Regenerated sand powder green concrete, and preparation method thereof

A technology of reclaimed sand and concrete, which is applied in ceramic products, other household utensils, applications, etc., can solve the problems of complex calcination process, difficult city implementation, and increased urban environmental load, so as to achieve good corrosion resistance and promote construction waste. Effect of weight reduction and saving of sand and gravel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

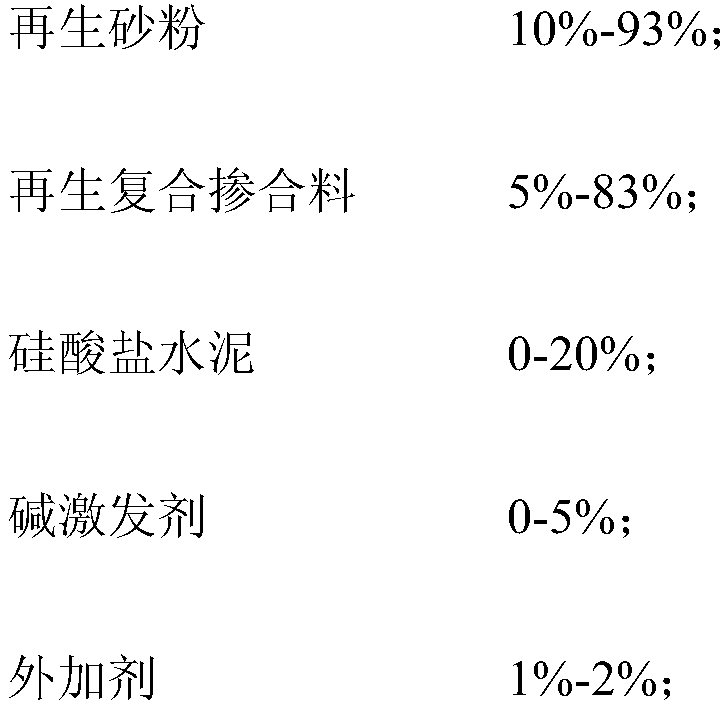

Method used

Image

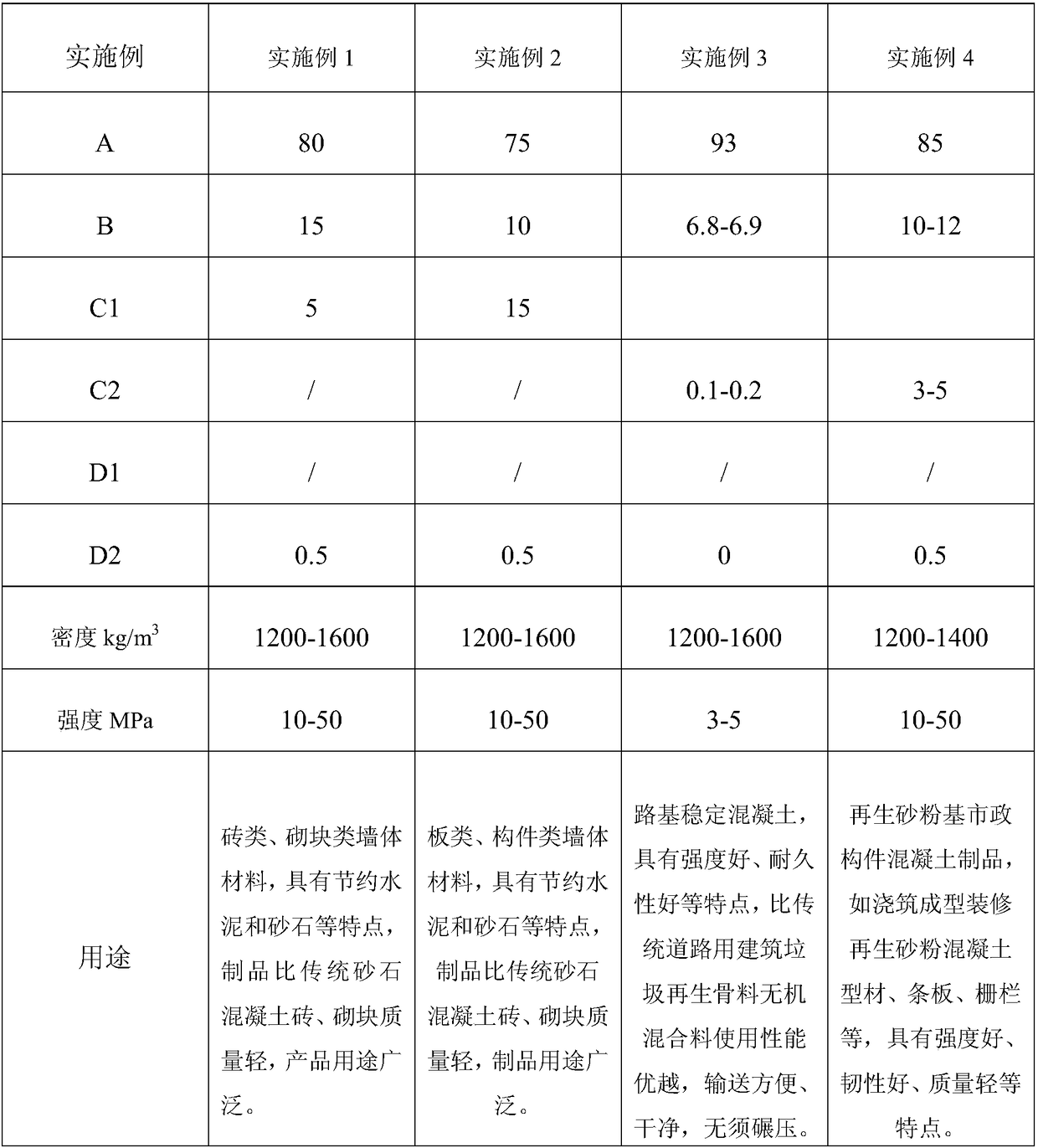

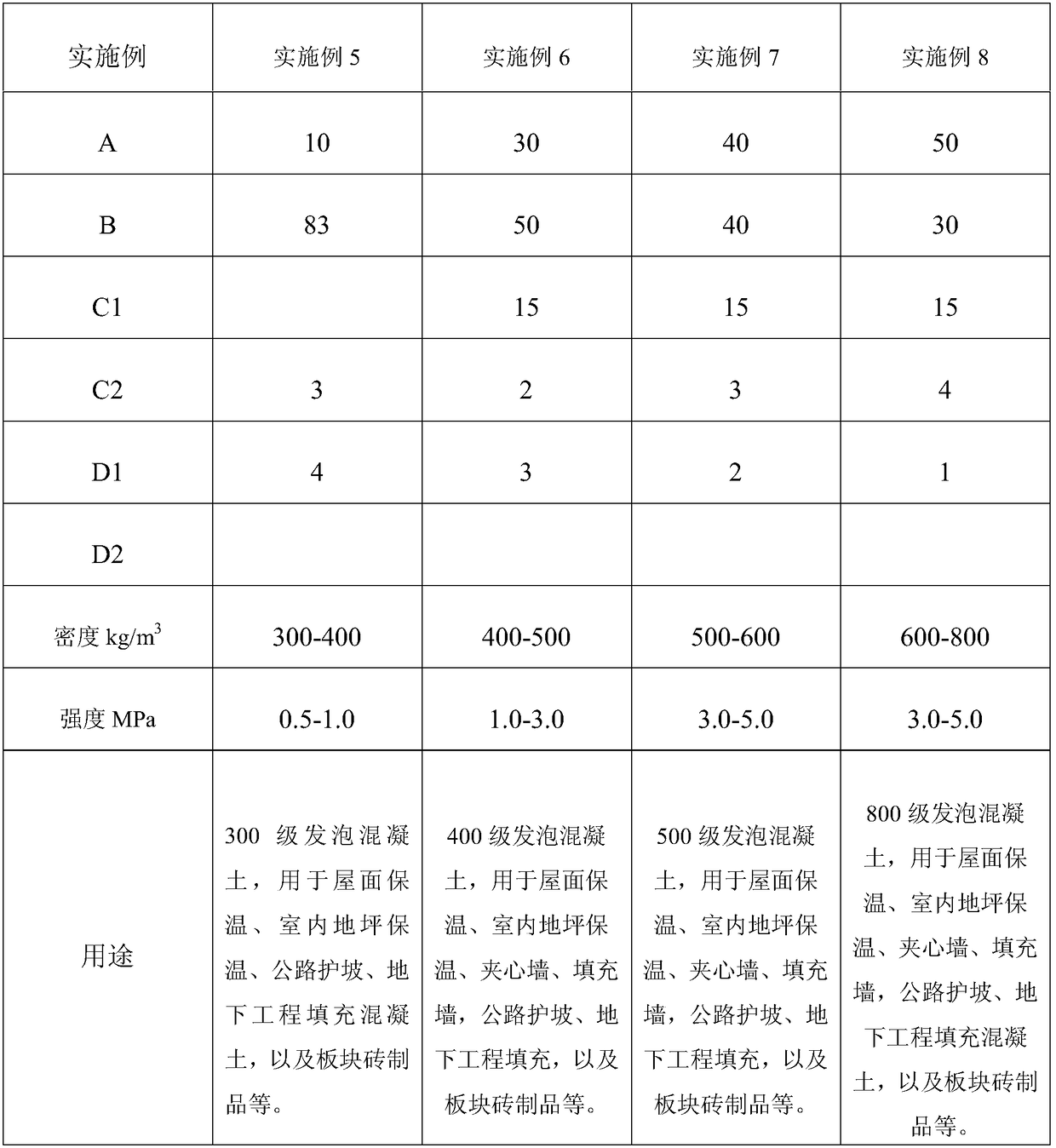

Examples

Embodiment 1~8

[0056] A preparation method for recycled sand powder green concrete, comprising the steps of:

[0057] Step (1), the preparation of regenerated sand powder:

[0058] Usually, the demolition site of the house is pretreated with a mobile crusher, and the construction waste after coarse crushing is transported to the factory for recycling.

[0059] The coarsely crushed construction waste enters the factory, and the slag with a large soil content less than 5mm is stripped out through a bar sieve, and then the following are used:

[0060] Step (1) Preparation process of recycled sand powder:

[0061] 1. Lamination: The recycled coarse aggregate of construction waste with a particle size of 5-50mm is pulverized by the lamination equipment of the high-pressure roller press;

[0062] 2. Impurity removal: use sorting equipment such as a drum screen to separate sand and gravel or light impurities with a particle size greater than 5mm, and recover recycled sand powder with a particle s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com