A kind of fully recycled concrete and preparation method thereof

A technology of recycled concrete and concrete, which is applied in the field of building solid waste recycling, can solve the problems of increasing cost and energy consumption, and achieve the effects of improving efficiency, reducing cost, and improving the uniformity of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

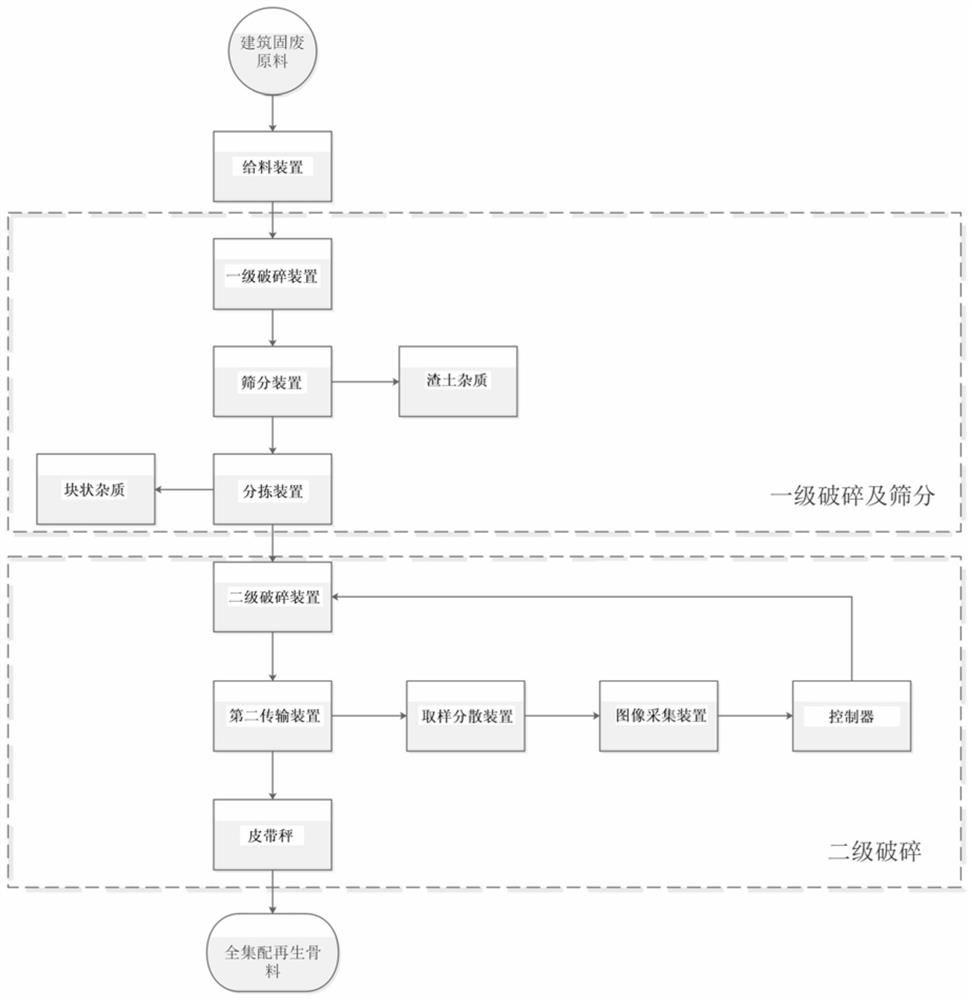

[0088] The present invention provides a method for preparing continuously graded regenerated aggregate, which is prepared by using a continuous graded regenerated aggregate intelligent crushing integrated system, comprising the following steps:

[0089] 1) The construction solid waste raw materials are input into the primary crushing device from the feeding device for crushing, and the crushed construction solid waste raw materials are screened by the screening device to remove the slag impurities to obtain material a;

[0090] 2) The material a is transported to the secondary crushing device through the first transmission device for crushing, and the bulk impurities in the material a are sorted out by the sorting device to obtain the material b;

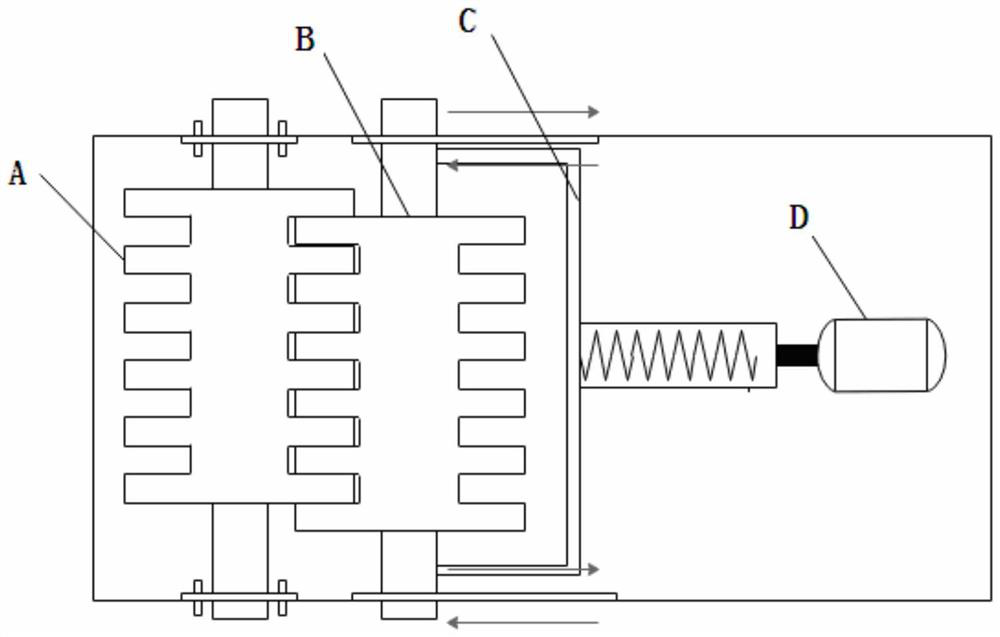

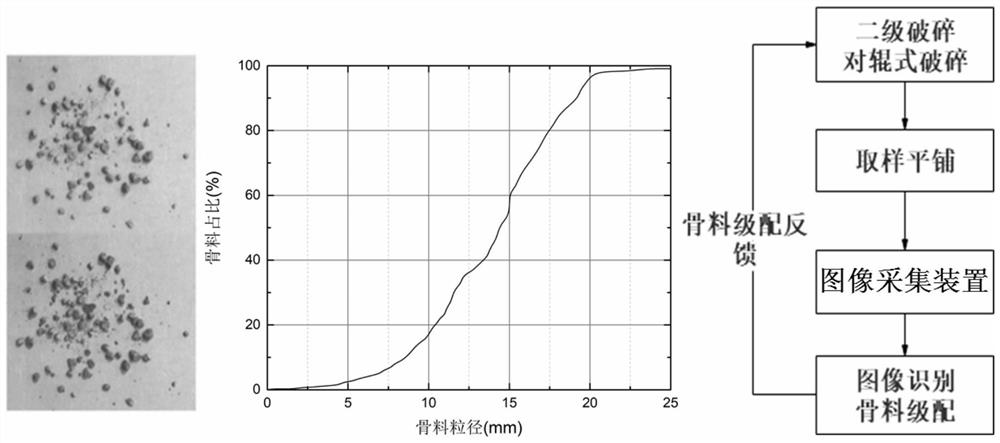

[0091] 3) The material b is transported to the sampling and dispersing device and the belt scale respectively through the second transmission device, and the material b transported to the sampling and dispersing device is vibrated an...

Embodiment 1

[0165] The construction solid waste raw materials are fed from the raw material silo to the feeder through the conveyor belt, and then fed into the jaw crusher for crushing. The jaw crusher is a PE-600×750 type jaw crusher. It is 400-600mm, preferably 500mm, the discharge particle size is 150-200mm, preferably 180mm, and the crushing capacity is 80-240t / h, preferably 160t / h.

[0166] The crushed construction solid waste raw materials are screened by a vibrating screen to remove the slag impurities, and the material a after the slag is screened is obtained. Then, the material a is transported to the roller crusher at a constant speed of 0.2m / s by the conveyor belt through the lower chute for crushing, and the material b is obtained. And the block impurities are sorted by intelligent jet sorting equipment, the density-based material types are distinguished, and the block materials with too low density are screened and sent to the block impurity storage room, and the sorting rate...

Embodiment 2

[0172]The continuously graded recycled aggregate sample 1* prepared in Example 1 was mixed with other components to prepare the fully recycled concrete water-stable material sample 1#. In the fully recycled concrete water-stable material sample 1#, by mass percentage, the continuously graded recycled aggregate sample 1* is 90%, Portland cement is 3%, water is 6.7%, and sodium sulfate is 0.3%. In the specific preparation, firstly add the continuously graded recycled aggregate sample 1* and half the amount of water according to the above proportions for stirring, then add other components and the other half of the water for vibration stirring, and then press and shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com