A process for preparing heat storage balls

A heat storage ball and process technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of small earth reserves, expensive products, artificial manufacturing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

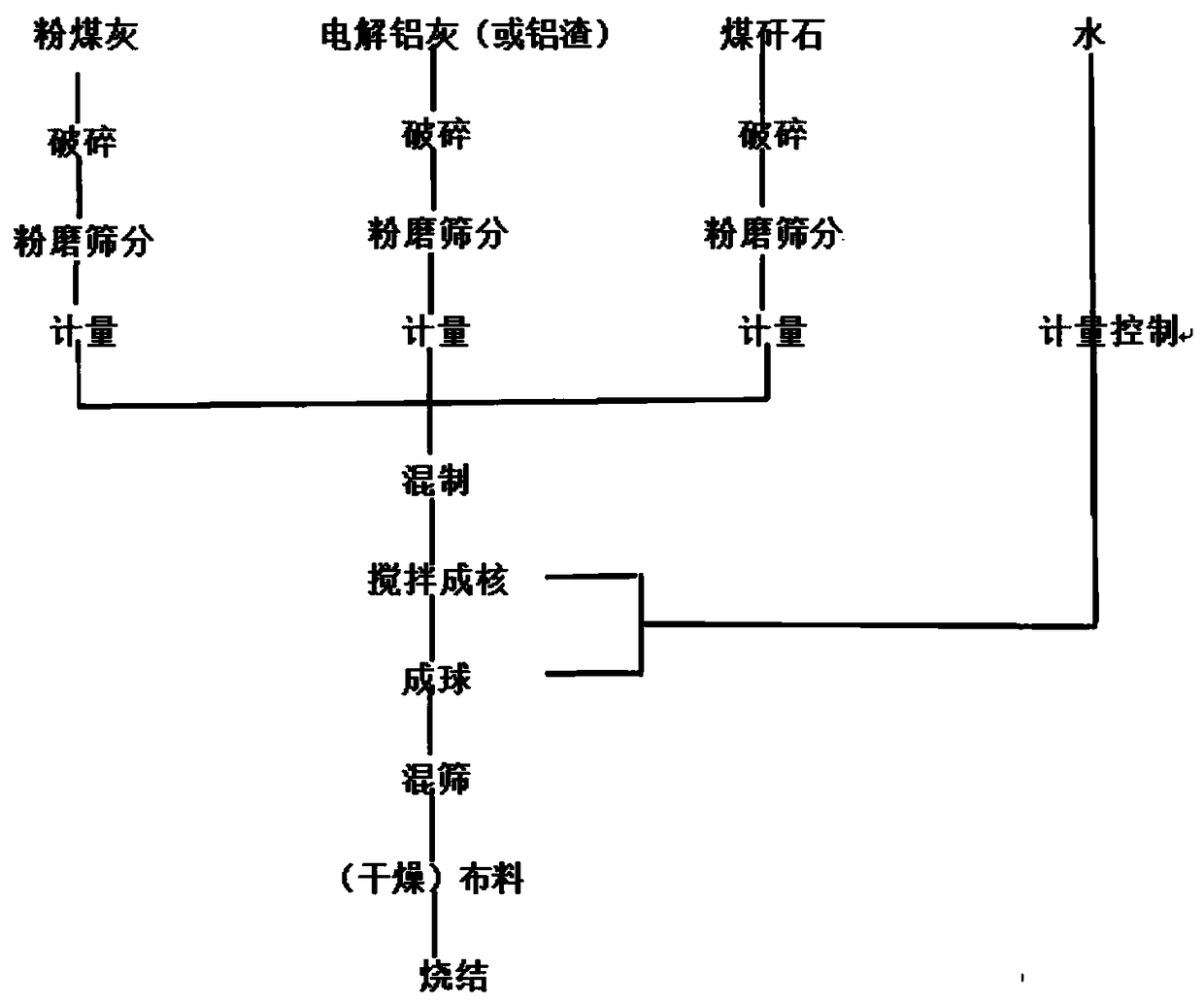

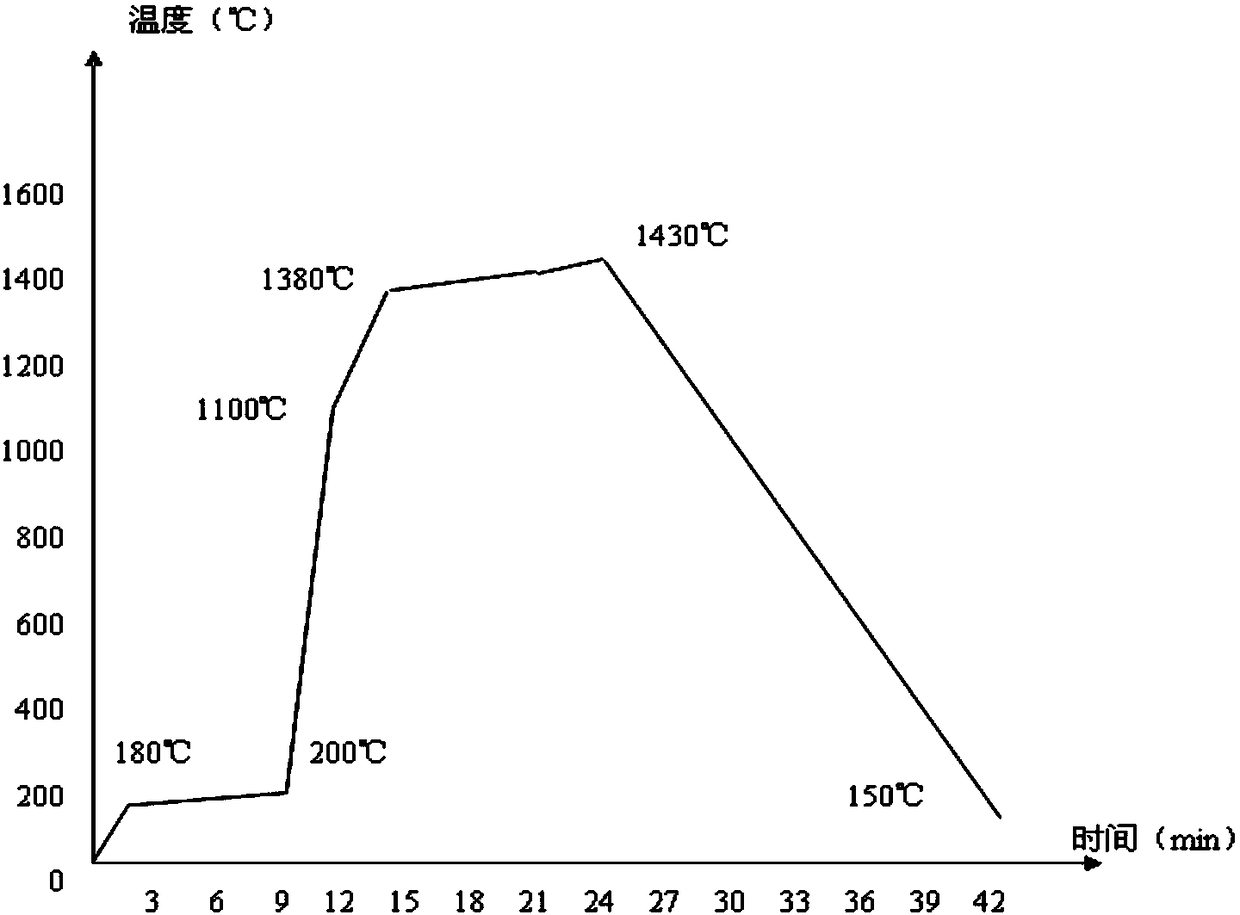

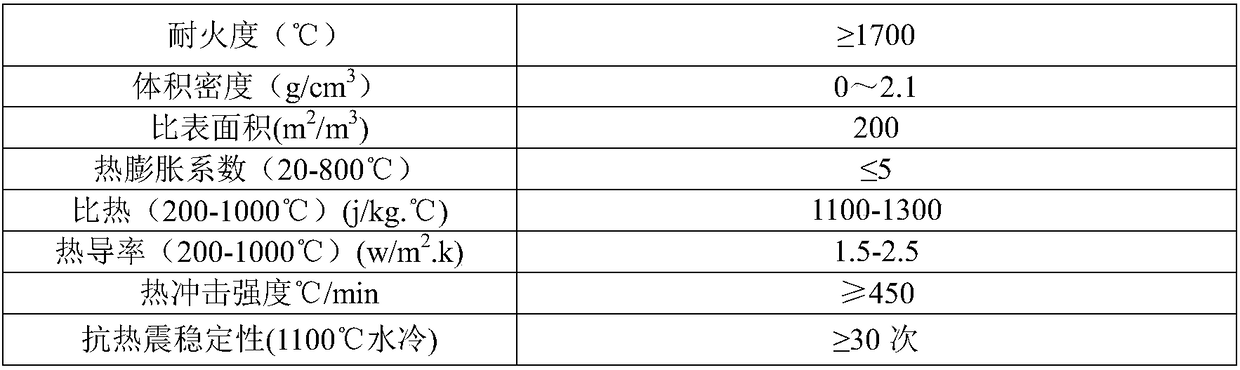

[0029] Prepare heat storage balls as follows:

[0030] (1) Raw material

[0031] A. Fly ash, in accordance with the requirements of the "national standard GB / T1596-2005 for fly ash used in cement and concrete" and "national standard GB / 6566-2001 for radionuclide limits in building materials", select F-class fly ash, And through chemical composition analysis, it is recommended to require high aluminum, low sulfur, low calcium ash. In the present embodiment, the fly ash is collected from Inner Mongolia Datang Tuoketuo Power Plant, and it is tested, and the fly ash contains: SiO 2 : 35-40%, Al 2 o 3 : 39-50%, Fe 2 o 3 : 2~4%, TiO 2 : 0~1%, MgO: 2~3%, CaO: 0.8%, Na 2 O: 0~1%, K 2 O: 0~1%, SO 3 : 0~1%, burning vector: 0.8%.

[0032] B, aluminum ash, the aluminum ash in the present embodiment is collected from the electrolytic aluminum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com