Method for processing plant material by use of plasma

A plasma and plant material technology, which is applied in the field of plasma treatment of plant materials, can solve the problems of continuous operation, large volume of vacuum chamber, and limited application range, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

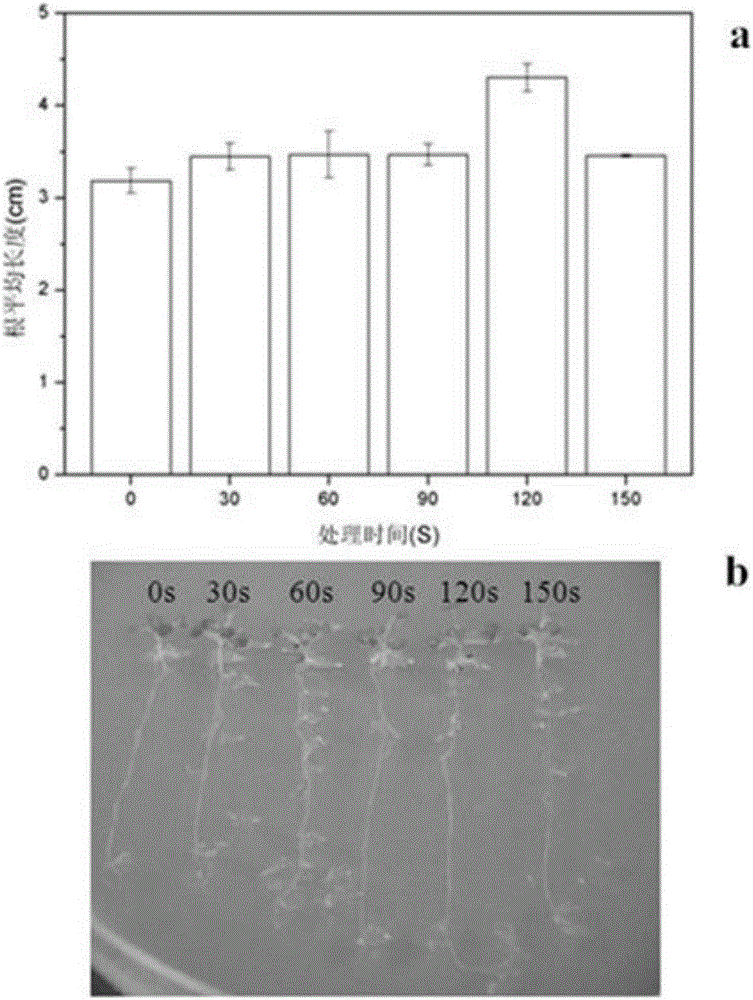

[0033] Using plasma to treat Arabidopsis seeds, the steps are as follows:

[0034] (1) Put 100 mature seeds of Arabidopsis thaliana into each petri dish, spread them flat in the petri dish, and place the petri dish directly below the plasma outlet;

[0035] (2) Start the plasma mutagenesis breeding instrument, release the plasma jet, and the processing time is respectively 0s, 30s, 60s, 90s, 120s, 150s;

[0036] (3) Take out the Arabidopsis seeds, utilize 10% sodium hypochlorite to sterilize the Arabidopsis seeds after the plasma treatment, then inoculate on the MS solid medium, cultivate in the light incubator, and the roots of the Arabidopsis seedlings are cultivated along the The basal surface grows vertically downward.

[0037] After cultivating for a period of time, count the germination rate, seedling root length and seedling fresh weight of Arabidopsis under different treatment time, the results are as follows:

[0038] (1) After 1 week, the germination rate of Arabid...

Embodiment 2

[0043] Using plasma to treat sunflower sprouts, the steps are as follows:

[0044] (1) Put 15 sunflower sprouts in each petri dish, disperse them in the petri dish, place the petri dish directly below the plasma outlet;

[0045] (2) Start the plasma mutagenesis breeding instrument, release the plasma jet, and the processing time is 0min and 8min respectively;

[0046] (3) Take out the young sunflower buds and plant them in flowerpots with good ventilation, the soil thickness is 10cm, and place the flowerpots in a sunny place outdoors.

[0047] image 3 A graph showing the growth status of sunflowers cultivated for 2 months, image 3 a is the growth status figure of the 0min control group and the 8min treatment group on October 10, the 0min control group has bloomed flowers, and the 8min control group has only flower buds; image 3 a is the growth status graph on October 27, the flowers in the control group withered at 0 min, while the flowers in the treatment group bloomed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com