Method for preparing high-dosage cement active mixed material from metal tailings

A technology of active admixture and metal tailings, applied in cement production and other directions, can solve the problems of ineffective activation of activity and inability to refine specific surface area, achieve comprehensive utilization of high added value, reduce cement hydration heat, and protect ecology effects of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

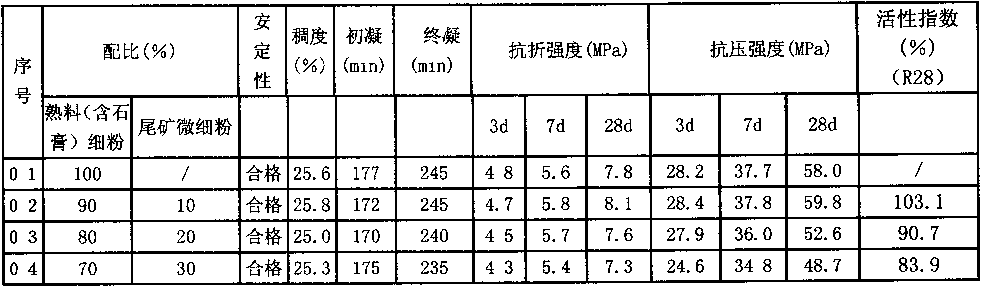

[0024] 1. The metal tailings and tailings special activator are calculated according to the weight percentage, that is, 1kg of metal tailings is added with 0.3‰kg tailings special activator, the amount of gypsum is 2%, SO 3 The content does not exceed 3.5%. The specific surface area of the entering mill is 420(±10)m 2 / g of metal tailings fine powder.

[0025] 2. The clinker grinding shall be carried out in accordance with the "Technical Conditions for the Determination Method of Cement Clinker Label", and the specific surface area shall be controlled at 300(±10)m 2 / kg. The dosage of gypsum is uniformly 5%, SO 3 The content does not exceed 3.5%.

[0026] 3. According to the percentage by weight, the metal tailing fine powder is mixed with the finely ground clinker (including gypsum) powder in an even ratio of 10%, 20% and 30% respectively. Prepare the test block according to the standard method, according to GB / T17671-1999 cement mortar strength test method, GB / T12957-...

Embodiment 2

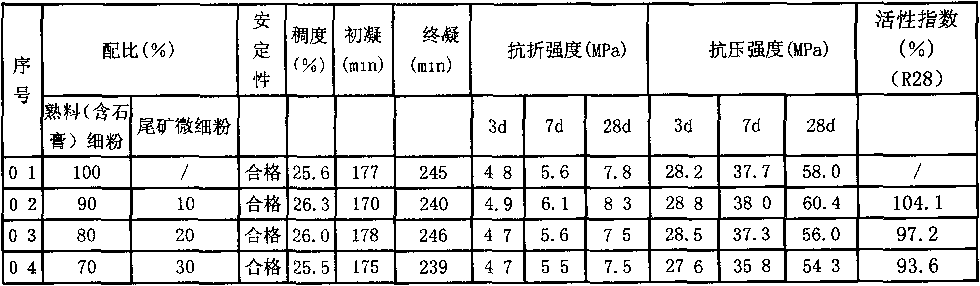

[0030] 1. The metal tailings and tailings special activator are calculated according to the weight percentage, that is, 1kg of metal tailings is added with 0.4‰kg of tailings special activator, the amount of gypsum is 2.5%, SO 3 The content does not exceed 3.5%. The specific surface area of the entering mill is 500(±10)m 2 / g of metal tailings fine powder.

[0031] 2. The clinker grinding shall be carried out in accordance with the "Technical Conditions for the Determination Method of Cement Clinker Label", and the specific surface area shall be controlled at 300(±10)m 2 / kg. The dosage of gypsum is uniformly 5%, SO 3 The content does not exceed 3.5%.

[0032]3. According to the percentage by weight, the metal tailing fine powder is mixed with the finely ground clinker (including gypsum) powder in an even ratio of 10%, 20% and 30% respectively. Prepare the test block according to the standard method, according to GB / T17671-1999 cement mortar strength test method, GB / T12...

Embodiment 3

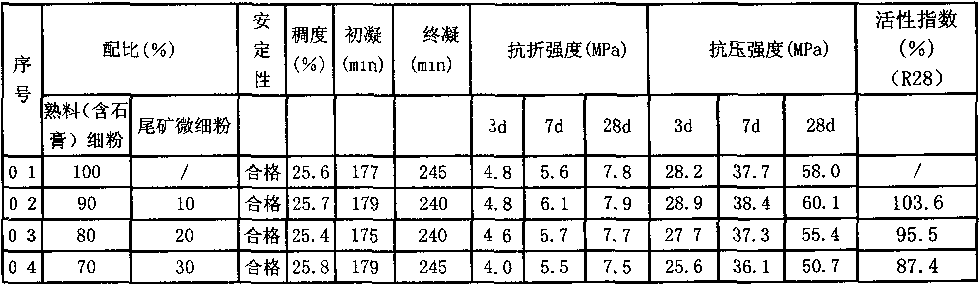

[0036] 1. The metal tailings and tailings special activator are calculated according to weight percentage, that is, 1kg of metal tailings is added with 0.3‰kg tailings special activator, the amount of gypsum is 3%, SO 3 The content does not exceed 3.5%. The specific surface area of the entering mill is 600(±10)m 2 / g of metal tailings fine powder.

[0037] 2. The clinker grinding shall be carried out in accordance with the "Technical Conditions for the Determination Method of Cement Clinker Label", and the specific surface area shall be controlled at 300(±10)m 2 / kg. The dosage of gypsum is uniformly 5%, SO 3 The content does not exceed 3.5%.

[0038] 3. According to the percentage by weight, the metal tailing fine powder is mixed with the finely ground clinker (including gypsum) powder in an even ratio of 10%, 20% and 30% respectively. Prepare the test block according to the standard method, according to GB / T17671-1999 cement mortar strength test method, GB / T12957-2005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com