Rock pillar rockburst step-by-step relief water filling blasting method in deep-buried tunnel penetrating process

A tunnel and column type technology, applied in blasting and other directions, can solve the problem of rock column type rock burst, and achieve the effect of reducing the probability of rock burst, improving construction safety, and reducing the level of energy accumulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

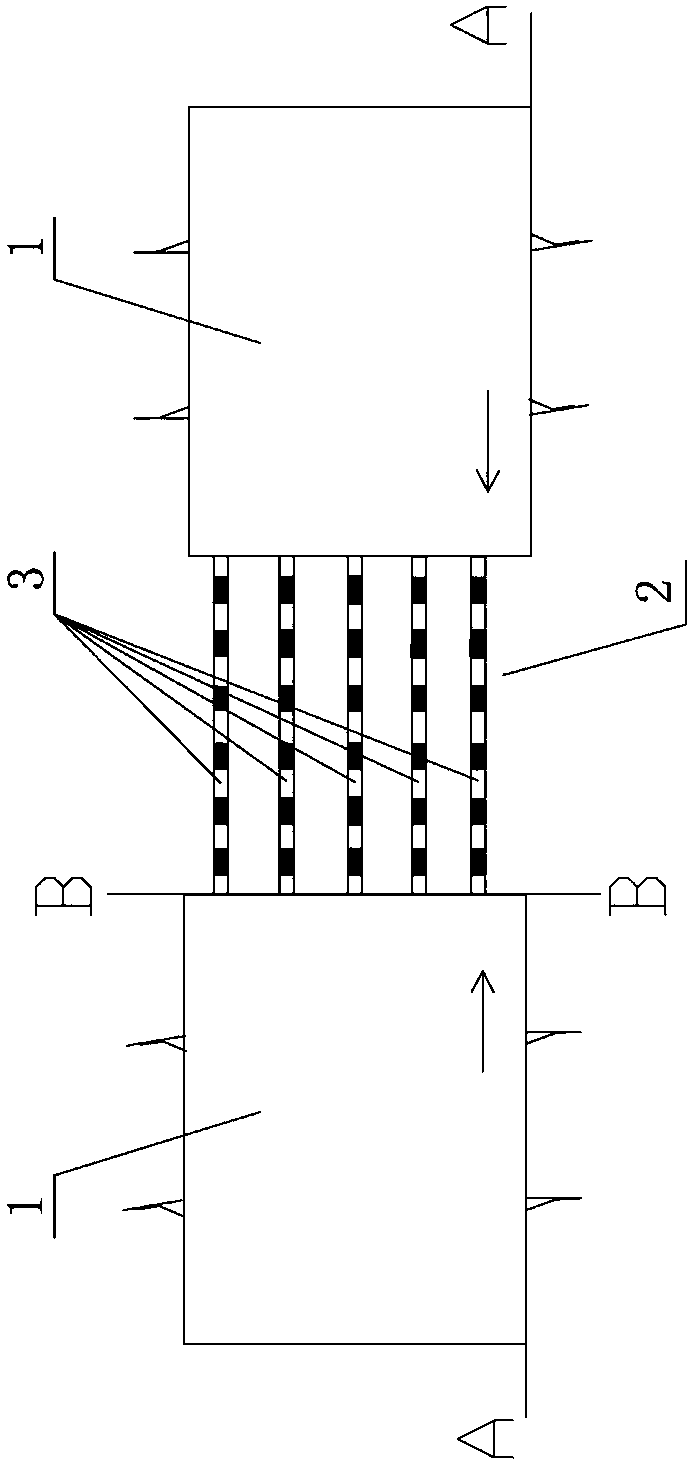

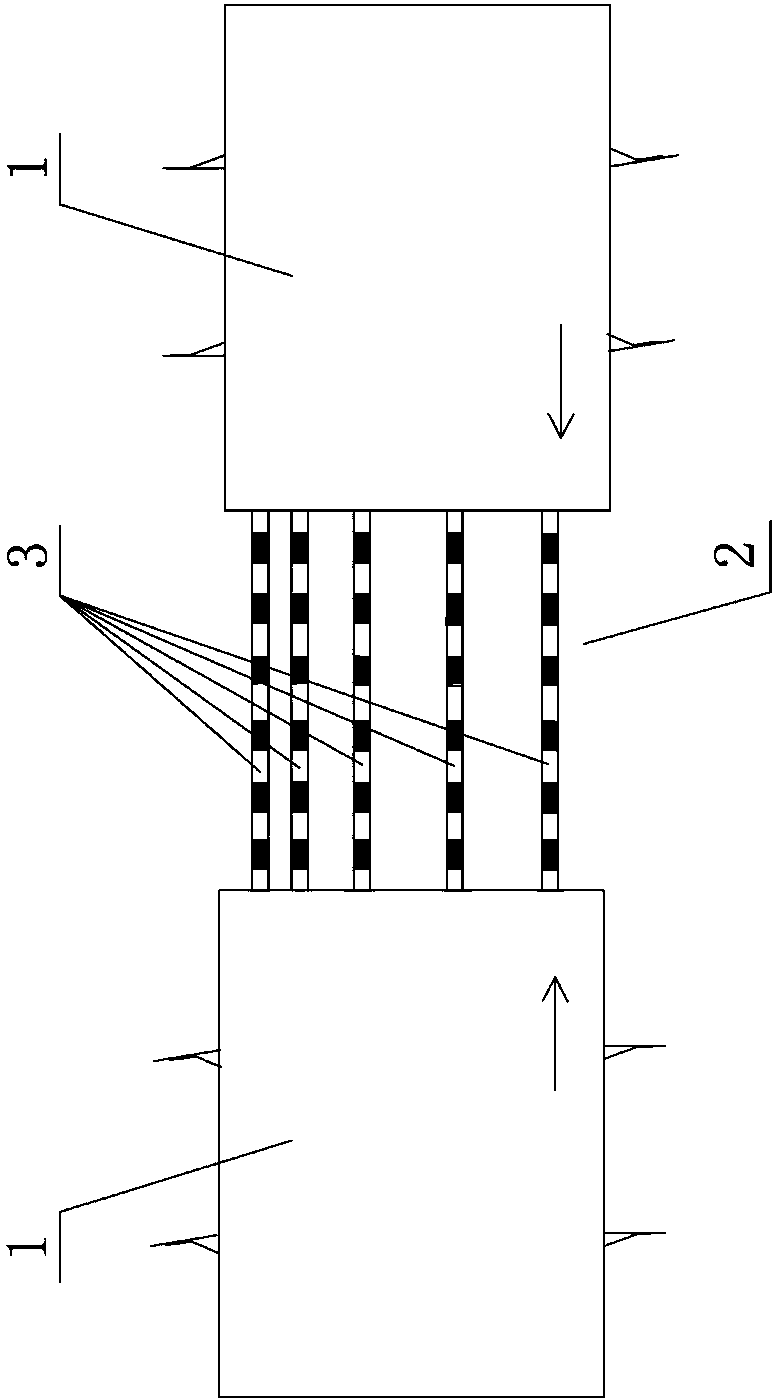

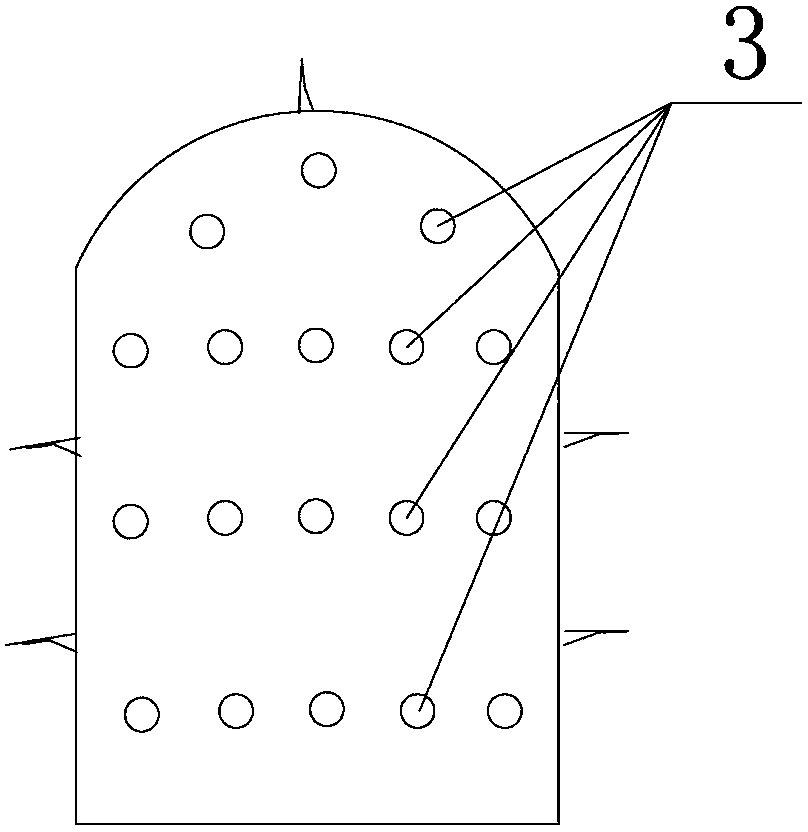

[0017] Such as Figure 1-Figure 3 As shown, in this embodiment, before the deep tunnel is penetrated, through a series of orderly working methods such as rationally arranging the blast holes and their detonation sequence, the properties of the rock mass are changed, and the energy accumulation of the rock pillar is eliminated or reduced, so as to control this Type of rock pillar type rockburst purpose. First detonate the explosives in the inner rock mass, release its stress to the surrounding deep rock mass, and then extend outward in turn, slowly release the stress of the rock pillars to the deep part of the rock walls on both sides and the bottom of the cave roof. Water must be injected for a period of time to moisten the rock mass and reduce the possibility of rockbursts.

[0018] The specific steps are as follows:

[0019] a. For the two underground tunnels 1 that are being excavated in opposite directions at the same time, when the thickness of the rock pillar 2 between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com