A kind of production method of instant condiment powder soy sauce

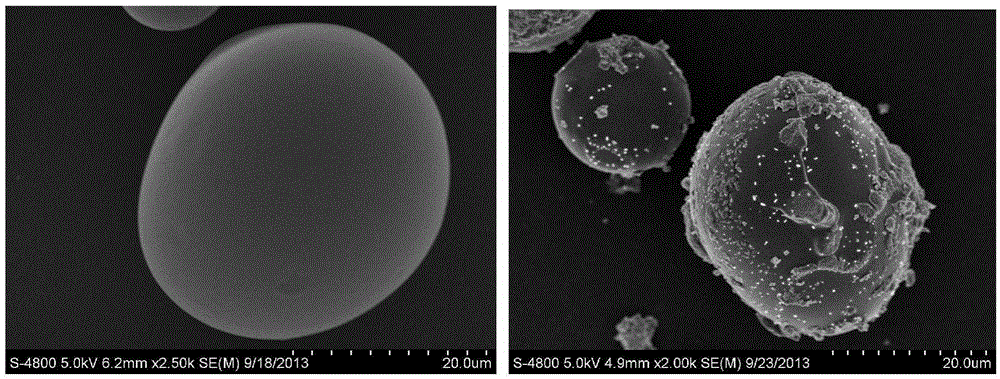

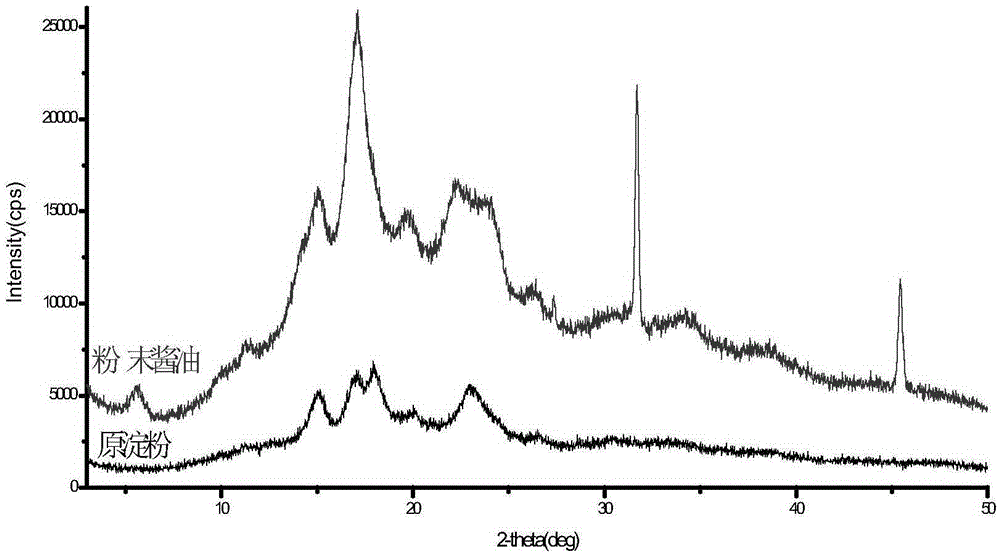

A powder soy sauce and production method technology, applied in the direction of food science, etc., can solve the problems of inconvenient carrying, high transportation cost, and restrictions on the application of soy sauce, and achieve the effect of improving adsorption characteristics and dissolution characteristics, and reducing transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

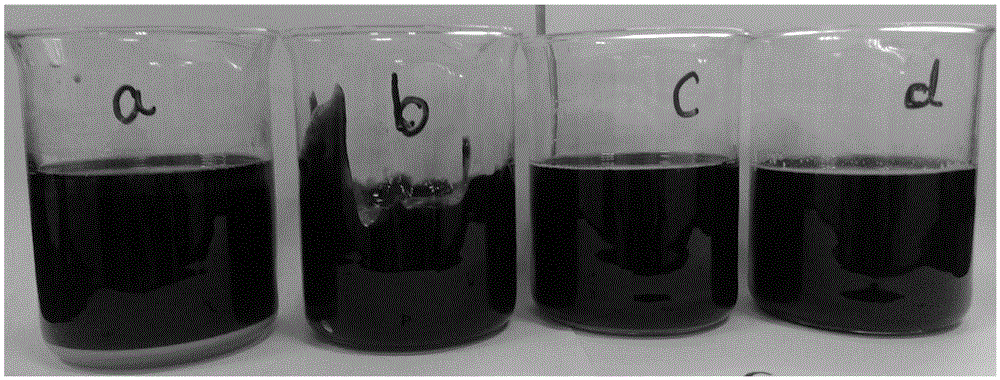

Method used

Image

Examples

Embodiment 1

[0029] 1) Add the original starch into 5wt% NaOH ethanol solution, suspend and disperse evenly, react at 45°C for 35min, stand at room temperature and remove the supernatant, add 40vt% ethanol solution to the remaining sediment and mix evenly, Then use the ethanol solution of HCl to adjust the pH value to neutrality, wash with 80vt% ethanol solution, 95vt% ethanol solution and absolute ethanol successively, obtain the starch filter cake after filtering;

[0030] The ethanol solution of the HCl is obtained by mixing the hydrochloric acid solution of 3mol / L and the ethanol solution of 40vt% in a volume ratio of 2:3;

[0031] 2) Mix the starch filter cake with Na at pH=5.2 2 HPO 4 - The citric acid buffer solution is mixed according to the volume ratio of 1:1 to obtain starch milk, and 0.5‰ of starch milk glucoamylase is added to the starch milk, enzymatically hydrolyzed at 50°C for 4h, filtered, and dried at 40°C to obtain modified porous starch, The enzyme activity of glucoam...

Embodiment 2

[0034] 1) Add the original starch into 15wt% NaOH ethanol solution, suspend and disperse evenly, react at 30°C for 50min, let stand at room temperature and remove the supernatant, add 60vt% ethanol solution to the remaining sediment and mix evenly, Then use the ethanol solution of HCl to adjust the pH value to neutrality, wash with 80vt% ethanol solution, 95vt% ethanol solution and absolute ethanol successively, obtain the starch filter cake after filtering;

[0035] The ethanol solution of the HCl is obtained by mixing the hydrochloric acid solution of 3mol / L and the ethanol solution of 60vt% in a ratio of 3:2 by volume;

[0036] 2) Mix the starch filter cake with Na at pH=3.4 2 HPO 4 - The citric acid buffer solution is mixed according to the volume ratio of 1:8 to obtain starch milk, and 0.6‰ glucoamylase of starch milk mass is added to the starch milk, enzymatically hydrolyzed at 30°C for 8h, filtered, and dried at 40°C to obtain modified porous starch, The enzyme activi...

Embodiment 3

[0039] 1) Add raw starch into 10wt% NaOH ethanol solution, suspend and disperse evenly, react at 40°C for 40 minutes, leave at room temperature to separate layers and remove the supernatant, add 50vt% ethanol solution to the remaining sediment and mix evenly, Then use the ethanol solution of HCl to adjust the pH value to neutrality, wash with 80vt% ethanol solution, 95vt% ethanol solution and absolute ethanol successively, obtain the starch filter cake after filtering;

[0040] The ethanol solution of the HCl is obtained by mixing the hydrochloric acid solution of 3mol / L and the ethanol solution of 50vt% in a volume ratio of 1:1;

[0041] 2) Mix the starch filter cake with Na at pH=4.2 2 HPO 4 - The citric acid buffer solution is mixed according to the volume ratio of 1:5 to obtain starch milk, and 0.7‰ of starch milk glucoamylase is added to the starch milk, enzymatically hydrolyzed at 40°C for 6h, filtered, and dried at 40°C to obtain modified porous starch, The enzyme activ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com