Biological liquid fuel and preparation method thereof

A biological and mixture technology, used in fuels, liquid carbon-containing fuels, petroleum industry, etc., can solve the problems of high production process requirements, alcohol fuels cannot be mixed, and fuel synthesis cannot be carried out at room temperature, etc. , make up for the shortage of supply and increase the effect of varieties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A bio-combustion liquid, which is a mixture of the following components, the content of each component in the mixture is calculated in parts by weight:

[0026] Ethanol 55kg Isopropanol 700g

[0027] Methanol 25kg Isobutanol 200g

[0028] Naphtha 15kg n-propanol 200g

[0029] Xylene 2kg Neopentyl Glycol 200g

[0030] Pyridine 200g Acetone 200g

[0031] Dimethyl carbonate 200g

[0032] The preparation method of this biological combustion liquid is:

[0033] A. In the reaction vessel, add 55 kilograms of main ingredient ethanol and 200 grams of ethanol denaturing additive pyridine simultaneously, stir while feeding, and continue to stir for 2 minutes after the feeding is completed to obtain a denatured ethanol mixed solution;

[0034] B, add methyl alcohol: add 25 kilograms of main ingredient methyl alcohol in the denatured ethanol mixed solution that makes, stir while feeding, after the addition is finished, continue to stir for 2 minutes, stand still for 2 minutes,...

Embodiment 2 Embodiment 8

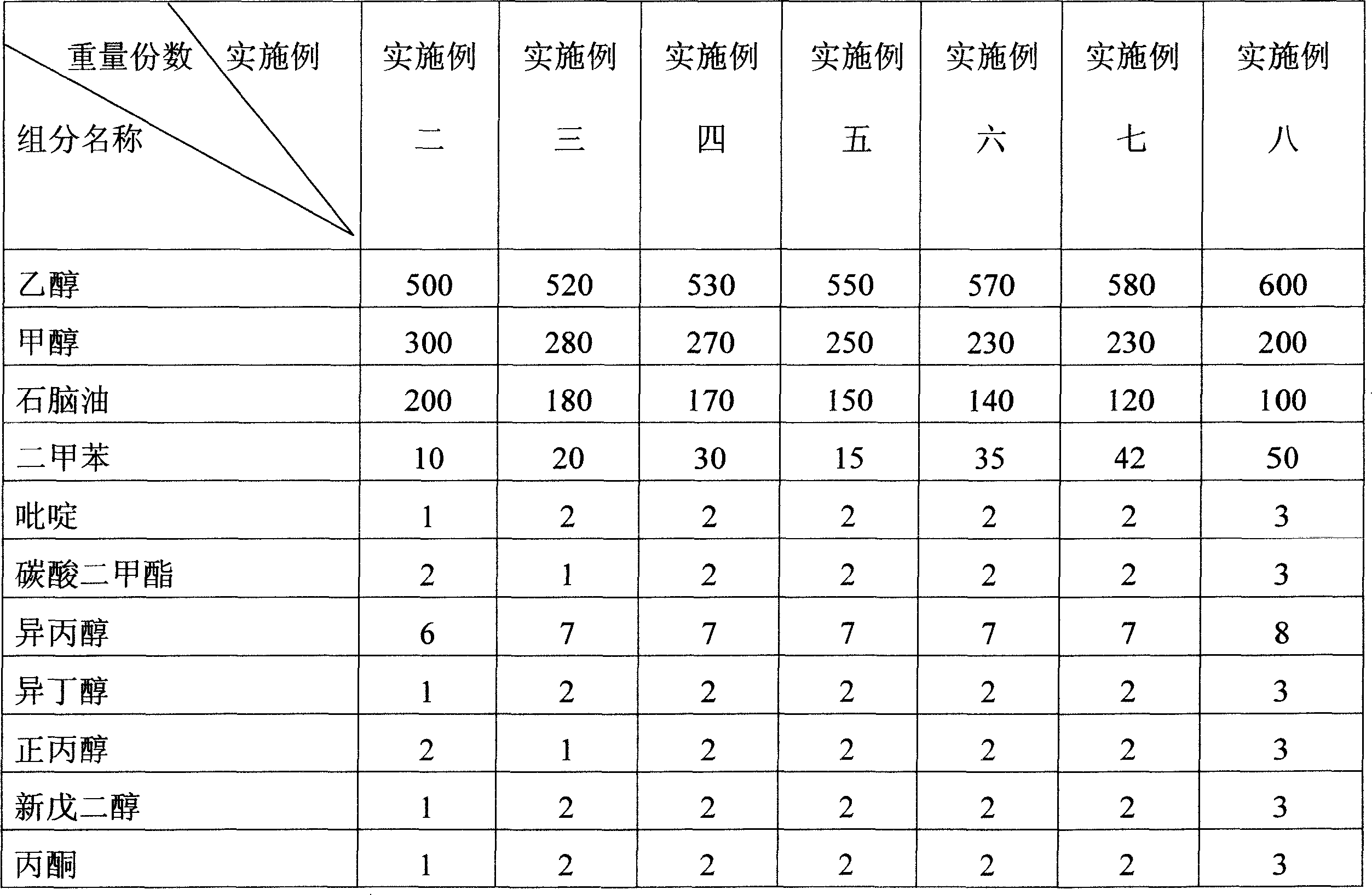

[0039] Various bio-combustion fluids with different proportions, the bio-combustion fluid is a mixture composed of the following components, and the content of each component in the mixture is calculated in parts by weight:

[0040] 500-600 parts by weight of ethanol 6-8 parts by weight of isopropanol

[0041] Methanol 200~300 parts by weight Isobutanol 1~3 parts by weight

[0042] 100-200 parts by weight of naphtha 1-3 parts by weight of n-propanol

[0043] Xylene 10-50 parts by weight Neopentyl glycol 1-3 parts by weight

[0044] Pyridine 1-3 parts by weight Acetone 1-3 parts by weight

[0045] 1 to 3 parts by weight of dimethyl carbonate

[0046] For the specific ratio of each component in the above-mentioned embodiments, please refer to Attached Table II.

[0047] The ethanol and methanol described in the above embodiments are respectively industrial ethanol and industrial methanol; the xylene is p-xylene or o-xylene or a mixture of p-xylene and o-xylene.

[0048] The...

Embodiment 9

[0060] A preparation method of a bio-combustion liquid, which is to mix the components of the bio-combustion liquid of the present invention at normal temperature and pressure according to the following steps:

[0061] A. Add ethanol denaturing additives to ethanol: add 500-600 parts by weight of ethanol and 1-3 parts by weight of pyridine into the reaction kettle at the same time, stir while feeding, and continue stirring for 2-4 minutes after the addition is complete to obtain denatured ethanol mixed solution;

[0062] B. Adding methanol: add 200-300 parts by weight of methanol to the denatured ethanol mixture, stir while adding, continue to stir for 2-4 minutes after the addition is complete, and then stand still for 2-4 minutes to obtain first and ethanol mixed solution;

[0063] C. Adding naphtha: Add 100-200 parts by weight of naphtha to the mixed solution of A and ethanol, stir while feeding, and continue stirring for 2 minutes after the feeding is completed, then add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com