Energy-saving and emission-reduction synergist for coal

A technology of energy saving, emission reduction and synergist, which is applied in the field of coal additives, can solve problems such as unsatisfactory effect, low sulfur fixation efficiency, and easy decomposition of sulfur fixation products, so as to improve the sulfur fixation effect, improve utilization rate, and reduce emissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

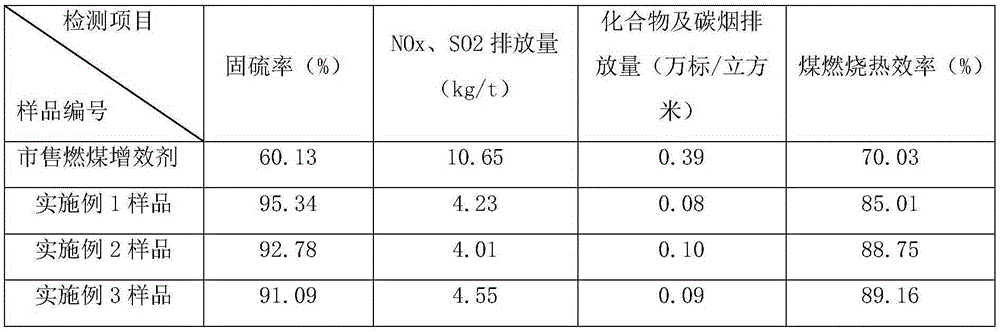

Embodiment 1

[0020] A coal-fired energy-saving emission reduction synergist, comprising the following raw materials in parts by weight: 6kg of yttrium oxide, 8kg of manganese dioxide, 10kg of iron dioxide, 10kg of ferrous oxide, 3kg of sodium carbonate, 3kg of potassium nitrate, and 2kg of sulfonated lignin , ammonium bicarbonate 10kg, potassium carbonate 10kg, urea 10kg, activated carbon 5kg, diatomaceous earth 8kg, activated alumina 3kg.

Embodiment 2

[0022] A coal-burning energy-saving emission reduction synergist, comprising the following raw materials in parts by weight: 8kg of yttrium oxide, 10kg of manganese dioxide, 15kg of iron dioxide, 15kg of ferrous oxide, 3kg of sodium carbonate, 3kg of potassium nitrate, and 2kg of sulfonated lignin , ammonium bicarbonate 4kg, potassium carbonate 5kg, urea 6kg, activated carbon 3kg, diatomaceous earth 2kg, activated alumina 2kg.

Embodiment 3

[0024] A coal-burning energy-saving emission reduction synergist, comprising the following raw materials in parts by weight: 7kg of yttrium oxide, 9kg of manganese dioxide, 11kg of iron dioxide, 13kg of ferrous oxide, 4kg of sodium carbonate, 5kg of potassium nitrate, and 5kg of sulfonated lignin , ammonium bicarbonate 6kg, potassium carbonate 8kg, urea 8kg, activated carbon 5kg, diatomaceous earth 5kg, activated alumina 2kg.

[0025] The method for preparing embodiment 1-3 synergist sample is: mix yttrium oxide, manganese dioxide, ferric oxide, ferrous oxide, sodium carbonate, potassium nitrate, then add sulfonated lignin and ammonium bicarbonate and mix for 20 Minutes later, add potassium carbonate, urea, activated carbon, diatomaceous earth, and activated alumina, mix evenly, crush and process to 90-100 mesh, measure and pack, and obtain the coal-fired energy-saving and emission-reducing synergist.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com