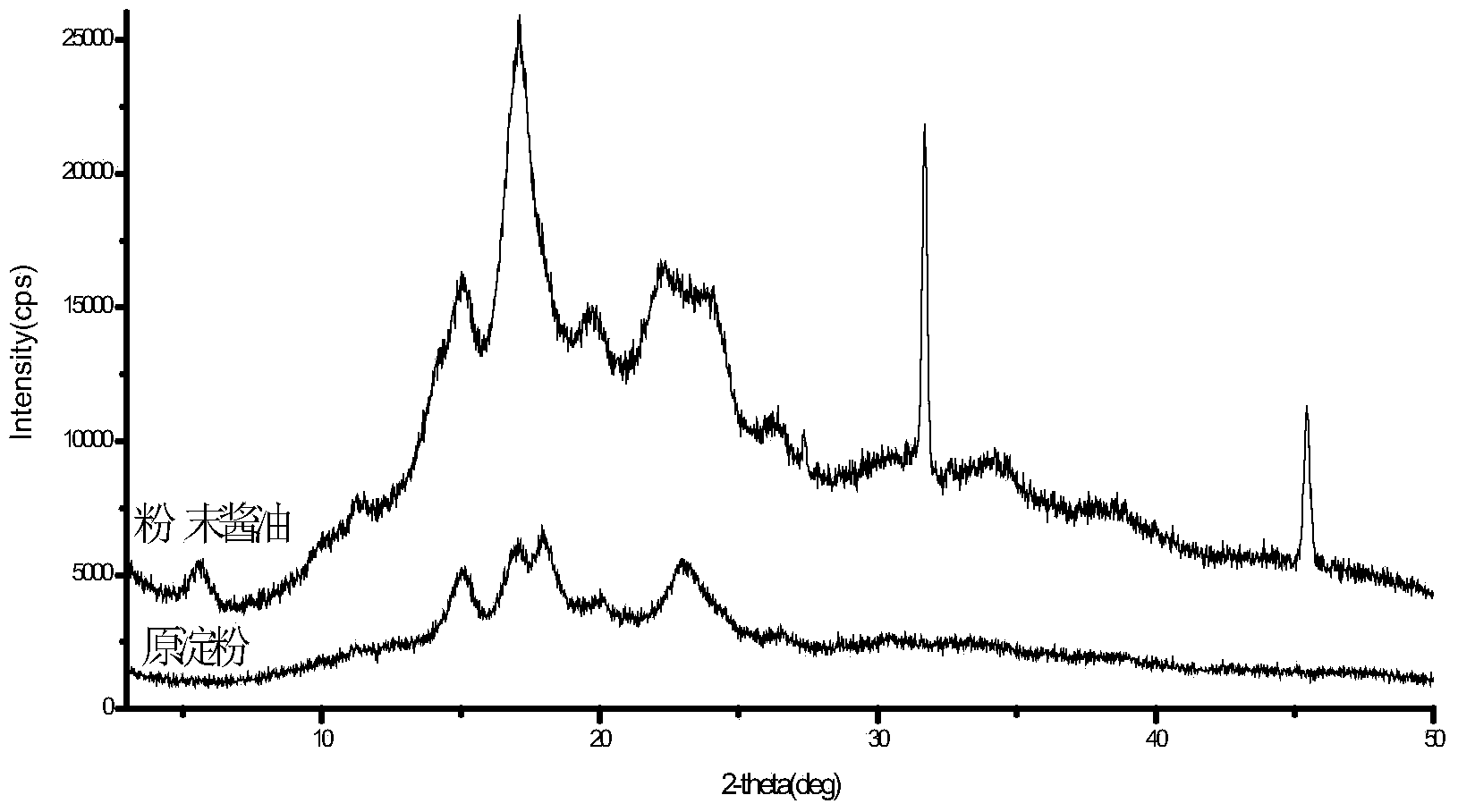

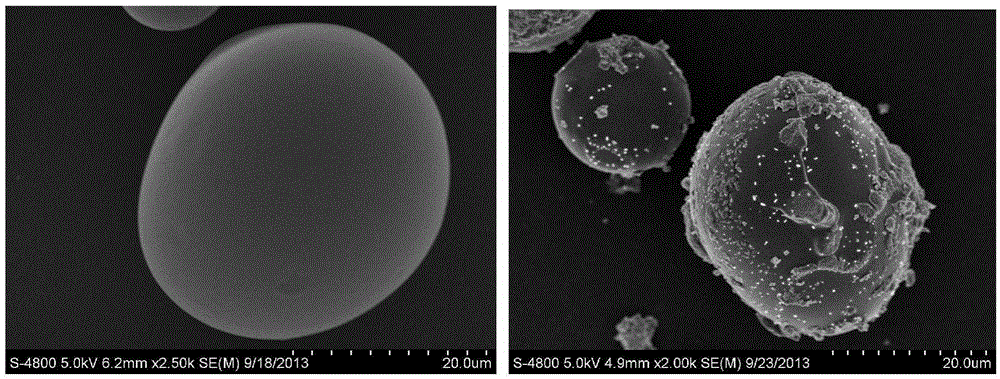

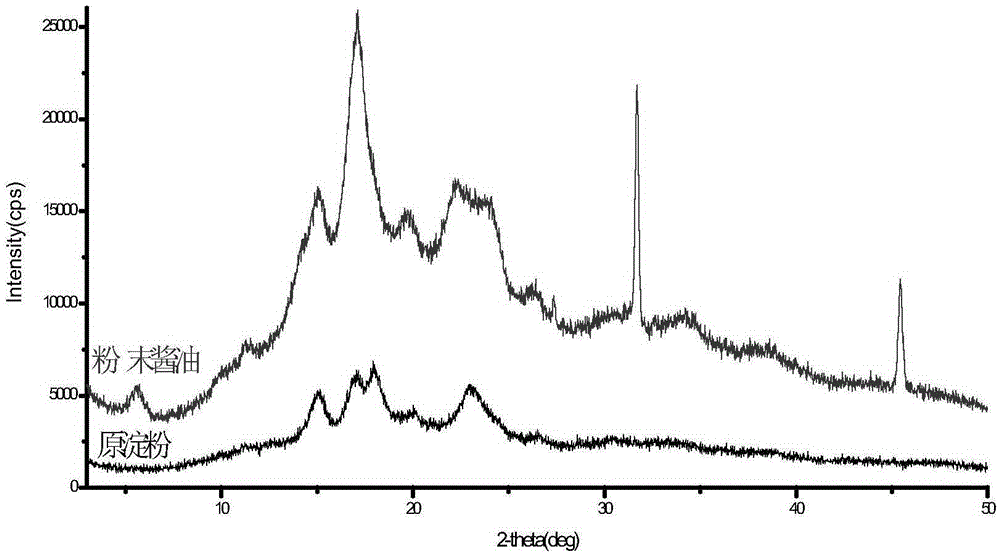

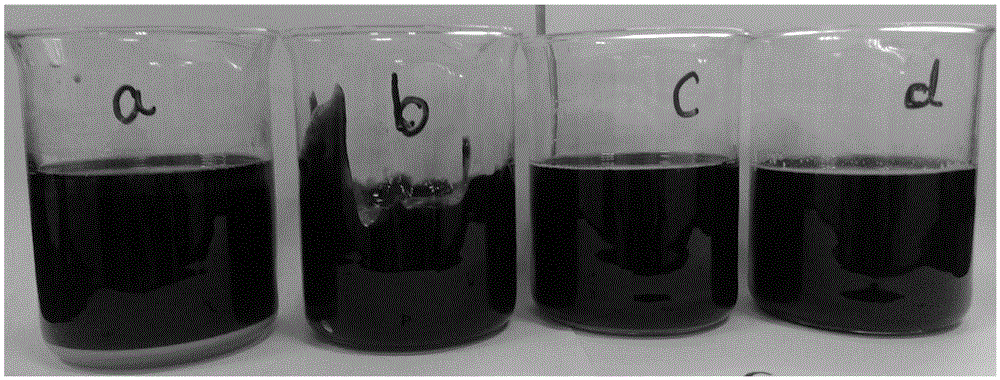

Production method of fast food seasoning powder soybean sauce

ActiveCN103844239ARetains volatile flavor compoundsPreserve Solubility PropertiesFood preparationAlcoholVolatile flavor

The invention discloses a production method of fast food seasoning powder soybean sauce. The production method comprises the following steps: with native starch as the material, obtaining modified porous starch through an alcohol-alkaline process and an enzymolysis technology; and then, after mixing the modified porous starch and liquid soybean sauce, vacuum freezing and drying to obtain powder soybean sauce. On one hand, powder soybean sauce produced by the production method disclosed by the invention keeps various indexes of a conventional soybean sauce, and amino nitrogen content and volatile flavor substance content of the powder soybean sauce are almost consistent with those of the conventional soybean sauce; on the other hand, a problem that the powder soybean sauce is easy to paste in an application process is solved very well.

Owner:ANHUI GUOKE TESTING TECH CO LTD

A kind of production method of instant condiment powder soy sauce

The invention discloses a production method of fast food seasoning powder soybean sauce. The production method comprises the following steps: with native starch as the material, obtaining modified porous starch through an alcohol-alkaline process and an enzymolysis technology; and then, after mixing the modified porous starch and liquid soybean sauce, vacuum freezing and drying to obtain powder soybean sauce. On one hand, powder soybean sauce produced by the production method disclosed by the invention keeps various indexes of a conventional soybean sauce, and amino nitrogen content and volatile flavor substance content of the powder soybean sauce are almost consistent with those of the conventional soybean sauce; on the other hand, a problem that the powder soybean sauce is easy to paste in an application process is solved very well.

Owner:ANHUI GUOKE TESTING TECH CO LTD

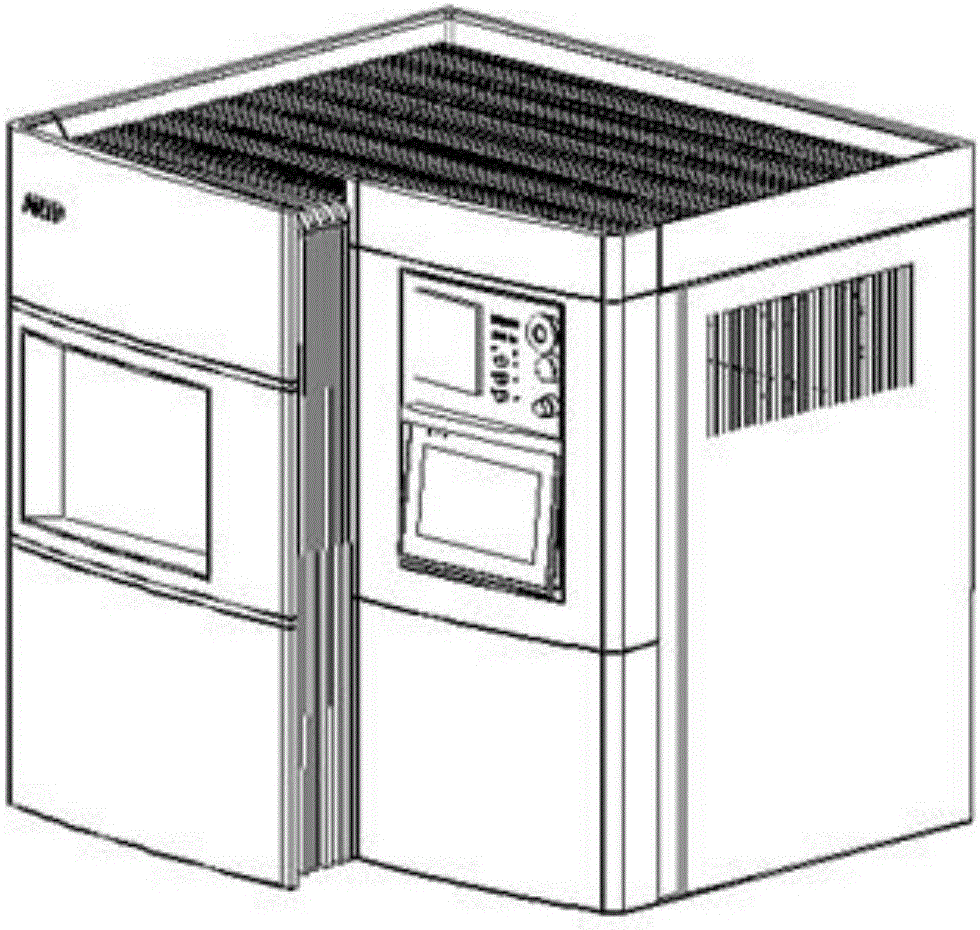

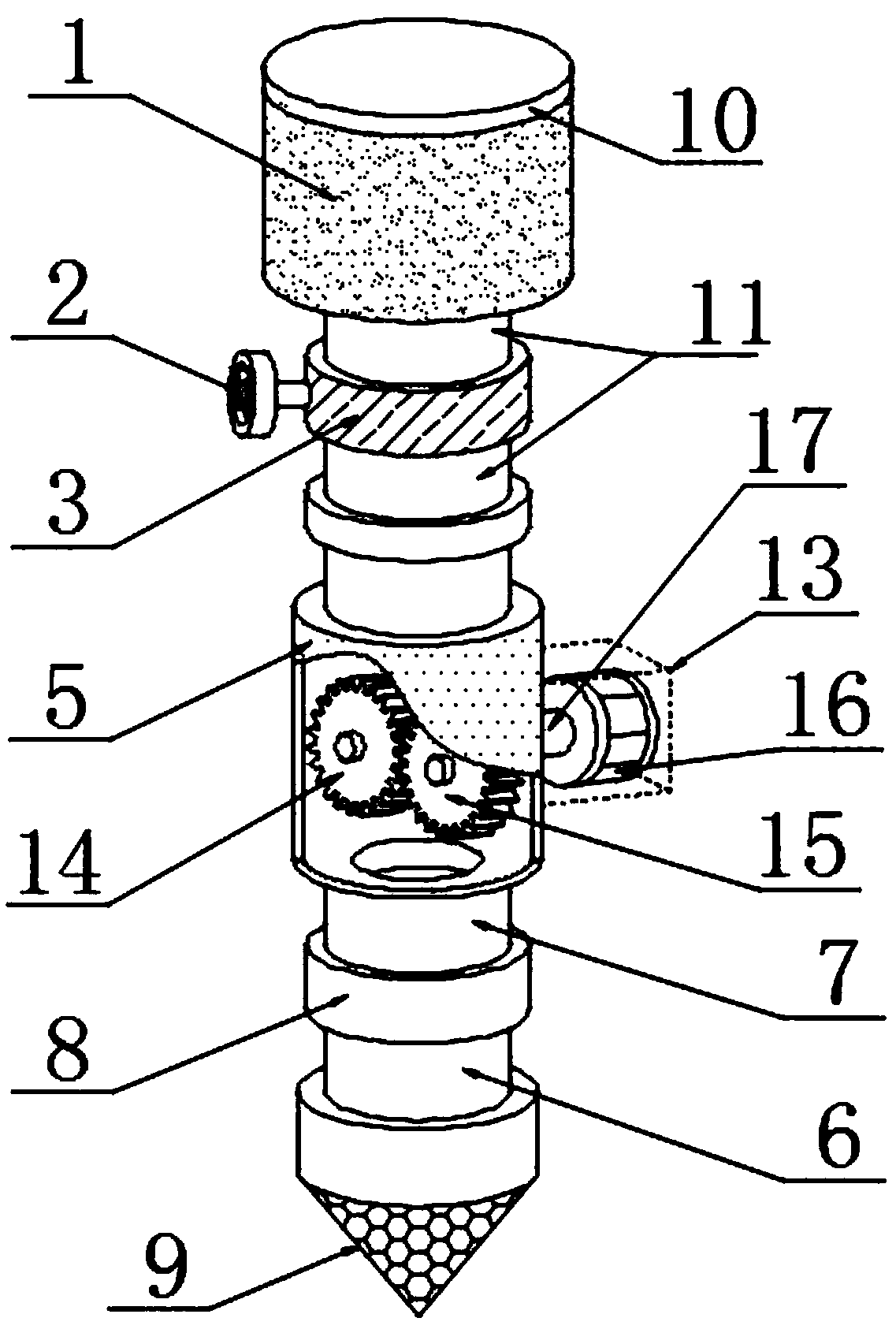

Modular uninterrupted printing and feeding 3D (three-dimensional) printer system

PendingCN109571951AChange traitsEnsure stabilityManufacturing driving means3D object support structuresEngineering3d printer

The invention discloses a modular uninterrupted printing and feeding 3D (three-dimensional) printer system. The modular uninterrupted printing and feeding 3D printer system comprises a third connecting pipeline, wherein the upper end of the third connecting pipeline is in through connection with a storage bin being of a circular and hollow structure; a storage bin top cover which is adaptive to the storage bin is arranged at an upper port of the storage bin; and a valve for controlling the conveying of printing raw materials in the storage bin is arranged at the middle part of the third connecting pipeline. The storage bin and a printing spray head of the modular uninterrupted printing and feeding 3D printer system can be disassembled through bayonets, so that different types of storage bins and printing spray heads are selected according to different printing requirements; meanwhile, the continuous driving force can be generated through a gear pump so as to send the printing raw materials to the printing spray head; the volume of the storage bin is much larger than the piston volume of a traditional piston extrusion type 3D printer, and plenty of printing raw materials can be placed in the storage bin, so that when the printing raw material is exhausted, no pause or loading operation is required, and the stability of the environment in which the printing raw materials are located in the printing process is ensured.

Owner:江苏兴瑞医疗科技有限公司 +1

Biological alcohol-based liquid fuel and preparation method thereof

The invention discloses a biological alcohol-based liquid fuel and a preparation method thereof, and the biological alcohol-based liquid fuel is formed by mixing the following raw materials in parts by weight: 600-700 parts by weight of alcohol-based liquid, 125-175 parts by weight of xylene, 125-175 parts by weight of naphtha and 40-60 parts by weight of additives. The preparation method comprises the step of adding methanol, the naphtha, the xylene and the additives of the raw materials into a container to obtain the biological alcohol-based liquid fuel. The biological alcohol-based liquid fuel is characterized by abundant resources of the raw materials, low manufacturing cost, simple preparation method and capability of fully replacing gasoline for use, and additionally has the advantages of good environmental protection performance and high combustion value.

Owner:国润金华(北京)国际能源投资有限公司

Preservation method of dendrobium

InactiveCN107279131AExtended shelf lifeChange traitsDead plant preservationHermetic packagingPre treatment

The invention discloses a preservation method of dendrobium. The method comprises the following steps of carrying out pretreatment on a harvest wound of the dendrobium, and then subjecting the dendrobium to cooling treatment, incision washing, drying treatment, hermetic packaging and refrigeration treatment in sequence. By adopting the preservation method, the preservation period of the dendrobium is as long as 93 days to 110 days; the water loss rate is between 5 percent and 10 percent; the trait of the dendrobium cannot be changed; a nutrient substance that the dendrobium contains cannot be also degraded; an operation method of the preservation method is simple; used materials are environmentally friendly and moreover materials are taken widely; the popularization range is not limited by a device and a facility.

Owner:深圳市天之宝生物科技股份有限公司

Ultrasonic and hot air combined carrot drying method and ultrasonic and hot air combined drying device

InactiveCN103109919BChange traitsIncrease the gapFood processingFruits/vegetable preservation by dehydrationProcess engineeringUltrasonic irradiation

The invention discloses an ultrasonic and hot air combined carrot drying method and an ultrasonic and hot air combined drying device. The ultrasonic and hot air combined carrot drying method comprises the following steps of: (1) pretreatment of a carrot raw material, namely washing and slicing fresh carrots; and (2) ultrasonic and hot air combined drying, namely, putting carrot slices on a sieve, sequentially starting a heating and blowing device and an ultrasonic irradiation device, and carrying out ultrasonic and hot air combined drying on the carrot slices, wherein the drying temperature is 30-70 DEG C, the drying air speed is 0.3-3m / s, the ultrasonic power is 100-200W, the ultrasonic frequency is 20kHz, the distance between the ultrasonic irradiation device and the sieve is 5-15cm and the drying time is 3-6 hours. According to the ultrasonic and hot air combined carrot drying method, an ultrasonic technology is directly and effectively coupled to a hot air drying process, so that the heat transfer and mass transfer efficiencies in the drying process are improved, the drying time is shortened, the energy consumption is saved and the product quality is improved.

Owner:HENAN UNIV OF SCI & TECH

Fire coal energy saving and emission reduction synergist

The present invention discloses a fire coal energy saving and emission reduction synergist comprising the following starting materials in parts by weight: 2-8 parts of yttrium oxide, 1-5 parts of magnesium hydroxide, 1-5 parts of manganese dioxide, 5-10 parts of ferroferric oxide, 10-13 parts of ferrous oxide, 1-3 parts of sodium carbonate, 2-6 parts of potassium nitrate, 1-5 parts of sulfonated lignin, 1-5 parts of ammonium bicarbonate, 5-10 parts of potassium carbonate, 1-5 parts of urea, 5-8 parts of diatomite and 1-2 parts of activated alumina. The fire coal energy saving and emission reduction synergist has a good sulfur fixation effect, a sulfur fixation product is stable, and pollution emissions are greatly reduced.

Owner:GUANGXI KUONENGBA ENERGY TECH DEV CO LTD

A kind of vegetable oil microcapsule powder applied to grain granules and preparation method thereof

ActiveCN110367341BRetain nutritional valueChange traitsEdible oils/fatsNutritive valuesVegetable oil

The invention discloses a vegetable oil microcapsule powder applied to grain granules, which comprises sucrose fatty acid ester, citric acid, psyllium husk powder, maltodextrin, Tween-80, tocopherol, vegetable oil and calcium chloride solution. Through the above-mentioned method, the vegetable oil microcapsule powder applied to grain granules and the preparation method thereof provided by the present invention emulsify the vegetable oil and psyllium seed husk gel into a uniform "oil / water" gel system through the principle of oil-water emulsification, and then pass Psyllium seed shell gel particles are prepared by the principle of cross-linking and hardening of psyllium seed gel and calcium ions, and finally these particles are dried at low temperature to obtain vegetable oil microcapsule powder. On the basis of retaining the original nutritional value of vegetable oil, the The properties of vegetable oil, the liquid vegetable oil is made into vegetable oil powder through microcapsule technology, which greatly improves the stability and application range of vegetable oil, especially suitable for grain granules.

Owner:镇江市智农食品有限公司

Burn ointment and preparation method thereof

PendingCN113940948ACause pain and other discomfortSuitable for long-term treatmentAerosol deliveryOintment deliveryDressing changeTherapeutic effect

Owner:王海峰

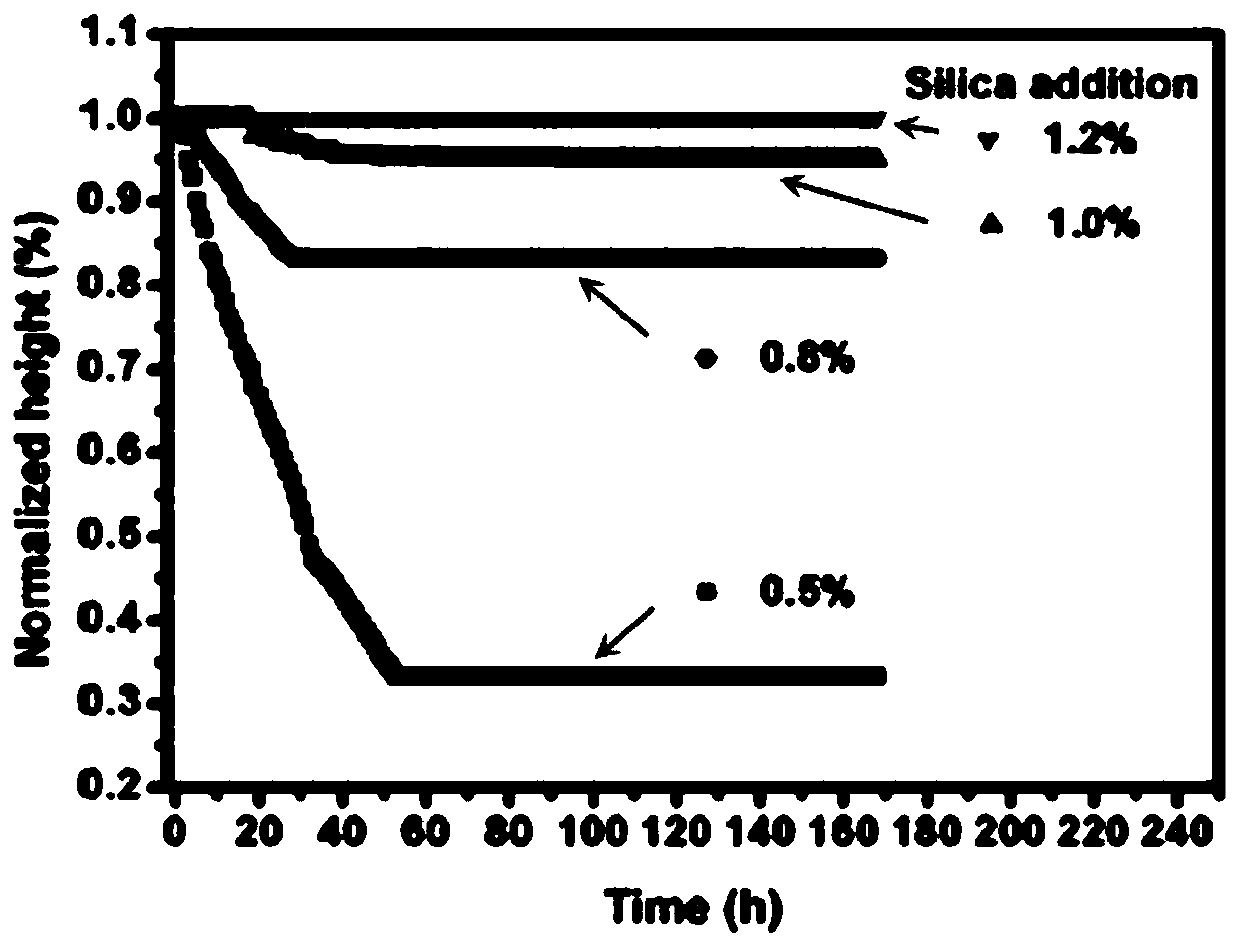

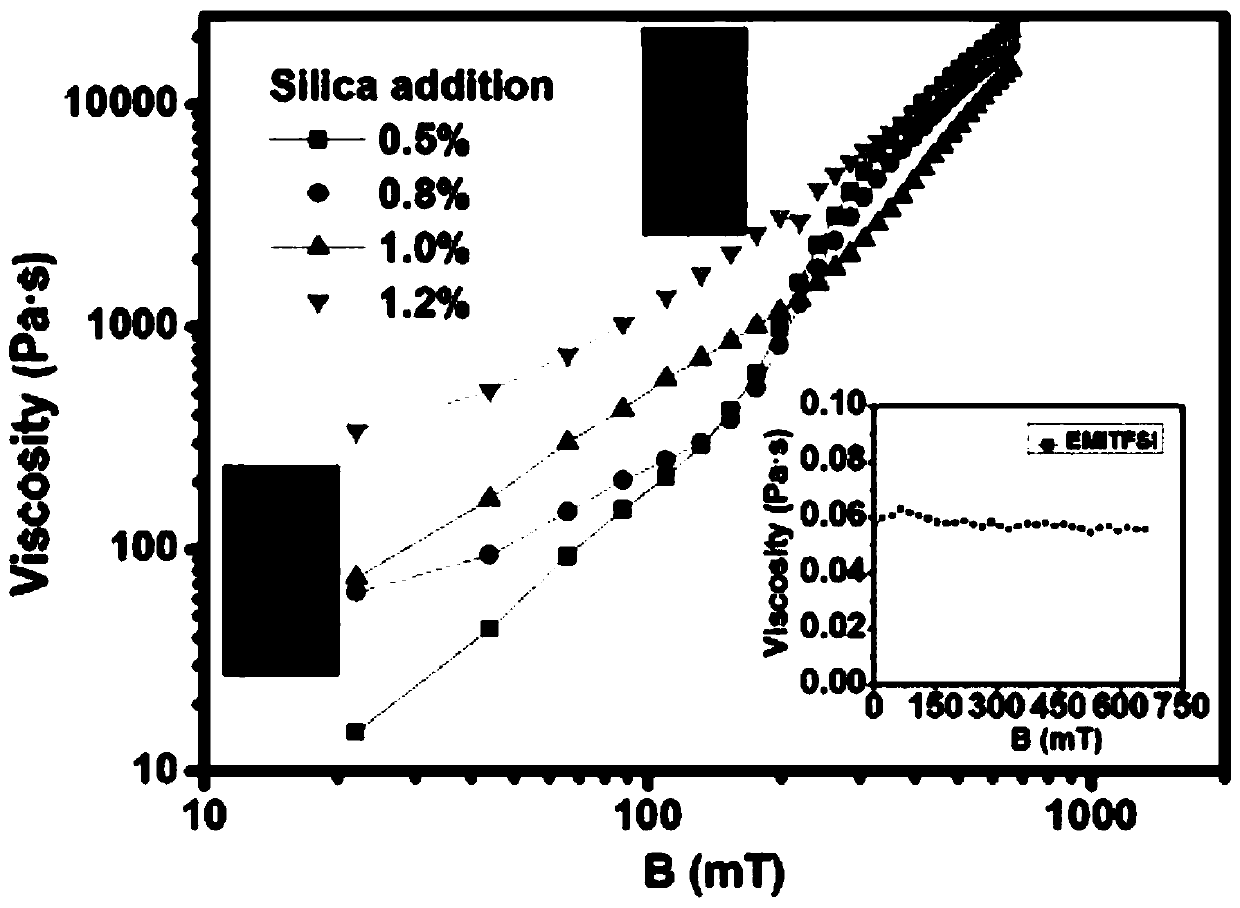

Magnetorheological technology based novel liquid electrolyte with controllable properties

InactiveCN110473716ASuspension stabilityImprove conductivityHybrid capacitor electrolytesNano siliconMagnetorheological fluid

The invention discloses a magnetorheological technology based novel liquid electrolyte with controllable properties. The liquid electrolyte includes silicon-coated Fe3O4 nanoparticles, EMITFSI and nano silicon particles; and the mass of the EMITFSI is taken as reference, the EMITFSI is marked as 100 wt%, the content of the silicon-coated Fe3O4 nanoparticles is 2-20 wt%, and the content of the nanosilicon particles is 0.2-1.2 wt%. Ionic liquid magnetorheological fluid can be suspended stably, has good electrical conductivity and can be applied to electric equipment such as supercapacitors; andthe liquid electrolyte is simple in preparation, stably suspended ferromagnetic particles can be introduced into a material system without obviously affecting the electrical conductivity of originalliquid electrolytes, namely, a control source with rapid response can be introduced to stably change the property of the novel liquid electrolyte in real time, so that leakage proof mechanism and safety characteristics can be provided for the electric equipment adopting the novel material.

Owner:深圳市天劲新能源研究院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com