A kind of vegetable oil microcapsule powder applied to grain granules and preparation method thereof

A vegetable oil, microcapsule powder technology, applied in application, edible oil/fat, food science and other directions, can solve the problems of easy oxidative deterioration, reduce product shelf life, etc., and achieve the effect of changing properties and increasing the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

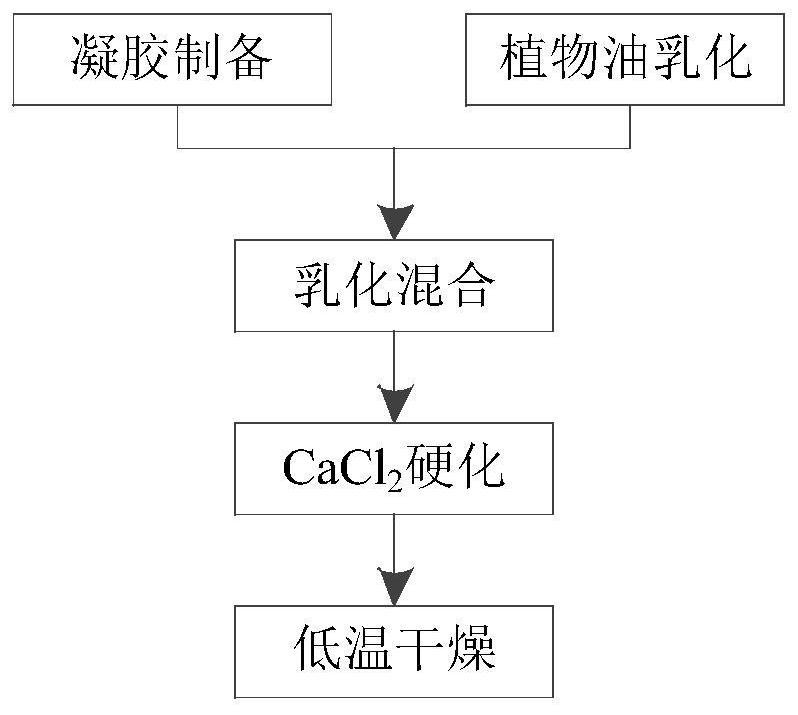

[0027] like figure 1 As shown, the present invention also provides a kind of preparation method of the vegetable oil microcapsule powder applied to grain granules, comprising the following specific steps:

[0028] Step 1: prepare psyllium husk gel emulsion, add a certain amount of sucrose fatty acid ester and citric acid into water and stir to dissolve, then add a certain amount of psyllium husk and maltodextrin, and stir at constant temperature until solid All the substances are dissolved into a uniform gel emulsion;

[0029] Step 2: preparing a vegetable oil emulsion, adding a certain amount of Tween-80 and tocopherol to the vegetable oil, stirring and dissolving at a constant temperature to obtain the emulsified vegetable oil;

[0030] Step 3: blending and emulsification, slowly adding the vegetable oil emulsion in step 2 to the psyllium shell gel emulsion in step 1, and emulsification uniformly at constant temperature;

[0031] Step 4: Preparation of microcapsule powder....

Embodiment 1-5

[0037] The effect of embodiment 1-5 on the gel properties of psyllium husk under different conditions

[0038] Add the required sucrose fatty acid ester and citric acid into 100 mL of water and stir to dissolve, then add the required psyllium husk and maltodextrin, and stir at a constant temperature until the solids are all dissolved into a uniform psyllium husk. Latex, see Table 1 for details.

Embodiment 11-13

[0053] Embodiment 11-13 Determination of emulsification conditions

[0054] Add 2g of sucrose fatty acid ester and 0.8g of citric acid to 100mL of water and stir to dissolve, then add 9g of psyllium husk and 25g of maltodextrin, and stir at constant temperature until the solids are all dissolved into a uniform psyllium husk gel. Lotion, spare. 3 g of Tween-80 and 0.8 g of tocopherol were added to 21 g of vegetable oil, and the mixture was stirred and dissolved at a constant temperature to obtain an emulsified vegetable oil. Then the emulsified vegetable oil was slowly added to the psyllium husk gel emulsion, and the emulsification was uniform, as shown in Table 5.

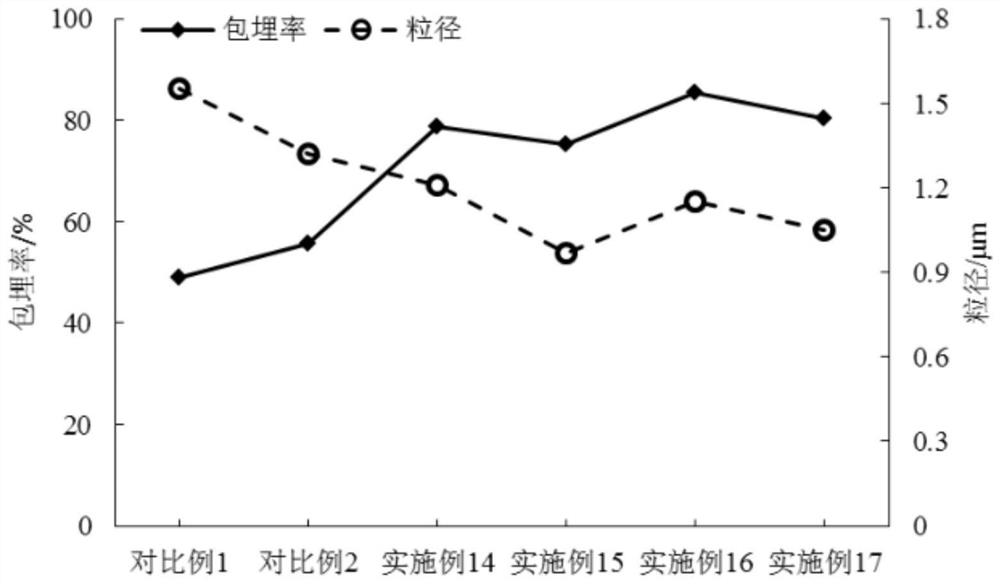

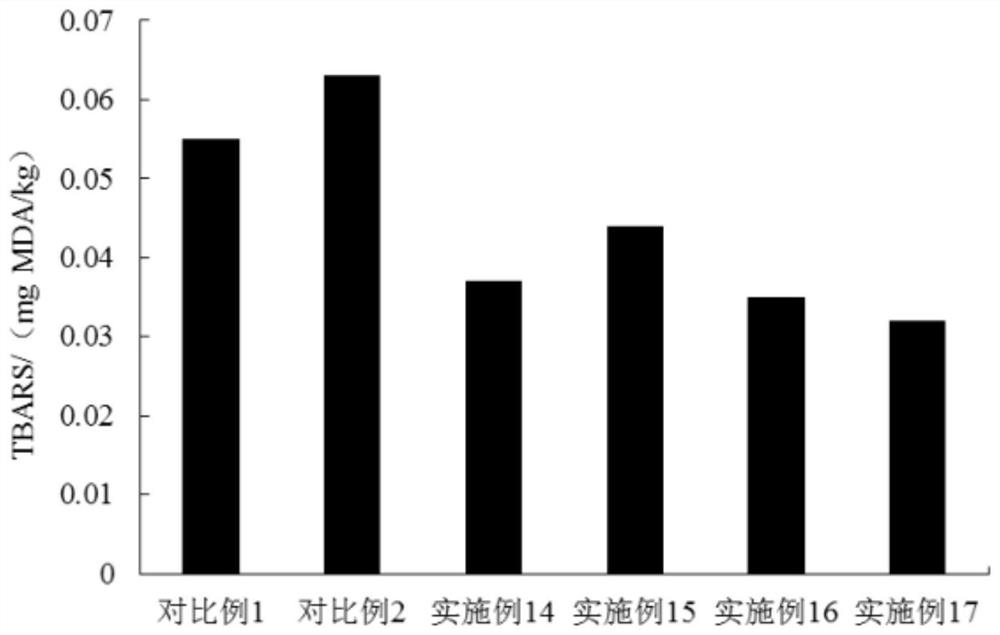

[0055] Comparative example 1 is based on the mass concentration of 1.2g / 100mL 水 of sodium alginate instead of psyllium husk.

[0056] Comparative example 2 is based on the mass concentration of 1.0g / 100mL 水 of sodium carboxymethylcellulose instead of psyllium husk.

[0057] Table 5 different embodiments:

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com